Page 1

Dell PowerEdge M420 Systems

Owner's Manual

Regulatory Model: QHB

Regulatory Type: QHB Series

Page 2

Notes, Cautions, and Warnings

NOTE: A NOTE indicates important information that helps you make better use of your computer.

CAUTION: A CAUTION indicates either potential damage to hardware or loss of data and tells you

how to avoid the problem.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

Copyright © 2014 Dell Inc. All rights reserved. This product is protected by U.S. and international copyright and

intellectual property laws. Dell™ and the Dell logo are trademarks of Dell Inc. in the United States and/or other

jurisdictions. All other marks and names mentioned herein may be trademarks of their respective companies.

2014 - 11

Rev. A02

Page 3

Contents

1 About Your System................................................................................................7

Overview................................................................................................................................................ 7

Front-Panel Features And Indicators....................................................................................................8

Solid State Drive Features..................................................................................................................... 8

Using USB Diskette Or USB DVD/CD Drives...................................................................................... 10

iKVM Access.........................................................................................................................................10

Other Information You May Need...................................................................................................... 10

2 Using The System Setup And Boot Manager................................................. 12

Choosing The System Boot Mode......................................................................................................12

Entering System Setup........................................................................................................................ 13

Responding To Error Messages.....................................................................................................13

Using The System Setup Navigation Keys.....................................................................................13

System Setup Options.........................................................................................................................14

System Setup Main Screen............................................................................................................14

System BIOS Screen...................................................................................................................... 14

System Information Screen...........................................................................................................15

Memory Settings Screen................................................................................................................15

Processor Settings Screen.............................................................................................................16

Boot Settings Screen......................................................................................................................17

Integrated Devices Screen.............................................................................................................17

Serial Communications Screen.....................................................................................................18

System Profile Settings Screen......................................................................................................19

System Security Screen.................................................................................................................20

Miscellaneous Settings..................................................................................................................20

System And Setup Password Features................................................................................................21

Assigning A System And/Or Setup Password............................................................................... 21

Using Your System Password To Secure Your System................................................................22

Deleting or changing an existing system and/or setup password.............................................. 22

Operating with a setup password enabled...................................................................................23

Entering the UEFI Boot Manager........................................................................................................ 23

Using the Boot Manager navigation keys.....................................................................................23

Boot Manager screen....................................................................................................................24

UEFI Boot menu............................................................................................................................ 24

Embedded System Management........................................................................................................25

iDRAC Settings Utility.......................................................................................................................... 25

Entering the iDrac Settings utility................................................................................................. 25

Page 4

3 Installing Blade Components...........................................................................26

Recommended Tools......................................................................................................................... 26

Removing And Installing A Sleeve...................................................................................................... 26

Removing The Sleeve....................................................................................................................26

Installing The Sleeve......................................................................................................................27

Removing And Installing A Blade........................................................................................................28

Removing A Blade......................................................................................................................... 28

Installing A Blade........................................................................................................................... 28

Inside The Blade..................................................................................................................................29

I/O Module Mezzanine Card.............................................................................................................. 29

Mezzanine Card Installation Guidelines....................................................................................... 29

Removing A Mezzanine Card....................................................................................................... 30

Installing A Mezzanine Card.......................................................................................................... 31

LOM Riser Card................................................................................................................................... 32

Removing The LOM Riser Card.................................................................................................... 32

Installing The LOM Riser Card...................................................................................................... 32

Solid State Drives.................................................................................................................................33

Removing A Solid State Drive........................................................................................................33

Installing A Solid State Drive..........................................................................................................33

Shutdown Procedure For Servicing A Solid State Drive.............................................................. 34

Configuring the boot drive........................................................................................................... 34

Removing An SSD From The SSD Carrier.....................................................................................34

Installing An SSD In The SSD Carrier............................................................................................ 35

Solid State Drive Backplane................................................................................................................ 35

Removing The SSD Backplane......................................................................................................35

Installing The SSD Backplane........................................................................................................36

Processors........................................................................................................................................... 37

Removing A Processor.................................................................................................................. 37

Installing A Processor....................................................................................................................39

NVRAM backup battery....................................................................................................................... 41

Replacing The NVRAM Backup Battery.........................................................................................41

System board.......................................................................................................................................42

Removing The Blade System Board............................................................................................. 42

Installing The Blade System Board............................................................................................... 43

Processor/DIMM blank....................................................................................................................... 44

Removing A Processor/DIMM Blank............................................................................................ 44

Installing A Processor/DIMM Blank.............................................................................................. 44

System memory.................................................................................................................................. 45

General Memory Module Installation Guidelines........................................................................ 46

Mode-Specific Guidelines.............................................................................................................46

Sample Memory Configurations...................................................................................................48

Page 5

Removing Memory Modules.........................................................................................................49

Installing Memory Modules...........................................................................................................50

Management Riser Card......................................................................................................................51

Removing The Management Riser Card.......................................................................................51

Installing The Management Riser Card.........................................................................................52

Replacing The SD Card................................................................................................................. 52

Replacing The SD vFlash Card...................................................................................................... 53

4 Troubleshooting Your System......................................................................... 55

Safety First—For You and Your System.............................................................................................. 55

Troubleshooting System Memory...................................................................................................... 55

Troubleshooting Solid State Drives.................................................................................................... 56

Troubleshooting USB devices............................................................................................................ 56

Troubleshooting An Internal SD Card................................................................................................ 57

Troubleshooting Processors...............................................................................................................57

Troubleshooting The Blade System Board........................................................................................ 58

Troubleshooting The NVRAM Backup Battery...................................................................................58

5 Using system diagnostics..................................................................................59

Dell Online Diagnostics...................................................................................................................... 59

Dell embedded system diagnostics....................................................................................................59

When to use the embedded system diagnostics.........................................................................59

Running the embedded system diagnostics................................................................................60

System diagnostic controls.......................................................................................................... 60

6 Jumpers and connectors.................................................................................. 61

System Board Jumper Settings...........................................................................................................61

System Board Connectors.................................................................................................................. 61

Disabling A Forgotten Password........................................................................................................ 62

7 Technical Specifications....................................................................................63

8 System messages................................................................................................66

LCD status messages..........................................................................................................................66

Viewing LCD messages.................................................................................................................66

Removing LCD messages............................................................................................................. 66

System Error Messages.......................................................................................................................66

Warning messages.............................................................................................................................137

Diagnostic messages.........................................................................................................................137

Alert messages...................................................................................................................................137

9 Getting help.......................................................................................................138

Page 6

Contacting Dell................................................................................................................................. 138

