Page 1

FOLDING MITER SAW STAND

www.DeltaMachinery.com

Instruction Manual

To reduce risk of serious

injury, thoroughly read and comply with all warnings

and instructions inthis manual and on product.

KEEP THIS MANUAL NEAR YOUR STAND FOR EASY

REFERENCE AND TO INSTRUCT OTHERS

36-267

Page 2

TABLE OF CONTENTS

PRODUCT SPECIFICATIONS ...................................................2

SAFETY INFORMATION ........................................................... 2

UNPACKING ..............................................................................4

Package Contents ............................................................... 5

Hardware ............................................................................ 5

ASSEMBLY .................................................................................6

Pivot Bolt ........................................................

Vertical Stabilizer and Rubber Feet ..................................... 6

Front Handle and Wheels .................................................... 7

Mounting Brackets and Workpiece Supports ..................... 7

Attaching Miter Saw to the Stand ....................................... 8

Using a Mounting Platform ................................................. 8

....

................ 6

PRODUCT SPECIFICATIONS

DESCRIPTION SPECIFICATIONS

Height (with mounting brackets) 36.06" (916mm)

Dimensions (folded for transport) 56.3”X 25.4” X 23.67” (1430mm X 645mm X 601mm)

Dimensions (extended for use) 57.83” X 25.4” X 36.1” (1469mm X 645mm X 916mm)

ADJUSTMENTS .........................................................................9

Workpiece Supports and Stop Plates ....................................... 9

Rail Extensions ........................................................................... 9

Collapsing the stand for transport

Mounting bracket clamping pressure

PARTS, SE

THREE-YEAR LIMITED WARRANTY ...................................... 10

REPLACEMENT PARTS ............................................................10

SERVICE AND REPAIRS ...........................................................10

RVICE OR WARRANTY ASSISTANCE ..................10

..............................................

..............................................99

Total Width with Fully Extended (114") (2896mm)

IMPORTANT SAFETY INSTRUCTIONS

CAREFULLY READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS ON YOUR

PRODUCT AND IN THIS MANUAL. SAVE THIS MANUAL. MAKE SURE ALL USERS

ARE FAMILIAR WITH ITS WARNINGS AND INSTRUCTIONS WHEN USING THE TOOL. Improper operation,

maintenance or modification of tools or equipment could result in serious injury and/or property damage.

DEFINITIONS – SAFETY SYMBOLS

This manual contains information that is important for you to know and understand. This information relates to

protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided,

may result in property damage.

2

Page 3

GENERAL SAFETY RULES

WARNING FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

FOR YOUR OWN SAFETY, READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE OPERATING THE

•

PRODUCT STAND. KEEP WORK AREA CLEAN AND WELL LIT. Cluttered or poorly-lit work areas, surfaces and

benches can lead to accidents. Do not leave anything on stand when machine is in use. Allow enough room and

provide proper support for work piece and operation of the machine.

KEEP CHILDREN AND BYSTANDERS AWAY from work area.

•

WEAR PROPER APPAREL. DO NOT wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which

•

may get caught in moving parts. Nonslip protective footwear is recommended. Wear protective hair covering to

contain long hair.

EYE PROTECTION. All persons in work area should wear safety glasses with side shields. Everyday eyeglasses

•

with impact resistant lenses are not safety glasses. Eye equipment should comply with ANSI Z87.1 or CAN/CSA

Z94.3 standards.

HEARING PROTECTION. All people in work area should wear proper hearing protection consistent with noise

•

levels and exposure. Hearing equipment should comply with ANSI S3.19 standards.

DUST PROTECTION. Use of power tools can generate and/or disburse dust, which may cause serious and

•

permanent respiratory damage. Direct particles away from face and body. Always operate machines in well-

ventilated area and provide for proper dust removal. Use dust collection system whenever possible. Exposure

to dust may cause serious and permanent respiratory or other injury, including silicosis (a serious lung disease),

cancer, and death. Avoid breathing dust and avoid prolonged contact with dust. Allowing dust to get into your

mouth or eyes, or lay on your skin may promote absorption of harmful material. Use properly fitting NIOSH/

OSHA/MSHA approved respiratory protection appropriate for the dust exposure and wash exposed areas with

soap and water.

THIS PRODUCT WAS DESIGNED TO BE USED PRIMARILY AS A STAND FOR MITER SAWS. IT MAY BE USED

•

WITH PORTABLE PLANERS. DO NOT alter the stand, use it with other products, or for other purposes. The stand

will support 400 lbs., including both machine and work piece. Any misuse or abuse can result in product damage

or personal injury.

USE CARE WHEN ASSEMBLING, MOVING, RAISING OR LOWERING THE STAND to avoid the risk of pinching

•

hands and fingers.

PLACE THE STAND ON A FLAT AND LEVEL SURFACE to prevent rocking or tipping. Do not use the stand on an

•

uneven, unstable or slippery surface. Always check the stability of the stand before connecting machine to power

source.

DO NOT STAND ON THIS PRODUCT or use the support extensions as a ladder or scaffolding. It is unsafe to

•

climb, sit or stand on this product.

CHECK PRODUCT FOR DAMAGE. Before using stand, and after it has been dropped or damaged, check moving

•

and affected components of stand and any attached machines FOR ALIGNMENT, BINDING, BREAKAGE AND

ANY OTHER CONDITION THAT MAY AFFECT THE MACHINE’S PERFORMANCE AND THE STAND’S ABILITY

TO PROPERLY SUPPORT AND SECURE THE MACHINE. DO NOT USE A DAMAGED PRODUCT. A DAMAGED

PRODUCT SHOULD BE PROPERLY REPAIRED USING ONLY IDENTICAL REPLACEMENT PARTS.

CHECK ALL SUPPORTS TO CONFIRM THAT THEY ARE PROPERLY LOCKED IN PLACE BEFORE CONNECTING

•

MACHINE TO POWER SOURCE.

DISCONNECT MACHINE FROM POWER SOURCE BEFORE ATTACHING IT TO STAND, AND WHEN MACHINE IS

•

NOT IN USE.

PROPERLY MOUNT MACHINE AND ADJUST WORK PIECE SUPPORTS SO THE WORK PIECE(S) WILL BE

•

LEVEL WITH MACHINE TABLE.

PROPERLY SECURE THE MACHINE TO THE STAND BEFORE CONNECTING IT TO POWER SOURCE.

•

DO NOT ATTEMPT TO USE STAND FOR OPERATIONS INVOLVING AN AWKWARD OR OVERSIZED WORK PIECE

•

THAT COULD CAUSE THE STAND TO TIP OVER.

WHEN TRANSPORTING STAND, MAKE SURE IT IS PROPERLY SECURED TO PREVENT MOVEMENT AND

•

POSSIBLE DAMAGE.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

If stand is loaned to someone, also loan them these instructions.

3

Page 4

PROPOSITION 65 WARNING:

Dust created by power sanding, sawing, grinding, drilling, and other

construction activities may contain chemicals known to the state of California to cause cancer, birth

defects or other reproductive harm. Some examples are:

– Lead from lead-based paints

– Crystalline silica from bricks and cement and other masonry products

– Asbestos dust

– Arsenic and chromium from chemically-treated lumber

• Your risk from these exposures varies depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well-ventilated area and work with approved safety equipment, such as dust masks that

are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap and water

If you have any questions or concerns relative to the use of your tool or the contents of this manual,

stop using the tool and call DELTA® Power Equipment Corporation Customer Care at 1-800-223-7278.

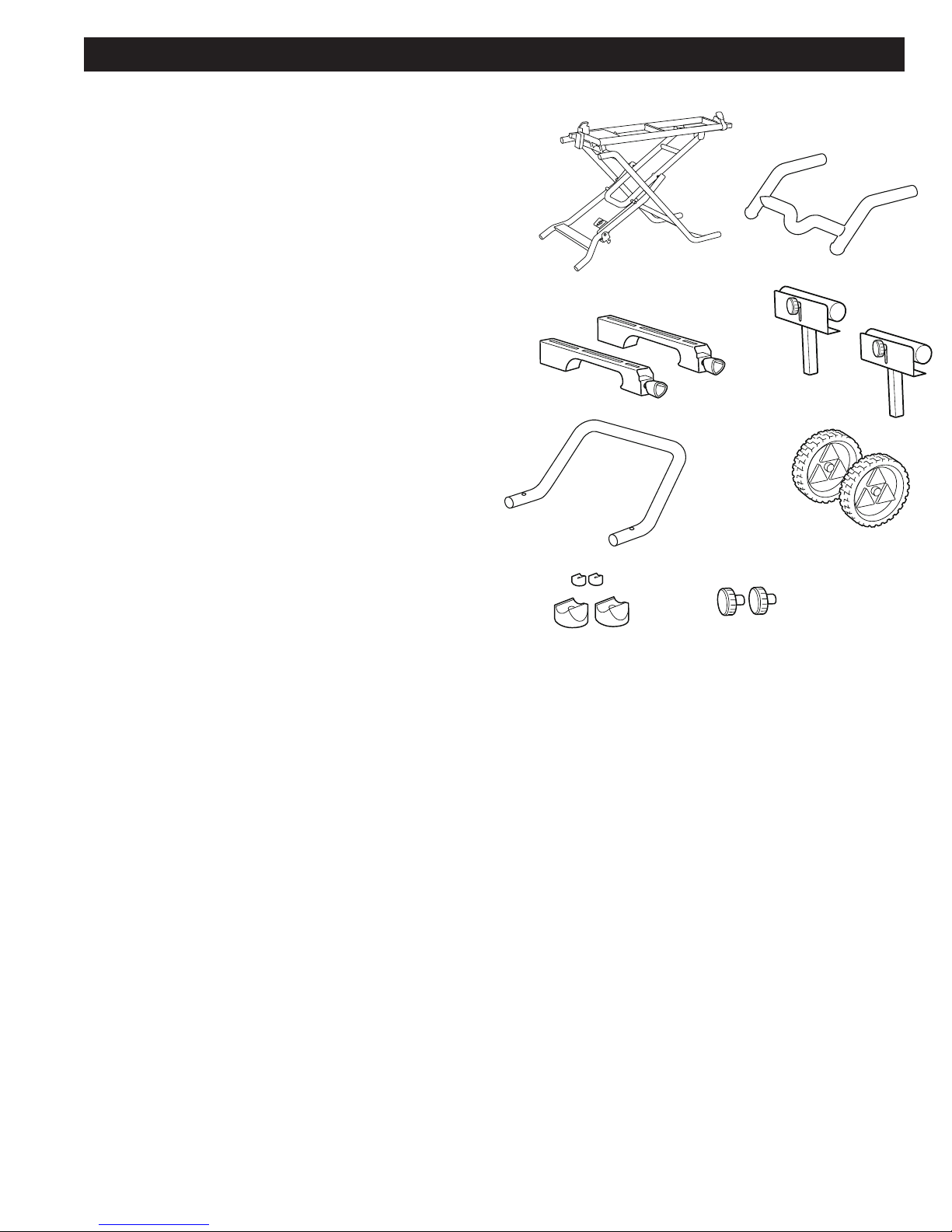

UNPACKING

1. Remove all contents from the shipping carton.

2. Set aside the packing material; place the stand on the ground and lay out all loose parts and hardware.

3. Using the illustration below, locate and identify all parts and hardware to make sure they are all accounted for

before discarding packing material or beginning to assemble.

NOTE: If any part is missing or damaged, DO NOT attempt to assemble the product and call DELTA® Power

Equipment Corporation Customer Care at 1-800-223-7278.

4

Page 5

UNPACKING

PACKAGE CONTENTS DESCRIPTION (QTY)

1. Miter saw stand (1)

2. Handle (1)

3. Mounting bracket (2)

4. Workpiece support w/stop plate (2)

5. Vertical stabilizer (1)

6. Wheel (2)

7. Rubber Feet (2 Small and 2 Large)

8. Knob – Large (2)

HARDWARE DESCRIPTION (QTY)

1

3

2

4

• M6 Hex Locknut (2)

• M8 Locknut (2)

• M10 Locknut (2)

• M12 Hex Locknut (2)

• M6 x 50mm Slot Pan-Head

Screw (2)

• M8 x 20mm Self-Tapping

Screw (2)

• M10 X 55mm Hex Screw (2)

• M12 x 110mm Hex Head

Screw (2)

• M8 (ID) x 25mm (OD) X

3mm (thick) Flat Washer (2)

• M12 (ID) x 20mm (OD) x

2mm (thick) Flat Washer (2)

• M13 (ID) x 28mm (OD) x

2.8mm (thick) Flat Washer

(2)

• Wheel shaft M8*93L Hex

shoulder screw (2)

• M8 x 55mm hex bolt (4)

• M8 washer (4)

• M8 hex nut (4)

NOTE: All hardware uses

right-handed threads.

5

6

7 8

5

Page 6

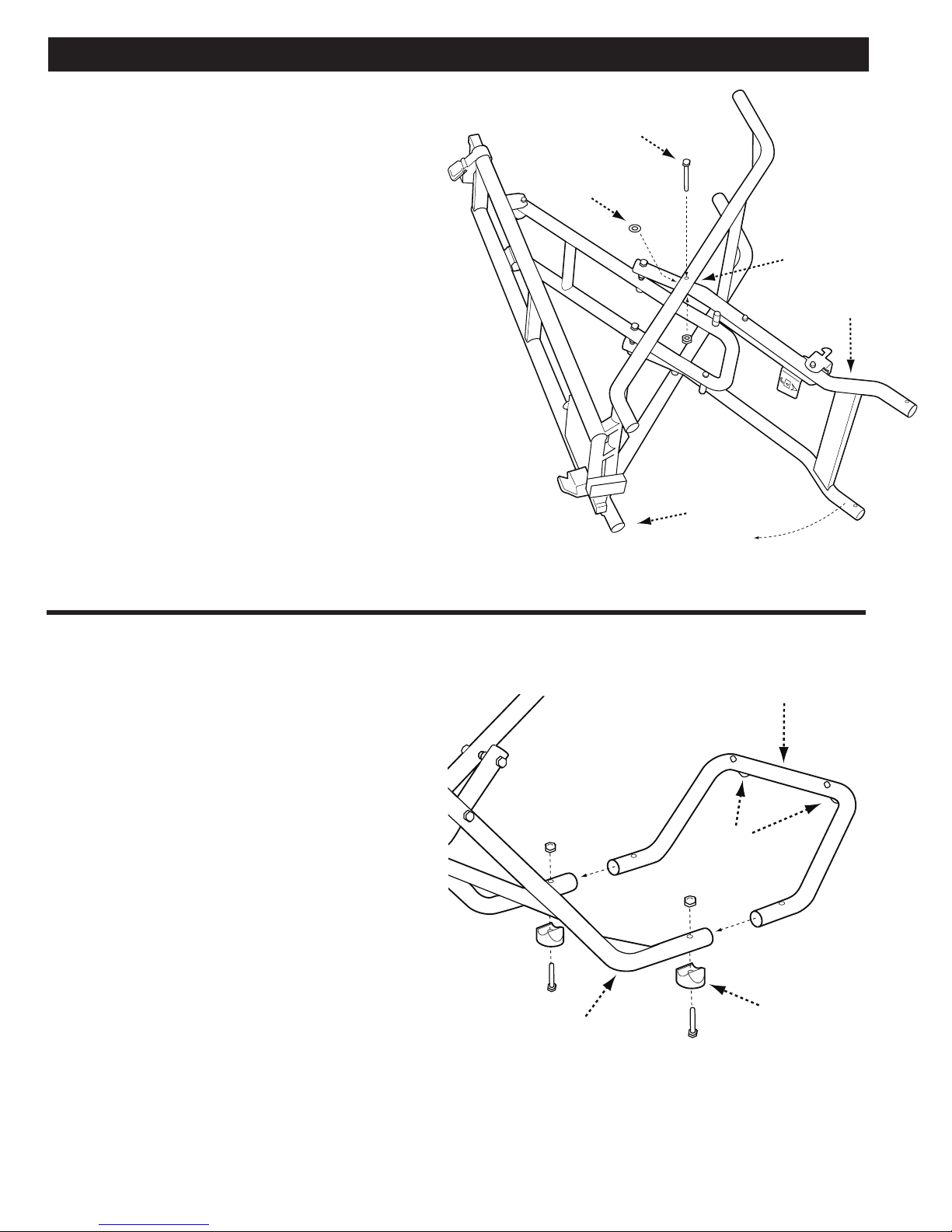

ASSEMBLY

Tools Required for Assembly (not included):

Phillips screwdriver, socket set, and an

adjustable wrench.

C

PIVOT BOLT

1. Lay the stand on its side.

2. Pull the rear folding support (A) toward the

handle tube openings (B) in order to align the

holes in the rear folding support and front

folding support.

3. Insert an M12 x 110mm hex bolt (C) through

the front folding leg. Place an M12 washer (D)

between the front and rear supports and feed

the bolt through the washer and rear support.

4. Secure with an M12 hex nut. The nut should be

snug but not over-tight.

5. Place the stand upright. The holes in the

supports on the opposite side should be nearly

aligned. Repeat Steps 3 and 4 to secure other

side.

D

Align holes

A

B

VERTICAL STABILIZER AND

RUBBER FEET

1. Place the stand on its side.

2. Insert the vertical stabilizer (A) into the ends

of the rear folding supports (B) with the end of

the stabilizer angling up. Align the holes in the

stabilizer and supports.

3. Attach the larger rubber feet (C) to the bottom of

the vertical stabilizer by feeding an M10 x 55mm

hex bolt through the bottom of the feet. Secure

with an M10 hex nut, remembering to rotate it

clockwise to tighten.

4. Attach the smaller rubber pads (D) to the end of

the vertical stabilizer using two M6 x 50mm pan

head bolts and M6 locknuts.

A

D

C

B

6

Page 7

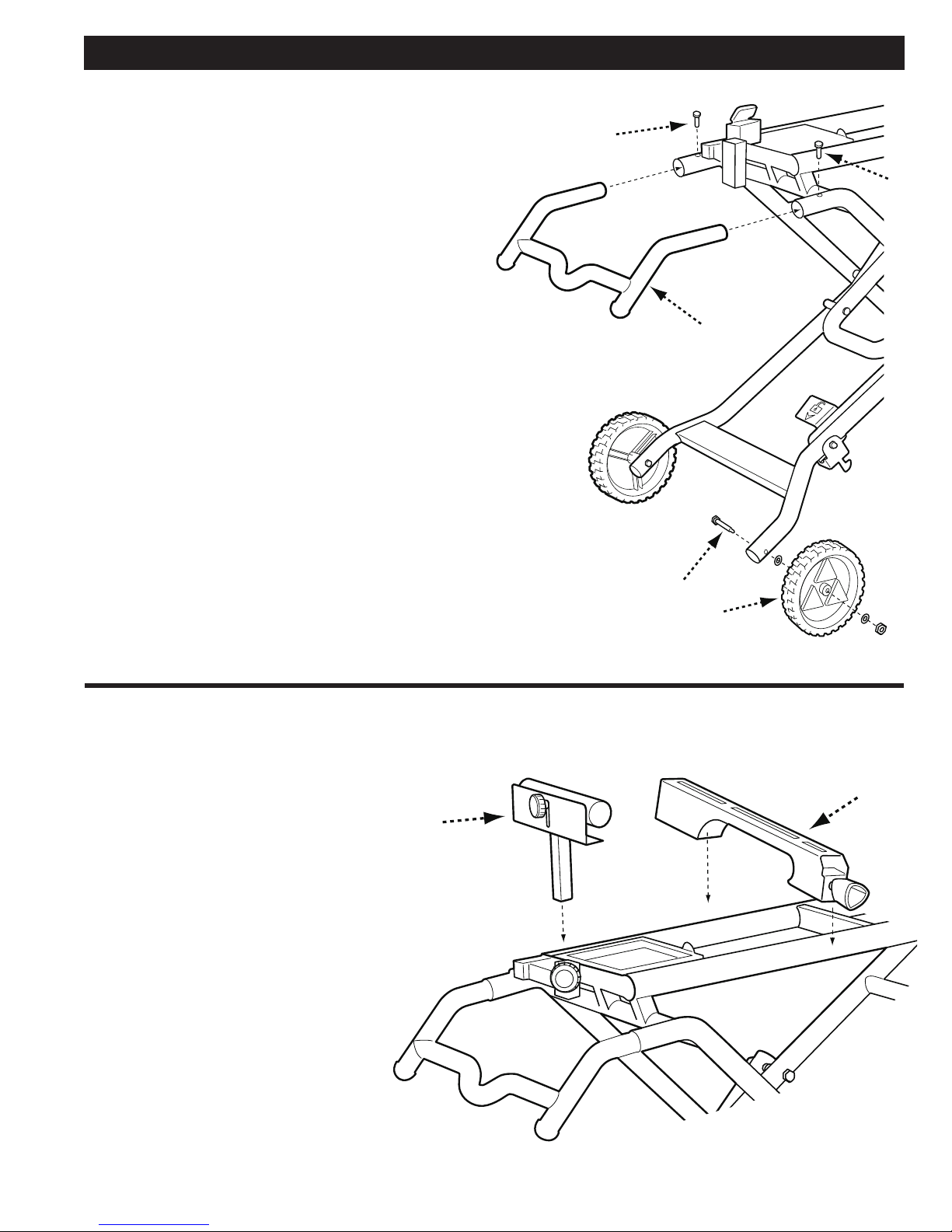

ASSEMBLY

FRONT HANDLE AND WHEELS

1. Attach handle (A) by inserting the tubes into the

top of the front folding supports. The handle

should be angled down.

