Page 1

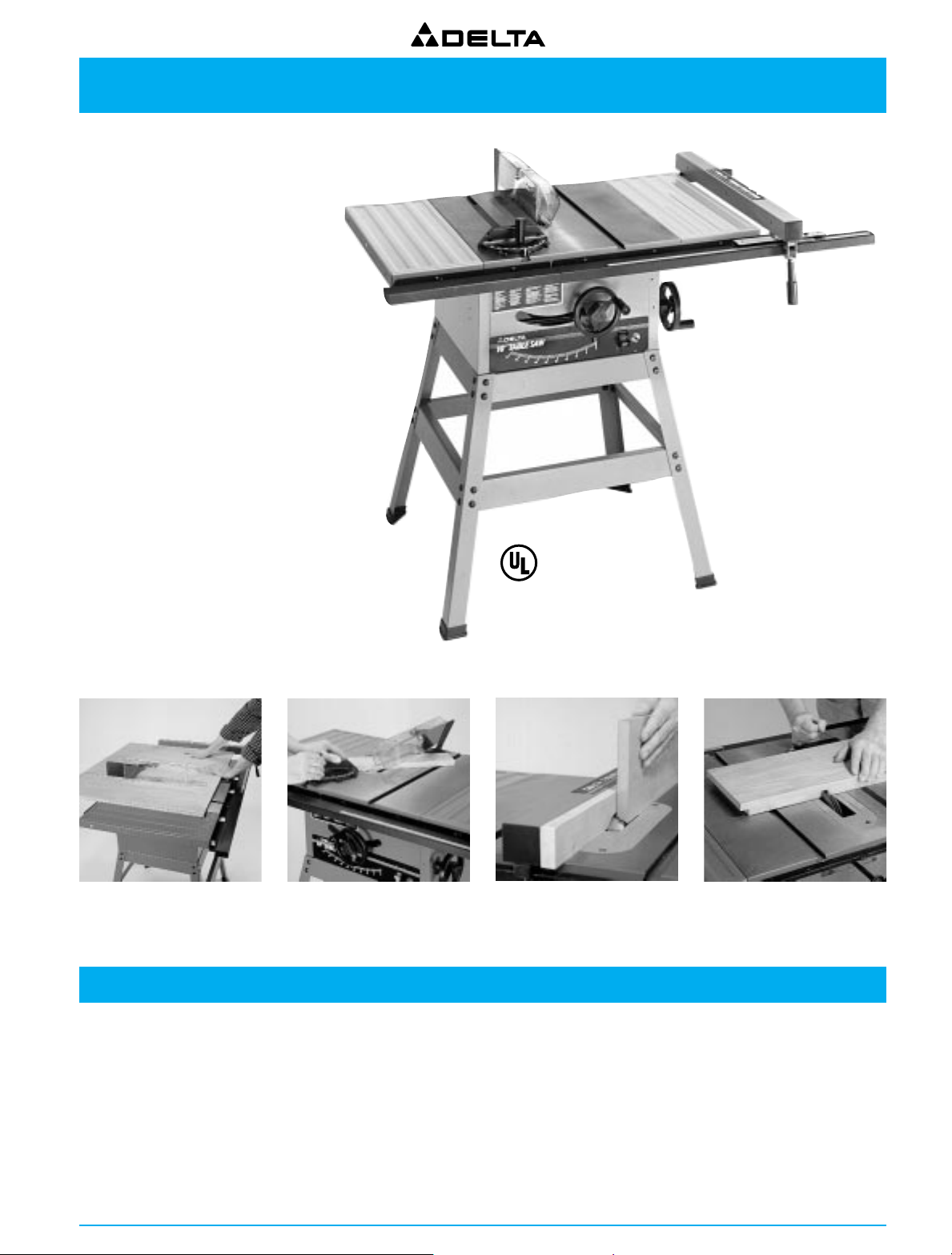

10” Tilting Arbor Saw

®

High quality and feature loaded.

Magnetic motor starter with thermal

•

overload and no-voltage protection.

Full cabinet with motor cover

•

for sawdust containment.

Built-in storage for miter

•

gage, rip fence and blade

wrench.

Extra-large cast-iron table with

•

extension wings provides ample

support for large work.

Integral T-slot grooves prevent

•

miter gage from falling during wide

cut-off operations.

Convenient up-front blade raising and

•

tilting controls for safe, easy operation.

Model 36-751 10Ó Tilting Arbor Saw

with 30Ó Unifence Saw Guide and

34-914 Accessory Table Board.

Model 36-755 10Ó Tilting Arbor Saw.

Includes basic machine with Jet-Lock

Micro-Set

®

rip fence; see-thru blade guard,

®

,

splitter and anti-kickback attachment; front

graduated guide bar, rear guide bar, miter

gage, 10Ó dia. saw blade, table insert, arbor

and motor pulleys, V-belt, (2) table extension

wings, motor cover; 2HP, 230V, single phase,

Model 36-755 10Ó Tilting Arbor Saw

60 Hz., TEFC motor; motor starter and

instruction manual.

Model 36-751 10Ó Tilting Arbor Saw with 30Ó Unifence

Saw Guide. Same as Model 36-755 above less Jet-Lock®,

Micro-Set

table extension wing, but with Unifence

®

rip fence with front and rear guide bars and (1)

®

Saw Guide which

®

includes fence, carriage assembly, front guide bar, table

frame, legs and mounting hardware.Less table board.

Model 36-752 10Ó Tilting Arbor Saw with 52Ó Unifence

Saw Guide. Same as Model 36-755 above less Jet-Lock®,

Micro-Set

table extension wing, but with Unifence

®

rip fence with front and rear guide bars and (1)

®

Saw Guide which

®

includes fence, carriage assembly, front guide bar, table

frame, legs, shelf support brackets and mounting hardware.

Less table and shelf boards.

Model 36-752 10Ó Tilting Arbor Saw

with 52Ó Unifence Saw Guide

and 34-998 Accessory Table and

Shelf Boards.

Cuts stock 31⁄8Ó thick; a full

21⁄8Ó at 45° blade tilt. 2 HP

motor delivers plenty of power

for fast, efficient cutting.

Unique “table top located”

adjusting screws for accurate

setting of 45° and 90° positive

blade stops.

SPECIFICATIONS

Motor ........................................... 2 HP, 230V, 60 Hz., single phase

Blade:

Diameter .................................................................... 10Ó (254 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 4000 rpm

Capacity:

Max. depth of cut 90° ................................................. 31⁄8Ó (79 mm)

Max. depth of cut 45° ................................................. 21⁄8Ó (54 mm)

Max. rip R of blade .................................................... 25Ó (635 mm)

Max. rip L of blade .................................................. 151⁄2Ó (394 mm)

Max. rip R of blade w/30Ó Unifence Saw Guide ........ 30Ó (762 mm)

Max. rip R of blade w/52Ó Unifence Saw Guide ...... 52Ó (1321 mm)

Max. rip L of blade w/30Ó or

52Ó Unifence Saw Guide ....................................... 83⁄4Ó (222 mm)

Table in front of saw blade at

max. cutting height .............................................. 121⁄4Ó (311 mm)

Max. width of dado .....................................................13⁄16Ó (21 mm)

Table:

Size w/extension wings .......................... 36Ó x 27Ó (914 x 686 mm)

Size w/ext.wing and 30Ó

Unifence Saw Guide ...................... 621⁄2Ó x 27Ó (1588 x 686 mm)

Size w/ext.wing and 52Ó

Unifence Saw Guide ...................... 781⁄2Ó x 27Ó (1994 x 686 mm)

Height ...................................................................... 341⁄4" (870 mm)

Miter gage groove ........................................3⁄8Ó x 3⁄4Ó (10 x 19 mm)

Overall Dimensions:

Width ....................................................................... 45Ó (1143 mm)

Width w/30Ó Unifence Saw Guide ........................ 671⁄2Ó (1715 mm)

Width w/52Ó Unifence Saw Guide ........................... 83Ó (2108 mm)

Depth ......................................................................... 32Ó (813 mm)

Height ........................................................................ 39Ó (991 mm)

Weight: Model 36-755 ......................................... 288 Ibs. (131 kg)

5

Model 36-751 ......................................... 290 Ibs. (132 kg)

Model 36-752 ......................................... 293 Ibs. (133 kg)

For accessories, see page 27

Page 2

10” Contractor’s Saw

®

New Series 2000 10˝ Contractor’s

Saws take woodworking into the

next century.

Series 2000 10˝ Contractor’s Saws are available

•

with your choice of the UniRip Fence, Unifence®,

Precision Saw Guide or Biesemeyer Saw Fence

systems.

New UniRip T-Square style fence (model 36-444

•

only) offers up to 30˝ of right-hand cutting capacity. Provides additional stock support in front of the

blade and includes built-in T-slots for adding jigs or

other accessories.

Each Series 2000 10˝ Contractor’s Saw comes

•

with a new sturdy steel stand that features an integral dust chute for improved dust collection and

built-in storage for rip fence, miter gage and blade

wrenches.

Maximum 31Ú8Ó depth of cut at 90°; 21Ú8Ó at 45°

•

for clean cutting of standard stock sizes.

Patented Auto-Set®T-Slot miter gage with

•

adjustable stops at 90° and 45° positions

for accurate straight and angle cutting.

Integral T-slot table grooves prevent miter gage

•

from falling during wide cut-off operations.

Extra-large table provides ample support for

•

large work.

Unique “table top located” adjusting screws for

•

accurate setting of 45° & 90° positive blade stops.

Large on/off paddle switch is positioned near the

•

top of the table for quick access.

Convenient up-front blade raising and tilting

•

controls for safe, easy operation.

Heavy-duty 11⁄2 HP induction motor delivers

•

plenty of extra power and speed for the toughest

cutting jobs.