Page 7

1

About Your System

Overview

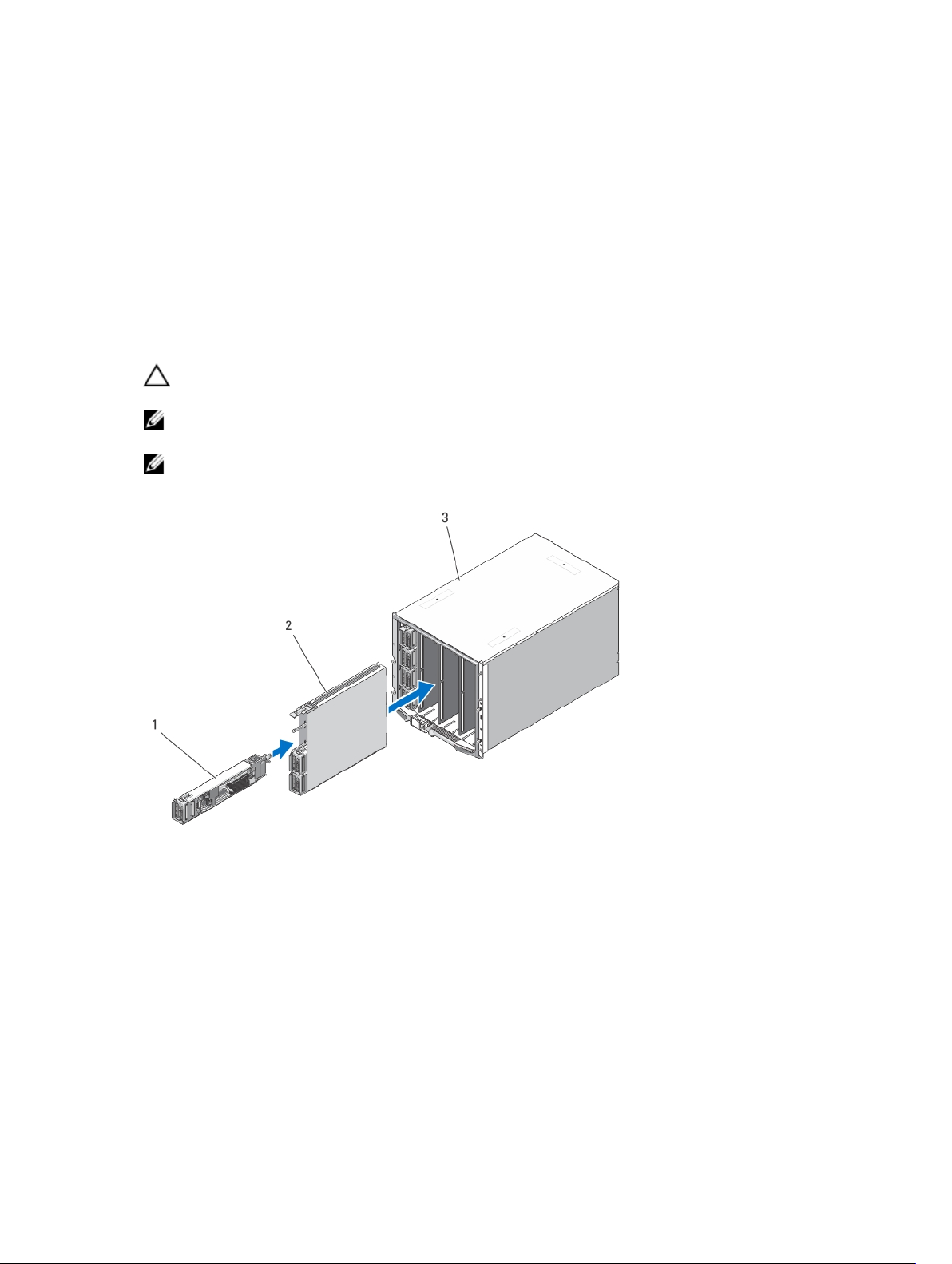

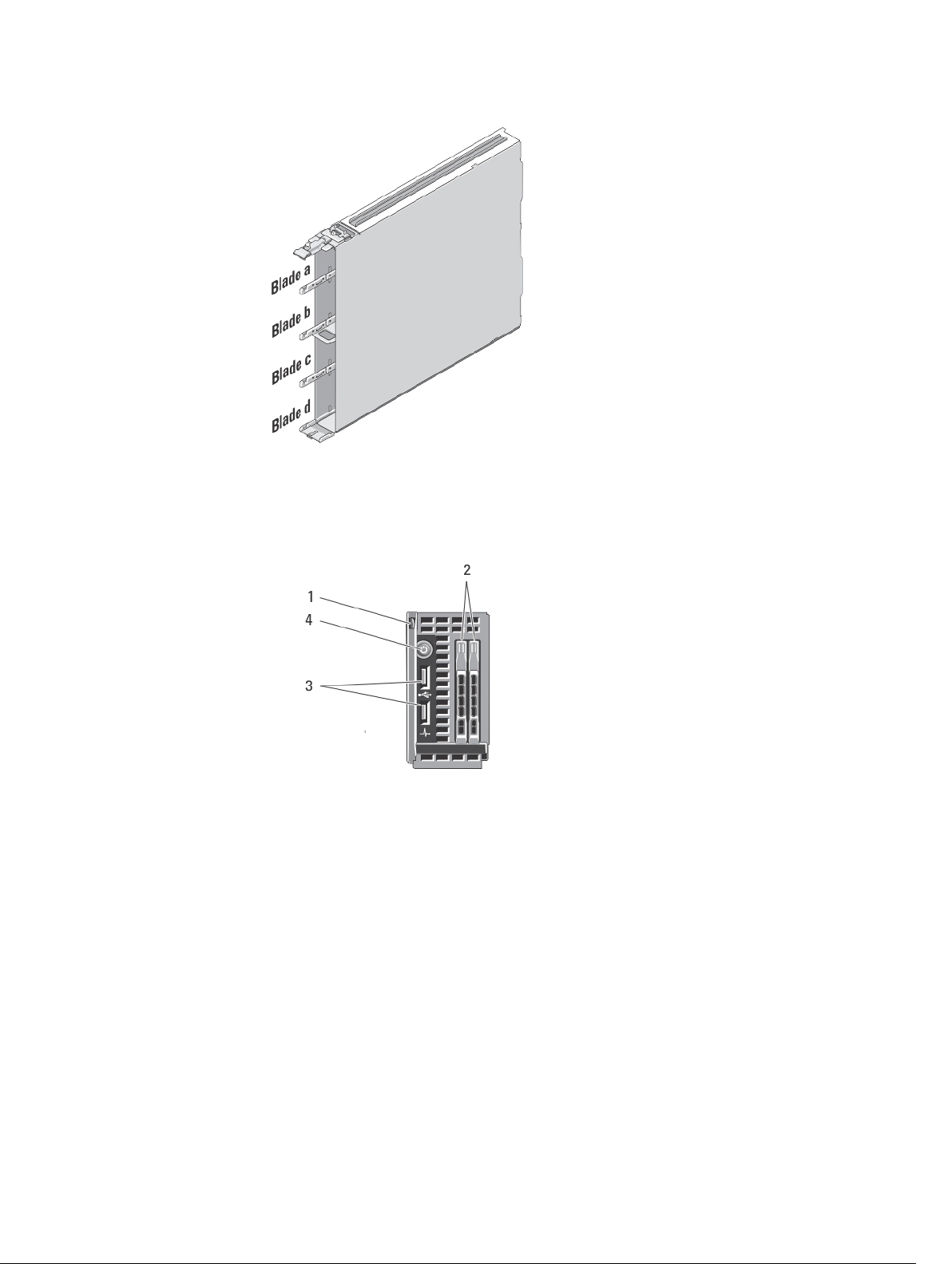

Your system includes up to four quarter-height blades installed in a sleeve. To function as a system, the

sleeve is inserted into an M1000e enclosure (chassis).

CAUTION: Exercise care while handling the sleeve to prevent damage to the internal

components.

NOTE: To ensure proper operation and cooling, all blade slots in the sleeve must be populated at all

times with either a blade or quarter-height blade blank(s).

NOTE: For complete instructions on operating the quarter-height blades, see the M1000e

Enclosure Owner's Manual and the CMC User's Guide at support.dell.com/manuals.

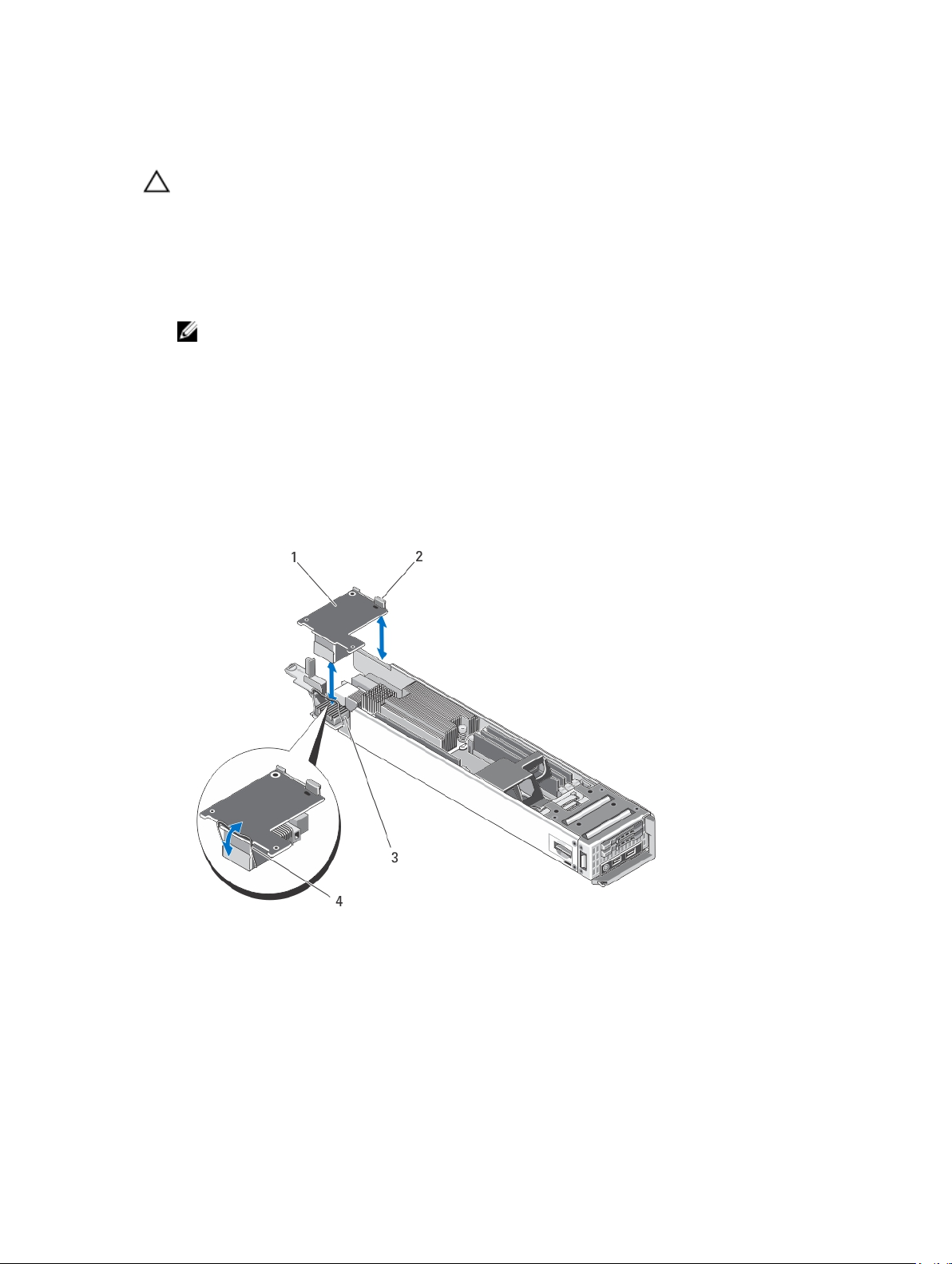

Figure 1. Sleeve and Blade — Overview

1. quarter-height blade 2. sleeve

3. enclosure

The following figure shows the blade slot numbering in a sleeve.

