Page 1

Dell Interactive Projector S520 Screen/Whiteboard

PTDRV

Page 2

Important Safety Instructions

WARNING: Failure to read, thoroughly

understand, and follow all instructions can result

in serious personal injury, damage to equipment,

or voiding of factory warranty! It is the installer’s

responsibility to make sure all components are

properly assembled and installed using the

instructions provided.

WARNING: Failure to provide adequate

structural strength for this component can

result in serious personal injury or damage to

equipment! It is the installer’s responsibility

to make sure the structure to which this

component is attached can support ve

times the combined weight of all equipment.

Reinforce the structure as required before

installing the component. The wall to which

the screen/whiteboard is being attached may

have a maximum drywall thickness of 5/8”

(1.6cm) for wood stud installation, and 1/2”

(1.3cm) minimum for steel stud installation.

WARNING: Use this screen/whiteboard

system only for its intended use as described

in these instructions. Do not use attachments

not recommended by the manufacturer.

WARNING: Do not use this product outdoors.

2

Page 3

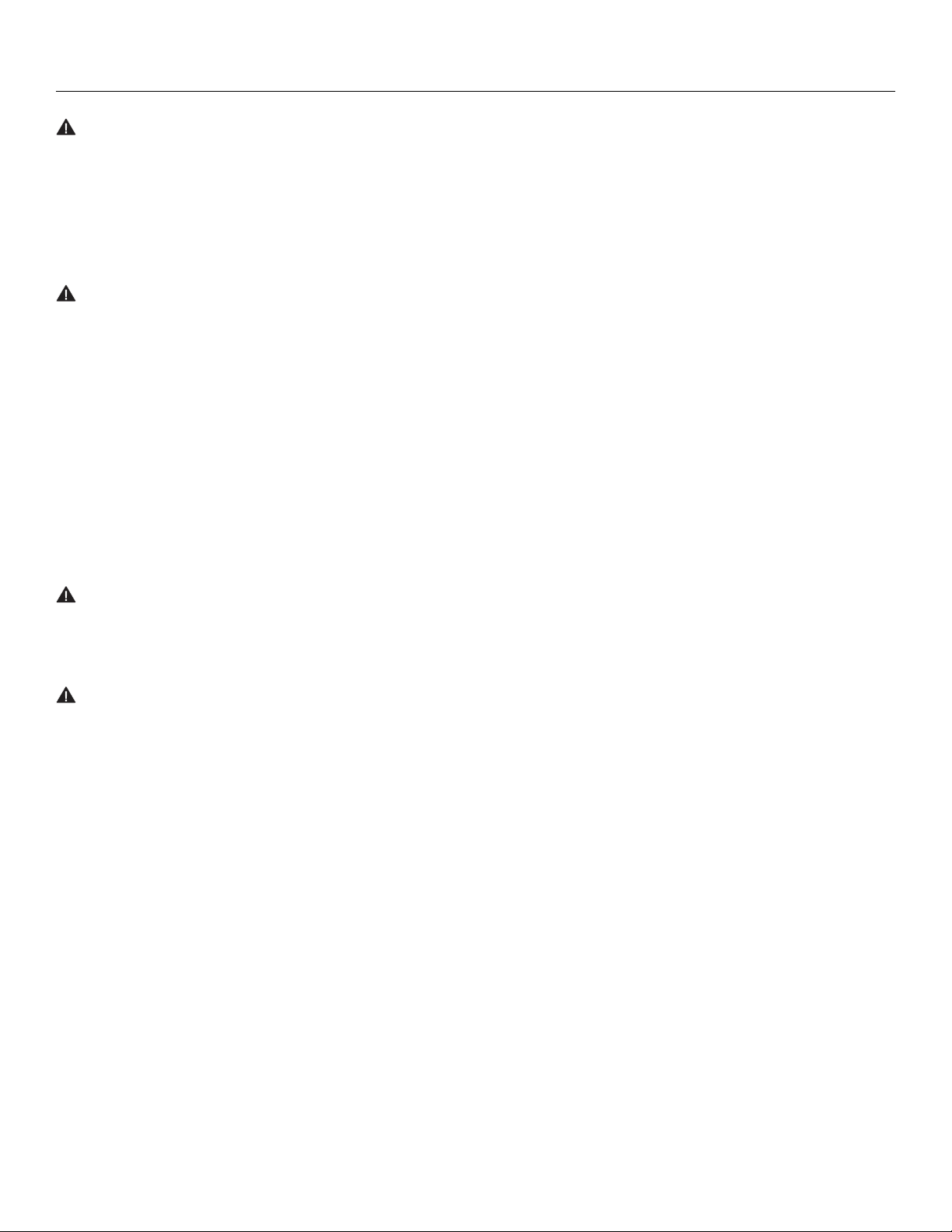

Product Dimensions

Front View

78.75 in. (2000.1 mm)

14.02 in.