Model 36-445

10Ó Contractor’s Saw

with 30Ó Unifence

Saw Guide

®

Model 36-444

10Ó Contractor’s Saw

®

®

Model 36-444 10Ó Contractor’s Saw®. Includes basic

machine with two table extension wings, stand, belt and

pulley guard, see-thru blade guard with splitter and

anti-kickback attachment, miter gage, UniRip fence with

front and rear guide bars, 10Ó saw blade, V-belt, arbor and

motor pulleys plus 1

Model 36-445 10Ó Contractor’s Saw

Unifence

one table extension wing and 30Ó Unifence

which includes front and rear guide bars, table support

legs and mounting hardware. Less table board.

Model 36-440 10Ó Contractor’s Saw

Precision Saw Guide. Same as model 36-444 but with

one table wing extension and 29Ó Precision Saw Guide

which includes fence, carriage assembly, front guide rail,

table frame and mounting hardware.Less table board

and legs.

Model 36-450 10Ó Contractor’s Saw

Precision Saw Guide. Same as model 36-444,

but with one table extension wing and 50Ó Precision Saw

Guide which includes fence, carriage assembly, front

guide rail, table frame, table support legs and mounting

hardware. Less table board.

®

Saw Guide. Same as model 36-444 but with

1

⁄2 HP, 115/230V, single phase motor.

®

with 30Ó

®

Saw Guide

®

with 29Ó

®

with 50Ó

Model 36-440

10Ó Contractor’s

Saw®with

29Ó Precision

Saw Guide

6

For accessories, see page 27

Page 3

10” Contractor’s Saw

®

Model 36-460 10Ó Contractor’s Saw®with 28Ó

Biesemeyer T -Square

System. Same as model 36-444, but with one table

extension wing and 28Ó Biesemeyer T-Square

®

Home Shop Saw Fence

®

Home

Shop Saw Fence System which includes T-Square

fence, front and rear rails, guide tube and mounting

hardware.Less table board and legs.

Model 36-470 10Ó Contractor’s Saw

Biesemeyer T -Square

®

Home Shop Saw Fence

System. Same as model 36-444, but with one table

extension wing and 40Ó Biesemeyer T-Square

®

with 40Ó

®

Home

Shop Saw Fence System which includes T-Square

fence, front and rear rails, table support legs, guide

tube and mounting hardware.Less table board.

Model 36-480 10Ó Contractor’s Saw

Biesemeyer T -Square

®

Home Shop Saw Fence

System. Same as model 36-444, but with one table

extension wing and 52Ó Biesemeyer T-Square

®

with 52Ó

®

Home

Shop Saw Fence System which includes T-Square

fence, front and rear rails, table support legs, guide

tube and mounting hardware.Less table board.

Model 36-490 10Ó Contractor’s Saw’ with 30Ó

Biesemeyer T -Square

System. Same as model 36-444, but with one table

extension wing and 30Ó Biesemeyer T-Square

®

Commercial Saw Fence

®

Commercial Saw Fence System which includes

T-Square fence, front and rear rails, guide tube and

mounting hardware. Less table board and legs.

Model 36-480

10Ó Contractor’s Saw

with 52Ó Biesemeyer

T-Square®Home Shop

Saw Fence System

®

Motor ................... 11⁄2 HP,115/230V, 60 Hz.,

single phase

Blade:

Diameter................................. 10Ó (254 mm)

Arbor..........................................5Ú8Ó (16 mm)

Speed ........................................... 3000 rpm

Capacities:

Max. depth of cut .................... 31Ú8Ó (79 mm)

Max. depth of cut at 45° ......... 21Ú8Ó (54 mm)

Max. rip to right of blade for:

Model 36-444 .................... 30Ó (762 mm)

Model 36-445 .................... 30Ó (762 mm)

Model 36-440 .................... 29Ó (737 mm)

Model 36-450 .................. 50Ó (1270 mm)

Model 36-460 .................... 28Ó (711 mm)

Model 36-470 .................. 40Ó (1016 mm)

Model 36-480 .................. 52Ó (1321 mm)

Model 36-490 .................... 30Ó (762 mm)

Max. rip to left of blade for:

Model 36-444 ................. 131Ú2Ó (343 mm)

Model 36-445 ................... 83Ú4Ó (222 mm)

Models 36-440, 36-450, 36-460, 36-470,

36-480 and 36-490 ........ 12Ó (305 mm)

Table in front of saw at

max. depth of cut .......... 121Ú4Ó (311 mm)

Max. width of dado .................13Ú16Ó (21 mm)

Model 36-490

10Ó Contractor’s Saw

with 30Ó Biesemeyer

T-Square®Commercial

Saw Fence System

SPECIFICATIONS

Table:

Size ................... 20Ó x 27Ó (508 x 686 mm)

Size with extension wings ............ 40Ó x 27Ó

Size with extension wing and:

Unifence table board ................62Ó x 27Ó

29Ó Precision Saw Guide table

board .......... 54Ó x27Ó (1372x 686 mm)

50Ó Precision Saw Guide table

board ........ 78Ó x 27Ó (1981 x 686 mm)

28Ó Biesemeyer T-Square Home Shop

Saw Fence System .................. 52Ó x 27Ó

40Ó Biesemeyer T-Square Home Shop

Fence System .......................... 64Ó x 27Ó

52Ó Biesemeyer T-Square Home Shop

Fence System .......................... 76Ó x 27Ó

30Ó Biesemeyer T-Square Commercial

Saw Fence System .................. 54Ó x 27Ó

Miter gage groove ..........................3Ú8Ó x

Height on steel stand ......... 341Ú4Ó (185 mm)

(1016 x 686 mm)

(1575 x 686 mm)

(1321 x 686 mm)

(1626 x 686 mm)

(1930 x 686 mm)

(1372 x 686 mm)

(10 x 19 mm)

3

Ú4Ó

®

Overall Dimensions:

Height (on steel stand) ...........39Ó (991 mm)

Width with wings and guide bar ..............57Ó

(1448 mm)

Width with wing and:

Model 36-445 .................. 62Ó (1575 mm)

Model 36-440 .................. 59Ó (1499 mm)

Model 36-450 .................. 80Ó (2032 mm)

Model 36-460 .................. 58Ó (1473 mm)

Model 36-470 .................. 70Ó (1778 mm)

Model 36-480 .................. 82Ó (2083 mm)

Model 36-490 .................. 60Ó (1524 mm)

Depth Model 36-444 ........... 42Ó (1067 mm)

Models 36-445, 36-440

and 36-450 .......................43Ó (1092 mm)

Models 36-460, 36-470

and 36-480 .........................36Ó (914 mm)

Model 36-490 ...................42Ó (1067 mm)

Weight:

Model 36-444 .................. 220 lbs. (99 kg)

Model 36-445 ................ 248 lbs. (112 kg)

Model 36-440 ................ 245 lbs. (111 kg)

Model 36-450 ................ 266 lbs. (120 kg)

Model 36-460 ................ 267 lbs. (121 kg)

Model 36-470 ................ 275 lbs. (125 kg)

Model 36-480 ................ 282 lbs. (128 kg)

Model 36-490 ................ 286 lbs. (130 kg)

7

For additional accessories, see page 28

Page 4

10” Contractor’s Saw®II

®

Solid construction and

quality features make this

saw one smooth operator.

Powerful 11⁄2 HP, single phase induction

•

motor provides the power to handle any

cutting operation.

Auto-Set®T-Slot miter gage has adjustable stops at 45°

•

and 90° for precision straight and angle cutting jobs.

Rack and worm gear blade elevating mechanism

•

raises and lowers blade smoothly and easily.

See-through blade guard with splitter and anti-

•

kickback fingers promotes operator safety.

Accessory dust collector connector mounts to saw

•

carriage for attaching a dust collection system

right at the source of dust and chips.

Large on/off paddle switch.

•

Model 36-630 10Ó Contractor’s Saw®Il. Includes basic

machine with 1

splitter and anti-kickback fingers, Jet-Lock

bars, Auto-Set

arbor pulley, motor pulley, V-belt, two extension wings,

steel leg stand and instruction manual.

Model 36-640 10Ó Contractor’s Saw

Saw Guide. Same as above less Jet-Lock

front and rear guide bars and one table extension wing,

but with 29Ó Precision Saw Guide, carriage assembly, front

guide rail, table frame, mounting hardware and

instruction manual. Less table board.

1

⁄2 HP, single phase motor, blade guard,

®

miter gage, 10Ó saw blade, table insert,

®

rip fence, guide

®

Il with Precision

®

rip fence with

Model 36-630

10Ó Contractor's Saw

®

II

Cast iron 20Ó x 27Ó table with

T-slotted miter gage grooves

and two extension wings.

Self-aligning Jet-Lock

Micro-Set®rip fence glides

on chrome-plated rails.

®

Model 36-640 10Ó Contractor’s Saw II

with 29Ó Precision Saw Guide

SPECIFICATIONS

Motor ................................. 11⁄2 HP, 115/230V, single phase, 60 Hz.