7

Page 8

Figure 2. Blade Slot Numbering

Front-Panel Features And Indicators

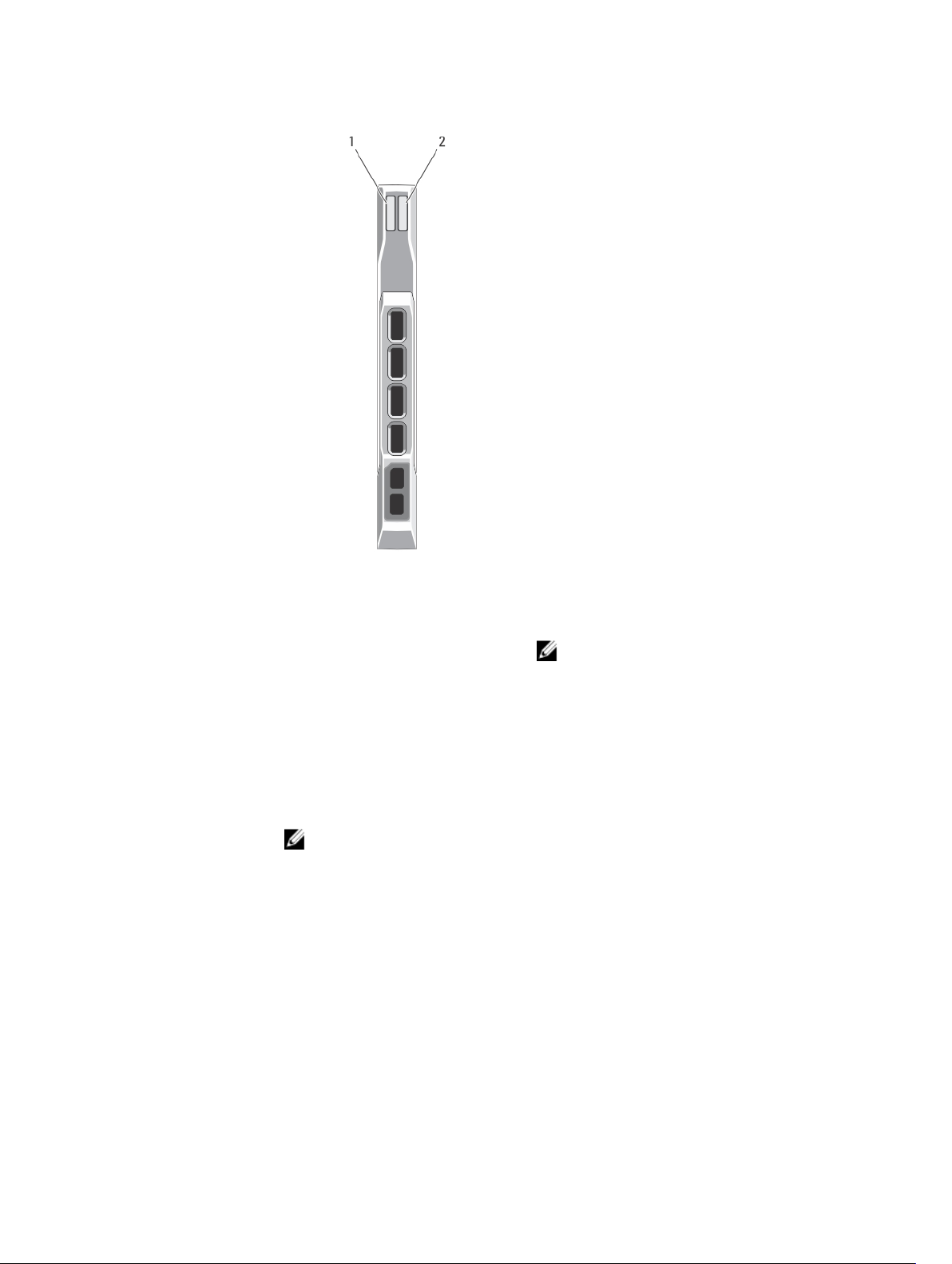

Figure 3. Front-Panel Features and Indicators

1. blade handle release button 2. solid state drives (2)

3. USB connectors (2) 4. blade power button/indicator

Solid State Drive Features

Your system supports two 1.8 inch uSATA Solid State Drives (SSD).

The SSDs plug into the SSD backplane inside the blade. On blades with a diskless configuration, you must

install SSD blanks in all drive slots, and the SSD backplane must still be installed to maintain proper

airflow.

The SSD indicators display different patterns as drive events occur in the system.

8

Page 9

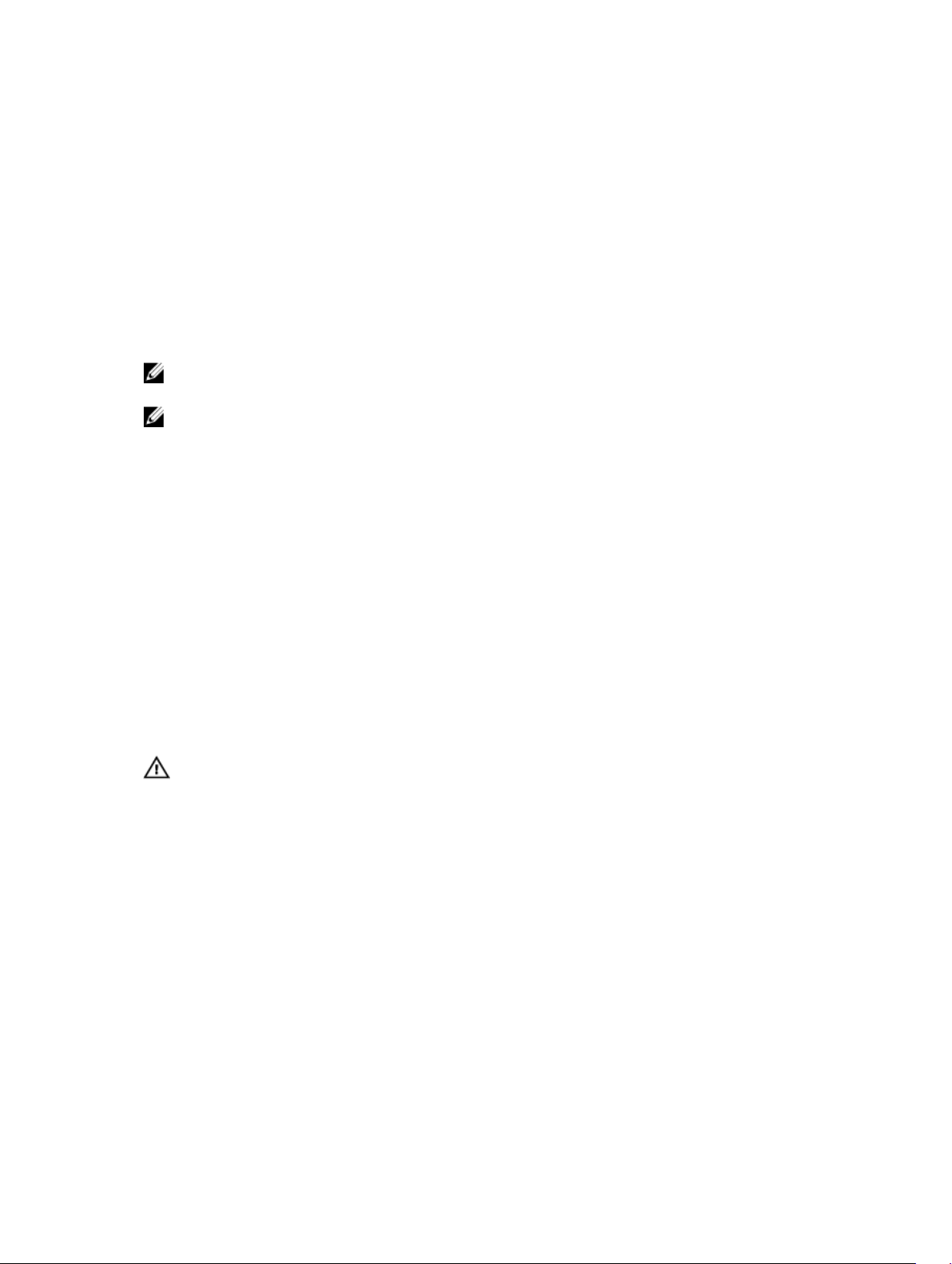

Figure 4. SSD Features

1. activity indicator (green) 2. status indicator (green and amber)

NOTE: If the SSD is in Advanced Host

Controller Interface (AHCI) mode, the

status LED remains off.

Drive-Status

Condition

Indicator Pattern

Blinks green two

Identifying drive or preparing for removal

times per second

Off Drive ready for insertion or removal

NOTE: The drive status indicator remains off until all SSDs are initialized after

system power is applied. Drives are not ready for insertion or removal during

this time.

Blinks green,

Drive predicted failure

amber, and off

Blinks amber four

Drive failed

times per second

Blinks green slowly Drive rebuilding

Steady green Drive online

9

Page 10

Drive-Status

Indicator Pattern

Condition

Blinks green three

seconds, amber

three seconds, and

off six seconds

Rebuild aborted

Using USB Diskette Or USB DVD/CD Drives

The blade has USB ports on the front which allow you to connect a USB diskette drive, USB flash drive,

USB DVD/CD drive, keyboard, or mouse. The USB drives can be used to configure the blade.

NOTE: Your blade supports only Dell-branded USB 2.0 drives. Use the optional external drive

storage tray to support the drive while in use.

NOTE: If the drive must be designated as the boot drive, connect the USB drive, restart the system,

then enter the System Setup and set the drive as first in the boot sequence. The USB device is

displayed in the boot order setup screen only if it is attached to the system before you run the

System Setup. You can also select the boot device by pressing <F11> during system start-up and

selecting a boot device for the current boot sequence.

iKVM Access

To toggle video among the M420 blades installed in a sleeve:

1. Press <Print Screen> to launch the OSCAR interface (iKVM GUI).

2. Select the slot where the sleeve and blade are installed, and press <Enter> to exit the OSCAR

interface.

3. Press <Scroll Lock> twice in quick repetition to toggle between the quarter-height blades installed in

the sleeve.

Other Information You May Need

WARNING: See the safety and regulatory information that shipped with your system. Warranty

information may be included within this document or as a separate document.

• The Getting Started Guide provides an overview of system features, setting up your system, and

technical specifications.

• The Rack Installation Instructions included with your rack solution describes how to install your

system into a rack.

• The Dell PowerEdge M1000e Enclosure Owner’s Manual provides information about enclosure

features and describes how to troubleshoot the enclosure and install or replace the enclosure's

components.

• The Dell Chassis Management Controller User’s Guide provides information on installing, configuring

and using the Chassis Management Controller (CMC).

• For the full name of an abbreviation or acronym used in this document, see the Glossary at

www.dell.com/support/manuals.

• Dell systems management application documentation provides information about installing and using

the systems management software.

• Any media that ships with your system that provides documentation and tools for configuring and

managing your system, including those pertaining to the operating system, system management

software, system updates, and system components that you purchased with your system.

10

Page 11

NOTE: Always check for updates on www.dell.com/support/manuals and read the updates first

because they often supersede information in other documents.

11

Page 12

Using The System Setup And Boot Manager

System Setup enables you to manage your system hardware and specify BIOS-level options.

The following keystrokes provide access to system features during startup:

Keystroke Description

<F2> Enters the System Setup.

<F10> Enters System Services, which opens the Dell Lifecycle Controller 2 (LC2). The Dell

LC2 allows you to access utilities such as embedded system diagnostics. For more

information, see the Dell LC2 documentation.

<F11> Enters the BIOS Boot Manager or the Unified Extensible Firmware Interface (UEFI)

Boot Manager, depending on the system's boot configuration.

<F12> Starts Preboot eXecution Environment (PXE) boot.

From the System Setup, you can:

• Change the NVRAM settings after you add or remove hardware

• View the system hardware configuration

• Enable or disable integrated devices

• Set performance and power management thresholds

• Manage system security

2

You can access the System Setup using the:

• Standard graphical browser, which is enabled by default

• Text browser, which is enabled using Console Redirection

To enable Console Redirection, in System Setup, select System BIOS → Serial Communication screen

→ Serial Communication, select On with Console Redirection.

