Page 1

Dell Precision 7920 Rack

Owner's Manual

Reg ula tor y M ode l: E38 S

Reg ula tor y T ype : E 38S 001

Nov emb er 202 0

Rev . A 02

Page 2

Notes, cautions, and warnings

NOTE: A NOTE indicates important information that helps you make better use of your product.

CAUTION: A CAUTION indicates either potential damage to hardware or loss of data and tells you how to avoid

the problem.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

© 2018 2020 Dell Inc. or its subsidiaries. All rights reserved. Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries.

Other trademarks may be trademarks of their respective owners.

Page 3

Contents

Chapter 1: Working on your computer........................................................................................... 6

Safety instructions.............................................................................................................................................................. 6

Before working inside your computer.............................................................................................................................6

After working inside your computer................................................................................................................................7

Chapter 2: Chassis View................................................................................................................ 8

Front chassis view...............................................................................................................................................................8

Back chassis view................................................................................................................................................................9

Inside the system.................................................................................................................................................................9

LCD panel.............................................................................................................................................................................10

Viewing Home screen.................................................................................................................................................. 11

Setup menu.................................................................................................................................................................... 11

View menu......................................................................................................................................................................12

Chapter 3: Product Overview.......................................................................................................13

System information label..................................................................................................................................................13

Chapter 4: Disassembly and reassembly.......................................................................................14

Product Positioning........................................................................................................................................................... 14

Recommended tools..........................................................................................................................................................15

Need to know......................................................................................................................................................................15

Common error messages............................................................................................................................................15

Startup-Shutdown sequence.....................................................................................................................................17

Diagnostics and indicators............................................................................................................................................... 17

Chassis LEDs.......................................................................................................................................................................17

Status LED indicators..................................................................................................................................................17

Hard drive indicator codes......................................................................................................................................... 19

NIC indicator codes.....................................................................................................................................................20

Power supply unit indicator codes.......................................................................................................................... 20

iDRAC Direct LED indicator codes........................................................................................................................... 21

iDRAC Quick Sync 2 indicator codes......................................................................................................................22

Enhanced Preboot System Assessment................................................................................................................ 23

Jumpers and connectors ................................................................................................................................................25

System board jumpers and connectors..................................................................................................................26

System board jumper settings..................................................................................................................................27

Disabling forgotten password...................................................................................................................................28

Disassembly and reassembly...........................................................................................................................................28

Front Bezel....................................................................................................................................................................28

System cover................................................................................................................................................................29

Optical drive..................................................................................................................................................................30

Air shroud....................................................................................................................................................................... 31

Cooling fan assembly.................................................................................................................................................. 32

Cooling fans.................................................................................................................................................................. 33

Intrusion switch............................................................................................................................................................34

Contents 3

Page 4

Hard drive......................................................................................................................................................................35

Memory modules......................................................................................................................................................... 43

Processors and heat sinks.........................................................................................................................................45

Expansion card............................................................................................................................................................. 49

vFlash card – optional................................................................................................................................................56

Network daughter card..............................................................................................................................................57

Hard drive backplane.................................................................................................................................................. 57

Front USB module.......................................................................................................................................................58

Internal USB memory key (optional)...................................................................................................................... 59

Power supply unit........................................................................................................................................................60

System board................................................................................................................................................................ 61

Trusted Platform Module.......................................................................................................................................... 63

Control panel ............................................................................................................................................................... 64

GPU Host Card Installation.............................................................................................................................................66

Alternate Riser Installation........................................................................................................................................ 66

Teradici Tera2220 Host Cards Installation............................................................................................................ 68

NVIDIA Quadro K4200 Graphics Cards Installation ............................................................................................73

Cabling Teradici Host Cards to GPUs.....................................................................................................................78

Updating BIOS ................................................................................................................................................................... 81

Restoring the Service Tag using Easy Restore ......................................................................................................... 81

Manually update the Service Tag ............................................................................................................................81

Installation............................................................................................................................................................................81

Rack Rails...................................................................................................................................................................... 82

Initialization................................................................................................................................................................... 90

Basic configuration...................................................................................................................................................... 91

Accessing system information by using QRL.............................................................................................................. 91

Quick Resource Locator for 7920R........................................................................................................................ 92

Chapter 5: Technology and components...................................................................................... 93

iDRAC9.................................................................................................................................................................................93

iDRAC 9 - New features............................................................................................................................................ 93

Dell Lifecycle Controller...................................................................................................................................................94

Processors.......................................................................................................................................................................... 95

Supported processors................................................................................................................................................ 96

Chipset............................................................................................................................................................................... 102

System memory............................................................................................................................................................... 102

General memory module installation guidelines.................................................................................................. 103

Memory........................................................................................................................................................................ 104

LCD panel.......................................................................................................................................................................... 105

Viewing Home screen............................................................................................................................................... 106

Setup menu................................................................................................................................................................. 106

View menu...................................................................................................................................................................106

Expansion cards and expansion card risers............................................................................................................... 107

Expansion card installation guidelines................................................................................................................... 107

Storage...............................................................................................................................................................................108

Power supply units..........................................................................................................................................................109

Hot spare feature...................................................................................................................................................... 109

Trusted platform module ............................................................................................................................................... 110

4

Contents

Page 5

Chapter 6: BIOS and UEFI........................................................................................................... 111

Options to manage the pre-operating system applications.................................................................................... 111

System Setup.....................................................................................................................................................................111

Viewing System Setup............................................................................................................................................... 111

System Setup Main Menu........................................................................................................................................ 112

System BIOS screen.................................................................................................................................................. 112

System information screen details......................................................................................................................... 113

Memory settings screen details.............................................................................................................................. 113

Processor settings screen details...........................................................................................................................114

SATA settings screen details...................................................................................................................................115

Boot settings screen details.....................................................................................................................................117

Network settings screen details............................................................................................................................. 118

Integrated devices screen details........................................................................................................................... 119

Serial Communication screen details..................................................................................................................... 121

System profile settings screen details...................................................................................................................121

System security settings screen details............................................................................................................... 122

Miscellaneous settings screen details...................................................................................................................124

Technical specifications................................................................................................................................................. 124

System dimensions.................................................................................................................................................... 125

Chassis weight............................................................................................................................................................125

Processor specifications.......................................................................................................................................... 125

PSU specifications.....................................................................................................................................................126

System battery specifications................................................................................................................................ 126

Expansion bus specifications.................................................................................................................................. 126

Memory specifications..............................................................................................................................................127

Ports and connectors specifications..................................................................................................................... 127

Video specifications...................................................................................................................................................128

Environmental specifications.................................................................................................................................. 128

Chapter 7: Troubleshooting your system.................................................................................... 131

System diagnostics.......................................................................................................................................................... 131

Dell Embedded System Diagnostics....................................................................................................................... 131

Chapter 8: Getting help............................................................................................................. 133

Contacting Dell.................................................................................................................................................................133

Contents

5

Page 6

Working on your computer

Topics:

• Safety instructions

Before working inside your computer

•

• After working inside your computer

Safety instructions

Prerequisites

Use the following safety guidelines to protect your computer from potential damage and to ensure your personal safety. Unless

otherwise noted, each procedure included in this document assumes that the following conditions exist:

● You have read the safety information that shipped with your computer.

A component can be replaced or, if purchased separately, installed by performing the removal procedure in reverse order.

●

About this task

NOTE:

Disconnect all power sources before opening the computer cover or panels. After you finish working inside the

computer, replace all covers, panels, and screws before connecting to the power source.

1

WARNING: Before working inside your computer, read the safety information that shipped with your computer.

For additional safety best practices information, see the Regulatory Compliance Homepage

CAUTION: Many repairs may only be done by a certified service technician. You should only perform

troubleshooting and simple repairs as authorized in your product documentation, or as directed by the online or

telephone service and support team. Damage due to servicing that is not authorized by Dell is not covered by

your warranty. Read and follow the safety instructions that came with the product.

CAUTION: To avoid electrostatic discharge, ground yourself by using a wrist grounding strap or by periodically

touching an unpainted metal surface at the same time as touching a connector on the back of the computer.

CAUTION: Handle components and cards with care. Do not touch the components or contacts on a card. Hold a

card by its edges or by its metal mounting bracket. Hold a component such as a processor by its edges, not by

its pins.

CAUTION: When you disconnect a cable, pull on its connector or on its pull-tab, not on the cable itself. Some

cables have connectors with locking tabs; if you are disconnecting this type of cable, press in on the locking

tabs before you disconnect the cable. As you pull connectors apart, keep them evenly aligned to avoid bending

any connector pins. Also, before you connect a cable, ensure that both connectors are correctly oriented and

aligned.

NOTE: The color of your computer and certain components may appear differently than shown in this document.

CAUTION: System will shut down if side covers are removed while the system is running. The system will not

power on if the side cover is removed.

Before working inside your computer

About this task

To avoid damaging your computer, perform the following steps before you begin working inside the computer.

6 Working on your computer

Page 7

Steps

1. Ensure that you follow the Safety instructions.

2. Turn off the system, including any attached peripherals.

3. Disconnect the system from the electrical outlet and disconnect the peripherals.

4. If applicable, remove the system from the rack.

5. Remove the system cover.

After working inside your computer

About this task

After you complete any replacement procedure, ensure that you connect any external devices, cards, and cables before turning

on your computer.

Steps

1. Replace the cover.

2. If applicable, install the system into the rack.

3. Reconnect the peripherals and connect the system to the electrical outlet.

4. Turn on the system, including any attached peripherals.

Working on your computer 7

Page 8

Topics:

• Front chassis view

Back chassis view

•

• Inside the system

• LCD panel

Front chassis view

2

Chassis View

1. System Status Indicator 2. System health and system ID

3. iDRAC Quick Sync 2 wireless indicator 4. Hard drive (x8)

5. USB 3.0 connector 6. Optical-drive (optional)

7. USB 2.0 connector 8. Power button/Power light

9. VGA connector 10. USB management port/iDRAC Direct

11. USB 2.0 connector

8 Chassis View

Page 9

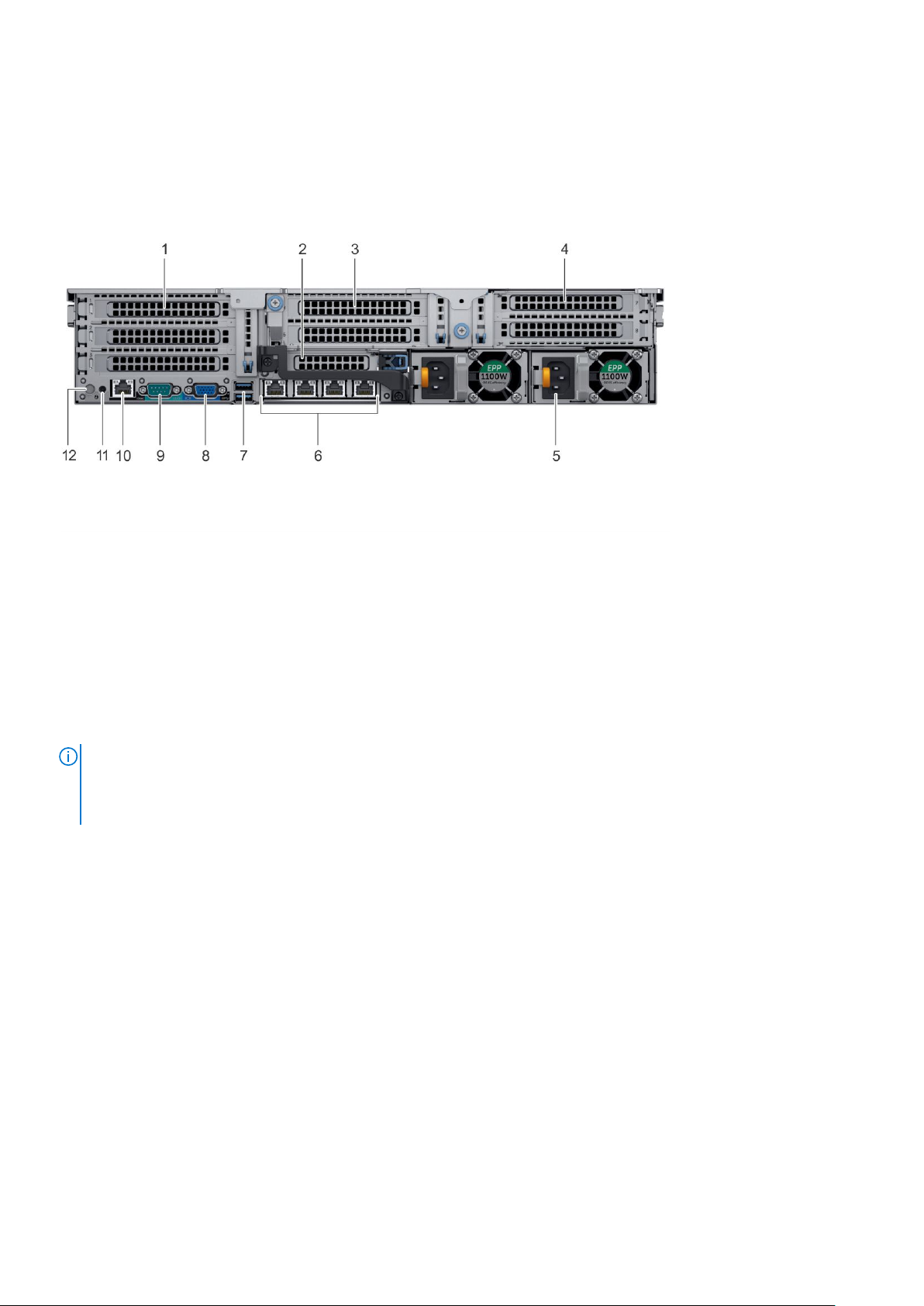

Back chassis view

1. PCIe expansion card slots 2. PCIe expansion card slots

3. PCIe expansion card slots 4. PCIe expansion card slots

5. Power supply (x2) 6. Network connectors (x4)

7. USB 3.0 connectors (x2) 8. VGA connector

9. Serial connector 10. iDRAC9 Enterprise Network connector

11. System identification connector 12. System identification button

Inside the system

NOTE:

Many repairs may only be done by a certified service technician. You should only perform troubleshooting and simple

repairs as authorized in your product documentation, or as directed by the online or telephone service and support team.