Blade:

Diameter .................................................................... 10Ó (254 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 3000 rpm

Capacity:

Maximum depth of cut at 90° ..................................... 31⁄8Ó (79 mm)

Maximum depth of cut at 45° ..................................... 21⁄8Ó (54 mm)

Maximum rip to right of blade:

Model 36-630 ....................................................... 24Ó (610 mm)

Model 36-640 ....................................................... 29Ó (737 mm)

Maximum rip to left of blade ................................... 121⁄4Ó (311 mm)

Table in front of saw blade at max. cut ................... 121⁄4Ó (311 mm)

Maximum width of dado .............................................13⁄16Ó (21 mm)

Table:

Size ........................................................ 20Ó x 27Ó (508 x 686 mm)

Size with extension wings .................... 40Ó x 27Ó (1016 x 686 mm)

Height ..................................................................... 351⁄2Ó (902 mm)

T-slotted miter gage grooves .......................3⁄8Ó x 3⁄4Ó (10 x 19 mm)

Overall Dimensions:

Length:

Model 36-630 ..................................................... 44Ó (1118 mm)

Model 36-640 ..................................................... 42Ó (1067 mm)

Width:

Model 36-630 ..................................................... 48Ó (1219 mm)

Model 36-640 ..................................................... 59Ó (1499 mm)

Height:

Model 36-630 ..................................................... 40Ó (1016 mm)

Model 36-640 .................................................. 401Ú2Ó (1029 mm)

Weight:

Model 36-630 ..................................................... 188 lbs. (85 kg)

Model 36-640 ..................................................... 202 lbs. (92 kg)

8

For accessories, see page 27

Page 5

The home shop saw

®

that combines power

with precision

T-square

Powerful 15 amp. motor provides

•

5500 rpm blade speed.

Full 221⁄4Ó x 383⁄8Ó table with

•

extension wings provides ample

work support for ripping large

panels.

Maximum 31⁄8Ó depth of cut at

•

90°, 21⁄8Ó at 45° blade tilt. Rips to

the center of a 4Õ panel.

T-Square®Fence System for

•

precision accuracy.

See-thru blade guard with

•

anti-kickback fingers.

Miter gage with 45° R&L and 90°

•

stops for accurate angle cutting.

T-slot miter gage grooves hold

•

miter gage beyond table.

Model 36-600 10Ó Table Saw. Includes

basic machine with 15 amp., 115V, single phase motor, stand, miter gage, TSquare rip fence, table insert,

see-thru blade guard with splitter

and anti-kickback fingers,

10Ó carbide-tipped saw blade,

wrench and instruction manual.

®

accuracy.

10” Table Saw

Model 36-600

10Ó Table Saw

Full 221⁄4Ó x 383⁄8Ó table with

extension wings and T-slot

grooves provides ample work

support for ripping large panels.

Miter gage has positive stops

at 45° and 90° for accurate

angle cutting. Compound

angles can be achieved by tilting blade.

Saw can be converted for

moulding operations with

accessory cutterhead and

table insert.

Cut dados in any width up to

13

⁄16Ó simply by mounting

accessory dado and table

insert.

SPECIFICATIONS

Motor ........................................................... 15 amp., 115V, 60 Hz.

Blade:

Diameter of Arbor .........................................................5⁄8Ó (16 mm)

Speed ............................................................................... 5500 rpm

Diameter of Blade ...................................................... 10Ó (254 mm)

Capacity:

Max. depth of cut at 90° ............................................. 31⁄8Ó (79 mm)

Max. depth of cut at 45° ............................................. 21⁄8Ó (54 mm)

Table distance in front of blade at

1Ó depth of cut ...................................................... 113⁄4Ó (298 mm)

Max. width of dado .....................................................13⁄16Ó (21 mm)

Max. rip to right of blade ............................................ 27Ó (686 mm)

Table:

Size .................................................. 221⁄4Ó x 203⁄8Ó (565 x 518 mm)

Size with both extension wings ................................. 221⁄4Ó x 383⁄8Ó

Height on stand ...................................................... 347⁄8Ó (886 mm)

Miter gage groove ........................................3⁄8Ó x 3⁄4Ó (10 x 19 mm)

Overall Dimensions:

Height ...................................................................... 40Ó (1016 mm)

Width ....................................................................... 51Ó (1295 mm)

Depth ...................................................................... 351⁄2Ó (902 mm)

Weight .................................................................... 145 Ibs. (66 kg)

9

For accessories, see page 27

(565 x 975 mm)

Page 6

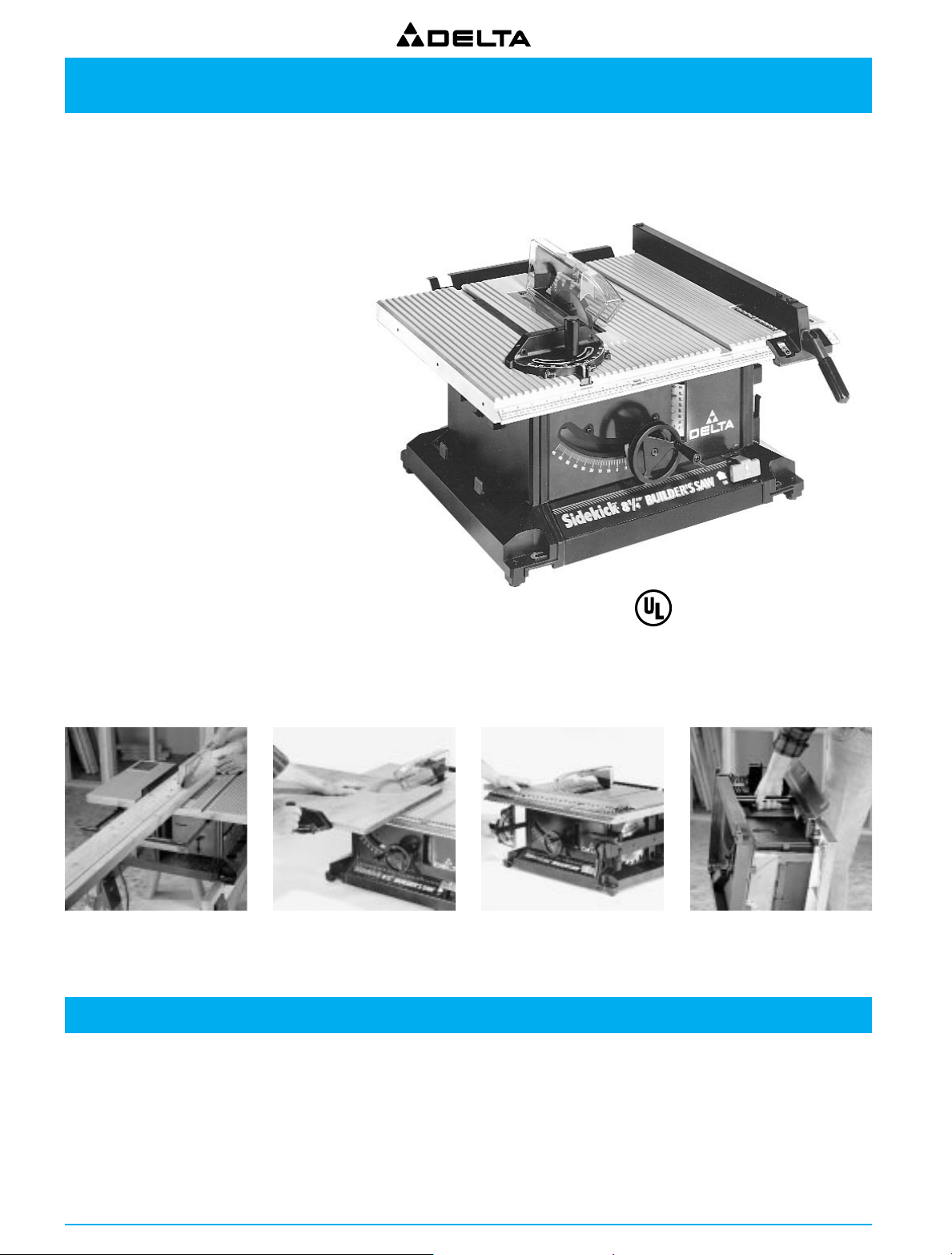

Sidekick®81⁄4” Builder’s Saw

®

The Builder’s Saw that’s

got it all.

Cuts 21⁄4Ó at 90°; 15⁄8Ó at 45° blade

•

tilt—enough capacity to cut dimensional 2 x 4 lumber.

Diecast aluminum table, with inte-

•

gral outfeed work support and T-slot

miter gage grooves, measures a full

26Ó x 20Ó.

Miter gage with adjustable positive

•

stops at 90° and 45° R&L for accurate straight and angle cutting.

Self-aligning rip fence with single

•

control handle and easy-to-read

English/Metric rip scale.

Carbide-tipped 81⁄4Ó dia. x 18 ATB

•

saw blade included as standard

equipment.

Built-in holders and compartments

•

for miter gage, cord, rip fence,

blade guard, extra blade and

wrench set storage.

®

Model 36-275 Sidekick®81⁄4Ó Builder’s

®

. Includes basic machine with

Saw

15 amp., 120V, 60 Hz. motor; rip fence,

miter gage, see-through blade guard with

splitter and anti-kickback fingers, carbidetipped 8

insert, wrenches and instruction manual.

Integral outfeed work support handles large panels and

long stock; slides in, out of the

way, when not in use.

1

⁄4Ó dia. x 18 ATB saw blade, table

T-slot grooves hold miter

gage securely beyond front of

table, preventing it from falling

during wide cut-off operations.

Model 36-275

Sidekick®81⁄4Ó Builder’s

Saw

Built-in holders and compartments for out-of-the-way miter

gage, rip fence, blade guard, extra

blade and wrench set storage;

easier accessibility when needed.

®

Convenient carrying handle

and cord holder bracket for

safe and easy transport from

job to job.

SPECIFICATIONS

Motor ..................................... 15 amp., 120V, single phase, 60 Hz.

Blade:

Diameter ................................................................... 81⁄4Ó (210 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 4500 rpm

Capacity:

Maximum depth of cut at 90° ..................................... 21⁄4Ó (57 mm)

Maximum depth of cut at 45° ..................................... 15⁄8Ó (41 mm)

Maximum rip to right of blade .................................... 12Ó (305 mm)

Table in front of blade at 1Ó depth of cut ..................... 8Ó (203 mm)

Maximum width of dado .............................................13⁄16Ó (21 mm)

Table:

Size ........................................................ 26Ó x 20Ó (660 x 508 mm)

with accessory extension wing ............ 32Ó x 20Ó (813 x 508 mm)

Height ..................................................................... 121⁄8Ó (308 mm)

T-slot ............................................................3⁄8Ó x 3⁄4Ó (10 x 19 mm)

Overall Dimensions:

Height ..................................................................... 157⁄8Ó (403 mm)

Width ......................................................................... 26Ó (660 mm)

Depth ...................................................................... 253⁄8Ó (645 mm)

Weight ................................................................... 481⁄2 Ibs. (22 kg)

10

For accessories, see page 29

Page 7

10” Bench Saw

®

Big saw capacity in an

economical package.