NOTE: By default, help text for the selected field is displayed in the graphical browser. To view the

help text in the text browser, you must press <F1>.

Choosing The System Boot Mode

System Setup enables you to specify the boot mode for installing your operating system:

• BIOS boot mode (the default) is the standard BIOS-level boot interface.

12

Page 13

• UEFI boot mode is an enhanced 64-bit boot interface based on Unified Extensible Firmware Interface

(UEFI) specifications that overlays the system BIOS.

You must select the boot mode in the Boot Mode field of the Boot Settings Screen of System Setup.

Once you specify the boot mode, the system boots in the specified boot mode and you proceed then to

install your operating system from that mode. Thereafter, you must boot the system in the same boot

mode (BIOS or UEFI) to access the installed operating system. Trying to boot the operating system from

the other boot mode will cause the system to halt at startup.

NOTE: Operating systems must be UEFI-compatible to be installed from the UEFI boot mode. DOS

and 32-bit operating systems do not support UEFI and can only be installed from the BIOS boot

mode.

NOTE: For the latest information on supported operating systems, see dell.com/ossupport.

Entering System Setup

1. Turn on or restart your system.

2. Press <F2> immediately after you see the following message:

<F2> = System Setup

If your operating system begins to load before you press <F2>, allow the system to finish booting,

and then restart your system and try again.

Responding To Error Messages

If an error message is displayed while the system is booting, make a note of the message. See System

Error Messages section of this manual for an explanation of the message and suggestions for correcting

errors.

NOTE: After installing a memory upgrade, it is normal for your system to display a message the first

time you start your system.

Using The System Setup Navigation Keys

Keys Action

Up arrow Moves to the previous field.

Down arrow Moves to the next field.

<Enter> Allows you to type in a value in the selected field (if applicable) or follow the link in

the field.

Spacebar Expands or collapses a drop-down list, if applicable.

<Esc> Moves to the previous page until you view the main screen. Pressing <Esc> in the

main screen exits System Setup. A message prompts you to save any unsaved

changes.

<F1> Displays the System Setup help file.

NOTE: For most of the options, any changes that you make are recorded but do not take effect until

you restart the system.

13

Page 14

System Setup Options

System Setup Main Screen

NOTE: Press <Alt><F> to reset the BIOS or UEFI settings to their default settings.

Menu Item Description

System BIOS This option is used to view and configure BIOS settings.

iDRAC Settings This option is used to view and configure iDRAC settings.

Device Settings This option is used to view and configure device settings.

System BIOS Screen

NOTE: The options for System Setup change based on the system configuration.

NOTE: System Setup defaults are listed under their respective options in the following sections,

where applicable.

Menu Item Description

iDRAC Settings This option is used to view and configure iDRAC settings.

Device Settings This option is used to view and configure device settings.

System

Information

Memory Settings Displays information and options related to installed memory.

Processor Settings Displays information and options related to the processor such as speed, cache

Boot Settings Displays options to specify the boot mode (BIOS or UEFI). Enables you to modify

Integrated Devices Displays options to enable or disable integrated device controllers and ports, and to

Serial

Communication

System Profile

Settings

System Security Displays options to configure the system security settings like, system password,

Miscellaneous

Settings

Displays information about the system such as the system model name, BIOS

version, Service Tag, and so on.

size, and so on.

UEFI and BIOS boot settings.

specify related features and options.

Displays options to enable or disable the serial ports and specify related features

and options.

Displays options to change the processor power management settings, memory

frequency, and so on.

setup password, TPM security, and so on. It also enables or disables support for

local BIOS update and the power button on the system.

Displays options to change the system date, time, and so on.

14

Page 15

System Information Screen

Menu Item Description

System Model

Name

System BIOS

Version

System Service Tag Displays the system Service Tag.

System

Manufacturer

System

Manufacturer

Contact

Information

Displays the system model name.

Displays the BIOS version installed on the system.

Displays the name of system manufacturer.

Displays the contact information of the system manufacturer.

Memory Settings Screen

Menu Item Description

System Memory

Size

System Memory

Type

System Memory

Speed

Displays the amount of memory installed in the system.

Displays the type of memory installed in the system.

Displays the system memory speed.

System Memory

Voltage

Video Memory Displays the amount of video memory.

System Memory

Testing

Memory Operating

Mode

Displays the system memory voltage.

Specifies whether system memory tests are run during system boot. Options are

Enabled and Disabled. By default, the System Memory Testing option is set to

Disabled.

Specifies the memory operating mode. The options available depending on the

memory configuration of your system are Optimizer Mode, Advanced ECC Mode,

Mirror Mode, Spare Mode, Spare with Advanced ECC Mode, and Dell Fault

Resilient Mode. By default, the Memory Operating Mode option is set to

Optimizer Mode.

NOTE: The Memory Operating Mode can have different defaults and available

options based on the memory configuration.

NOTE: The Dell Fault Resilient Mode establishes an area of memory that is

fault resilient. This mode can be used by an operating system that supports the

feature to load critical applications or enables the operating system kernel to

maximize system availability.

15

Page 16

Menu Item Description

Node Interleaving If this field is Enabled, memory interleaving is supported if a symmetric memory

configuration is installed. If Disabled, the system supports Non-Uniform Memory

architecture (NUMA) (asymmetric) memory configurations. By default, Node

Interleaving option is set to Disabled.

Serial Debug

Output

By default, it is set to disabled.

Processor Settings Screen

Menu Item Description

Logical Processor Allows you to enable or disable logical processors and display the number of

logical processors. If the Logical Processor option is set to Enabled, the BIOS

displays all the logical processors. If this option is set to Disabled, the BIOS only

displays one logical processor per core. By default, the Logical Processor option is

set to Enabled.

QPI Speed Allows you to set the QuickPath Interconnect data rate settings. By default, the QPI

Speed option is set to Maximum data rate.

NOTE: The QPI Speed option is displayed only when both the processors are

installed.

Virtualization

Technology

Adjacent Cache

Line Prefetch

Allows you enable or disable the additional hardware capabilities provided for

virtualization. By default, the Virtualization Technology option is set to Enabled.

Allows you to optimize the system for applications that require high utilization of

sequential memory access. By default, the Adjacent Cache Line Prefetch option is

set to Enabled. You can disable this option for applications that require high

utilization of random memory access.

Hardware

Prefetcher

DCU Streamer

Prefetcher

DCU IP Prefetcher Allows you to enable or disable DCU IP prefetcher. By default, the DCU IP

Execute Disable Allows you enable or disable execute disable memory protection technology. By

Number of Cores

per Processor

Processor 64-bit

Support

Processor Core

Speed

Processor Bus

Speed

16

Allows you to enable or disable hardware prefetcher. By default, the Hardware

Prefetcher option is set to Enabled.

Allows you to enable or disable DCU streamer prefetcher. By default, the DCU

Streamer Prefetcher option is set to Enabled.

Prefetcher option is set to Enabled.

default, the Execute Disable option is set to Enabled.

Allows you to control the number of enabled cores in each processor. By default,

the Number of Cores per Processor option is set to All.

Specifies if the processor(s) support 64-bit extensions.

Displays the maximum core frequency of the processor.

Displays the bus speed of the processors.

Page 17

Menu Item Description

NOTE: The processor bus speed option is displayed only when both the

processors are installed.

Boot Settings Screen

Menu Item Description

Boot Mode Allows you to set the boot mode of the system.

CAUTION: Switching the boot mode may prevent the system from booting if

the operating system is not installed in the same boot mode.

If the operating system supports UEFI, you can set this option to UEFI. Setting this

field to BIOS allows compatibility with non-UEFI operating systems. By default, the

Boot Mode option is set to BIOS.

NOTE: Setting this field to UEFI disables BIOS Boot Settings menu. Setting this

field to BIOS disables the UEFI Boot Settings menu.

Boot Sequence

Retry

BIOS Boot Settings Allows you to enable or disable BIOS Boot options.

UEFI Boot Settings Allows you to enable or disable UEFI Boot options. The Boot options include IPv4

One-Time Boot Allows you to enable or disable a one-time boot from a selected device.

Allows you to enable or disable the boot sequence retry feature. If this field is

enabled and the system fails to boot, the system reattempts the boot sequence

after 30 seconds. By default, the Boot Sequence Retry option is set to Disabled.

NOTE: This option is enabled only if the boot mode is BIOS.

PXE and IPv6 PXE. By default, the UEFI PXE boot protocol is set to IPv4.

NOTE: This option is enabled only if the boot mode is UEFI.

Integrated Devices Screen

Menu Item Description

Integrated RAID

Controller

User Accessible

USB Ports

Allows you to enable or disable the integrated RAID controller. By default, the

Integrated RAID Controller option is set to Enabled.

Allows you to set the user accessible ports. Selecting All Ports Off disables all USB

ports. By default, the User Accessible USB Ports option is set to All Ports On.

Internal SD Card

Redundancy

Internal SD Card

Port

If set to Mirror mode, data is written on both SD cards. If any one of the SD card

fails, data is written to the active SD card. Data from this card is copied to the

replacement SD card at the next boot.

Enables or disables the system’s internal SD card port.

17

Page 18

Menu Item Description

NOTE: If you enable this option, access to the vFlash partition is disabled.

Integrated

Network Card 1

OS Watchdog

Timer

Embedded Video

Controller

SR-IOV Global

Enable

Memory Mapped

I/O above 4GB

Slot Disablement The Slot Disablement feature controls the configuration of mezzanine cards

Allows you to enable or disable the integrated network card. By default, the

Integrated Network Card 1 option is set to Enabled.

Allows you to enable or disable the OS wacthdog timer. When this field is enabled,

the operating system initializes the timer and the OS watchdog timer helps in

recovering the operating system. By default, the OS Watchdog Timer option is set

to Disabled.

Allows you to enable or disable the Embedded Video Controller. By default, the

embedded video controller is Enabled.

Allows you to enable or disable the BIOS configuration of Single Root I/O

Virtualization (SR-IOV) devices. By default, the SR-IOV Global Enable option is set

to Disabled.

Allows you to enable support for PCIe devices that require large amounts of

memory. By default, the option is set to Enabled.

installed in the specified slots. Only mezzanine card slots that are present on your

system are available for control.

Serial Communications Screen

Menu Item Description

Serial

Communication

Allows you to enable the COM port or Console Redirection options.

Serial Port Address Allows you to set the port address for serial devices. By default, the Serial Port

Address option is set to COM1.

