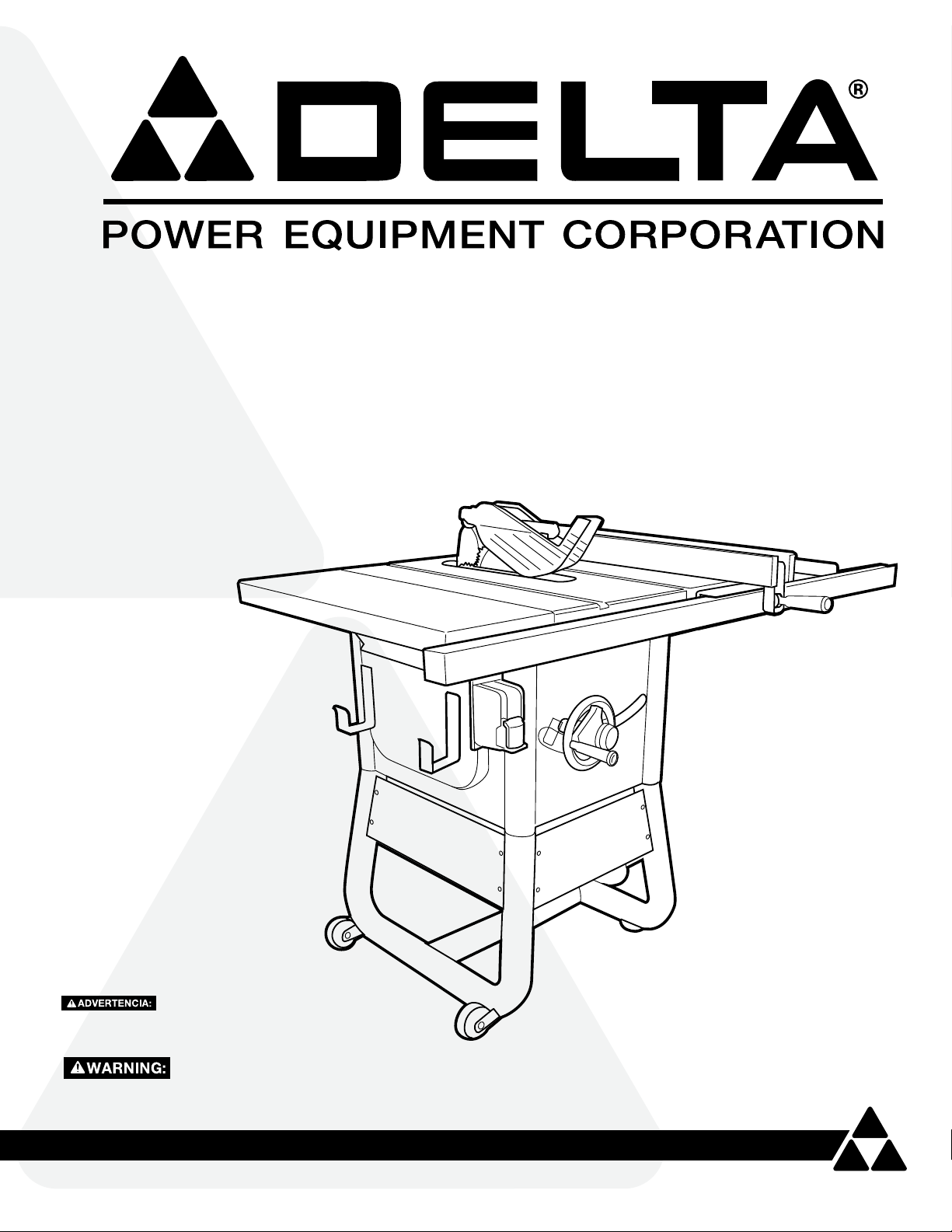

Page 1

10-INCH CONTRACTOR TABLE SAW

Scie de table de 10 pouces

(254 mm) pour entrepreneurs

Sierra de mesa de 10 pulgadas

(254 mm) para contratista

Français (34)

Español (67)

www.DeltaMachinery.com

Instruction Manual

Manuel d’utilisation

Manual de instrucciones

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

To reduce risk of serious injury, thoroughly read and comply with all warnings and instructions in

this manual and on product.

KEEP THIS MANUAL NEAR YOUR SAW FOR EASY REFERENCE AND TO INSTRUCT OTHERS

36-5000

36-5100

36-5052

36-5152

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ...................................3

Safety Logos ...................................................................... 3

GENERAL POWER TOOL SAFETY RULES ........................... 3

TABLE SAW SAFETY RULES .................................................. 5

POWER CONNECTIONS .......................................................... 7

Power Source ...................................................................... 7

Grounding Instructions ....................................................... 7

Extension Cords .................................................................. 8

UNPACKING ............................................................................. 9

Components and Parts List ................................................9

Hardware Package ............................................................ 10

ASSEMBLY ..............................................................................11

Stand ................................................................................. 11

Fixed Wheels and Stationary Feet .................................... 12

Extension Wings ...............................................................12

Front and Rear Rails ......................................................... 13

Wood Extension Table ...................................................... 14

Fence Guide and Power Control Box ............................... 14

Throat Plate .......................................................................15

Blade and Riving Knife ..................................................... 15

Anti-kickback Pawls .......................................................... 15

Blade Guard ..................................................................... 16

Rip Fence .......................................................................... 16

Miter Gauge ......................................................................16

On-Board Storage ............................................................. 16

Adjusting the 90° and 45° Positive Bevel Stops ..............17

Securing Saw to Floor ......................................................17

PREPARING TO CUT .............................................................17

Raising and Lowering the Blade ....................................... 18

Tilting the Blade ................................................................ 18

Selecting and Storing Saw Blades ................................... 19

Changing the Saw Blade .................................................. 19

Riving Knife Position ......................................................... 19

Height Settings .......................................................... 20

Checking Riving Knife Alignment .............................. 20

Using the Miter Gauge ......................................................21

Using Blade Guard Assembly ........................................... 21

Checking Fence Alignment .............................................. 21

OPERATION .............................................................................22

Starting and Stopping the Saw.........................................22

Overload Protection .......................................................... 24

Making Cuts ...................................................................... 23

Rip Cuts .............................................................. 24

Bevel Rip Cuts ..................................................... 24

Cross-Cuts ......................................................... 25

Bevel Cross-Cuts ................................................ 25

Miter Cuts ............................................................ 25

Compound Miter Cuts ......................................... 26

Large Panel Cuts .................................................26

Non-Through Cuts ............................................................ 26

Non-through Cuts................................................26

Dado Cuts ...........................................................27

Using Cutting Aids ............................................................ 27

Push Sticks .......................................................... 27

Auxiliary Rip Fence Facing .................................. 28

Auxiliary Miter Gage Facing .............................. 28

Push Blocks ......................................................... 28

Featherboards ..................................................... 29

Cutoff Gauge ....................................................... 29

Jigs ......................................................................29

ALIGNMENT ............................................................................ 30

Riving Knife Alignment With The Blade ............................30

Adjusting The Miter Stops ................................................ 30

Aligning Fence Parallel To Miter Slot ................................ 31

Aligning Fence Perpendicular to the Table .......................31

240 VOLT SINGLE PHASE OPERATION ................................32

MAINTENANCE ....................................................................... 33

TROUBLESHOOTING ............................................................. 33

ACCESSORIES ........................................................................ 33

WARRANTY ............................................................................. 34

PARTS, SERVICES AND WARRANTY ASSISTANCE ...........34

REPLACEMENT PARTS ..........................................................34

FRENCH ................................................................................... 34

SPANISH ...................................................................................67

FUNCTIONAL DESCRIPTION

The DELTA® #36-5000 series 10-inch Contractor

Table Saw is designed for portability and high quality

performance. It includes: basic machine, sturdy tubular

steel stand, integral dust chute, a T-Square® fence

system, t-slot miter gage, 15-amp induction motor,

on/off switch, cast iron table, extension wings, seethrough blade guard with anti-kickback fingers, and

10-inch carbide blade.

NOTICE: The manual cover illustrates the current production model. All other illustrations contained in the manual

are representative only and may not be exact depictions of the actual labeling or accessories included. They are

intended for illustrative purposes only.

SPECIFICATIONS

Max depth of cut at 90 degrees: 3-½"

Max depth of cut at 45 degrees: 2-½”

Max rip to right of blade: 30" or 52"

Max rip to left of blade: 15"

Max width of dado: 13/16"

MOTOR SPECIFICATIONS:

Amps 15/7.5

Voltage 120/240

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

CAREFULLY READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS ON YOUR PRODUCT

AND IN THIS MANUAL. SAVE THIS MANUAL. MAKE SURE ALL USERS ARE FAMILIAR WITH ITS

WARNING AND INSTRUCTIONS WHEN USING THE TOOL. Improper operation, maintenance or modification of

tools or equipment could result in serious injury and/or property damage.

If you have any questions or concerns relative to the use of your tool or the contents of this manual, stop using the

tool and contact DELTA® Power Equipment Corporation Customer Care at 1-800-223-7278.

SAFETY LOGOS

The definitions below describe the level of severity for each signal word. Please read the manual and pay attention

to these symbols.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

GENERAL POWER TOOL SAFETY RULES

Failure to follow these rules may

result in serious personal injury.

1. READ INSTRUCTION MANUAL AND KNOW YOUR

TOOL. Read and familiarize yourself with entire

instruction manual. Learning the tool’s proper

applications, limitations, and specific potential

hazards will greatly minimize the possibility of

accidents and injury. Make sure all users are familiar

with its warnings and instructions before using tool.

2. KEEP GUARDS AND SAFETY DEVICES IN PLACE

and working properly.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that all adjusting keys

and wrenches are removed before starting tool.

4. KEEP WORK AREA CLEAN AND WELL LIT.

Cluttered or poorly-lit work areas, surfaces and

benches can lead to accidents.

5. DO NOT USE OR STORE TOOL IN DANGEROUS

ENVIRONMENTS. Exposure to rain and damp or

wet locations can result in shock or electrocution,

or damage the tool. Do not operate electric tools

near flammable liquids or in gaseous or explosive

atmospheres. Motors and switches in these tools

may spark and ignite fumes.

6. KEEP CHILDREN AND BYSTANDERS AWAY from

work area.

7. LOCK TOOLS AND WORK AREA. Use padlocks,

and master switches, or remove and store starter

keys to prevent operation by children and other

unauthorized users.

8. DO NOT FORCE TOOL OR WORKPIECE. Operate

tool at intended speed and feed rate for better and

safer operation.

9. USE PROPER TOOL. Do not force tool to do a task

for which it was not designed.

10. DO NOT ABUSE POWER CORDS. NEVER yank

cord to disconnect from receptacle, crush cord, or

expose it to heat, oil or sharp objects.

11. USE PROPER EXTENSION CORD. If you use an

extension cord, make sure it is in good condition

and heavy enough to carry the current your product

will draw. An undersized cord will cause a drop

in line voltage, resulting in loss of power and

overheating. See Extension Cord Chart for correct

size depending on cord length and data plate

ampere rating. If in doubt, use the next smaller

gauge number. The smaller the gauge number, the

heavier the cord. When working outside, make sure

extension cord is rated for outdoor use. Consult

power connection section of this manual for

Extension Cord Chart and power connection safety.

12. SECURE WORKPIECE. Use clamps or a vise to

hold the workpiece when practical. It is safer than

using your hands and frees both hands to operate

tool.

13. DO NOT OVERREACH. Keep proper footing and

balance to maintain control.

14. MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for best and safest performance.

Follow instructions for lubricating and changing

accessories.

15. DISCONNECT TOOL from power source before

servicing, adjusting or changing set-ups or blades,

bits, cutters and other accessories.

16. TO REDUCE RISK OF ACCIDENTAL STARTING,

make sure power switches are in “OFF” position

before plugging tool in.

17. Do not touch the plug’s metal prongs when

unplugging or plugging in the cord.

continued on page 4

3

Page 4

GENERAL POWER TOOL SAFETY RULES

18. USE RECOMMENDED ACCESSORIES. Consult

manual for recommended accessories. Use of

inappropriate accessories may cause personal

injury or property damage.

19. NEVER STAND ON TOOL. Serious injury could

occur if the tool tips or if you unintentionally contact

the cutting surface.

20. CHECK TOOLS FOR DAMAGE. Before using,

and after tool or accessory has been dropped or

damaged, check guards and affected parts for

alignment of moving parts, binding of moving

parts, breakage of parts, and any other condition

that may affect its operation to make sure tool will

operate properly and all parts will perform their

intended function. Do not use a damaged product.

A guard or any other part that is damaged should

be properly repaired or replaced using factoryapproved service parts.

21. USE PROPER FEED DIRECTION. Feed workpiece

against the direction of rotation of the tool’s blade,

cutter, or abrasive surface. Feeding in the other

direction may cause the workpiece to be thrown at

high speed.

22. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Do not leave tool until it comes

to a complete stop. In the event of a power failure,

move switch to “OFF” position.

23. STAY ALERT, WATCH WHAT YOU ARE DOING,

AND USE COMMON SENSE. Do not use power

tools when tired or under the influence of drugs,

alcohol, or medication. A moment of inattention

while operating power tools may result in injury.

24. SERVICE PARTS. Use only identical replacement

parts when servicing your tool.

25. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts.

Nonslip protective footwear is recommended. Wear

protective hair covering to contain long hair.

26. WEAR PROPER EYE PROTECTION. All persons

in work area should wear safety glasses with side

shields. Everyday eyeglasses with impact resistant

lenses are not safety glasses. Eye equipment

should comply with ANSI Z87.1 standards.

27. HEARING PROTECTION. All people in work area

should wear proper hearing protection consistent

with noise levels and exposure. Hearing equipment

should comply with ANSI S3.19 standards.

28. DUST PROTECTION. Use of power tools can

generate and/or disburse dust, which may cause

serious and permanent respiratory or other injury,

including silicosis (a serious lung disease), cancer,

and death. Direct particles away from face and

body. Always operate tool in well-ventilated area

and provide for proper dust removal. Use dust

collection system whenever possible. Avoid

breathing dust and avoid prolonged contact with

dust. Allowing dust to get into your mouth or eyes,

or lay on your skin may promote absorption of

harmful material. Use properly fitting NIOSH/OSHA

approved respiratory protection appropriate for the

dust exposure and wash exposed areas with soap

and water.

PROPOSITION 65 WARNING:

power sanding, sawing, grinding, drilling, and other

construction activities may contain chemicals known to

the state of California to cause cancer, birth defects or

other reproductive harm. Some examples are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other

masonry products

• Asbestos dust

• Arsenic and chromium from chemically-treated

lumber

Dust created by

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

If tool is loaned to someone, also loan them these instructions.

Your risk from these exposures varies depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well-ventilated

area and work with approved safety equipment, such

as dust masks that are specially designed to filter out

microscopic particles.

4

Page 5

TABLE SAW SAFETY RULES

Failure to follow these rules may result in serious personal injury.

• SEE GENERAL POWER TOOL SAFETY SECTION OF THIS MANUAL. Read entire instruction manual before

operating saw. Learning the saw's proper applications, limitations, and specific potential hazards will greatly

minimize the possibility of accidents and injury. Make sure all users are familiar with its warnings and instructions

before using saw.

• SEE POWER CONNECTION SECTION OF THIS MANUAL for instructions and warnings regarding power cords and

connections.

TERMINOLOGY

The following terms will be used throughout the manual and you should become familiar with them.

– Through-cut refers to any cut that completely cuts

through the workpiece.

– Non-through cut refers to any cut that does not

completely cut through the workpiece.

_ Push stick refers to a wooden or plastic stick, usually

homemade, that is used to push a small workpiece

through the saw and keeps the operator’s hands clear

of the blade.

– Kickback occurs when the saw blade binds in the cut

or between the blade and the fence and thrusts the

workpiece back toward the operator.

Failure to follow these rules may result

in serious personal injury.

1. NEVER Perform freehand cutting, plunge cutting,

resawing, or cove cutting.

2. WEAR EYE PROTECTION, appropriate apparel,

hearing protection and dust protection as specified

in the General Power Tool Safety Section of this

manual.

3. USE SAW BLADE GUARD, RIVING KNIFE AND

ANTI-KICKBACK PAWLS. Your saw is equipped

with a modular blade guard, riving knife and

anti-kickback pawl assembly, each component

of which should be used for every possible

operation, including all through cuts. This

assembly is discussed in more detail below. Make

sure components are securely installed prior to

operation.

4. KEEP HANDS AND OTHER BODY PARTS OUT OF

THE BLADE PATH. NEVER have any part of your

body in line with the path of the saw blade.

5. USE A PUSH STICK that is appropriate to the

application to push and hold down a workpiece

through the completion of the cut. A push stick is

a wooden or plastic stick, usually homemade, that

should be used whenever the size or shape of the

workpiece would cause you to place your hands

within 6 in. (152 mm) of the blade. Instructions for

making a push stick are included in this manual.

6. AVOID KICKBACK. Pay particular attention to

instructions (below) for reducing risk of kickback.

7. NO FREEHAND CUTS. Always use a rip fence,

miter gauge, or other appropriate devices to guide

or hold down the workpiece. Use hold-downs, jigs,

fixtures or feather boards to help guide and control

– Freehand refers to cutting without the use of a miter

gauge or rip fence or any other means of guiding or

holding the workpiece other than the operator’s hand.

– Plunge cutting refers to blind cuts in the workpiece

made by either raising the blade through the workpiece

or lowering the workpiece down to the blade.

– Re-sawing – Flipping material to make a cut the saw is

not capable of making in one pass.

– Cove cutting – Also known as coving, cove cutting is an

operation where the work is fed at an angle across the

blade.

the workpiece. Accessories for use with your saw

are available at extra cost from your local dealer or

authorized service center.

8. DO NOT USE RIP FENCE AND MITER GAUGE AT

THE SAME TIME.

9. DO NOT REACH OVER/REACH AROUND. Never

reach over, in back of, or around the cutting tool

with either hand while the blade is in motion.

10. STABILITY. Make sure table saw is properly

assembled and located on a stable surface before

use to keep saw from moving during cut.

11. PROPER ASSEMBLY. Do not operate this saw until

it is completely assembled and installed according

to the instructions.

12. CHECK WORKPIECE AND SET-UP before

each operation. Knots, irregularities, or nails

in workpiece and positioning mistakes or

incomplete set-up may interfere with or affect saw

performance and personal safety.

13. USE PROPER THROAT PLATE. The proper throat

plate must be in place and properly secured at all

times to reduce the risk of a thrown workpiece and

possible injury.

14. USE CORRECT BLADE AND RIVING KNIFE for the

intended operation. The blade must be installed

so the points of the teeth are pointing toward the

front of the saw. Do not use oversized blade or

blade with incorrect arbor opening. Always tighten

the blade arbor nut securely. Before use, inspect

the blade for cracks or missing teeth. Do not use

a damaged or dull blade. Always use blade within

the thickness range for which the riving knife is

designed.

5

continued on page 6

Page 6

TABLE SAW SAFETY RULES (continued)

15. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause a

hand to move into a saw blade. Operate with table

at or near waist level for maximum balance and

control. Anticipate effect of workpiece size on

your ability to adjust position and maintain control

through completion of cut.

16. KEEP ARMS, HANDS AND FINGERS AT LEAST SIX

INCHES AWAY FROM THE BLADE.

17. NEVER CUT METALS, CEMENT BOARD OR

MASONRY. Certain man-made materials have

special instructions for cutting on table saws.

Follow the manufacturer’s recommendations at all

times.

18. NEVER ATTEMPT TO FREE A STALLED BLADE

OR TRAPPED WORKPIECE without first turning

the machine off and disconnecting the saw from the

power source.

19. NEVER START THE MACHINE WITH THE

WORKPIECE AGAINST THE BLADE to reduce the

risk of a thrown workpiece.

20. NEVER PERFORM LAYOUT, ASSEMBLY OR SETUP WORK ON THE TABLE/WORK AREA when the

saw is running.

21. BEFORE LEAVING THE SAW , wait for the blade to

come to a complete stop, then disconnect from the

power source, clean the table and work area, and

lock out switch to prevent unauthorized use.

22. SUPPORT YOUR WORKPIECE based on its size

and the type of operation to be performed. Hold

the work firmly against the fence and down against

the table surface. Do not leave a wide panel or long

board (or other large workpiece) unsupported – the

weight of the board may causes it to shift on the

table resulting in loss of control.

23. AN UNFAMILIAR NOISE OR EXCESSIVE

VIBRATION may indicate a problem with your

saw. If this happens, turn it off and disconnect it

from the power source until the problem has been

located and corrected. Contact customer service

for assistance if the problem cannot be solved.

24. OBTAIN ADVICE from your supervisor, instructor, or

another qualified person if you are not thoroughly

familiar with the operation of this machine.

Knowledge is safety.

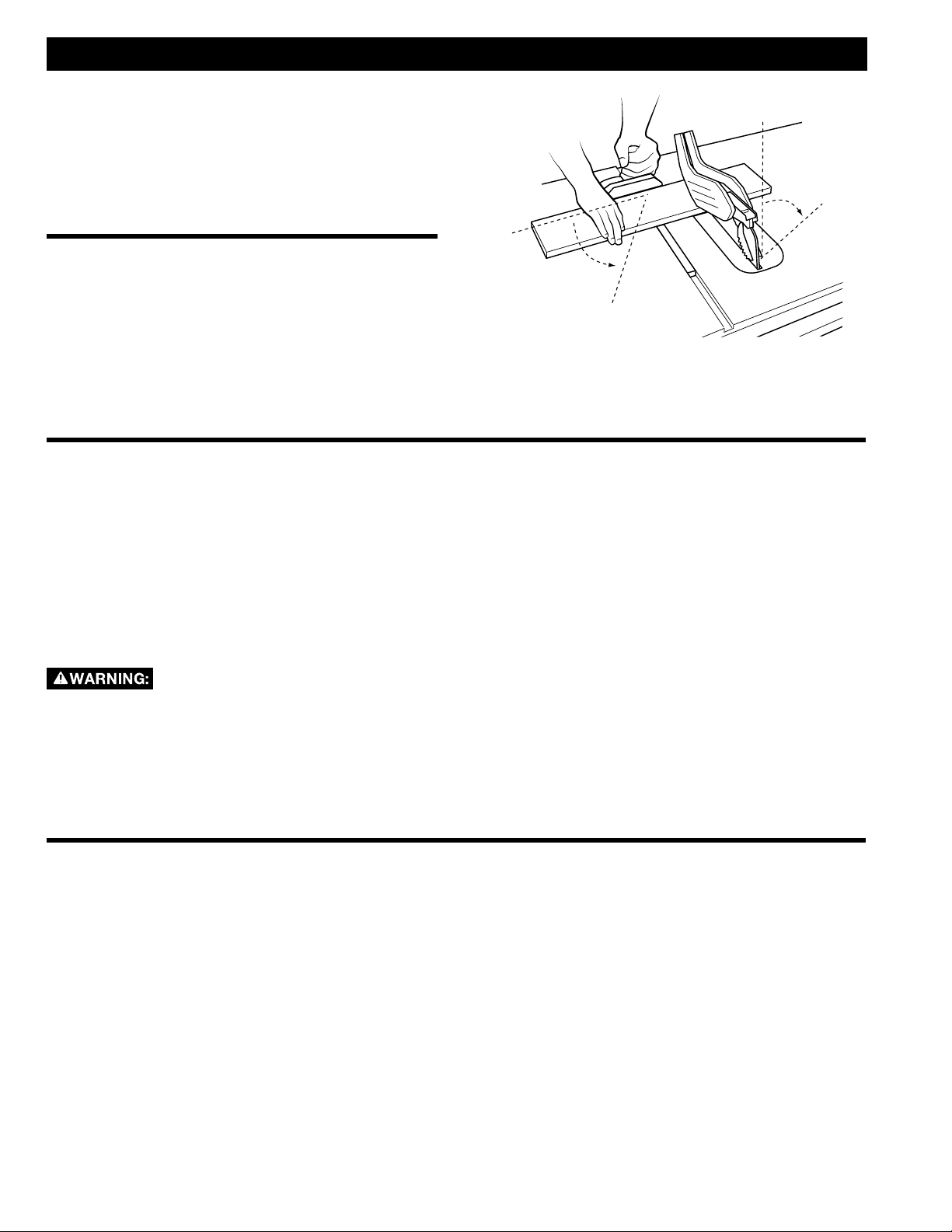

SAW BLADE GUARD, ANTI-KICKBACK PAWLS

AND RIVING KNIFE ASSEMBLY

Your table saw is equipped with a blade guard, antikickback pawls and riving knife assembly that covers

the blade and reduces the possibility of accidental

blade contact. The riving knife is a flat plate that fits

into the cut made by the saw blade and effectively

fights kickback by lessening the tendency of the blade

to bind in the cut. Two anti-kickback pawls are located

on the sides of the riving knife that allow the wood

to pass through the blade in the cutting direction but

reduce the possibility of the material being thrown

backwards toward the operator. The blade guard and

anti-kickback pawls can only be used when making

through cuts that sever the wood. When making

rabbets and other non-through cuts, the blade guard

and anti-kickback pawls must be removed and riving

knife lowered to the non-through cut position marked

on the riving knife.

Use all components of the guarding system (blade

guard assembly, riving knife and anti-kickback pawls)

for every operation for which they can be used

including all through-cutting. If you elect not to use

any of these components for a particular application,

exercise additional caution regarding control of the

workpiece, the use of push sticks, the position of

your hands relative to the blade, the use of safety

glasses, the means to avoid kickback and all other

warnings contained in this manual and on the saw

itself. Replace the guarding systems as soon as you

return to through-cutting operations. Keep the guard

assembly in working order.

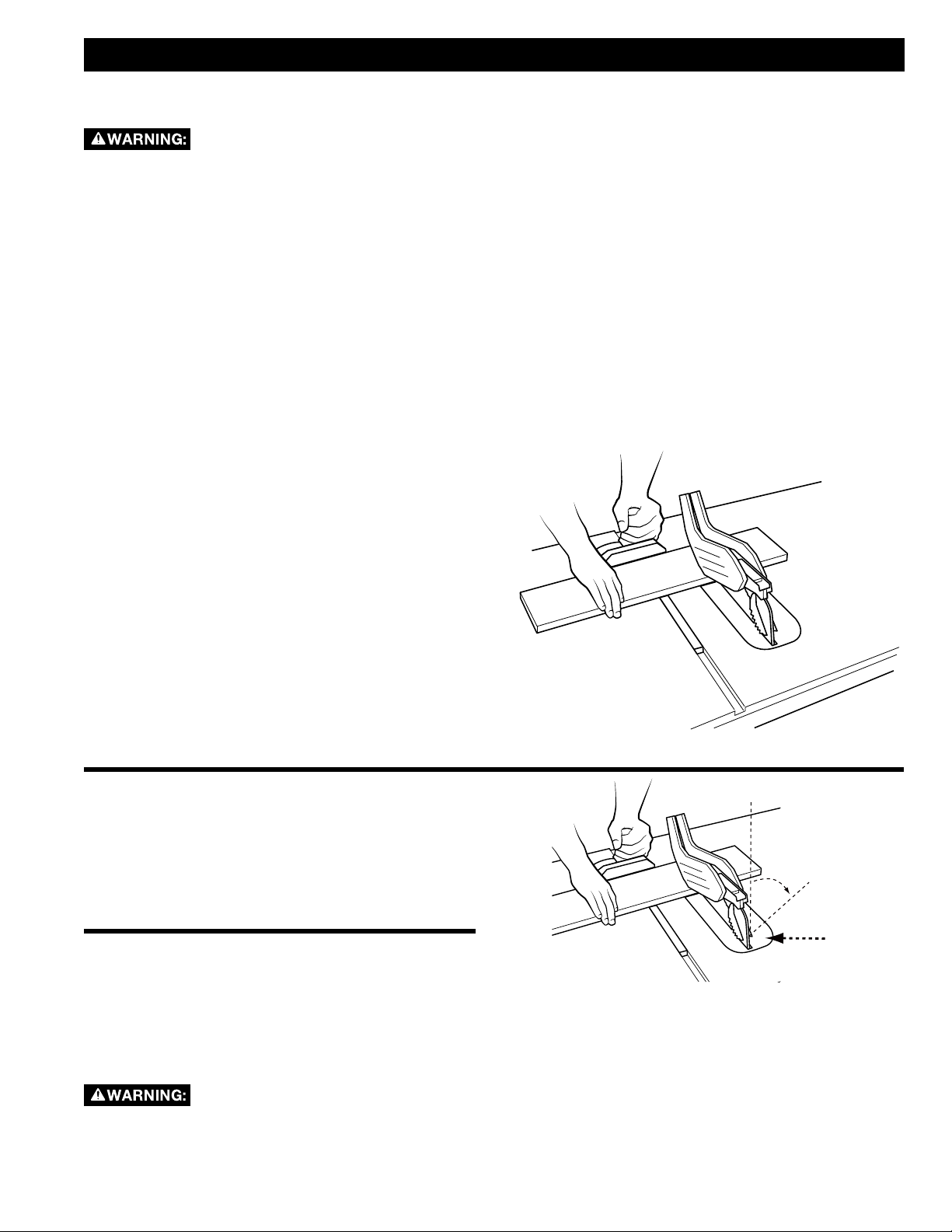

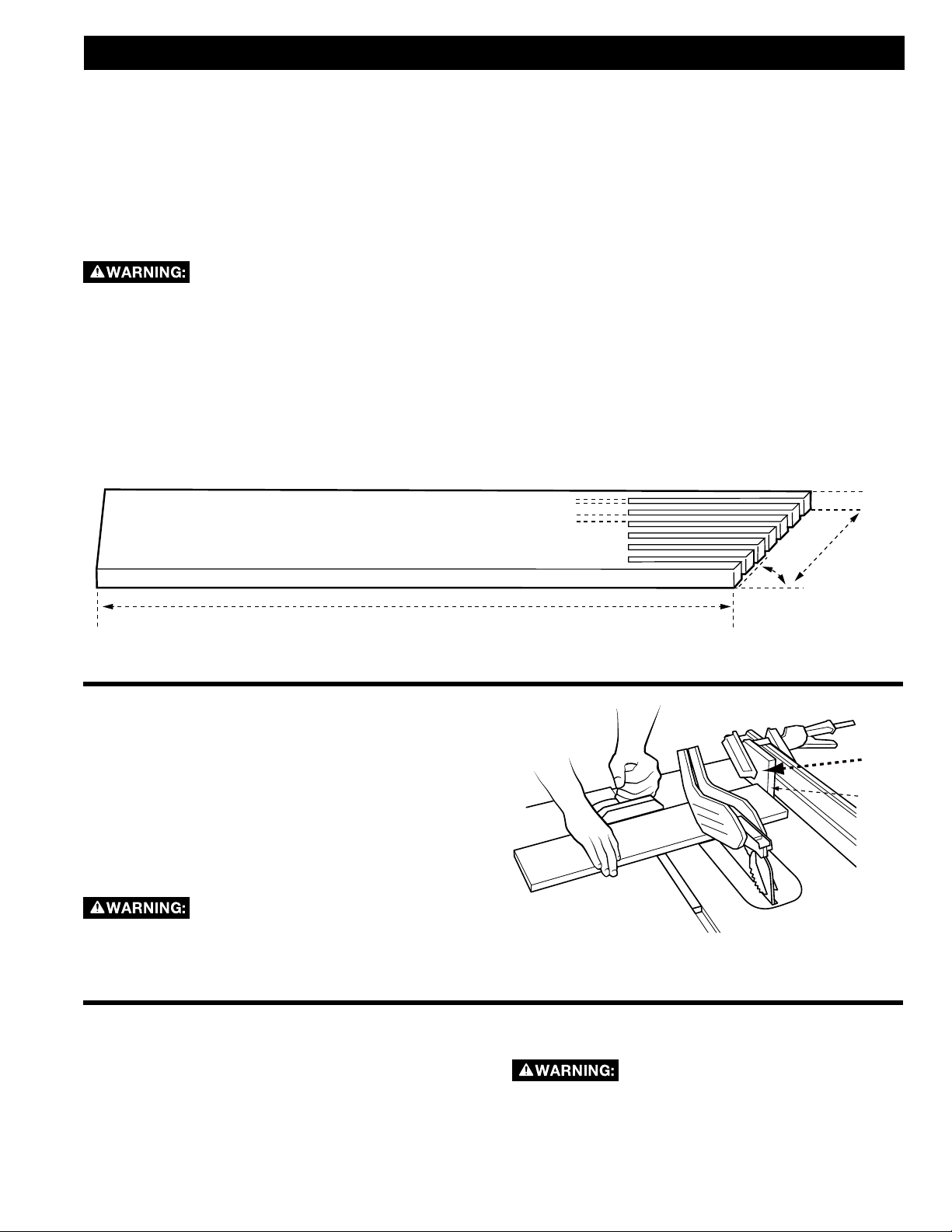

MAKING A PUSH STICK

In order to operate your table saw safely, you must

use a push stick whenever the size or shape of the

workpiece would otherwise cause your hands to be

within 6 inches (152 mm) of the saw blade or other

cutter. A push stick is included with this saw.

No special wood is needed to make additional push

sticks as long as they are sturdy and long enough

and the wood is free of knots, checks and cracks. A

length of 16 inches (400 mm) is recommended with a

notch that fits against the edge of the workpiece to

prevent slipping. It’s a good idea to have several push

sticks of the same minimum length, 16 inches (400

mm), with different size notches for different workpiece

thicknesses.

The shape can vary to suit your own needs as long as

it performs its intended function of keeping your hands

away from the blade. Angling the notch so the push

stick can be held at a 20- to 30-degree angle from the

saw’s table will help you to hold down the workpiece

while also moving it through the saw. Refer to diagram

in cutting aids section on page 25 of this manual.

6

Page 7

TABLE SAW SAFETY RULES (continued)

KICKBACKS

Kickbacks can cause serious injury. A kickback occurs

when a part of the workpiece binds between the saw

blade and the rip fence, or other fixed object, and

rises from the table and is thrown toward the operator.

Kickbacks can be avoided by attention to the following

conditions.

HOW TO REDUCE THE RISK OF

KICKBACKS AND PROTECT YOURSELF

FROM POSSIBLE INJURY:

• Be certain that the rip fence is parallel to the saw

blade.

• DO NOT rip by applying the feed force to the section

of the workpiece that will become the cut-off (free)

piece. Feed force when ripping should always be

applied between the saw blade and the fence; use a

push stick for narrow work, 6 inches (152 mm) wide or

less.

• Keep saw blade guard, riving knife and antikickback assembly in place and operating properly.

The riving knife must be in alignment with the saw

blade and the anti-kickback assembly must stop

a kickback once it has started. Check their action

before ripping by pushing the wood under the antikickback assembly. The teeth must prevent the

wood from being pulled toward the front of the saw.

If any part of assembly is not operational, return to

the nearest authorized service center for repair.

• Plastic and composite materials (like hardboard) may

be cut on your saw. However, since these are usually

quite hard and slippery, the anti-kickback pawls may

not stop a kickback. Therefore, be especially attentive

to following proper set up and cutting procedures for

ripping.

• Use saw blade guard, anti-kickback pawls, and riving

knife assembly for every possible operation, including

all through-cut sawing.

• Push the workpiece past the saw blade prior to

releasing control.

• NEVER rip a workpiece that is twisted or warped,

or does not have a straight edge to guide along the

fence.

• NEVER saw a large workpiece that cannot be

controlled.

• NEVER use the fence as a guide or length stop when

crosscutting.

• NEVER saw a workpiece with loose knots, flaws, nails

or other foreign objects.

• NEVER rip a workpiece shorter than 10 inches (254

mm).

• NEVER use a dull blade. A dull blade should be

replaced or re-sharpened.

POWER CONNECTIONS

POWER SOURCE

This saw is equipped with a 15-amp motor for use with

a 120-volt, 60-HZ alternating current. It can be re-wired

for use with a 240-volt power source by a qualified

electrician. See instructions below regarding proper

connections for your saw as wired.

For voltage, the wiring in a shop is as important as

the motor’s rating. A line intended only for lights may

not be able to properly carry the current needed for a

power tool motor; wire that is heavy enough for a short

distance may be too light for a greater distance; and a

line that can support one power tool may not be able to

support two or three.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

GROUNDING INSTRUCTIONS

THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current

to reduce the risk of electric shock. This machine is

equipped with an electric cord having a grounding

conductor and a grounding plug. The plug must be

plugged into a matching receptacle that is properly

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug as provided on your saw

or as rewired by your electrician. If it will not fit the

7

A separate electrical circuit should be used for your

machines. This circuit should not be less than #12

wire and should be protected with a 20-amp time lag

fuse. If an extension cord is used, use only 3-wire

extension cords which have 3-prong grounding-type

plugs and matching receptacle which will accept the

machine’s plug. Before connecting the machine to the

power line, make sure the switch (s) is in the “OFF”

position and be sure that the electric current is of the

same characteristics as indicated on the machine. A

substantial voltage drop will cause a loss of power and

overheat the motor. It may also damage the machine.

receptacle, have the proper receptacle installed by a

qualified electrician.

Improper connection of the equipment-grounding

conductor can result in risk of electric shock. The

conductor with insulation having an outer surface that

is green with or without yellow stripes is the grounding

conductor. If repair or replacement of the electric cord

or plug is necessary, do not connect the equipmentgrounding conductor to a live terminal.

Page 8

POWER CONNECTIONS

(continued)

Check with a qualified electrician or service personnel

if the grounding instructions are not completely

understood, or if in doubt as to whether the machine is

properly grounded.

Use only 3-wire extension cords that have 3-prong

3-conductor receptacles that accept the machine’s

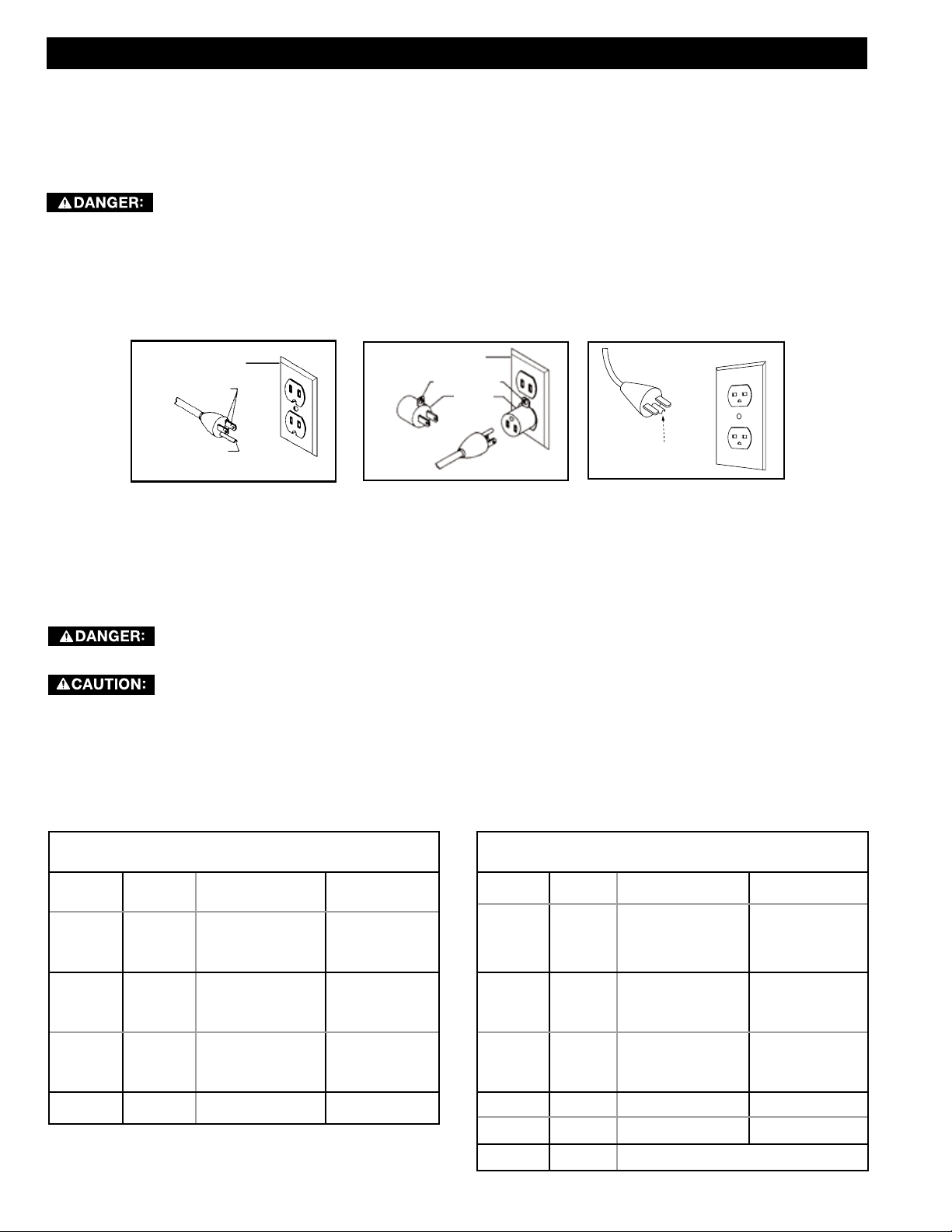

plug, as shown in Figure A, or a properly grounded

receptacle with a grounding means adaptor, as shown

in Figure B.

Repair or replace damaged or worn cord immediately.

grounding type plugs and matching, properly grounded

IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED. IF

YOU ARE NOT SURE, HAVE A qualified ELECTRICIAN CHECK THE RECEPTACLE.

This is a grounded, cord-connected tool intended for use on a supply circuit having a nominal voltage of 120 volts.

It is intended to for use on a circuit that has an outlet as shown in FIG. A. It has a plug as shown in FIG A. If you

have a 2 pole receptacle as shown in FIG. B you may use a temporary adapter, as shown in FIG. B. if a properly

grounded outlet is not available. The green ear lug extending from the adapter must be connected to a permanent

grounded outlet box. The temporary adapter should be used only until a properly grounded outlet can be installed

by a qualified electrician.

GROUNDED

OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

FIG. A

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

FIG. B

Grounding Pin

FIG. C

This tool may be converted to 240 volt power supply circuit by a qualified electrician. If it is converted to 240 volts

it must be equipped with a grounding plug shown in FIG. C and must be connected to an outlet as shown in FIG. C,

which is connected to a permanent ground. No adapter is available or should be used with this tool when converted

to 240 volts.

EXTENSION CORDS

Never use a damaged extension cord. Check extension cords before each use. If damaged,

replace immediately. Touching the damaged area could case electrical shock resulting in serious injury.

Keep the extension cord clear of the work area. Position the cord so it will not get caught on lumber,

tools or other obstructions

• Use proper extension cords. Make sure your extension cord is a 3-wire extension cord which has a 3-prong

grounding type plug and matching receptacle which will accept the machine’s plug, as described in this manual’s

Grounding Instructions. When using an extension cord, be sure to use one heavy enough to carry the current of the

machine. An undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. The table

below shows the maximum gauge to use depending on the cord length. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord. Only round, jacketed cords listed by Underwriter’s Laboratories (UL)

should be used.

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Rating

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

Volts Total Length of

Cord in Feet

240

240

240

240

240

240

240

240

240

240

240

240

240

240

up to 50

50-100

100-200

200-300

up to 50

50-100

100-200

200-300

up to 50

50-100

100-200

200-300

up to 50

50-100

Gauge of

Extension Cord

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

Ampere

Rating

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16 120 up to 25 14 AWG

12-16 120 25-50 12 AWG

12-16 120

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

0-6

0-6

0-6

0-6

Volts Total Length of

Cord in Feet

120

120

120

120

120

120

120

120

120

120

120

120

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

GREATER THAN 50 FEET NOT RECOMMENDED

Gauge of

Extension Cord

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

8

Page 9

UNPACKING

• The machine is heavy, two people are required to

unpack and lift.

• Use a safety strap to avoid tip over when lifting

machine.

• Prior to tool assembly and use, read this manual

thoroughly to familiarize yourself with proper

assembly, maintenance and safety procedures.

Check shipping carton and machine for damage

before unpacking. Carefully remove components in

top foam layer. Remove the top layer of foam then

remove all components in the bottom layer of foam.

Lay out all parts on a piece of cardboard or other

clean, flat surface. Two or more people are needed to

lift the saw out of the carton. Always check for and

remove protective shipping materials around motors

and moving parts. Do not discard shipping carton and

packing materials until you have carefully inspected the

contents, assembled the machine and are satisfied that

it operates correctly.

Compare package contents to Component Parts List

and Hardware Package List prior to assembly to make

sure all items are present. Carefully inspect parts to

make sure no damage occurred during shipping. If

any parts are missing, damaged or preassembled, do

not assemble. Instead, call DELTA

1-800-223-7278 for assistance.

After assembly remove any protective materials and

coatings from all of the parts and the table saw. The

protective coatings can be removed by spraying

WD-40

This may need to be redone several times before all of

the protective coatings are removed completely.

After cleaning, apply a good quality paste wax to any

unpainted cast iron surfaces. Make sure to buff out the

wax before assembly.

®

on them and wiping them off with a soft cloth.

®

Customer Care at

COMPONENT

PARTS LIST

DESCRIPTION (QTY)

1. Table Saw with attached

Carbide Blade, and ClosedEnd Wrench (1)

2. Extension Wing

3. Switch Box (attached to

saw) (1)

4. Tubular Stand (2)

5. Support Panels (4)

6. Fixed Wheels (2)

7. Adjustable Feet (2)

8. Pivoting Pedal and Caster

(not shown) (attached to

saw) (1)

9. Handwheel Handles (2)

(attached to saw)

10. Lock Knobs (2)

11. Miter Gauge (1)

12. Rip Fence Handle (1)

13. Extension Wing (2) with

36-5000 and 5100

(1) with 36-5052 and

36-5152

14. Rip Fence (1)

15. Throat Plate (1)

16. Blade Guard and

Anti-Kickback Pawls

17. Blade (1)

18. Push Stick (1)

19

2

1

4

5

These contents in

separate carton

19. Rear Rail

20. Fence Guide

21. Front Fence Rail

18

3

6

17

16

These contents in separate carton

for 36-5052 and 36-5152 only

22. Wood Table Extension

23. Legs

15

14

22

13

11

21

20

12

10

23

9

8

7

9

Page 10

UNPACKING

HARDWARE PACKAGES

(continued)

30" Fence versions (36-5000 and 36-5100)

Description Qty. Where used

M8 x 70mm Carriage bolt 1 Connect stand halves

M8 nyloc nut 1 Connect stand halves

M8 spring washer 1 Connect stand halves

M6 x 72 mm Carriage bolt 4 Connect stand leg to stand

M6 lock nut 4 Connect stand leg to stand

M8 x 53mm axle pin 2 Wheels

M8 locking nut 2 Wheels

M6 x 10mm Phillips head self tapping screw 16 Stand Panels

5/16-18 x 7/8" Hex Head screw w/spring washer 17 Wings to table 6, wing to wing 3,

1/4-20 x 1/2" Hex Soc button head screw 6 Guid tube to rail

5/16-18 x 1" Flat head screw 8 Front rail to table and wings 8

5/16-18 hex flange nut 19 Wings to table 6, wing to wing 3

Rail alignment gauge 1

Conical Toothed washer 5/16” 1 On 1 screw for the front rail going into table

Flat Toothed washer 5/16” 1 On 1 screw for the rear rail going into table

*

rear rail

rear rail 8, Front rail 8

for electrical ground.

for electrical ground.

8

(36-5000),

* Hardware supplied will accommodate the 36-5000 model saw that uses the most hardware.

Item #

Parts List

153

155

154

144

145

151

155

146

58

35

19

16

190

191

192

52" Fence versions (36-5052 and 36-5152)

Description Qty. Where used

M8 x 70mm Carriage bolt 1 Connect stand halves

M8 nyloc nut 1 Connect stand halves

M8 spring washer 1 Connect stand halves

M6 x 72mm Carriage bolt 4 Connect stand leg to stand

M6 lock nut 4 Connect stand leg to stand

M8 x 53mm axle pin 2 Wheels

M8 locking nut 2 Wheels

M6 x 10mm Phillips head self tapping screw 16 Stand Panels

5/16-18 x 7/8" Hex Head screw w/spring washer 15 Wings to table 6, rear rail 6,

5/16-18 Flat washer 6 wing to wood table, both sides on 36-5052

1/4-20 x 1/2" Hex Soc button head screw 8 Guide tube to rail

5/16-18 x 1" Flat head screw 6 Front rail to table and wings 6

5/16-18 Hex flange nut 15

1/4-20 X 1 1/2" Hex Head Screw 6 Rails to wood table

1/4" Flat washer 12 Rails to wood table

1/4-20 hex nuts 12 Rails to wood table

#8 x 3/4" Phillips head self tapping screw 8 legs to table

#10-32 x 1 3/4" screws 4 legs to table

#10 flat washer 4 legs to table

#10-32 hex nuts 4 legs to table

Rail alignment gauge 1

Conical Toothed washer 5/16” 1 On 1 screw for the front rail going into table

Flat Toothed washer 5/16” 1 On 1 screw for the rear rail going into table

**

Wing to wood ta

Rear rail 6, Front rail 6, wing to wood

table 3,

for electrical ground.

for electrical ground.

(36-5052)

ble 3

Item #

Parts List

153

155

154

144

145

151

155

146

58

193

35

19

16

183

184

185

182

180

179

181

190

191

192

** Hardware supplied will accommodate the 36-5052 model saw that uses the most hardware.

10

Page 11

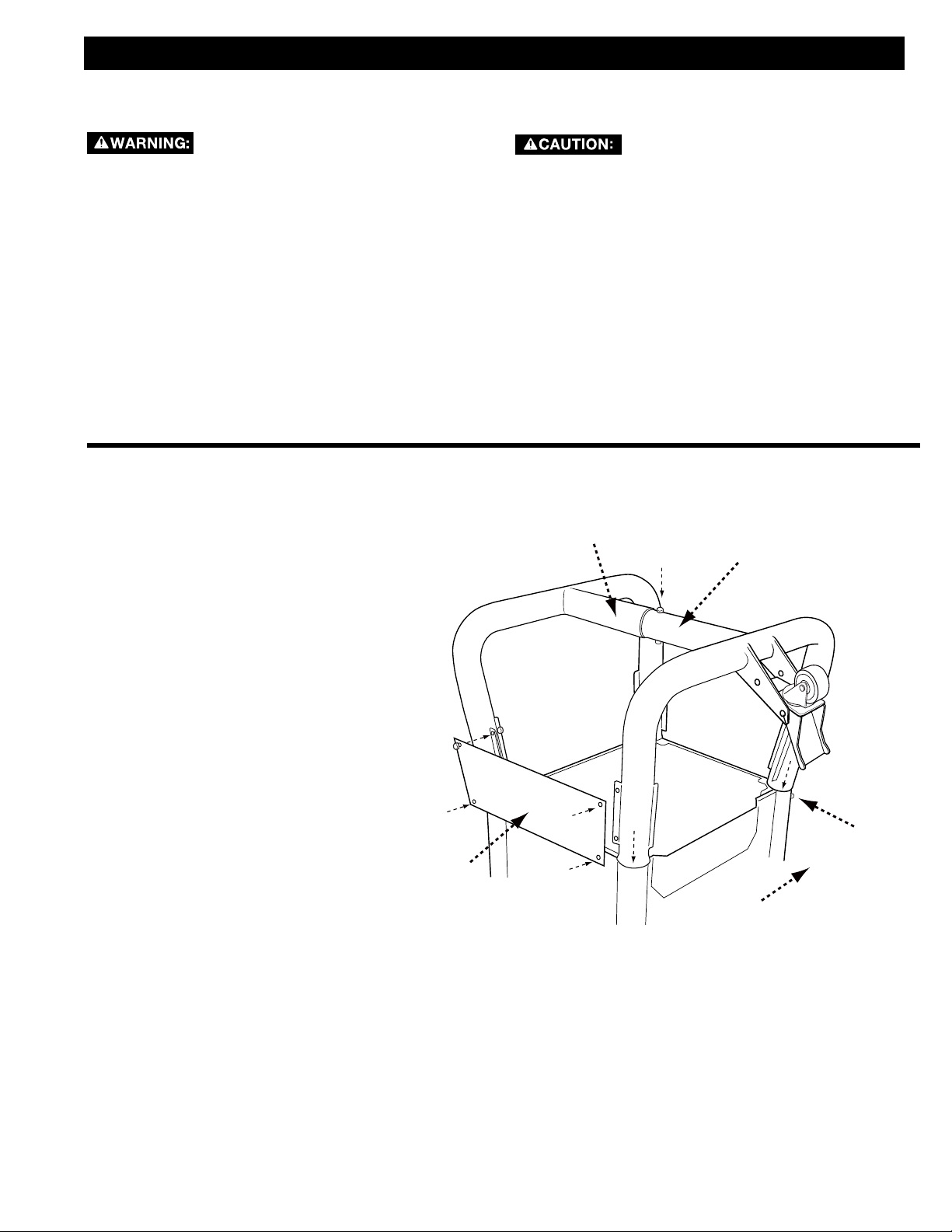

ASSEMBLY

B

• Do not lift saw without help. Hold it close to your

body while lifting. Keep knees bent and lift with your

legs, not your back.

• Fully assemble saw with leg assembly prior to use.

Leg assembly is an integral and necessary part of the

support structure for this saw.

• Do not modify saw, or create accessories not

recommended for use with this saw.

• Make sure power switch is in “OFF” position before

connecting to power supply.

• Do not connect to power supply until assembly is

complete

STAND

Avoid contact with blade teeth. Keep

blade stored or lowered when possible.

TOOLS REQUIRED FOR ASSEMBLY

(not included)

• Slotted screwdriver

• Phillips head screwdriver

• 8mm wrench

• 10mm wrench

• 12mm wrench

• 13mm wrench

• 3/8-inch wrench

• 7/16-inch wrench

• 1/2-inch wrench

• 9/16-inch wrench

• 6mm Allen hex wrench

• 5/32-

• 3/16-inch Allen wrench

inch Allen wrench

1. Connect the two tube legs by inserting

the end of the left leg (A) into the end

of the right leg (B) as shown in Figure 1.

Secure with a M8 x 70mm carriage bolt,

lock washer and nyloc nut and tighten.

2. Insert the four open ends of the tube

legs into the leg collars (C) as shown.

Secure each leg with a 6mm x 70mm

bolt and nut.

3. Attach the back and front leg support

panels (D) to the legs using four M6 x

12mm self-tapping bolts.

A

C

D

Saw Front

11

FIGURE 1

Page 12

ASSEMBLY

(continued)

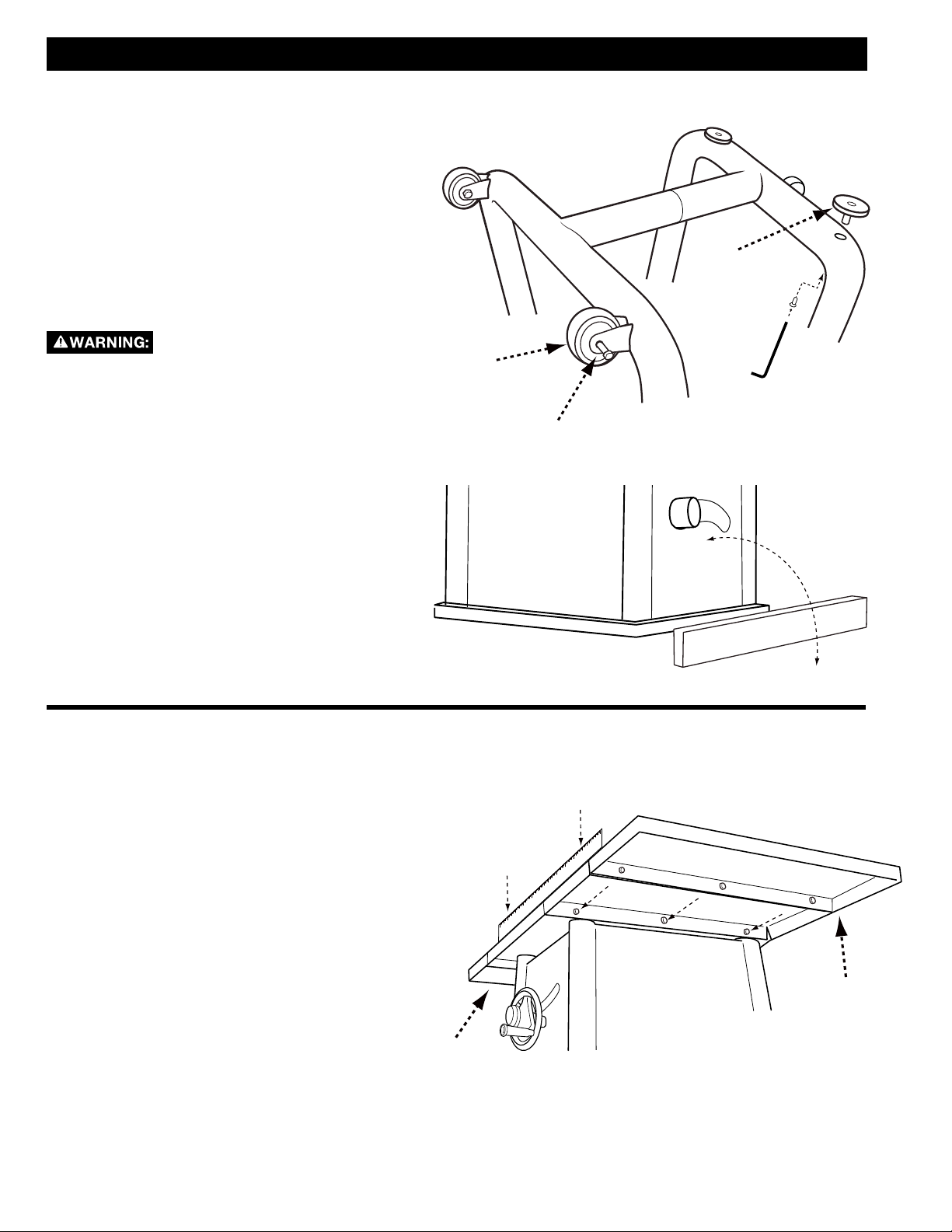

FIXED WHEELS AND STATIONARY FEET

1. Attach the two fixed wheels (A) to the two

left leg, opposite the pivot caster, using the

carriage shoulder bolt as in Figure 2.

2. Screw the adjustable feet (C) into the threaded

inserts in the right leg, next to the pivot caster.

3. Lay a scrap piece of 2x4 in back of the saw, as

shown in Figure 3, to prevent damage to the

dust chute when righting the saw.

4. Stand the saw right side up.

The machine is heavy, two

people are required to stand the

machine up.

5. The two adjustable feet (C) can be raised and

lowered by rotating them. The feet may be

adjusted to level the saw and locked in place

with the locking set screws already assembled

in the frame, using a 6mm allen hex wrench.

See Figure 2.

A

C

FIGURE 2

B

EXTENSION WINGS

For Models with Three Extension Wings

1. Attach the left side extension wing (A) to the

table using three 5/16-18 x 7/8” hex head

screws.

2. Lay the two remaining wings upside down on

the saw table. Place the side of the wing that

will mount to the saw table near the edge of

the saw table, so that the hole pattern in the

wing matches the hole pattern of the saw. If

you have cast iron wing, it will mount to the

saw table. Place the other wing adjacent to

the wing so the holes patterns match. Fasten

the two wings together using three 5/16-18

x 7/8 inch hex head screws and mating hex

flange nuts.

3. Turn the two wings fastened together (B) over

and fasten them to the saw table using three

5/16-18 x 7/8 inch hex head screws.

4. Make sure the top edges of the wings are flush

with the top of the table and tighten all six

screws.

A

FIGURE 3

12

11

10

9

8

7

6

5

4

3

2

1

INCH

0

B

FIGURE 4

12

Page 13

ASSEMBLY

Table

Gauge

Rail

Table

Gauge

Rail

(continued)

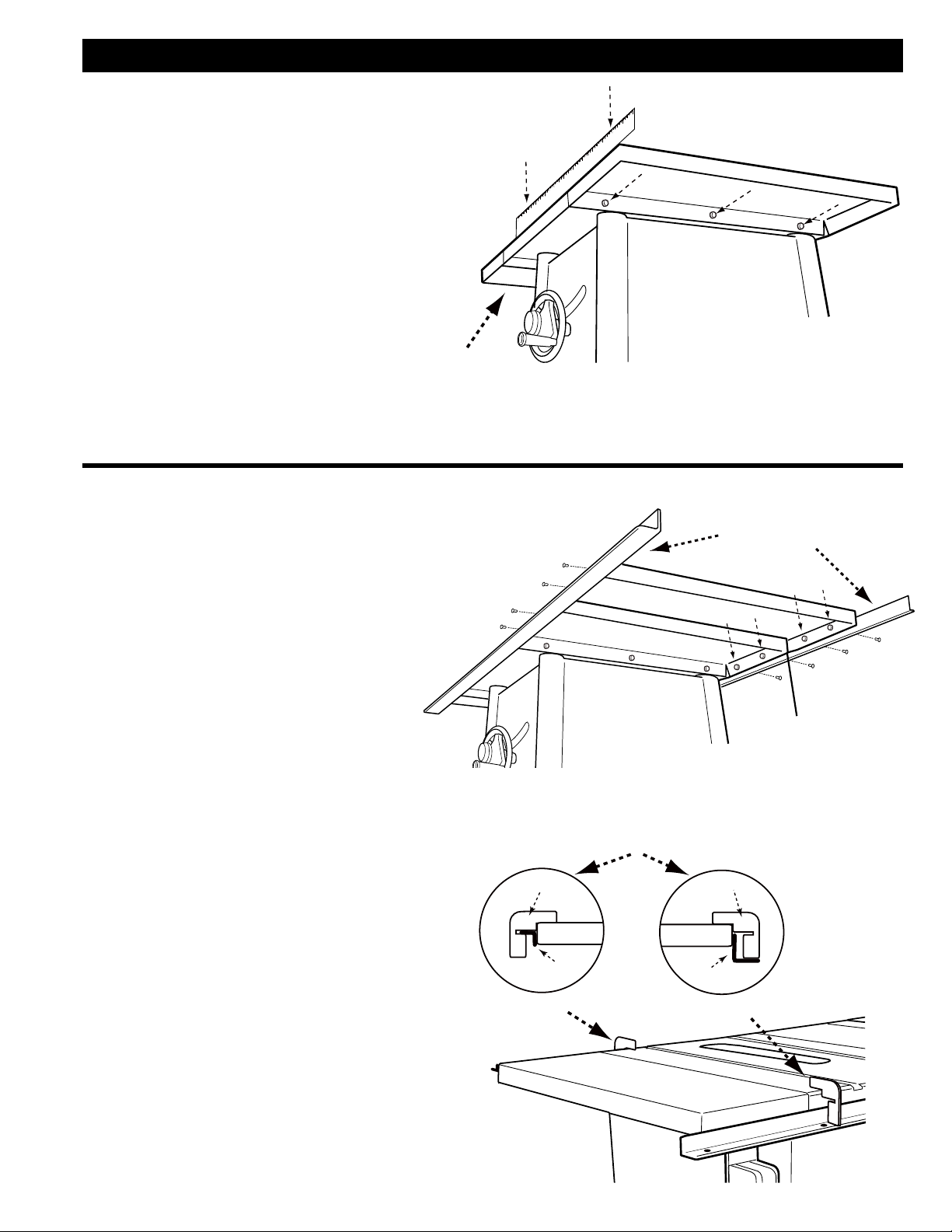

EXTENSION WINGS

For Models with Two Extension

Wings and a Wood Extension Table

1. Attach the left and right side extension

wings (A) to the table using three 5/1618 x 7/8” hex head screws for each

wing.

2. Make sure the top edges of the wings

are flush with the top of the table and

tighten all six screws.

3. Proceed to rail assembly.

FRONT AND REAR RAILS

1. Attach the front rail (A) (2” X 2” X 57” for

the 30” rip capacity models), (2” X 2” X

79” for the 52” rip capacity models), to

the saw table and extension wings using

5/16-18 x 1 1/8inch flat head screws.

Align the holes in the rail with the holes

in the table and extension wings.

2. Use supplied rail alignment gage (B) to

ensure the rail is the proper distance

from the top of the table at each side of

the cast iron table. (fig 6) Then use the

alignment gage to set the same proper

distance for the extension wings.

3. Align the rear rail to the holes in the

rear of the saw table and extension

wings. Attach the rear rail to the saw

table using two 5/16-18 x 7/8 Hex head

screws.

4. Attach the rear rail to the extension

wings using 5/16-18 X 7/8 inch hex head

screws and Hex flange nuts.

5. Use supplied rail alignment gage (B) to

ensure the rail is the proper distance

from the top of the table at each side of

the cast iron table. (fig 6) Then use the

alignment gage to set the same proper

distance for the extension wings.

A

2

1

INCH

0

Back

12

11

10

9

8

7

6

5

4

3

FIGURE 5

A

C

B

Front

FIGURE 6

13

Page 14

ASSEMBLY

D

G

(continued)

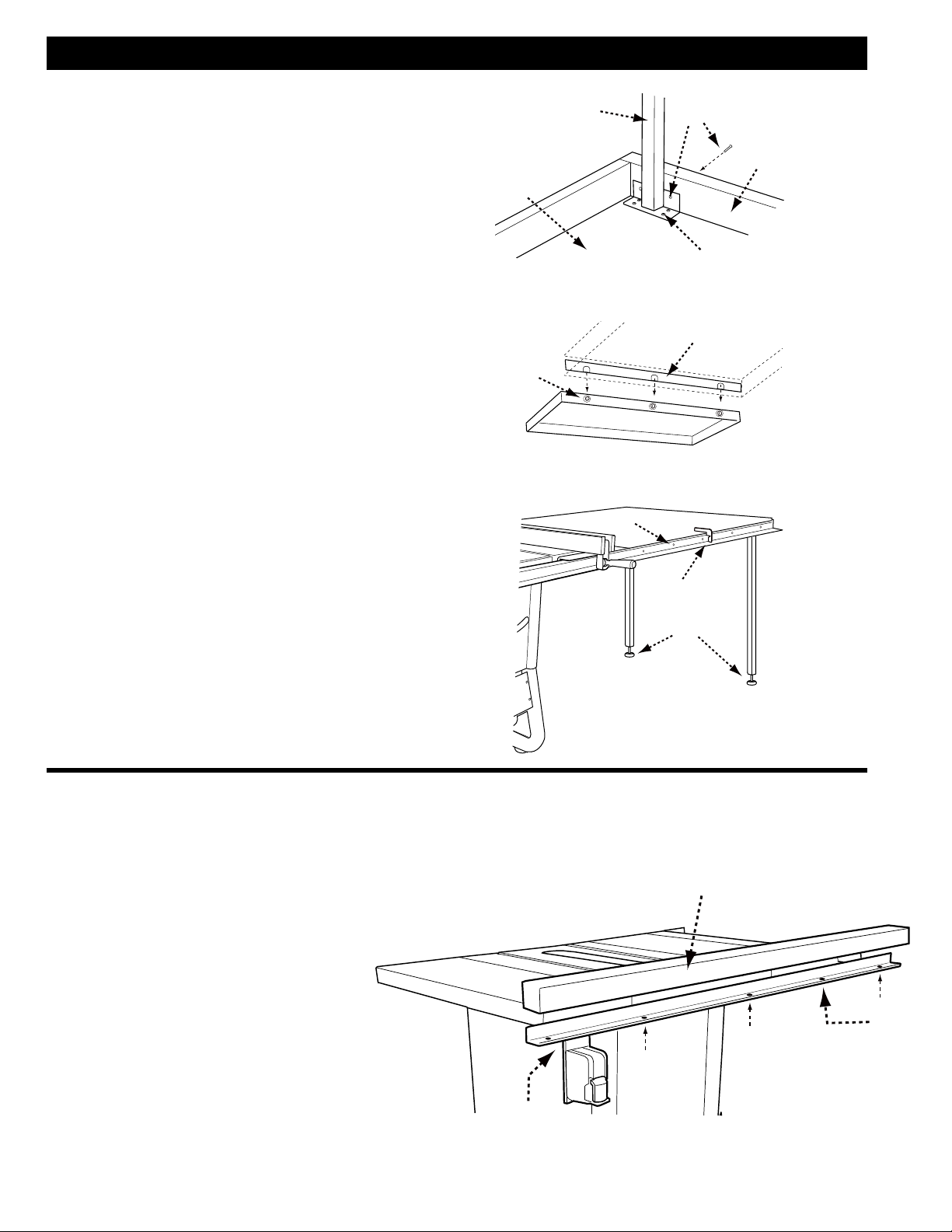

WOOD EXTENSION TABLE

52” rip capacity models only

1. Lay the wood table (A) upside down on floor or

bench.

2. Position legs (B) in corner as shown (fig 7) the

vertical wall of the angle plate on the leg should

be against the end wood wall (C) of the table.

3. Fasten the legs to the table board with (8) #8 x

5/8” self-tapping screws (D).

4. Carefully drill through the holes in the vertical

angle plate holes and the wood wall of the table

with a ¼ inch drill. Feed the #10 by 1 ¾” screws

(E) through the drilled holes from the outside,

then assemble the #10 washers and nuts onto

the screws and tighten.

5. Loosely assemble (3) 5/16-18 x 7/8 inch screws,

washers and nuts (F) into the three holes in the

side of the extension wing as shown. (fig 8)

6. Carefully lower the slotted steel angle table

bracket (G) down onto the screws on the

extension wing. Tighten the screws after the

wood table is leveled with the extension wing.

7. Using the rail alignment gauge (H) adjust the

feet in the legs (I) so the top of the table is at the

proper distance from the rail.

8. Drill ¼ inch holes through the rail holes (J) into

the wood table on the front and back rails. (fig 9)

9. Fasten wood table to rails with ¼-20 X 1 ½ inch

screws, flat washers, lock washers, and nuts.

A

F

B

E

C

FIGURE 7

FIGURE 8

J

H

I

FENCE GUIDE AND POWER CONTROL BOX

1. Connect the fence guide tube (A) by inserting the smaller

end into the larger end. See Figure 10

2. Attach the fence guide to the front rail using four (for

30" versions) six (for 52" versions) 1/4-20 x 1/2-inch hex

button head screws and ¼-inch spring washers

through the holes (B) on the bottom side of

the front rail.

3. Align the two holes in the power

control box bracket with the holes

underneath the front rail (C), located

on the left side of the saw. Secure

the power control box to the front rail

using two1/4-20 x 1/2-inch button

head screws.

4. Fix the hanging power cord at rear side of

front rail by wire clip and M5 x 6mm round

head cross screw.

C

FIGURE 9

A

B

FIGURE 10

14

Page 15

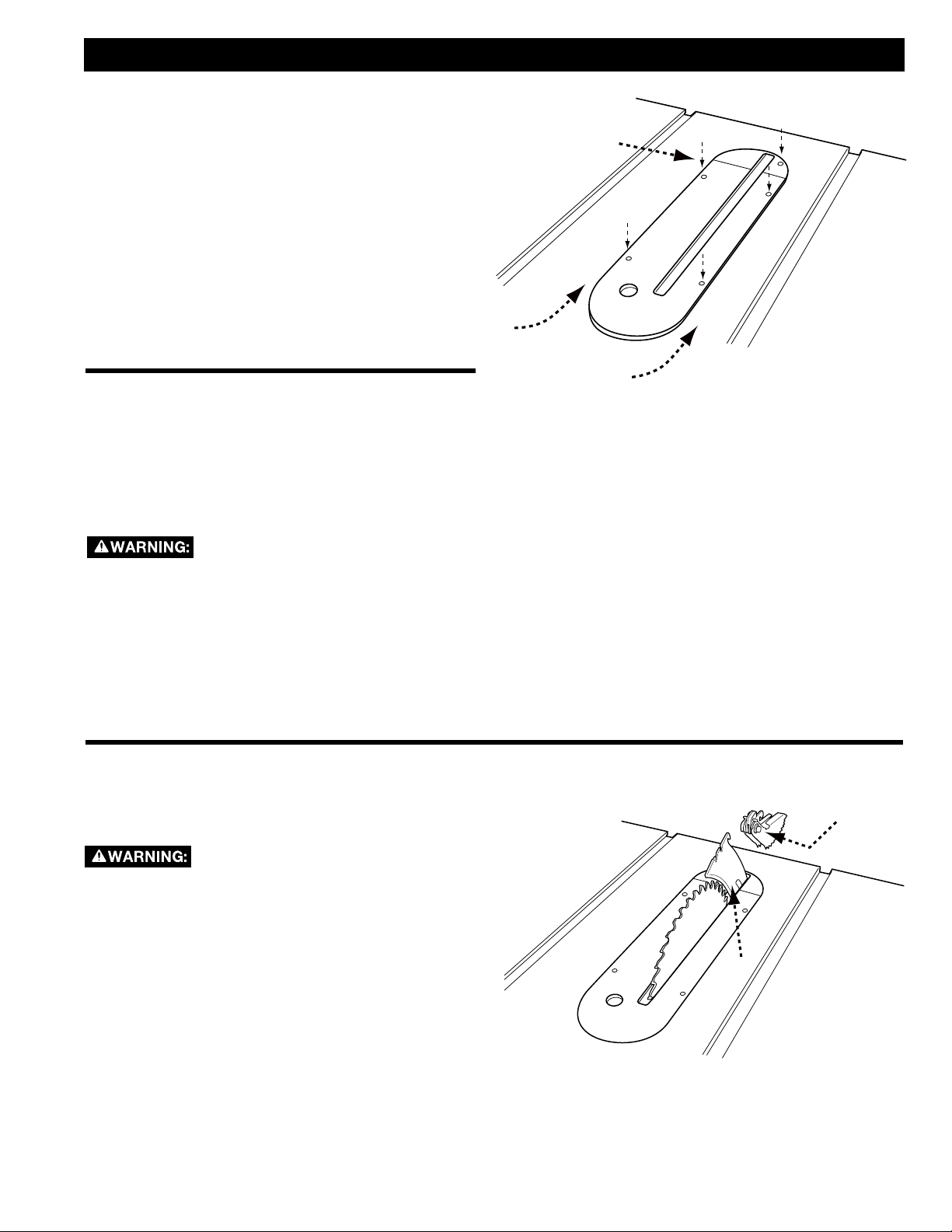

THROAT PLATE

ASSEMBLY

(continued)

1. To install throat plate, lower blade below tabletop,

then carefully feed the throat plate, with plate end

first, from the front of the table to the rear, keeping

the blade centered within the slot on the throat

plate. See Figure 11. The plate should rest within

the cavity in the tabletop on top of 5 flat head

screws.

2. Ensure that the throat plate is flush with the top of

the table.

3. If the throat is not flush with the tabletop, adjust

the height of the throat plate using the five set

screws (A) below the throat plate.

NOTE: When installing riving knife, anti-kickback

pawls and blade guard, blade must be at 90° setting

and raised to the maximum height. See Raising and

Lowering Blade, page 18.

BLADE AND RIVING KNIFE

To reduce the risk of serious

personal injury, the riving knife must

be installed and properly positioned for every

possible through and non-through cut.

1. Your saw is shipped with the blade and riving knife

installed and properly aligned. The riving knife

comes installed in the low, non-through cutting

position. Prior to operating your saw, check

to make sure the alignment of the blade to the

A

FIGURE 11

miter slot and the riving knife to the blade was not

affected by shipping. To check alignment of the

blade and riving knife, see page 28 in the Alignment

section of this manual.

2. The riving knife comes installed in the low, nonthrough cutting position. To attach the antikickback pawls and blade guard assemblies, the

riving knife must be in the raised position as shown

in Figure 12. To raise and lower the riving knife, see

Riving Knife Height Settings on page 20.

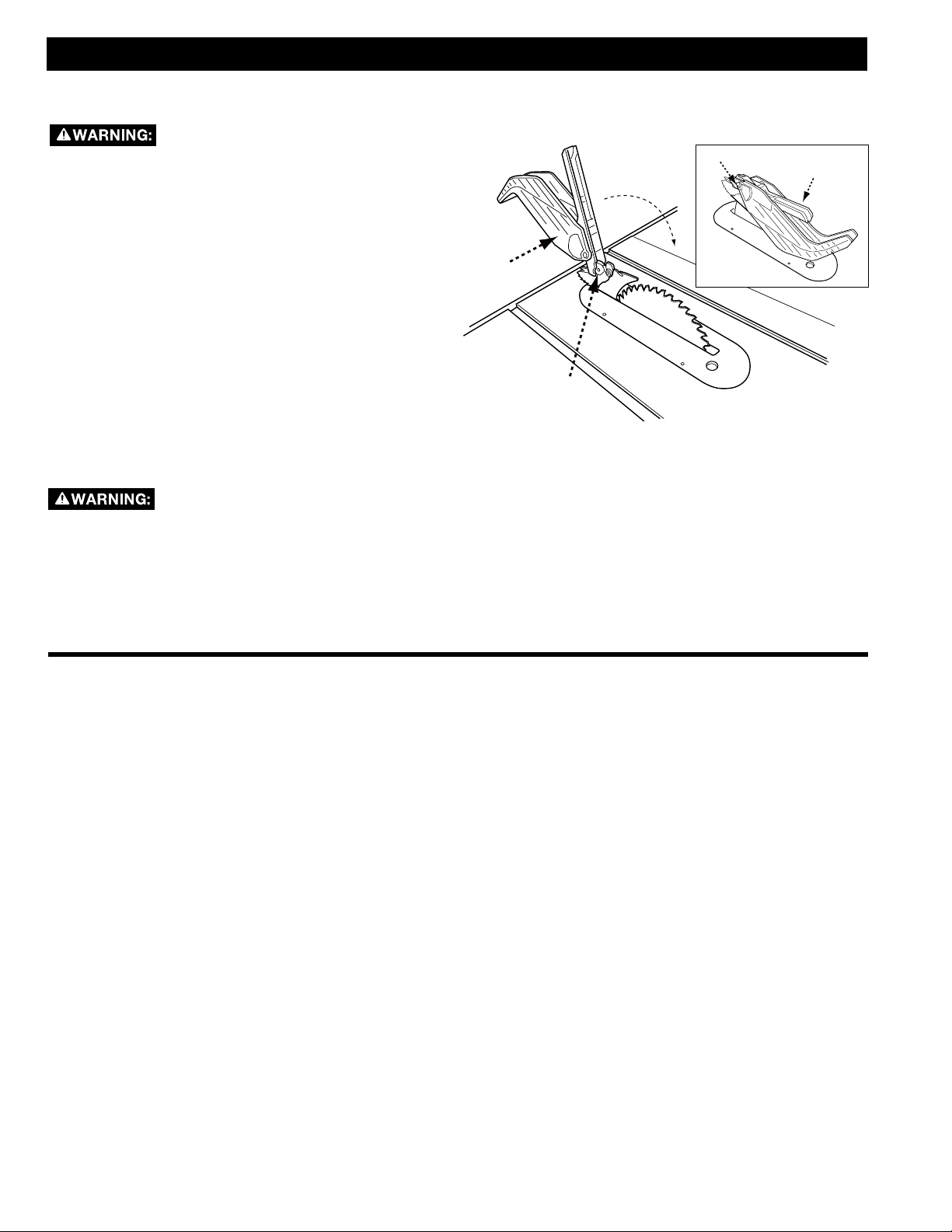

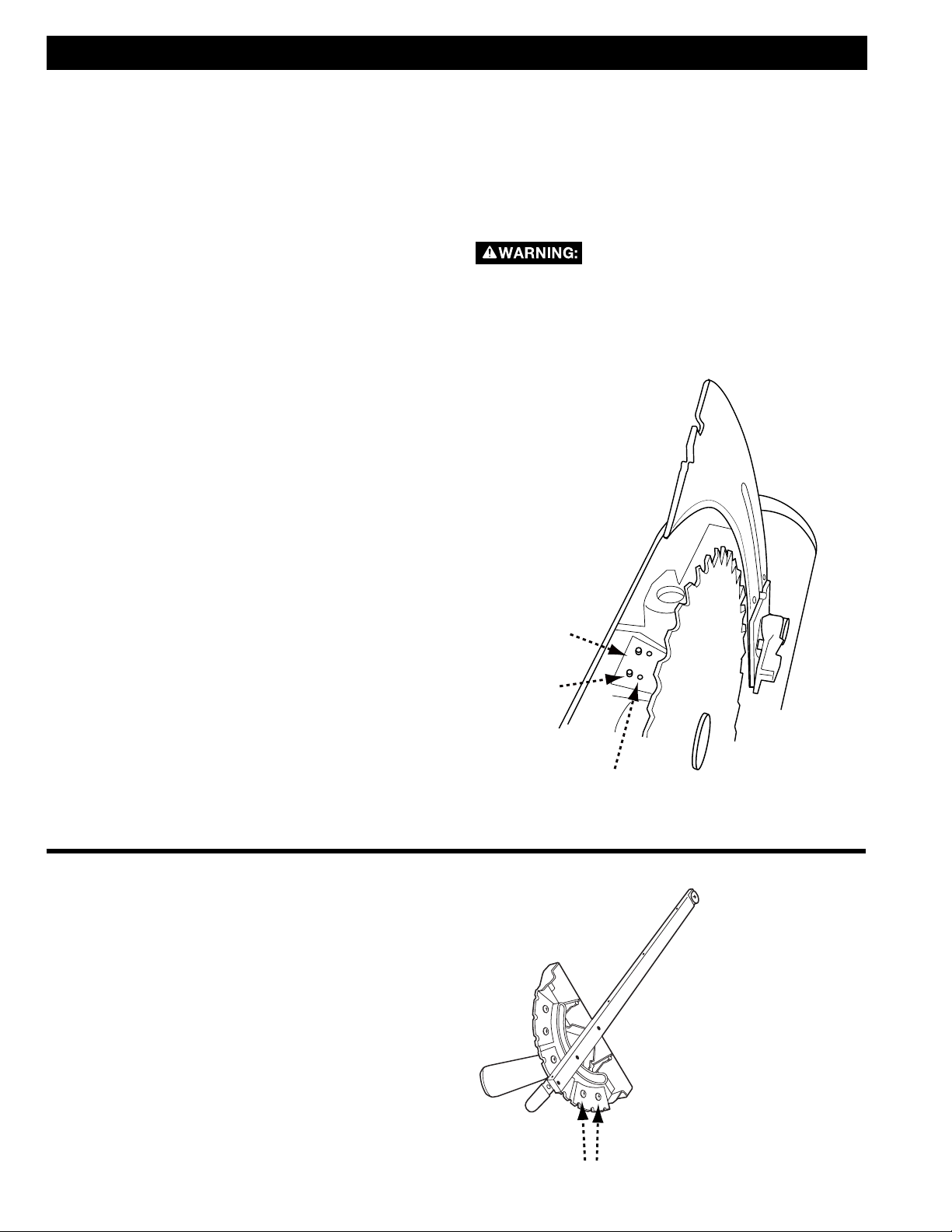

ANTI-KICKBACK PAWLS AND BLADE GUARD

ANTI-KICKBACK PAWLS

To reduce the risk of serious

personal injury, anti-kickback pawls

must be in place when making a through cut.

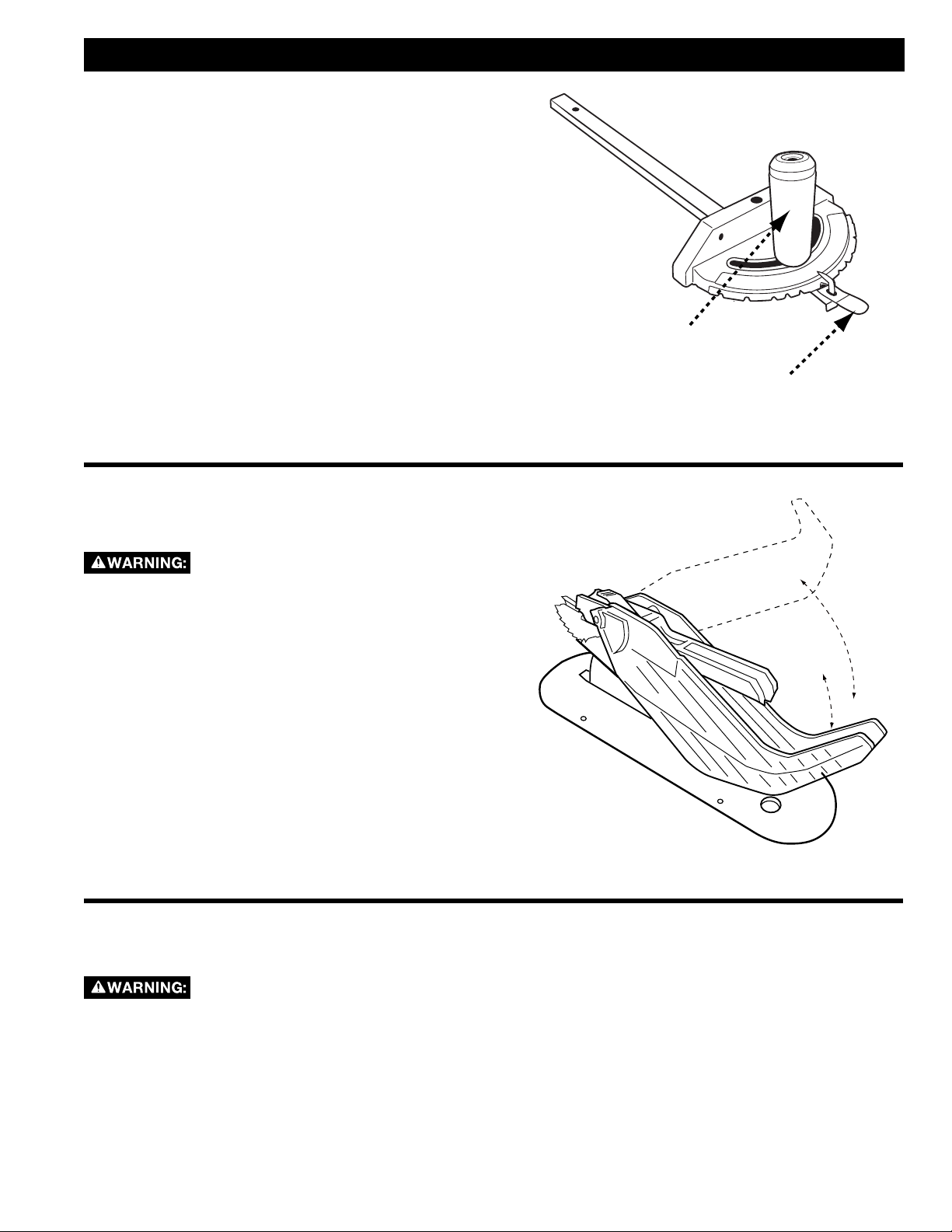

1. Refer to Figure 12 and locate the anti-kickback

pawls mounting slot (A) in the middle of the top

edge of the riving knife.

2. Slide slot in the middle of the anti-kickback pawls

assembly along the top of the riving knife until the

stem (B) locates the center slot on the riving knife.

3. Depress the stem on the anti-kickback pawls

assembly (B) to allow the assembly to drop

into the slot. Push down on the anti-kickback

pawls assembly until it snaps into place and

locks. Release stem. NOTE: Pull up on the anti-

kickback pawls to make sure it is locked in

place.

15

To remove the anti-kickback pawls, depress the stem

(B) and pull the anti-kickback assembly off the riving

knife.

B

A

FIGURE 12

Page 16

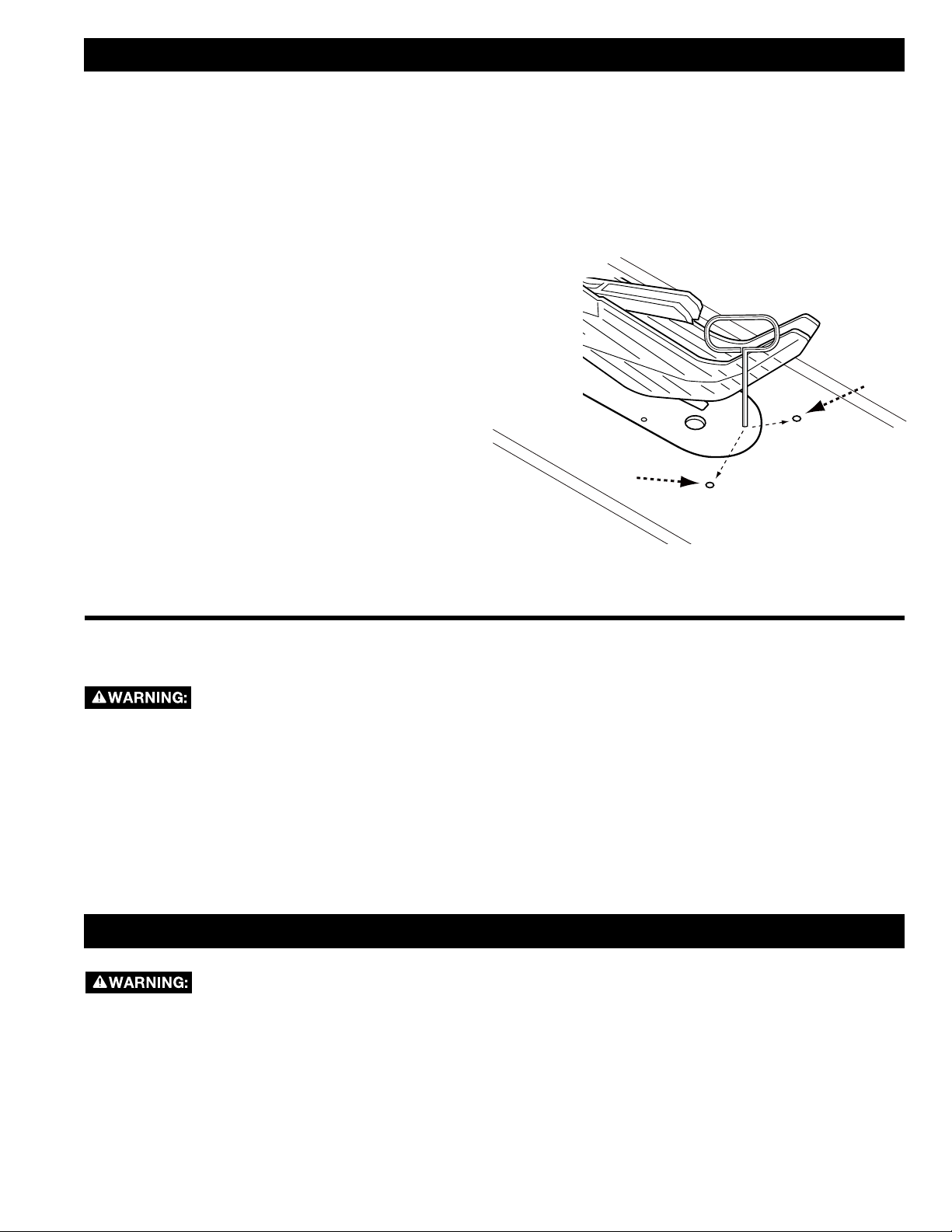

ASSEMBLY

BLADE GUARD

To reduce the risk of serious personal

injury, the blade guard must be in

place when making a through cut.

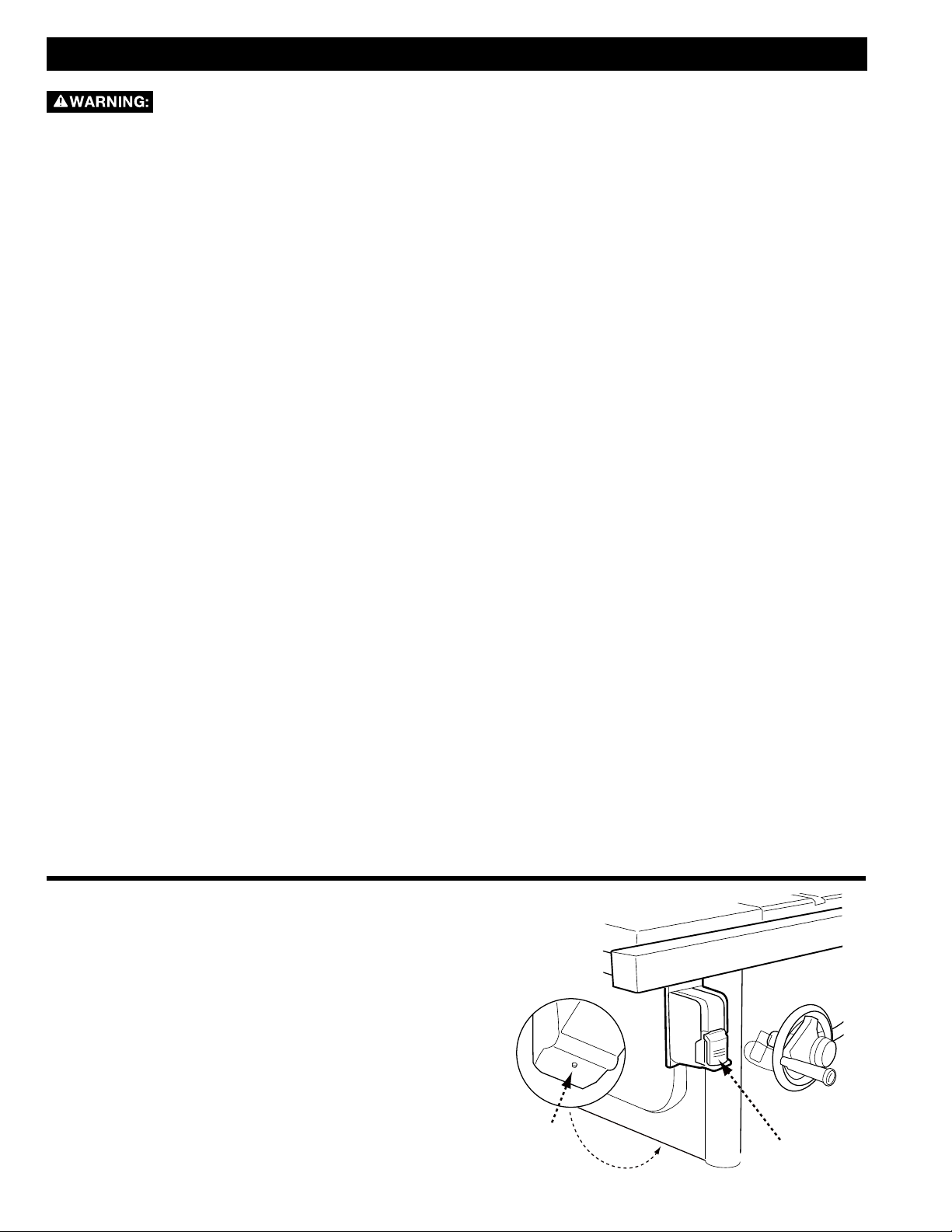

1. While holding the blade guard assembly (A) in a

vertical position, hook the locating pin (B) at the

back end of the blade guard assembly into the slot

at the back edge of the riving knife.

2. Rotate the blade guard assembly toward the front

of the saw until the metal portion (C) of the blade

guard assembly is parallel to the table as shown in

Figure 13.

3. While holding down on the front of the metal

portion of the guard (C) press the blade guard

lock lever (D) down until it snaps into the locked

position. Check to make sure the guard is locked

onto the riving knife by pulling on the guard. If the

guard is not locked, the blade guard lock lever will

flip up to the unlocked position.

If the metal portion of the blade guard

assembly (C) is not parallel to the

table, the riving knife is not in the raised position.

Remove blade guard assembly and anti-kickback

pawls and raise riving knife, then reinstall the antikickback pawls and the blade guard assembly.

(continued)

D

C

A

B

FIGURE 13

To remove the blade guard assembly:

1. Lift the blade guard assembly lock lever (D) to the

unlocked position.

2. Rotate the guard back and slide the pin (B) from the

riving knife slot.

RIP FENCE

Attach the handle to the fence cam

The rip fence slides onto the rear fence rail so that the

hook is under the rear rail and rides on the front guide

tube. The fence locks in place by applying pressure in

a downward motion on the rip fence handle. Rip fence

alignment should be checked prior to using your saw.

To check alignment of the rip fence, see alignment

instructions on page 29.

MITER GAUGE

Insert miter gauge into each miter slot to make sure it

slides freely. See Adjusting the Miter Stops section on

page 28 for adjustment of miter gauge accuracy.

ON-BOARD STORAGE

The Delta #36-5000 series contractor table saw

comes with on-board storage for the provided miter

gauge, arbor wrench, push stick and fence. There

is also on-board storage for spare saw blades (sold

separately). The miter gauge, spare blade and arbor

wrench storage areas are located on the right side

panel of the machine and come pre-installed.

On-board storage for the fence and the push stick is

located on the left side of the saw.

16

Page 17

(continued)

ASSEMBLY

ADJUSTING 90° AND 45° POSITIVE BEVEL STOPS

There are positive stops at each end of the bevel

range. To ensure accurate cuts, the positive stops

must be positioned at exactly at 90° and 45°. The bevel

stops are properly adjusted as shipped. However, for

maximum accuracy, you should check the position

of the stops upon assembly and from time to time to

assure that the settings remain satisfactory. To check

the position of the stops and adjust if necessary, refer

to Figure 14 and do the following.

1. Release the blade tilt lock knob.

2. Rotate the blade tilt handwheel clockwise and tilt the

blade away from, then back toward perpendicular

until the stop is reached the "stop position".

3. Using a carpenter’s square, check the angle of the

blade face to the table, as shown in Figure 20b,

page 20. If the blade is at 90° to the table, proceed

to Step 6.

4. If the blade is not perpendicular to the table, turn

handwheel to slightly tilt the blade away from the

stop position then adjust the 90° stop by rotating

the socket set screw located in the table top

immediately in front of the left side of throat plate

(A). Re-check angle using the carpenter’s square

and continue to adjust until the blade is at 90

degrees when returned to the stop position.

5. Rotate the blade tilt wheel counterclockwise until

it rests on the 45° stop. Then repeat Steps 4 and

5, adjusting the 45° stop by rotating the socket set

screw located in front of the right side of the throat

plate. (B)

B

A

FIGURE 14

SECURING SAW TO FLOOR

This saw is designed for portability. Do

not attempt to use the saw to cut a

large or cumbersome workpiece without first taking

appropriate steps to protect against tipping the saw.

Examples of appropriate steps include the use of

support tables and/or securing the saw legs to the floor

by replacing the saw feet with connecting bolts or by

attaching the legs to a floor mounted bracket with

u-straps.

PREPARING TO CUT

Failure to comply with the following

warnings may result in serious

personal injury.

ALWAYS

•

with the blade before operating the switch to start

the saw. Blade contact could result in kickback or

thrown workpiece.

• To reduce the risk of accidental starting, ALWAYS

make sure the switch is in the off position before

plugging saw into power source.

make sure your workpiece is not in contact

DO NOT

•

this tool. Failure to heed this warning could result in

serious personal injury.

• Turn unit off and disconnect it from power source

before installing and removing accessories, before

adjusting and when making repairs. An accidental

start-up can cause injury.

• Prior to operating the saw, make sure you are familiar

with its features and controls, and have made all

necessary adjustments as described below.

use blades rated less than the speed of

17

Page 18

PREPARING TO CUT

ASSEMBLY

RAISING AND LOWERING THE

BLADE

For most applications, it is recommended that you

raise the blade 1/8-inch (3.2mm) to 1/4-inch (6.4mm)

above the top surface of the workpiece.

Raise or lower the blade with the hand wheel (A)

located on the front of the saw (fig 15).

1. Before raising or lowering the blade, be

sure to loosen the lock knob (B) by turning it

counterclockwise.

2. To raise the saw blade, turn the hand wheel

clockwise. To lower the saw blade, turn the hand

wheel counter-clockwise.

3. Tighten lock knob to keep blade at the desired

height. Only a small amount of force is required to

lock the blade raising mechanism securely. Any

added force merely puts unnecessary strain on the

locking device.

4. When done operating the saw, and when

performing maintenance, adjustments or repairs,

lower blade below surface of table.

(continued)

B

A

FIGURE 15

TILTING THE BLADE

The blade can be tilted up to 45° to the left using the

blade tilt wheel (A) located on the right side panel of

the saw. The angle of tilt is measured by the bevel

gauge on the front of the saw. To tilt the saw blade:

1. Loosen the lock knob (B) counterclockwise and

turn the hand wheel clockwise. A pointer on

the front of the saw indicates the angle of tilt in

½-degree increments.

2. To lock the saw blade at your desired angle, tighten

the lock knob by rotating it clockwise.

A

B

FIGURE 16

18

Page 19

PREPARING TO CUT

ASSEMBLY

SELECTING AND STORING SAW BLADES

(continued)

Riving knives must be matched to saw blade

dimensions in order to function effectively.

The saw blade furnished with your new saw is a

10-inch (254 mm) combination blade, used for cross

cutting (across the grain) and ripping (with the grain)

through the workpiece. The arbor hole of the blade is

5/8-inch (16 mm) diameter. This blade will produce a

good quality cut for most applications.

There are many types of blades available to do specific

and special jobs such as cross cut only, rip only, dado

cuts thin plywood, paneling, etc.

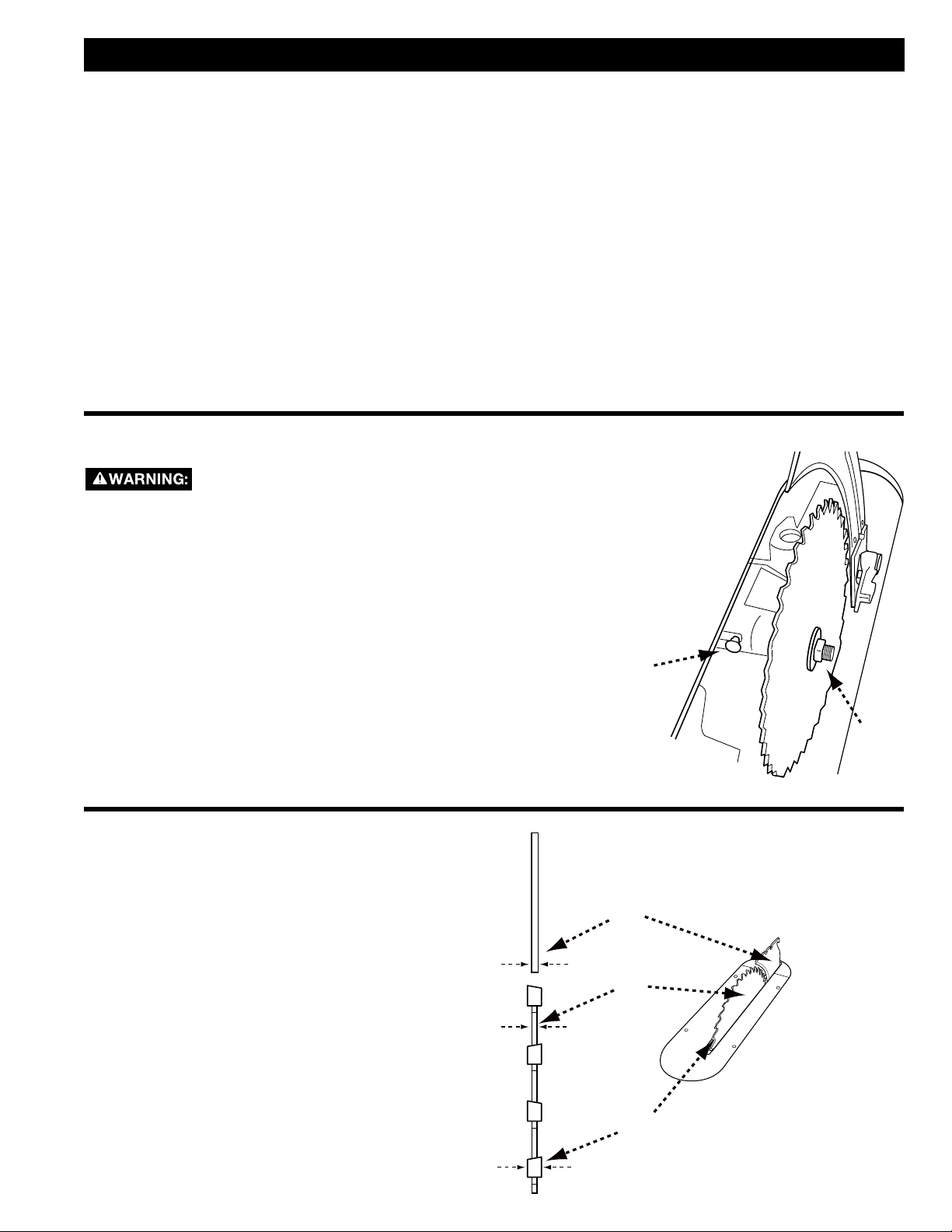

CHANGING THE SAW BLADE

• Use only 10-inch (254 mm) diameter blades with

5/8-inch (16mm) arbor holes, rated at 3,600 rpm or

higher, 0.102-inch (2.6mm) minimum kerf width and

0.073-inch (1.8mm) maximum body thickness.

• To reduce the risk of injury, turn unit off and

disconnect it from power source before installing

and removing blades and accessories, before

adjusting and when making repairs. An accidental

start-up can cause injury.

1. Remove the throat plate and raise the saw blade

to its maximum height.

2. Push and hold arbor lock button (A) shown in

Figure 17.

3. Use included arbor wrench to remove the blade

retaining nut and flange (B). Remove old blade.

Use only saw blades designed for maximum safe

operating speeds of 3,600 RPM or greater.

Saw blades should always be kept sharp. It is

recommended that you locate a reputable sharpening

service to sharpen your blades when needed.

Never stack blades on top of one another to store.

Place material such as cardboard between them to

keep the blades from coming in contact with one

another, or place them in storage drawer.

Abrasive wheels or blades (including diamond) should

not be used on this saw.

4. Place the new blade on the arbor

with the teeth pointing down as

the blade rotates toward the

front of the saw table.

5. Replace and tighten the blade

retaining nut and flange.

6. Replace throat plate.

A

B

FIGURE 17

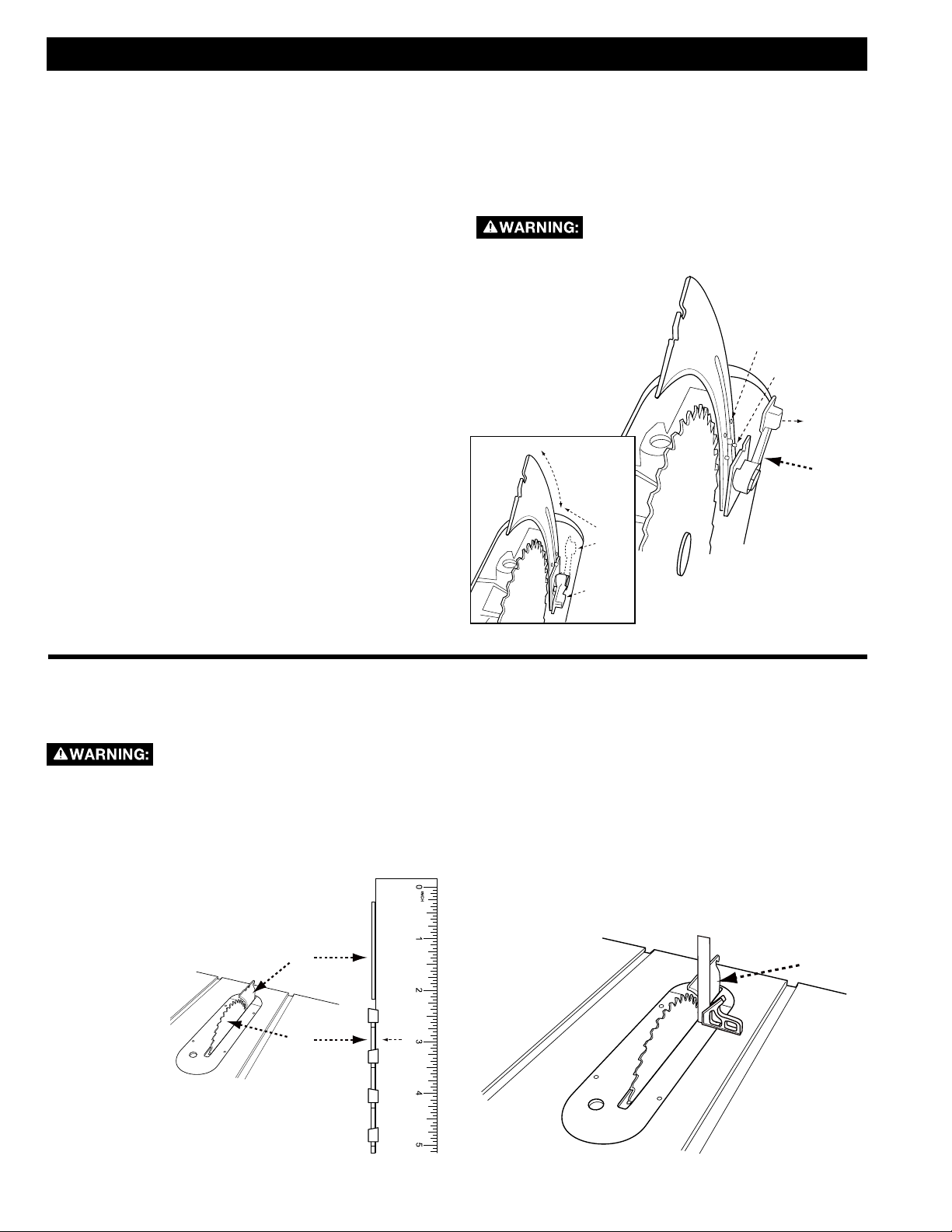

RIVING KNIFE POSITION

NOTE: Safety devices, blade guard assembly and anti-

kickback assembly have been removed in Figure 18 in

order to show the location of specific features. When

operating the saw, these safety devices should be in

place and working properly.

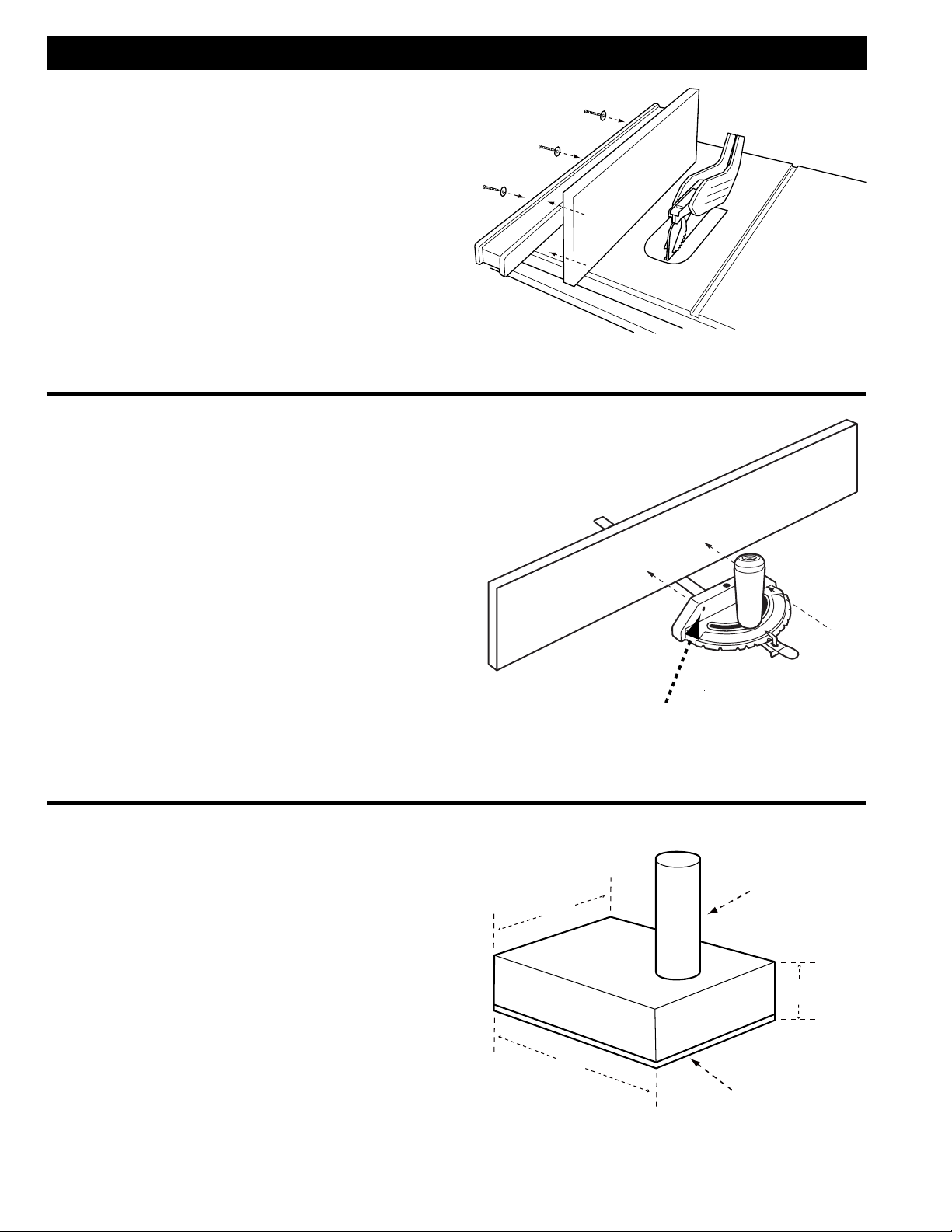

The riving knife is a flat plate that fits into the cut made

by the saw blade and effectively fights kickback by

lessening the tendency of the blade to bind in the cut.

It must be installed and properly positioned for every

through cut and for every non-through cut unless the

riving knife would interfere with the workpiece.

The riving knife thickness (A) must be greater than the

blade body or plate thickness (B) and less than the

kerf or cutting width (C) as shown in Figure 15. The

riving knife provided with this saw is 2.2mm thick and

may be used only with a 10-inch (254mm) blade with

0.102-inch (2.6mm) minimum kerf width and 0.073-inch

(1.8mm) maximum body thickness. Do not attempt to

use this riving knife with blades that are not

within these dimensions.

A

B

C

FIGURE 18

19

Page 20

PREPARING TO CUT

A

B

(continued)

RIVING KNIFE HEIGHT

SETTINGS

The height of the riving knife should be adjusted based

on the type of cut being made. For all through cuts

(when the wood is completely severed), it should be

in the raised position, with anti-kickback fingers and

guard installed. For non-through cuts (when the blade

does not penetrate the top of the workpiece), the

riving knife should be in the lowered position and antikickback fingers and guard removed.

TO RAISE OR LOWER THE RIVING KNIFE:

1. Remove throat plate.

2. Raise blade to full height above table.

3. Pull riving knife release lever (A) up to release riving

knife from clamping mechanism. See Figure 19.

4. Push riving knife and release lever to the arbor side

of the blade to disengage riving knife from pins.

a. To adjust the riving knife into the through-cut

position, pull riving knife up to lower detent

pins.

b. To move the riving knife into the non-through

cut position, push it down to upper detent

pins.

NOTE: When adjusting the riving knife up or down, be

sure to pull in a radial motion, as shown.

1. Release lever and pull on riving knife to make sure it

is properly seated in the raised or lowered position.

2. Securely clamp riving knife by pushing riving

knife clamping lever back down to the horizontal

position.

3. Replace throat plate.

DO NOT operate saw unless riving

knife is securely clamped in the raised

position for through-cutting or the lowered position

for non through-cutting.

Lower

Position

Detents

Upper Position

Detents on Pins

Pull Away

to Release

Riving Knife

A

Adjust

Locked

FIGURE 19

CHECKING RIVING KNIFE

ALIGNMENT

Before connecting the table saw to

the power source and operating the

saw, always inspect the blade guard assembly and

riving knife for proper alignment and clearance with

saw blade. Check the riving knife alignment after

each blade change.

TO CHECK ALIGNMENT:

1. Horizontal Alignment: Lay a

straight edge on the table against

blade face (A) and make sure

it extends out along the

riving knife (B),

as shown

in Figure

20a. The

riving knife

should just

touch the

straight

edge.

Be sure the straight edge

goes between the teeth and

rests on the blade face and

the riving knife for proper

alignment.

FIGURE 20a

1. Vertical Alignment: Place a carpenter’s square on

the table and against the blade face and make sure

it extends up along the riving knife (B) as shown in

figure 20b. The riving knife and blade should touch

the carpenter’s square with no gaps. Be sure the

straight edge goes between the teeth and rests

on the blade face and the riving knife for proper

alignment.

If the riving knife and blade are out of horizontal or

vertical alignment, refer to riving knife alignment

instructions on page 30 of this manual.

B

FIGURE 20b

20

Page 21

PREPARING TO CUT

USING THE MITER GAUGE

The miter gauge is equipped with adjustable index

stops at 90°, 75°, 60°, 45° and 30°. To set the miter for

an angled cut, see Figure 21 and:

1. Loosen the handle (A).

2. Depress the thumb lever (B).

3. Move the body of the miter gauge to the desired

angle.

4. Release the thumb lever and retighten the handle.

The miter gauge is equipped with a washer on the end

of the bar which fits into the t-slot in the table. This

allows the miter gauge to be pulled off the front edge

of the table without falling. This allows for an increased

workpiece capacity in front of the blade.

USING BLADE GUARD

ASSEMBLY

(continued)

A

FIGURE 21

B

The anti-kickback pawls and blade

guard must be used for all throughcuts. Keep both guard shields down and arms, hands

and fingers away from the blade, blade guard and

anti-kickback pawls when power is on to prevent

serious injury. See assembly instructions on page 13

for proper installation and removal of anti-kickback

pawls and blade guard.

If there is a need to briefly raise the blade guard (for

example, to make a measurement) the guard can be

parked in a raised position.

1. Refer to Figure 22 and, lifting the guard from the

front, raise the guard shield until it snaps into a

locked position above the table. One or both guard

shields can be raised.

2. When done making the measurement, return guard

to operating position.

CHECKING FENCE ALIGNMENT

Do not attempt to use a rip fence that

is not properly aligned.

Every time you use the rip fence, check its alignment

to make sure the fence is parallel to the miter slot. To

check the alignment of your rip fence, place the fence

adjacent to miter slot and lock the fence in place. If the

fence is not aligned to the miter slot from the front to

the back, see instructions for aligning rip fence on page

29 of this manual. If you are not able to successfully

align the rip fence, replace the rip fence or contact

1-800-223-7278 for further instructions.

FIGURE 22

21

Page 22

OPERATION

Failure to comply with the following the warnings may result in serious personal injury.

READ ENTIRE MANUAL. In addition to reading these operating instructions, it is important to read and understand

the entire manual before operating this saw. Follow all applicable instructions regarding assembly, preparation, and

adjustment prior to making any cuts and comply with all safety rules and warnings in this section and elsewhere

throughout this manual.

1. Each time you use the saw, run through the

following checklist:

• Are the power source and power connections

adequate for the saw?

• Are the saw and work area free of clutter and

by-standers?

• Is the blade tight and properly aligned?

• Does the riving knife thickness match the blade?

• Are the blade and riving knife properly aligned?

• Is the operator qualified to make the cut and familiar

with all of the relevant safety rules, warnings and

instructions included in this manual?

• Is the operator and everyone in proximity to the saw

wearing appropriate eye, hearing and respiratory

equipment?

• Are the bevel angle and height adjustment knobs

locked in the proper position?

• Is the blade set at the proper height?

• If ripping, is the rip fence parallel to the blade and

securely locked in position?

• If crosscutting, is the miter gauge knob tight?

• If making through cuts with a standard blade, are

the blade guard riving knife and anti-kickback pawls

properly attached and properly functioning with both

guards contacting the table surface?

• Is there proper clearance and support for the

workpiece as it leaves the blade?

• Are any cutting aids needed? If so, are they in place,

or within reach for proper use?

2. The use of attachments and accessories not

recommended by DELTA® Power Equipment

Corporation may result in injury.

3. Replace or sharpen the anti-kickback fingers

when the points become dull.

4. Make sure saw is stable and cutting can be

accomplished without tipping the saw. Do not

attempt to cut large workpieces without securing

saw to a stable surface. To properly secure the

saw, see instructions in section entitled Securing

Saw to the Floor on page 15 of this manual.

5. Never use the fence and miter gauge together

without using a cutoff block as previously

described.

6. The proper throat plate must be in place at all

times.

7. If your saw makes an unfamiliar noise or if it

vibrates excessively, cease operating immediately

until the source has been located and the problem

corrected.

8. Never perform freehand cutting, plunge cutting,

re-sawing or cove cutting.

AVOID KICKBACK

A kickback can occur when the workpiece pinches

the blade, or binds between the saw blade and the

rip fence or other fixed object. This can cause the

workpiece to rise from the table and/or be thrown back

toward the operator. See instructions for reducing the

risk of kickback on page 7 of this manual.

IF KICKBACK OCCURS, turn the saw "OFF" and verify

proper alignment of the blade, riving knife and miter

gauge or rip fence, and the proper functioning of the

riving knife, anti-kickback assembly and blade guard

assembly before resuming work.

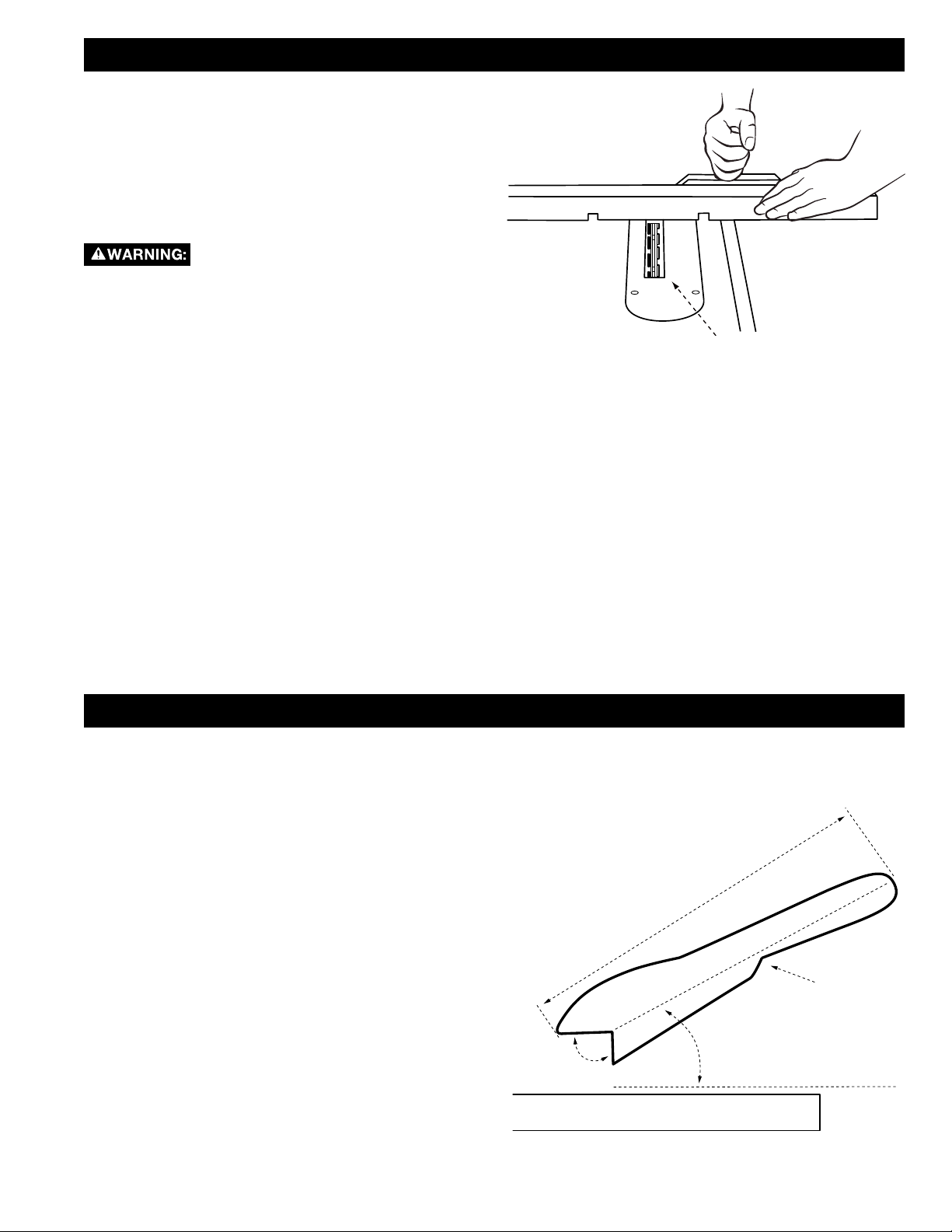

STARTING AND STOPPING THE SAW

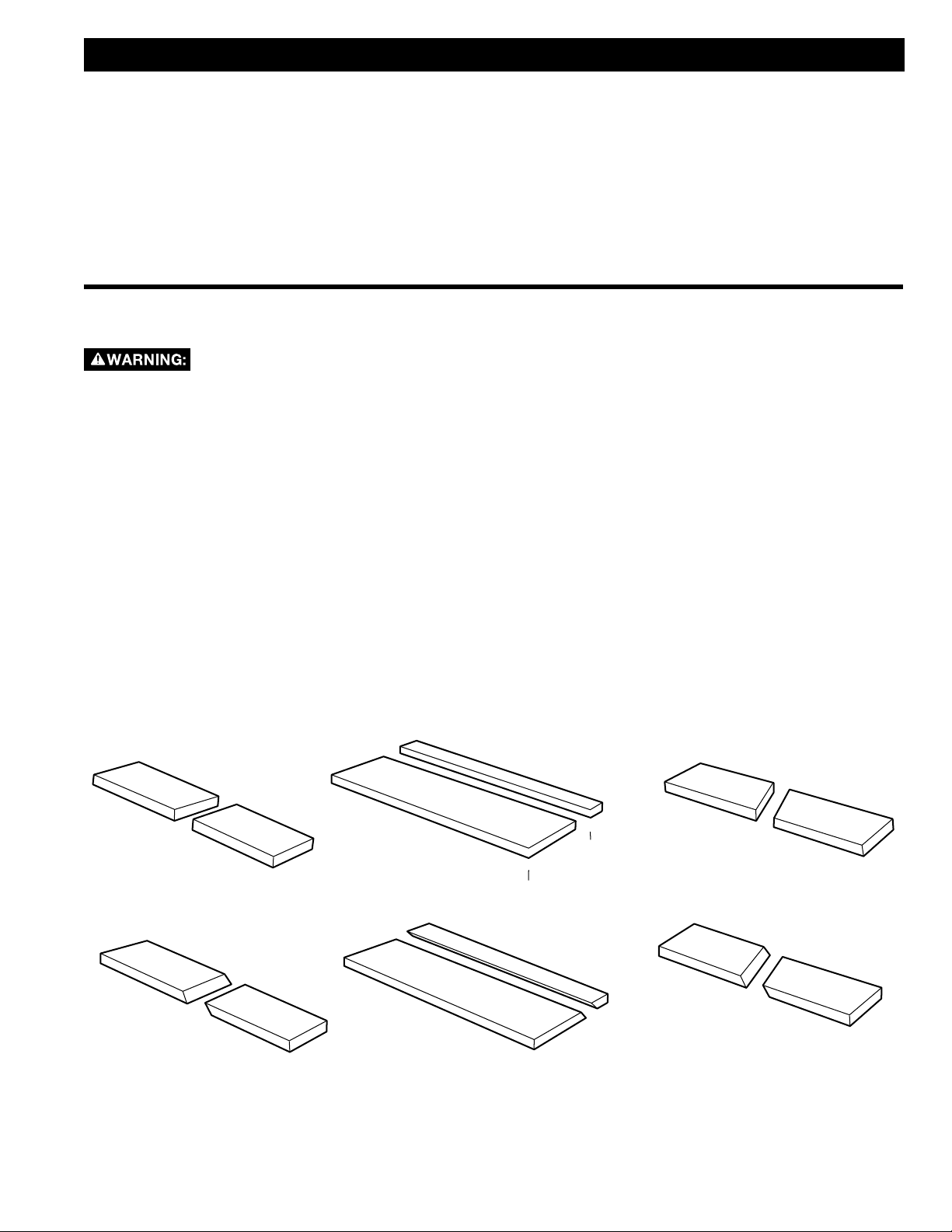

The POWER switch (Figure 23) is located

underneath the front left extension wing.

1. To turn the saw "ON", pull the red paddle switch

(A) up and toward you.

2. To turn the saw "OFF", push the red paddle

switch in.

When not in use, the saw should be turned off and

the power switch locked out to prevent unauthorized

use. To lock out power switch, use a standard long

shackle lock, with a shackle that is at least 2 ¾ inches (70mm) long and with shackle posts no larger

than 9/32-inch (7mm) thick.

22

B

A

FIGURE 23

Page 23

OPERATION

OVERLOAD PROTECTION

(continued)

Your saw is supplied with overload protection. If the

motor shuts off or fails to start due to overloading

(cutting stock too fast, using a dull blade, using the

saw beyond its capacity, etc.) or low voltage, let the

motor cool three to five minutes. Then depress the red

MAKING CUTS

Failure to comply with the following

the warnings may result in serious

personal injury.

• Never touch the free end of the workpiece or a free

piece that is cut off, while the power is on and/or the

saw blade is rotating. Blade contact or binding may

occur, resulting in a thrown workpiece

• When sawing a long workpiece or a panel, use a

work support, such as a sawhorse, rollers or outfeed

table at the same height as the table surface of the

saw.

• Never try to pull the workpiece back with the blade

turning. If you need to pull the workpiece back or lift

it off the table, turn the switch off, allow the blade to

stop, raise the anti-kickback teeth on each side of

the riving knife if necessary, and slide the workpiece

out.

reset button (B), on the motor under the saw, shown in

Figure 20, and restart the saw.

NOTICE: If the motor continually shuts off due to

overloading, contact a qualified electrician.

• Before connecting the table saw to the power source

or operating the saw, always inspect the blade guard

assembly and riving knife for proper alignment and

clearance with saw blade. Check alignment after

each change of beveling angle.

• A rip fence should ALWAYS be used for ripping

operations to prevent loss of control and personal

injury. Always lock the fence to the rail. NEVER

perform a ripping operation freehand.

• When making bevel cuts, place the fence on the right

side of the blade so that the blade is tilted away from

the fence and hands. Keep hands clear of the blade

and use a push stick to feed the workpiece unless

the workpiece is large enough to allow you to hold it

more than 6inches (152 mm) from the blade.

• Before leaving the saw unattended, lock out power

switch, or take other appropriate measures to

prevent unauthorized use of the saw.

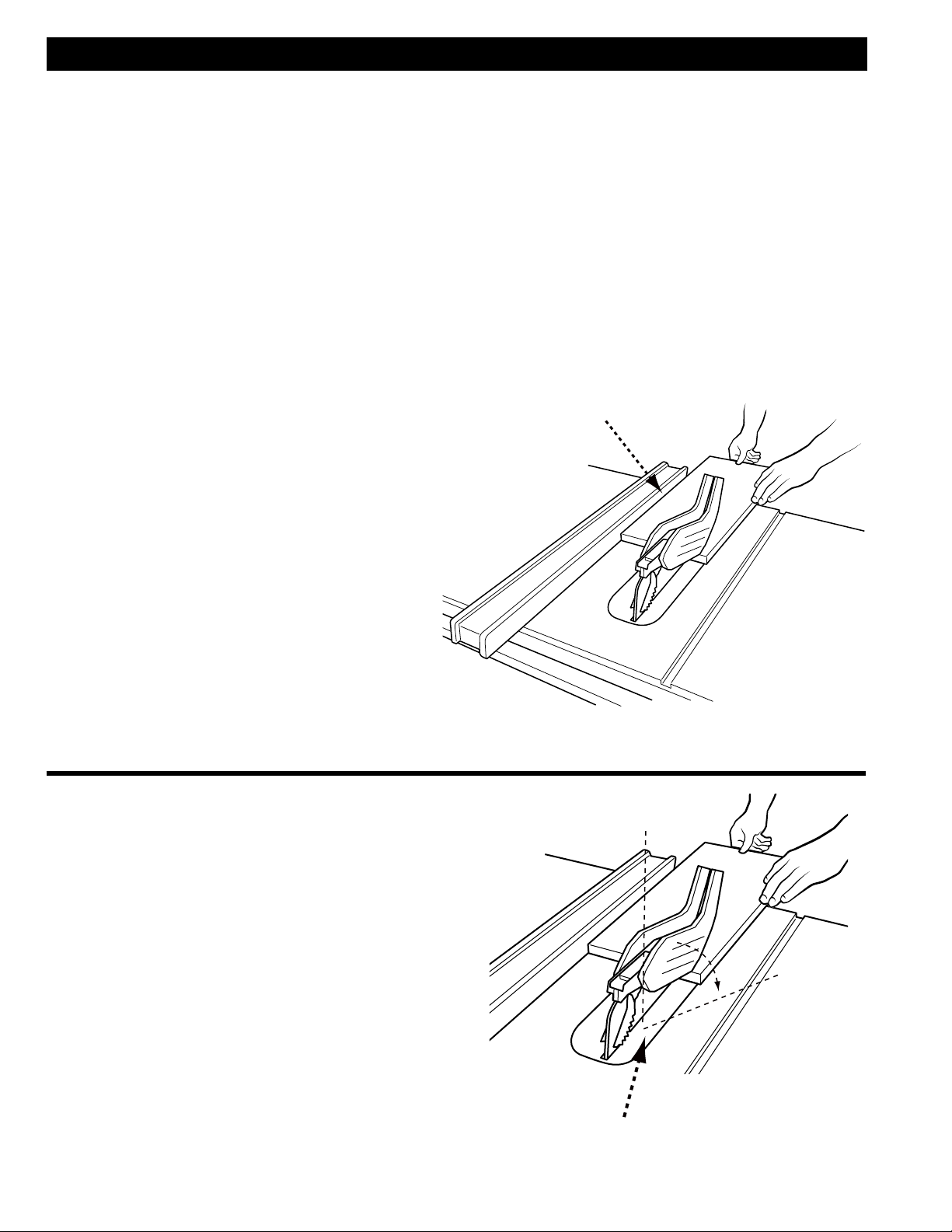

Cross Cut Mitered Crosscut

Beveled Cross Cut

Rip Cut

Beveled Rip Cut Compound Miter Cut

23

Page 24

OPERATION

A

(continued)

RIP CUTS

1. Remove miter gauge

2. Make sure bevel angle is set to 0°.

3. Set blade to correct height for workpiece.

4. Install rip fence and lock it down parallel with and

at desired distance from blade.

5. Keep fingers at least 6 inches from the blade at

all times. When the hand cannot be safely put

between the blade and the rip fence, select a

larger workpiece, or use a push stick and other

cutting aids, as needed, to control the workpiece.

6. Make sure the workpiece is clear of the blade (at

least 1 inch or 25mm away) before starting the

saw

7. Turn saw on.

8. Hold the workpiece flat on the table and against

the fence (A). The workpiece must have a straight

edge against the fence and must not be warped,