IMPORTANT - PLEASE READ AND FOLLOW

✓ Before beginning, please read these instructions completely and carefully.

✓ Do not remove permanently affixed labels, warnings, or plates from the product. This

may void the warranty.

✓ Please observe all local and national codes and ordinances.

✓ Please ensure that this product is properly grounded.

✓ The installer should leave these instructions with the consumer who should retain

for local inspector's use and for future reference.

Installation must conform with local codes or in the absence of codes, the National Fuel

Gas Code ANSIZ223.1 - Iatest edition. Electrical installation must be in accordance with the

National Electrical Code, ANSI/NFPA70 - latest edition and/or local codes. IN CANADA:

Installation must be in accordance with the current CAN/CGA-B149.1 National Gas

Installation Code or CAN/CGA-B149.2, Propane Installation Code and/or local codes.

Electrical installation must be in accordance with the current CSA C22.1 Canadian

Electrical Codes Part 1 and/or local codes.

INSTALLATION IN MANUFACTURED (MOBILE) HOME: The installation must conform with

the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 [formerly the Federal Standard for Mobile Home Construction and Safety, Title 24, HUD (Part

280)] or, when such standard is not applicable, the Standard for Manufactured Home

Installations, ANSI/NCSBCS A225.1, or with local codes where applicable.

INSTALLATION IN RECREATIONAL PARK TRAILERS: The installation must conform with

state or other codes or, in the absence of such codes, with the Standard for Recreational

Park Trailers, ANSI A119.5.

Installation of any gas-fired equipment should be made by a Iicensed plumber. A manual

gas shut-off valve must be installed in the gas supply line ahead of the appliance in the gas

stream for safety and ease of service.

If an external electrical source is utilized, the appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local codes, with the

national Electrical Code, ANSI/NFPA 70.

This range is supplied with a protective film on steel and aluminium parts.

This film must be removed before installing/using the appliance.

FOR INSTALLER ONLY

THIS RANGE IS FOR RESIDENTIAL USE ONLY

• INSTALLATION INSTRUCTIONS

IMPORTANT - PLEASE READ AND FOLLOW

DUAL FUEL SELF CLEANING RANGE

for residential use only

Models: DL 48 P6G

DL 48 P6GE

2

✓ Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

✓ WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• lmmediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• lf you cannot reach your gas supplier, call the fire department.

✓ Installation and service must be performed by a qualified installer,

service agency, or the gas supplier.

WARNING: IF THE INFORMATION IN THIS MANUAL IS NOT

FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT

CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

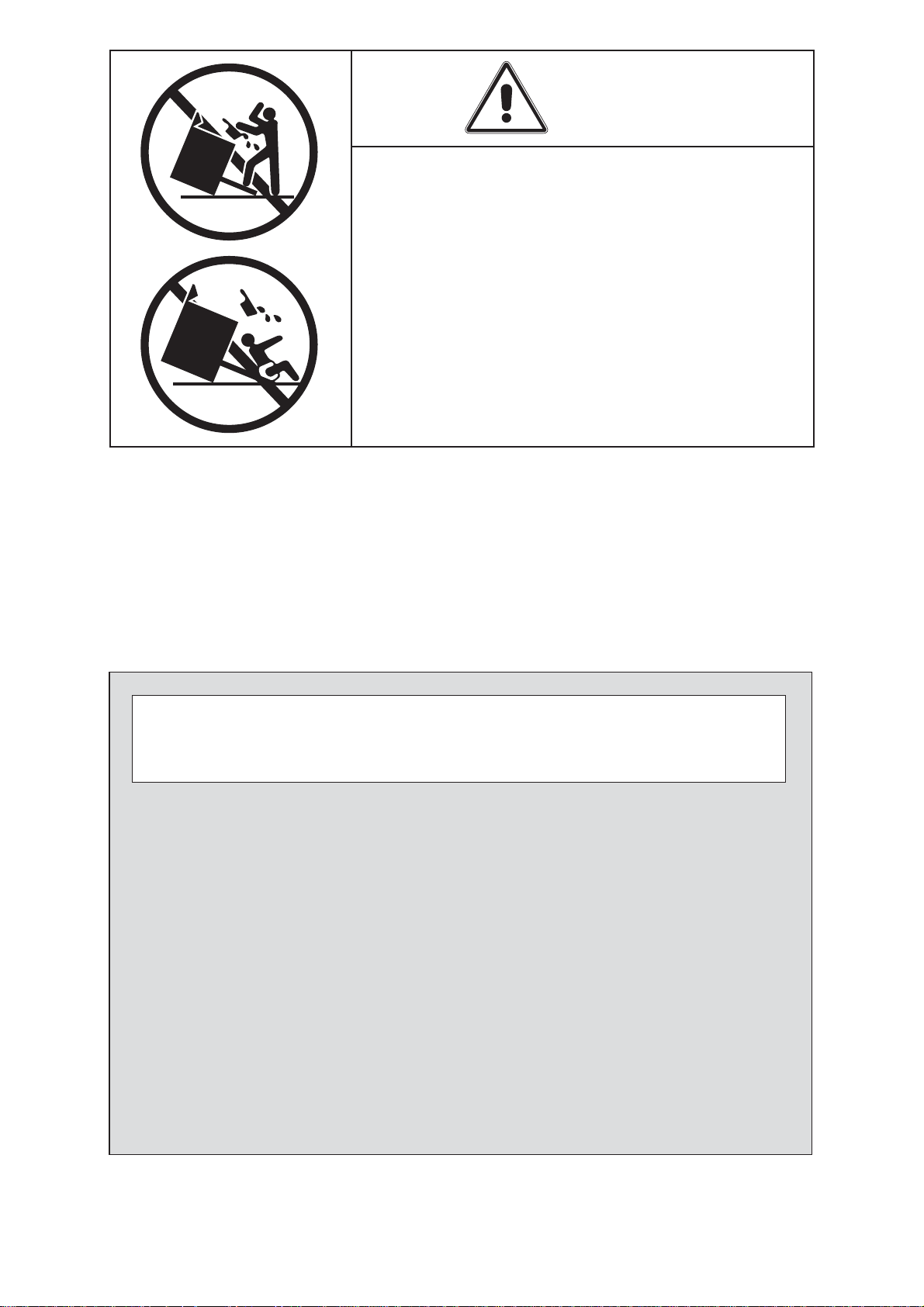

WARNING

• ALL RANGES CAN TIP

• INJURY TO PERSON COULD RESULT

• INSTALL ANTI-TIP DEVICE PACKED

WITH RANGE

• SEE INSTALLATION INSTRUCTIONS

3

DATA PLATE

CONVERSION LABEL

This appliance is designed and manufactured solely for the cooking of domestic (household)

food and in not suitable for any none domestic application and therefore should not be used

in a commercial environmement.

The appliance guarantee will be void if the appliance is used within a none domestic

environmement i.e. a semi commercial, commercial or communal environment.

4

WARNING!

THIS APPLIANCE HAS TO BE INSTALLED BY A QUALIFIED INSTALLER.

Improper installation, adjustment, alteration, services, or maintenance can cause injury or property damage. Consult a

qualified installer, service agent, or the gas supplier.

IMPORTANT: The use of suitable protective clothing/gloves is recommended when handling, installing of this appliance.

INSTALLATION INSTRUCTIONS

TOOLS NEEDED FOR INSTALLATION

Screwdriver 2 - Wrench

Suitable protective

gloves

Hammer

T-handle

wrench

Adjustable

wrench

Adjustable

pliers

Tape

measurePencil

Drill

5

GENERAL INFORMATION

1. Installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1-Latest Edition.

2. Installation in manufactured (mobile) home: installation

must conform with the Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280 [formerly

the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD (Part 280)] or, when such standard

is not applicable, the Standard for Manufactured Home

Installations, ANSI/NCSBCS A225.1, or with local codes

where applicable.

3. Installation in Recreational Park Trailers: installation must

conform with state or other codes or, in the absence of

such codes, with the Standard for Recreational Park

Trailers, ANSI A119.5.

4.

WARNING!!

This appliance shall not be used for space heating. This

information is based on safety considerations.

5. AlI openings in the wall behind the appliance and in the floor

under the appliance shall be sealed.

6. Keep appliance area clear and free from combustible

materials, gasoline, and other flammable vapors.

7. Do not obstruct the flow of combustion and ventilation air.

8. Disconnect the electrical supply to the appliance before

servicing.

9. When removing appliance for cleaning and/or service;

A. Shut off gas at main supply.

B. Disconnect AC power supply.

C. Disconnect gas line to the inlet pipe.

D. Carefully remove the range by pulling outward.

CAUTION: Range is heavy; use care in handling.

10.

Electrical Requirement

Electrical installation should comply with national and local

codes.

11.

Air Supply and Ventilation

The installer must refers to local/national codes.

12.

Gas Manifold Pressure

Natural gas - 4.0” W.C.P.

LP/Propane - 11.0” W.C.P.

13. The misuse of oven door (e.g. stepping, sitting, or leaning

on them) can result in potential hazards and/or injuries.

14. When installing or removing the range for service, a rolling

lift jack should be used. Do not push against any of the

edges of the range in an attempt to slide it into or out of

the installation. Pushing or pulling a range (rather than using

a lift jack) also increases the possibility of bending the leg

spindles or the internal coupling connectors.

WARNING!!

ELECTRICAL GROUNDING INSTRUCTIONS

The range must be electrically grounded in accordance

with local codes or, in the absence of local codes, with the

National Electrical Code, ANSI/NFPA No. 70-latest edition.

Installation should be made by a Iicensed electrician.

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED.

If an external electrical source is utilized, the installation must

be electrically grounded in accordance with local codes or, in

the absence of local codes, with the national Electrical Code,

ANSI/NFPA 70.

REPLACEMENT PARTS

Only authorized replacement parts may be used in performing

service on the range. Replacement parts are available from

factory authorized parts distributors. Contact the nearest parts

distributor in your area.

6

installation

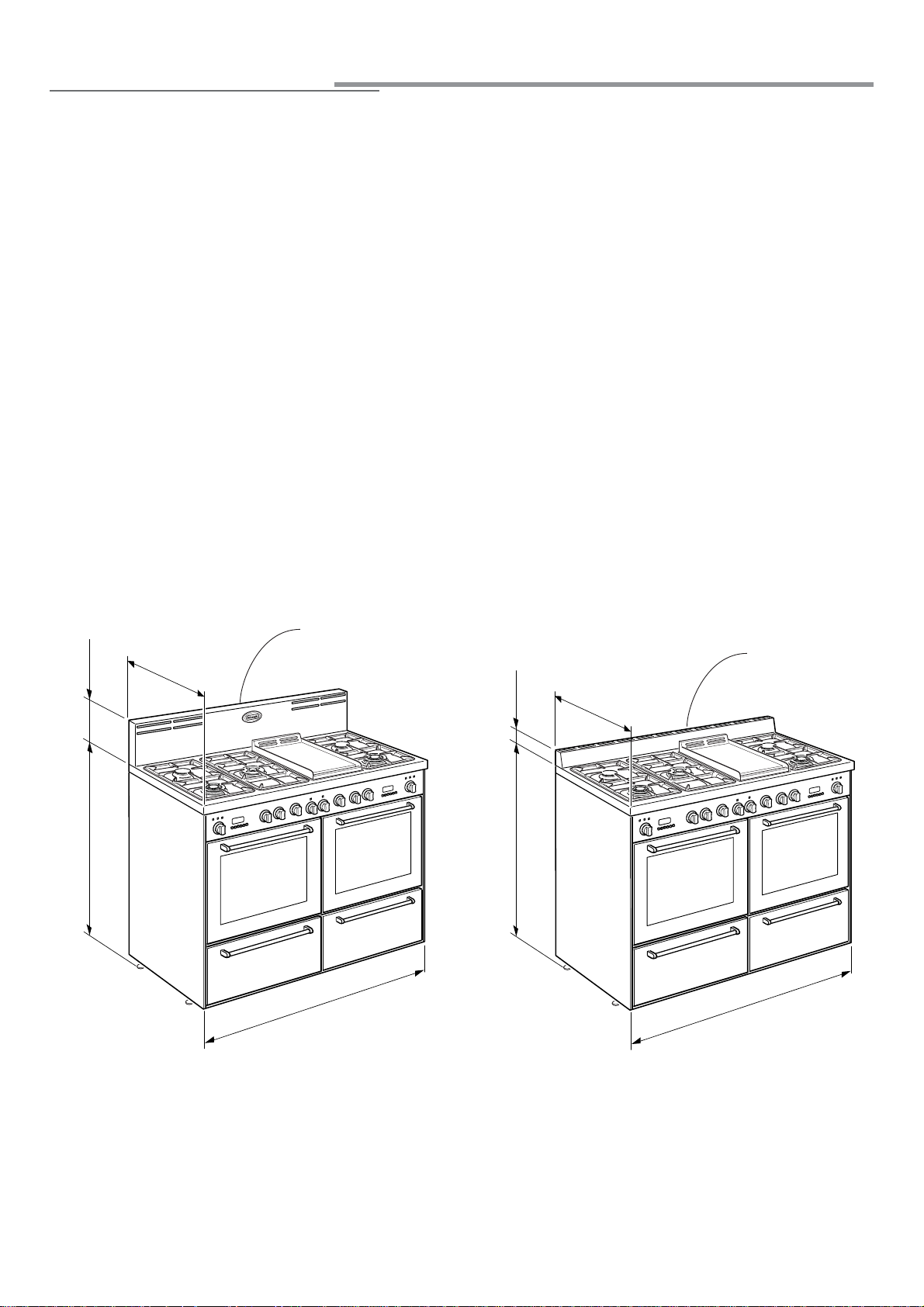

PROXIMITY TO SIDE CABINETS

1. This range may be installed directly adjacent to existing 36"

(914 mm) high base cabinets.

Range dimensions:

• width: 47” 7/8 (1216 mm)

• depth: 23” 15/16 (608 mm)

• height (with backguard): MIN 44” 1/16 (1118 mm) - MAX 44”

1/2 (1130 mm)

• height (with island trim): MIN 39” 1/64 (991 mm) - MAX 39”

1/2 (1003 mm)

• backguard (height): 8” (203 mm)

• island trim (height): 3” (76 mm)

Gas line opening:

Wall - 21 /32” (16.5 mm) from the left/right sides to centre of

range; from 4” 7/32 (107 mm) to 4" 11 /16 (119 mm) [depending on feet regulation] from the floor. This area can be extended on left/right sides: 15" 3/4 (400 mm) from the floor; 2"

51/64 (71 mm) toward centre of range.

Grounded outlet:

Same as per gas line opening.

8"

(203 mm)

23"

15/16

(608 mm)

(1216 m

m

)

47"

7/8

MIN 36" 1/64 (915 mm)

MAX 36"

1/2 (927 mm)

3"

(76 mm)

23"

15/16

(608 mm)

(1216 m

m

)

47"

7/8

MIN 36" 1/64 (915 mm)

MAX 36"

1/2 (927 mm)

Fig. 1.1a Fig. 1.1b

2. The range CANNOT be installed directly adjacent to sidewalls, tall cabinets, tall appliances, or other side vertical surfaces above 36” (914 mm) high.

There must be a minimum of 11” 13/16 (300 mm) side clearance from the range to such combustible surfaces TO THE

LEFT or TO THE RIGHT above the 36” (914 mm) high countertop.

IMPORTANT: One side (left or right) above the 36” (914

mm) high countertop must always be kept clear.

Installation with island trim: There must be a minimum of 12”

(305 mm) clearance from the back of the island trim to such

combustible surface on the back of the range above the 36”

(914 mm) high countertop.

3. The maximum upper cabinet depth recommended is 13” (330

mm). Wall cabinet above the range must be a minimum of 30”

(762 mm) above the countertop for a width of minimum 47”

7/8 (1216 mm): it has to be centred with the range. Side wall

cabinets above the range must be a minimum of 18” (457

mm) above the countertop.

Backguard

Island trim

7

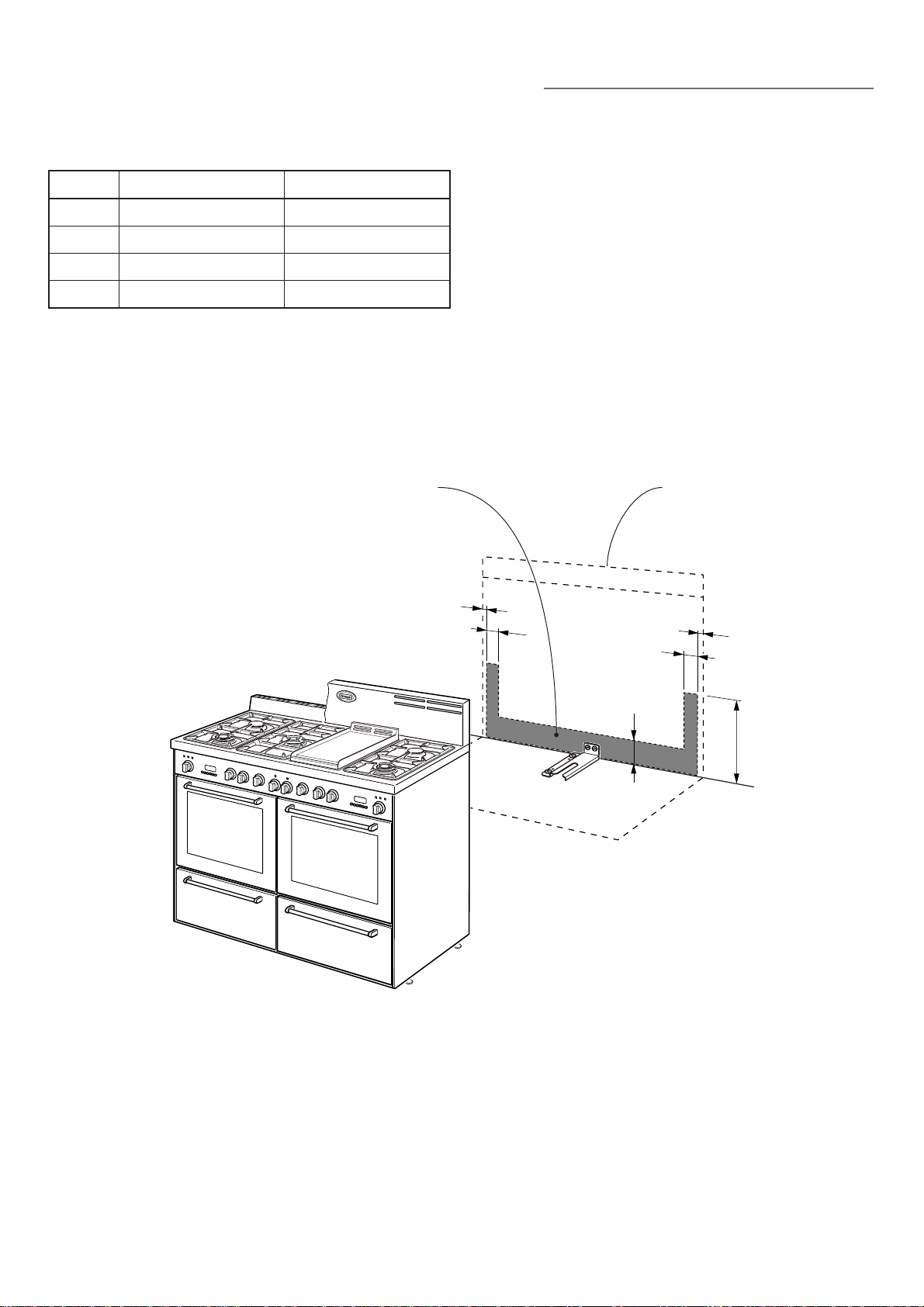

GAS AND ELECTRIC CONNECTION

Dotted line showing the position

* : Depending on feet regulation

Area for GAS and ELECTRIC connection

Fig. 1.2

Rif. inch mm

A 15” 3/4 400

B 2” 51/64 71

C 21/32” 16.5

D

4” 7/32 - 4” 11/16

(*)

107 - 119

(*)