NOTE: Only Serial Device 2 can be used for Serial Over LAN (SOL). To use

console redirection by SOL, configure the same port address for console

redirection and the serial device.

Failsafe Baud Rate Displays the failsafe baud rate for console redirection. The BIOS attempts to

determine the baud rate automatically. This failsafe baud rate is used only if the

attempt fails and the value must not be changed. By default, the Failsafe Baud Rate

option is set to 11520.

Remote Terminal

Type

Redirection After

Boot

18

Allows you to set the remote console terminal type. By default, the Remote

Terminal Type option is set to VT 100/VT220.

Allows you to enable or disable to the BIOS console redirection when the

operating system is loaded. By default, the Redirection After Boot option is set to

Enabled.

Page 19

System Profile Settings Screen

Menu Item Description

System Profile Allows you to set the system profile. If you set the System Profile option to a mode

other than Custom, the BIOS automatically sets the rest of the options. You can

only change the rest of the options if the mode is set to Custom. By default, the

System Profile option is set to Performance Per Watt Optimized (DAPC). DAPC is

Dell Active Power Controller.

NOTE: The following parameters are available only when the System Profile is

set to Custom.

CPU Power

Management

Memory

Frequency

Turbo Boost Allows you to enable or disable the processor to operate in turbo boost mode. By

C1E Allows you to enable or disable the processor to switch to a minimum

C States Allows you to enable or disable the processor to operate in all available power

Monitor/Mwait Allows you to enable Monitor/Mwait instructions in the processor. By default, the

Memory Patrol

Scrub

Memory Refresh

Rate

Allows you to set the CPU power management. By default, the CPU Power

Management option is set to System DBPM (DAPC). DBPM is Demand-Based

Power Management.

Allows you to set the memory frequency. By default, the Memory Frequency

option is set to Maximum Performance.

default, the Turbo Boost option is set to Enabled.

performance state when it is idle. By default, the C1E option is set to Enabled.

states. By default, the C States option is set to Enabled.

Monitor/Mwait option is set to Enabled for all system profiles, except Custom.

NOTE: This option can be disabled only if the C States option in Custom

mode is disabled.

NOTE: When C States is enabled in Custom mode, changing the Monitor/

Mwait setting does not impact system power/performance.

Allows you to set the memory patrol scrub frequency. By default, the Memory

Patrol Scrub option is set to Standard.

Allows you to set the memory refresh rate. By default, the Memory Refresh Rate

option is set to 1x.

Memory Operating

Voltage

Collaborative CPU

Performance

Control

Allows you to set the DIMM voltage selection. When set to Auto, the system

automatically sets the system voltage to the optimal setting based on the DIMM

capacity and the numbers of DIMMs installed. By default, the Memory Operating

Voltage option is set to Auto.

When set to enabled, the CPU power management is controlled by the OS DBPM

and the System DBPM (DAPC). By default, the option is set to Disabled

19

Page 20

System Security Screen

Menu Item Description

Intel AES-NI The Intel AES-In option improves the speed of applications by performing

encryption and decryption using the Advanced Encryption Standard set and is set

to Enabled by default.

System Password Allows you to set the system password. This option is read-only if the password

jumper is not installed in the system.

Setup Password Allows you to set the setup password. This option is read-only if the password

jumper is not installed in the system.

Password Status Allows you to lock the system password. By default, the Password Status option is

set to Unlocked.

TPM Security Allows you to control the reporting mode of the Trusted Platform Module (TPM).

By default, the TPM Security option is set to Off. You can only modify the TPM

Status, TPM Activation , and Intel TXT fields if the TPM Status field is set to either

On with Pre-boot Measurements or On without Pre-boot Measurements.

TPM Activation Allows you to change the operational state of the TPM. By default, the TPM

Activation option is set to No Change.

TPM Status Displays the TPM status.

TPM Clear

Intel TXT Allows you enable or disable Intel Trusted Execution Technology. To enable Intel

Power Button Allows you to enable or disable the power button on the front of the system. By

AC Power

Recovery

CAUTION: Clearing the TPM results in loss of all keys in the TPM. The loss of

TPM keys may affect booting to the operating system.

Allows you to clear all the contents of the TPM. By default, the TPM Clear option is

set to No.

TXT, Virtualization Technology must be enabled and TPM Security must be enabled

with Pre-boot measurements. By default, the Intel TXT option is set to Off.

default, the Power Button option is set to Enabled.

Allows you to set how the system reacts after AC power is restored to the system.

By default, the AC Power Recovery option is set to Last.

Miscellaneous Settings

Menu Item Description

System Time Allows you to set the time on the system.

System Date Allows you to set the date on the system.

Asset Tag Displays the asset tag and allows you to modify it for security and tracking

purposes.

Keyboard

NumLock

Allows you to set whether the system boots with the NumLock enabled or

disabled. By default the Keyboard NumLock is set to On.

20

Page 21

Menu Item Description

NOTE: This field does not apply to 84-key keyboards.

Report Keyboard

Errors

F1/F2 Prompt on

Error

In-System

Characterization

Allows you to set whether keyboard-related error messages are reported during

system boot. By default, the Report Keyboard Errors field is set to Report.

Allows you to enable or disable the F1/F2 prompt on error. By default, F1/F2

Prompt on Error is set to Enabled.

This field enables or disables In-System Characterization. By default, In-System

Characterization is set to Enabled.

System And Setup Password Features

You can create a system password and a setup password to secure your system. To enable creation of

the system and setup password, the password jumper must be set to enabled. For more information on

the password jumper settings, see System Board Jumper Settings.

System

password

Setup

password

CAUTION: The password features provide a basic level of security for the data on your system.

CAUTION: Anyone can access the data stored on your system if the system is running and

unattended.

This is the password that you must enter to log on to your system.

This is the password that you must enter to access and make changes to the BIOS

or UEFI settings of your system.

NOTE: Your system is shipped with the system and setup password feature disabled.

Assigning A System And/Or Setup Password

NOTE: The password jumper enables or disables the System Password and Setup Password

features. For more information on the password jumper settings, see System Board Jumper

Settings.

You can assign a new System Password and/or Setup Password or change an existing System Password

and/or Setup Password only when the password jumper setting is enabled and Password Status is

Unlocked. If the Password Status is Locked, you cannot change the System Password and/or Setup

Password.

If the password jumper setting is disabled, the existing System Password and Setup Password is deleted

and you need not provide the system password to log on to the system.

To assign a system and/or setup password:

1. To enter System Setup, press <F2> immediately after a power-on or reboot.

2. In the System Setup Main Menu, select System BIOS and press <Enter>.

The System BIOS screen is displayed.

3. In the System BIOS screen, select System Security and press <Enter>.

The System Security screen is displayed.

21

Page 22

4. In the System Security screen, verify that Password Status is Unlocked.

5. Select System Password , enter your system password, and press <Enter> or <Tab>.

Use the following guidelines to assign the system password:

• A password can have up to 32 characters.

• The password can contain the numbers 0 through 9.

• Only lower case letters are valid, upper case letters are not allowed.

• The following special characters are allowed: space, (”), (+), (,), (-), (.), (/), (;), ([), (\), (]), (`).

A message prompts you to re-enter the system password.

6. Re-enter the system password that you entered earlier and click OK.

7. Select Setup Password, enter your system password and press <Enter> or <Tab>.

A message prompts you to re-enter the setup password.

8. Re-enter the setup password that you entered earlier and click OK.

9. Press <Esc> to save the changes.

NOTE: Password protection does not take effect until the system reboots.

Using Your System Password To Secure Your System

NOTE: If you have assigned a setup password, the system accepts your setup password as an

alternate system password.

1. Turn on or reboot your system.

2. Type your password and press <Enter>.

When Password Status is Locked, type the password and press <Enter> when prompted at reboot.

If an incorrect system password is entered, the system displays a message and prompts you to re-enter

your password. You have three attempts to enter the correct password. After the third unsuccessful

attempt, the system displays an error message that the system has halted and must be powered down.

Even after you shut down and restart the system, the error message is displayed until the correct

password is entered.

NOTE: You can use the Password Status option in conjunction with the System Password and

Setup Password options to protect your system from unauthorized changes.

Deleting or changing an existing system and/or setup password

Ensure that the Password jumper is set to enabled and the Password Status is Unlocked before

attempting to delete or change the existing System and/or Setup password. You cannot delete or change

an existing System or Setup password if the Password Status is Locked.

To delete or change the existing System and/or Setup password:

1. To enter System Setup, press <F2> immediately after a power-on or reboot.

2. In the System Setup Main Menu, select System BIOS and press <Enter>.

The System BIOS screen is displayed.

3. In the System BIOS Screen, select System Security and press <Enter>.

The System Security screen is displayed.

4. In the System Security screen, verify that Password Status is Unlocked.

5. Select System Password, alter or delete the existing system password and press <Enter> or <Tab>.

22

Page 23

6. Select Setup Password, alter or delete the existing setup password and press <Enter> or <Tab>.

NOTE: If you change the System and/or Setup password a message prompts you to re-enter

the new password. If you delete the System and/or Setup password, a message prompts you to

confirm the deletion.

7. Press <Esc> to save the changes.

NOTE: You can disable password security while logging on to the system. To disable the password

security, turn on or reboot your system, type your password and press <Ctrl><Enter>.

Operating with a setup password enabled

If Setup Password is Enabled, enter the correct setup password before modifying most of the System

Setup options.

If you do not enter the correct password in three attempts, the system displays the message

Incorrect Password! Number of unsuccessful password attempts: <x> System

Halted! Must power down.

Even after you shut down and restart the system, the error message is displayed until the correct

password is entered. The following options are exceptions:

• If System Password is not Enabled and is not locked through the Password Status option, you can

assign a system password.

• You cannot disable or change an existing system password.

NOTE: You can use the Password Status option in conjunction with the Setup Password option to

protect the system password from unauthorized changes.

Entering the UEFI Boot Manager

NOTE: Operating systems must be 64-bit UEFI-compatible (for example, Microsoft Windows Server

2008 x64 version) to be installed from the UEFI boot mode. DOS and 32-bit operating systems can

only be installed from the BIOS boot mode.

The Boot Manager enables you to:

• Add, delete, and arrange boot options

• Access System Setup and BIOS-level boot options without rebooting

To enter the Boot Manager:

1. Turn on or restart your system.

2. Press <F11> after you see the following message:

<F11> = UEFI Boot Manager

If your operating system begins to load before you press <F11>, allow the system to finish booting,

and then restart your system and try again.