(356.2 mm)

Side View

5.02 in.

(127.4 mm)

4.99 in.

(126.7 mm)

55.52 in.

(1410.1 mm)

80.37 in. (2041.4 mm)

41.60 in.

(1056.5 mm)

6.6 in. (167.52 mm)

38.77 in.

(984.8 mm)

15.23 in.

(386.8 mm)

1.21 in.

(30.65 mm)

Back View

1.67 in. (42.3 mm) 2.4 in. (60.9 mm)

Top View

28.07 in.

(712.9 mm)

3

Page 4

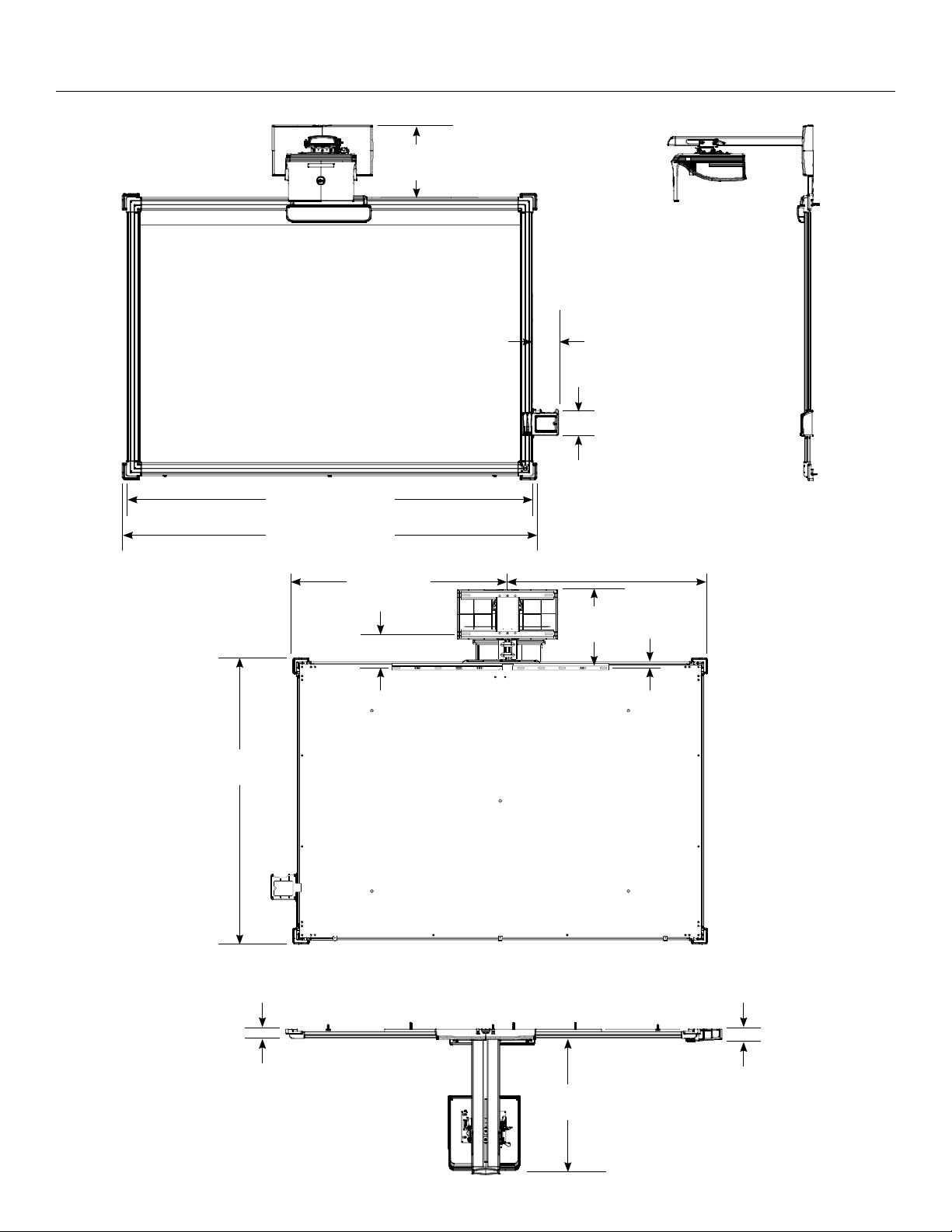

Tools Required for Installation

1/8 in. (wood)

1/2 in. (drywall)

8 mm (concrete)

6 mm (concrete –

AF6 toggler)