C

B

B

D

C

A

8

(

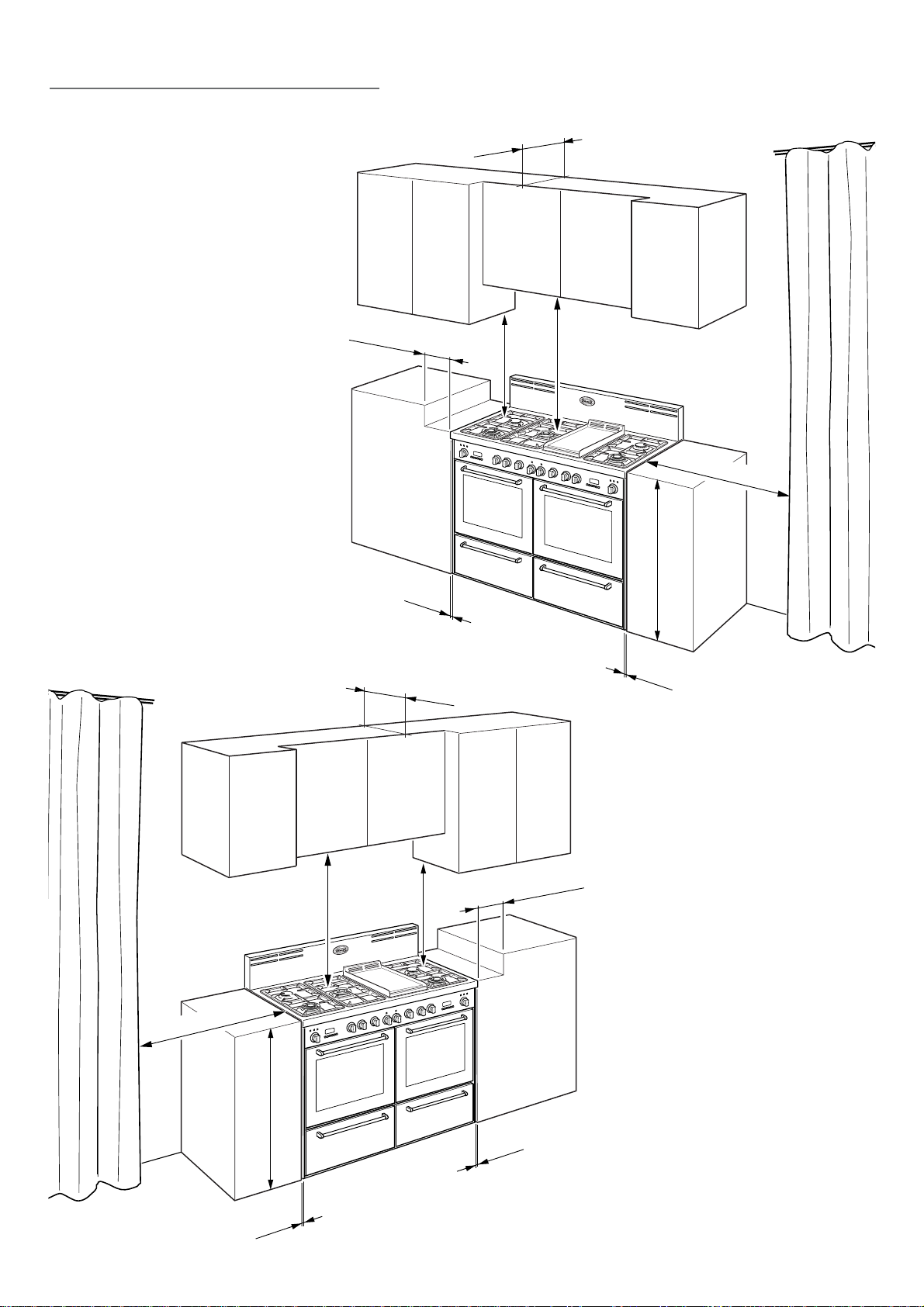

Fig. 1.3b

Fig. 1.3a

PROXIMITY TO SIDE CABINETS

RANGE WITH BACKGUARD

11"

13/16

m

in. (300 m

0"

(0 mm)

13" max. (330 mm)

m

)

18" min.

(457 mm)

30" min.

(762 mm)

20" m

36"

(914 mm)

in. (500 mm

)

20" m

in. (500 m

m

)

36"

(914 mm)

13" m

30" min.

(762 mm)

ax. (330 m

m

18" min.

(457 mm)

)

min. (300 mm)

13/16

11"

0"

(0 mm)

0"

(0 mm)

0"

0 mm)

9

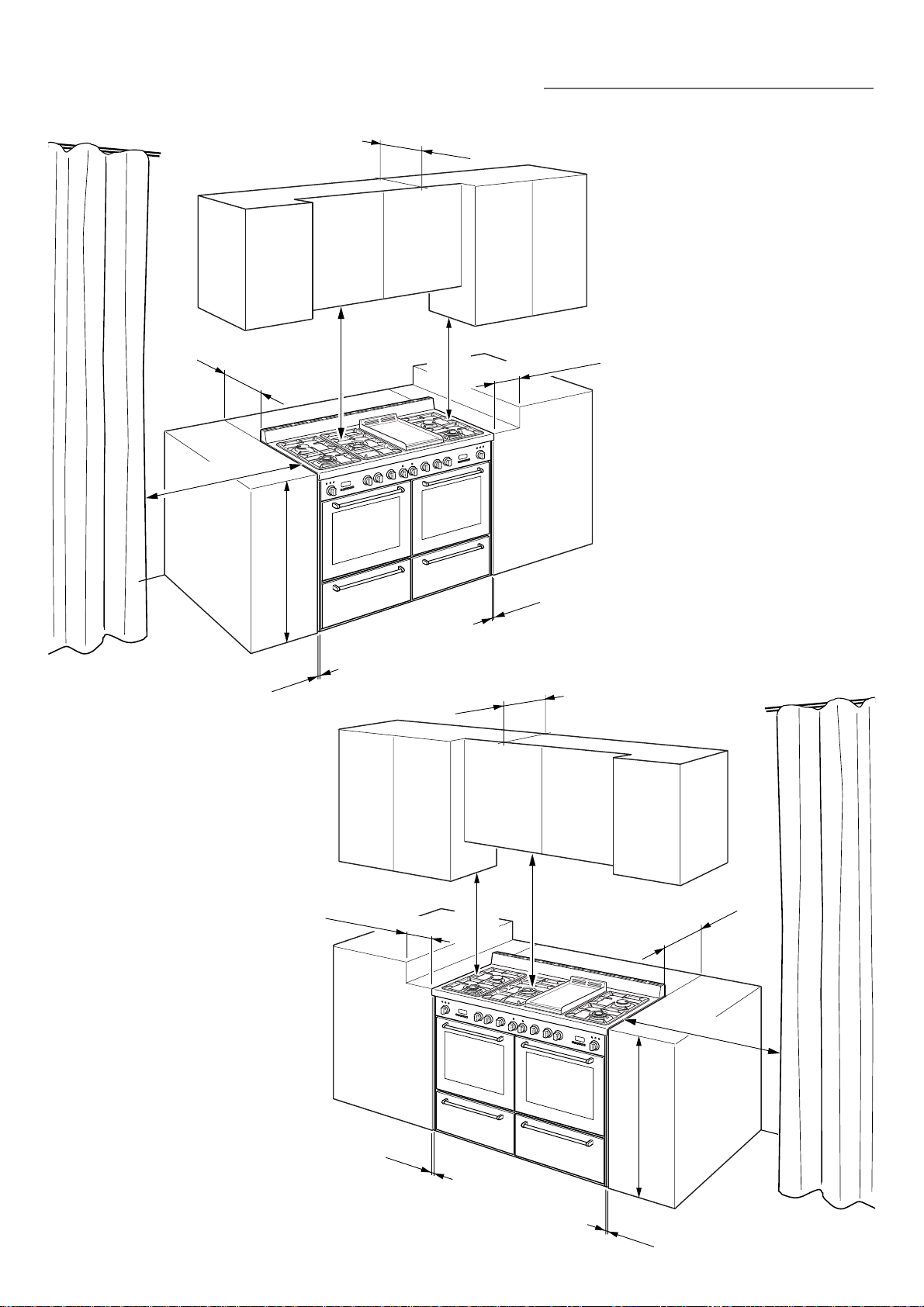

Fig. 1.3c

Fig. 1.3d

PROXIMITY TO SIDE

CABINETS

RANGE WITH ISLAND TRIM

12"

min. (305 mm)

0

. (5

in

" m

0

2

13" m

ax. (330 m

30" min.