Using the Boot Manager navigation keys

Key Description

Up arrow Moves to the previous field.

23

Page 24

Key Description

Down arrow Moves to the next field.

<Enter> Allows you to type in a value in the selected field (if applicable) or follow the link in

the field.

Spacebar Expands or collapses a drop-down list, if applicable.

<Esc> Moves to the previous page till you view the main screen. Pressing <Esc> in the

main screen exits System Setup. A message prompts you to save any unsaved

changes.

<F1> Displays the System Setup help file.

NOTE: For most of the options, any changes that you make are recorded but do not take effect until

you restart the system.

Boot Manager screen

Menu Item Description

Continue Normal

Boot

BIOS Boot Menu Displays the list of available BIOS boot options (marked with asterisks). Select the

UEFI Boot Menu Displays the list of available UEFI boot options (marked with asterisks). Select the

Driver Health

Menu

Launch System

Setup

System Utilities Enables you to access the BIOS Update File Explorer, run the Dell Diagnostics

The system attempts to boot to devices starting with the first item in the boot

order. If the boot attempt fails, the system continues with the next item in the boot

order until the boot is successful or no more boot options are found.

boot option you wish to use and press <Enter>.

boot option you wish to use and press <Enter>. The UEFI Boot Menu enables you

to Add Boot Option, Delete Boot Option, or Boot From File.

Displays a list of the drivers installed on the system and their health status.

Enables you to access the System Setup.

program, and reboot the system.

UEFI Boot menu

Menu Item Description

Boot From File Sets a one-time boot option not included in the boot option list.

Select UEFI Boot

Option

Displays the list of available UEFI boot options (marked with asterisks), select the

boot option you wish to use and press <Enter>.

Add Boot Option Adds a new boot option.

Delete Boot

Option

24

Deletes an existing boot option.

Page 25

Embedded System Management

The Dell Lifecycle Controller provides advanced embedded systems management throughout the

server’s lifecycle. The Lifecycle Controller can be started during the boot sequence and can function

independently of the operating system.

NOTE: Certain platform configurations may not support the full set of features provided by the

Lifecycle Controller.

For more information about setting up the Lifecycle Controller, configuring hardware and firmware, and

deploying the operating system, see the Lifecycle Controller documentation at support.dell.com/

manuals.

iDRAC Settings Utility

The iDRAC Settings utility is an interface to setup and configure the iDRAC parameters using UEFI. You

can enable or disable various iDRAC parameters using the iDRAC7 Settings Utility, for example:

NOTE: Some of the features mentioned in the list may require the iDRAC7 Enterprise License

upgrade.

• Configure, enable, or disable the iDRAC local area network through the dedicated iDRAC Enterprise

card port or the embedded NIC

• Enable or disable IPMI over LAN

• Enable a LAN Platform Event Trap (PET) destination

• Attach or detach the Virtual Media devices

For more information on using iDRAC7, see the iDRAC7 User's Guide, at support.dell.com/manuals.

Entering the iDrac Settings utility

1. Turn on or restart the managed system.

2. Press <F2> during Power-on Self-test (POST).

3. In the System Setup Main Menu page, click iDRAC Settings.

The iDRAC Settings page is displayed.

25

Page 26

3

Installing Blade Components

Recommended Tools

You may need the following items to perform the procedures in this section:

• #1 and #2 Phillips screwdrivers

• T10 and T15 Torx screwdrivers

• Wrist grounding strap (connected to ground)

Removing And Installing A Sleeve

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

• Before you remove or install a sleeve in the enclosure, ensure that the top slot (Blade a) of the sleeve

is empty.

• You can remove or install a sleeve in the enclosure with blades or blade blanks installed in the slots

Blade b, Blade c, and Blade d.

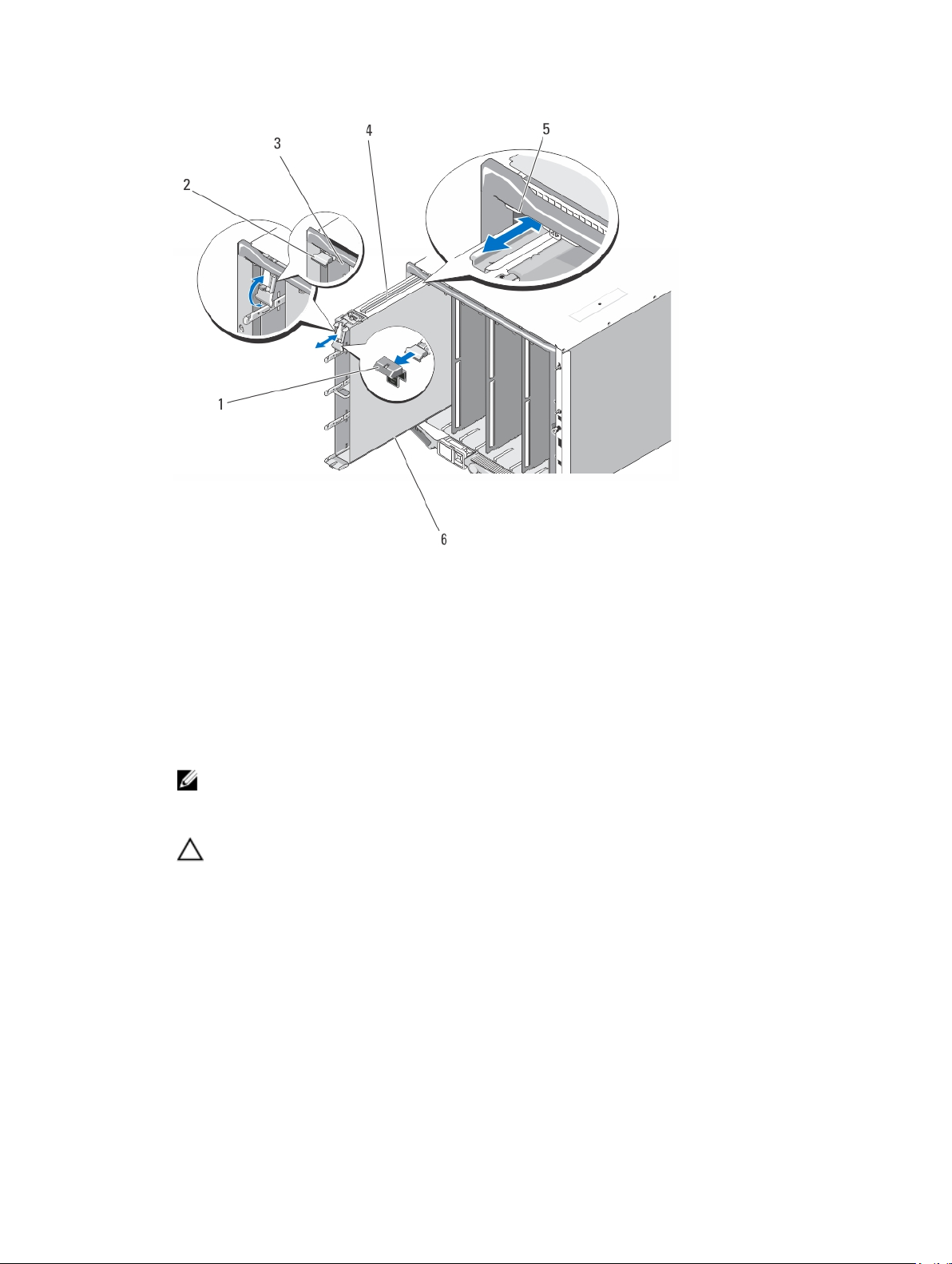

Removing The Sleeve

1. Power down the blades in the sleeve using operating system commands or the CMC.

When a blade is powered off, its front-panel power indicator is off.

CAUTION: Before removing a sleeve from slots 3 or 4 of the enclosure, rotate the LCD panel

to the storage position to prevent accidental damage to the LCD screen.

2. Remove the blade from the top slot (Blade a) of the sleeve.

CAUTION: If you are permanently removing a sleeve from the enclosure, install two halfheight blade blanks. Operating the system for extended periods of time without blade blanks

installed can cause the enclosure to overheat.

3. Pull the sleeve handle to release the sleeve from the locked position.

4. Push down on the sleeve handle and slide the sleeve out of the enclosure.

CAUTION: To protect the I/O connector pins at the back of the sleeve, install the I/O

connector covers any time a sleeve is removed from the enclosure.

5. Install the cover on the sleeve handle.

6. Install the I/O connector covers over the I/O connectors on the sleeve.

26

Page 27

Figure 5. Removing and Installing a Sleeve

1. sleeve handle cover 2. sleeve handle

3. sleeve/blade slot 4. guide rail on sleeve

5. guide rail on enclosure 6. sleeve

Installing The Sleeve

1. Remove the I/O connector covers from the I/O connectors on the sleeve and save for future use.

2. Remove the cover from the sleeve handle.

NOTE: To ensure optimal thermal performance, do not replace the cover on the sleeve handle

after the sleeve is installed in the enclosure.

3. If installed, remove the blade or blade blank from the top slot (Blade a) of the sleeve.

CAUTION: If you are installing a sleeve in bays 3 or 4, rotate the LCD module to the

horizontal storage position to prevent accidental damage to the LCD screen.

4. Align the guide rail on the upper edge of the sleeve so that the rail fits between the plastic guides on

the enclosure.