Parts

Included InstallationHardware

#8 x 3/4” Screw (1)

7/16” Wrench

Carpenter’s Level Ruler

#8 x 1” Screw (10)

#2 Phillips Screwdriver

Screen (1) Wall Bracket (1)

1/4” Washer (3)

1/4” x 1-1/2”

Lag Screw (3)

#8-10 Wall

Anchor (10)

Screen Bracket (5)

4

#8 X 1/2” Screw (7)

Sensor Cover (1)

Cable Cover

Clip (2)

Cleaning Cloth (1)

Cable Cover (1)

Marker Tray (1)

Page 5

Installation

1. Determine desired height of image (measured from oor)

(Figure 1).

2. Determine desired center of image area (Figure 1).

3. Measure 4-1/16” up from desired height (top) of image

and 4” to the right of center of screen and mark location

(Figure 1).

4. Determine location of studs behind drywall.

5. Drill one pilot hole into a wall stud at location

marked in Step 3 (Figure 1).

4 in.

4-1/16 in.

Height

from Floor

Center of

Screen

46-1/8 in.

73-3/4 in.

Studs

Floor

Figure 1

5

Page 6

Installation (continued)

NOTE: The (3) 1/4” x 1-1/2” bolts and (3) washers required in

Steps 6-8 are NOT INCLUDED with the screen/whiteboard

packaging.

6. Install (1) 1/4” x 1-1/2” bolt and (1) washer through middle

of bracket into previously drilled hole, leaving 1/2” of the

bolt extending from wall. Use carpenter’s level to make

sure bracket is properly level (Figure 2).

7. Position level on top of wall bracket. Move bracket until

level. Drill (2) holes for the other bolts in wall studs.

8. Install the other (2) 1/4” x 1-1/2” bolts and (2) 1/4” washers

in the previously drilled holes. Tighten all bolts against wall

bracket.

9. Measure down 52-1/4” on center and mark spot. Move

right and left of screen until wall studs are found and mark

(Figure 3).

Center of

Screen

Previously

Drilled Hole

Middle Fastener

Figure 2

Center of Screen

52-1/4 in.

Figure 3

6

Page 7

10. Install the (3) screen brackets using:

Wood or steel studs: (3) supplied #8 x 1” screws.

Concrete wall or no studs: (3) supplied #8-10 wall anchors

and (3) supplied #8 x 1” screws.

11. Install projector mount. Refer to the S520 Dual Stud Wall

Mount (MSP-DCCUST2) manual. Do not install

the (2) plastic covers for mount (Figure 4).

12. Run cables for projector up through hole in wall bracket and

cover to projector location (Figure 5).

Figure 4

Projector Signal Cable

IR Sensor Power

Projector Power Cord

Figure 5

7

Page 8

Installation (continued)

DETAIL E

SCALE 1 : 2

13. Mount screen onto wall bracket by hooking into the back groove of

the screen frame (Figure 6).

NOTE: The bumpers on the back side of the screen/whiteboard are

used to maintain planarity when pressure is applied to the projection

surface during usage. If the bumpers are obstructing installation on

your wall during Steps 13 and 14, they can be removed.

14. Secure bottom of screen to wall using (3) of the supplied #8 x 1/2”

screws through bottom brackets into the lower channel of the screen

frame (Figure 7).

15. Install the (2) top brackets (Figure 8) using:

Wood or steel studs: (2) supplied #8 x 1” screws.

Concrete wall or no studs: (2) supplied #8-10 wall anchors

and (2) supplied #8 x 1” screws.

16. Secure top of screen to wall using (2) of the supplied #8 x 1/2”

screws through top brackets into the top channel of the screen

(Figure 8).

Figure 6

Figure 7 Figure 8

E

8

Page 9

17. Secure marker tray to right side of screen frame

DETAIL F

SCALE 1 : 2

F

at desired height by using (2) of the supplied

#8 x 1/2” screws into the side channel of the

screen frame (Figure 9).

18. Secure marker tray (Figure 10) to wall using:

Wood or steel studs: (1) supplied #8 x 1” screw.

Concrete wall or no studs: (1) supplied #8-10 wall

anchor and (1) #8 x 1” screw.

19. Secure IR sensor bar (packaged with the S520

Projector) to screen by sliding it onto the metal

bracket. Insert safety screw through IR sensor

bar into bracket (Figure 11).

Attach marker

tray to frame with

(2) screws into the

side channel.

Figure 9

Safety

Screw

Figure 11Figure 10

9

Page 10

Installation (continued)

20. Attach sensor cover by snapping clips over screen frame.

Secure to frame by screwing down into the upper channel of

the screen frame with supplied #8 x 3/4” screw (Figure 12).