(762 mm)

)

m

m

0

m

)

11"

18" min.

(457 mm)

min. (300 mm)

13/16

36"

(914 mm)

0"

(0 mm)

11"

13/16

m

in. (300 m

(0 mm)

13" max. (330 mm)

m

18" min.

)

(457 mm)

0"

30" min.

(762 mm)

"

12

in. (305 m

m

20" m

in. (500 m

m

)

m

)

0"

(0 mm)

36"

0"

(0 mm)

(914 mm)

10

A

A

Fig. 1.4

Fig. 1.5

ASSEMBLING THE BACKGUARD

OR THE ISLAND TRIM

It is mandatory to install the

backguard or the island trim

• Assemble the backguard or the island trim as

shown in figure 1.4 or 1.5 and fix it by screwing the 5 screws “A”.

A

A

11

LEVELLING THE RANGE

The range is equipped with 6 LEVELLING FEET (already fitted on the appliance) and

may be levelled by screwing or unscrewing the feet (fig. 1.9).

It is important to observe

the prescriptions of figures 1.6, 1.7, 1.8.

Fig. 1.6

Fig. 1.7 Fig. 1.8

Supplied with the range

in a separate kit

Fig. 1.9

0 mm

0"

+ 5/16"

+ 8 mm

+ 5/16"

+ 8 mm

+ 15/32"

+ 12 mm

12

ANTI-TIP STABILITY DEVICE INSTALLATION INSTRUCTIONS

1. The anti-tip bracket has to be attached as shown on figure below (only rear central

position), it has to be fixed on the floor and on the rear wall by no. 4 (four) suitable

screws (not supplied).

2. After fixing the anti-tip bracket, slide range into place. Be sure the rear central foot

slides under the anti-tip bracket attached.

Dotted line showing the position

of the range when installed

ANTI-TIP STABILITY

DEVICE FIXING

Rear central

feet of range

Fig. 1.10

Anti-tip

stability device

YOU MUST USE STABILITY

ANTI TIP BRACKET TO

PREVENT UNIT FROM

TIPPING.

=

=

13

Fig. 2.1

All gas connections must be made according to national and local codes. This gas

supply (service) line must be the same size or greater than the inlet line of the

appliance. Sealant on all pipe joints must be resistant to the action of LP/Propane

gas.

The range is equipped for the use with NATURAL gas. It is design-certified by CSA

International for NATURAL and L.P. gases with appropriate conversion.

The model/serial rating plate, located on the back of the appliance, has information

on the type of gas that can be used. If this information does not agree with the type

of gas available, check with the local gas supplier. See page from 17 to 22 for L.P.

gas conversion instructions.

1. Manual Shut-off Valve (fig. 2.1):

The supply line shall be equipped with an approved shutoff valve. This valve should

be located in the same room as the range and should be in a location that allows

ease of opening and closing (in a position where it can be reached quickly in the

event of an emergency).

Do not block access to the shutoff valve. The valve is for turning on or shutting off

gas to the appliance.

2. Pressure Regulator:

a) All heavy duty, commercial type cooking equipment must have a pressure regulator

on the incoming service line for safe and efficient operation, since service pressure

may fluctuate with local demand.

Before installing the regulator mount the 1/2” NPT (conical) male connector to the

regulator (see picture 2.2a). Gasket supplied have to be placed between 1/2” NPT

(conical) connector/extension pipe male pipe fitting (see picture 2.2b).

The regulator supplied with this range must be installed before any gas connections

are made.

Use supplied pressure regulator only.

gas connection

Explosion Hazard

Use a new CSA or UL approved

gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure gas pressure does not exceed 14" water

column.

Examples of a qualified person

include licensed heating personnel, authorized gas company personnel, and authorized

service personnel.

Failure to do so can result in

death, explosion, or fire.

Shutoff valve

“open” position

To range

Gas supply line

14

PRESSURE REGULATOR INSTALLATION

STEP 1

Mount the 1/2” NPT (conical) male connector to the pressure

regulator and tighten by using a wrench.

Do not over tighten the connector.

Over tightening may crack regulator.

STEP 2

Assemble the 1/2” NPT connector + pressure regulator group to the extension pipe interposing the gasket supplied. The

regulator cover must be oriented toward the front side of the range.

IMPORTANT: use two spanners to tighten the connection.

Regulator cover

Fig. 2.2a

Fig. 2.2b

LOCK

Arrow

15

Fig. 2.3

GAS CONNECTION SPECIFICATION

Range

manifold

1/2” G cylindrical

(ISO 228-1) male

Manifold male pipe fitting

Gasket

Extension

Extension

pipe female

pipe female

pipe fitting

pipe fitting

Extension

pipe male

pipe fitting

Gasket

1/2” NPT (conical)

male

1/2” G cylindrical

(ISO 228-1) female

Extension

pipe

1/2” G cylindrical

(ISO 228-1) male

1/2” G cylindrical

(ISO 228-1) female

Connector

1/2” NPT

female

To range

To mains

connection

Pressure

regulator

1/2” NPT

female

WARNING: check the right positioning

of the gas regulator. The arrow on the

back of the gas regulator must be

oriented toward the connector.

Arrow

16

5. Leak Testing:

IMPORTANT: Leak testing of the appliance shall be conducted as follows:

• After final gas connection is made, turn on manual gas valve and test all

connections in gas supply piping and appliance for gas leaks with a soapy water

solution. During this test all appliance gas valves have to be closed.

• In order to avoid property damage or serious personal injury, never use a Iighted

match. If a leak is present, tighten joint or unscrew, apply more joint compound,

tighten again and retest connection for leak.

b) Any conversion required must be performed by your dealer or a qualified licensed

plumber or gas service company. Please provide the service person with this

manual before work is started on the range. (Gas conversions are the responsibility

of the dealer or end user.)

c) This range can be used with NATURAL or LP/PROPANE gas. It is shipped from

the factory adjusted for use with NATURAL gas.

d) Manifold pressure should be checked with a manometer and by operating as below

detailed:

- Remove the injector from the front left burner and mount the proper test point

adapter which is available from the After-Sales Service (see side figure and the

“OPERATIONS TO BE PERFORMED WHEN SUBSTITUTING THE INJECTORS”

chapter).

-Turn the front left burner control knob to the maximum position ( position)

-Press the knob and keeping it pressed check the manifold pressure with a

manometer; NATURAL gas requires 4.0” W.C.P. and LP/PROPANE requires 11.0”

W.C. P.