5. Slide the sleeve into the enclosure.

6. Lift the sleeve handle up to secure the sleeve in the enclosure.

27

Page 28

Removing And Installing A Blade

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

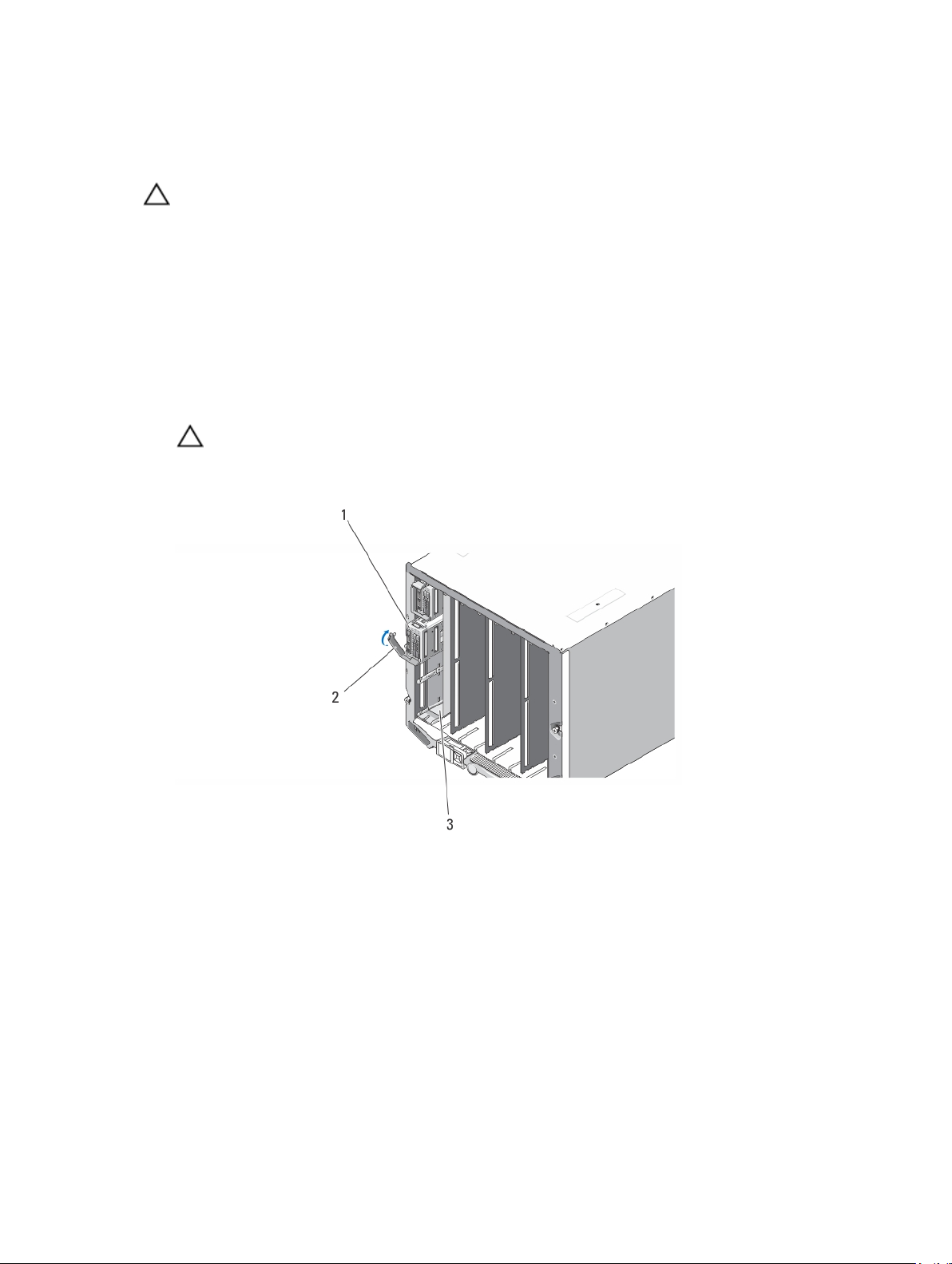

Removing A Blade

1. Power down the blade in the sleeve using operating system commands or the CMC, and ensure that

the blade is turned off.

When a blade is turned off, its front-panel power indicator is off.

2. Pull down on the blade release handle and slide the blade out of the sleeve.

CAUTION: If you are permanently removing the blade, install a blade blank. Operating the

system for extended periods of time without a blade blank installed can cause the enclosure

to overheat.

Figure 6. Removing and Installing a Blade

1. blade 2. blade release handle

3. sleeve

Installing A Blade

1. If you are installing a blade in the top slot (Blade a) of the sleeve, ensure that the sleeve is installed in

the enclosure.

2. If installed, remove the blade blank from the blade slot in the sleeve.

3. Orient the blade so that the blade release handle faces the sleeve release handle.

4. Slide the blade into the sleeve until the blade release handle engages and locks the blade in place.

28

Page 29

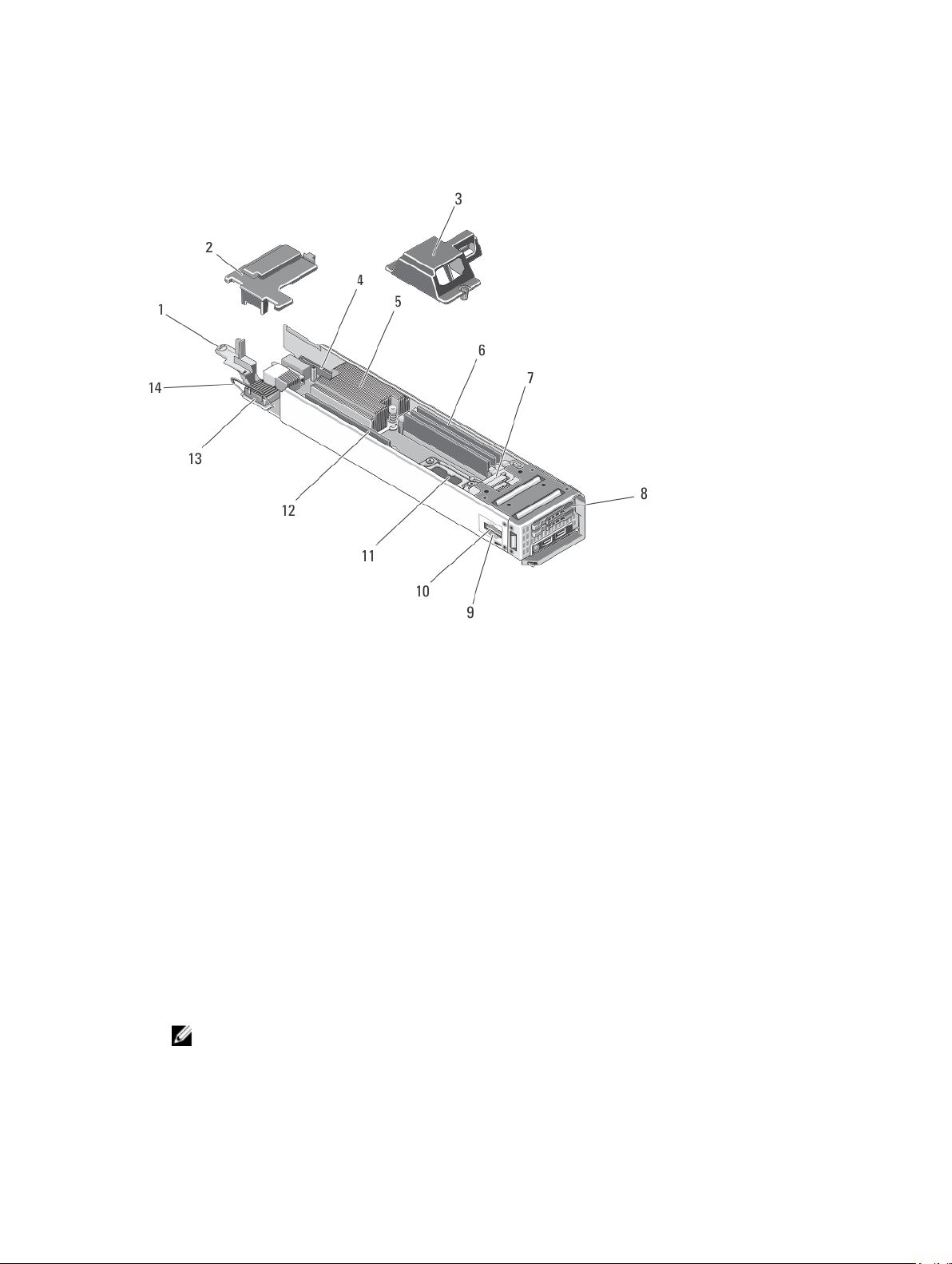

Inside The Blade

Figure 7. Inside the Blade

1. blade system board release handle 2. mezzanine card blank

3. processor/DIMM blank 4. LOM riser card connector

5. heat sink (for processor 1) 6. memory modules (3) (for processor 2)

7. SSD backplane 8. solid state drives (2)

9. SD card 1 slot 10. SD vFlash card/SD card 2 slot

11. processor 2 socket 12. memory modules (3) (for processor 1)

13. optional mezzanine card (Fabric B or C) 14. mezzanine card release latch

I/O Module Mezzanine Card

Mezzanine Card Installation Guidelines

• The blade supports one SFF mezzanine card.

• The mezzanine card slot supports Fabric B or Fabric C, depending on the slot in the sleeve where the

blade is installed. This card must match the fabric type of the I/O modules installed in the

corresponding I/O module bays.

NOTE: For more information on I/O modules, see "Guidelines for Installing I/O Modules" in the

M1000e Enclosure Owner's Manual at support.dell.com/manuals.

29

Page 30

Removing A Mezzanine Card

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

1. Remove the blade from the sleeve.

2. Rotate the mezzanine card retention latch to unlock the mezzanine card.

NOTE: Hold the mezzanine card by its edges only.

3. Lift the mezzanine card up and away from the blade system board.

4. If you are permanently removing the mezzanine card, you must install a mezzanine blank over the

vacant mezzanine card slot. To install a mezzanine blank:

a. Place the mezzanine blank on the mezzanine card connector.

When properly seated, the tabs underneath the mezzanine blank cover all corners of the

mezzanine card connector and the tab on the side of the mezzanine blank rests over the slot on

the chassis wall.

b. Rotate the mezzanine card retention latch over the mezzanine blank to secure it in position.

5. Install the blade in the sleeve.

Figure 8. Removing and Installing a Mezzanine Card

1. mezzanine card 2. locking tab on the side of the

3. mezzanine card slot 4. mezzanine card retention latch

30

mezzanine card

Page 31

Figure 9. Removing and Installing a Mezzanine Blank

1. tabs under the mezzanine blank (4) 2. mezzanine blank

3. locking tab on the side of the mezzanine

blank

5. mezzanine card retention latch

4. mezzanine card slot

Installing A Mezzanine Card

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

1. Rotate the mezzanine card retention latch to unlock the mezzanine blank.

2. Release the locking tab on the side of the mezzanine blank secured to the wall of the chassis and lift

the mezzanine blank away from the system.

NOTE: Hold the mezzanine card by its edges only.

3. Orient the card to align the connector on the bottom of the mezzanine card with the mezzanine

card slot on the blade system board.