Lightweight for portability; goes where

•

you go, when you need it.

Ample capacity to cut 3Ó at 90°;

•

21⁄2Ó at 45°.

Powered by a heavy duty 13 amp.,

•

115V motor for dependability.

Rip fence locks front and rear to

•

maintain accuracy at the cut.

Blade tilting and height control knobs are

•

up-front for convenience.

Self-aligning rip fence aligns and locks itself

•

parallel to blade with single control lever.

Big 171⁄4Ó x 26Ó table provides ample

•

support for large ripping operations.

Removable on-off switch to prevent

•

unauthorized use.

Convenient holder for out-of-the-way

•

miter gage storage.

See-thru blade guard with integral

•

splitter and anti-kickback fingers for operator safety.

Model 36-540 Type 2 10Ó Bench Saw. Includes

basic machine with 13 amp., 115V, 60 Hz. motor;

rip fence, miter gage, see-thru blade guard with

splitter and anti-kickback fingers, 10Ó carbidetipped saw blade, standard table insert, blade

wrenches and instruction manual.

Model 36-540

10Ó Bench Saw

Cuts stock 3Ó thick at 90°, offers full 21⁄2Ó

cutting capacity at 45° blade tilt.

T-slot table groove prevents miter gage

from falling during wide cut-off operations.

Model 36-545 10Ó Bench Saw

with Stand. Same as above, but with

steel stand.

SPECIFICATIONS

Motor .......................................13 amp., 115V, single phase, 60 Hz.

Blade:

Diameter ......................................................................10Ó (254 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed .................................................................................4700 rpm

Capacity:

Max. depth of cut at 90° .................................................3Ó (76 mm)

Max. depth of cut at 45°...............................................21⁄2Ó (64 mm)

Max. rip to right of blade.............................................97⁄8Ó (252 mm)

Max. width of cut-off at 1Ó depth of cut

with T-slot miter gage................................................10Ó (254 mm)

Max. width of dado.........................................................1⁄2Ó (13 mm)

Table:

Size.......................................................171⁄4Ó x 26Ó (438 x 660 mm)

T-slot ...............................................................3⁄16Ó x 5⁄8Ó (5 x 16 mm)

Overall Dimensions:

Model 36-540...........15ÓH x 26ÓW x 24ÓD (381 x 660 x 610 mm)

Model 36-545...........39ÓH x 26ÓW x 24ÓD (991 x 660 x 610 mm)

Weight:

Model 36-540........................................................ 40 Ibs. (18 kg)

Model 36-545........................................................ 51 Ibs. (23 kg)

11

For accessories, see page 29

Page 8

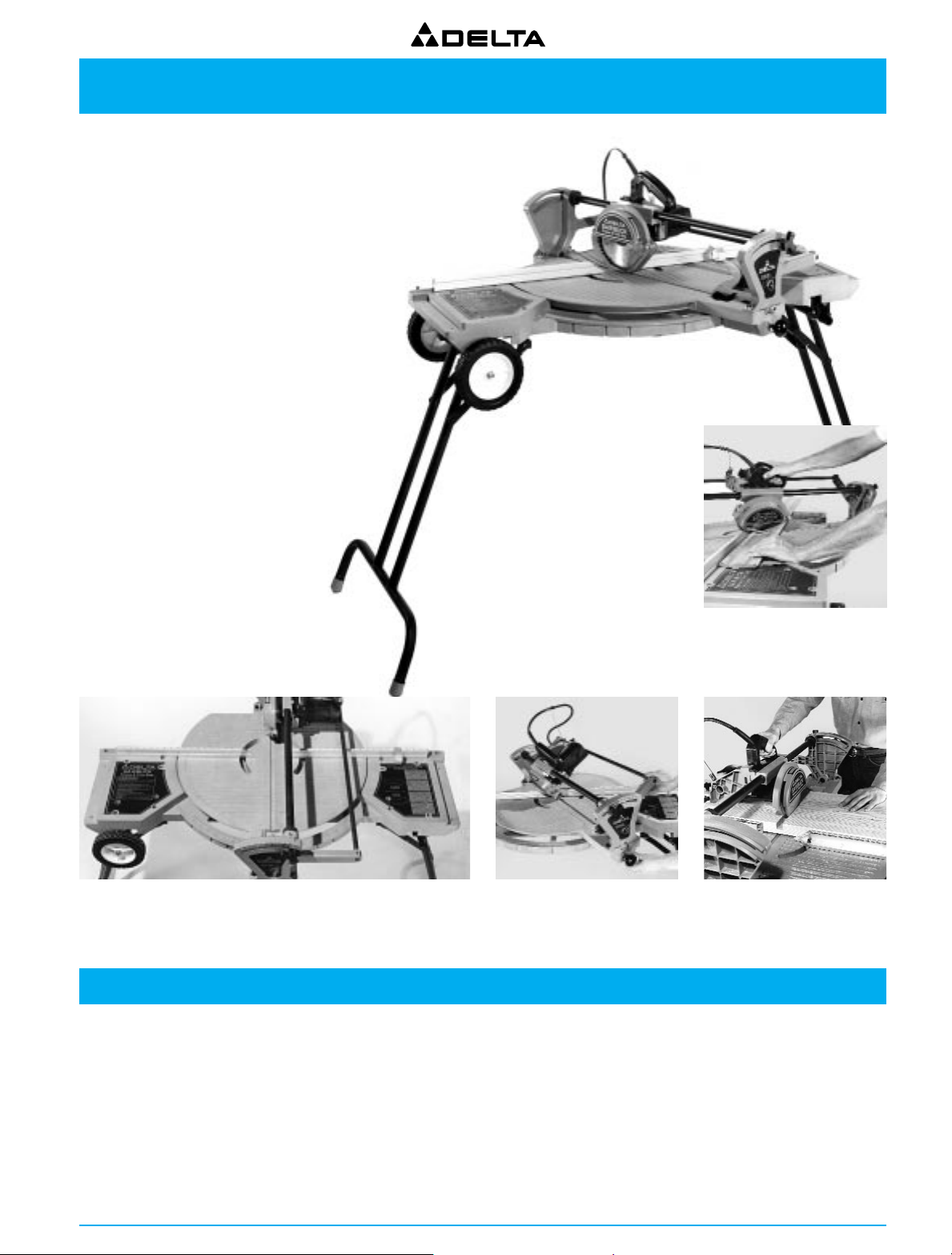

Sidekick®Saw Stand

Adds sturdy support and

complete job-site mobility.

Holds Delta 81⁄4Ó and 10Ó Bench

•

Saws as well as most other

competitive models.

Storage slots hold rip fence out

•

of the way when not in use.

Two-year limited warranty.

•

Model 50-170 Sidekick®Saw Stand.

Includes stand, folding legs, fence guide

rail, 13Ó diameter wheels, hardware and

instruction manual.

Model 50-170 Sidekick®Saw Stand.

Sidekick 81Ú4Ó Builder’s Saw not included.

Precision fence and guide rail

included for ripping operations to

the right and left of saw blade.

Folds flat for storing or

transporting from job to job.

SPECIFICATIONS

Overall Dimensions:

Length ....................................................................... 73Ó (1854 mm)

Width ........................................................................... 27Ó (686 mm)

Height ...................................................................... 351Ú2Ó (902 mm)

Opening Size: ..................................... 221Ú4Ó x 23Ó (565 x 584 mm)

Weight: (without saw) .............................................. 65 lbs. (29 kg)

Rip Capacity (to right of blade):

With Model 36-275 Sidekick 81Ú4Ó Builder’s Saw ........ 27Ó (686 mm)

Note: Rip capacity may vary according to your bench saw model.

The Sidekick Saw Stand helps

you move your bench saw quickly

and easily.

Large 13Ó diameter wheels

for quick, easy movement—

even up steps.

ACCESSORIES

No. 50-171 Rear Outfeed Work Support. Provides an additional

12Ó of stock support.

12

Page 9

Deluxe Sawbuck®Frame and Trim Saw

Try it once and you won’t be

able to get along without it.

Perfect for crosscuts up to 16Ó at 90°,

•

12Ó at 45° on hard and soft woods, vinyl

and aluminum siding.

Saw head miters and tilts for angle and

•

compound cutting operations.

Large 2913⁄16Ó miter scale has 1⁄4Ó between

•

degree markings for easy reading with

positive stops at 0°, 221⁄2° and 45° R and L

including a special 31.62° position for cutting crown mouldings.

Exclusive SMC construction eliminates

•

table rust and corrosion; steel guide bars

are Nitrotec™ treated for rust-free,

smooth gliding operation.

Powerful 15 amp. gear dr iven motor

•

features an electric brake that

automatically stops blade in seconds

after the switch trigger is released.

Model 33-055 Deluxe Sawbuck

Frame and Trim Saw. Includes

basic machine with 15 amp., 115V,

25-60 Hz., AC motor with electric

automatic brake, 6 foot cord, leg

set, blade guard with retractable

leaf guard, 8Ó diameter crosscut

saw blade, blade wrench and

instruction manual.

®

Model 33-055

Deluxe Sawbuck

Frame and Trim Saw

®

Special 31.62° miter stop and

33.85° bevel setting facilitates

compound cutting standard

52°/38° crown moulding.

Table is made of an entirely new reinforced polyester resin

compound that prevents warping, springing and rusting. Cutting

head is supported at both ends by corrosion-proof steel guide rails.