- Incoming line pressure upstream from the regulator must be 1” W.C.P. higher

than the manifold pressure in order to check the regulator.

- The regulator used on this range can withstand a maximum input pressure of

1/2 PSI (14.0” W.C.P). If the line pressure is in excess of that amount, a stepdown regulator will be required.

e) The appliance, its individual shut-off valve, and pressure regulator must be

disconnected from the gas supply piping system during any pressure testing of

that system at pressures in excess of 1/2 PSI (3.5 kPa).

f) The appliance must be isolated from the gas supply piping system by closing its

individual manual shut-off valve during any pressure testing of the gas supply

piping system at test pressure equal to or less than 1/2 PSI (3.5 kPa).

3. Flexible Connections:

If local codes permit, CSA design-certified, flexible metal appliance connector is

recommended for connecting this range to the gas supply line. Do Not kink or damage

the flexible connector when moving the range. The pressure regulator has 1/2" NPT

female pipe threads.You will need to determine the fittings required, depending on

the size of your gas supply line, flexible metal connector and shutoff valve.

Fig. 2.4

4. Rigid Pipe Connections:

If rigid pipe is used as a gas supply line, a combination of pipe fittings must be used

to obtain an in-line connection to the range. All strains must be removed from the

supply and fuel lines so range will be level and in line.

• Use joint compounds and gaskets that are resistant to action of natural or

propane gas on all male pipe threads.

• Do not over tighten gas fitting when attaching to pressure regulator. Over

tightening may crack regulator.

TEST POINT ADAPTER

The Test Point adapter is available from

the After-Sales Service.

17

CONVERSION TO LP/PROPANE GAS

Every range is provided with a set of injectors for the various types of gas.

Select the injectors to be replaced according to the “INJECTORS TABLE”.

The nozzle diameters, expressed in hundredths of a millimetre, are marked on the

body of each injector.

SETTING THE PRESSURE REGULATOR (fig. 2.5)

The pressure regulator is accessible by removing the left warmer drawer; the pressure

regulator is positioned on the rear left side of the range.

To remove the warming drawer:

1. Open the drawer completely (fig. 2.5)

2. Move down the lever of left guide (fig. 2.6) and up the lever of right guide (fig. 2.7).

3. Remove the drawer; the levers have to be keep moved (fig. 2.5).

Fig. 2.5

Fig. 2.7

Fig. 2.6

2

2

3

18

1

2

NATURAL GAS

REGULATION

LP/PROPANE

REGULATION

A

To set the pressure regulator (fig. 2.8):

1. Unscrew the regulator cover;

2. Unscrew the A component, reverse and screw it according to the LP/PROPANE

regulation.

Fitting the warming drawer (fig. 2.9):

1. Insert the drawer guides into the range guides (fig. 2.9)

2. Gently close the drawer completely; the safety catchs will be automatically hooked.

Fig. 2.8

REGULATOR COVER

Pressure

regulator

Fig. 2.9

19

The burner are conceived in such a

way so as not to require the regulation

of the primary air.

OPERATIONS TO BE PERFORMED WHEN SUBSTITUTING

THE INJECTORS (Rapid, triple ring and dual burners)

✓ Remove the gratings and the burner covers;

✓ Using a wrench substitute the nozzle injectors “J” (figs. 2.10a - 2.10b - 2.10c) with

those most suitable for the kind of gas for which it is to be used.

Fig. 2.10a

Fig. 2.10b

Fig. 2.10c

INJECTORS TABLE

Rapid

burner

Triple ring

burner

DUAL

burner

J

Injector for inner crown

J

Injectors for

outer crowns

J

J

BURNERS

NOMINAL POWER

BTU/hr

REDUCED POWER

BTU/hr

LP/PROPANE

11” W.C.P.

NATURAL GAS

4” W.C.P.

Ø injector

[1/100 mm]

By-pass

[1/100 mm]

Ø injector

[1/100 mm]

By-pass

[1/100 mm]

Rapid (R)

10000 2000 94 42 155

adjustable

Triple ring (TC)

12000 5000 102 65 170

adjustable

Griddle

12000 5000 105 65 175

adjustable

Dual (D)

Inner crown

2800 for NATURAL GAS (*)

3500 for LP/PROPANE GAS (*)

1000 (*)

55

(no. 1 central)

27

80

(no. 1 central)

adjustable

Outer crowns

16000 for NATURAL GAS (#)

15000 for LP/PROPANE GAS (#)

6500 for NATURAL GAS (#)

4500 for LP/PROPANE GAS (#)

72

(no. 2 outer)

60

130

(no. 2 outer)

adjustable

(*) Power calculated only with inner crown operating

(#) Power calculated with inner and outer crowns operating

20

OPERATIONS TO BE EXECUTED FOR THE

REPLACEMENT OF THE INJECTOR

OF THE

GRIDDLE BURNER

■ Lift and remove the griddle stainless steel plate.

■ Unscrew the no. 2 (two) screws and remove the plate "B"

(fig. 2.11).

■ Unscrew the no. 2 (two) screws and remove the shield

"P" (fig. 2.12).

■ Unscrew the no. 4 (four) screws and remove the no. 4

(four) clips "S" (fig. 2.13).

■ Unscrew the no. 2 (two) screws and remove the

thermocouple protection "T" (fig. 2.14).

■ Unscrew the no. 2 (two) burner front fixing screws (fig.

2.15).

■ Gently unlock the safety valve probe "V" and the ignition

electrode "I" (fig. 2.16). Take care not to damage the probe

and the ignition electrode.

Fig. 2.11

Fig. 2.12 Fig. 2.13

Fig. 2.14 Fig. 2.15 Fig. 2.16

B

P

T

S

V

I

21

■ Remove the burner as shown in figure 2.17.

■ Using a 7 mm box spanner, unscrew the injector

(indicated by the arrow in fig. 2.18) and replace it by the

proper one according to the kind of gas.

■ Then replace the burner and other components repeating

the above steps in reverse order.

IMPORTANT: Pay special attention to replace correctly

the safety valve probe "V" and the ignition electrode "I"

as per figures 2.19 and 2.20. Check the correct operation

of the safety valve and the ignition electrode.

Fig. 2.17

Fig. 2.19 Fig. 2.20

Fig. 2.18

Anchorage

clip

I

V

V

I

Anchorage

clip

22

SETTING THE BURNER MINIMUM

When switching from one type of gas to another, the minimum flow rate must also be

correct: the flame should not go out even when passing suddenly from maximum to

minimum flame.

To r egulate the flame follow the instructions below:

Rapid, triple ring and griddle burners

– Light the burner

– Set the gas valve to position

– Remove the knob

– With a thin screwdriver pass by the hole of microswitch and turn the screw F until

adjustment is correct (fig. 2.21).

Inside crown of DUAL burner

– Light the DUAL burner

– Set the gas valve to position

– Remove the knob

– Using a screwdriver turn the screw H until the correct setting is obtained (fig. 2.22).

Outside crowns of DUAL burner

– Light the DUAL burner

– Set the gas valve to position

– Remove the knob

– Using a screwdriver turn the screw G until the correct setting is obtained (fig. 2.22).