4. Lower the card into place until it is fully seated.

5. Rotate the mezzanine card retention latch over the mezzanine card to secure it in position.

6. Install the blade in the sleeve.

31

Page 32

LOM Riser Card

Removing The LOM Riser Card

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

1. Remove the blade from the sleeve.

2. Remove the two screws that secure the LOM riser card to the blade system board.

3. Lift the card away from the blade system board.

Figure 10. Removing and Installing the LOM Riser Card

1. LOM riser card 2. screws (2)

3. LOM riser card connector

Installing The LOM Riser Card

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

1. Remove the blade from the sleeve.

2. Install the LOM riser card:

a. Lower the LOM riser card into place until the card connector fits into the corresponding

connector on the blade system board.

b. Secure the card with the two screws.

3. Install the blade in the sleeve.

32

Page 33

Solid State Drives

• The system supports up to two 1.8 inch uSATA Solid State Drives (SSDs).

• All SSDs connect to the blade system board through the SSD backplane.

• SSDs are supplied in special hot-swappable drive carriers that fit in the SSD slots.

• For a single SSD configuration, an SSD blank must be installed in the other drive bay to maintain

proper cooling airflow.

Removing A Solid State Drive

NOTE: Not all operating systems support hot-swappable drive installation. See the documentation

supplied with your operating system.

1. Take the SSD offline and wait until the indicator codes on the SSD-drive carrier signal that the drive

may be removed safely.

When all indicators are off, the drive is ready for removal.

See your operating system documentation for more information on taking the SSD offline.

2. Open the SSD carrier release handle to release the drive from the SSD connector on the SSD

backplane.

3. Slide the SSD out until it is free of the drive bay.

If you are permanently removing an SSD, install a blank insert.

Figure 11. Removing and Installing an SSD

1. SSD carrier release handle 2. SSD

3. SSD connectors (2) 4. SSD backplane

Installing A Solid State Drive

CAUTION: When a replacement hot-swappable SSD is installed and the blade is powered on, the

SSD automatically begins to rebuild. Make absolutely sure that the replacement SSD is blank or

contains data that you wish to have over-written. Any data on the replacement SSD is

immediately lost after the SSD is installed.

33

Page 34

NOTE: Not all operating systems support hot-swappable drive installation. See the documentation

supplied with your operating system.

1. If installed, remove the SSD blank.

2. If closed, open the SSD carrier release handle.

3. Insert the SSD drive carrier into the drive slot until the carrier connects with the SSD backplane.

4. Close the release handle to lock the SSD in place.

NOTE: The status LED indicator displays a steady green light if the SSD is installed correctly. The

SSD carrier LED green indicator flashes as the drive rebuilds.

Shutdown Procedure For Servicing A Solid State Drive

NOTE: This section applies only when the blade must be powered down to service an SSD. In many

situations, the SSD can be serviced while the blade is powered on.

If you need to power off the blade to service an SSD, wait for 30 seconds after the blade’s power

indicator turns off, before removing the SSD. Otherwise, the SSD may not be recognized after it is

reinstalled and the blade is powered on again.

Configuring the boot drive

The drive or device from which the system boots is determined by the boot order specified in the System

Setup.

Removing An SSD From The SSD Carrier

CAUTION: To avoid damaging the SSD or the SSD carrier, do not use excessive force.

1. Slightly pull outward on the edges of the SSD carrier in the direction of the arrows marked on the

SSD carrier and disengage the SSD from the carrier.

2. Slide the SSD out of the SSD carrier.

34

Page 35

Figure 12. Removing and Installing an SSD Into an SSD Carrier

1. arrows (2) 2. SSD carrier

3. SSD 4. SSD connectors

5. connector alignment label

Installing An SSD In The SSD Carrier

1. Align the SSD with the SSD carrier so that the connectors on the SSD face up and match the

connector alignment label on the SSD carrier.

CAUTION: To avoid damaging the SSD or the SSD carrier, do not use excessive force.

2. Slide the SSD into the SSD carrier until it is secured inside the SSD carrier.

Solid State Drive Backplane

Removing The SSD Backplane

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

1. Remove the blade from the sleeve.

CAUTION: To prevent damage to the SSDs and the backplane, you must remove the SSDs

from the blade before removing the SSD backplane.

CAUTION: You must note the number of each SSD and temporarily label them before

removal so that you can replace them in the same locations.

2. Remove the SSD(s).

3. Slide the blue release latches up.

35

Page 36

4. Slide the SSD backplane away from the card-edge connector on the management riser card and lift

the SSD backplane out of the blade.

Figure 13. Removing and Installing the SSD Backplane

1. SSD backplane 2. SSD backplane connector

3. card-edge connector (on management

riser card)

4. release latches (2)

Installing The SSD Backplane

1. Align the backplane connector with the card edge connector on the management riser card.

2. Slide the SSD backplane in until it engages securely with the card-edge connector on the

management riser card.

3. Push the blue release tabs down to lock the SSD backplane.

4. Install the SSD(s).

5. Install the blade in the sleeve.

36

Page 37

Processors

• Your system supports up to two Intel Xeon processor E5-2400 or E5-2400v2 product family.

• Single-processor configuration is supported.

Use the following procedure when:

• Installing an additional processor

• Replacing a processor

Removing A Processor

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

1. Remove the blade from the sleeve.

WARNING: The processor and heat sink can become extremely hot. Be sure the processor

has had sufficient time to cool before handling.

CAUTION: Never remove the heat sink from a processor unless you intend to remove the

processor. The heat sink is necessary to maintain proper thermal conditions.

2. Loosen the two retention sockets that secure the heat sink to the blade system board.

3. Remove the heat sink.

37

Page 38

Figure 14. Removing and Installing a Heat Sink

1. heat sink 2. retention sockets (2)

3. retention screws (2)

4. Use a clean, lint-free cloth to remove any thermal grease from the surface of the processor shield.

CAUTION: The processor is held in its socket under strong pressure. Be aware that the

release lever can spring up suddenly if not firmly grasped.

5. Position your thumb firmly over the processor socket-release lever and release the lever from the

locked position. Rotate the lever 90 degrees upward until the processor is released from the socket.

6. Use the tab on the processor shield to rotate the processor shield upward and out of the way.

7. If applicable, remove the socket protective cap from the processor shield. To remove the socket

protective cap, push the cap from the inside of the processor shield and move it away from the

socket pins.

NOTE: It is recommended that you install/remove the socket protective cap from the processor

shield with the processor shield in the open position.

CAUTION: The socket pins are fragile and can be permanently damaged. Be careful not to

bend the pins in the socket when removing the processor out of the socket.

8. Lift the processor out of the socket and leave the release lever up so that the socket is ready for the

new processor.

CAUTION: If you are permanently removing a processor, you must install a socket protective

cap and a processor/DIMM blank in the vacant socket to ensure proper system cooling. The

processor/DIMM blank covers the vacant sockets for the DIMMs and the processor.

38

Page 39

NOTE: For more information on installing a processor/DIMM blank, see Removing A Processor/

DIMM Blank.

Figure 15. Removing and Installing a Processor

1. processor 2. processor shield

3. notches in the processor (4) 4. socket keys (4)

5. pin-1 indicator (on the processor socket) 6. pin-1 indicator (on the processor)

7. socket-release lever

Installing A Processor

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

NOTE: If you are installing just one processor, it must be installed in socket CPU1.

1. If applicable, remove the heat-sink blank.

2. Unlatch and rotate the socket-release lever 90 degrees upward and ensure that the socket-release

lever is fully open.

3. Use the tab on the processor shield to rotate the processor shield upward and out of the way.

4. If applicable, remove the socket protective cap from the processor shield. To remove the socket

protective cap, push the cap from the inside of the processor shield and move it away from the

socket pins.

39

Page 40

NOTE: It is recommended that you install/remove the socket protective cap from the processor

shield with the processor shield in the open position.

CAUTION: Positioning the processor incorrectly can permanently damage the system board

or the processor. Be careful not to bend the pins in the socket.

CAUTION: Do not use force to seat the processor. When the processor is positioned

correctly, it engages easily into the socket.

5. Install the processor in the socket:

a. Identify the pin-1 corner of the processor by locating the tiny gold triangle on one corner of the

processor. Place this corner in the same corner of the ZIF socket identified by a corresponding

triangle on the processor socket.

b. Align the pin-1 corner of the processor with the pin-1 corner of the processor socket.

c. Set the processor lightly in the socket.

Because the system uses a ZIF processor socket, do not use force. When the processor is

positioned correctly, it drops down into the socket with minimal pressure.

d. Verify that the processor is properly aligned and seated.

e. Close the processor shield.

f. Rotate the socket release lever down until it is locked in position.

6. Install the heat sink:

If you are:

Reinstalling a

heat sink

Upgrading a

processor

Reinstalling a

processor

CAUTION: Applying too much thermal grease can result in excess grease coming in contact

with and contaminating the processor socket.

a. Open the grease applicator included with your processor kit and apply all of the thermal grease in

the applicator to the center of the topside of the new processor.

b. Place the heat sink onto the processor.

c. Tighten the retention sockets to secure the heat sink to the blade system board.

7. Install the blade in the sleeve.

As the system boots, it detects the presence of the new processor and automatically changes the

system configuration information in the System Setup.

8. Press <F2> to enter the System Setup and check that the processor information matches the new

system configuration.

9. Run the system diagnostics to verify that the new processor operates correctly.

10. Update the system BIOS.

Use a clean, lint-free cloth to remove the existing thermal grease from the

heat sink.

If a new heat sink was supplied with the processor, install it.

Clean any remnants of thermal grease from the processor.

40

Page 41

NVRAM backup battery

Replacing The NVRAM Backup Battery

WARNING: There is a danger of a new battery exploding if it is incorrectly installed. Replace the

battery only with the same or equivalent type recommended by the manufacturer. Discard used

batteries according to the manufacturer's instructions. See the safety instructions that came with

your system for additional information.

CAUTION: Many repairs may only be done by a certified service technician. You should only

perform troubleshooting and simple repairs as authorized in your product documentation, or as

directed by the online or telephone service and support team. Damage due to servicing that is

not authorized by Dell is not covered by your warranty. Read and follow the safety instructions

that came with the product.

1. Remove the blade from the sleeve.

2. To disengage the battery from the battery connector, support the battery connector by pressing on

the sides of the connector, and push the battery to the positive side of the connector.

3. Lift the battery out of the securing tabs of the battery connector.

4. To install a new system battery: