Page 1

MACCHINE DA CAFFE' / COFFEE MACHINES

KAFFEE-MASCHINEN/ MACHINES A CAFE

MAQUINAS DE CAFE

DE' LONGHI BAR M 200

DATI TECNICI / TECHNICAL DATA / TECHNISCHE DATEN

DONNEES TECHNIQUES / DATOS TECNICOS

Voltaggio / Voltage / Spannung / Voltage / Voltaje V / Hz 230-240 / 50

Max. potenza assorbita / Max. input power / Max. Leistungsaufnahme W 1700

Max. puissance absorbée / Max. potencia absorbida

MACCHINA DA CAFFE' / COFFEE MACHINE / KAFFEE-MASCHINE

MACHINE A CAFE / MAQUINA DE CAFE

Termostato / Thermostat / Thermostat / Thermostat / Termostato °C 105

Fusibile termico / Thermal fuse / Thermische-Sicherung °C 226-228

Fusible thermique / Fusible térmico

(Int.)

Resistenza riscaldamento / Heating element / Heizelement W 800

Elément chauffant / Resistencia de calefación

Pompa / Pump / Pumpe / Pompe / Bomba TYPE / W ULKA EP5 / 48

Interruttore / Switch / Schalter / Interrupteur / Interruptor V / A 250 / 10

SEZIONE CAPPUCCINO / SECTION CAPPUCCINO / SEKTION CAPPUCCINO

SECTION CAPPUCCINO / SECCION CAPPUCCINO

Termostato / Thermostat / Thermostat / Thermostat / Termostato °C 150

Fusibile termico / Thermal fuse / Thermische-Sicherung °C 315

Fusible thermique / Fusible térmico

Resistenza riscaldamento / Heating element / Heizelement W 800

Elément chauffant / Resistencia de calefación

Pompa / Pump / Pumpe / Pompe / Bomba TYPE / W NM 3 / 17

Interruttore / Switch / Schalter / Interrupteur / Interruptor V / A 250 / 10

Microinterruttore / Microswitch / Mikroschalter Type SAIA XGAóCROUZET 86161.010

Microrpteur / Microinterruptor V / A 250 / 12

Elettrovalvola / Electrovalve / Elektroventil / Electrosoupape / Electrovalvùla Type CEME 5515 EN 2,0 S AIF