2. Align holes and secure using two M8 x 20mm

self-tapping screws (B) and Phillips head

screwdriver.

3. Place a M13 (ID) x 28mm (OD) washer on each of

the fixed axles (C).

4. Slide the wheels (D) onto the axle with the wheel

collar facing in. Place a M8.2 (ID) x 25mm (OD)

washer onto the end of each axle.

5. Secure with an M8 lock nut. Rotate the nut

clockwise to tighten. Do not over-tighten.

B

B

A

C

D

MOUNTING BRACKETS AND WORKPIECE SUPPORTS

1. Place the mounting brackets (A) onto

the front and rear rails by engaging

the front end of the bracket on the

rail first, then lowering the rear end

over the rail.

2. Insert the workpiece supports (B)

as shown with the clamping knobs

facing out.

B

A

7

Page 8

ASSEMBLY

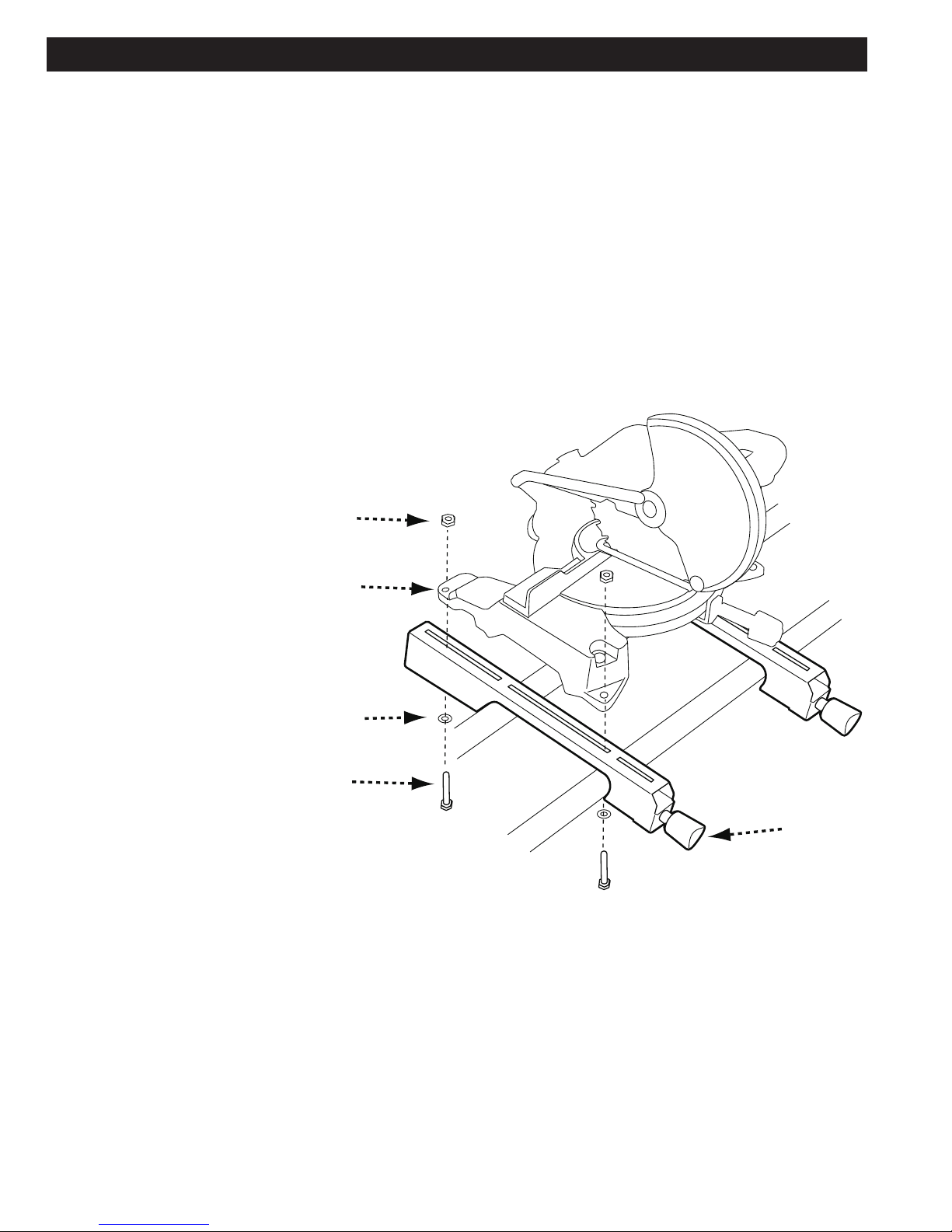

ATTACHING THE MITER SAW TO THE STAND

NOTE: This stand comes with four M8 x 55mm bolts

with M8 washers and hex nuts. If your saw requires a

different number or size of mounting bolt, use hardware

that will properly secure your saw. Make sure bolt ends

do not extend above the saw table.

NOTE: The DELTA 36-267 miter saw stand is designed

to work with virtually all miter saws. In the event that

the mounting holes on the saw do not line up with the

slots in the mounting brackets, skip to the next section,

“Using a Mounting Platform”

1. Ensure the saw is disconnected from the power

source and the blade and arm are locked in the

down position.

2. With both mounting brackets attached to the rails,

lock one of the mounting brackets in position by

turning the lock knob (A) clockwise.

3. Place the saw on top of the mounting brackets so

that the mounting holes in the saw (B) align with the

slots in the stationary bracket.

NOTE: The exact location of the mounting holes may

vary from saw to saw. Figure 6 is given as an example.

4. Feed an M8 x 55mm hex bolt (C) fitted with an M8

washer (D) up through the slots in the bracket and

through the mounting holes in the saw. Secure

with an M8 hex nut (E).

5. Adjust the other bracket under the saw so that

the brackets slots align with the saw’s mounting

holes. Lock bracket in place by turning lock knob

clockwise.

6. Repeat Step 4 to secure saw to second mounting

bracket.

E

B

D

C

USING A MOUNTING PLATFORM

Should the existing mounting holes in your saw not fit

the slots in the mounting brackets, it will be necessary

to mount a wooden platform to the brackets then mount

the saw to the platform.

The platform can be made from any rectangular or

square piece of wood scrap that is at least ½-inch thick

and large enough to extend beyond the saw’s base by at

least an inch.

1. Unlock and remove mounting brackets from the rails.

Place them upside down on the top of board so that

they are centered top to bottom and aligned with the

edge of the board.

2. Use a pencil to mark the midpoint in the top and

bottom slots on each bracket.

A

3. Remove the brackets and drill a ¼-inch hole at each

mark.

4. Place the saw on the platform so that it is centered

on the board. Mark the mounting holes with a pencil.

5. Remove the saw and use a 5/16 - inch drill bit to drill

the holes in the platform.

6. Mount the saw to the board using bolts, washers and

nuts (not provided).

7. Follow Steps 4-6 in above section (Attaching the

Miter Saw to the Stand) to secure the platform to the

brackets.

8

Page 9

ADJUSTMENTS

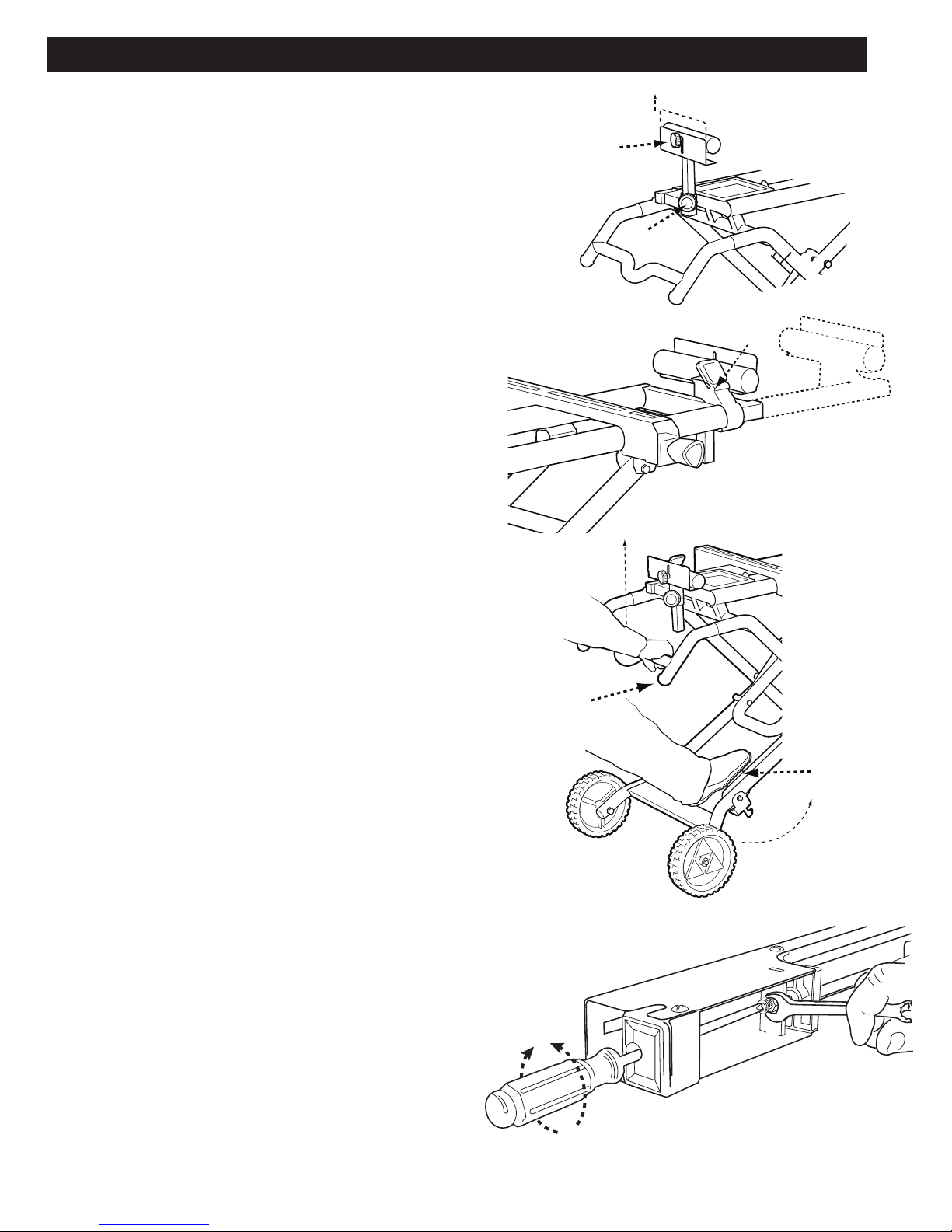

WORKPIECE SUPPORTS AND

STOP PLATES

The workpiece supports hold the workpiece level with the stop

plates, preventing it from moving side to side. To raise or lower the

1.

Loosen the support lock knob (A).

2.

Position the supports so they are level and at the

desired height and re-tighten the lock knob.

To position the stop plate on the workpiece supports:

1.

Loosen the stop plate lock knob (B).

2.

Position the stop plate at the desired height and

re-tighten the lock knob.

RAIL EXTENSIONS

The DELTA 36-267 Miter Saw Stand features left and right rail

extensions to accomodate longer work pieces. To extend the right or

left extensions:

1.

Depress the rail lock (A) and pull the rail out to

the desired length.

2.

Release the lock.

B

A

A

COLLAPSING THE STAND FOR

TRANSPORT

The stand folds down for easy transport and can be collapsed

and moved with the saw mounted. To fold the stand for

transport:

1.

Ensure the saw is unplugged and cord wrapped and the

mounting brackets are secured on the rails and locked down.

2.

Grasping the handle (A) from underneath, depress the foo

pedal lock (B) and slowly lift up on the handle.

3.

Continue to raise the handle, guiding the stand forward and

up, until the support legs click into place.

4.

You can now lower the folded stand to a comfortable position

for transport.

5.

To redeploy the stand and saw, grasp the handle, depress

the foot pedal and slowly guide the handle end of the stand

down and back until you hear the support legs click into

place. Make sure the lock has clicked into place before using

it for any cutting operation.

MOUNTING BRACKET CLAMPING

PRESSURE

t

A

B

Adjust mounting bracket pressure as shown.

9

Page 10

PARTS, SERVICE OR WARRANTY ASSISTANCE

All DELTA® machines and accessories are manufactured to high quality standards and are serviced by a network

of Authorized Service Centers. To obtain additional information regarding your DELTA® quality product or to obtain

parts, service, warranty assistance, or the location of the nearest service center, please call 1-800-223-7278.

Two Year Limited New Accessories Warranty

DELTA will repair or replace, at its expense and at its option, any machine accessory which in normal use

has proven to be defective in workmanship or material, provided that the customer returns the product

prepaid to a DELTA factory service center or authorized service station with proof of purchase of the

product within two years and provides DELTA with reasonable opportunity to verify the alleged defect by

inspection. For all refurbished DELTA product, the warranty period is 180 days. DELTA may require that

electric motors be returned prepaid to a motor manufacturer’s authorized station for inspection and repair

or replacement. DELTA will not be responsible for any asserted defect which has resulted from normal wear,

misuse, abuse or repair or alteration made or specifically authorized by anyone other than an authorized

DELTA service facility or representative. Under no circumstances will DELTA be liable for incidental or

consequential damages resulting from defective products. This warranty is DELTA ’s sole warranty and sets

forth the customer’s exclusive remedy, with respect to defective products; all other warranties, express or

implied, whether of merchantability, fitness for purpose, or otherwise, are expressly disclaimed by DELTA.

For further detail of warranty coverage and warranty repair information, visit www.DeltaMachinery.com or

call 1-800-223-7278. This warranty gives you specific legal rights and you may have other rights which vary

in certain states or provinces.

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at www.DeltaMachinery.com/service. You

can also order parts from your nearest Authorized Warranty Service Center or by calling Technical Service Manager at 1-800-2237278 to receive personalized support from one of our highly-trained representatives.

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call

1-800-223-7278

for a free replacement.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about DELTA®

Power Equipment Corporation, its factory-owned branches, or to locate an Authorized Warranty Service Center,

visit our website at www.DeltaMachinery.com/service or call Customer Care at 1-800-223-7278. All repairs

made by our service centers are fully guaranteed against defective material and workmanship. We cannot

guarantee repairs made or attempted by others. By calling this number you can also find answers to most

frequently asked questions 24 hours/day.

You can also write to us for information at DELTA® Power Equipment Corporation, 99 Roush St., Anderson, SC

29625-3113 - Attention: Technical Service Manager.

10

Page 11

SOMMAIRE

:

:

MISE EN GARDE:

MISE EN GARDE:

SPECIFICATIONS DU PRODUIT ............................................ 11

INSTRUCTIONS DE SECURITE IMPORTANTES ..................11

DEBALLAGE ............................................................................13

Contenu des cartons ......................................................... 14

Accessoires de montage .................................................. 14

ASSEMBLAGE ...................

Boulon de pivot ................................................................ 15

Stabilisateur vertical et pieds en caoutchouc ................... 15

Poignées avant et roues .................................................... 16

Fixations de montage et supports de pièces de travail .... 16

Fixer la scie à onglet sur l'établi .............................

Utiliser une plateforme de montage .................................. 17

......................................................15

........... 17

SPECIFICATIONS DU PRODUIT

DESCRIPTION SPECIFICATION

Hauteur (avec les

Dimensions (plié pour le transport) 54.3”X 25.4” X 23.67” (1380mm X 645mm X 601mm)

Dimensions (déplié pour l'utilisation) 57.83” X 25.4” X 36.1” (1469mm X 645mm X 916mm)

ns de montage) 36.06" (916mm)

REGLAGES ..............................................................................18

Supports et plaques de butée des pièces de travail ............... 18

Rallonges de rail ....................................................................... 18

Plier l'établi pour le transporter

Pression de support de montage

ASSISTANCE PIECES DETACHEES, SERVICE APRES-

VENTE OU GARANTIE ............................................................20

GARANTIE LIMITEE DE TROIS ANS .....................................20

PIECES DE RECHANGE .........................................................20

SERVICE APRES-VENTE ET REPARATION ..........................20

................................................. 19

...

.................................... 19

Largeur totale quand totalement déplié (114") (2896mm)

INSTRUCTIONS DE SECURITE IMPORTANTES

AVERTISSEMENT

UTILISATEURS LES CONNAISSENT LORS DE L'UTILISATION DE CE PRODUIT. Une utilisation, un entretien ou une

modification impropre des outils ou équipements pourrait entraîner de graves blessures ou des dommages

matériels.

LIRE TOUS LES AVERTISSEMENTS ET INSTRUCTIONS D'UTILISATION PRESENTS

SUR VOTRE PRODUIT ET DANS CE MANUEL. S'ASSURER QUE TOUS LES

SYMBOLES DE SECURITE – DEFINITIONS

Ce manuel contient des informations importantes que vous devriez bien assimiler. Ces informations portent

sur VOTRE SECURITE et LA PREVENTION DES PROBLEMES D’EQUIPEMENT. Pour vous aider à identifier ces

informations, nous utilisons les symboles ci-dessous. Veuillez lire attentivement ce manuel en portant une attention

particulière à ces sections.

Indique une situation dangereuse imminente qui, si elle n’est pas évitée, causera la mort ou des

blessures graves.

AVERTISSEMENT

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait causer la mort

ou des blessures graves.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait causer des

blessures mineures ou modérées.

utilisé sans le triangle de sécurité, indique une situation potentiellement dangereuse qui, si elle n'est

pas évitée, pourrait causer des dommages matériels.

11

Page 12

REGLES GENERALES DE SECURITE

AVERTISSEMENT:

LE NON RESPECT DE CES REGLES PEUT CAUSER DES BLESSURES SERIEUSES.

POUR SA SECURITE PERSONNELLE, LIRE LE MANUEL D’UTILISATION AVANT D'UTILISER L'ETABLI. GARDER

•

L'AIRE DE TRAVAIL PROPRE ET BIEN ECLAIREE. Des zones, surfaces ou bancs de travail encombrés et mal

éclairés favorisent les accidents. Débarrasser l'établi lors de l'utilisation de la machine. Conserver suffisamment

d'espace libre lors de l'utilisation de la machine et supporter de manière appropriée les pièces de travail.

GARDER LES ENFANTS ET LES VISITEURS A DISTANCE de l'aire de travail.

•

PORTER UNE TENUE APPROPRIEE. PAS DE cravates, gants, vêtements amples, bagues, bracelets ni autres

•

bijoux qui peuvent être pris dans les pièces mobiles. L'usage de chaussures antidérapantes est recommandé.

Placer les cheveux longs sous une protection.

PROTECTIONS OCULAIRES. Toutes les personnes situées dans la zone de travail doivent porter des lunettes

•

de sécurité pourvues de protections latérales. Les lunettes ordinaires NE sont PAS des lunettes de sécurité. Les

dispositifs de protection oculaires doivent être conformes aux normes ANSI Z87.1 ou CAN/CSA Z94.3.

PROTECTIONS AUDITIVES. Toutes les personnes situées dans la zone de travail doivent porter des protections

•

auditives appropriées au niveau du bruit et à l'exposition à celui-ci. Les protection auditives doivent être

conformes aux normes ANSI S3.19.

PROTECTION CONTRE LA POUSSIERE. L'utilisation d'outils électriques peut produire et/ou disperser de la

•

poussière ce qui peut entraîner des troubles respiratoires. Diriger les particules loin du visage et du corps.

Toujours utiliser l'outil dans un espace bien ventilé et prévoir l'évacuation de la poussière. Utiliser un système

de dépoussiérage si possible. L'exposition à la poussière peut causer des problèmes de santé graves et

permanents, respiratoires ou autres, tels que la silicose (maladie pulmonaire grave) et le cancer, et même la mort

de la personne affectée. Éviter de respirer de la poussière et de laisser la peau en contact prolongé avec celleci. En laissant la poussière pénétrer dans les yeux ou la bouche, ou en la laissant reposer sur la peau, il existe

un risque de promouvoir l'absorption de substances toxiques. Toujours porter des dispositifs de protection

respiratoire de taille appropriée homologués NIOSH/OSHA, conçus pour l'exposition à la poussière et laver à

l'eau et au savon les surfaces corporelles exposées.

CE PRODUIT A ETE CONCU POUR ETRE TOUT D'ABORD UTILISE COMME ETABLI POUR UNE SCIE A ONGLET.

•

IL PEUT ETRE UTILISE AVEC DES RABOTS PORTATIFS. NE PAS modifier l'établi, l'utiliser avec d'autres produits,

ou pour d'autres buts. L'établi peut supporter jusqu'à 400 livres, y compris la machine et la pièce de travail. Tout

excès ou mauvaise utilisation peut endommager le produit ou blesser.

FAIRE ATTENTION LORS DU MONTAGE, DEPLACEMENT, ELEVATION OU ABAISSEMENT DE L'ETABLI pour

•

éviter de vous pincer les mains et les doigts.

PLACER L'ETABLI SUR UNE SURFACE PLANE ET D'APLOMB pour l'empêcher de vaciller ou de basculer. Ne

•

pas utiliser l'établi sur une surface glissante, non plane ou pas d'aplomb. Toujours vérifier la stabilité de l'établi

avant de brancher la machine à l'alimentation électrique.

NE PAS SE TENIR DEBOUT SUR CE PRODUIT ou utiliser les rallonges de support comme échelle ou

•

échafaudage. Il est dangereux de monter, s'asseoir ou se tenir debout sur produit.

INSPECTER LE PRODUIT POUR DECELER TOUT DOMMAGE. Avant d'utiliser l'établi et après son éventuel chute

•

ou endommagement, vérifier les éléments mobiles et ceux endommagés de l'établi et toute machine en contact

POUR VERIFIER LES ALIGNEMENTS, ATTACHES, BRIS OU TOUTE AUTRE CONDITION PREJUDICIABLE

POUVANT AFFECTER LES PERFORMANCES DE LA MACHINE ET LA CAPACITE DE L'ETABLI A SUPPORTER

DE FACON SURE LA MACHINE. NE PAS UTILISER UN PRODUIT ENDOMMAGE. TOUT PRODUIT ENDOMMAGE

DOIT ETRE REPARE EN N'UTILISANT QUE DES PIECES DE RECHANGE IDENTIQUES.

VERIFIER QUE LES FIXATIONS SONT BIEN EN PLACE AVANT DE BRANCHER LA MACHINE.

•

DEBRANCHER LA MACHINE AVANT DE LA FIXER SUR SON ETABLI OU SI ELLE N'EST PAS UTILISEE.

•

INSTALLER LA MACHINE ET REGLER LES SUPPORT DE PIECES DE TRAVAIL DE MANIERE APPROPRIEE DE

•

SORTE QUE LES PIECES DE TRAVAIL SOIENT D'APLOMB AVEC L'ETABLI DE MACHINE.

BIEN FIXER LA MACHINE SUR L'ETABLI AVANT DE LA BRANCHER SUR L'ALIMENTATION ELECTRIQUE.

•

NE PAS ESSAYER D'UTILISER L'ETABLI AVEC DES PIECES DE TRAVAIL INHABITUELLES OU DE TROP

•

GRANDE TAILLE POUVANT ENTRAINER LE BASCULEMENT DE L'ETABLI.

LORS DU TRANSPORT DE L'ETABLI, S'ASSURER QU'IL EST BIEN ATTACHE POUR EVITER TOUT

•

DEPLOIEMENT ET POSSIBLE DOMMAGE.

CONSERVER CES INSTRUCTIONS.

Les consulter souvent et les partager avec les autres utilisateurs.

Joindre ces instructions à l'établi en cas de prêt de celui-ci.

12

Page 13

PROPOSITION 65 DE LA CALIFORNIE

:

AVERTISSEMENT

reproductrices. Voici quelques exemples de ces produits chimiques:

– Le plomb contenu dans les peintures à base de plomb

– La silice cristalline de la brique, du ciment et d'autres produits de maçonnerie

– La poussière d'amiante

– L'arséniate de cuivre et de chrome provenant du bois traité chimiquement (CCA)

• Les risques reliés à l'exposition à ces poussières varient selon la fréquence à laquelle l'utilisateur travaille avec

ce type de matériaux. Pour réduire l'exposition à ces produits chimiques, travailler dans un endroit bien ventilé et

porter un équipement de sécurité approuvé comme un masque anti poussières conçu spécialement pour filtrer les

particules microscopiques.

• Éviter tout contact prolongé avec les poussières produites par des activités de ponçage, sciage, meulage, perçage

et autres activités de construction. Porter des vêtements de protection et laver à l'eau et au savon les surfaces

corporelles exposées.

Pour toute question relative à l'utilisation de cet outil ou au contenu de ce manuel, veuillez tout d'abord arrêter

d'utiliser l'outil et appeler le Service Clientèle de DELTA® Power Equipment Corporation au 1-800-223-7278.

Certaines poussières produites par les activités de ponçage, sciage, meulage, perçage et

autres activités de construction contiennent des produits chimiques connus de l'État de Californie

pour causer le cancer, des anomalies congénitales ou d'autres problèmes liés aux fonctions

DEBALLAGE

1. Retirer tous le contenu des cartons de transport.

2. Mettre de côté les cartons d'emballage. Placer l'établi sur le sol et étaler sur le sol tous les accessoires de

montage et les pièces détachées.

3. En s'aidant du dessin ci-dessous, localiser, identifier et s'assurer de la présence de tous les accessoires de

montage et les pièces détachées avant de jeter les emballages ou de commencer l'assemblage.

NOTE: Si un élément manque ou est endommagé, NE PAS essayer d'assembler le produit et appeler le Service

Clientèle de DELTA® Power Equipment Corporation au 1-800-223-7278.

13

Page 14

DESCRIPTION DU CONTENU DES

CARTONS (QTE)

1. Établi pour scie à onglet (1)

2. Poignée (1)

3. Fixations de montage (2)

4. Supports de pièce de travail avec plaque de

butée (2)

5. Stabilisateur vertical (1)

6. Roues (2)

7. Pieds en caoutchouc (2 petits et 2 grands)

8. Boutons (2)

DESCRIPTION DE LA VISSERIE

D'ASSEMBLAGE

DEBALLAGE

1

3

2

4

• Écrou de blocage

hexagonal M6 (2)

• Écrou de blocage M8 (2)

• Écrou de blocage M10 (2)

• Écrou de blocage

hexagonal M12 (2)

• Vis à tête cylindrique

fendue M6 x 50mm (2)

• Vis auto taraudeuse M8 x

20mm (2)

• Vis hexagonale M10 x

55mm (2)

• Vis à tête hexagonale M12

x 110mm (2)

• Rondelle plate M8 (ID)

x 25mm (OD) x 3mm

(épaisseur) (2)

• M12 (ID) x 20mm (OD) x

2mm (Rondelle plate M12

(ID) x 20mm (OD) x 2mm

(épaisseur) (2)

• Rondelle plate M13 (ID)

x 28mm (OD) x 2,8mm

(épaisseur) (2)

• Vis à épaulement

hexagonale M8*93L axe de

roue (2)

• boulon hexagonal M8 x

55mm (4)

• rondelle M8 (4)

• écrou hexagonal M8 (4)

NOTE: Tous ces éléments

utilisent des filetages à droite.

5

6

7 8

14

Page 15

ASSEMBLAGE

Outils (non inclus) nécessaires pour

l'assemblage : un tournevis Phillips, un jeu de

douille, et une clé réglable.

C

BOULON DE PIVOT

1. Coucher l'établi sur son côté.

2. Tirer le support pliable arrière (A) vers les

ouvertures des tubes de la poignée (B) de

façon à aligner les trous du support pliable

arrière et du support pliable avant.

3. Insérer un boulon hexagonal M12 x 110 (C)

au travers du pied pliable avant. Placer une

rondelle M12 (D) entre les supports avant et

arrière et engager le boulon au travers de la

rondelle et du support arrière.

4. Fixer avec un écrou hexagonal M12. Le serrer

mais pas trop.

5. Placer l'établi debout. Les trous du support du

côté opposé devraient être presque alignés.

Répéter les étapes 3 et 4 pour fixer l'autre

côté.

D

Aligner les trous

A

B

STABILISATEUR VERTICAL ET

PIEDS EN CAOUTCHOUC

1. Coucher l'établi sur son côté.

2. Insérer le stabilisateur vertical (A) dans les

extrémités des supports pliables arrières (B)

avec les extrémités du stabilisateur formant

un angle vers le haut. Aligner les trous du

stabilisateur et des supports.

3. Attacher les pieds en caoutchouc les plus

grands (C) à la base du stabilisateur vertical

en faisant passer un boulon hexagonal M10 x

55mm au travers de la base du pied. Fixer avec

un écrou hexagonal M10, en se rappelant de le

tourner dans le sens horaire pour le serrer.

4. Attacher les pieds en caoutchouc les plus petits

(D) à l'extrémité du stabilisateur vertical à l'aide

de deux vis à tête cylindrique fendue M6 x 50mm

et écrous de blocage M6.

A

D

C

B

15

Page 16

ASSEMBLAGE

POIGNEE AVANT ET ROUES

1. Attacher la poignée (A) en insérant les tubes

dans le sommet des supports pliables avant. La

poignée devrait former un angle vers le bas.

2. Aligner les trous et fixer à l'aide de deux vis auto

taraudeuse M8 x 20mm (B) et d'un tournevis à

tête Phillips.

3. Placer une rondelle M13 (ID) x 28mm (OD) sur

chaque axe fixe (C).

4. Faire glisser les roues (D) sur les axes avec

l'intérieur des roues se faisant face. Placer une

rondelle M8,2 (ID) x 25mm (OD) sur l'extrémité de

chaque axe.

5. Fixer avec un écrou de blocage M8. Tourner

l'écrou dans le sens horaire pour le serrer. Ne pas

trop le serrer.

B

B

A

C

D

SUPPORTS DE MONTAGE ET SUPPORTS DE PIECE DE TRAVAIL

1. Placer les fixations de montage

(A) sur les rails avant et arrière en

engageant d'abord l'extrémité

avant du support sur le rail, puis en

abaissant l'extrémité arrière sur le

rail.

2. Insérer les supports de pièce de

travail (B) tel illustré avant les

boutons de serrage vers l'extérieur.

B

A

16

Page 17

ASSEMBLAGE

FIXER LA SCIE À ONGLET SUR L'ÉTABLI

NOTE: Cet établi est livré avec quatre boulons M8 x

55mm, des rondelles M8 et des écrous hexagonaux. Si

votre scie nécessite un nombre différent de boulons de

montage, utilisez du matériel qui fixera la scie de façon

appropriée. S'assurer que les extrémités des boulons ne

dépassent pas de l'établi de scie.

NOTE: L'établi pour scie à onglet DELTA 36-267 est

conçu pour recevoir théoriquement toutes scies

à onglet. Dans le cas où les trous de montage ne

s'alignent pas sur les rainures des fixations de montage,

passer à la section suivante, 'Utiliser une plateforme de

montage'

1. S'assurer que la scie est débranchée de

l'alimentation électrique et que la lame et le bras

sont verrouillés en position basse.

2. Avec les deux fixations de montage attachés aux

rails, verrouiller l'une des fixations de montage en

position en tournant le bouton de verrouillage (A)

dans le sens horaire.

3. Placer la scie sur les fixations de montage de sorte

que les trous de montage (B) s'alignent avec les

rainures de la fixation fixe.

NOTE : L'emplacement des trous de montage peut

varier en fonction de la scie. La Figure 6 est un

exemple.

4. Engager vers le haut un boulon hexagonal M8 x

55mm (C) muni d'une rondelle M8 (D) au travers

des rainures dans la fixation et du trou de montage

dans la scie. Fixer avec un écrou hexagonal M8

(E).

5. Ajuster l'autre fixation sous la scie de sorte que les

rainures des fixations s'alignent sur les trous de

montage de la scie.

Verrouiller la fixation en position en tournant le bouton

de verrouillage dans le sens horaire.

6. Répéter l'étape 4 pour fixer la scie à la seconde

fixation de montage.

E

B

D

C

UTILISER UNE PLATEFORME DE MONTAGE

Si les trous de montage existants de votre scie

ne correspondent pas aux rainures des fixations

de montage, il sera alors nécessaire de monter une

plateforme en bois sur les fixations et de monter votre

scie sur la plateforme.

La plateforme peut être réalisée à partir de n'importe

quel morceau de rebut de bois rectangulaire ou

carré d'une épaisseur minimale de ½'' (13mm) et

suffisamment large pour s'étendre au-delà de la base de

la scie d'au moins un pouce (26mm)..

1. Déverrouiller et retirer les fixations de montage

des rails. Les placer sens dessus dessous sur le

sommet de la planche de sorte qu'ils soient centrés

du sommet à la base et alignés sur le bord de la

planche.

A

17

Page 18

ASSEMBLAGE

2. Marquer le milieu dans les rainures du sommet et de

la base de chaque fixation à l'aide d'un crayon.

3. Retirer les fixations et percer un trou de ¼'' sur

chaque marque.

4. Placer la scie sur la plateforme de sorte qu'elle

soit centrée sur la planche. Marquer les trous de

montage à l'aide d'un crayon.

REGLAGES

SUPPORTS ET PLAQUES DE

BUTÉE DES PIÈCES DE TRAVAIL

Les supports de pièces de travail maintiennent le

niveau de la pièce de travail à l'aide des plaques de

butées en l'empêchant de bouger. Pour monter ou

abaisser les supports:

1. Desserrer le bouton de verrouillage du support (A).

2. Placer les supports de sorte qu'ils soient de niveau

et à la hauteur désirée, puis resserrer le bouton de

verrouillage.

Pour placer la plaque de butée sur les supports de

pièce de travail:

1. Desserrer le bouton de verrouillage de la plaque de

butée (B).

2. Placer la plaque de butée à la hauteur désirée, puis

resserrer le bouton de verrouillag.

5. Retirer la scie et percer les trous dans la plateforme à

l'aide d'une mèche de 5/16''.

6. Fixer la scie sur la planche à l'aide de boulons,

rondelles et écrous (non inclus).

7. Suivre les étapes 4-6 de la section précédente (Fixer

la scie à onglet sur l'établi) pour fixer la plateforme

aux fixations.

B

A

RALLONGES DE RAIL

L'établi pour scie à onglet DELTA 36-267 comprend

des rallonges gauche et droite de rail pour permettre

le travail de pièces plus longues. Pour étendre les

rallonges gauche et droite:

1. Depress the rail lock (A) and pull the rail out to the

Appuyer sur le dispositif de verrouillage du rail (A) et

tirer le rail jusqu'à la longueur désirée.

2. Relâcher le dispositif de verrouillage.

A

18

Page 19

REGLAGES

PLIER L'ÉTABLI POUR LE

TRANSPORTER

L'établ i se repli e pour être tra nsporté f acileme nt e t ce

éventuellement avec la scie installée dessus. Pour plier l'établi pour

le transporter:

1. S'assurer que la scie est débranchée et le fil électrique enroulé,

et que les fixations de montage sont fixées sur les rails et

verrouillées.

2. Saisir la poignée (A) par en dessous et appuyer sur le dispositif

de verrouillage de la pédale (B), puis élever doucement la

poignée.

3. Continuer à élever la poignée en guidant l'établi vers l'avant et le

haut jusqu'à ce que les pieds de support s'enclenchent.

4. Vous pouvez maintenant abaisser l'établi plié jusqu'à une

position confortable pour le transport.

5. Pour déplier l'établi et la scie, saisir la poignée, appuyer

pédale à pied et guider doucement l'extrémité de la poignée

de l'établi vers le bas et l'arrière jusqu'à entendre les pieds de

support s'enclencher. S'assurer que le dispositif de verrouillage

soit enclenché avant d'utiliser l'établi avec la scie.

sur la

A

B

PRESSION DE SUPPORT DE MONTAGE

Ajustez la pres sion de su pport de m ontage comm e indiq ué .

19

Page 20

ASSISTANCE PIECES DETACHEES, SERVICE APRES-VENTE OU GARANTIE

Tous les accessoires et machines DELTA® sont fabriqués en respectant de hauts standards de qualité et le service

après-vente est effectué par un réseau de Centres SAV Agréés. Pour obtenir des informations supplémentaires sur

vos produits DELTA® ou obtenir des pièces, bénéficier du SAV ou de la garantie, ou connaître le centre SAV le plus

proche, appeler le 1-800-223-7278.

Garantie Nouveau Accessoires Limitée à Deux Ans

Delta réparera ou remplacera, à ses frais et à sa discrétion, tout accessoire de machine qui, dans des

circonstances d'utilisation normale, s'est avéré défectueux en raison de défauts de matériau ou de

fabrication, à condition que le client retourne le produit (transport payé d'avance) à un centre de réparation

d'usine DELTA ou à un centre de réparation agréé accompagné d'une preuve d'achat et dans les deux

ans de la date d'achat du produit, et fournisse à DELTA une opportunité raisonnable de vérifier le défaut

présumé par une inspection. La période de garantie des produits DELTA remis à neuf est de 180 jours.

DELTA peut demander que les moteurs électriques soient retournés (transport payé d'avance) a un

centre de réparation agréé du fabricant du moteur en vue d'une inspection, d'une réparation ou d'un

remplacement. DELTA ne peut être tenu pour responsable des défauts résultants d'une usure normale,

d'une mauvaise utilisation, d'un abus, d'une réparation ou d'une modification du produit, sauf en cas

d'autorisation spécifique d'un centre de réparation ou d'un représentant DELTA agréé. DELTA ne peut être

en aucune circonstance tenu pour responsable des dommages accidentels ou indirects résultant d'un

produit défectueux. Cette garantie constitue la seule garantie de DELTA et le recours exclusif des clients en

ce qui concerne les produits défectueux ; toutes les autres garanties, expresses ou implicites, de qualité

marchande, d'adéquation a un usage particulier, ou autre, sont expressément déclinées par DELTA. Pour

obtenir de plus amples renseignements sur les pièces ou les réparations couvertes par la présente garantie,

visiter le site www.DeltaMachinery.com ou appeler le 1-800-223-7278. Cette garantie confère des droits

légaux particuliers à l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un état ou

d’une province à l’autre.

PIECES DE RECHANGE

Utiliser seulement des pièces de rechange identiques. Pour obtenir une liste des pièces de rechange ou pour en commander,

consulter notre site Web www.DeltaMachinery.com. Il est aussi possible de commander des pièces auprès d’un Centre de

Réparation sous Garantie Agréé ou en appelant le Directeur du Service Technique au 800-223-7278 pour recevoir un soutien

personnalise de l’un de nos représentants hautement qualifiés.

REMPLACEMENT GRATUIT D'ETIQUETTES D'AVERTISSEMENT

Si vos étiquettes d'avertissement deviennent illisibles ou sont manquantes, appelez le 1-800-223-7278 pour obtenir une

étiquette de remplacement gratuite.

SERVICE APRES-VENTE ET REPARATION

All quality tools will eventually require servicing and/or replacement of parts. For information about DELTA®

Tous les outils de qualité finissent par demander un entretien ou un changement de pièce. Pour de plus

amples renseignements sur nos Centres de Réparation sous Garantie Agréés, consulter notre site Web www.

DeltaMachinery.com ou appeler le Directeur du Service Technique au 800-223-7278. Toutes les réparations

effectuées dans nos centres de réparation sont entièrement garanties contre les défauts de matériaux et de

main-d'œuvre. Nous ne pouvons garantir les réparations effectuées en partie ou totalement par d’autres.

Pour de plus amples renseignements, écrire à Delta® Power Equipment Corporation, 99 Roush Street,

Anderson, SC 29625-3113, E.-U., à l'attention du Directeur du Service Technique/Technical Service Manager.

20

Page 21

TABLA DE CONTENIDO

ESPECIFICACIONES DEL PRODUCTO ................................21

INFORMACIÓN DE SEGURIDAD ..........................................21

DESEMBALAJE .......................................................................23

Contenido de la caja ......................................................... 24

Tornillería ........................................................................... 24

ENSAMBLAJE ..................

Perno de pivote ................................................................ 25

Estabilizador vertical y pies de goma ............................... 25

Asa frontal y ruedas .......................................................... 26

Montando las

Acoplando la sierra ingletadora a la base ......................... 27

Usando una plataforma de montaje ................................. 27

.......................................................25

s y soportes para piezas .............. 26

ESPECIFICACIONES DEL PRODUCTO

DESCRIPCIÓN ESPECIFICACIONES

Altura (con soportes de montaje) 36,06 pulg. (916mm)

Medidas (plegada para transporte) 54,3 x 25,4 x 23,67 pulg. (1380 x 645 x 601mm)

Medidas (extendida para usarse) 57,83 x 25,4 x 36,1 pulg. (1469 x 645 x 916mm)

AJUSTES ..................................................................................28

Soportes para piezas y placas de detención .......................... 28

Extensiones

Plegando la base para transporte

Presión de soporte de montaje

PIEZAS, REVISIÓN O ASISTENCIA EN GARANTÍA ............. 30

GARANTÍA LIMITADA DE TRES AÑOS ................................. 30

PIEZAS DE RECAMBIO ..........................................................30

REVISIÓN Y REPARACIÓN ................................

......................................................... 28

............................................ 29

............................................ 29

....................30

Anchura total al desplegarse totalmente (114 pulg.) (2896mm)

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

LEA ATENTAMENTE Y SIGA TODOS LOS AVISOS E INSTRUCCIONES EN SU

PRODUCTO Y EN ESTE MANUAL. GUARDE ESTE MANUAL. ASEGÚRESE QUE

TODOS LOS USUARIOS ESTÁN FAMILIARIZADOS CON SUS AVISOS E INSTRUCCIONES CUANDO USEN LA

HERRAMIENTA. El manejo, mantenimiento o modificación incorrectos de herramientas y equipos podría resultar en

heridas graves y/o daños a la propiedad.

DEFINICIONES – SÍMBOLOS DE SEGURIDAD

Este manual contiene información que es importante que usted comprenda y conozca. Esta información es referente

a la protección de SU SEGURIDAD y para PREVENIR PROBLEMAS CON EL EQUIPO. Para ayudarle a reconocer

esta información, utilizamos los símbolos indicados más adelante. Por favor, lea el manual y preste atención a estas

secciones.

Indica una situación de riesgo inminente que, de no evitarse, puede resultar en heridas graves o

incluso la muerte.

Indica una situación de riesgo potencial que, de no evitarse, podría resultar en heridas graves o

incluso la muerte.

Indica una situación de riesgo potencial que, de no evitarse, puede resultar en heridas leves o

moderadas.

Cuando se usa sin el símbolo de alerta de seguridad, indica una situación de peligro potencial que,

de no evitarse, podría resultar en daños materiales.

21

Page 22

NORMAS GENERALES DE SEGURIDAD

NO SEGUIR ESTAS NORMAS PUEDE RESULTAR EN HERIDAS PERSONALES GRAVES.

POR SU PROPIA SEGURIDAD, LEA EL MANUAL DE INSTRUCCIONES ANTES DE USAR LA BASE DEL

•

PRODUCTO. CONSERVE EL ÁREA DE TRABAJO LIMPIA Y BIEN ILUMINADA. Áreas y mesas abarrotadas o

mal iluminadas inducen a accidentes. No deje nada en la base cuando la máquina está en uso. Deje suficiente

espacio y proporcione suficiente apoyo para las piezas y para operar la máquina.

MANTENGA LEJOS del área de trabajo A NIÑOS Y A TERCEROS.

•

LLEVE INDUMENTARIA APROPIADA. NO use ropa suelta, guantes, corbatas, anillos, brazaletes u otra joyería

•

que pueda quedar atrapada por las partes móviles. Se recomienda utilizar calzado de protección antideslizante.

Lleve siempre una red de protección para recoger el pelo largo.

EPROTECCIÓN OCULAR. Todas las personas del área de trabajo deben llevar gafas de seguridad con

•

protección lateral. Las gafas de uso cotidiano NO son gafas de seguridad. El equipo de protección ocular debe

cumplir con los estándares ANSI Z87.1 o CAN/CSA Z94.3.

PROTECCIÓN AUDITIVA. Todo el personal del área de trabajo debe utilizar protección auditiva de acuerdo a los

•

niveles y exposición al ruido. El equipo auditivo debe cumplir con los estándares ANSI S3.19.

PROTECCIÓN CONTRA EL POLVO. El uso de herramientas eléctricas puede generar y desalojar polvo, que

•

puede producir daños respiratorios graves y permanentes. Dirija las partículas lejos de su cara y cuerpo. Opere

siempre las herramientas en una área bien ventilada y disponga de un sistema de eliminación de polvo. Utilice

un sistema extractor para reunir el polvo siempre que sea posible. La exposición al polvo puede causar heridas

o enfermedades respiratorias graves y permanentes, incluyendo silicosis (una enfermedad grave del sistema

respiratorio), cáncer, y la muerte. Evite respirar el polvo, y también el contacto prolongado con el mismo. El

contacto del polvo con su boca, ojos o piel puede favorecer la absorción de material nocivo. Utilice siempre

protección adecuada de la medida correcta que esté homologada por la NIOSH/OHSA contra la exposición al

polvo, y lave las áreas expuestas con agua y jabón.

ESTE PRODUCTO FUE DISEÑADO PARA USARSE PRINCIPALMENTE COMO BASE PARA SIERRAS

•

INGLETADORAS. PUEDE USARSE TAMBIÉN CON CEPILLADORAS PORTÁTILES. NO altere la base, ni la use con

otros productos o para otros propósitos. La base soporta 400 libras, incluyendo el peso de la máquina y la pieza

de trabajo. Cualquier mal uso o abuso puede dañar el producto o producir heridas personales.

UCUANDO MONTE, MUEVA, ELEVE O BAJE LA BASE PONGA ESPECIAL CUIDADO para evitar pellizcarse las

•

manos y dedos.

COLOQUE LA BASE EN UNA SUPERFICIE PLANA Y A NIVEL para evitar que se tumbe o balancee. No utilice la

•

base en una superficie irregular, inestable o resbaladiza. Compruebe siempre la estabilidad de la base antes de

connectar la máquina a la red eléctrica.

NO SE PONGA DE PIE EN ESTE PRODUCTO o utilice las extensiones de soporte como escalera o andamio.

•

Sentarse, ponerse de pie o subirse a este producto no es seguro.

COMPRUEBE LA INTEGRIDAD DEL PRODUCTO. Antes de usar la base, y después que haya sido dañada

•

o sufrido una caída, compruebe los componentes móviles y los afectados, y cualquier máquina acoplada:

ALINEAMIENTO, SUJECIÓN, ROTURAS Y CUALQUIER OTRA CONDICIÓN QUE PUEDA AFECTAR AL

DESEMPEÑO DE LA MÁQUINA Y LA CAPACIDAD DE LA BASE PARA DAR UN SOPORTE ADECUADO Y

ASEGURAR LA MÁQUINA. NO UTILICE UN PRODUCTO DAÑADO. UN PRODUCTO DAÑADO DEBE SER

REPARADO ADECUADAMENTE UTILIZANDO SÓLO PIEZAS DE RECAMBIO IDÉNTICAS A LAS ORIGINALES.

COMPRUEBE TODOS LOS SOPORTES PARA CONFIRMAR QUE ESTÁN FIJOS EN SU SITIO ANTES DE

•

CONECTAR LA MÁQUINA A LA RED ELÉCTRICA.

DESCONECTE LA MÁQUINA DE LA RED ELÉCTRICA ANTES DE ACOPLARLA A LA BASE, Y CUANDO LA

•

MÁQUINA NO ESTÉ EN USO.

MONTE LA MÁQUINA EN LA BASE DE LA FORMA CORRECTA Y AJUSTE LOS SOPORTES DE LAS PIEZAS DE

•

TRABAJO PARA QUE ÉSTAS ESTÉN A NIVEL CON LA MESA DE LA MÁQUINA.

ASEGURE CORRECTAMENTE LA MÁQUINA A LA BASE ANTES DE CONECTARLA A LA RED ELÉCTRICA.

•

NO INTENTE USAR LA BASE PARA TRABAJAR CON PIEZAS EXTRAÑAS O DEMASIADO GRANDES QUE

•

PUDIERAN HACER QUE LA BASE SE TUMBARA.

CUANDO TRANSPORTE LA BASE, ASEGÚRESE QUE ESTÁ FIJADA CORRECTAMENTE PARA EVITAR

•

MOVIMIENTOS Y POSIBLES DAÑOS.

GUARDE ESTAS INSTRUCCIONES.

Consúltelas a menudo y úselas para instruir a otros.

Si presta la base a alguien, préstele también estas instrucciones.

22

Page 23

AVISO RELATIVO AL PROYECTO DE LEY 65 :

El polvo producido por el lijado, corte, afilado, taladrado y otras actividades de la construcción

puede contener productos químicos que el estado de California ha determinado como carcinógenos

y capaces de producir defectos en el nacimiento y daño reproductivo. Algunos ejemplos:

– Plomo de pinturas basadas en plomo

– Sílice cristalina procedente de ladrillos, cemento y otros productos de masonería

– Polvo de amianto, y

– Arsénico y cromo procedente de madera tratada químicamente

• Su nivel de riesgo a estas exposiciones varía dependiendo de la frecuencia con la que usted realice este tipo

de trabajo. Para reducir su exposición a estos productos, trabaje en un área bien ventilada y utilice equipo de

protección regulado, como las mascarillas para polvo especialmente diseñadas para filtrar partículas microscópicas.

• Evite el contacto prolongado con polvo originado por el lijado, corte, afilado, taladrado y otras actividades de la

construcción. Lleve ropa de protección y lave las áreas expuestas con agua y jabón.

Si tiene cualquier duda o pregunta relativas al uso de su herramienta o los contenidos de este manual, no utilice la

herramienta y llame al Centro de Atención al Cliente de DELTA® Power Equipment Corporation al 1-800-223-7278.

DESEMBALAJE

1. Extraiga todo el contenido de la caja.

2. Separe el material de embalaje; coloque la base en el suelo y disponga ordenadamente todas las piezas sueltas y

tornillería.

3. Usando la ilustración que hay más abajo, localice e identifique todas las piezas y tornillería para comprobar que

no falte ninguna antes de tirar el material de embalaje o empezar a montar.

NOTA: si falta cualquier pieza o hay alguna dañada, NO intente montar el producto y llame al Centro de Atención al

Cliente de DELTA® Power Equipment Corporation al 1-800-223-7278.

23

Page 24

DESEMBALAJE

DESCRIPCIÓN DEL CONTENIDO (CANT.)

1. Base de sierra ingletadora (1)

2. Asa (1)

3. Fijaciones (2)

4. Soportes para piezas con placa de detención (2)

5. Estabilizador vertical (1)

6. Ruedas (2)

7. Pies de goma (2 grandes y 2 pequeños)

8. Pomos – grandes (2)

DESCRIPCIÓN DE LA TORNILLERÍA (CANT.)

uerca de seguridad M6 (2)

• T

• Tuerca de seguridad M8 (2)

• Tuerca de seguridad M10

(2)

• Tuerca de seguridad

hexagonal M12 (2)

• Tornillo de cabeza

redondeada con ranura

M6x50mm (2)

• Tornillo autorroscante

M8x20mm (2)

• Tornillo hexagonal

M10x55mm (2)

• Tornillo de cabeza

hexagonal M12x110mm (2)

• Arandela plana M8(int)

x25mm(ext)x3mm(grosor)

(2)

• Arandela plana M12(int)

x20mm(ext)x2mm(grosor)

(2)

• Arandela plana M13(int)

x28mm(ext)x2,8mm(grosor)

(2)

• Tornillos de eje para rueda

con reborde hexagonal M8

x 93L (2)

• perno hexagonal M8x55mm

(4)

• arandela M8 (4)

• tuerca hexagonal M8 (4)

NOTA: toda la tornillería usa

roscas a derechas.

1

3

5

7 8

2

4

6

24

Page 25

ENSAMBLAJE

Herramientas necesarias para el montaje (no

incluidas): Destornillador Phillips, llaves de

tubo, llave inglesa graduable.

C

PERNO DE PIVOTE

1. Ponga la base sobre su lateral.

2. Tire del soporte plegable trasero (A) hacia las

aberturas de los tubos para el asa (B) para

alinear los orificios de los soportes plegables

trasero y delantero.

3. Introduzca un perno hexagonal M12x110mm

(C) a través de la pata plegable frontal. Ponga

una arandela M12 (D) entre los soportes

delantero y trasero y pase el perno a través de

la arandela y soporte trasero.

4. Asegure con una tuerca hexagonal de M12. La

tuerca debe estar ajustada pero no demasiado

apretada.

5. Ponga la base en posición vertical. Los orificios

de los soportes del lado contrario deberían

estar casi alineados. Repita los pasos 3 y 4

para asegurar ese lado.

D

Alinee los

oricios

A

B

ESTABILIZADOR VERTICAL Y

PIES DE GOMA

1. Coloque la base sobre su lateral.

2. Inserte el estabilizador vertical (A) en los tubos

que hay al final del soporte plegable trasero

(B) con el ángulo del estabilizador hacia el lado

superior. Alinee los orificios del estabilizador y

soportes.

3. Monte los pies de goma grandes (C) al lado

inferior del estabilizador vertical colocando un

perno hexagonal M10x55mm a través de la

parte inferior del pie. Asegure con una tuerca

M10, recordando girarla en sentido horario para

apretar.

4. Monte las zapatas de goma más pequeñas (d) al

final del estabilizador vertical usando dos pernos

de cabeza redondeada M6x50mm y tuercas de

seguridad M6.

A

D

C

B

25

Page 26

ENSAMBLAJE

ASA DELANTERA Y RUEDAS

1. Monte el asa (A) insertando los tubos en la parte

superior del soporte plegable frontal. El ángulo

del asa debe ir hacia abajo.

2. Alinee los orificios y asegure usando dos tornillos

autorroscantes M8x20mm (B) y un destornillador

Phillips.

3. Coloque una arandela M13(int)x28mm(ext) en cada

uno de los ejes fijos (C).

4. Deslice las ruedas (D) en cada eje con el collar

de rueda hacia el interior. Coloque una arandela

M8,2(int)x25mm(ext) al final de cada eje.

5. Asegure con una tuerca de M8. Gire la tuerca

en sentido horario para apretar. No la apriete

demasiado.

B

B

A

FIJACIONES Y SOPORTES PARA PIEZAS

1. Coloque las fijaciones (A) en el perfil

frontal y posterior colocando primero

la parte delantera en el perfil, y luego

bajando la parte trasera sobre el

perfil.

2. Inserte los soportes para piezas (B) tal

y como se muestra, con los pomos

de sujeción hacia el exterior.

B

C

D

A

26

Page 27

ENSAMBLAJE

ACOPLANDO LA SIERRA INGLETADORA A LA BASE

NOTA: Esta base viene con cuatro pernos M8x55mm

con arandelas M8 y tuercas hexagonales. Si su sierra

requiriera un número o tamaño de perno diferentes,

utilice tornillería que le asegure un montaje adecuado.

Asegúrese que los extremos de los pernos no

sobresalgan por encima de la mesa de la sierra.

NOTA: La base para sierra ingletadora DELTA 36-267

está diseñada para poder funcionar con prácticamente

todas las sierras de ingletes. En caso que los orificios

de montaje en la sierra no se puedan alinear con los de

las fijaciones, pase a la siguiente sección, "usando una

plataforma de montaje".

1. Asegúrese que la sierra no está conectada a la red

eléctrica y que el disco de corte y brazo están fijos

en su posición inferior.

2. Con ambas fijaciones en los perfiles, fije una de ellas

en posición girando el pomo (A) en sentido horario.

3. Coloque la sierra encima de las fijaciones para que

los orificios de la sierra (B) coincidan con las

ranuras de la fijación estática.

NOTA: la localización exacta de los orificios de

montaje puede variar de sierra a sierra. La Figura 6

se da como ejemplo.

4. Introduzca un perno hexagonal M8x55mm (C) con

una arandela M8 (D) en sentido ascendente a

través de lasranuras de la fijación y a través de los

orificios de montaje de la sierra. Asegure con una

tuerca hexagonal M8 (E).

5. Ajuste la otra fijación bajo la sierra de forma que

sus ranuras se alineen con los orificios de montaje

de la sierra. Fíjela en su sitio girando el pomo en

sentido horario.

6. Repita el paso 4 para asegurar la sierra a la

segunda fijación.

E

B

D

C

USANDO UNA PLATAFORMA DE MONTAJE

En caso que los orificios de montaje de su sierra no

coincidiesen con las ranuras de las fijaciones, será

necesario montar una plataforma de madera en las

fijaciones y luego montar la sierra a esta plataforma.

Dicha plataforma puede hacerse de cualquier pieza de

madera rectangular o cuadrada que tenga al menos

1/2 pulgada de grosor y suficientemente grande para

abarcar toda la base de la sierra y dejar un margen de 1

pulgada alrededor de la misma.

1. Desbloquee y retire las fijaciones de los perfiles.

Colóquelas boca abajo en la parte superior del

tablero para que estén centradas verticalmente y

alineadas con los bordes del mismo.

2. Utilice un lápiz para marcar el punto medio en las

ranuras superior e inferior de cada fijación.

3. Retire las fijaciones y taladre un agujero de 1/4 de

pulgada en cada marca.

A

27

Page 28

ENSAMBLAJE

4. Coloque la sierra en la plataforma de manera que

esté centrada en el tablero. Marque los orificios de

montaje con un lápiz.

5. Retire la sierra y utilice una broca de 5/16 para

taladrar los agujeros en la plataforma.

AJUSTES

SOPORTE PARA PIEZAS Y

PLACAS DE DETENCIÓN

Los soportes para piezas mantienen la pieza en

la que usted trabaja a nivel con las placas de

detención, evitando que se mueva lateralmente.

Para subir o bajar los soportes:

1. Afloje el pomo de fijación (A).

2. Coloque los soportes de forma que estén al

mismo nivel y a la altura deseada y vuelva a

apretar los pomos de fijación.

Para colocar la placa de detención en los soportes

para piezas:

1. Afloje el pomo de fijación de la placa de

detención (B).

2. Coloque la placa de detención a la altura

deseada y vuelva a apretar el pomo.

6. monte la sierra al tablero usando pernos, arandelas y

tuercas (no incluidos).

7. Siga los pasos 4-6 de la sección superior (acoplando

la sierra ingletadora a la base) para asegurar la

plataforma a las fijaciones.

B

A

EXTENSIONES DE LOS

PERFILES

La base para sierra ingletadora DELTA 36-267 tiene

extensiones para los perfiles derecho e izquierdo que

permiten acomodar piezas de trabajo más largas. Para

prolongar las extensiones derecha o izquierda:

1. Presione la fijación de perfil (A) y tire del perfil hasta

alcanzar la longitud deseada.

2. Suelte la fijación.

A

28

Page 29

AJUSTES

PLEGANDO LA BASE PARA SU

TRANSPORTE

La base se pliega para un transporte más fácil y puede plegarse

y moverse aún con la sierra montada. Para plegar la base para su

transporte:

1. Ensure the saw is unplugged and cord wrapped and the

Asegúrese que la sierra está desenchufada, su cable enrollado,

las fijaciones aseguradas en los perfiles y fijas en su sitio.

2. Agarrando el asa (A) desde abajo, pise el pedal

levante lentamente el asa.

3. Continúe levantando el asa, guiando la base adelante y hacia

arriba, hasta que las patas de soporte se bloqueen en su sitio

haciendo "clic".

4. Ahora usted puede bajar la base ya plegada a una posición

cómoda para su transporte.

5. Para volver a plantar la base y la sierra, agarre el asa, pise

el pedal de bloqueo y guíe lentamente el extremo donde se

halla el asa hacia abajo y atrás ha

bloqueo de las patas de soporte. Asegúrese que el cierre está

efectivamente bloqueado antes de usar la sierra para cualquier

operación de corte.

sta que oiga el "clic" de

de bloqueo (B) y

A

B

PRESIÓN DE SOPORTE DE MONTAJE

Ajuste la presión de soporte de montaje como se muestra.

29

Page 30

PIEZAS, REVISIÓN O ASISTENCIA EN GARANTÍA

Todas las máquinas y accesorios DELTA® se fabrican con estándares de alta calidad y se revisan y reparan en

una red de Centros de Servicio Autorizados. Para obtener más información con respecto a si producto de calidad

DELTA® o para obtener recambios, mantenimiento, asistencia en garantía, o la localización del centro de servicio

más cercano, llame por favor al 1-800-223-7278.

Garantía limitada de dos años para nuevos accesorios

DELTA reparará o sustituirá, según considere necesario, cualquier accesorio que, sometido a un uso

normal, haya sido objeto de fallos de fabricación o materiales, siempre que el cliente devuelva el producto

ya pagado a un centro de cervicio de fábrica DELTA o centro de servicio autorizado junto con la prueba

de compra del producto dentro de un plazo de dos años, y que proporcione a DELTA la posibilidad de

realizar una inspección para comprobar los supuestos fallos. Para todos los productos restaurados DELTA,

el periodo de garantía es de 180 días. DELTA puede exigir que los motores eléctricos se devuelvan, ya

pagados, a un centro de servicio autorizado del fabricante del motor para su inspección, reparación o

reemplazo. DELTA no se hace responsable de cualquier defecto comprobado que resulte del desgaste

natural, mal uso, abuso, reparación o alteración hechas por cualquiera que no sea un Centro de Servicio

Autorizado o representante de DELTA. Bajo ninguna circunstancia se hará responsable a DELTA por

daños accidentales o resultantes debidos a productos defectuosos. Esta garantía es la única que

proporciona DELTA y establece el único recurso del cliente con respecto a productos defectuosos;

cualquier otra garantía, expresa o implícita, ya sea de comerciabilidad, adecuación de uso o cualquier

otra, son expresamente rechazadas por la Compañía, excepto en los casos mencionados anteriormente.

Para cualquier otro detalle sobre la cobertura de la garantía y para información sobre las reparaciones en

periodo de garantía, visite http://www.deltamachinery.com/ o llame al 1-800-223-7278. Esta garantía le da a

usted derechos legales específicos, usted puede tener otros derechos que varían en según qué estados o

provincias.

RECAMBIOS

Utilice sólo recambios idénticos a las piezas originales. Para una lista de piezas o para pedir piezas, visite nuestro sitio web

www.DeltaMachinery.com. También puede encargar las piezas a su Centro Autorizado de Servicio en Garantía o llamando al

Responsable de Servicio Técnico al 1-800-223-7278 para recibir soporte personalizado de uno de nuestros especialistas.

REEMPLAZO GRATUITO DE ETIQUETAS DE ADVERTENCIA

Si sus etiquetas de advertencia se han vuelto ilegibles o se han extraviado, llame al 1-800-223-7278 para conseguir otras

de forma gratuita.

REVISIÓN Y REPARACIONES

Todas las herramientas de calidad acaban necesitando revisiones y/o sustitución de piezas. Para información

sobre DELTA® Power Equipment Corporation, sus franquicias, o para localizar un Centro Autorizado de Servicio

en Garantía visite nuestro sitio web en www.DeltaMachinery.com/service o llame a nuestro Centro de Atención

al Cliente en el 1-800-223-7278. Todas las reparaciones realizadas por nuestros centros de servicio tienen

completa garantía contra materiales defectuosos y mano de obra. No podemos garantizarle reparaciones

hechas o intentadas por terceros. Llamando al número indicado también encontrará respuesta a las preguntas

más frecuentes durante 24 horas al día.

También puede escribirnos pidiendo información a DELTA® Power Equipment Corporation, 99 Rousch Street,

Anderson, SC 29625, Estados Unidos, A/At: Responsable del Servicio Técnico.

30

Page 31

31

Page 32

99 ROUSH ST

ANDERSON, SC 29625-3113

(800) 223-7278

www.DeltaMachinery.com

Copyright © 2014 DELTA® Power Equipment Corporation DPEC002900 03-19-14

Loading...

Loading...