Damage due to servicing that is not authorized by Dell is not covered by your warranty. Read and follow the safety

instructions that are shipped with your product.

Chassis View 9

Page 10

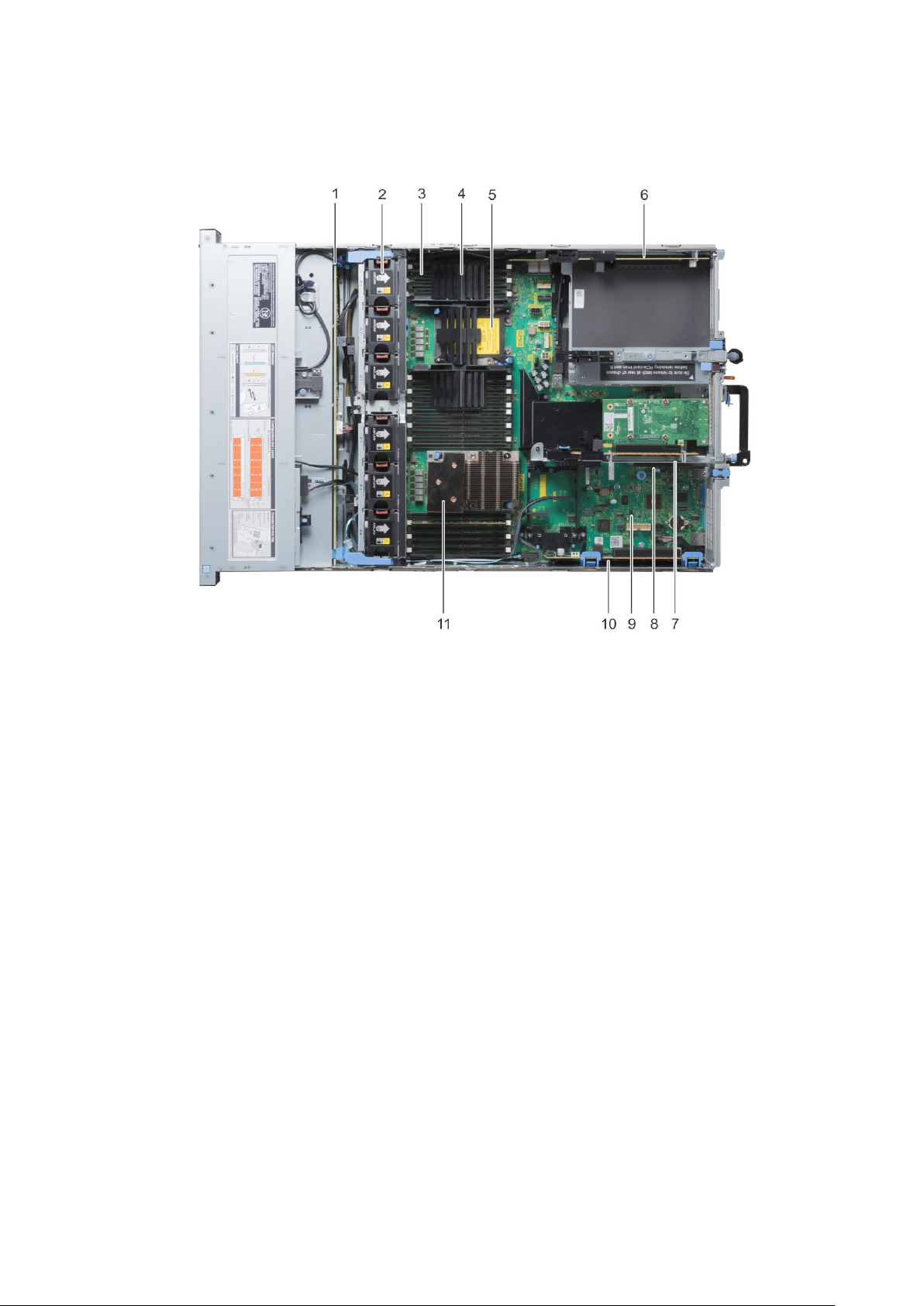

Figure 1. Inside chassis view

1. hard drive backplane

2. cooling fan (6) in the cooling fan assembly

3. DIMM sockets

4. CPU DIMM blank

5. CPU 2

6. expansion card riser 3A

7. expansion card riser 2A

8. VFlash connector

9. system board

10. expansion card riser 1C

11. CPU 1

LCD panel

The LCD panel provides system information, status, and error messages to indicate if the system is functioning correctly or

requires attention. The LCD panel can also be used to configure or view the system’s iDRAC IP address. For information about

the event and error messages generated by the system firmware and agents that monitor system components, see the Error

Code Lookup page at qrl.dell.com.

The LCD panel is available only on the optional front bezel. The optional front bezel is hot pluggable.

The statuses and conditions of the LCD panel are outlined here:

● The LCD backlight is white during normal operating conditions.

10

Chassis View

Page 11

● When the system needs attention, the LCD backlight turns amber, and displays an error code followed by descriptive text.

NOTE: If the system is connected to a power source and an error is detected, the LCD turns amber regardless of

whether the system is turned on or off.

● When the system turns off and there are no errors, LCD enters the standby mode after five minutes of inactivity. Press any

button on the LCD to turn it on.

● If the LCD panel stops responding, remove the bezel and reinstall it.

If the problem persists, see Getting help section.

● The LCD backlight remains off if LCD messaging is turned off using the iDRAC utility, the LCD panel, or other tools.

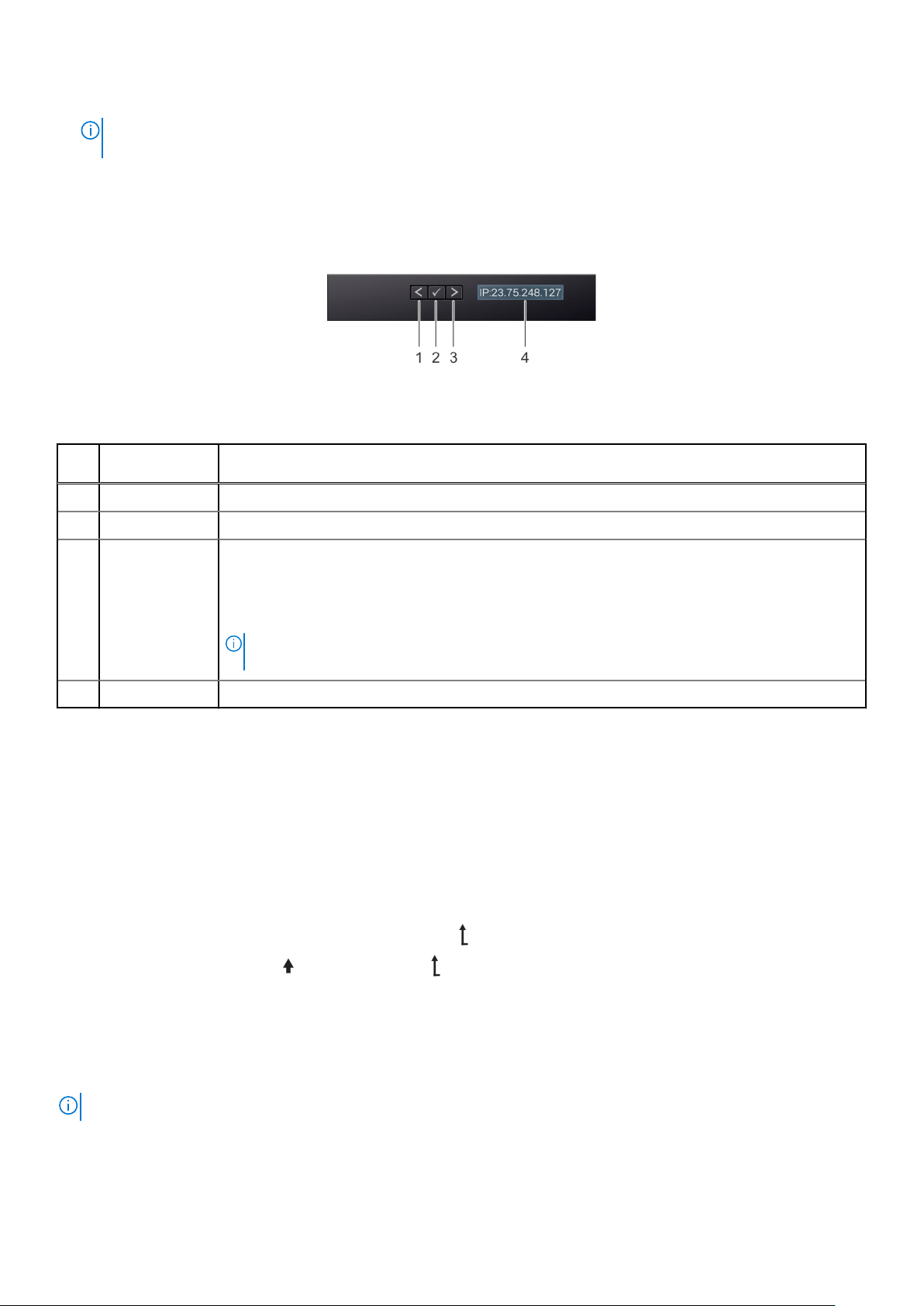

Figure 2. LCD panel features

Table 1. LCD panel features

Item Button or

display

1 Left Moves the cursor back in one-step increments.

2 Select Selects the menu item highlighted by the cursor.

3 Right Moves the cursor forward in one-step increments.

4 LCD display Displays system information, status, and error messages or iDRAC IP address.

Description

During message scrolling:

● Press and hold the right button to increase scrolling speed.

● Release the button to stop.

NOTE: The display stops scrolling when the button is released. After 45 seconds of inactivity,

the display starts scrolling.

Viewing Home screen

The Home screen displays user-configurable information about the system. This screen is displayed during normal system

operation when there are no status messages or errors. When the system turns off and there are no errors, LCD enters the

standby mode after five minutes of inactivity. Press any button on the LCD to turn it on.

Steps

1. To view the Home screen, press one of the three navigation buttons (Select, Left, or Right).

2. To navigate to the Home screen from another menu, complete the following steps:

a. Press and hold the navigation button until the up arrow is displayed.

b. Navigate to the Home icon using the up arrow .

c. Select the Home icon.

d. On the Home screen, press the Select button to enter the main menu.

Setup menu

NOTE: When you select an option in the Setup menu, you must confirm the option before proceeding to the next action.

Chassis View 11

Page 12

Option Description

iDRAC Select DHCP or Static IP to configure the network mode. If Static IP is selected, the available fields are

IP, Subnet (Sub), and Gateway (Gtw). Select Setup DNS to enable DNS and to view domain

addresses. Two separate DNS entries are available.

Set error Select SEL to view LCD error messages in a format that matches the IPMI description in the SEL. This

enables you to match an LCD message with an SEL entry.

Select Simple to view LCD error messages in a simplified user-friendly description.

Set home Select the default information to be displayed on the Home screen. See View menu section for the

options and option items that can be set as the default on the Home screen.

View menu

NOTE: When you select an option in the View menu, you must confirm the option before proceeding to the next action.

Option Description

iDRAC IP Displays the IPv4 or IPv6 addresses for iDRAC9. Addresses include DNS (Primary and Secondary),

Gateway, IP, and Subnet (IPv6 does not have Subnet).

MAC Displays the MAC addresses for iDRAC, iSCSI, or Network devices.

Name Displays the name of the Host, Model, or User String for the system.

Number Displays the Asset tag or the Service tag for the system.

Power Displays the power output of the system in BTU/hr or Watts. The display format can be configured in the

Set home submenu of the Setup menu.

Temperature Displays the temperature of the system in Celsius or Fahrenheit. The display format can be configured in

the Set home submenu of the Setup menu.

12 Chassis View

Page 13

Product Overview

The following pages contain information about Dell Precision 7920 Rack product overview.

Topics:

• System information label

System information label

Precision 7920 Rack – Front system information label

3

Figure 3. LED Behavior, Express Service Tag, Configuration and Layout

Precision 7920 Rack – Service information

Figure 4. System touchpoint, electrical overview, jumper settings and memory information

Product Overview 13

Page 14

Topics:

• Product Positioning

Recommended tools

•

• Need to know

• Diagnostics and indicators

• Chassis LEDs

• Jumpers and connectors

• Disassembly and reassembly

• GPU Host Card Installation

• Updating BIOS

• Restoring the Service Tag using Easy Restore

• Installation

• Accessing system information by using QRL

Product Positioning

4

Disassembly and reassembly

The Precision 7920 Rack is a general-purpose platform with highly expandable memory (up to 1536 GB), massive storage

capacity and impressive I/O capability to match. The Precision 7920 Rack adds extraordinary storage capacity options, making it

well-suited for data intensive applications that require greater storage, while not sacrificing I/O performance.

● Performance

○ Two Intel Xeon Skylake Processor Scalable Family processors

○ Twenty four DIMM Slot supporting up total up to 1.5TB of memory

○ Support total up to eight hard drives.

● Availability

○ Redundant power supply units (PSUs)

○ Hot-plug and hot-swappable PSUs, hard disk drives, and fans

○ PERC9/PERC10/Chipset SATA.

○ Internal vFLASH card

○ iDRAC9 Express or Enterprise with Dell Lifecycle Controller

○ Optional iDRAC Quick Sync II

● Expandability, I/O Storage

○

Only 8x 3.5" SAS,SATA(front) hard drives

○ Up to eight optional NVMe Express Flash PCIe SSDs with two PCIe Zoom4 cards.

○ System Network Architecture (SNA): 4x 1GbE or 2x 10GbE + 2x 1GbE

○ Choice of RAID options for even higher performance

14 Disassembly and reassembly

Page 15

Recommended tools

Table 2. Recommended tools and optional tools

Recommended tools Optional tools

● Key to the system keylock

● #1 and #2 Phillips screwdriver

● T30 and T8 Torx screwdrivers

● Wrist-grounding strap connected to the ground

● ESD Mat

● Needle-nose pliers to disconnect cables and connectors in

hard-to-reach locations

● Small flat-head screwdriver to disconnect small cables

from boards

Need to know

Before you begin servicing the system, you must read the following information:

● Critical callouts

● Common error codes

● Version control for BIOS/ Firmware/ Software

● Startup/Shutdown sequence

Common error messages

The Event Message Reference contains the error and event information generated by firmware and other agents that monitor

system components. These events might be logged, presented to the user on one of the system management consoles, or both

logged and displayed.

Each event consists of the following fields:

Disassembly and reassembly

15

Page 16

Table 3. Common error messages

Event Message Fields

Item Description

Message ID The unique alphanumeric identifier for the event. This identifier can be up

to eight characters long and consist of two parts:

● Message ID Prefix — Up to four alphabetic characters.

● Message ID Sequence — Up to four numeric digits.

Message The message text that is displayed to the user or logged as a result of

the event. If the message has variable content in it, the variable

substitution is reflected by text in italics. The substitution variables are

described in the Arguments field of the event.

Arguments Describes the values for any substitution variables appearing in the event

message text. If there is no variable content in the message, this field is

omitted from the event description.

Detailed Description Additional information describing the event.

Recommended Response Action The recommended action to remedy the event described. The response

action can vary based on the specific platform.

Category Dell Lifecycle Controller log filter used to select a subset of messages

from different domains or agents.

Subcategory Additional filter to further subset the event.

Trap/EventID The identification number used as the Trap ID for SNMP alert traps and

as the Event ID when the message is logged in operating system logs.

Severity The classification of the event based on its impact to the platform or

system. The severity can be:

● Severity 1 Critical — Indicates a catastrophic production problem that

might severely impact production systems or components, or systems

are down or not functioning.

● Severity 2 Warning — Indicates a high-impact problem where a

system or component is disrupted but can remain productive and

perform business-level operations.

● Severity 3 Information — Indicates a medium-to-low impact problem

that involves a partial or noncritical loss of functionality; operations

are impaired but can continue to function.

LCD Message The event message text that is displayed on the system's LCD.

Initial Default Event messages result in event actions such as logging, SNMP or email

alerts. Generally, the event actions are configurable using the Dell iDRAC

event action filtering feature. This item describes the initial default and

possible event actions for the message.

Event Action Filter Describes additional configurable actions that are available for the event

action for this message. This information is presented in a table, and each

entry has a value of TRUE or FALSE to indicate its applicability.

● Filter Visibility — Event visible to iDRAC event filtering.

● IPMI Alert — Event can generate an IMPI alert.

● SNMP Alert — Event can generate an SNMP trap.

● Email Alert — Event can generate an email alert.

● LC Log — Event can generate a Dell Lifecycle Controller log entry.

● LCD — Event is displayed on the system's LCD.

● Power Off — Event can cause the system to power off.

Power Cycle — Event can cause the system to perform a power

●

cycle.

● Reset — Event can cause the system to perform a reset.

For more information on the list of error and event messages, see the Dell Event Messages Reference Guide

16

Disassembly and reassembly

Page 17

Startup-Shutdown sequence

NOTE: Precision 7920 Rack BIOS is pure UEFI with a legacy compatibility layer. This layer is called the Compatibility

Support Module.

New POST display

The following are the POST display enhancements:

● The look of the boot process has been revamped for Precision 7920 Rack.

● The Dell high-resolution splash screen displays instantly after power-on.

● Both a progress bar and descriptive text appear on-screen.

● Hotkey behavior remains unchanged (<F2> still takes you to System Setup).

● There is a uniform look and feel through the boot process (one exception — the system will drop to text mode briefly to run

legacy option ROMs when booting in legacy mode).

● POST error messages are now compliant with Error Exception Message Initiative (EEMI).

NOTE: All POST error and warning messages will be logged in the LC log.

● UEFI option ROMs display error/warning messages on the screen via the Driver Health Protocol (DHP). The auto-repair logic

is also included in Boot Device Selection (BDS) just before booting. Show the repair GUI and load the controller formset if

EfiDriverHealthStatsuConfigurationRequired status is returned.

Enhanced boot support

The following lists the boot support enhancements:

● Enhanced method to change the boot list based on Fully Qualified Descriptors (FQDDs). This allows for systems

management consoles and the factory to specify a boot list for devices that are not currently present, for example, disabled

NDC or other boot mode.

● New ability to toggle between LC and BIOS.

● The Boot Manager (<F11>) and BIOS Setup (<F2>) will only contain the boot option enumeration of the current Boot mode.

● Completely revised boot flow.

Diagnostics and indicators

The following pages contain the information about diagnostics and indicators for Precision 7920 Rack.

Chassis LEDs

The following pages contain the information about the chassis LEDs.

Status LED indicators

NOTE: The diagnostic indicators are not present if the system is equipped with an LCD display.

NOTE: The status LED indicators are always off and only turns on to a solid amber if any error occurs.

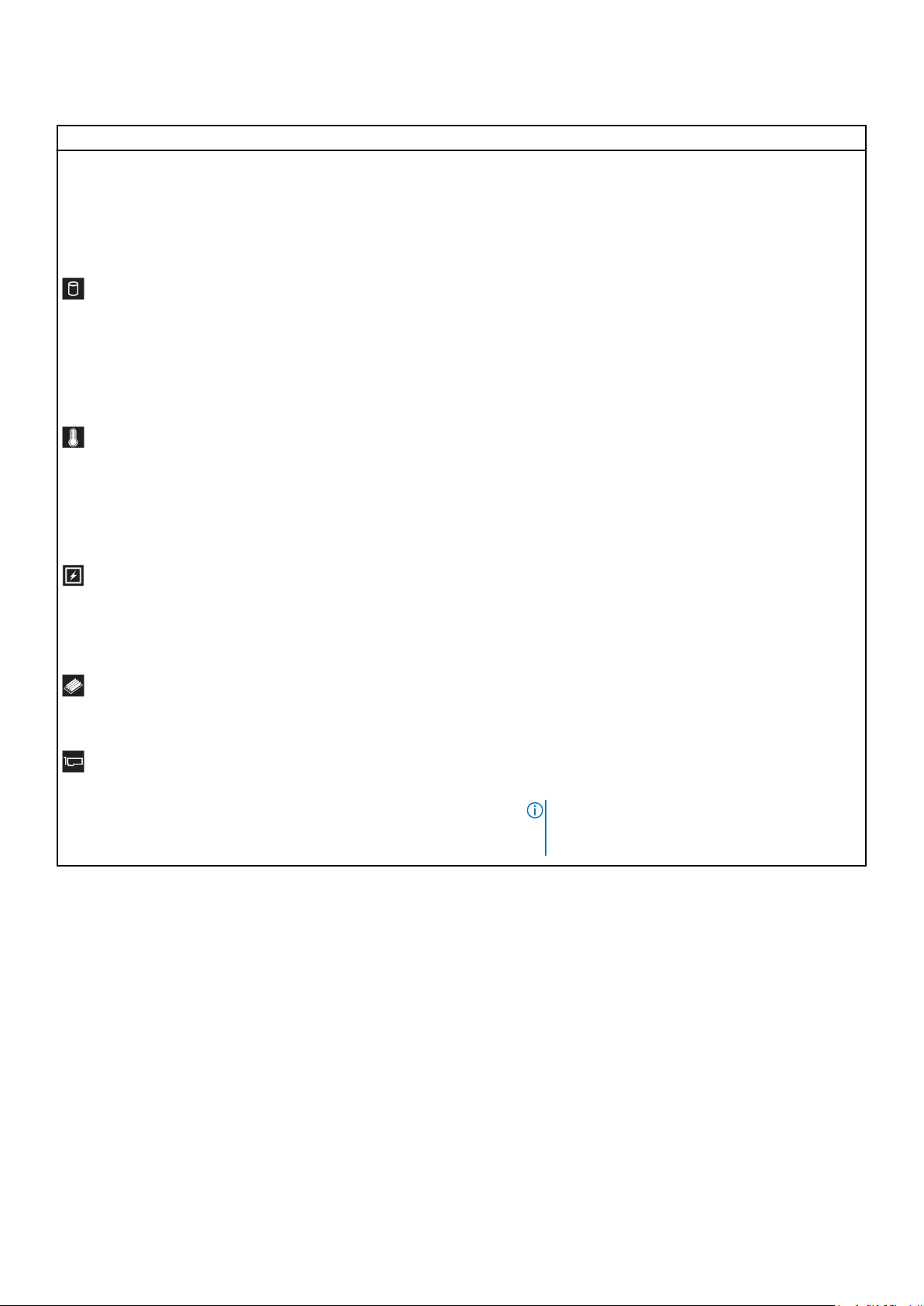

Table 4. Status LED indicators and descriptions

Icon Description Condition Corrective action

Health indicator The indicator turns solid blue if the

is in good health.

The indicator blinks amber:

● When the is turned on.

None required.

Check the System Event Log or system messages

for the specific issue. For more information about

Disassembly and reassembly 17

Page 18

Table 4. Status LED indicators and descriptions (continued)

Icon Description Condition Corrective action

● When the is in standby.

● If any error condition exists. For

example, a failed fan, PSU, or a

hard drive.

error messages, see the Dell Event and Error

Messages Reference Guide at Dell.com/

openmanagemanuals > OpenManage software.

The POST process is interrupted without any video

output due to invalid memory configurations. See the

Getting help section.

Drive indicator The indicator turns solid amber if

there is a drive error.

Temperature

indicator

Electrical

indicator

Memory indicator The indicator turns solid amber if a

PCIe indicator The indicator turns solid amber if a

The indicator turns solid amber if

the system experiences a thermal

error (for example, the ambient

temperature is out of range or

there is a fan failure).

The indicator turns solid amber if

the system experiences an

electrical error (for example,

voltage out of range, or a failed

power supply unit (PSU) or voltage

regulator).

memory error occurs.

PCIe card experiences an error.

● Check the System Event Log to determine if the

drive has an error.

● Run the appropriate Online Diagnostics test.

Restart the system and run embedded

diagnostics (ePSA).

● If the drives are configured in a RAID array,

restart the system, and enter the host adapter

configuration utility program.

Ensure that none of the following conditions exist:

● A cooling fan has been removed or has failed.

● System cover, air shroud, memory module blank,

or back filler bracket is removed.

● Ambient temperature is too high.

● External airflow is obstructed.

If the problem persists, see the Getting help section.

Check the System Event Log or system messages

for the specific issue. If it is due to a problem with

the PSU, check the LED on the PSU. Reseat the

PSU. If the problem persists, see the Getting help

section.

Check the System Event Log or system messages

for the location of the failed memory. Reseat the

memory module. If the problem persists, see the

Getting help section.

Restart the system. Update any required drivers for

the PCIe card. Reinstall the card. If the problem

persists, see the Getting help section.

NOTE: For more information about the

supported PCIe cards, see the Expansion card

installation guidelines section.

18 Disassembly and reassembly

Page 19

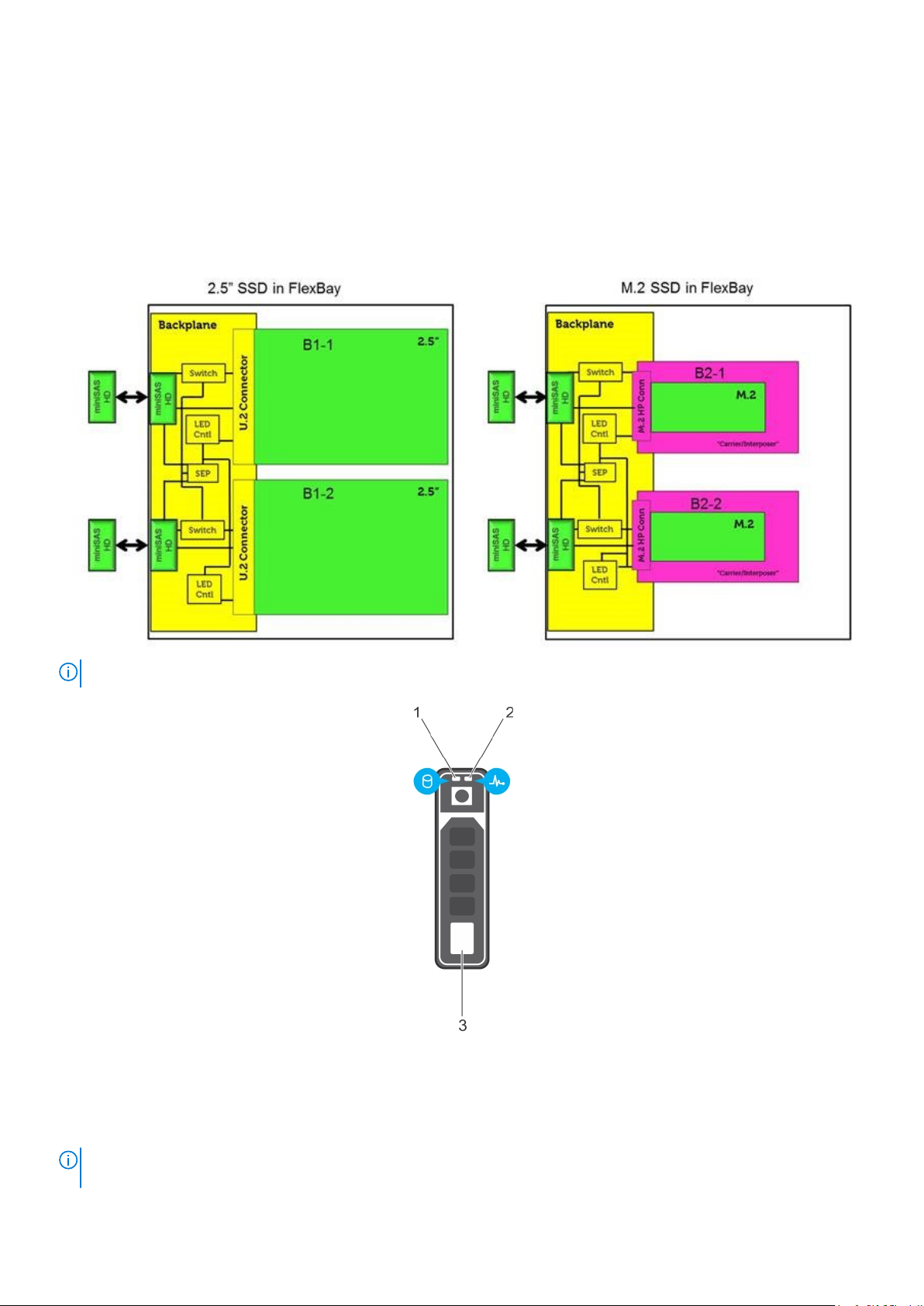

Hard drive indicator codes

Each hard drive carrier has an activity LED indicator and a status LED indicator. The indicators provide information about the

current status of the hard drive. The activity LED indicator indicates whether the hard drive is currently in use or not. The status

LED indicator indicates the power condition of the drive.

Hard drive indicators

NOTE: LED status or activity indicators will only work with a backplane with each carriers shown below.

Figure 5. Hard drive indicators

1. hard drive activity LED indicator

2. hard drive status LED indicator

3. hard drive

If the hard drive is in the Advanced Host Controller Interface (AHCI) mode, the status LED indicator does not turn

NOTE:

on.

Disassembly and reassembly 19

Page 20

NOTE: Drive status indicator behavior is managed by Storage Spaces Direct. Not all drive status indicators may be used.

Table 5. Hard drive indicator codes

Hard drive status indicator code Condition

Flashes green twice per second Identifying drive or preparing for removal.

Off Drive ready for removal.

NOTE: The drive status indicator remains off until all drives

are initialized after the system is turned on. Drives are not

ready for removal during this time.

Flashes green, amber, and then turns off Predicted drive failure.

Flashes amber four times per second Drive failed.

Flashes green slowly Drive rebuilding.

Solid green Drive online.

Flashes green for three seconds, amber for three

seconds, and then turns off after six seconds

Rebuild stopped.

NIC indicator codes

Each NIC on the back of the system has indicators that provide information about the activity and link status. The activity LED

indicator indicates if data is flowing through the NIC, and the link LED indicator indicates the speed of the connected network.

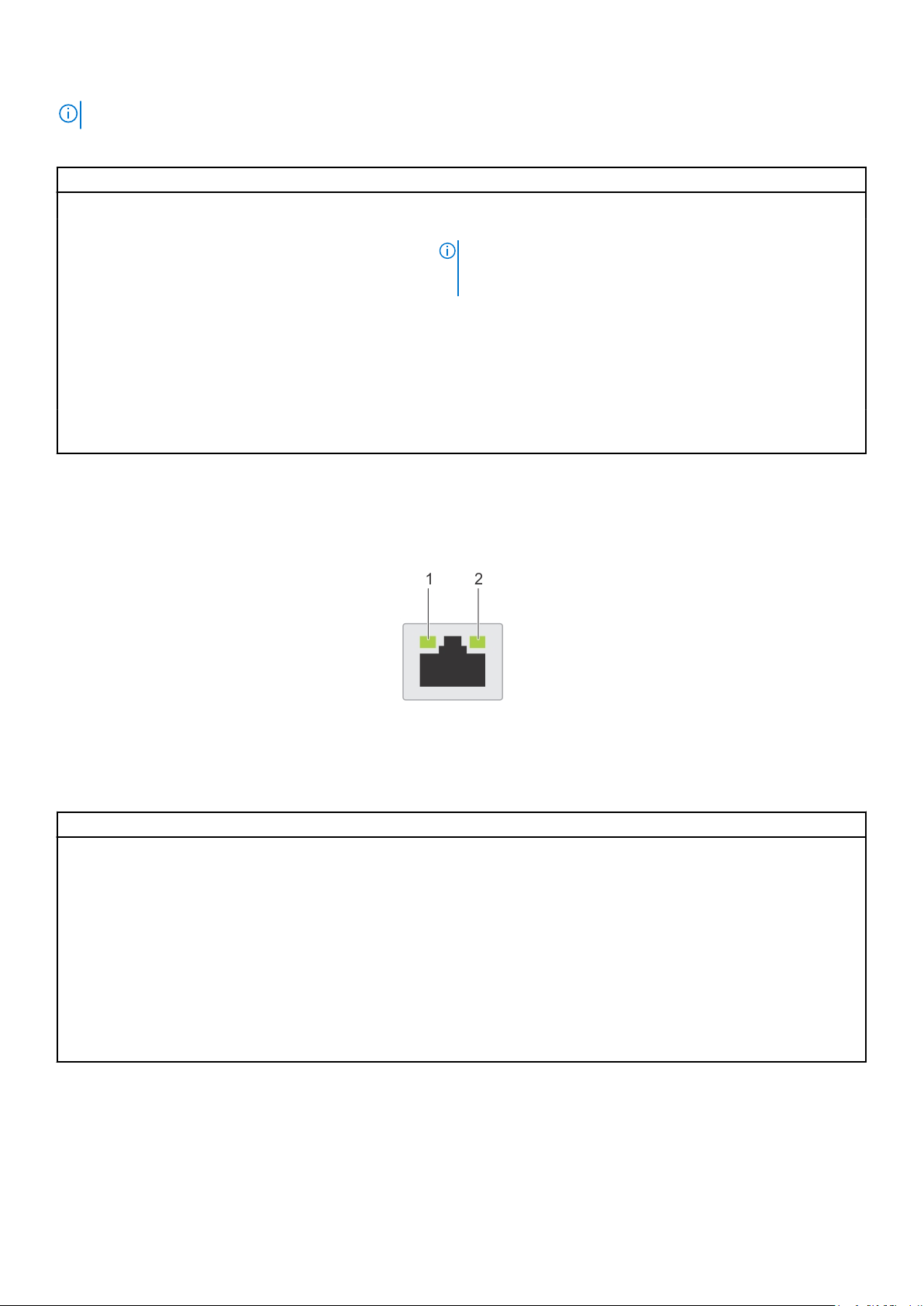

Figure 6. NIC indicator codes

1. Link LED indicator

2. Activity LED indicator

Table 6. NIC indicator codes

Status Condition

Link and activity indicators are off. The NIC is not connected to the network.

Link indicator is green, and activity indicator is blinking

green.

Link indicator is amber, and activity indicator is blinking

green.

Link indicator is green, and activity indicator is off. The NIC is connected to a valid network at its maximum port speed,

Link indicator is amber, and activity indicator is off. The NIC is connected to a valid network at less than its maximum

Link indicator is blinking green, and activity is off. NIC identify is enabled through the NIC configuration utility.

The NIC is connected to a valid network at its maximum port speed,

and data is being sent or received.

The NIC is connected to a valid network at less than its maximum

port speed, and data is being sent or received.

and data is not being sent or received.

port speed, and data is not being sent or received.

Power supply unit indicator codes

AC power supply units (PSUs) have an illuminated translucent handle that serves as an indicator. The indicator shows whether

power is present or a power fault has occurred.

20

Disassembly and reassembly

Page 21

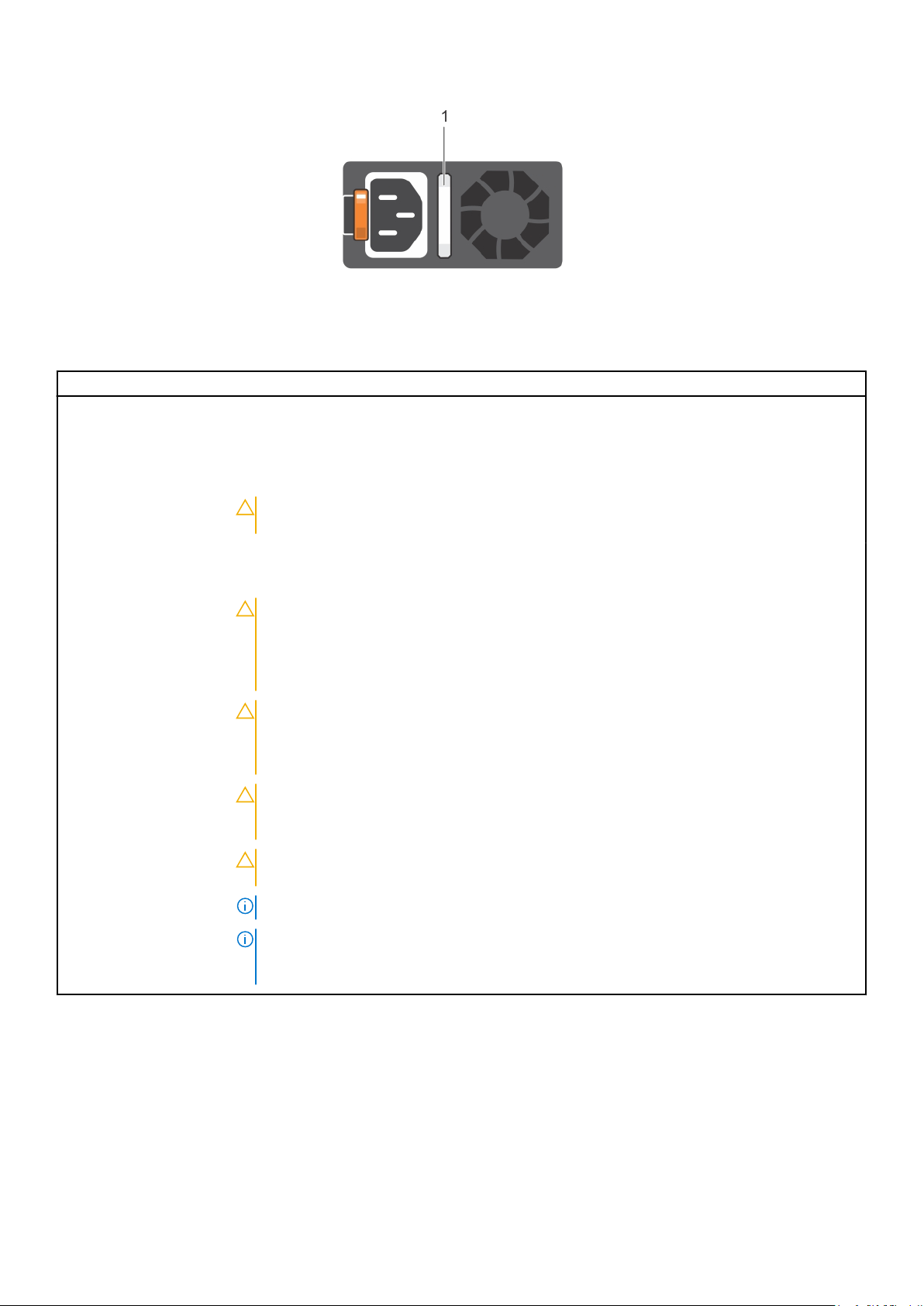

Figure 7. AC PSU status indicator

1. AC PSU status indicator/handle

Table 7. AC PSU status indicator codes

Power indicator codes Condition

Green A valid power source is connected to the PSU and the PSU is operational.

Blinking amber Indicates a problem with the PSU.

Not illuminated Power is not connected to the PSU.

Blinking green When the firmware of the PSU is being updated, the PSU handle blinks green.

CAUTION: Do not disconnect the power cord or unplug the PSU when updating

firmware. If firmware update is interrupted, the PSUs do not function.

Blinking green and turns

off

When hot-plugging a PSU, the PSU handle blinks green five times at a rate of 4 Hz and turns off.

This indicates a PSU mismatch with respect to efficiency, feature set, health status, or supported

voltage.

CAUTION: If two PSUs are installed, both the PSUs must have the same type of label.

For example, Extended Power Performance (EPP) label. Mixing PSUs from previous

generations of Precision Workstation is not supported, even if the PSUs have the

same power rating. This results in a PSU mismatch condition or failure to turn the

system on.

CAUTION: When correcting a PSU mismatch, replace only the PSU with the blinking

indicator. Swapping the PSU to make a matched pair can result in an error condition

and unexpected system shutdown. To change from a high output configuration to a

low output configuration or vice versa, you must turn off the system.

CAUTION: AC PSUs support both 240 V and 120 V input voltages with the exception of

Titanium PSUs, which support only 240 V. When two identical PSUs receive different

input voltages, they can output different wattages, and trigger a mismatch.

CAUTION: If two PSUs are used, they must be of the same type and have the same

maximum output power.

NOTE: Ensure that both the PSUs are of the same capacity.

NOTE: Mixing PSUs (even the PSUs that have the same power rating) from previous

generations of Precision Workstation is not supported. This results in a PSU mismatch

condition or failure to turn the system on.

iDRAC Direct LED indicator codes

The iDRAC Direct LED indicator lights up to indicate that the port is connected and is being used as a part of the iDRAC

subsystem.

iDRAC Direct LED indicator is located below the iDRAC Direct port on the right control panel.

You can configure iDRAC Direct by using a USB to micro USB (type AB) cable, which you can connect to your laptop or tablet.

The following table describes iDRAC Direct activity when the iDRAC Direct port is active:

Disassembly and reassembly

21

Page 22

Table 8. iDRAC Direct LED indicator codes

iDRAC Direct LED

indicator code

Solid green for two

seconds

Flashing green (on for

two seconds and off for

two seconds)

Turns off Indicates that the laptop or tablet is unplugged.

Condition

Indicates that the laptop or tablet is connected.

Indicates that the laptop or tablet connected is recognized.

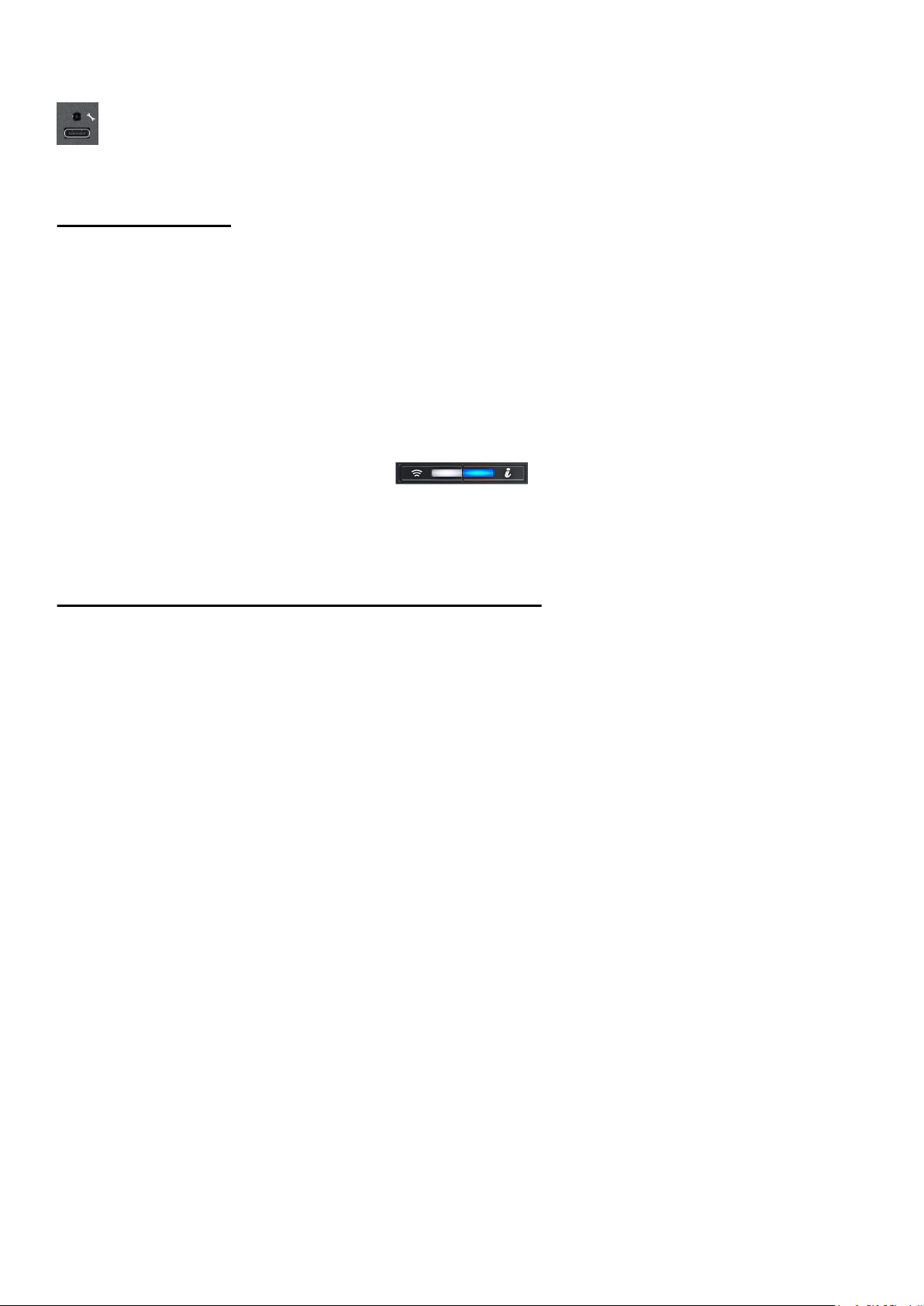

iDRAC Quick Sync 2 indicator codes

iDRAC Quick Sync 2 module (optional) is on the front panel of your system.

Figure 8. iDRAC Quick Sync 2 indicator

Table 9. iDRAC Quick Sync 2 indicators and descriptions

iDRAC Quick Sync 2 indicator

code

Off (default state) Indicates that the iDRAC Quick Sync 2

Solid white Indicates that iDRAC Quick Sync 2 is

Blinks white rapidly Indicates data transfer activity. NA

Condition Corrective action

feature is turned off. Press the iDRAC

Quick Sync 2 button to turn on the

iDRAC Quick Sync 2 feature.

ready to communicate. Press the iDRAC

Quick Sync 2 button to turn off.

If the LED fails to turn on, reset the left control

panel flex cable and check. If the problem

persists, see the Getting help section.

If the LED fails to turn off, restart the system. If

the problem persists, see the Getting help

section.

If the problem persists, see the Getting help

section.

Blinks white slowly Indicates that firmware update is in

progress.

Blinks white five times rapidly

and then turns off

Solid amber Indicates that the system is in fail-safe

Blinking amber Indicates that the iDRAC Quick Sync 2

22 Disassembly and reassembly

Indicates that the iDRAC Quick Sync 2

feature is disabled.

mode.

hardware is not responding properly.

NA

If the indicator continues to blink indefinitely, see

the Getting help section.

Check if iDRAC Quick Sync 2 feature is

configured to be disabled by iDRAC.

If the problem persists, see the Getting help

section.

For more information, see Integrated Dell Remote

Access Controller User's Guide at dell.com/

idracmanuals or Dell OpenManage Server

Administrator User’s Guide at dell.com/

openmanagemanuals .

Restart the system.

If the problem persists, see the Getting help

section.

Restart the system.

Page 23

Table 9. iDRAC Quick Sync 2 indicators and descriptions (continued)

iDRAC Quick Sync 2 indicator

code

Condition Corrective action

If the problem persists, see the Getting help

section.

Enhanced Preboot System Assessment

If you experience a problem with your system, run the system diagnostics before contacting Dell for technical assistance. The

purpose of running system diagnostics is to test your system hardware without requiring more equipment or risking data loss. If

you are unable to fix the problem yourself, service and support personnel can use the diagnostics results to help you solve the

problem.

Dell Embedded system diagnostics

NOTE: The Dell Embedded System Diagnostics is also known as Enhanced Preboot System Assessment (ePSA) diagnostics.

The embedded system diagnostics provides a set of options for particular device groups or devices allowing you to:

● Run tests automatically or in an interactive mode.

● Repeat tests

● Display or save test results.

● Introduce more test options for extra information about the failed devices, run a thorough test.

● View status messages that inform you if tests are completed successfully.

● View error messages that inform you of problems encountered during testing.

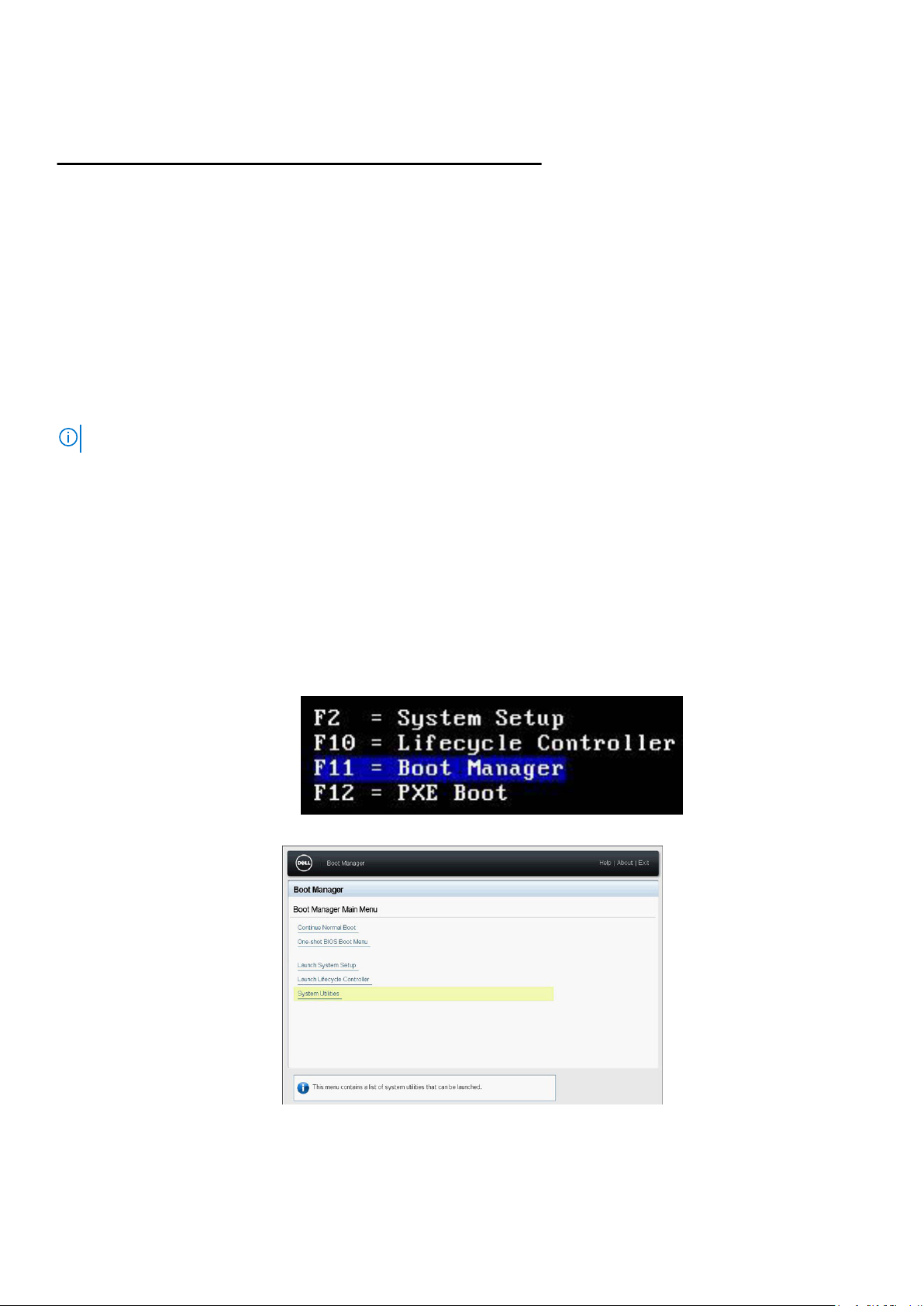

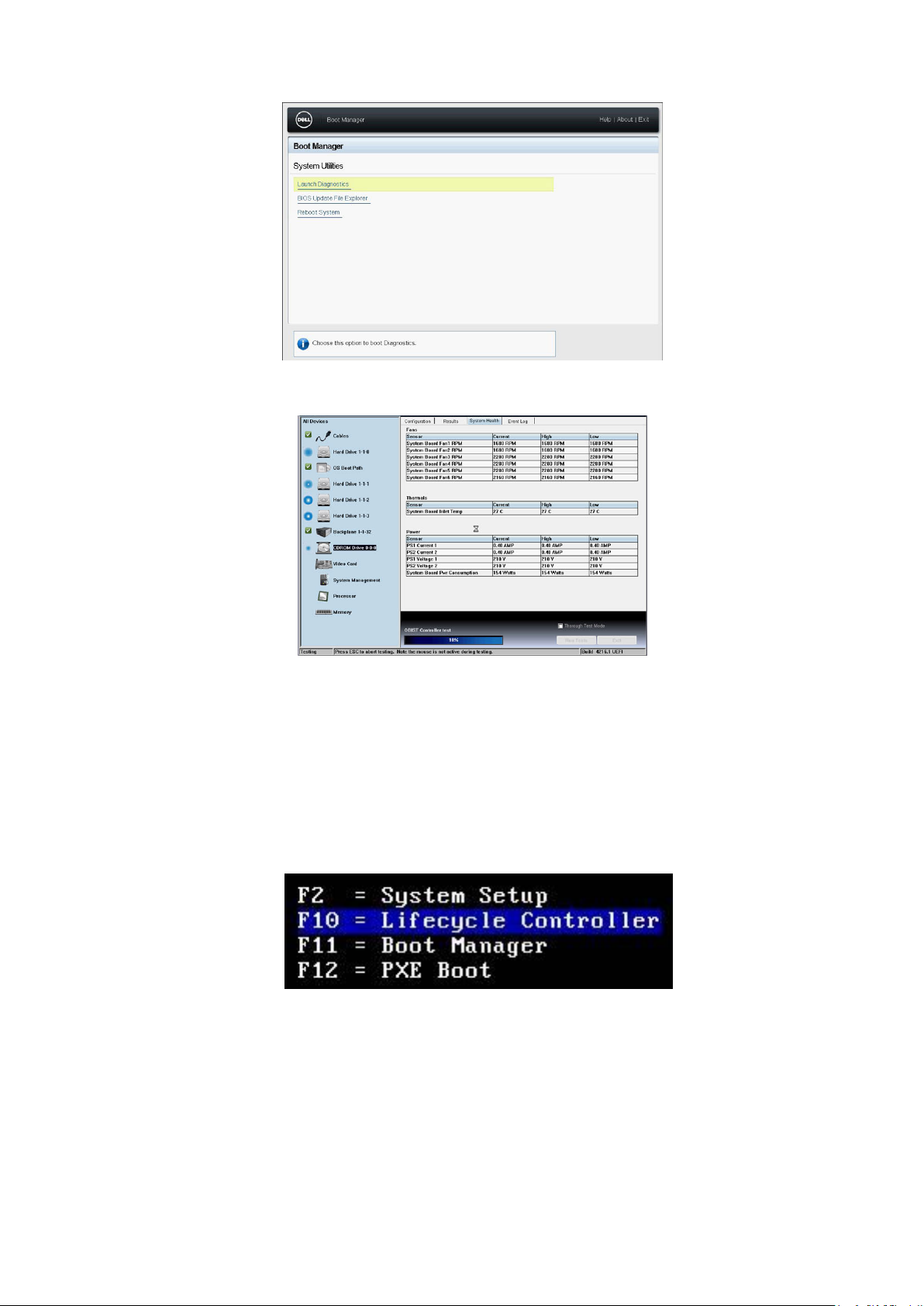

Running the Embedded system diagnostics from Boot Manager

To run the embedded system diagnostics from Boot Manager:

1. As the system boots, press <F11>.

2. Using the arrow keys select System Utilities → Launch Diagnostics.

Figure 9. Boot Manager Main Menu

Disassembly and reassembly

23

Page 24

Figure 10. System Utilities

3. Wait while the Quick Tests automatically run.

Figure 11. Quick Test

4. Once the tests have been completed, you can view the results and additional information on the Results tab, the System

Health tab, the Configuration tab, and the Event Log tab.

5. Close the Embedded System Diagnostics utility.

6. To leave the diagnostics, click Exit.

7. Click OK when prompted, and the system reboots.

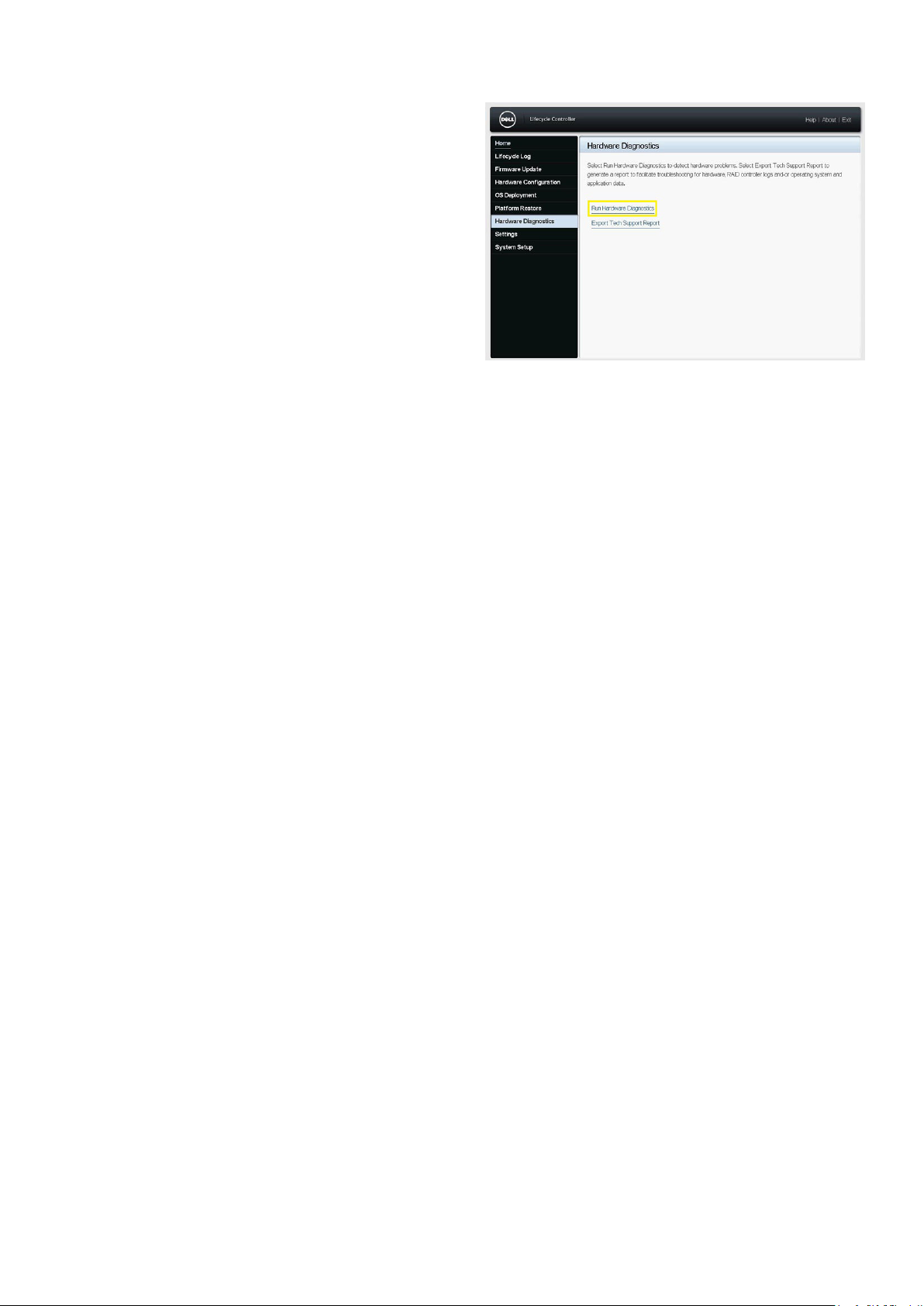

Running the Embedded System Diagnostics from the Dell Lifecycle Controller

To run the embedded system diagnostics from the Dell Lifecycle Controller:

As the system boots, press F10.

1.

24

Disassembly and reassembly

Page 25

2. Select Hardware Diagnostics → Run Hardware Diagnostics.

Jumpers and connectors

This topic provides specific information about the jumpers. It also provides some basic information about jumpers and switches

and describes the connectors on the various boards in the system. Jumpers on the system board help to disable the system and

setup passwords. You must know the connectors on the system board to install components and cables correctly.

Disassembly and reassembly 25

Page 26

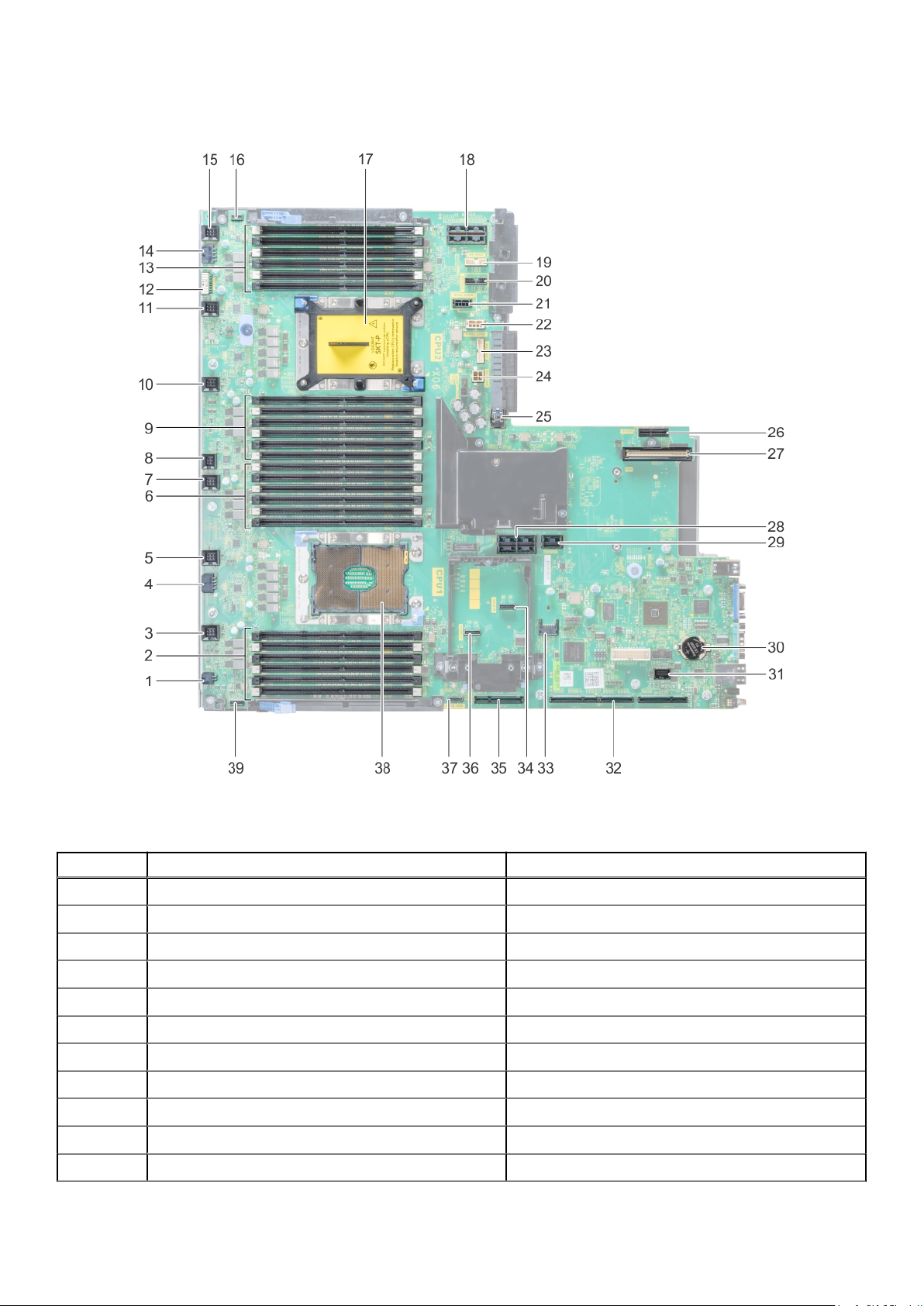

System board jumpers and connectors

Figure 12. System board jumpers and connectors

Table 10. System board jumpers and connectors

Item Connector Description

1 J_ODD Optical drive power connector

2 A7, A1, A8, A2, A9, A3 Memory module sockets

3 J_FAN2U_6 Cooling fan 6 connector

4 J_BP3 Backplane 3 power connector

5 J_FAN2U_5 Cooling fan 5 connector

6 A6, A12, A5, A11, A4, A10 Memory module sockets

7 J_FAN2U_4 Cooling fan 4 connector

8 INTRUSION_DET Intrusion switch connector

9 B7, B1, B8, B2, B9, B3 Memory module sockets

10 J_FAN2U_3 Cooling fan 3 connector

11 J_FAN2U_2 Cooling fan 2 connector

26 Disassembly and reassembly

Page 27

Table 10. System board jumpers and connectors (continued)

Item Connector Description

12 J_BP_SIG1 Backplane 1 signal connector

13 B6, B12, B5, B11, B4, B10 Memory module sockets

14 J_BP1 Backplane 1 power connector

15 J_FAN2U_1 Cooling fan 1 connector

16 P_LFT_CP Left control panel connector

17 CPU2 CPU2 processor and heat sink module socket (with

dust cover)

18 J_R3_X24 Riser 3 connector

19 J_BP_SIG2 Backplane 2 signal connector

20 J_BP_SIG0 Backplane 0 signal connector

21 J_BP0 (RSR3_225W) Backplane 0 power connector (Riser 3 PCIe 225 W

power)

22 J_BP2 (RSR2_225W) Backplane 2 power connector (Riser 2 PCIe 225 W

power)

23 J_BATT_SIG NVDIMM-N battery signal connector

24 J_BATT_PWR NVDIMM-N battery power connector

25 J_USB_INT Internal USB connector

26 J_IDSDM IDSDM/vFlash connector

27 J_NDC NDC connector

28 J_R2_X24_IT9 Riser 2 connector

29 J_R2_3R_X8_IT9 Riser 2 connector

30 BATTERY Battery connector

31 J_FRONT_VIDEO Video connector

32 J_R1_SS82_3 and J_R1_SS60_1 Riser 1 connector

33 J_TPM_MODULE TPM connector

34 J_SATA_B SATA B connector

35 J_R1_SS82_1 Riser 1 connector (Mini PERC option)

36 J_SATA_A SATA A connector

37 J_SATA_C SATA C connector (Optical drive SATA connector)

38 CPU1 CPU1 processor and heat sink module

39 P_RGT_CP Right control panel connector

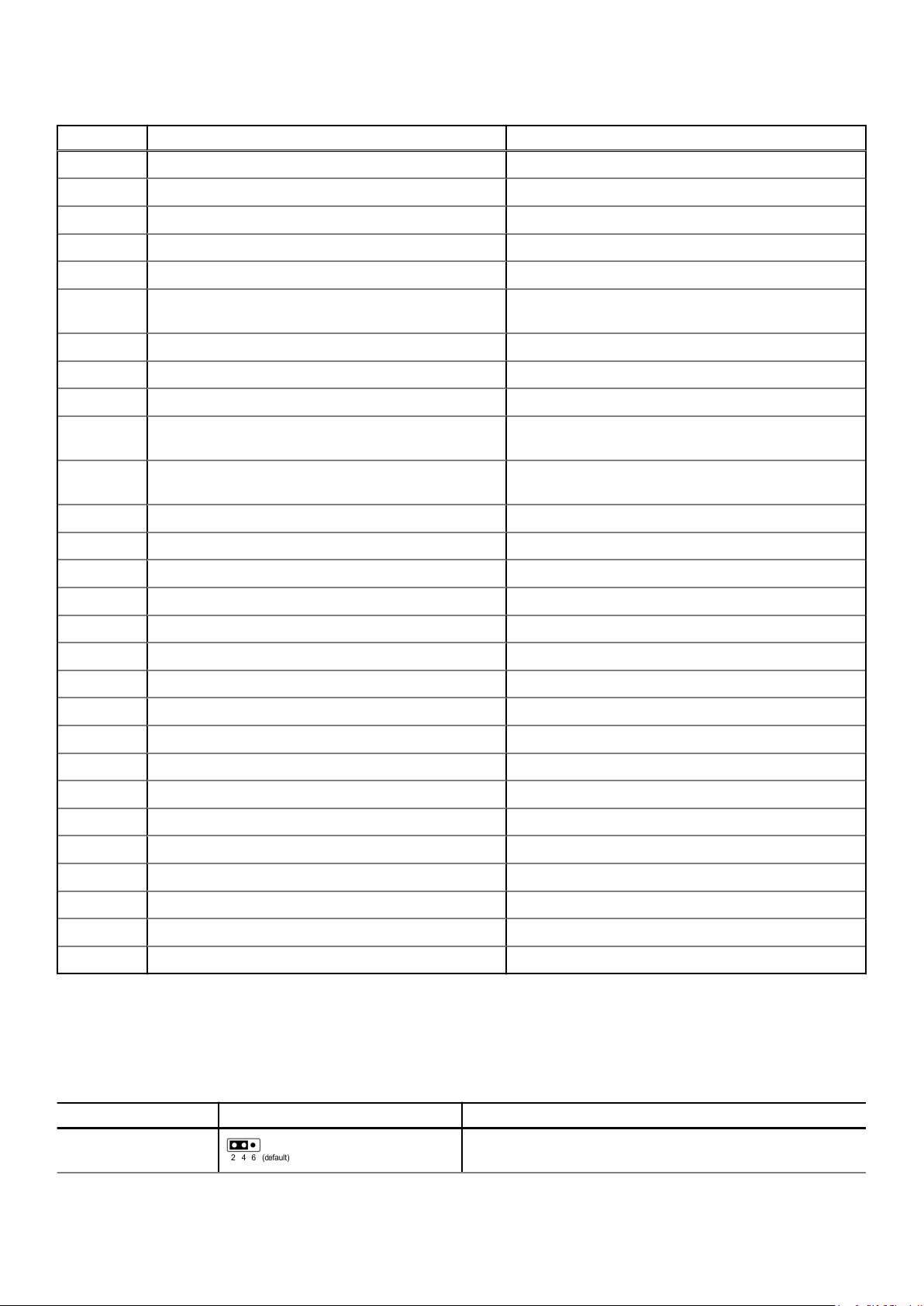

System board jumper settings

For information on resetting the password jumper to disable a password, see the Disabling a forgotten password section.

Table 11. System board jumper settings

Jumper Setting Description

PWRD_EN The BIOS local access is protected with the software security

features.

Disassembly and reassembly 27

Page 28

Table 11. System board jumper settings (continued)

Jumper Setting Description

The BIOS local access security features are unlocked on the

next AC power cycle.

NVRAM_CLR The BIOS configuration settings are retained at system boot.

The BIOS configuration settings are cleared at system boot.

Disabling forgotten password

The software security features of the system include a system password and a setup password. The password jumper enables or

disables password features and clears any password(s) currently in use.

Prerequisites

CAUTION: Many repairs may only be done by a certified service technician. You should only perform

troubleshooting and simple repairs as authorized in your product documentation, or as directed by the online or

telephone service and support team. Damage due to servicing that is not authorized by Dell is not covered by

your warranty. Read and follow the safety instructions that are shipped with your product.

Steps

1. Turn off the system, including any attached peripherals, and disconnect the system from the electrical outlet.

2. Remove the system cover.

3. Move the jumper on the system board jumper from pins 2 and 4 (default) to pins 4 and 6.

4. Install the system cover.

The existing passwords are not disabled (erased) until the system boots with the jumper on pins 4 and 6. However, before

you assign a new system and/or setup password, you must move the jumper back to pins 2 and 4.

NOTE:

If you assign a new system and/or setup password with the jumper on pins 4 and 6, the system disables the new

password(s) the next time it boots.

5. Reconnect the system to its electrical outlet and turn on the system, including any attached peripherals.

6. Turn off the system, including any attached peripherals, and disconnect the system from the electrical outlet.

7. Remove the system cover.

8. Move the jumper on the system board jumper from pins 4 and 6 to pins 2 and 4 (default).

9. Install the system cover.

10. Reconnect the system to its electrical outlet and turn on the system, including any attached peripherals.

11. Assign a new system and/or setup password.

Disassembly and reassembly

The following sections contain the procedures for removing and replacing system components.

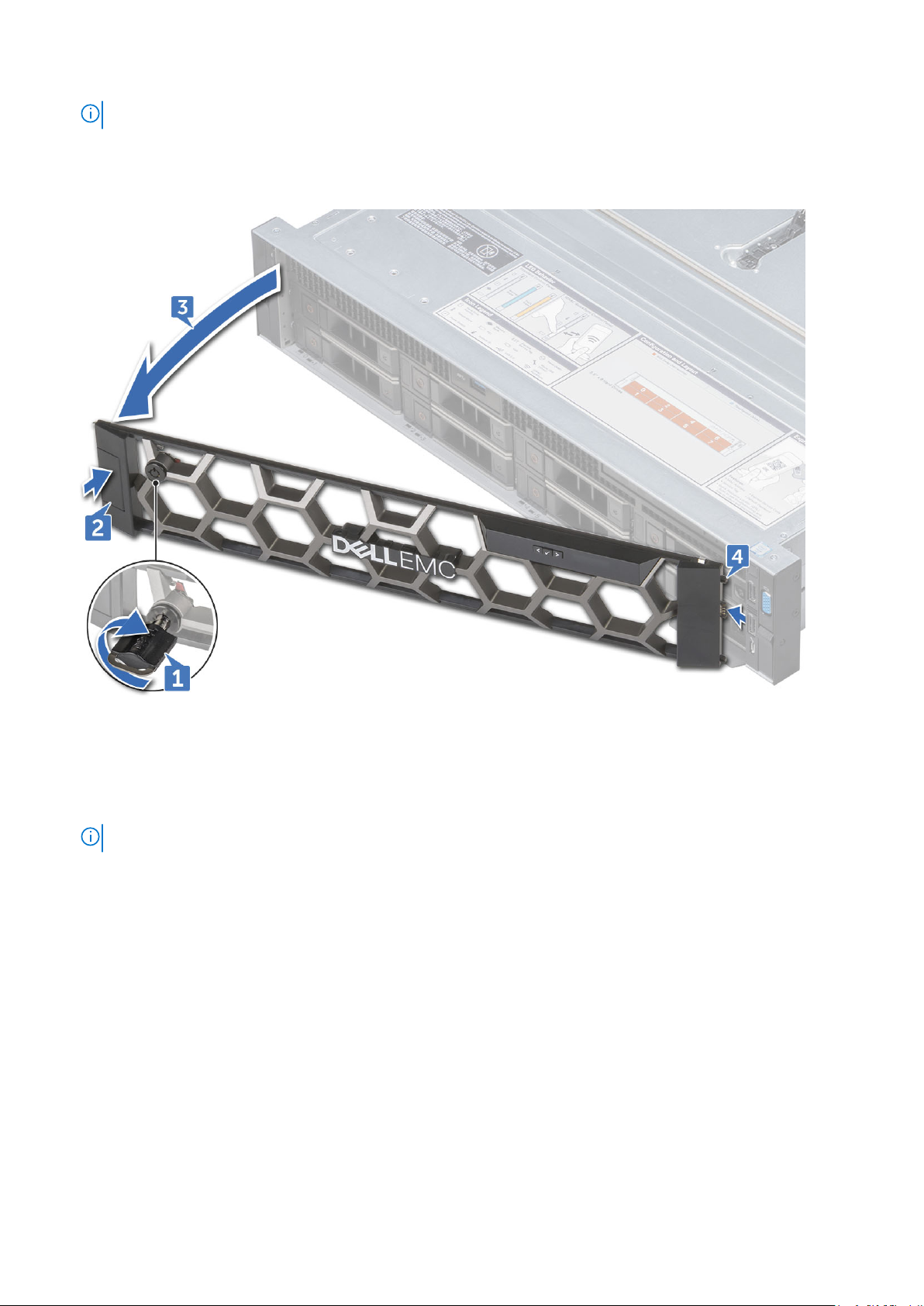

Front Bezel

Removing the optional front bezel

Steps

1. Locate and remove the bezel key.

28

Disassembly and reassembly

Page 29

NOTE: The bezel key is attached to the LCD bezel package.

2. Unlock the bezel by using the key.

3. Press the release button to release the bezel, and pull the left end of the bezel.

4. Unhook the right end, and remove the bezel.

Installing the optional front bezel

Steps

1. Locate and remove the bezel key.

NOTE: The bezel key is attached to the LCD bezel package.

2. Align and insert the right end of the bezel onto the system .

3. Press the release button and fit the left end of the bezel onto the system.

4. Lock the bezel by using the key.

System cover

Removing system cover

Prerequisites

1. Turn off the system, including any attached peripherals.

2. Disconnect the system from the electrical outlet and disconnect the peripherals.

Steps

1. Using a flat head screwdriver, rotate the latch release lock counter clockwise to the unlocked position.

Disassembly and reassembly

29

Page 30

2. Lift the latch till the system cover slides back and the tabs on the system cover disengage from the slots on the system.

3. Hold the cover on both sides, and lift the cover away from the system.

Installing system cover

Prerequisites

1. Ensure that all internal cables are routed correctly and connected, and no tools or extra parts are left inside the system.

Steps

1. Align the tabs on the system cover with the slots on the system.

2. Push the system cover latch down.

3. Using a flat head screwdriver, rotate the latch release lock clockwise to the locked position.

Next steps

1. Reconnect the peripherals and connect the system to the electrical outlet.

2. Turn on the system, including any attached peripherals.

Optical drive

Removing optical drive

Prerequisites

1. If installed, remove the front bezel.

2. Remove the system cover.

Steps

1. Disconnect the optical drive cable from the optical drive.

2. Press the blue latch and slide the optical drive from the system.

30

Disassembly and reassembly

Page 31

Next steps

Install the optical drive.

Installing optical drive

Steps

1. Slide the optical drive to the system, until the locks into place.

2. Connect the optical drive cable on the optical drive.

3. Install system cover and front bezel if applicable.

Air shroud

Removing air shroud

Prerequisites

CAUTION:

Never operate your system with the air shroud removed. The system may get overheated quickly, resulting in

shutdown of the system and loss of data.

1. If installed, remove the full length PCIe cards.

2. If applicable, remove the GPU cards.

Steps

Hold the shroud at both ends and lift it away from the system.

Disassembly and reassembly

31

Page 32

Next steps

Install the shroud.

Installing air shroud

Prerequisites

1. If applicable, route the cables inside the system along the system wall and secure the cables by using the cable securing

bracket.

Steps

1. Align the tabs on the air shroud with the slots on the system.

2. Lower the air shroud into the system until it is firmly seated.

When firmly seated, the memory socket numbers marked on the air shroud align with the respective memory sockets.

Next steps

1. If removed, install the full length PCIe cards.

2. If applicable, install the GPU cards.

Cooling fan assembly

Removing cooling fan assembly

Steps

1. Lift the release levers to unlock the cooling fan assembly from the system.

2. Hold the release levers and lift the cooling fan assembly away of the system.

32

Disassembly and reassembly

Page 33

Installing cooling fan assembly

Steps

1. Align the guide rails on the cooling fan assembly with the standoffs on the system.

2. Lower the cooling fan assembly into the system until the cooling fan connectors engage with the connectors on the system

board.

3. Press the release levers to lock the cooling fan assembly into the system.

Cooling fans

Removing cooling fan

Prerequisites

NOTE:

Opening or removing the system cover when the system is ON may expose you to a risk of electric shock. Exercise

utmost care while removing or installing cooling fans.

NOTE: The system will shutdown if the system cover is removed before shutting down the system

CAUTION: The cooling fans are hot swappable. To maintain proper cooling while the system is on, replace only

one fan at a time.

Steps

Press the release tab and lift the cooling fan out of the cooling fan assembly.

Disassembly and reassembly

33

Page 34

Installing cooling fan

Steps

1. Holding the release tab, align the connector at the base of the cooling fan with the connector on the system board.

2. Slide the cooling fan into the cooling fan assembly until the release tab locks into place.

Intrusion switch

Removing intrusion switch

Prerequisites

1. Remove the cooling fan assembly.

Steps

Press the intrusion switch and slide it out of the from the intrusion switch slot.

34

Disassembly and reassembly

Page 35

Installing intrusion switch

Steps

1. Align the tabs on the intrusion switch with the slots on the cooling fan assembly.

2. Pull the intrusion switch up and push it until the switch locks in place.

Next steps

1. Install the cooling fan assembly.

Hard drive

Removing hard drive blank

Prerequisites

1. If installed, remove the front bezel.

CAUTION:

installed.

Steps

Press the release button and slide the hard drive blank out of the hard drive slot.

To maintain proper system cooling, all empty hard drive slots must have hard drive blanks

Disassembly and reassembly

35

Page 36

Installing hard drive blank

Steps

Insert the hard drive blank into the hard drive slot and push until the release button clicks into place.

Next steps

1. If removed, install the front bezel.

Removing hard drive

Prerequisites

1. If applicable, remove the front bezel.

2. Using the management software, prepare the hard drive for removal. If the hard drive is online, the green activity or fault

indicator flashes while the drive is turning off. When the hard drive indicators are off, the hard drive is ready for removal. For

more information, see the documentation for the storage controller.

CAUTION:

See the documentation supplied with your operating system.

CAUTION: Before attempting to remove or install a hard drive while the system is running, see the

documentation for the storage controller card to ensure that the host adapter is configured correctly to support

hard drive removal and insertion.

CAUTION: Mixing hard drives from previous generations of Precision Workstations is not supported.

To prevent data loss, ensure that your operating system supports hot swappable drive installation.

Steps

1. Press the release button to open the hard drive release handle.

2. Holding the handle, slide the hard drive out of the hard drive slot.

36

Disassembly and reassembly

Page 37

Next steps

Install the hard drive.

NOTE: If you are not replacing the hard drive immediately, insert a hard drive blank in the empty hard drive slot.

Installing hard drive

Prerequisites

CAUTION:

carrier and attempting to lock its handle next to a partially installed carrier can damage the partially installed

carrier's shield spring and make it unusable.

NOTE: To prevent data loss, ensure that your operating system supports hot-swap drive installation. See the

documentation supplied with your operating system.

NOTE: When a replacement hot swappable hard drive is installed and the system is powered on, the hard drive

automatically begins to rebuild. Make absolutely sure that the replacement hard drive is blank or contains data that you wish

to have over-written. Any data on the replacement hard drive is immediately lost after the hard drive is installed.

Steps

1. Press the release button on the front of the hard drive to open the release handle.

2. Insert the hard drive into the hard drive slot until the hard drive connects with the backplane.

3. Close the hard drive handle to lock the hard drive in place.

When installing a hard drive, ensure that the adjacent drives are fully installed. Inserting a hard drive

Disassembly and reassembly

37

Page 38

Figure 13. Installing hard drive

Next steps

If applicable, install the front bezel.

Removing 3.5 inch hard drive from hard drive carrier

Steps

1. Using Phillips #1 screwdriver, remove the screws from the slide rails on the hard drive carrier.

2. Lift the hard drive out of the hard drive carrier.

Next steps

Install hard drive into the hard drive carrier.

38

Disassembly and reassembly

Page 39

Installing 3.5 inch hard drive into hard drive carrier

Steps

1. Insert the hard drive into the hard drive carrier with the connector end of the hard drive toward the back of the carrier.

2. Align the screw holes on the hard drive with the screws holes on the hard drive carrier.

When aligned correctly, the back of the hard drive is flush with the back of the hard drive carrier.

3. Using the Phillips #1 screwdriver, tighten the screws to secure the hard drive to the hard drive carrier.

Removing hard drive

Prerequisites

1. If applicable, remove the front bezel.

2. Using the management software, prepare the hard drive for removal. If the hard drive is online, the green activity or fault

indicator flashes while the drive is turning off. When the hard drive indicators are off, the hard drive is ready for removal. For

more information, see the documentation for the storage controller.

CAUTION:

See the documentation supplied with your operating system.

CAUTION: Before attempting to remove or install a hard drive while the system is running, see the

documentation for the storage controller card to ensure that the host adapter is configured correctly to support

hard drive removal and insertion.

CAUTION: Mixing hard drives from previous generations of Precision Workstations is not supported.

Steps

1. Press the release button to open the hard drive release handle.

2. Holding the handle, slide the hard drive out of the hard drive slot.

To prevent data loss, ensure that your operating system supports hot swappable drive installation.

Disassembly and reassembly

39

Page 40

Next steps

Install the hard drive.

NOTE: If you are not replacing the hard drive immediately, insert a hard drive blank in the empty hard drive slot.

Installing 2.5 inch hard drive

Prerequisites

CAUTION:

carrier and attempting to lock its handle next to a partially installed carrier can damage the partially installed

carrier's shield spring and make it unusable.

NOTE: To prevent data loss, ensure that your operating system supports hot-swap drive installation. See the

documentation supplied with your operating system.

NOTE: When a replacement hot swappable hard drive is installed and the system is powered on, the hard drive

automatically begins to rebuild. Make absolutely sure that the replacement hard drive is blank or contains data that you wish

to have over-written. Any data on the replacement hard drive is immediately lost after the hard drive is installed.

Steps

1. Press the release button on the front of the hard drive to open the release handle.

2. Insert the hard drive into the hard drive slot until the hard drive connects with the backplane.

3. Close the hard drive handle to lock the hard drive in place.

When installing a hard drive, ensure that the adjacent drives are fully installed. Inserting a hard drive

40

Disassembly and reassembly

Page 41

Figure 14. Installing hard drive

Next steps

If applicable, install the front bezel.

Removing 2.5 inch hard drive from 3.5 inch hard drive carrier

Steps

1. Using Phillips #1 screwdriver, remove the screws from the slide rails on the 3.5 inch hard drive carrier and lift the hard drive.

Disassembly and reassembly

41

Page 42

2. Remove the screws that secures 2.5 inch hard drive to the hard drive assembly and remove the hard drive.

Next steps

Install hard drive into the hard drive carrier.

Installing 2.5 inch hard drive into 3.5 inch hard drive carrier

Steps

1. Insert the 2.5 inch hard drive into the hard drive carrier and tighten the screws.

42

Disassembly and reassembly

Page 43

2. Place the 2.5 inch hard drive into the 3.5 inch hard drive carrier.

3. Align the screw holes on the hard drive with the screws holes on the hard drive carrier.

Memory modules

Removing memory modules

Prerequisites

1. If applicable, remove the air shroud.

WARNING:

the card edges and avoid touching the components or metallic contacts on the memory module.

Allow the memory modules to cool after you power off the system. Handle the memory modules by

Disassembly and reassembly 43

Page 44

CAUTION: To ensure proper system cooling, memory module blanks must be installed in any memory socket that

is not occupied. Remove memory module blanks only if you intend to install memory modules in those sockets.

Steps

1. Locate the appropriate memory module socket.

2. Push the ejectors outward on both ends of the memory module socket, to release the memory module from the socket.

3. Lift and remove the memory module from the system.

Installing memory modules

Steps

1. Locate the appropriate memory module socket.

2. Open the ejectors on the memory module socket outward to allow the memory module to be inserted into the socket.

3. Align the edge connector of the memory module with the alignment key of the memory module socket, and insert the

memory module in the socket.

CAUTION:

memory module evenly.

NOTE: The memory module socket has an alignment key that enables you to install the memory module in the socket in

only one orientation.

4. Press the memory module with your thumbs until the socket levers firmly click into place.

5. Repeat step 1 through step 4 of this procedure to install the remaining memory modules.

Next steps

1. If applicable, install the air shroud.

2. To verify if the memory module has been installed properly, press F2 and navigate to System Setup Main Menu> System

BIOS > Memory Settings. In the Memory Settings screen, the System Memory Size must reflect the updated capacity of

the installed memory.

3. If the value is incorrect, one or more of the memory modules may not be installed properly. Ensure that the memory module

is firmly seated in the memory module socket.

4. Run the system memory test in system diagnostics.

Do not apply pressure at the center of the memory module; apply pressure at both ends of the

44

Disassembly and reassembly

Page 45

Processors and heat sinks

Removing processor and heat sink module

Steps

1. Using Torx #T30 screwdriver, loosen the screws.

NOTE: Ensure that the screw is completely loosened before moving on to the next screw.

2. Pushing both retention clips simultaneously, lift the processor heat sink module out of the system

3. Set the module aside with processor side facing up.

Figure 15. Removing heat sink (2U)

Removing processor from processor heat sink module

Steps

1. Place the heat sink with the processor side facing up.

2. Insert a flat blade screwdriver into the release slot marked with a yellow label. Twist (do not pry) the screwdriver to break

the thermal paste seal.

3. Push the retaining clips on the processor bracket to unlock the bracket from the heat sink.

Disassembly and reassembly

45

Page 46

4. Lift the bracket and the processor away from the heat sink, and place the processor connector side down on the processor

tray.

5. Flex the outer edges of the bracket to release the processor from the bracket.

NOTE: Ensure that the processor and the bracket are placed in the tray after you remove the heat sink.

Installing processor into processor heat sink module

Steps

1. Place the processor in the processor tray.

NOTE: Ensure that pin 1 indicator on the CPU tray is aligned with the pin 1 indicator on the processor.

2. Flex the outer edges of the bracket around the processor ensuring that the processor is locked into the clips on the bracket.

Ensure pin 1 indicator on the bracket is aligned with the pin 1 indicator on the processor before placing the

NOTE:

bracket on the processor.

46 Disassembly and reassembly

Page 47

Figure 16. Installing the processor bracket

3. If you are using an existing heat sink, remove the thermal grease from the heat sink by using a clean lint-free cloth.

4. Use the thermal grease syringe included with your processor kit to apply the grease in a spiral quadrilateral design on the top

of the processor.

CAUTION:

contaminating the processor socket.

NOTE: The thermal grease syringe is intended for single use only. Dispose the syringe after you use it.

Applying too much thermal grease can result in excess grease coming in contact with and

Figure 17. Applying thermal grease on top of the processor

5. Place the heat sink on the processor and push down until the bracket locks onto the heat sink.

Disassembly and reassembly

47

Page 48

NOTE: