Dell Neworking S4810–Open Networking

(ON) Installation Guide

July 2014

Notes, Cautions, and Warnings

NOTE: A NOTE indicates important information that helps you make better use of your computer.

CAUTION: A CAUTION indicates either potential damage to hardware or loss of data and tells you

how to avoid the problem.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

Copyright © 2014 Dell Inc. All rights reserved. This product is protected by U.S. and international copyright and

intellectual property laws. Dell™ and the Dell logo are trademarks of Dell Inc. in the United States and/or other

jurisdictions. All other marks and names mentioned herein may be trademarks of their respective companies.

2014 - 07

Rev. A01

Contents

1 About this Guide....................................................................................................6

Information Symbols.............................................................................................................................6

Related Documents...............................................................................................................................7

2 The S4810–ON System........................................................................................8

Introduction...........................................................................................................................................8

Orderable S4810–ON Components...............................................................................................9

Prerequisite............................................................................................................................................9

Features............................................................................................................................................... 10

Ports.....................................................................................................................................................10

System Status.......................................................................................................................................10

LED Displays...................................................................................................................................10

3 Site Preparations................................................................................................. 13

Site Selection....................................................................................................................................... 13

Cabinet Placement.............................................................................................................................. 13

Rack Mounting.....................................................................................................................................14

Grounding (Optional).......................................................................................................................... 14

Fans and Airflow.................................................................................................................................. 14

Power...................................................................................................................................................14

Storing Components........................................................................................................................... 15

4 Install the S4810–ON........................................................................................ 16

Installing the S4810–ON Chassis in a Rack or Cabinet..................................................................... 16

Attaching the Mounting Brackets into a Two-Post Rack or Cabinet.......................................... 16

Installing the System into a Two-Post Rack or Cabinet...............................................................17

Attaching the Mounting Brackets into a Four-Post Rack or Cabinet..........................................18

Installing the System into a Four-Post Rack or Cabinet.............................................................. 19

Attaching the Ground Cable...............................................................................................................20

Installing the SFP+ and QSFP+ Optics................................................................................................21

Remove the SFP+ and QSFP+ Optics.......................................................................................... 22

Splitting QSFP+ Ports to SFP+ Ports.................................................................................................. 22

Supply Power and Power Up the System...........................................................................................22

AC Power.......................................................................................................................................22

After Installing the S4810–ON............................................................................................................23

5 Power Supplies....................................................................................................24

Components....................................................................................................................................... 24

Installing an AC Power Supply............................................................................................................25

Replacing an AC Power Supply.......................................................................................................... 26

6 Fans........................................................................................................................27

Components........................................................................................................................................27

Installing a Fan Module....................................................................................................................... 28

Replacing a Fan Module......................................................................................................................28

7 Console Ports...................................................................................................... 30

Accessing the RJ-45 Console Port (RS-232).....................................................................................30

Access the RJ-45 Console Port with a DB-9 Adapter....................................................................... 31

Before You Install an Operating System.............................................................................................31

ONIE Service Discovery.................................................................................................................31

8 Troubleshooting................................................................................................. 33

Command Line Interface Options......................................................................................................33

Viewing S4810-ON System Information............................................................................................33

Boot Processes....................................................................................................................................34

POST.............................................................................................................................................. 34

EDA (Quick Test Mode).................................................................................................................34

Restoring the S4810–ON Factory Defaults..................................................................................35

Capture Support Data from ONIE.................................................................................................35

Downloading the Diagnostic Package............................................................................................... 35

Troubleshooting Tools........................................................................................................................37

edatool...........................................................................................................................................38

pcitool............................................................................................................................................39

i2ctool............................................................................................................................................40

memtool........................................................................................................................................40

pltool..............................................................................................................................................42

gpiotool......................................................................................................................................... 45

storagetool.................................................................................................................................... 45

psutool...........................................................................................................................................46

fantool........................................................................................................................................... 46

temptool........................................................................................................................................ 47

nvramtool...................................................................................................................................... 47

Troubleshooting Issues for the S4810–ON System.......................................................................... 47

9 Specifications......................................................................................................49

Chassis Physical Design......................................................................................................................49

IEEE Standards...............................................................................................................................50

Agency Compliance............................................................................................................................50

USA Federal Communications Commission (FCC) Statement................................................... 50

European Union EMC Directive Conformance Statement..........................................................50

Japan: VCCI Compliance for Class A Equipment.........................................................................51

Korean Certification of Compliance.............................................................................................52

Safety Standards and Compliance Agency Certifications........................................................... 52

Electromagnetic Compatibility (EMC).......................................................................................... 52

Product Recycling and Disposal................................................................................................... 53

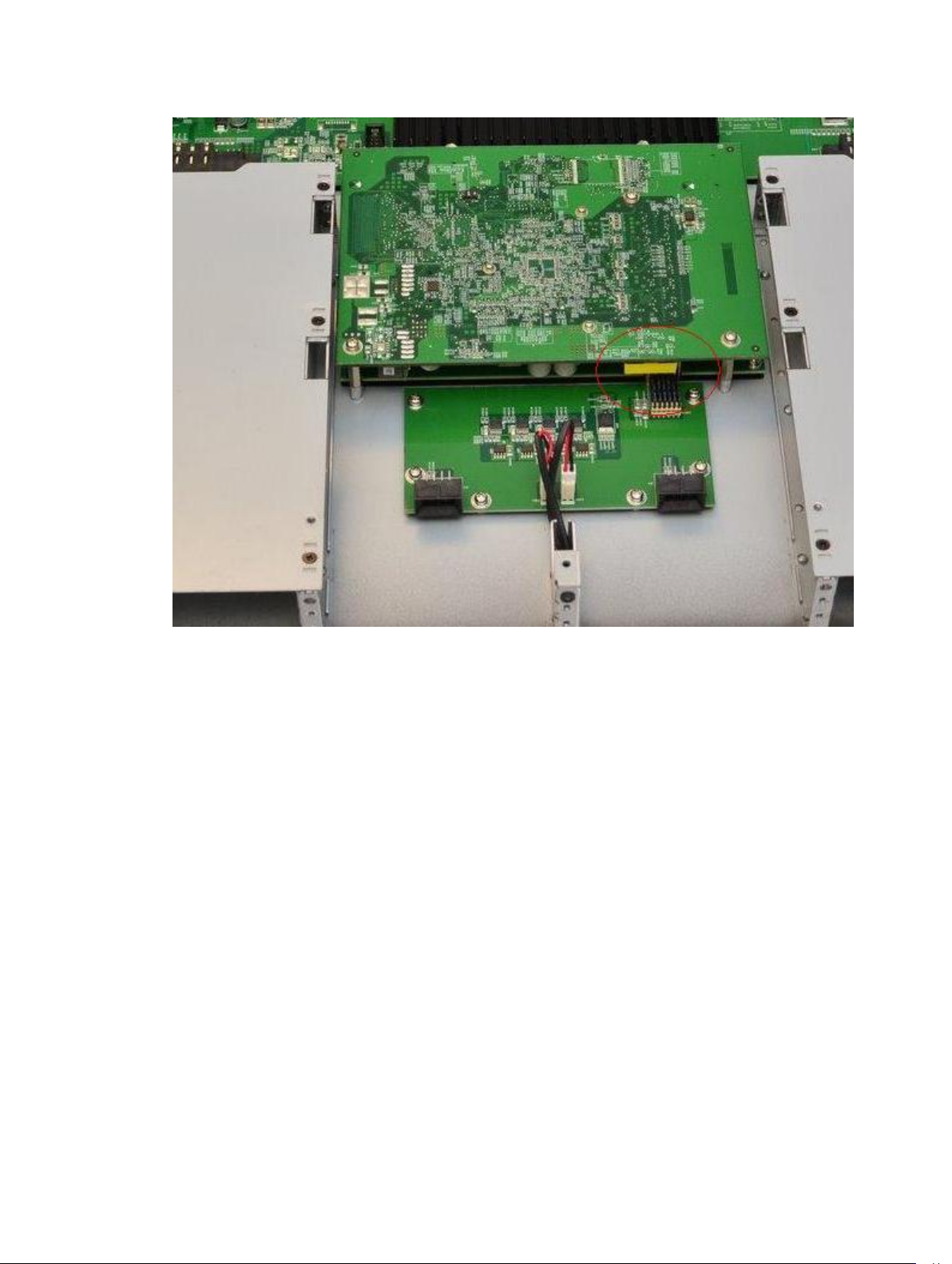

Removing the SD Card..................................................................................................................54

Replacing the Battery on the S4810–ON.....................................................................................54

10 Technical Support............................................................................................ 58

The iSupport Website..........................................................................................................................58

Accessing iSupport Services......................................................................................................... 58

Contacting the Technical Assistance Center.....................................................................................58

Requesting a Hardware Replacement................................................................................................59

1

About this Guide

This guide provides site preparation recommendations, step-by-step procedures for rack mounting and

desk mounting, inserting optional modules, and connecting to a power source.

.

CAUTION: To avoid electrostatic discharge (ESD) damage, wear grounding wrist straps when

handling this equipment.

WARNING: Only trained and qualified personnel can install this equipment. Read this guide

before you install and power up this equipment. This equipment contains two power cords.

Disconnect both power cords before servicing.

WARNING: This equipment contains optical transceivers, which comply with the limits of Class 1

laser radiation.

WARNING: When no cable is connected, visible and invisible laser radiation may be emitted from

the aperture of the optical transceiver ports. Avoid exposure to laser radiation and do not stare

into open apertures.

Information Symbols

This book uses the following information symbols:

NOTE: The Note icon signals important operational information.

CAUTION: The Caution icon signals information about situations that could result in equipment

damage or loss of data.

WARNING: The Warning icon signals information about hardware handling that could result in

injury.

WARNING: The ESD Warning icon requires that you take electrostatic precautions when handling

the device.

6

About this Guide

Related Documents

For more information about the S4810–ON system, refer to the Dell Networking S4810–Open

Networking (ON) Getting Started Guide.

NOTE: For the most recent documentation, visit iSupport: http://www.dell.com/support/my-

support.

About this Guide

7

2

The S4810–ON System

The following sections describe the Dell Networking S4810–ON system.

Introduction

The Dell Networking S4810–ON platform is a next-generation switch/router designed to meet the

requirements for distributed data center cores.

It is a one-rack unit (RU) chassis that supports 48 ports of 10GbE small form-factor pluggable plus (SFP+)

and four quad small form-factor pluggable plus (QSFP+) ports. For system access, the S4810–ON

includes an RS-232/RJ-45 console port and a management port for system access.

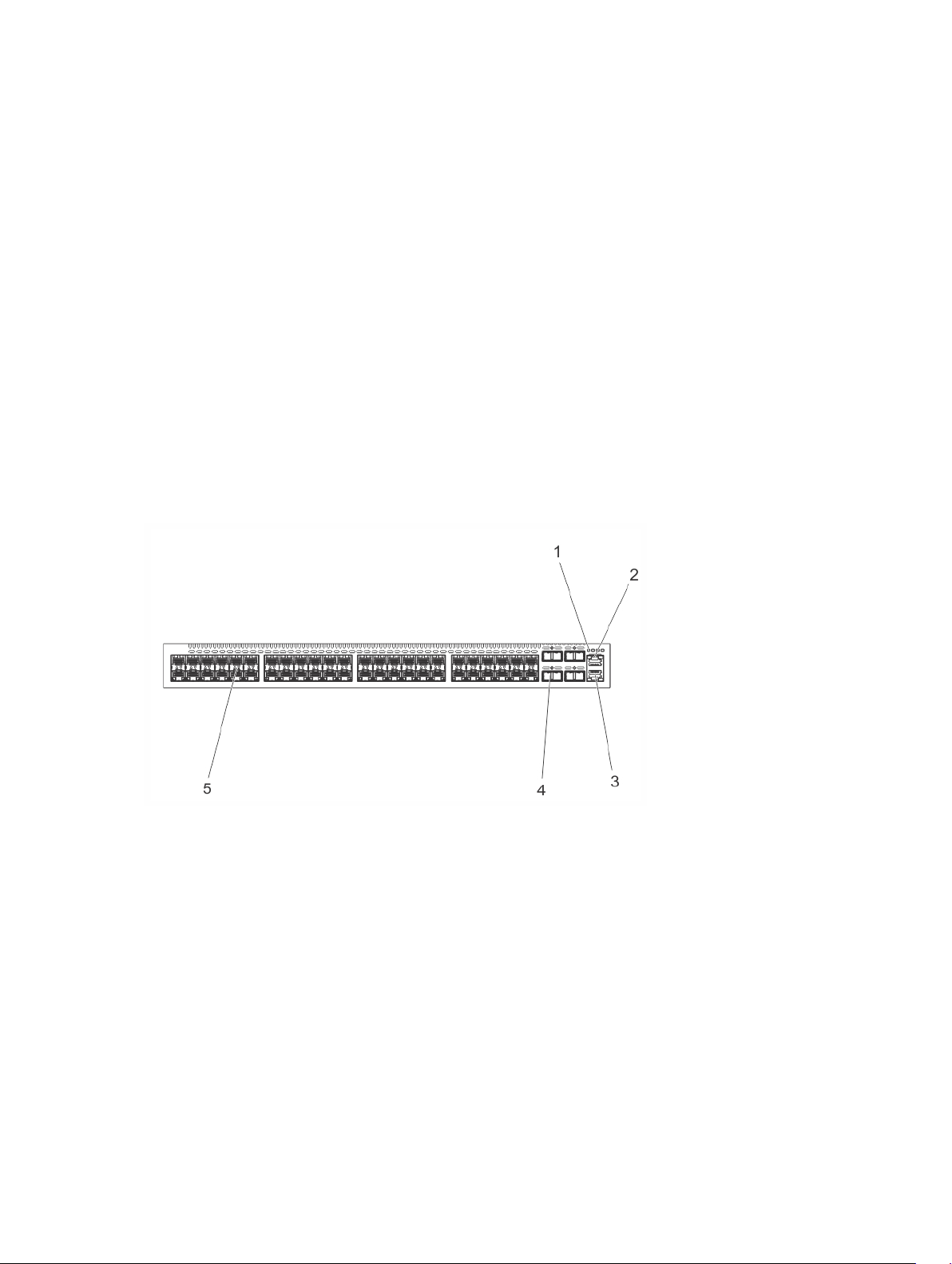

The S4810–ON input/output (I/O) side (shown in the following illustration) contains the 48 ports of

10GbE and four uplink ports of 40GbE QSFP+ autosensing ports and management ports.

Figure 1. S4810–ON I/O-Side View

1. System LEDs

2. RS-232/RJ-45 Console Port

3. Management (Ethernet) Port

4. 40GE QSFP+ Ports

5. 10GE SFP+ Ports

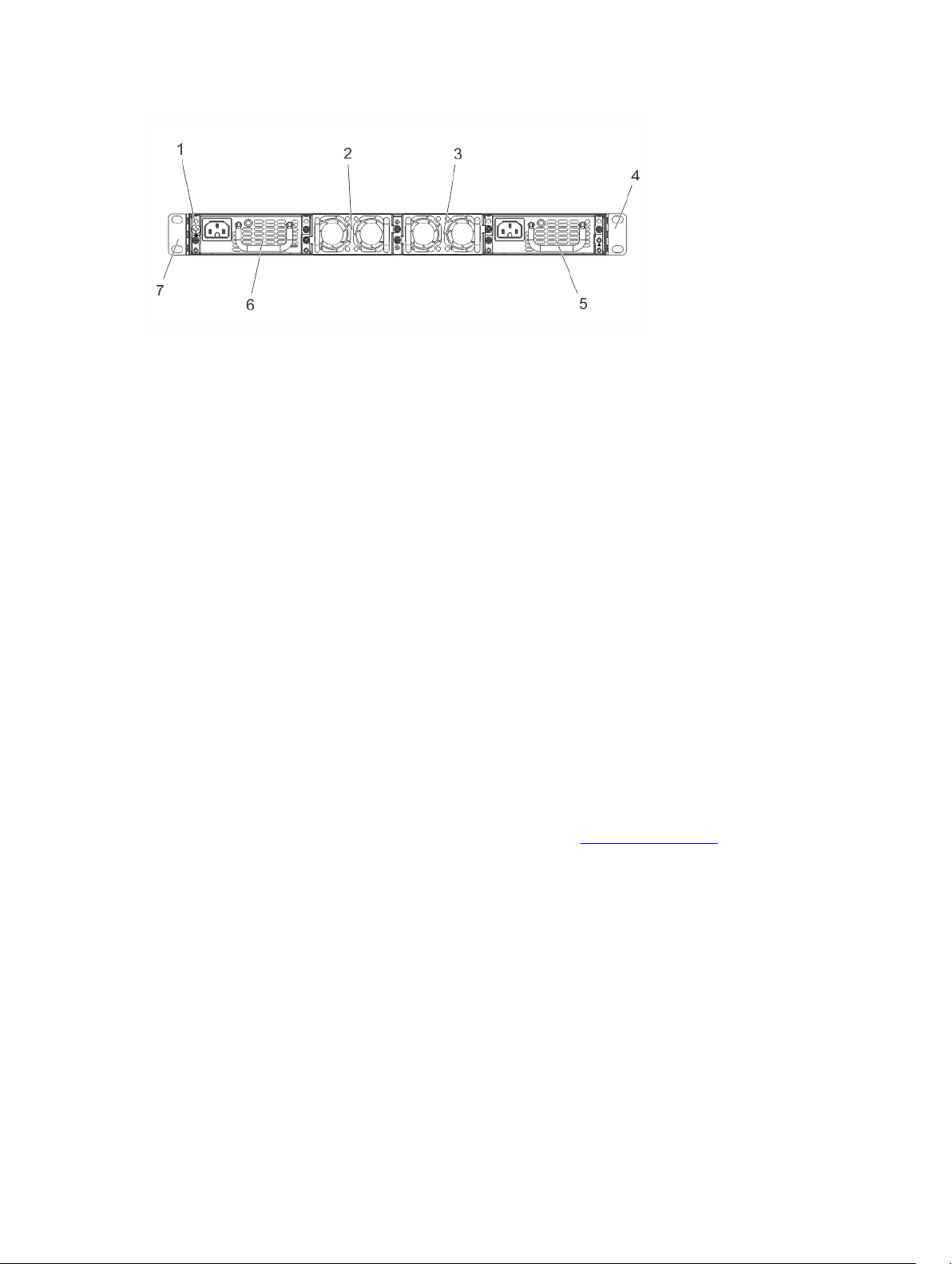

The S4810–ON power supply unit (PSU) side (shown in the following illustration) contains the PSU and

fan modules.

8

The S4810–ON System

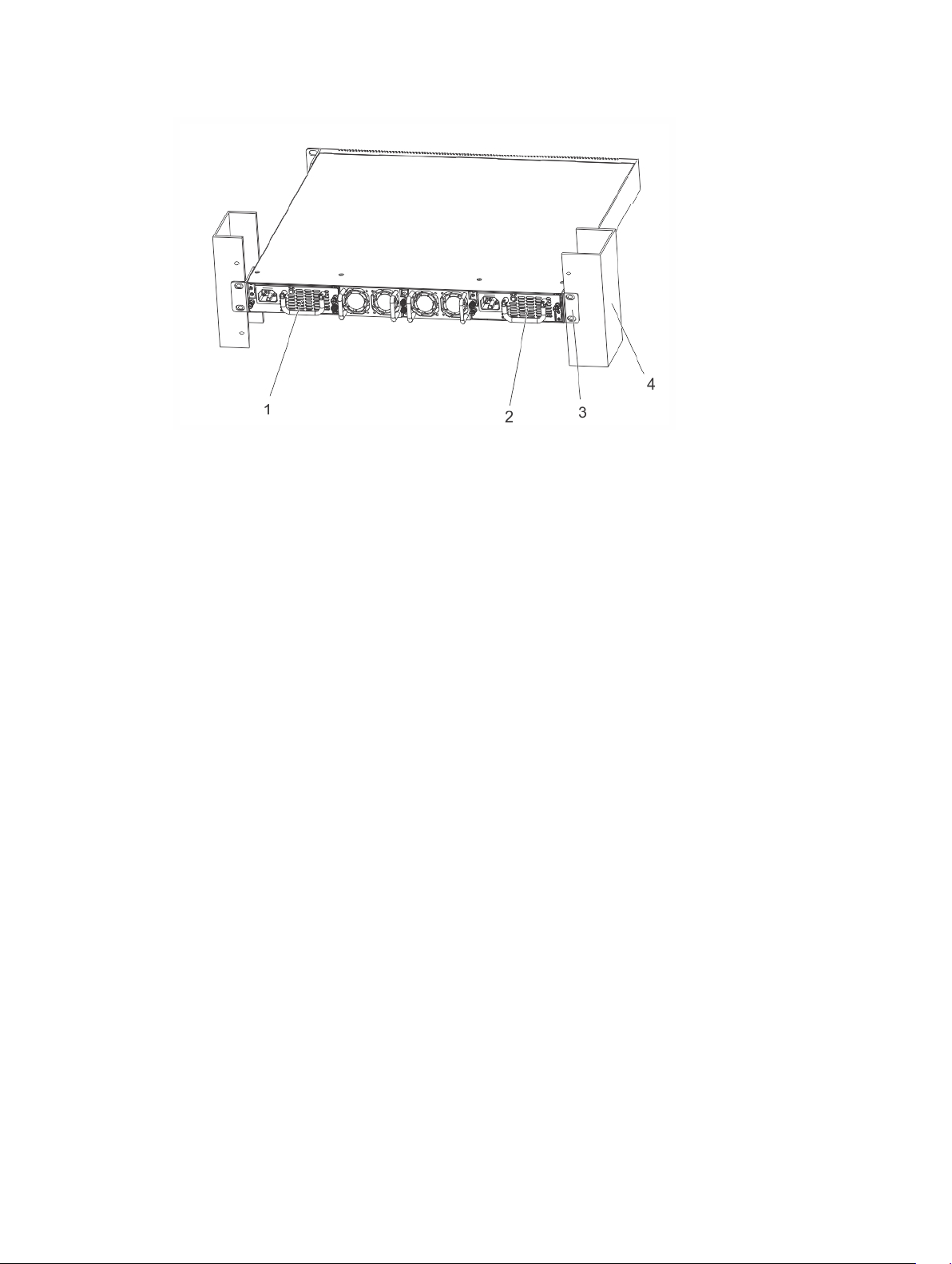

Figure 2. S4810–ON PSU-Side View

1. Mounting Bracket

2. Fan Module 1

3. Fan Module 2

4. Mounting Bracket

5. Power Supply (PSU2)

6. Power Supply (PSU1)

7. Grounding Screw

Orderable S4810–ON Components

You can order the S4810–ON system in several different configurations. You can also order optional

modules and optics separately.

You can order the following supported hardware components.

• 48-port 10G SFP+ with four QSFP+, 40G ports, one AC power supply and two fan subsystems (airflow

from I/O side to power supply side)

• 48-port 10G SFP+ with four QSFP+, 40G ports, one AC power supply and two fan subsystems (airflow

from power supply side to I/O side)

• S4810–ON Series — Fan with airflow from the I/O side to the PSU side

• S4810–ON Series — Fan with airflow from the PSU side to the I/O side

• S4810–ON Series — AC Power supply with airflow from the I/O side to the PSU side

• S4810–ON Series — AC Power supply with airflow from the PSU side to the I/O side

For a list of supported optics, refer to the S4810–ON data sheet at http://www.dell.com or contact your

Dell Networking representative.

Prerequisite

To successfully install the S4810–ON, ensure that you have the following components.

• S4810–ON chassis

• At least one grounded AC power source per chassis

• Cable to connect the AC power source to the chassis (US power cables included)

• Mounting brackets for rack installation (included)

• Screws for rack installation and #1 and #2 Phillips screwdrivers (not included)

The S4810–ON System

9

• Ground cable (not included, optional)

• Ground cable screws (included)

• Copper/fiber cables

Other optional components are:

• Additional power supply unit

• Additional fan module

• Additional mounting brackets (if installing in a four-post rack or cabinet)

Features

The S4810–ON offers the following features.

• S4810–ON CPU and switch processor

• Hot-swappable redundant power supply

• 19 inch rack-mountable

• Standard 1U chassis height

Ports

The S4810–ON offers the following ports.

• External Serial RS-232 port (RJ45 type)

• Remote management port

• 48–ports 10GbE and 4–ports 40GbE

• Universal serial bus (USB)-A port

• USB-B port

System Status

You can view S4810–ON status information using the light emitting diodes (LEDs).

LED Displays

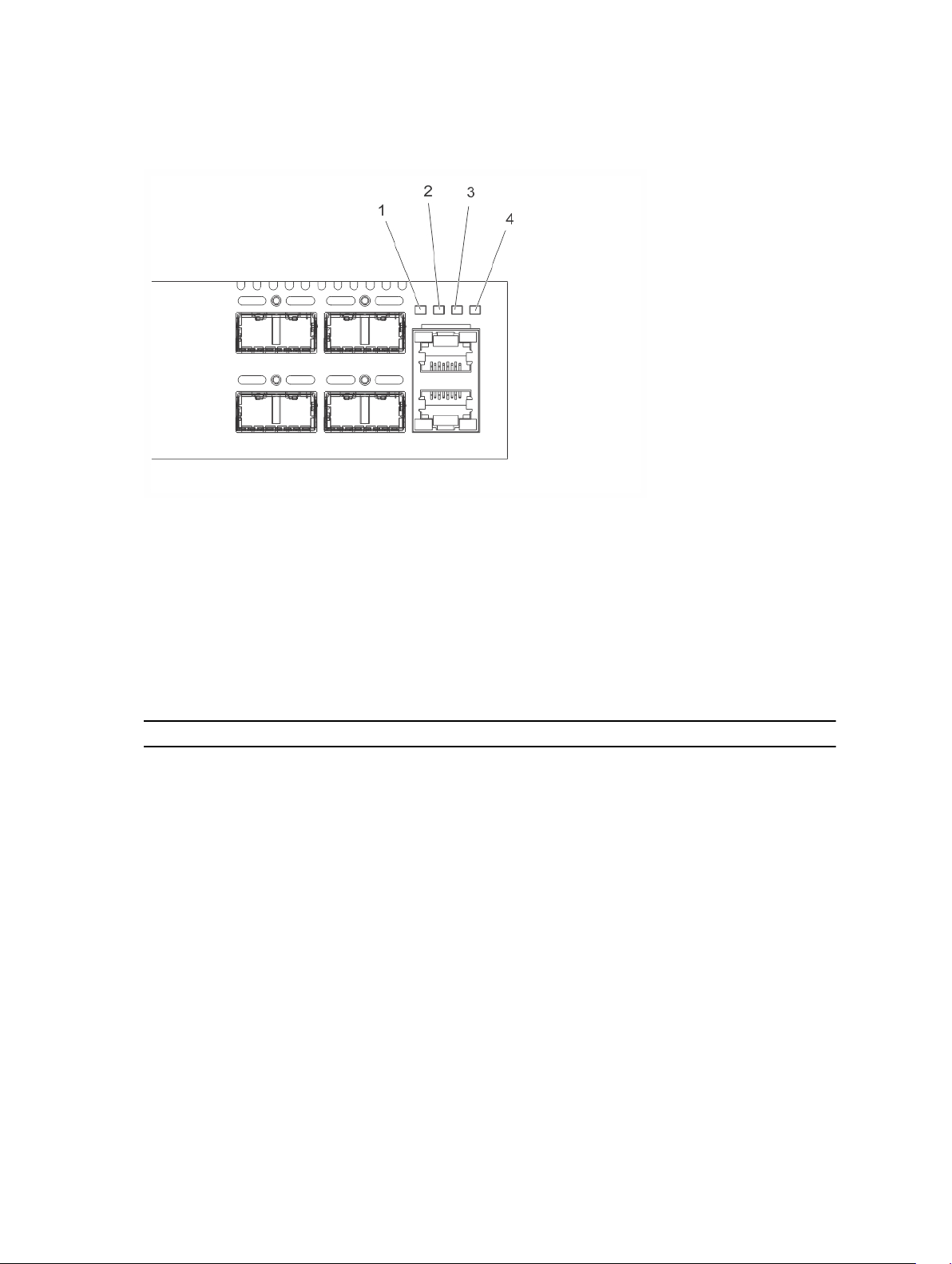

The S4810–ON includes LED displays on the I/O side of the chassis (shown in the following illustration).

When the S4810–ON powers up or reloads, the PSU LED is solid green. For additional LED information,

refer to your third-party operating software documentation.

The S4810–ON system LEDs are:

• System status (SYS)

• Stack Master indicator (MASTER)

• Fan status (FAN)

• Power status (PSU)

Additionally, the PSUs and fans have LEDs that indicate their individual status:

• PSU status

10

The S4810–ON System

• Fan tray status

• System

Figure 3. S4810–ON LEDs

1. SYS

2. MASTER

3. FAN

4. PSU

LED Behavior on the S4810–ON System

The following S4810–ON system LED behavior is seen during U-Boot and ONIE operations.

Table 1. S4810–ON LED Behavior

LED Description

System Status LED

Master LED

Fan LED

Power Status LED

• Off — no power

• Blinking green — booting or system is in

Diagnostic mode

• Solid green — normal operation

• Solid red — critical alarm

• Blinking red — non-critical alarm

• Solid green — system is in Stacking Master

mode

• Off — System is in Slave mode

• Solid green — Fan is powered on and running

at the expected RPM

• Solid yellow — Fan failed including

incompatible airflow direction

• Off — no power

• Solid green — normal operations

The S4810–ON System

11

LED Description

• Blinking yellow — one power supply has failed

12

The S4810–ON System

3

Site Preparations

The S4810–ON is suitable for installation as part of a common bond network (CBN).

You can install the system in:

• network telecommunication facilities

• data centers

• other locations where the National Electric Code (NEC) applies

For more information about S4810–ON specifications, refer to Specifications.

NOTE: Install the S4810–ON system into a rack or cabinet before installing any optional

components.

Site Selection

Install Dell Networking equipment in restricted access areas.

A restricted access area is one in which service personnel can only gain access using a special tool, lock,

key or other means of security and access is controlled by the authority responsible for the location.

Ensure that the area where you install your S4810–ON system meets the following safety requirements:

• Near an adequate power source. Connect the system to the appropriate branch circuit protection as

defined by your local electrical codes.

• Environmental temperature between 32° to 104°F (from 0° to 40°C).

• Relative humidity that does not exceed 85 percent noncondensing.

• In a dry, clean, well-ventilated and temperature-controlled room, away from heat sources such as hot

air vents or direct sunlight.

• Away from sources of severe electromagnetic noise.

• Positioned in a rack or cabinet, or on a desktop with adequate space in the front, rear, and sides of the

S4810–ON for proper ventilation and access.

Cabinet Placement

Install the S4810–ON only in indoor cabinets designed for use in a controlled environment.

Do not install the S4810–ON in outside plant cabinets. For cabinet placement requirements, refer to Site

Selection.

The cabinet must be a minimum cabinet size. Airflow must be according to the Electronic Industries

Alliance (EIA) standard. Ensure that there is a minimum of 5 inches (12.7 cm) between the intake and

exhaust vents and the cabinet wall.

Site Preparations

13

Rack Mounting

When you prepare your equipment rack, ensure that the rack is earth ground.

Ground the equipment rack to the same ground point the power service in your area uses. The ground

path must be permanent.

Grounding (Optional)

Use the S4810–ON in a common bond network (CBN).

Connect the grounding cables as described in Install the S4810-ON.

Fans and Airflow

The S4810–ON fans support two airflow options.

Be sure to order the fans suitable to support your site’s ventilation. Use a single type of airflow fan in your

system. Do not mix reverse and normal airflows in a single S4810–ON chassis.

• Normal — airflow is from the I/O panel to the power supply. The grab-handle is labeled Exhaust.

• Reversed — airflow is from the power supply to the I/O panel. The grab-handle is labeled Intake.

For proper ventilation, position the S4810–ON in an equipment rack (or cabinet) with a minimum of 5

inches (12.7 cm) of clearance around the exhaust vents. When you install two S4810–ON systems near

each other, position the two chassis at least 5 inches (12.7 cm) apart to permit proper airflow. The

acceptable ambient temperature ranges are listed in Specifications.

The fan speed increases and decreases automatically based on the system’s state and temperature. The

switch never intentionally turns off the fans.

Power

To connect the chassis to the applicable power source, use the appropriate power cord with the S4810–

ON. An AC power cord is included with the system.

When installing AC systems, follow the requirements of the National Electrical Code, ANSI/NFPA 70

where applicable.

The system is powered-up as soon as the power cord is connected between the system and the power

source.

CAUTION: Always disconnect the power cable before you service the power supply slots.

CAUTION: Use the power supply cord as the main disconnect device on the AC system. Ensure

that the socket-outlet is located/installed near the equipment and is easily accessible.

14

Site Preparations

Storing Components

If you do not install your S4810–ON and components immediately, Dell Networking recommends

properly storing the system and all optional components until you are ready to install them.

WARNING: ESD damage can occur when components are mishandled. Always wear an ESDpreventive wrist or heel ground strap when handling the S4810–ON and its accessories. After you

remove the original packaging, place the S4810–ON and its components on an antistatic surface.

Follow these storage guidelines:

• Storage temperature must remain constant ranging from -40° to 158°F (from -40°C to 70°C).

• Store on a dry surface or floor, away from direct sunlight, heat, and air conditioning ducts.

• Store in a dust-free environment.

Site Preparations

15

4

Install the S4810–ON

To install the S4810–ON system, Dell Networking recommends completing the installation procedures in

the order presented in this chapter.

Always handle the S4810–ON and its components with care. Avoid dropping the system or its field

replaceable units (FRUs).

This chapter describes the installation procedures as follows:

1. Installing the S4810–ON Chassis in a Rack or Cabinet

a. Attaching the Mounting Brackets into a Two-Post Rack or Cabinet

b. Installing the System into a Two-Post Rack or Cabinet

c. Attaching the Mounting Brackets into a Four-Post Rack or Cabinet

d. Installing the System into a Four-Post Rack or Cabinet

2. Attaching the Ground Cable

3. Installing the SFP+ and QSFP+ Optics

4. Splitting QSFP+ Ports to SFP+ Ports

5. Supply Power and Power Up the System

6. After Installing the S4810-ON

WARNING: ESD damage can occur if components are mishandled. Always wear an ESDpreventive wrist or heel ground strap when handling the S4810–ON and its components. As with

all electrical devices of this type, take all the necessary safety precautions to prevent injury when

installing this system.

Installing the S4810–ON Chassis in a Rack or Cabinet

The following sections describe how to install the S4810–ON in a rack or cabinet.

Attaching the Mounting Brackets into a Two-Post Rack or Cabinet

The S4810–ON ships with mounting brackets (rack ears) and the required screws for a two-post rack or

cabinet installation. The brackets are sent in a package with the system.

NOTE: Dell Networking recommends attaching the brackets at the power supply unit (PSU) side.

This set up provides the greatest weight support for the chassis in the rack or cabinet.

To attach the brackets to the system, follow these steps.

1. Take the brackets and screws out of their packaging.

2. Attach the brackets to the PSU sides of the system using four screws for each bracket. Attach the

bracket so that the “ear” is parallel to the PSU and the outside of the system.

16

Install the S4810–ON

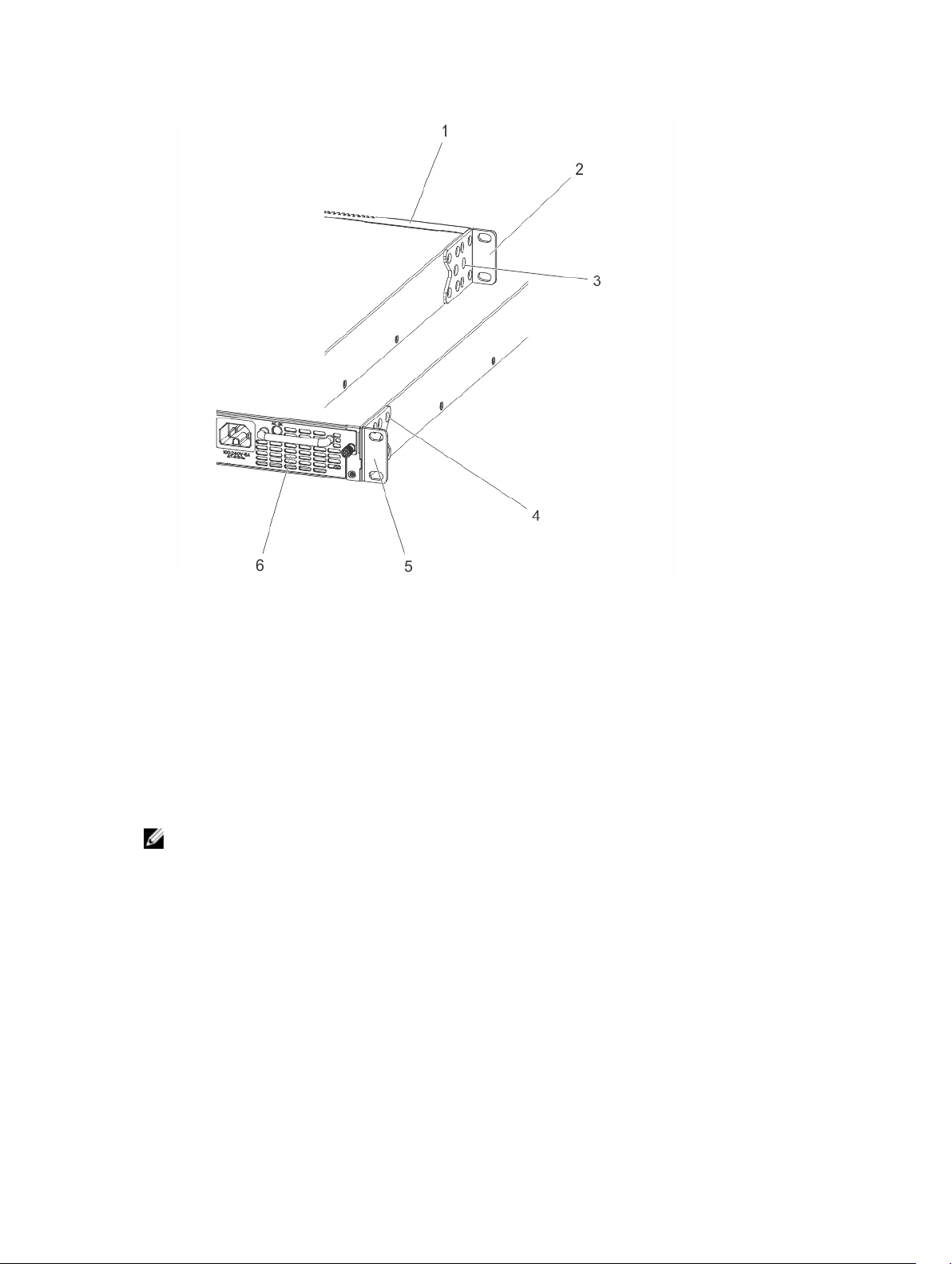

Figure 4. Attaching Mounting Brackets into a Two-Post Rack or Cabinet

1. View from the chassis I/O side 2. Connect to the Rack or Cabinet (ears)

3. Screws 4. Screws

5. Connect to the Rack or Cabinet (ears) 6. Power Supply

Installing the System into a Two-Post Rack or Cabinet

Ensure that there is adequate clearance surrounding the rack or within the cabinet to permit access and

airflow.

To install a system into a two-post 19-inch equipment rack using the already attached mounting

brackets, follow these steps.

NOTE: Dell Networking recommends using one person to hold the S4810–ON chassis in place

while another person attaches the brackets to the posts.

Attach the bracket “ears” to the rack or cabinet posts using the two screws for each bracket. Ensure

the screws are tightened firmly.

Install the S4810–ON

17

Figure 5. Installing the System into a Two-Post Rack or Cabinet

1. PSU1 2. PSU2

3. Rack Mounting Ears 4. Rack or Cabinet Post

Attaching the Mounting Brackets into a Four-Post Rack or Cabinet

The S4810–ON ships with mounting brackets (rack ears) and the required screws for a two-post rack or

cabinet installation.

To install the S4810–ON in a four-post rack or cabinet, you must order additional brackets separately.

Use the brackets included with the S4810–ON on the I/O side of system and use the brackets you

ordered separately on the PSU side of the system.

Unlike the two-post installation, the four-post installation requires attaching brackets to the rack prior to

installing the system.

To attach the brackets to the rack or cabinet, follow these steps.

1. Ensure that there is adequate clearance surrounding the rack or within the cabinet to permit access

and airflow.

2. Take the brackets and screws out of their packaging.

3. Attach the brackets to the PSU sides of the chassis using four screws for each bracket. Attach the

bracket so that the “ear” is parallel to the PSU and the outside of the chassis.

18

Install the S4810–ON

Figure 6. Attaching the Mounting Brackets into a Four-Post Rack or Cabinet

1. View from the chassis I/O side 2. Connect to the rack or cabinet

3. Screws 4. Screws

5. Connect to the rack or cabinet (ears) 6. Power Supply

4. Attach the long bracket to each side of the chassis using the provided countersink screws. Use two

screws on each side of the chassis.

5. Install the rack mount ears into the I/O-facing posts using rack mount screws (not included with the

system).

NOTE: Mount the rack mount ears so that the system is level when fully installed.

6. Using the provided pan head screws, attach the rack ears on the I/O facing posts to the long bracket

(attached to the system). To secure, tighten the pan head screws.

Installing the System into a Four-Post Rack or Cabinet

To install a system into a four-post equipment rack using the already attached mounting brackets, follow

these steps.

1. Ensure that there is adequate clearance surrounding the rack or within the cabinet to permit access

and airflow.

2. Install the system into the rack. Ensure the long brackets dock into the previously installed rack ears.

3. Fasten the system to the PSU-facing posts using rack mount screws (not included with the system).

Install the S4810–ON

19

Figure 7. Installing the System into a Four-Post Rack or Cabinet

1. I/O Side 2. Rack Ears

3. Long Brackets 4. Rack Ears

5. PSU Side

4. Use the provided pan head screws to attach the rack ears on the I/O-facing posts to the long bracket

previously attached to the system. Tighten the pan head screws to secure the system.

Attaching the Ground Cable

To attach the ground cable to the chassis, use a single M4x0.7 screw.

The cable itself is not included with the S4810–ON. To properly ground the chassis, Dell Networking

recommends using a 6AWG one-hole lug, #10 hole size, 63" spacing (not included in shipping). The onehole lug must be a UL recognized, crimp-type lug.

NOTE: The rack installation “ears” are not suitable for grounding.

CAUTION: Grounding conductors must be made of copper. Do not use aluminum conductors.

To connect the ground cable to the system, follow these steps.

NOTE: Coat the one-hole lug with an anti-oxidant compound prior to crimping. Also, bring any unplated mating surfaces to a shiny finish and coat with an anti-oxidant prior to mating. Plated mating

surfaces must be clean and free from contamination.

1. Take the one M4x0.7 screw from the package.

2. Cut the cable to the desired length. The cable length must facilitate proper operation of the fault

interrupt circuits. Dell Networking recommends using the shortest cable route allowable.

3. Attach the one-hole lug to the chassis using the supplied 10-32 screw with the captive internal tooth

lock washer. Torque the screw to 20 in-lbs.

20

Install the S4810–ON

Figure 8. Attaching the Ground Cable

a. Lug hole

b. Ground Screw

4. Attach the other end of the ground cable to a suitable ground point. The rack installation ears are not

a suitable grounding point.

Installing the SFP+ and QSFP+ Optics

The S4810–ON has 48 SFP+ optical ports and four QSFP+ optical ports.

WARNING: ESD damage can occur if components are mishandled. Always wear an ESDpreventive wrist or heel ground strap when handling the S4810–ON and its components.

WARNING: When working with optical fibers, follow all warning labels and always wear eye

protection. Never look directly into the end of a terminated or unterminated fiber or connector

as it may cause eye damage.

To install SFP+ or QSFP+ optics into an open port, follow these steps:

1. Position the optic so it is in the correct position. The optic has a key that prevents it from being

inserted incorrectly.

2. Insert the optic into the port until it gently snaps into place.

NOTE: Both rows of QSFP+ ports require that the 40G optics be inserted with the tabs facing

up.

Install the S4810–ON

21

Remove the SFP+ and QSFP+ Optics

Remove an optic by pushing the tab on the optic and sliding the optic from the port.

When removing optics with direct attach cables (DACs) from the port, pull the release tab firmly and

steadily. Prior to pulling the release tab, you may need to gently push the optic into the port to ensure it is

seated properly. Do not jerk or tug repeatedly on the tab.

Splitting QSFP+ Ports to SFP+ Ports

The S4810–ON supports splitting a single 40G QSFP+ port into four 10G ports using one of the

supported breakout cables.

Supply Power and Power Up the System

Supply power to the S4810–ON after it is mounted in a rack or cabinet.

Dell Networking recommends re-inspecting your system prior to powering up. Verify that:

• the equipment is properly secured to the rack and properly grounded.

• the equipment rack is properly mounted and grounded.

• the ambient temperature around the unit (which may be higher than the room temperature) is within

the limits specified for the S4810–ON.

• there is sufficient airflow around the unit.

• the input circuits are correctly sized for the loads and that you use sufficient over-current protection

devices.

• all protective covers are in place.

• blank panels are installed if you do not install optional modules.

NOTE: A US AC power cable is included for powering up an AC power supply. You must order all

other power cables separately.

NOTE: ESD damage can occur if components are mishandled. Always wear an ESD-preventive wrist

or heel ground strap when handling the S4810–ON system and its components.

AC Power

To add AC power, connect the power cord plug to each AC power connector. Make sure that the power

cord is secure (as shown in the following illustration).

CAUTION: Ensure that you correctly install the PSU. When correctly installed, the AC power

connector is on the left side of the PSU and the status LED is at the top of the PSU (as shown in

the following illustration).

As soon as the cable is connected between the S4810–ON and the power source, the system is

powered-up; there is no on/off switch.

22

Install the S4810–ON

Figure 9. AC Power Connection

1. Power Connection

2. LED

After Installing the S4810–ON

After you have securely installed and powered on the S4810-ON, to configure your system, refer to your

open network installation environment (ONIE)-compatible third-party operating system documentation

at http://onie.org.

Install the S4810–ON

23

5

Power Supplies

The S4810–ON supports two hot-swappable power supply units (PSUs) with integrated fans that provide

cooling for the system.

The S4810–ON supports AC power supplies with two air-flow directions (normal and reversed). Two

PSUs are required for full redundancy, but the system can operate with a single PSU.

NOTE: If you use a single PSU, install a blank plate in the other PSU slot. Dell Networking

recommends using power supply 2 (PSU2) as the blank plate slot.

The PSUs are field replaceable. When running with full redundancy (two power supplies installed and

running), you can remove and replace one PSU while the other PSU is running without disrupting traffic.

The power supply LED indicates the power supply status:

• Off — no power

• Solid Green — Power supply is present and working

WARNING: ESD damage can occur if components are mishandled. Always wear an ESDpreventive wrist or heel ground strap when handling the S4810–ON and its components.

WARNING: To prevent electrical shock, ensure that the S4810–ON is grounded properly. If you

ground your equipment incorrectly, excessive emissions may result. To ensure that the power

cables meet your local electrical requirements, use a qualified electrician.

Components

The following power supply options are available for the S4810–ON.

• AC power supply with integrated fan

• AC power supply with integrated reverse flow fan

Power supply 1 (PSU1) is on the left side of the chassis; power supply 2 (PSU2) is on the right side of the

chassis.

The PSUs in the S4810–ON are field replaceable. When both power supplies are installed and running,

you can remove one power supply without interrupting traffic.

The PSUs are in a single piece with the PSU fans. You can replace the fan trays individually, but you

cannot replace the fans that are attached to the PSUs — if the fans attached to the PSU fail, you must

replace the entire PSU. For fan tray replacement procedures, refer to Fans.

WARNING: Prevent exposure and contact with hazardous voltages. Do not attempt to operate

this system with the safety cover removed.

CAUTION: Remove the power cable from the PSU prior to removing the PSU. Also, do not

connect the power cable before you insert the PSU in the chassis.

24

Power Supplies

NOTE: To comply with the GR-1089 Lightning Criteria for Equipment Interfacing with AC Power

Ports, use an external SPD at the AC input of the router.

Installing an AC Power Supply

To install an AC power supply, follow these steps.

NOTE: The PSU slides into the slot smoothly. Do not force a PSU into a slot as this action may

damage the PSU or the S4810–ON chassis.

NOTE: Ensure that the PSU is correctly installed. When the PSU is correctly installed, the power

connector is on the left side of the PSU and the status LED is at the top of the PSU (refer to the

following illustration).

Figure 10. Installing an AC Power Supply

1. PSU1

2. Fan Module

3. Fan Module

4. Cable Connector

5. PSU2

6. Grab Handle

NOTE: If you use a single PSU, you must install a blank plate in the other PSU slot. Dell Networking

recommends using power supply 2 (PSU2) as the blank plate slot.

1. Take the PSU out of the shipping box.

2. Use the grab handle to slide the PSU into the power supply bay.

3. Tighten the securing screw on the side of the PSU. Ensure that the PSU is secure.

4. Attach the power cables.

NOTE: The system powers up as soon as the cables are connected between the power supply

and the power source.

Power Supplies

25

Replacing an AC Power Supply

To replace an AC power supply, follow these steps:

NOTE: The PSU slides into the slot smoothly. Do not force a PSU into a slot as this action may

damage the PSU or the S4810–ON chassis.

NOTE: If a PSU fails, you must completely replace it. There are no field serviceable components in

the PSU. To request a hardware replacement, refer to Technical Support.

NOTE: If you use a single PSU, you must install a blank plate in the other PSU slot. Dell Networking

recommends using power supply 2 (PSU2) as the blank plate slot.

1. Disconnect the power cable from the PSU.

2. Use the grab handle to slide the PSU out of the power supply bay.

3. Use the grab handle on the replacement PSU to slide it into the power supply bay.

4. Tighten the securing screws on the replacement PSU with a screwdriver. Ensure that the PSU is

secure.

5. Attach the power cord to the replacement PSU.

The system powers up as soon as the cables are connected between the power supply and the

power source.

26

Power Supplies

6

Fans

The S4810–ON comes from the factory with one power supply unit (PSU) and two fan modules installed

in the system.

If two or more fans are installed and running, the fan modules are hot-swappable.

NOTE: To run the system, both slots must have operating fan units. If a module is not installed in

each slot (either as part of the PSU or as an independent fan module), the system shuts down in one

minute.

In addition to the integrated fan/power supply modules, you can order and install fan modules separately.

The S4810–ON supports two airflow direction options. Do not mix airflow types in a chassis; you can use

only a single airflow direction in a chassis.

• Normal — airflow is from the I/O panel to the PSU

• Reversed — airflow is from the PSU to the I/O panel

Environmental factors can decrease the amount of time required between fan replacements. Check the

environmental factors regularly. An increase in temperature and/or particulate matter in the air might

affect performance (for example, new equipment installation).

CAUTION: Check the fans at six-month intervals and replace them as necessary. Regularly

monitor the speeds of the cooling fans in order to accurately determine replacement intervals.

Components

The following are the S4810–ON fan components.

• S4810–ON Fan module

• S4810–ON Fan module - Reverse flow

Fans

27

Figure 11. S4810–ON Fan Module

1. PSU1

2. Fan Module 1

3. Fan Module 2

4. Grab Handle

5. PSU2

Installing a Fan Module

The fan modules in the S4810–ON are field replaceable.

Module slot 0 is on the left side of the chassis; module slot 1 is on the right side of the chassis.

CAUTION: DO NOT mix airflow directions. Both fans must use the same airflow direction (reverse

or normal).

To install a fan module, follow these steps.

1. Take the fan module out of the shipping box.

2. Use the grab handle to slide the fan module into the bay.

3. Tighten the securing screws on the sides of the fan module.

Replacing a Fan Module

To replace a fan module, follow these steps.

1. Loosen the securing screws on the sides of the fan module.

CAUTION: You must complete steps 2 and 3 within one minute or the system powers down.

2. Use the grab handle to slide the fan module out of the bay.

3. Use the grab handle on the replacement module to slide it into the bay.

28

Fans

4. Tighten the captive screws on the replacement module with a screwdriver. Ensure that the module is

secure.

Fans

29

Console Ports

You can access the S4810–ON directly through the console port at the input/output (I/O) side of the

system.

Accessing the RJ-45 Console Port (RS-232)

The RS-232/RJ-45 console port is labeled on the upper-right-hand side of the S8410–ON chassis (the

I/O side) (as shown in the following illustration).

NOTE: Before starting this procedure, be sure that you have a terminal emulation program already

installed on your PC.

7

Figure 12. S4810–ON Serial Console Port Connector

1. RJ-45 Console Port

The following table lists the console port pinout assignments.

To access the console port, follow these steps.

1. Install an RJ-45 copper cable into the console port. Use a rollover cable to connect the S4810–ON

console port to a terminal server.

2. Connect the other end of the cable to the dumb terminal emulator (DTE) server.

3. Keep the default terminal settings on the console as follows:

• 115200 baud rate

• No parity

• 8 data bits

• 1 stop bit

30

Console Ports

• No flow control

Access the RJ-45 Console Port with a DB-9 Adapter

If the DTE has a DB-9 interface, you can connect to the console using an RJ-45 to DB-9 adapter along

with the RJ-45 rollover cable.

The following table lists the pin assignments.

Table 2. Pin Assignments Between the Console and a DTE Terminal Server

Console Port RJ-45 to RJ-45

Rollover Cable

Signal RJ-45 Pinout RJ-45 Pinout DB-9 Pin Signal

RTS 1 8 8 CTS

NC 2 7 6 DSR

TxD 3 6 2 RxD

GND 4 5 5 GND

GND 5 4 5 GND

RxD 6 3 3 TxD

NC 7 2 4 DTR

CTS 8 1 7 RTS

RJ-45 to RJ-45

Rollover Cable

RJ-45 to DB-9

Adapter

Terminal Server

Device

Before You Install an Operating System

After powering on the system, the S4810-ON uses the U-Boot bootloader and goes through a power-on

self-test (POST). POST runs every time the switch is initialized and checks hardware components to

determine if the switch is fully operational before completing the boot process. Your system comes with

open networking installation environment (ONIE) installed.

During initial setup, the system boots to ONIE Install. ONIE Install boots with ONIE Discovery to the ONIE

console (ONIE:).

ONIE Service Discovery

ONIE attempts to locate the installer through a number of discovery methods, as shown. To download

and run an installer, the ONIE Service Discovery feature uses the first successful method found.

1. Passed from the boot loader.

2. Search locally attached storage devices for one of the ONIE default installer filenames (for example,

USB).

3. Exact the URLs from DHCPv4.

4. Inexact URLs based on DHCPv4 responses.

5. Query to IPv6 link-local neighbors using HTTP for an installer.

6. TFTP waterfall — from DHCPv4 option 66

Console Ports

31

Example of the ONIE Commands

If none of the ONIE Service Discovery methods are successful, you can disable is using the oniediscovery-stop command.

You can install an operating system manually from HTTP, FTP, or TFTP using the onie-nos-install

<URL> command.

The ONIE Install environment uses DHCP to assign an IP address to the management interface (eth0). If

that fails, it uses the default IP address 192.168.3.10/255.255.255.0.

To display the IP address, use the ifconfig eth0 command.

Example of the ONIE ifconfig eth0 command.

ONIE:/ # ifconfig eth0

eth0 Link encap:Ethernet HWaddr 90:B1:1C:F4:9C:76

inet addr:10.11.53.33 Bcast:10.255.255.255 Mask:255.0.0.0

inet6 addr: fe80::92b1:1cff:fef4:9c76/64 Scope:Link

UP BROADCAST RUNNING MULTICAST MTU:1500 Metric:1

RX packets:18 errors:0 dropped:0 overruns:0 frame:0

TX packets:24 errors:0 dropped:0 overruns:0 carrier:0 collisions:0

txqueuelen:1000

RX bytes:1152 (1.1 KiB) TX bytes:6864 (6.7 KiB)

Interrupt:21 Memory:ff300000-ff320000

To assign an IP address to the management interface (eth0) and verify the network connectivity, use the

ifconfig eth0 <ip address> command.

Example of the ONIE ifconfig eth0 <ip address> command.

ONIE:/ # ifconfig eth0 10.11.53.33/16

Verify the network connection with ping.

ONIE:/ # ping 10.11.8.12

PING 10.11.8.12 (10.11.8.12): 56 data bytes

64 bytes from 10.11.8.12: seq=0 ttl=62 time=1.357 ms

64 bytes from 10.11.8.12: seq=1 ttl=62 time=0.577 ms

^C

32

Console Ports

8

Troubleshooting

This chapter describes system diagnostics and troubleshooting. After running the diagnostic tools, your

system displays pass or fail test results. If all tests pass, the diagnostic tools exit normally. If a test fails,

each diagnostic tool offers a different result.

NOTE: The troubleshooting package includes a README file that lists the tools version and the

overall troubleshooting package version. For more information, refer to this README file.

NOTE: To download the Release Notes, go to http://www.dell.com/support.

This system uses the following troubleshooting tools:

• Power-On Self Test (POST) diagnostic — Automatically runs during the system power-on at the BIOS

or U-boot level. This tool tests for catastrophic hardware failures that prevent booting the system. If a

test fails, the system halts from booting further. The error code is saved in CMOS for the next boot.

There is no physical alarm indication.

• Extended diagnostic application (EDA) — Tests the hardware for system failures. This is an ondemand diagnostic tool. EDA verifies platform-specific hardware. There are options to perform

diagnostics from a Quick Test to a thorough Intrusive test. If a test fails, you can halt or continue

boot-up. If you select the halt-on failure option, EDA testing does not continue. If you do not

select the halt-on failure option, EDA testing continues. Test results are saved in a user-defined

storage area. There is no physical alarm indication.

NOTE: To test your hardware, Dell Networking strongly recommends using the EDA tool.

NOTE: EDA runs in the ONIE environment, not in the networking operating system. You must be at

the ONIE prompt to run EDA.

Command Line Interface Options

Each diagnostic tool has the following options:

Command Description

—h

test

Help topics. Use help to find software-specific tools.

Tests against the preconfigured test file.

Viewing S4810-ON System Information

To view your system information; for example, the model, part number, serial number, and service tag,

follow these steps.

1. Reboot your system and enter U-Boot mode.

2. Enter the sys_eeprom command.

Example of the sys_eeprom Command

dell_s4810_on-> sys_eeprom

TlvInfo Header:

Troubleshooting

33

Id String: TlvInfo

Version: 1

Total Length: 73

TLV Name Code Len Value

-------------------- ---- --- -----

MAC Addresses 0x2A 2 65

Base MAC Address 0x24 6 00:E0:0C:02:01:FD

Vendor Name 0x2D 4 Dell

Product Name 0x21 8 S4810-ON

Part Number 0x22 10 7590009602

Serial Number 0x23 13 HADL127B20077

Manufacturer 0x2B 1 1

Service Tag 0x2F 2 123A1B2

Label Revision 0x27 3 A00

CRC-32 0xFE 4 0x4AF6A929

Checksum is valid.

Boot Processes

After the BIOS or U-Boot hardware verifications, POST tests run to verify the CPU and memory prior to

booting the system software.

After POST testing, there are three additional types of diagnostic tools you can use for testing your

system.

• Manual diagnostic boot process — To run additional testing, manually download and run the EDA

tool. The EDA tool reports and logs pass/fail results.

• ONIE with EDA — EDA is installed; you do not have to manually download the tool. Select the

diagnostic option at boot-up. You can run this tool without a management interface.

• Autorun EDA — EDA is installed; you do not have to manually download the tool. Select the diagnostic

option at boot-up. You can run this tool without a management interface. The system always

launches EDA in Quick Test mode to verify the hardware components before loading the software. If

there is a failure at boot-up, based on the EDA configuration, the software may or may not continue

the boot process.

POST

POST diagnostics verifies system memory before the software loads. Test configuration parameters are

saved in CMOS for the next boot-up.

EDA (Quick Test Mode)

Quick Test mode runs basic device access tests for the system hardware to verify that the device is active

and responding.

In Quick Test mode, the EDA tool quickly tests if the hardware components are accessible. It confirms

the components respond to read access and in some cases, simple write access. Tests are read-only and

non-destructive (except the memtool command, which does allow read/write operations).

34

Troubleshooting

Restoring the S4810–ON Factory Defaults

If you need to restore the S4810-ON factory defaults, reboot the system to ONIE Rescue using the run

onie-rescue or run onie-diag commands. If it is not possible to do this with the operating system

you installed, reboot the system and hit any key to stop autoboot.

CAUTION: Restoring factory defaults erases any installed operating system and requires a long

time to erase storage.

1. To restore the S4810–ON factory defaults, run this command.

U-boot mode

run onie_rescue OR run onie_diag

ONIE Rescue bypasses the installed operating system and boots the system into ONIE until you

reboot the system.

2. Press ENTER to activate the console.

Example of the ONIE-uninstall Command

After ONIE Rescue completes, the system resets and boots to the ONIE console.

ONIE:/ # onie-uninstall

Erasing unused NOR flash region

Erasing 128 Kibyte @ 20000 - 100% complete.

Erasing internal mass storage device: /dev/mmcblk0 (7832MB)

Percent complete: 100%

Capture Support Data from ONIE

To capture support data from ONIE, use the following commands.

• To capture support data to the screen, use the ONIE:/ # dmesg command.

• To capture support data to the onie-support.tar.bz2 gzip file, use the ONIE:/ # onie-

support <output_directory> command.

Downloading the Diagnostic Package

To download the diagnostic package, follow these steps.

1. Assign an ip address to the management interface and verify the network connectivity.

ONIE:/ # ifconfig eth0 10.11.53.33/16

ONIE:/ #

ONIE:/ #

ONIE:/ # ifconfig eth0

eth0 Link encap:Ethernet HWaddr 90:B1:1C:F4:9C:76

inet addr:10.11.53.33 Bcast:10.255.255.255 Mask:255.0.0.0

inet6 addr: fe80::92b1:1cff:fef4:9c76/64 Scope:Link

UP BROADCAST RUNNING MULTICAST MTU:1500 Metric:1

RX packets:18 errors:0 dropped:0 overruns:0 frame:0

TX packets:24 errors:0 dropped:0 overruns:0 carrier:0

collisions:0 txqueuelen:1000

RX bytes:1152 (1.1 KiB) TX bytes:6864 (6.7 KiB)

Interrupt:21 Memory:ff300000-ff320000

Troubleshooting

35

ONIE:/ # ping 10.11.8.12

PING 10.11.8.12 (10.11.8.12): 56 data bytes

64 bytes from 10.11.8.12: seq=0 ttl=62 time=1.357 ms

64 bytes from 10.11.8.12: seq=1 ttl=62 time=0.577 ms

^C

2. Upgrade the DIAG Installer. Again, boot to ONIE Rescue mode and install onie diag installer

NOTE: The command onie-self-update, shown in bold, is not available in S4810-ON ONIE

version 1.0.0.1, instead use update_url ONIE:/bin # update_url.

ONIE:/ # onie-self-update tftp://10.11.227.233/ON-DIAG/S4810/JUL-08-2014/diaginstaller-powerpc-dell_s4810_on_p2020-r0.bin

Stopping: discover... done.

Info: Fetching tftp://10.11.227.233/ON-DIAG/S4810/JUL-08-2014/diaginstaller-powerpc-dell_s4810_on_p2020-r0.bin ...

ON-DIAG/S4810/JUL-08 100% |*******************************| 1361k 0:00:00

ETA

ONIE: Executing installer: tftp://10.11.227.233/ON-DIAG/S4810/JUL-08-2014/

diag-installer-powerpc-dell_s4810_on_p2020-r0.bin

Verifying image checksum ... OK.

Preparing image archive ...

Preparing image archive ...sed -e '1,/^exit_marker$/d' /installer | tar xf

- OK.

Diag Installer: platform: powerpc-dell_s4810_on_p2020-r0

Erasing block: 128/128 (100%)

Writing kb: 16376/16384 (99%)

Verifying kb: 16376/16384 (99%)

ONIE:/ # umount: can't remount rootfs read-only

The system is going down NOW!

Sent SIGTERM to all processes

Sent SIGKILL toRestarting system.

Reset via the platform CPLD

3. Start ONIE diagnostics.

Platform specific diag found and launching.....

*****************************

* Diagnostics Application *

*****************************

Dell Diag ./edatool version 1.3, package 1.5 2014/7/23

Dell Diag ./fantool - version 1.3 package 1.5 2014/7/23

Dell Diag ./gpiotool - version 1.3 package 1.5 2014/7/23

Dell Diag ./i2ctool - version 1.3 package 1.5 2014/7/23

Dell Diag ./memtool - version 1.4 package 1.5 2014/7/23

Dell Diag ./nvramtool - version 1.4 package 1.5 2014/7/23

Dell Diag ./pcitool - version 1.3 package 1.5 2014/7/23

Dell Diag ./pltool - version 1.4 package 1.5 2014/7/23

Dell Diag ./psutool - version 1.3 package 1.5 2014/7/23

Dell Diag ./temptool - version 1.3 package 1.5 2014/7/23

Testing PCI devices:

+ Checking PCI 00:00.0, ID=57197000 ....................... Passed

+ Checking PCI 01:00.0, ID=e41445b8 ....................... Passed

PCI devices: Overall test results --------------------- >>> Passed

Testing I2C devices:

Checking I2C devices on bus 0:

+ Checking Dev found @ 0x52 ... ------ ------ 0x52 ..... Passed

+ Checking Dev found @ 0x54 ... ------ ------ 0x54 ..... Passed

+ Checking Dev found @ 0x55 ... ------ ------ 0x55 ..... Passed

+ Checking Dev found @ 0x56 ... ------ ------ 0x56 ..... Passed

+ Checking Dev found @ 0x57 ... ------ ------ 0x57 ..... Passed

+ Checking Dev found @ 0x68 ... ------ ------ 0x68 ..... Passed

Checking I2C devices on bus 1:

36

Troubleshooting

+ Checking Dev found @ 0x40 ... ------ ------ 0x40 ..... Passed

+ Checking Dev found @ 0x42 ... ------ ------ 0x42 ..... Passed

+ Checking Dev found @ 0x49 ... ------ ------ 0x49 ..... Passed

+ Checking Dev found @ 0x4a ... ------ ------ 0x4a ..... Passed

+ Checking Dev found @ 0x4c ... ------ ------ 0x4c ..... Passed

+ Checking Dev found @ 0x4d ... ------ ------ 0x4d ..... Passed

Checking I2C devices on bus 2:

I2C Devices: Overall test results --------------------- >>> Passed

Testing Programmable Devices:

PL Tool test:

+ Checking System CPLD 0xffdf0000 Reg: 0x10 .................... Passed

+ Checking System CPLD 0xffdf0000 Reg: 0xa0 .................... Passed

PL Tool: Overall test results ------------------------- >>> Passed

Power Supply Test all

Power Supply 1 ............................................ Passed

Power Supply 2 is not present

Power Supply Test ......................................... Passed

Testing Temp sensor devices:

+ Checking [CPU sensor] = 38.0 C ....................... Passed

+ Checking [MAC sensor] = 43.0 C ....................... Passed

+ Checking [Phy Right sensor] = 39.0 C ....................... Passed

+ Checking [Phy Left sensor] = 40.0 C ....................... Passed

Temp Sensors: Overall test results -------------------- >>> Passed

Fan Controller Short Test ................................. Passed

Fan 1 speed is 12240 RPM

Fan 2 speed is 12240 RPM

Fan 3 speed is 12240 RPM

Fan 4 speed is 12240 RPM

Testing Memory Regions:

Testing Memory Region 0:

Address Read Test ......................................... Passed

Address Write Test ........................................ Passed

Address Walking 1's Test .................................. Passed

Address Walking 0's Test .................................. Passed

Data Read Test ............................................ Passed

Data Write Test ........................................... Passed

Data Walking 1's Test ..................................... Passed

Data Walking 0's Test ..................................... Passed

Data Sliding 1's Test ..................................... Passed

Data Sliding 0's Test ..................................... Passed

Data Pattern Test ......................................... Passed

Memory: Overall test results -------------------------- >>> Passed

EDA: Overall test results ----------------------------- >>> PASSED.

NOTE: To return to your networking operating software, enter the reboot command.

Troubleshooting Tools

This section describes the diagnostic tools that provide debug and hardware tests.

To use the troubleshooting tools manually, you must be at the ONIE prompt and navigate to /mnt/dia/.

If you are not already at the ONIE prompt, reboot your system to Rescue mode. Refer to your network

operating software documentation for the procedure to reboot your system to Rescue mode.

NOTE: EDA Quick Test mode only uses the tools in Access Only method for minimal system

verification. EDA Extended mode uses the full system for debugging and verification.

Troubleshooting

37

The EDA tool is a script-based execution of the other troubleshooting tools. The configuration file is a

command-line execution for all tools to run in order.

NOTE: After running the troubleshooting tools, the system reboots to the ONIE prompt. To return

to your network operating software prompt, issue the reboot command.

edatool

The EDA tool (edatool) executes all of the other tools for testing and troubleshooting.

NOTE: For troubleshooting your system, Dell Networking strongly recommends using the EDA tool

and not individual tool commands.

The edatool is script-based and is easily extended or narrowed to meet your requirements.

Example of the edatool Output

ONIE:/diag # ./edatool

*****************************

* Diagnostics Application *

*****************************

Dell Diag ./edatool version 1.3, package 1.5 2014/7/23

Dell Diag ./fantool - version 1.3 package 1.5 2014/7/23

Dell Diag ./gpiotool - version 1.3 package 1.5 2014/7/23

Dell Diag ./i2ctool - version 1.3 package 1.5 2014/7/23

Dell Diag ./memtool - version 1.4 package 1.5 2014/7/23

Dell Diag ./nvramtool - version 1.4 package 1.5 2014/7/23

Dell Diag ./pcitool - version 1.3 package 1.5 2014/7/23

Dell Diag ./pltool - version 1.4 package 1.5 2014/7/23

Dell Diag ./psutool - version 1.3 package 1.5 2014/7/23

Dell Diag ./temptool - version 1.3 package 1.5 2014/7/23

Testing PCI devices:

+ Checking PCI 00:00.0, ID=57197000 ....................... Passed

+ Checking PCI 01:00.0, ID=e41445b8 ....................... Passed

PCI devices: Overall test results --------------------- >>> Passed

Testing I2C devices:

Checking I2C devices on bus 0:

+ Checking Dev found @ 0x52 ... ------ ------ 0x52 ..... Passed

+ Checking Dev found @ 0x54 ... ------ ------ 0x54 ..... Passed

+ Checking Dev found @ 0x55 ... ------ ------ 0x55 ..... Passed

+ Checking Dev found @ 0x56 ... ------ ------ 0x56 ..... Passed

+ Checking Dev found @ 0x57 ... ------ ------ 0x57 ..... Passed

+ Checking Dev found @ 0x68 ... ------ ------ 0x68 ..... Passed

Checking I2C devices on bus 1:

+ Checking Dev found @ 0x40 ... ------ ------ 0x40 ..... Passed

+ Checking Dev found @ 0x42 ... ------ ------ 0x42 ..... Passed

+ Checking Dev found @ 0x49 ... ------ ------ 0x49 ..... Passed

+ Checking Dev found @ 0x4a ... ------ ------ 0x4a ..... Passed

+ Checking Dev found @ 0x4c ... ------ ------ 0x4c ..... Passed

+ Checking Dev found @ 0x4d ... ------ ------ 0x4d ..... Passed

Checking I2C devices on bus 2:

I2C Devices: Overall test results --------------------- >>> Passed

Testing Programmable Devices:

PL Tool test:

+ Checking System CPLD 0xffdf0000 Reg: 0x10 .................... Passed

+ Checking System CPLD 0xffdf0000 Reg: 0xa0 .................... Passed

PL Tool: Overall test results ------------------------- >>> Passed

Power Supply Test all

Power Supply 1 ............................................ Passed

Power Supply 2 is not present

Power Supply Test ......................................... Passed

Testing Temp sensor devices:

38

Troubleshooting

+ Checking [CPU sensor] = 31.0 C ....................... Passed

+ Checking [MAC sensor] = 38.0 C ....................... Passed

+ Checking [Phy Right sensor] = 40.0 C ....................... Passed

+ Checking [Phy Left sensor] = 38.0 C ....................... Passed

Temp Sensors: Overall test results -------------------- >>> Passed

Fan Controller Short Test ................................. Passed

Fan 1 speed is 12240 RPM

Fan 2 speed is 12240 RPM

Fan 3 speed is 12240 RPM

Fan 4 speed is 12240 RPM

Testing Memory Regions:

Testing Memory Region 0:

Address Read Test ......................................... Passed

Address Write Test ........................................ Passed

Address Walking 1's Test .................................. Passed

Address Walking 0's Test .................................. Passed

Data Read Test ............................................ Passed

Data Write Test ........................................... Passed

Data Walking 1's Test ..................................... Passed

Data Walking 0's Test ..................................... Passed

Data Sliding 1's Test ..................................... Passed

Data Sliding 0's Test ..................................... Passed

Data Pattern Test ......................................... Passed

Memory: Overall test results -------------------------- >>> Passed

EDA: Overall test results ----------------------------- >>> PASSED.

The EDA tool tests the platforms using the default_eda_script.cfg configuration file. This script dictates

how EDA runs and which test runs first or multiple times. Each line of the script is the actual prompt

command line including parameters.

pcitool

The PCI tool (pcitool) allows testing of the PCI devices.

In EDA Quick Test mode, pcitool completes a simple check on the PCI bus. The tool scans the PCI bus

for all drivers and functions and writes the configuration registers to the configuration file.

Example of the pcitool Output

Syntax: ./pcitool <option>

-h := show this help

scan := scan all PCI devices

all := scan and show all config data

test := test using the default PCI test

config file

show <bus# dev# func#> := show config data for a specific

bus:dev.func

read <bus# dev# func# offset count> := read 8-bit config register for

bus:dev.func

write <bus# dev# func# offset data> := write 8-bit config register for

bus:dev.func

Example of the pcitool Configuation File Output

# more default_pci_list.cfg

Bus:Dev.Fn=00:00.0 ID=0c738086 NOT LISTED

0c738086 00000007 06000002 00000000 00000000 00000000 00000000 00000000

00000000 00000000 00000000 00008086 00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000 00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000 00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000 00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000 00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000 00000000 00000000 00000000 00000000

Troubleshooting

39

00000000 00000000 00000000 00000000 01080000 00000000 00020fb1 00000000

Bus:Dev.Fn=00:01.0 ID=0c468086 PCIe port

0c468086 00100147 06040002 00010010 ff760004 00000000 00010100 000000f0

…

i2ctool

The i2ctool allows testing of the devices on the i2c bus.

In EDA Quick Test mode, i2ctool scans busses and identifies all of the devices. If a device is behind a

MUX, i2ctool looks for devices through the MUX and, if present, a second-level MUX as well.

Example of the i2ctool Ouput

Syntax: ./i2ctool <option>

-h := show this help

test := test <user_i2c_file.cfg> the pre-programmed configuration

# ./i2ctool test userI2cFile.cfg

read := read I2C device with <bus> <dev> <address> <bytecount>

# ./i2ctool read /dev/i2c-0 0x50 0x00 10

write := write I2C device with <bus> <dev> <address> <data0> ... <dataN>

# ./i2ctool write /dev/i2c-0 0x50 0x00 0x0a 0x0b 0x0c

scan := scan <bus_prefix> the I2C devices on the specified bus prefix

# ./i2ctool scan /dev/i2c-

Example of the i2ctool Configuration File Output

# more gpio_00_i2c_devices.cfg

I2C devices found on bus #0: 10

Dev found @ 0x18,/dev/i2c-0,-,-,0x18,0x00,1

Dev found @ 0x30,/dev/i2c-0,-,-,0x30,0x00,1

Dev found @ 0x31,/dev/i2c-0,-,-,0x31,0x00,1

Dev found @ 0x32,/dev/i2c-0,-,-,0x32,0x00,1

Dev found @ 0x33,/dev/i2c-0,-,-,0x33,0x00,1

Dev found @ 0x3e,/dev/i2c-0,-,-,0x3e,0x00,1

Dev found @ 0x4d,/dev/i2c-0,-,-,0x4d,0x00,1

Dev found @ 0x50,/dev/i2c-0,-,-,0x50,0x00,1

Dev found @ 0x53,/dev/i2c-0,-,-,0x53,0x00,1

Dev found @ 0x69,/dev/i2c-0,-,-,0x69,0x00,1

I2C devices found on bus #1: 0

I2C devices found on bus #2: 2

Dev found @ 0x51,/dev/i2c-2,-,-,0x51,0x00,1

Dev found @ 0x59,/dev/i2c-2,-,-,0x59,0x00,1

memtool

The memory tool (memtool) tests system memory.

EDA Quick Test mode only completes simple access (read) tests. You can use memtool to test static

memory areas, such as L2Cache mapped as SRAM or DRAM on a memory mapped device.

The memory configuration file consists of lines that describe a region of memory and the tests performed

on that memory region. Therefore, you can have multiple entries for a region of memory. All parameters

are separated by a : character. The following describes the configuration file parameters.

Parameter Description

Region Name: The region name referred to in all output.

40

Troubleshooting

Parameter Description

Start Address: The starting address for the region of memory in hexadecimal format (without the

preceding 0x). If the operating software is defining how to manage memory, this is

dynamic and you can use “-” for the start address and the memory uses malloc’d

from the available system memory.

Size: The size of the contiguous memory area (in bytes) in hexadecimal (without the

preceding 0x). If memory is dynamic, use “-” for size and the tests use the

maximum system memory.

Access: The letter that describes how this memory is accessed:

b — byte (8 bits)

h — halfword (16 bits)

w — word (32 bits)

d — double-word (64 bits)

Increment: How many bytes to increment to the next cell.

ECC: Describes if ECC is supported — 0 or 1.

Chunk: Describes how many kilo bytes (1024 bytes) are tested in one chunk. Tests multiple

chunks across the memory region.

Max Cache: The maximum cache size for this memory.

Cacheline: The size of a cacheline.

Iterations: The number of times to perform the tests.

Test: The collection of bits that tell which test to perform on this region. The tests are

performed in bit order. Some tests may not be performed due to time limitations

and the purpose of the test (for example, dim cache memory test which is time

consuming and destructive to data). To run an excluded test, you must specifically

request the test. For example, to run all tests including the dim cache memory test,

which is a 0x800, set the tests to fff.

A-1 — run all available tests.

Descriptive Device: The descriptive device (for example, SPD in the case of a dimm), is described in one

comma-separated field of four parameters: address, type, start, and bytes.

Device Path: The path to the device driver (for example, /dev/i2c-0 for a PD on the i2c bus 0).

Address of

Memory

Description device

Describes the memory organization (for example, dimm memory which has an SPD

device) and the address of the device. For i2c devices, the address is presented in

7–bit hexadecimal format.

(SPD):

Type: SPD

Troubleshooting

41

Parameter Description

Range of bytes in

the Description

Device:

Example of the memtool Output

Syntax: ./memtool <option>

-h := show this help

test [[all]|list|region#] := test using the MEM test config file

info := display configuration info of device

read [b|h|w] address := read the specified physical address

write [b|h|w] address data [length] := write at the specified physical address

Example of the memtool Configuration File Output

// Memory Configuration File

//

// Example:

// SystemRam:-:-:w:4:1:2800:0:0:1:-1:SPD:/dev/i2c-0:50:0,ff:

// This describes the SystemRam which is dynamic in location and size. It

is accessed by words // and incremented addresses of 4 bytes. It is ECC

covered, and has a max chunk of 10KB max

// cache and cacheline size (unused at this time) are 0. The tests will be

performed once on this

// region, and the -1 denotes to run all tests, excluding dim cache memory

test. The Descriptive

// device is a SPD on /dev/i2c-0 at address 0x50, and we read registers 0-255.

//

// Note: a '-' address and size denotes a dynamic ram allocation

// =======================Tests================================

// -1 : all Tests Run

// 0h : No Address Test

// 1h : Address Read Test (Access)

// 2h : Address Read|Modify|Write|Verify

// 4h : Address walking 1's

// 8h : Address walking 0's

// 00h : No Data Test

// 10h : Data Read Test (Access)

// 20h : Data Read|Modify|Write|Verify

// 40h : Data walking 1's

// 80h : Data walking 0's

// 100h : Data walking 1's

// 200h : Data walking 0's

// 400h : patterns (00ff, ff00, 55aa, aa55)

// 800h : Cache (cacheKiller - Not Part of ALL Tests)

These two fields list the start and end registers to read descriptive entries for the

device.

SystemRam:-:-:d:8:1:2800:-1:-1:1:-1:i2c:0x52,SPD,0,255

pltool

The programmable logic tool (pltool) verifies access to the complex programmable logic devices

(CPLD) and field programmable gate array (FPGA) and verifies versions.

The pltool generates its configuration file based on the platform database. The configuration file is

generated with a specific version of devices in order to detect manufacturing misleads. The database

holds all the versions and is updated when new versions are released.

42

Troubleshooting

The configuration file displays in tree format. The base is the chip that can have multiple registers and

may or may not have bit descriptions and bit collection information. Each parameter in the tree is on an

individual line separated by the “|” character.

Example of the pltool Output

Syntax: ./pltool <option>

-h := show this help

test := test using the test config file

list := list devices and registers

read [b|h|w] device offset [length] := read the specified register

write [b|h|w] device offset data [length] := write at the specified register

The configuration file displays in tree format. The base is the chip that can have multiple registers and

may or may not have bit descriptions and bit collection information. Each parameter in the tree is on an

individual line separated by the “|” character.

The following describes the C-row configuration file tree output.

C-Row Parameter Description

C The row identifier.

Type CPLD, FPGA, or TPM.

Address The address of the device. For CPLD on an I2C bus, this is an 8–bit address. For

PCI, this is the bus:dev:function in a packed 32–bit word, 8–bits each. For memory,

this is the address. LPC is unknown.

Name The text name for the device.

Interface i2c, pci, mem, io, or lpc.

Bus For devices on multiple busses, this indicates the bus number (for example, 0 for

i2c indicates /dev/i2c-0. For PCI, this holds the bus-dev-func in a 32–bit value with

each byte representing bus, device and functions in that order (for example,

0x020304 represents bus 02, device 03, and function 04).

Version Reg The register that contains the version for the device.

Version Mask The bits to use to check the version.

The following describes the R-row configuration file tree output.

R-Row Parameter Description

R The register identifier.

Address The register addresses (offset) in the device.

Register Size Describes how many bits the register contains (for example, 8, 16, or 32).

Register Mask Lists the valid bits in this register.

Name The text name of this register.

Access Perm Access permissions:

RO — Read only

Troubleshooting

43

R-Row Parameter Description

RW — Read/Write

RC — Clear on Read

WO — Write only

Default Value The default value of this register.

Testable

1 — The register can be tested against the default value.

0 — The register is not testable.

Version The version of the register. There can be multiple definitions of a register based on

the version. When the test creates a configuration file from a device list with several

versions, a specific version is requested and if the version requested is the last

version prior to or equal to the requested version, it is put into the configuration

file.

The following describes the B-row configuration file tree output.

B-Row Parameter Description

B The bit row identifier.

Bit Number(s) This can be either a single bit number or a range starting with the highest bit

number (for example, 7 or 7:3).

Name The name of the bit.

Access The access type of the bit; the same as the register definition.

Default Value The default value of the bits.

The following describes the I-row configuration file tree output.