SPECIFICATIONS

Motor ............................................... 15 amp., 115V, 25-60 Hz., AC

Brake .................................................................. Electric, automatic

Blade:

Diameter ...................................................................... 8Ó (203 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 5500 rpm

Capacity:

Cut-Off at 90° ............................................................ 16Ó (406 mm)

Cut-Off at 45° ............................................................ 12Ó (305 mm)

Depth of cut at 90° ..................................................... 23⁄4Ó (70 mm)

Depth of cut at 45° ..................................................... 13⁄4Ó (44 mm)

Dado .......................................................13⁄16Ó (21 mm) Width using

6Ó Diameter Stackable Type

Set-up is simple and fast.

Table rotates with track arm for

mitering. Motor tilts around

common table-level pivot point

for beveling.

Cutting Head Height Adj. ................................ 1

Table:

Diameter of cutting surface .................................... 281⁄2Ó (724 mm)

Extension on both sides of table ............................ 113⁄4Ó (298 mm)

Overall length .......................................................... 52Ó (1321 mm)

Height ..................................................................... 351⁄4Ó (895 mm)

Fences .............................................. 23Ó (584 mm) R & L of Blade

Positive Stops:

Miter ............................................... 0°, 221⁄2°, 31.62° & 45° R & L

Overall Dimensions ........................................... 37Ó x 671⁄2Ó x 47Ó

Weight ...................................................................... 96 Ibs. (44 kg)

13

Deluxe Sawbuck accommodates accessory 6Ó diameter

stackable type dado head to

cut grooves up to 13⁄16Ó wide.

1

⁄4Ó (32 mm) max.

(940 x 1715 x 1194 mm)

For accessories, see page 29

Page 10

Sidekick®10” Sliding Compound Miter Saw

®

Packed with features that

place it on the cutting edge.

Cuts 111⁄2Ó at 90° and 8Ó at 45° miter ; 35⁄8Ó

•

depth of cut at 90° and 2Ó at 45° bevel.

Powerful 15 amp. motor provides plenty of

•

cutting power.

Built-in arbor lock for easy blade changes.

•

Standard-equipped stand features built-in

•

left and right table extensions, with stock

stops and wrench storage, that total 59" in

length.

Carbide-tipped 10Ó dia. x 40 ATB saw

•

blade included as standard equipment.

Electric blade brake automatically stops

•

blade in seconds.

Dust bag collects fine dust and chips for

•

cleaner work environment.

Extra long 10Õ cord for increased on-the-job

•

mobility.

Model 36-250 Sidekick®10Ó Sliding Compound

Miter Saw. Includes basic machine with 15 amp.,

120V, 60 Hz. motor; 10Õ 3-conductor cord with

ground-type plug, electric blade brake, carbidetipped 10Ó dia. x 40 ATB saw blade, base mounting feet, stand with table extensions and stock

stops, work clamp, retractable saw blade guard,

dust bag, wrench and instruction manual.

Model 36-250 Sidekick

10Ó Sliding Compound

Miter Saw

®

Quick-action miter lock elimi-

nates use of traditional screw

locks for faster miter setting.

Patented stand folds quickly

for carrying saw easily;

removes for bench mounting.

One-piece die-cast aluminum

table has dual rod, linear ball

bearing guide system for precision cutting.

Work clamp secures stock,

preventing material shifting for

increased cutting accuracy and

operator safety.

SPECIFICATIONS

Motor ........................................................... 15 amp., 120V, 60 Hz.

Blade:

Diameter .................................................................... 10Ó (254 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 5000 rpm

Capacity:

Cut-off at 90° ......................................................... 111⁄2Ó (305 mm)

Cut-off at 45° miter ...................................................... 8Ó (203 mm)

Depth of cut at 90° ..................................................... 35⁄8Ó (92 mm)

Depth of cut at 45° bevel ............................................... 2Ó (51 mm)

Table:

Diameter of cutting surface ....................................... 19Ó (483 mm)

Fence:

Length ........................................................................ 19Ó (483 mm)

Fence length with extensions .................................. 59Ó (1499 mm)

Positive miter stops .......................... 0°, 221⁄2° 31.62° & 45°, R&L

Bevel stops ................................................................. 0° and 45° L

Overall Dimensions with Stand and Table Extensions:

Height ................................................................... 541⁄2Ó (1384 mm)

Width ....................................................................... 59Ó (1499 mm)

Depth ...................................................................... 251⁄2Ó (648 mm)

Without Stand:

Height ..................................................................... 253⁄4Ó (654 mm)

Width ...................................................................... 281⁄2Ó (724 mm)

Depth ......................................................................... 25Ó (635 mm)

Weight with Stand ................................................... 56 lbs. (25 kg)

14

For accessories, see page 29

Page 11

Sidekick®10” Sliding Compound Miter Saw

®

A powerful, por table compound

slide saw built for today’s job sites.

Powerful 15 amp. motor handles the toughest

•

cutting jobs.

Die-cast aluminum table with large, easy-to-read

•

English/Metric miter scale.

Dual rod, linear ball-bearing guide system provides

•

precision cutting performance.

Secondary left and right fence supports to handle

•

thick workpieces or long stock.

Patented base mounts on job site 2 x 4’s for

•

fast, easy on-site setup.

Quick-action miter lock is designed for faster

•

miter settings.

Handy work clamp prevents stock from shifting to

•

maintain cutting accuracy.

Model 36-240 Delta Sidekick 10˝ Sliding

Compound Miter Saw. Includes basic machine

with 15 amp., 120V motor, 10-ft.

3-conductor cord with grounding plug,

electric blade brake, carbide-tipped

10˝ dia. saw blade, work clamp,

retractable blade guard, dust bag,

wrench and instruction manual.

Patented base fits over 2 x 4’s

for setting up shop anywhere

around the job site.

Built-in head lock keeps saw

head in place for transporting

safely from job to job.

SPECIFICATIONS

Motor ........................................................... 15 amp., 120V, 60 Hz.

Blade:

Diameter .................................................................... 10Ó (254 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 5000 rpm

Capacity:

Cut-Off at 90° ......................................................... 111⁄2Ó (292 mm)

Cut-Off at 45° Miter ..................................................... 8Ó (203 mm)

Depth of Cut at 90° .................................................... 35⁄8Ó (92 mm)

Max. Depth of Cut at 45° Bevel...................................... 2Ó (51 mm)

Table:

Diameter of Cutting Surface ...................................... 19Ó (483 mm)

Model 36-240 Sidekick

10Ó Sliding Compound

Miter Saw

Designed for large cutting

capacity, this saw cuts stock up

to 35⁄8˝ deep and up to 2˝ deep

when positioned at a 45°

bevel.

Fence:

Length ........................................................................ 19Ó (483 mm)

Fence Length with Supports ...................................... 26Ó (660 mm)

Positive Miter Stops ....................... 0°, 221⁄2°, 31.62° & 45° R & L

Bevel Stops ................................................................ 0° and 45° L

Overall Dimensions:

Length ........................................................................ 26Ó (660 mm)

Width ......................................................................... 27Ó (686 mm)

Height ........................................................................ 19Ó (483 mm)

Weight ...................................................................... 51 Ibs. (23 kg)

Large, easy-grip handle is

positioned horizontally for

better operating control and to

reduce operator fatigue.

®

15

For accessories, see page 29

Page 12

Sidekick®12” Compound Miter Saw

®

Now with improved extra-tall fence,

increased work support and more!

Powerful 15 amp., 3500 rpm motor for maximum

•

cutting power.

Large bevel scale for quick, easy tilt settings with

•

adjustable positive stops at 0° and 45° L.

Quick-action miter lock for faster miter settings.

•

High-quality 40T carbide-tipped blade included

•

as standard equipment.

Patented base designed for either bench or

•

job site 2 x 4 sawhorse mounting.

Electric blade brake automatically stops blade

•

in seconds.

Work clamp secures stock, prevents material

•

shifting for increased cutting accuracy and

operator safety.

Built-in arbor lock for easy, single wrench blade

•

changes.

Dust bag collects fine dust particles

•

and wood chips.

See-through blade guard covers blade at all times;

•

automatically retracts as cut is being made.

Model 36-235 Sidekick®12Ó Compound Miter Saw.

Includes basic machine with 15 amp., 120V, 60 Hz. motor; 9Õ

cord with grounding type plug, electric blade brake, 12Ó diame-

ter, 40T carbide-tipped saw blade, retractable blade guard, work

clamp, dust bag, wrenches and instruction manual.

Model 36-235 Sidekick

12Ó Compound Miter Saw

®

Sliding fence adjusts for increased work support and is extra tall for handling large workpieces,

or cutting crown moulding on edge instead of flat on the table.

Large, easy-grip handle is

positioned horizontally to

reduce operator fatigue and

provide better control during

operation.

SPECIFICATIONS

Motor ........................................................... 15 amp., 120V, 60 Hz.

Blade:

Diameter .................................................................... 12Ó (305 mm)

Arbor................................................................................1Ó (25 mm)

Speed .................................................................................3500 rpm

Capacity:

Crosscut......................................................8Ó x 21⁄2Ó (203 x 64 mm)

7Ó x 31⁄2Ó (178 x 89 mm)

Miter at 45° R&L .................................... 53⁄4Ó x 21⁄2Ó (146 x 64 mm)

Bevel at 45° L 61⁄2Ó x 21⁄2Ó (165 x 64 mm)

8Ó x 13⁄8Ó (203 x 35 mm)

Compound 45° x 45° ............................. 51⁄4Ó x 11⁄2Ó (133 x 38 mm)

45⁄8Ó x 21⁄4Ó (117 x 57 mm)

Fence Size:

Right Side .......................................... 25⁄8Ó x 101⁄8Ó (67 x 257 mm)

Left Side ............................................... 5Ó x 163⁄8Ó (127 x 416 mm)

Left Side (w/fence extended) ................ 5Ó x 235⁄8Ó (127 x 600 mm)

Table:

Diameter ................................................................ 137⁄8Ó (352 mm)

Sides .......................................................................... 33⁄4Ó (95 mm)

Miter Stops ..................................... 0°, 15°, 22.5°, 31.62°, 45° R&L

Bevel Stops .................................................................. 0° and 45° L

Overall Dimensions:

Height ...................................................................... 223⁄4Ó 578 mm)

Width (w/ fence extended) ........................................ 35Ó (889 mm)

Depth ......................................................................... 36Ó (914 mm)

Weight ...................................................................... 50 lbs. (23 kg)

16

For accessories, see page 29

Page 13

Sidekick®10” Compound Miter Saw

®

From crosscuts to

compounds—this one’s got

all the angles covered.

Powerful 15 amp., motor provides plenty of

•

power for tough cutting jobs.

Electric blade brake automatically stops saw

•

blade in seconds.

Bevel scale for quick, easy blade tilt settings

•

with adjustable positive stops at 0° and 45° L.

Built-in arbor lock for easy, single

•

wrench blade changes.

Work clamp to securely hold stock

•

for more accurate cutting.

Convenient lock handle ver tically

•

clamps the rotating table at the

selected miter setting; lessening

distortion or variances in miter settings

common to table edge locking systems.

Lubricated-for-life ball bearings at vital wear

•

points to assure trouble-free performance with

less maintenance.

High-quality steel 10Ó diameter, 40T carbide-

•

tipped blade included as standard equipment.

Model 36-210 Sidekick®10Ó Compound Miter Box.

Includes basic machine with 15 amp., 120V, 60Hz.

motor; 5Õ 3-conductor cord with grounding type plug,

electric blade brake, 10Ó diameter carbide-tipped saw

blade, retractable blade guard, dust bag, wor k clamp,

wrench and instruction manual.

Aggressive 15 amp. motor

develops plenty of power to

crosscut a nominal 2x6 or 4x4

at 90°; miter 2x4 flat or on

edge at 45° R&L.

Versatile tilting blade allows

you to bevel cut a nominal

2 x 6 at 45°, compound angle

cut a 2x4 at 45° miter and 45°

bevel cutting position.

SPECIFICATIONS

Motor ........................................................... 15 amp., 120V, 60 Hz.

Blade:

Diameter .................................................................... 10Ó (254 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 5000 rpm

Capacity:

Crosscut ................................................ 55⁄8Ó x 21⁄2Ó (143 x 64 mm)

Miter at 45° R & L ..................................... 4Ó x 21⁄2Ó (102 x 64 mm)

Bevel at 45° L ........................................ 55⁄8Ó x 15⁄8Ó (143 x 41 mm)

Compound 45° x 45° ................................ 4Ó x 15⁄8Ó (102 x 41 mm)

31⁄2Ó x 31⁄2Ó (89 x 89 mm)

31⁄2Ó x 21⁄2Ó (89 x 64 mm)

Model 36-210 Sidekick

10Ó Compound Miter Box

Patented trigger-controlled

miter indexing mechanism

facilitates quick, easy and

accurate selection of 0°, 221⁄2°

and 45° R & L miter settings.

Fence Size R & L ................................. 2

Table:

Diameter ................................................................. 103⁄8Ó (264 mm)

Sides ........................................................................... 33⁄4Ó (95 mm)

Miter Stops ................................................ 0°, 221⁄2° and 45° R & L

Bevel Stops .................................................................. 0° and 45° L

Overall Dimensions:

Height ........................................................................ 20Ó (508 mm)

Width ...................................................................... 181⁄4Ó (464 mm)

Depth ......................................................................... 28Ó (711 mm)

Weight ...................................................................... 30 Ibs. (14 kg)

Multi-position handle is verti-

cally adjustable for operator

preference, comfort and convenience. Provides better control;

lessens operator fatigue.

1

⁄2Ó x 81⁄2Ó (64 x 216 mm)

®

17

For accessories, see page 29

Page 14

Sidekick®10” Motorized Miter Box

®

A true cutting friend that will help

cut those big jobs down to size.

Powerful 12 amp. motor provides plenty of power

•

for tough cutting jobs.

Electric blade brake automatically stops saw

•

blade in seconds.

Lightweight aluminum alloy construction—weighs

•

only 30 pounds. Easily carried from job to job.

Extra-wide one-piece fence for maxi-

•

mum support of extra-wide materials.

Efficient dust collection system with

•

strategically positioned baffle and

dust spout, collects up to 80% of all

fine dust particles and wood chips.

Patented base design for either bench

•

or job site 2x4 sawhorse mounting.

Built-in arbor lock for easy, single

•

wrench blade changes.

See-through blade guard covers blade at all

•

times, automatically retracts as cut is being

made.

Model 36-090 Sidekick®10Ó Motorized Miter Box.

Includes basic machine with 12 amp., 120V, 25-60 Hz.

motor; 6 foot 3-conductor cord with grounding type plug,

electric blade brake, 10Ó diameter carbide-tipped saw

blade, retractable blade guard, dust bag, wrench and

instruction manual.

Model 36-090 Sidekick

10Ó Motorized Miter Box

®

Multi-position D-handle control. Vertically adjustable, for

operator preference, comfort

and convenience.Provides better control for easier, more efficient cutting with less operator

fatigue regardless of working

height.

Trigger-controlled miter

indexing mechanism.

Facilitates quick, easy and

accurate selection of 0°, 221⁄2°

and 45° R&L settings. Easy-toread scale for in-between

angles is accurate to 1⁄2 of a

degree.

Exclusive poly-v belt drive

system. Unique rear-mounted

motor delivers plenty of power

and speed to a separate, independent saw arbor through an

extra-wide poly-v belt drive.

Runs quieter; eliminates costly

repairs of gear driven systems.

Big cutting capacity.

Crosscuts a nominal 2x6 or

4x4; miters a 2x4, flat or on

edge, at 45°—all in a single

pass, using a 10" diameter

blade and without having to

adjust the fence.

SPECIFICATIONS

Motor ...................................................... 12 amp., 120V, 25-60 Hz.

Blade:

Diameter .................................................................... 10Ó (254 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 6000 rpm

Capacity:

Crosscut Max.WxH ............................... 51⁄2Ó x 21⁄2Ó (140 x 64 mm)

Max. HxW ................................................ 31⁄2Ó x 31⁄2Ó (89 x 89 mm)

Miter at 45° R&L Max. WxH .................... 37⁄8Ó x 21⁄2Ó (98 x 64 mm)

Max HxW ................................................ 31⁄2Ó x 21⁄2Ó (89 x 64 mm)

Miter at 221⁄2° R&L Max. WxH .................. 5Ó x 21⁄2Ó (127 x 64 mm)

Max HxW ................................................. 31⁄2Ó x 31⁄4Ó (89 x 83 mm)

Fence size R&L ................................. 2

Table:

Diameter ................................................................ 105⁄16Ó (262 mm)

Sides .......................................................................... 33⁄4Ó (95 mm)

Miter Stops ..................................................... 0°, 221⁄2° & 45° R&L

Overall Dimensions:

Height ........................................................................ 24Ó (610 mm)

Width ......................................................................... 18Ó (437 mm)

Depth ......................................................................... 20Ó (508 mm)

Weight ...................................................................... 30 Ibs. (14 kg)

18

1

⁄2Ó x 85⁄8Ó (64 x 219 mm)

For accessories, see page 29

Page 15

10” Compound Miter Saw

®

Efficiently handles bevel and

compound angle cutting jobs in

addition to big capacity miter

and square cuts.

Double insulated construction for operator

•

safety.

D-handle design with trigger switch for posi-

•

tive control; lock-out button to prevent accidental starts.

Electric brake automatically stops blade in

•

seconds.

Built-in arbor lock for easy single wrench

•

blade changes.

Automatic retracting see-through blade guard.

•

Dust bag to collect fine dust particles and

•

wood chips.

Replaceable cut-through table insert for

•

optimum chipbreaking.

Model 36-220 10Ó Compound Miter Saw. Includes

basic machine with 15 amp., 120V, 60 Hz. motor;

cord with 2-prong plug; electric blade brake,

10Ó diameter saw blade, retractable

blade guard, dust bag, work supports,

clamp and stock stop, wrench and

instruction manual.

Model 36-220

10Ó Compound Miter Saw

Aggressive 15 amp. motor

develops plenty of power to

crosscut standard 2 x 6 or

4 x 4 stock at 90°; miter a

2 x 4 at 45°.

Bevel cuts at full 13⁄4Ó x 53⁄4Ó

at 45° blade tilt compound

angle cuts 13⁄4Ó x 41⁄8Ó at its

maximum 45° miter and bevel

cutting position.

Extra-wide fence for extra

support with a work clamp to

securely hold the workpiece,

assures accurate cutting; simplifies compound angle cutting

crown moulding.

Work supports for cutting

extra-long material, with a

stock stop to facilitate repetitive

cut-off work are included as

standard equipment.

SPECIFICATIONS

Motor ........................................................... 15 amp., 120V, 60 Hz.

Blade:

Diameter ................................................................. 10Ó (254.0 mm)

Arbor ..........................................................................5⁄8Ó (15.8 mm)

Speed ............................................................................... 4900 rpm

Capacity with Fence in Front Position:

Crosscut ................................................ 23⁄4Ó x 51⁄8Ó (70 x 130 mm)

31⁄2Ó x 4Ó (89 x 102 mm)

Miter 45° R&L .......................................... 23⁄4Ó x 31⁄2Ó (70 x 89 mm)

Bevel 45° L ............................................ 13⁄4Ó x 51⁄8Ó (44 x 130 mm)

Compound 45° x 45° ............................... 13⁄4Ó x 31⁄2Ó (44 x 89 mm)

Capacity with Fence in Rear Position:

Crosscut ................................................. 23⁄4Ó x 53⁄4Ó (70 x 146 mm)

31⁄2Ó x 45⁄8Ó (89 x 117 mm)

Miter 45° R&L ........................................ 23⁄4Ó x 41⁄8Ó (70 x 105 mm)

Bevel 45° L ............................................ 13⁄4Ó x 53⁄4Ó (44 x 146 mm)

Compound 45° x 45° ............................ 13⁄4Ó x 41⁄8Ó (44 x 105 mm)

Fence Size:

Left ............................................................ 3Ó x 71⁄2Ó (76 x 191 mm)

Right ......................................................... 21⁄2Ó x 8Ó (64 x 203 mm)

Table:

Diameter ..................................................................101⁄2Ó (267 mm)

Sides ........................................................................... 33⁄4Ó (95 mm)

Bevel Positive Stops ................................................. 0° and 45° L

Miter Stops................................. 0°, 15°, 221⁄2°, 30° and 45° R & L

Overall Dimensions .................................... 201⁄2Ó x 381⁄2Ó x 201⁄2Ó

Weight ...................................................................... 49 Ibs. (22 kg)

19

For accessories, see page 29

(521 x 978 x 521 mm)

Page 16

10” Compound Power Miter Saw

®

High performance

without the high price.

Electric blade brake automatically stops

•

blade in seconds.

Lubricated-for-life ball bearings assure

•

trouble-free performance with less

maintenance.

Powerful 13 amp. motor provides plenty

•

of power for tough cutting jobs.

Easy-to-read bevel scale with adjustable

•

positive stops for quick tilt settings.

Convenient miter indexing mechanism

•

for quick, easy miter settings.

Large one-piece fence for maximum

•

support of extra-wide materials.

Lightweight aluminum alloy construction,

•

weighs only 28 Ibs.

Dust bag collects fine dust and woodchips.

•

Model 36-075 10˝ Compound Power Miter Saw.

Includes basic machine with 13 amp., 120V,

60 Hz. motor; 8´ cord with grounded plug,

electric blade brake, 10˝ diameter crosscut blade,

retractable blade guard, dust bag, blade wrench

and instruction manual.

Crosscuts a nominal 2 x 6 or 4 x 4 at 90°.

Miters a 2 x 4 flat or on edge at 45° R&L.

Makes quick work out of cutting

compound angles on crown moulding or

nominal 2 x 4’s.

SPECIFICATIONS

Motor ........................................................... 13 amp., 120V, 60 Hz.

Blade:

Diameter .................................................................... 10Ó (254 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 5200 rpm

Capacity:

90° Crosscut ..................................... 53⁄4ÓW x 23⁄8ÓH (146 x 60 mm)

Miter 45° R&L ................................... 41⁄8ÓW x 23⁄8ÓH (105 x 60 mm)

Bevel 45° L (90° miter) .................... 57⁄8ÓW x 19⁄16ÓH (149 x 40 mm)

Compound 45° x 45° ....................... 41⁄8ÓW x 19⁄16ÓH (105 x 40 mm)

33⁄8ÓW x 311⁄16ÓH (86 x 94 mm)

25⁄8ÓW x 35⁄8ÓH (67 x 92 mm)

35⁄8ÓW x 29⁄16ÓH (92 x 65 mm)

27⁄16ÓW x 27⁄8ÓH (62 x 73 mm)

Model 36-075

10Ó Compound Power Miter Saw

Convenient miter indexing mechanism for

quick and easy miter settings

Fence Size R&L ............................ 17

Table:

Diameter ................................................................. 111⁄2Ó (279 mm)

Sides ...................................................................... 3Ó R&L (76 mm)

Miter Stops ................................................... 0°, 221⁄2° and 45° R&L

Miter Range ........................................................................ 47° L&R

Bevel Stops ......................................................... 0°, 45° Adjustable

Bevel Range ....................................................................... -3°/+48°

Overall Dimensions:

(L x W x H) .................. 32Ó x 173⁄4Ó x 201⁄2Ó (813 x 451 x 521 mm)

Weight ...................................................................... 28 Ibs. (13 kg)

5

⁄8ÓW x 21⁄2ÓH (448 x 63 mm)

20

For accessories, see page 29

Page 17

10” Power Miter Saw

®

Power. Capacity. Portability.

Everything you could ask

for in a miter saw!

Convenient miter indexing control with

•

positive stops at 0°, 221⁄2° and 45° R&L.

Easy-to-read scale for in-between

angles is accurate to 1⁄2°.

Extra-wide one-piece fence for

•

maximum support of wide materials.

See-through blade guard covers blade

•

at all times; automatically retracts as cut

is being made.

Electric blade brake automatically stops

•

blade in seconds.

Pre-drilled base holes for easy bench

•

mounting.

Model 36-070 10Ó Power Miter Saw. Includes

basic machine with 13 amp., 120V, 60 Hz.

motor; 6Õ 3-conductor cord with ground-type

plug, electric blade brake, 10Ó dia. saw blade,

retractable saw blade guard, dust bag, wrenches and instruction manual.

13 amp., 5200 rpm motor provides plenty

of power and speed for tough cutting jobs.

Crosscuts a nominal 2 x 6

or 4 x 4 at 90°. Miters a 2 x 4 flat or on

edge in a single pass, at 45°.

SPECIFICATIONS

Motor ........................................................... 13 amp., 120V, 60 Hz.

Blade:

Diameter .................................................................... 10Ó (254 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 5200 rpm

Capacity:

Crosscut ................................................. 53⁄4Ó x 21⁄4Ó (146 x 57 mm)

Miter at 45° R&L .................................... 41⁄8Ó x 21⁄4Ó (105 x 57 mm)

33⁄4Ó x 33⁄4Ó (95 x 95 mm)

31⁄2Ó x 31⁄8Ó (89 x 79 mm)

Model 36-070

10Ó Power Miter Saw

Constructed of a lightweight aluminum

alloy—weighs only 28 Ibs.for easy carrying

from job to job.

Fence Size R&L ................................... 2

Table:

Diameter .................................................................... 11Ó (279 mm)

Sides ........................................................................... 31⁄4Ó (83 mm)

Miter stops ................................................... 0°, 221⁄2° and 45° R&L

Overall Dimensions:

Height ..................................................................... 201⁄4Ó (514 mm)

Width ...................................................................... 173⁄4Ó (451 mm)

Depth ........................................................................... 32Ó (81 mm)

Weight ...................................................................... 28 Ibs. (13 kg)

1

⁄2Ó x 77⁄8Ó (64 x 200 mm)

21

For accessories, see page 29

Page 18

81⁄4” Compound Miter Saw

®

The straightforward

answer to angle cutting.

Full 9 amp.motor powers through

•

crosscuts up to 21⁄8Ó x 51⁄8Ó thick.

Large 11Ó diameter table has positive

•

ball detents at 0°, 15°, 221⁄2°, 30° and

45° right and left. Bevel scale has

stops at 0° and 45° for quick setting of

common compound angles.

Nominal 153⁄4 Ib. weight makes it per-

•

fect for moving around the wor kshop

or the job site.

Articulating blade guard continuously

•

adjusts to cover the blade as it's

raised and lowered.

Built-in arbor lock for easy, single

•

wrench blade changes.

Replaceable cut-through table insert

•

for optimum chipbreaking.

Equipped with an electric brake that

•

automatically stops blade in seconds.

Model 36-040 81⁄4Ó Compound Miter Saw.

Includes basic machine with 9 amp.,

115V, 60 Hz., universal motor, 7Õ cord with

2-prong plug; automatic electric blade brake,

1

⁄4Ó diameter saw blade, retractable blade

8

guard, dust bag and instruction manual.

Compound angle and bevel

cutting is easy and accurate.

Blade tilts 0° to 45° left for

bevel and compound angle

cutting.

SPECIFICATIONS

Motor ...................................................... 9 amp., 115V, 60 Hz., AC

Blade:

Diameter ................................................................... 81⁄4Ó (210 mm)

Arbor .............................................................................5⁄8Ó (16 mm)

Speed ............................................................................... 5200 rpm

Capacity:

Crosscut ................................................. 21⁄8Ó x 51⁄8Ó (54 x 130 mm)

Miter 45° R & L ........................................ 21⁄8Ó x 31⁄2Ó (54 x 89 mm)

Bevel 45° L ............................................ 11⁄2Ó x 51⁄8Ó (38 x 130 mm)

Compound 45° R & L w/45° ................... 11⁄2Ó x 31⁄2Ó (38 x 89 mm)

Model 36-040

81⁄4Ó Compound Miter Saw

Accurately cuts stock 2Ó

thick and a full 5Ó wide.

Table:

Diameter of cutting surface ....................................... 11Ó (279 mm)

Extension on sides ........................................................ 2Ó (51 mm)

Bevel positive stops ..................................................... 0° and 45° L

Miter ball detent stops ... 0°, 15°, 221⁄2°, 30° and 45° Right and Left

Overall Dimensions ........................................ 141⁄2Ó x 151⁄4Ó x 16Ó

Weight ..................................................................... 153⁄4 Ibs. (7 kg)

Double insulated construction for operator safety.

Positive detents on table

facilitate miter cutting.

(368 x 387 x 406 mm)

22

For accessories, see page 29

Page 19

’kickstand Portable Work Stand

Helps make good tools even better by increasing

their mobility and performance level.

Designed to accommodate Delta Model 36-040, 36-

•

070, 36-075, 36-090, 36-210 and 36-220 miter saws

and compound miter saws.Can also be adapted to

hold other bench top tools.

Fence and table extension provide additional work

•

support, lessening material shifting and tipping.

Stock stop allows for repetitive cut-off and dimen-

•

sioning jobs.

Adjustable roller work supports help maintain proper

•

stock alignment and make handling extra-long stock

a one-man job.

Rugged 13˝ diameter wheels maneuver easily

•

around the job site even up and down steps.

Shown with Model 36-075

10Ó Compound Power Miter Saw.

Portable work stand folds quickly

•

and easily for storing or rolling to

the next job.

Unique stock lift inhibitor for

safety. Prevents the cut-off

workpiece from lifting up, and

falling off the table, after the

cut, when working with

extra-long materials.

No. 50-175 ’kickstand Portable Work Stand.

Includes stand with fiberboard tool mounting

base, fold-up legs and adjustable roller work

supports; wheels; fence and table extension

with stock stop, stock lift inhibitor, cord holder

brackets and instruction manual.

Built-on cord holder bracket

for convenient, out-of-the-way

cord storage. Bracket arm

swivels for quick, easy cord

removal – no unwinding

necessary.

SPECIFICATIONS

Stock stop is Included to

facilitate repetitive cut-off and

dimensional jobs.

Adjustable roller work supports help maintain correct

stock alignment; make handling

extra-long materials a one-man

operation.

Overall Dimensions:

Width ..................................................................... 114Ó (2896 mm)

Depth ......................................................................... 21Ó (533 mm)

Height ...................................................................... 42Ó (1067 mm)

Weight ...................................................................... 63 Ibs. (29 kg)

23

Page 20

14” Abrasive Cut-Off Saw

®

The saw with the mettle

to handle your toughest

metal-cutting jobs.

Fold-down cutting head with locking

•

chain and carrying handle for safe,

easy transport.

Switch can be padlocked to

•

prevent unauthorized use.

Extra-long 12-foot cord for

•

on-the-job mobility

Heavy-duty helical gear drive plus ball

•

and needle bearing construction for

smooth, efficient transmission of power.

Heavy-duty steel base with foot pads

•

for stable operation and less vibration.

Full grip handle design for positive

•

operating control.

Built-in arbor lock for easy single

•

wrench abrasive wheel changes.

Sturdy metal wheel guard for

•

operator safety.

Model 20-140 14Ó Abrasive Cut-Off Saw.

Includes basic machine with 15 amp., 115V

motor, 12-foot cord and grounding-type plug,

work clamp, 14Ó abrasive wheel, wheel guard,

wrench and instruction manual.

Powerful 15 amp. motor provides plenty of

power and speed to “gang cut”metal studs

and perform other tough metal-cutting jobs.

Work clamp secures workpiece for operator safety; swivels 45° during angle cutting

operations.

SPECIFICATIONS

Motor .............................................................. 15 amp., 115V, 60 Hz.

Abrasive Wheel:

Diameter ....................................................................... 14Ó (356 mm)

Arbor Hole ........................................................................ 1Ó (25 mm)

Speed .................................................................................. 3900 rpm

Cutting Capacity at 90° (Using Vise):

Round ......................................................................... 43Ú4Ó (121 mm)

Rectangular ............................................. 21Ú2Ó x 91Ú2Ó (64 x 241 mm)

Square ................................................... 41Ú4Ó x 41Ú4Ó (108 x 108 mm)

No. 20-140

14Ó Abrasive Cut-Off Saw

Large 14Ó diameter x 1Ú8Ó abrasive wheel

cuts most types of ferrous materials; provides long-lasting performance.

Overall Dimensions:

Length .......................................................................... 22Ó (559 mm)

Width ............................................................................ 12Ó (305 mm)

Height ....................................................................... 251Ú2Ó (648 mm)

Weight ......................................................................... 38 lbs. (17 kg)

24

For accessories, see page 29

Page 21

Built for capacity with

versatility.

Unique turret arm action permits

•

saw blade to rotate 360° above

work table.

Built-in mechanical brake stops

•

blade in seconds.

The rigid channel cast iron frame

•

and heavy column are virtually

distortion-proof for perfect alignment and continued accuracy.

Full 33⁄4Ó depth of cut at 90°, 21⁄2Ó

•

at 45° blade tilt. Crosscuts 143⁄8Ó

in a single pass.

Precision indexing with positive

•

stops for 90° and 45° miter cuts

is precision machined for lifetime

accuracy.

Model 33-890 12Ó Radial Saw with

2 HP Motor for Single Phase

Operation. Includes basic machine

with 230V, 60 Hz., 3450 rpm motor ;

on-off, key lock switch and overload

protection, set of legs, automatic

mechanical brake, blade guard with

anti-kickback attachment, retractable

leaf guard, 12Ó combination blade and

wrenches.

12” Radial Saw

Model 33-890

12Ó Radial Saw

Model 33-891 12Ó Radial Saw with

Low V oltage Control. Same as 33-890

except with 24V at on-off, key lock

switch, magnetic starter, transformer

and overload protection (LVC).

Model 33-892 12Ó Radial Saw with 2

HP Motor and Low Voltage Control

for Three Phase Operation. Includes

basic machine with 200-230/460V,

60 Hz., 3450 rpm motor, 24V at on-off,

key lock switch, magnetic starter, transformer and 3-leg overload protection

(LVC), set of legs, mechanical brake,

blade guard with anti-kickback attachment, retractable leaf guard, 12Ó com-

bination blade and wrenches.

Unique “T urret Arm” Action.

Permits saw blade to rotate a

full 360° above work table—

gives full table capacity for left

and right hand miters.

SPECIFICATIONS

Motor:

Horsepower .............................................................................. 2 HP

Speed ............................................................................... 3450 rpm

Blade:

Diameter (supplied) ................................................... 12Ó (305 mm)

Arbor ...................................................5⁄8Ó—12 L.H. Acme (16 mm)

Capacity:

Max. depth of cut

(less leaf guard) ........................................................ 33⁄4Ó (95 mm)

(with leaf guard) ........................................................ 33⁄4Ó (95 mm)

Dado Capacity.............................................................13Ú16Ó (21 mm)

Powerful Motor with Mechanical Brake.

2 HP motor develops up to 4 HP peak

under heavy workloads. Mechanical brake

that’s built into motor, stops blade automatically in seconds, after switch is turned

off.This eliminates excessive blade coasting enabling production schedules to be

maintained.

Max. depth of cut at 45° bevel,

(less leaf guard) ......................................................... 21⁄2Ó (64 mm)

(with leaf guard) ......................................................... 11⁄4Ó (32 mm)

Crosscut ................................................................. 143⁄8Ó (365 mm)

Rip .......................................................................... 241⁄4Ó (616 mm)

Bevel Positive Stops ................................................ 0°, 45° and 90°

Miter Positive Stops ............................................ 90° and 45° R & L

Table Size ........................................... 251⁄2Ó x 30Ó (635 x 762 mm)

Overall Dimensions ........................................... 30Ó x 32Ó x 631⁄2Ó

(762 x 813 x 1612 mm)

Weight .................................................................. 300 Ibs. (136 kg)

25

For accessories, see page 29

Page 22

Deluxe 10” Radial Saw

®

A workshop workhorse .

Powerful 11⁄2 HP capacitor start motor

•

develops up to 23⁄4 HP.

Built-in automatic blade brake stops

•

blade in seconds.

Big 3Ó depth of cut at 90° and 45°

•

miter: full 21⁄4Ó at 45° bevel.

Rips 24Ó wide and crosscuts 123⁄4Ó.

•

Cast iron track and column support

•

assures strength and continued

accuracy.

Up-front controls, including blade

•

elevating crank, for greater operator

convenience.

Extra-large 243⁄4Ó x 42Ó table provides

•

ample work support.

Built-in provisions for complete

•

adjustment and alignment of all

moving parts to maintain new saw

cutting accuracy for life of machine.

Model 33-990 Deluxe 10Ó Radial Saw.

Includes basic machine with stand, 1

single phase, 115/230V, 60 Hz., 3450 rpm

motor; automatic blade brake, 10Ó saw blade

and blade wrenches.

Ball bearing roller head for

smooth cutterhead travel and

effortless operation.

1

⁄2 HP,

Positive bevel and miter stops at commonly used angle positions.

Model 33-990

10Ó Radial Saw

Features a dual shaft (thread-

ed 5⁄8Ó-12LH and 1⁄2Ó-20RH)

for maximum utilization of

accessories.

SPECIFICATIONS

Motor: ...................................................... 11⁄2 HP, 115/230V, 60 Hz.

Speed ............................................................................... 3450 rpm

Arbor ................................................................................5⁄8Ó-12 LH,

Rear shaft 1Ú2Ó- 20 RH

Blade:

Diameter .................................................................... 10Ó (254 mm)

Arbor Hole ....................................................................5⁄8Ó (16 mm)

Capacity:

Max. depth of cut .............................................. approx. 3Ó (76 mm)

Max. depth of cut

at 45° bevel ................................................... approx. 21⁄4Ó (57 mm)

Crosscut ................................................................. 12

Rip ............................................................................. 24Ó (610 mm)

Dado Capacity ...........................................................13⁄16Ó (21 mm)

Bevel Positive Stops ................................................ 0°, 45° and 90°

Miter Positive Stops .................................................... 0°, 45° R & L

Table Size ......................................... 42Ó x 243⁄4Ó (1067 x 629 mm)

Overall Dimensions:

Width ....................................................................... 42Ó (1067 mm)

Depth ......................................................................... 37Ó (940 mm)

Height (on stand) ..................................................... 53Ó (1346 mm)

Weight .................................................................... 178 Ibs. (81 kg)

26

For accessories, see page 29

3

⁄4Ó (324 mm)

Page 23

Saw Fence Systems

The Delta Unifence®Saw Guide and Biesemeyer Commercial Fence

Systems offer precision accuracy and large cutting capacities.

Delta’s premium five-star fences feature:

Easy-gliding fence body to handle quick repetitive cut-off

•

work, precision ripping and squaring cuts.