For LP/PROPANE gas, tighten the adjustment screws completely.

Fig. 2.21

Fig. 2.22

After regulation repeat the operations indicated in paragraph “2. Pressure regulator” at

page 13.

If the range has been disconnected and then connected again to the gas supply line

repeat the operations indicated in paragraph “5. Leak Testing” at page 16.

IMPORTANT:

After conversion to LP/PROPANE gas has been carried out affix on the back of the

appliance, near the data plate, the conversion label supplied and also affix a conversion

label at page 3 of this instruction manual.

F

G

H

23

electrical connection

ELECTRICAL REQUIREMENTS

• This appliance must be properly installed and grounded by a qualified technician in

accordance with the National Electrical Code ANSI/NFPA No.70 (latest edition) and

local electrical code requirements. IN CANADA: Electrical installation must be in

accordance with the current CSA C22.1 Canadian Electrical Codes Part1 and/or local

codes.

• This appliance may be connected by means of permanent “Hard Wiring” or “Power

Supply Cord”. Power supply cord is not supplied, but it is available through your local

electric supply house.

• The range must be connected to the proper electrical voltage and frequency as specified on the rating plate.

• The range can be connected directly to the fused disconnect (or circuit breaker box)

through flexible, armoured or non-metallic sheathed, copper cable (with grounding

wire). Allow two to three feet of slack in the line so that it can be moved if servicing

is ever necessary.

ELECTRICAL CONNECTION WITH POWER CORD

Use a 3-wire power supply cord kit rated for 40 amps - 120/240 volts with closed loop

terminals and marked for use with ranges. Where local codes do not permit grounding

through neutral, use a 4-wire power supply cord.

The CSA/UL-listed cord must be secured to the range with the strain relief bracket. The

electrical connection is made at the terminal block, which is located behind the access

door on the back of the range.

WARNING

TO AVOID ELECTRICAL SHOCK

HAZARD, BEFORE INSTALLING THE

APPLIANCE, SWITCH POWER OFF AT

THE SERVICE PANEL AND LOCK THE

PANEL TO PREVENT THE POWER

FROM BEING SWITCHED ON

ACCIDENTALLY.

ELECTRICAL CONNECTION WITH CONDUIT

Use 1/2” (1.3 cm) trade size CSA/UL-listed conduit with a conduit clamp, 12 AWG/600

volt copper conductor colored red for line 1 and black for line 2 and 12 AWG/600

volt copper conductor (or 10 AWG/600 volt copper conductor if grounding through

neutral) colored white for neutral with closed loop terminals marked for use with ranges.

Where local codes do not permit grounding through neutral, use a green 10 AWG copper conductor as directed in the 4-wire connector directions. The conduit must be

secured to the range with the strain relief bracket. The electrical connection is made at

the terminal block which is located behind the access door on the back of the range.

24

Fig. 3.1

Fig. 3.2

3-Wire Flat Power Cord Installation

(See Figures 3.1 and 3.2)

1. Remove the Terminal Block Access Plate on the back of the

range by unscrewing the 4 fixing Screws (Figure 3.1).

2. Insert the Flat Power Cord through the Bracket; then tighten

the Flat Power Cord by using the Strain Relief. Allow enough

slack to easily attach the cord terminals to the Terminal

Block (Figure 3.2).

3. Remove the 3 wire terminal nuts and washers from the

Terminal Block.

4. Plug the terminal holes of Flat Power Cord. The Neutral or

Ground Wire of the Flat Power Cord must be connected to

the neutral terminal located in the center of Terminal Block.

The Power Wires must be connected to the outside terminals

(Figure 3.2).

5. Plug washers and tighten nuts securely.

6. Assemble the Terminal Block Access Plate (Figure 3.1).

Screws

Terminal Block

Access Plate

Neutral Wire

Power Wires

Terminal Block

Ground strap

Bracket

Strain Relief

Flat

Power Cord

25

3-Wire Power Cord Installation

(See Figures 3.1, 3.3, 3.4 and 3.5)

1. Remove the Terminal Block Access Plate on the back of the

range by unscrewing the 4 fixing Screws (Figure 3.1).

2. Remove the Bracket and Strain Relief group by unscrewing

the Bracket Fixing Screws (Figure 3.3).

3. Mount the Power Cord Bracket (supplied with the range in

a separate kit - make sure you are using the correct Power

Cord Bracket as indicated in Figure 3.4) inside the Opening

For Electrical Connection by screwing the 2 Fixing Screws

(as indicated in Figure 3.4).

4. Insert the Power Cord through the Power Cord Bracket;

then tighten the Power Cord by using the Power Cord Strain

Relief Bracket (fixed by 2 screws)(see Figure 3.5). The

Power Cord Strain Relief Bracket is supplied with the range

in a separate kit. Allow enough slack to easily attach the cord

terminals to the Terminal Block.

5. Remove the 3 wire terminal nuts and washers from the

Terminal Block.

6. Plug the terminal holes of Power Cord. The Neutral or

Ground Wire of the Power Cord must be connected to the

neutral terminal located in the center of Terminal Block. The

Power Wires must be connected to the outside terminals.

7. Plug washers and tighten nuts securely.

8. Assemble the Terminal Block Access Plate (Figure 3.1).

4-Wire Power Cord Installation

(See Figures 3.1, 3.3, 3.4 and 3.6)

1. Remove the Terminal Block Access Plate on the back of the

range by unscrewing the 4 fixing Screws (Figure 3.1).

2. Remove the Bracket and Strain Relief group by unscrewing

the Bracket Fixing Screws (Figure 3.3).

3. Mount the Power Cord Bracket (supplied with the range in

a separate kit - make sure you are using the correct Power

Cord Bracket as indicated in Figure 3.4) inside the Opening

For Electrical Connection by screwing the 2 Fixing Screws

(as indicated in Figure 3.4).

4. Insert the Power Cord through the Power Cord Bracket;

then tighten the Power Cord by using the Power Cord Strain

Relief Bracket (fixed by 2 screws) (see Figure 3.6). The

Power Cord Strain Relief Bracket is supplied with the range

in a separate kit. Allow enough slack to easily attach the cord

terminals to the Terminal Block.

5. Remove the 3 wire terminal nuts and washers from the

Terminal Block.

6. Remove the Ground Strap from the frame of range and terminal by removing its screw and cutting it as shown in Figure

3.6.

7. Plug the terminal holes of Power Cord. The Neutral Wire of

the Power Cord must be connected to the neutral terminal

located in the center of Terminal Block; the Power Wires

must be connected to the outside terminals; the Ground Wire

must be attached to the frame of range by using the

(Ground) identified Grounding Screw.

8. Plug washers and tighten nuts securely.

9. Assemble the Terminal Block Access Plate (Figure 3.1).

Fig. 3.3

Fig. 3.4

Fig. 3.5

Fig. 3.6

Bracket

Fixing Screws

Bracket

Strain Relief

A: D=1"

B: D=

Opening For

Electrical

Connection

/

9

64

/

" (22.5 mm)

7

8

(29 mm)

Fixing Screws

Power Cord

Bracket

Neutral Wire

Power Wires

Power Cord

Strain Relief Bracket

Screws

Power Cord

Neutral Wire

Power Wires

Power Cord

Strain Relief Bracket

Screws

Power Cord

Terminal Block

Terminal Block

Ground strap

Power Cord

Bracket

Cut Ground Strap

Grounding

Screw

Grounding Wire

Power Cord

Bracket

26

4-Wire Conduit Installation

(See Figures 3.1, 3.7, 3.8 and 3.10)

1. Remove the Terminal Block Access Plate on the back of the

range by unscrewing the 4 fixing Screws (Figure 3.1).

2. Remove the Bracket and Strain Relief group by unscrewing

the Bracket Fixing Screws (Figure 3.7).

3. Mount the Conduit Bracket (supplied with the range in a separate kit - make sure you are using the correct Conduit

Bracket as indicated in Figure 3.8) inside the Opening For

Electrical Connection by screwing the 2 Fixing Screws (as

indicated in Figure 3.8).

4. Feed 1/2” (1.3 cm) trade size Conduit through the hole in the

Conduit Bracket and secure to the Conduit Bracket with a

Conduit Clamp (Figure 3.10).

5. Remove the 3 wire terminal nuts and washers from the

Terminal Block.

6. Remove the Ground Strap from the frame of range and terminal by removing its screw and cutting it as shown in Figure

3.10.

7. Plug the terminal holes of conductors. The Neutral Wire of

the Power Cord must be connected to the neutral terminal

located in the center of Terminal Block; the Power Wires

must be connected to the outside terminals; the Ground Wire

must be attached to the frame of range by using the

(Ground) identified Grounding Screw.

8. Plug washers and tighten nuts securely.

9. Assemble the Terminal Block Access Plate (Figure 3.1).

Fig. 3.9

Fig. 3.10

3-Wire Conduit Installation

(See Figures 3.1, 3.7, 3.8 and 3.9)

1. Remove the Terminal Block Access Plate on the back of the

range by unscrewing the 4 fixing Screws (Figure 3.1).

2. Remove the Bracket and Strain Relief group by unscrewing

the Bracket Fixing Screws (Figure 3.7).

3. Mount the Conduit Bracket (supplied with the range in a separate kit - make sure you are using the correct Conduit

Bracket as indicated in Figure 3.8) inside the Opening For

Electrical Connection by screwing the 2 Fixing Screws (as

indicated in Figure 3.8).

4. Feed 1/2” (1.3 cm) trade size Conduit through the hole in the

Conduit Bracket and secure to the Conduit Bracket with a

Conduit Clamp (Figure 3.9).

5. Remove the 3 wire terminal nuts and washers from the

Terminal Block.

6. Plug the terminal holes of conductors. The Neutral or Ground

Wire of the Power Cord must be connected to the neutral

terminal located in the center of Terminal Block. The Power

Wires must be connected to the outside terminals.

7. Plug washers and tighten nuts securely.

8. Assemble the Terminal Block Access Plate (Figure 3.1).

Fig. 3.7

Fig. 3.8

Bracket

Fixing Screws

Bracket

Strain Relief

A: D=1"

B: D=

Opening For

Electrical

Connection

/

9

64

/

" (22.5 mm)

7

8

(29 mm)

Fixing Screws

Neutral Wire

Power Wires

Conduit Clamp

Conduit

Neutral Wire

Power Wires

Conduit Clamp

Conduit

Conduit

Bracket

Terminal Block

Terminal Block

Ground strap

Conduit

Bracket

Cut Ground strap

Grounding

Screw

Grounding Wire

Conduit

Bracket

27

WIRING DIAGRAM

16a

1

3

Oven door

latch switch

Safety

Thermostat

2

33 ETA

16

5

A

3a

1

2

34 ETA

EL 1000

control device

Door opened/closed

9

9a

LF

OVEN LAMP

LINE

PILOT LAMP

15

15a

BOTTOM ELEMENT EXT.

5a

PILOT LAMP

THERMOSTAT

1a

A

2a

ST3

AUX ETA

AUX ETA

ETA

OVEN DOOR LATCH

ST1 PROBE

2

∞C+/- ST2

TOP ELEMENT

GRILL ELEMENT

CIRCULAR ELEMENT

RELAY 2

EL 1000

6

7

B

E61

RELAY

3 ETA

42

ETA ETA

1

SIEBE

EL 1000

13

13a

Safety

Thermal overload

E61

RELAY SWITCH

THERMOSTAT

9

6

120

14

14a

BOTTOM ELEMENT INT.

12

12a

11

11a

SPIT MOTOR

V G

OVEN FAN

1

2

ST4

ENCODER

B

B

4

7

RELAY 1

EL 1000

8

8a

7

7a

AIR

SWITCH

PILOT LAMP

DOOR SAFETY

5

3

4

EL1000

RELAY 3

LOCK/UNLOCK

FAN

COOLING

0422255

2

P1

PILOT

4

P2

LINE

PILOT LAMP

E61

RELAY SWITCH

9

3

6

6a

6

B

6a

A

E61

LINE

RELAY

PILOT LAMP

RELAY

A1

A2

relay

Griddle

coil

Ignition

16

16a

Safety

Thermostat

5a

5

2

1

A

3a

3

THERMOSTAT

1

1a

2

2a

Energy Regulator

Energy Regulator

Ignition switces

group

PILOT LAMP

RELAY 2

EL 1000

6

A

E61

RELAY

S2

S1

2

P1

PILOT

4

P2

S2

S1

BOTTOM ELEMENT EXT.

TOP ELEMENT

BOTTOM ELEMENT INT.

GRILL ELEMENT

CIRCULAR ELEMENT

7

B

15

13

12

11

2

LINE

14

SPIT MOTOR

PILOT LAMP

OVEN FAN

1

15a

13a

14a

12a

11a

V G

AIR

Safety

8

7

SWITCH

Thermal overload

6

120

B

4

8a

7a

RIGHT VARMING DRAWER

LEFT VARMING DRAWER

OVEN LAMP

E61

RELAY SWITCH

9

9a

LF

9

THERMOSTAT

B

7

RELAY 1

EL 1000

PILOT LAMP

FAN

COOLING

5

4

EL1000

RELAY 3

LOCK/UNLOCK

DOOR SAFETY

3

L1 - L2 = 240V

L1 - N = 120V

L2 - N = 120V

EARTH

N

L2

34 ETA

33 ETA

Oven door

latch switch

ST3

AUX ETA

AUX ETA

EL 1000

control device

Door opened/closed

∞C+/- ST2

OVEN DOOR LATCH

ST1 PROBE

3 ETA

ETA

1

2

SIEBE

EL 1000

42

ETA ETA

ST4

ENCODER

L1

Cod. 1102725 - ß3

The manufacturer cannot be held responsible for possible inaccuracies due to printing or transcription errors in

the present booklet.

The manufacturer reserves the right to make all modifications to its products deemed necessary for manufacture

or commercial reasons at any moment and without prior notice, without jeopardising the essential functional and

safety characteristics of the appliances.

Loading...

Loading...