-avvolgimento / winding / wicklung / bobinage /envolvimiento V / KΩ 230 / 2,36

1

SCHEDA TECNICA 98033

Page 2

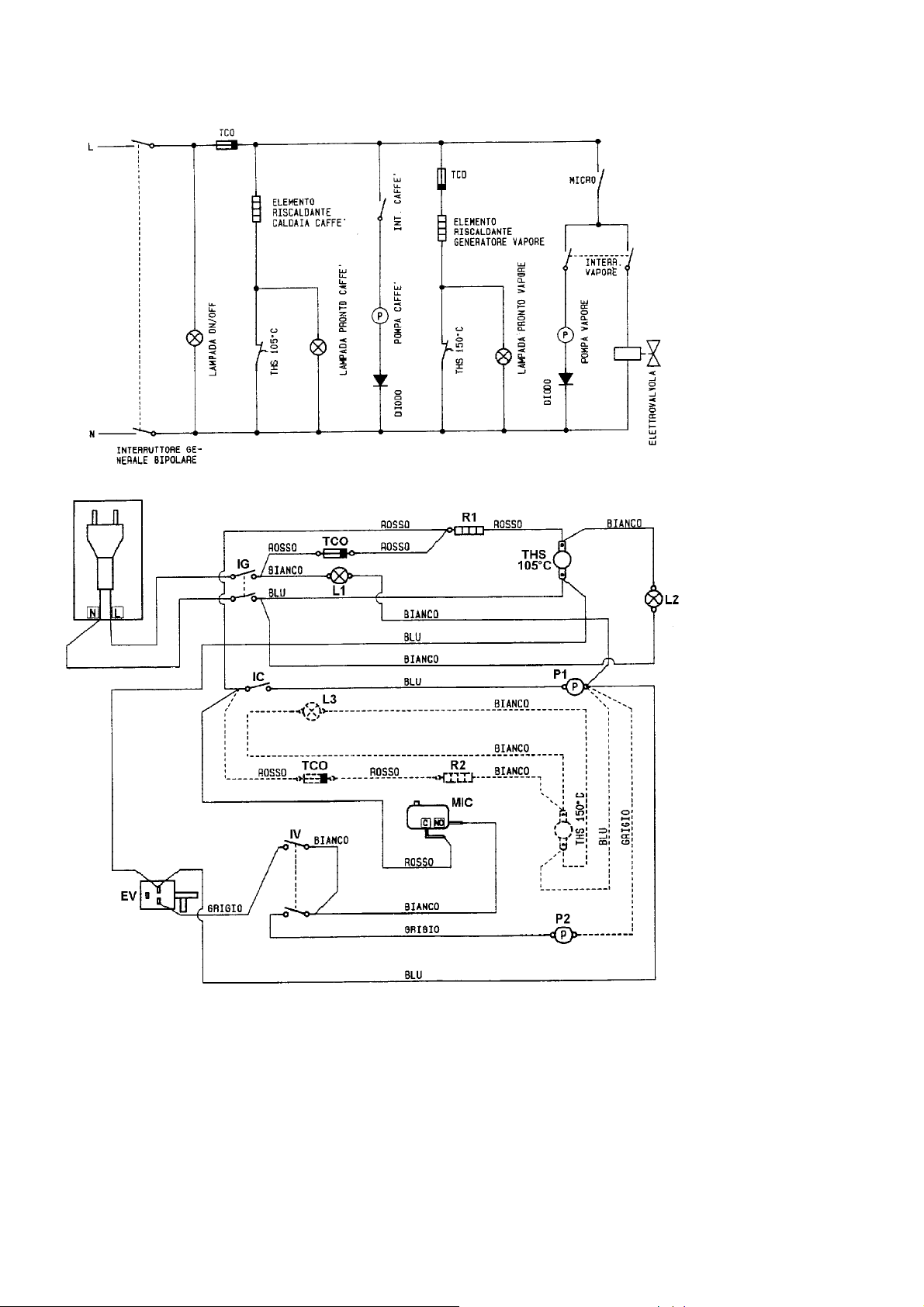

SCHEMI ELETTRICI / ELECTRICAL DIAGRAMS / SCHALTPLÄNE /

SCHEMAS ELECTRIQUES / ESQUEMAS ELECTRICOS

LEGENDA LEGEND FARBEN COULEURS COLORES

LEGENDA LEGEND LEGENDE LEGEND LEGENDA

EV Elettrovalvola Electrovalve Elektroventil Electrosoupape Electrovalvùla

IC Interruttore caffè Coffee switch Schalter "Kaffee" Interrpteur café Interruptor café

IG Interruttore "ON/OFF" Main switch "Ein/aus" Schalter Inter.gènèral Interruptor general

IV Interruttore vapore Steam switch Schalter "Dampf" Inter. vapeur Interruptor "Vapor"

L1 Spia acceso/spento On/off warning light Ein/aus Kontrolleuchte Voyant marche/arrêt Piloto encendido/apagado

L2 Lampada caffè "Ready"Pilot lamp Kaffee Kontrolleuchte Voyant prêt Piloto "listo"

L3 Lampada vapore "Steam"pilot lamp Dampf Kontrolleuchte Voyant "Vapeur" Piloto "Vapor"

MIC Microinterrut. vapore Microswitch Mikroschalter Microrpteur Microinterruptor

P1 Pompa caffè Coffeepump Kaffeepumpe Pompe café Bomba café

P2 Pompa vapore Steampump Dampfpumpe Pompe "Vapeur" Bompa "Vapor"

R1 Resistenza caffe' Coffee heating element Kaffee Heizelement Elément de chauffe Resistencia de calefación

R2 Generatore vapore Steam heating Dampf Heizelement Résistance à vapeur Resistencia "Vapour"

TCO TCO Thermal fuse Thermische Sicherung Fusibile Thermique Fusibile Témico

THS Termostato Thermostat Thermostat Thermostat Termostato

2

SCHEDA TECNICA 98033

Bianco White Weiß Blanc Blanco

Blu Blue Blau Bleu Azul

Grigio Gray Grau Gris Gris

Rosso Red Rot Rouge Rojo

Page 3

ACCESSIBILITA' / ACCESSIBILITY / ZUGÄNGLICHKEIT

ACCESSIBILITE / ACCESIBILIDAD

In order to gain access to the inner components of the appliance, it is necessary to proceed as follows:

1) Push the lever which secures the milk tank to the right and raise the tank at the same time.

2) Unscrew the four screws Torx (A) and remove them using the special insert (T20) for screws TORX.

3) Loosen and remove the two screws (B) which fix the cover on the rear side.

- Once the cover has been removed, one can easily gain access to all the main electric and hydraulic components of

the appliance.

IL CIRCUITO D'ACQUA / THE WATER CIRCUIT / DER WASSERKREISLAUF

Electrovalve with fit-in

Pump steam

section

è

è

è

over-pressure valve

è

è

steam outlet into

ð

ð

milk tank

è

Pump coffee

è

Anti drop device

section

è

è

è

è

è

Overpressure

discharge tube

ð

ð

ð

ð

ð

ð

suction tube with

filter

Heating element

coffee section

è

è

Heating element

steam section

3

SCHEDA TECNICA 98033

Page 4

DESCRIPTION OF MAIN COMPONENTS

IG: is the main switch, which gives power to the whole machine. When it is inserted, the control lamp L1 will light up

and the two heating elements will start working.

IC: starts the pump for the coffee section of the machine

IV: starts the pump for the steam section of the machine and opens the electrovalve in order to release the produced

steam, provided that the microswitch (MIC) is closed.

MIC: this microswitch is a safety device in case that the milk tank has been removed. It stops the steam pump and hinders

that the electrovalve can be opened releasing steam.

P1: is the pump for the coffee section. The pump has a diode in series with the motor windings which makes it impossible

to get a valuable resistance reading with the Ohmmeter.

P2: is the pump for the steam section. Also this pump has a build-in diode so that you can not measure the motor

resistance.

TCO: are thermal fuses which open contact in case the relative thermostat does not function anymore and hinders

that the heating element will burn out. Once that the TCO has intervened, it has to be replaced.

ANTI DROP DEVICE: The Bar M 200 is fitted with an anti drop device (see figure). This device is connected to the

outlet of the water pump and stops water dripping out from the boiler outlet when the coffee machine is on.

The anti drop device functions as follows:

- The water pump presses the water through the mouth of the no return valve into the boiler where it is been heated

and pressure builds up.

- The boiler outlet valve is designed to withstand a boiler pressure of 3.5-4.5 bar, which is the working pressure in

the coffee function. In the cappuccino function however the pressure rises above this level and water starts dripping out

from the boiler outlet.

-The spring behind the no return valve inside the anti drop device can withhold a pressure of 2.5 bar. If pressure

increases, the anti drop device opens and discharges slowly small quantities of water through the discharge tube,

stopping on this way the water drops at the boiler outlet.

- Is the boiler pressure drops below 2,5 bar (either by opening the steam valve or slowly releasing trough the anti drop

device), the spring closes the device again, preventing that the boiler runs out of water.

- If the water pressure inside the boiler rises to 21 bar an over pressure valve in the anti drop device releases the

overpressure through the discharge tube.

- If the bar loses water through the boiler outlet, it could be caused by the weekening of the boiler outlet

valve or an blockage of the anti drop device.

Ú

from

water pump

spring

(with opening

pressure of 2,5 bar)

no return valve

discharge tube

to water tank

Ú

to boiler

Ú

over pressure valve (21bar)

4

SCHEDA TECNICA 98033

Loading...

Loading...