21. In between the projector mount and the IR sensor

cover, cable clips will be mounted to the wall for cable

management. Attach clips to the wall using:

Wood studs: (4) supplied #8 x 1” screws.

Concrete wall or no studs: (4) supplied #8-10

wall anchors and (4) supplied #8 x 1” screws.

When secure, route cables and cords behind the two cable

clips. Attach cable cover to the cable clips (Figure 13).

NOTE: Two cable clips are shipped with the screen/

whiteboard. For some installations, only one cable clip may

be needed.

22. Install projector mount covers and projector (Figure 14).

Refer to the S520 Dual Stud Wall Mount (MSP-DCCUST1)

manual.

DC Power

Cable for

Sensor

Figure 12

10

Figure 13

Figure 14

Page 11

Recommended Screen/Whiteboard

Markers

Recommended Screen/Whiteboard

Cleaning

This Dell S520 Screen/Whiteboard is a dual-purpose projection

screen and whiteboard. The surface of the screen/whiteboard

can be used with dry erase markers from a wide variety of

manufacturers and brands. Do not use permanent markers with

this product.

The supplied cleaning cloth can be used to clean marks on the

Dell S520 Screen/Whiteboard surface made by everyday dry

erase marker usage. To clean persistent marks from dry erase

markers, only use a standard dry erase marker cleaning solution

and the cleaning cloth. To clean permanent marks and other

unintentional marks on the surface, use a non-abrasive or nonscouring spray cleaning solution with the cleaning cloth or a

melamine foam cleaning pad.

11

Page 12

• 日本語の説明書は、http://

downloads.chiefmfg.com/MANUALS-I/PTDRV-

I.pdf をご覧ください。

• 访问 http://downloads.chiefmfg.com/MANUALS-

I/PTDRV-I.pdf 参考说明书译本。

• 如需翻譯版指示說明,請前往 http://

downloads.chiefmfg.com/MANUALS-I/PTDRV-

I.pdf。

• 번역된 안내서를 보려면 http://

downloads.chiefmfg.com/MANUALS-I/PTDRV-

I.pdf 을 ( 를 ) 방문하십시오 .

• โปรดเข้าไปที่ http://downloads.chiefmfg.com/

MANUALS-I/PTDRV-I.pdf

สําหรับคําแนะนําฉบับแปล

• Go to http://downloads.chiefmfg.com/MANUALS-

• 日本語の説明書は、http://

• Go to http://downloads.chiefmfg.com/MANUALS-

• 日本語の説明書は、http://

• Go to http://downloads.chiefmfg.com/MANUALS-

• 日本語の説明書は、http://

• Go to http://downloads.chiefmfg.com/MANUALS-

• 日本語の説明書は、http://

• Go to http://downloads.chiefmfg.com/MANUALS-

• 日本語の説明書は、http://

Installation Video

For further guidance and helpful information about installing an S520 Dual Stud Wall

Mount and S520 Screen/Whiteboard, please reference the installation video:

http://downloads.chiefmfg.com/MANUALS-I/Dell Interactive Solution.mp4

• Go to http://downloads.chiefmfg.com/MANUALSI/PTDRV-I.pdf for translated instructions.

• Entre en http://downloads.chiefmfg.com/

MANUALS-I/PTDRV-I.pdf para obtener las

instrucciones traducidas en su idioma.

• Bedienungsanleitungen in Ihrer Sprache finden

Sie auf http://downloads.chiefmfg.com/

MANUALS-I/PTDRV-I.pdf.

• Pour la traduction des instructions, allez à http://

downloads.chiefmfg.com/MANUALS-I/PTDRVI.pdf.

• Visitare il sito http://downloads.chiefmfg.com/

MANUALS-I/PTDRV-I.pdf per le istruzioni

tradotte.

• Visite http://downloads.chiefmfg.com/

MANUALS-I/PTDRV-I.pdf para obter instruções

traduzidas.

CW88R Rev. A00

24695 Rev00

http://

downloads.chiefmfg.com/MANUALS-I/PTDRVI.pdf をご覧ください。

访问 http://downloads.chiefmfg.com/MANUALSI/PTDRV-I.pdf 参考说明书译本。

http://

downloads.chiefmfg.com/MANUALS-I/PTDRVI.pdf。

번역된 안내서를 보려면 http://

downloads.chiefmfg.com/MANUALS-I/PTDRV-

I.pdf 을 ( 를 ) 방문하십시오 .

โปรดเข ้าไปที่ http://downloads.chiefmfg.com/

MANUALS-I/PTDRV-I.pdf

สําหรับคําแนะนําฉบับแปล

Loading...

Loading...