Page 1

Dellt Metered Rack Power Distribution Unit

(rPDU)

User's Guide

w w w . d e l l . c o m | s u p p o r t . d e l l . c o m

DELLM0001, DELLM001A, DELLM0002, DELLM0003, DELLM0004

DELLM004A, DELLM0005, DELLM0006, DELLM0007

Page 2

Notes and Warnings

NOTE: A NOTE indicates important information that helps you make better use of your product.

CAUTION: A CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or in property damage incidents.

WARNING: A WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

injury.

DANGER: A DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

DANGER: Observe the following instruction to help prevent an imminently hazardous situation which, if not avoided,

will result in death or serious injury:

S This rPDU contains LETHAL VOLTAGES. All repairs and service should be performed by

AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS inside

the rPDU.

Information in this document is subject to change without notice.

E 2010 Dell Inc. All rights reserved.

Reproduction in any manner whatsoever without the written permission of Dell Inc. is strictly forbidden.

Trademarks used in this text: Dell and the DELL logo are trademarks of Dell Inc.; National Electrical Code and NEC are registered trademarks of

National Fire Protection Association, Inc.; Internet Explorer and HyperTerminal are registered trademarks of Microsoft; Firefox is a registered

trademark of Mozilla.

Other trademarks and trade names may be used in this document to refer to either the entities claiming the marks and names or their products.

Dell Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

December 2010 • 164201960 2

Page 3

Table of Contents

1 Introduction

Physical Description 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Configurations 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strain Relief Brackets 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ground Bonding Point 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delta and Wye Configurations 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attached Input Connections 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Breakers 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD Panel and Pushbutton Controls 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication and Monitoring Ports 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Finding Information 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety Warnings

3 Installation

Unpacking the rPDU 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspecting the Equipment 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Accessory Bag 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing for Installation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Hardware for Options 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Strain Relief Brackets 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Deep Mounting Pegs 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the rPDU in the Rack Enclosure 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attaching the Ground Wire 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Protected Equipment 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the rPDU 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutting Down the rPDU 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panels 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 External Signaling Ports

Communication Ports 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Port 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Port 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

|

3

Page 4

Monitoring Ports 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature and Humidity Sensor (Optional) 29. . . . . . . . . . . . . . . . . . . . . . . .

Dry Contact Sensor (Optional) 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 LCD Operation

LCD Panel and Control Buttons 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locking a Screen 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Alarm Notification 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Status Screen 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menu Selections 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a Menu 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Menu 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Retrieving Performance Information 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measured and Calculated Meters 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarms Menu 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Retrieving Active Alarms 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Event Log 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Retrieving the Event Log 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Info 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Retrieving System Identification Information 43. . . . . . . . . . . . . . . . . . . . . . . .

Settings 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Retrieving or Changing Configuration Settings in the Settings Menu 43. . . . . .

6 Serial Interface Operation

Supported Commands 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nomenclature 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the Internal rPDU NMC 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Network with a DHCP Server 54. . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Network without a DHCP Server 55. . . . . . . . . . . . . . . . . . . . .

alarm command 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

current command 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

exit command 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

factory_defaults command 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

help command 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

network command 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

power command 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

|

4

Table of Contents

Page 5

reboot command 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

sensors command 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

temperature command 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ver command 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

voltage command 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Web Interface Operation

Navigating the Web Interface 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing the Web Interface 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring DPI Administration Settings 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Administrator Access 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring User Access 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Date and Time 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Email Notification 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identifying Email Notification Recipients 71. . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Links to External Web Sites 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring DPI Attributes 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Basic DPI Attributes 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Returning Configuration Settings to Default Values 73. . . . . . . . . . . . . . . . . . .

Uploading a Configuration File 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading a Configuration File 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Default CSV File Opening Settings 75. . . . . . . . . . . . . . . . . . . . . . .

Configuring Network Access and Control 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting General TCP/IPv4 Configuration Options 75. . . . . . . . . . . . . . . . . . . . .

Setting General TCP/IPv6 Configuration Options 76. . . . . . . . . . . . . . . . . . . . .

Enabling TCP/IP Network Controls 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding and Rejecting IP Addresses for SNMP/HTTP Access Control 78. . . . .

Rejecting IP Addresses for SNMP/HTTP Access Control 78. . . . . . . . . . . . . . .

Configuring SNMP Protocol Settings 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring SNMP Trap Receivers 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring and Managing the rPDU 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Present rPDU Status 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing rPDU and Web/SNMP Card Identification 82. . . . . . . . . . . . . . . . . . . .

Viewing rPDU System Information 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring Input Statistics 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing Environment Sensors 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Present Alarms and Events 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Event and Data logs 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

|

5

Page 6

Clearing Logs 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving Logs to an External File 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restarting the Internal rPDU NMC 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

|

6

Table of Contents

Page 7

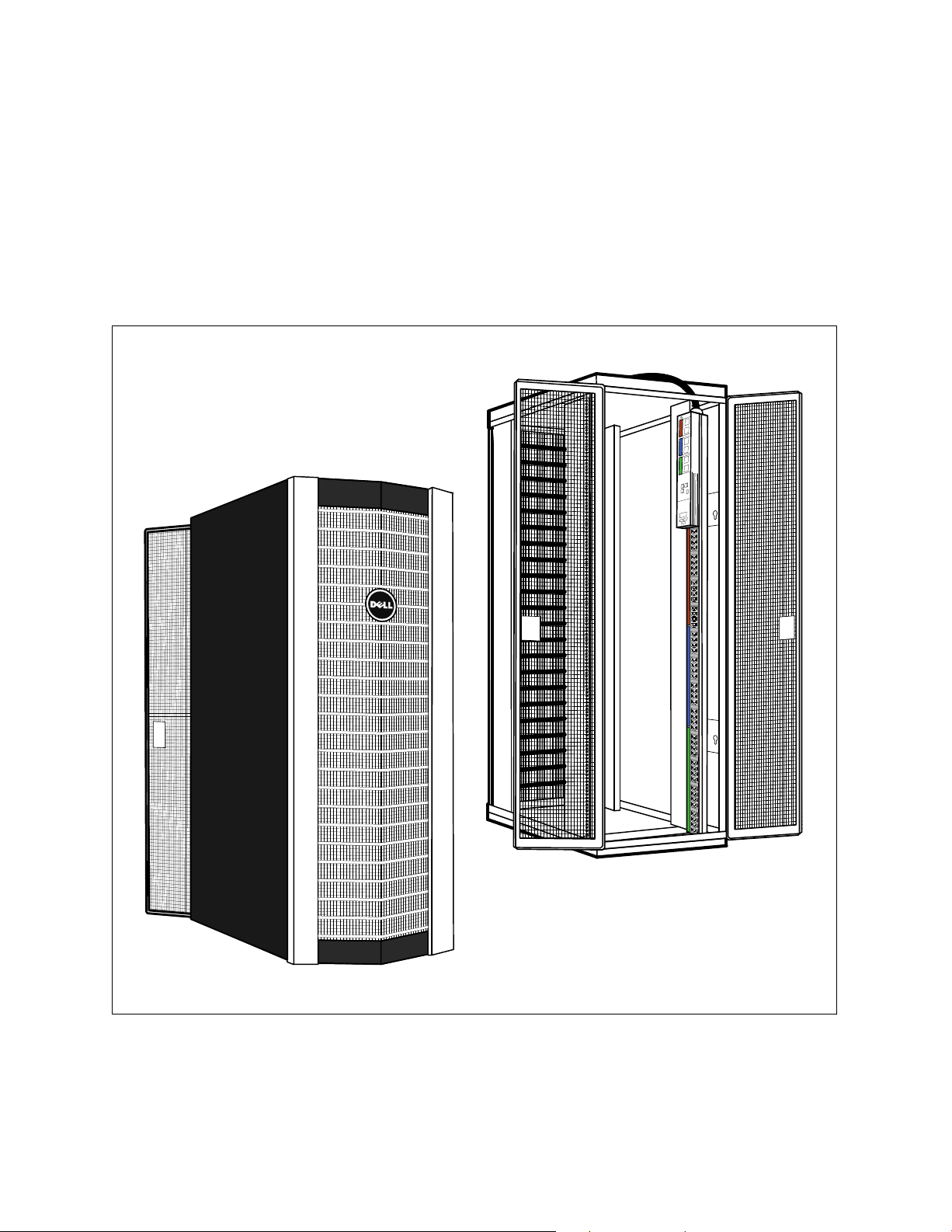

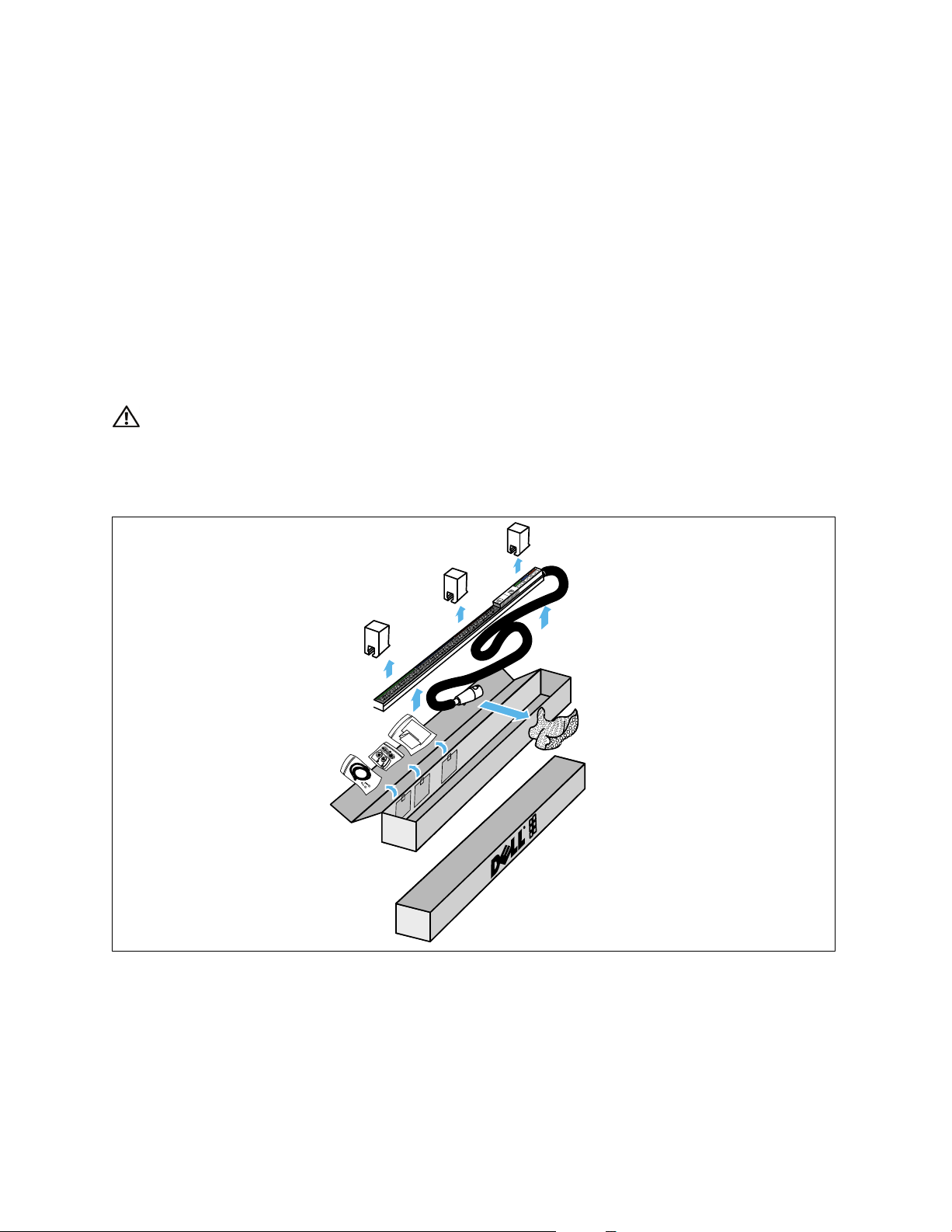

Introduction

The Dellt Metered Rack Power Distribution Unit (rPDU) models are installed at the rear in a rack enclosure.

The rack enclosure is designed to hold and protect server, network, and data storage equipment. The rPDUs

distribute power in the rack.

The rPDUs are mounted vertically in a recessed channel, providing more room for cabling within the rack

enclosure. The recessed location distances the rPDU from the other equipment and does not interfere with the

airflow in the rack enclosure.

1

Figure 1. Rack Enclosure with rPDU Installed

Introduction

|

7

Page 8

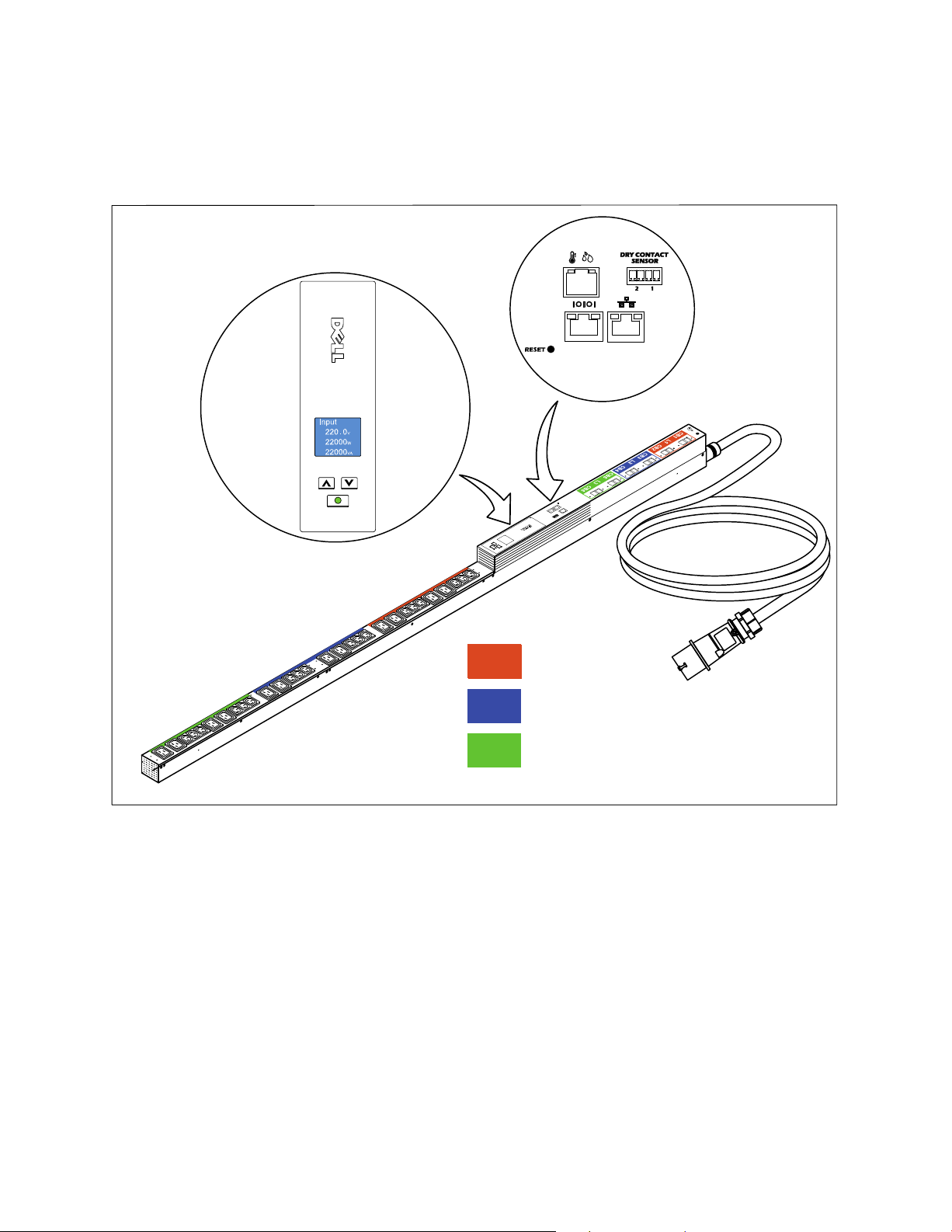

Providing outstanding performance and reliability, the rPDU benefits include the following:

S The rPDU can be installed as either 42U or 48U applications (depending on the model).

S The rPDU can be mounted using either factory-installed standard mounting pegs on the back of the rPDU,

or turned 90° by using user-installed deep mounting pegs on the side of the rPDU.

S Color-coded silk screening for outlet receptacles and circuit breakers clearly associate circuit breakers with

the receptacles they protect.

S The rPDU models provide several configurations of IEC 320 C-13 and IEC 320 C-19 outlet receptacles on

the front panel.

S The attached power cords for all models are 3m (10 ft) with IEC60309 input connector plugs.

S All receptacles, circuit breakers, ports, ground bonding point, and user interfaces are located on the front

panel of the rPDU for easy access.

S The rPDUs models are configured with either Delta or Wye topology.

S The rPDU provides an environmental monitoring sensor port, a dry contact sensor port, a 10/100 Base-T

Ethernet port, and a serial communication port.

S The LCD panel provides pushbutton controls for accessing performance monitoring data, event

notifications, and user-configured provisioning options.

S The rPDU provides an internal Dellt Network Management Card (NMC) for network communications.

The following options are available for the rPDU:

S Side- and front-mounted strain relief brackets for secure power cord retention (bracket type depends on

model)

S Dry contact sensor

S Temperature sensor

S Temperature and humidity sensor

The rPDU provides the following meters and measurements for reporting operational status:

S Input Voltage (V)

S Input Frequency in Hertz (Hz)

S Input Current in Amperes (A)

S Input Watts (W)

S Input Volt-amperes (VA)

S Instantaneous Headroom Watts

S Peak Headroom Watts (with time stamp)

S Peak Consumption Watts (with time stamp)

S Cumulative Kilowatt per Hour (with time stamp)

S Temperature (if an optional temperature sensor is installed)

S Humidity (if an optional humidity sensor is installed)

S Real-Time Clock

|

8

Introduction

Page 9

Physical Description

Installation Configurations

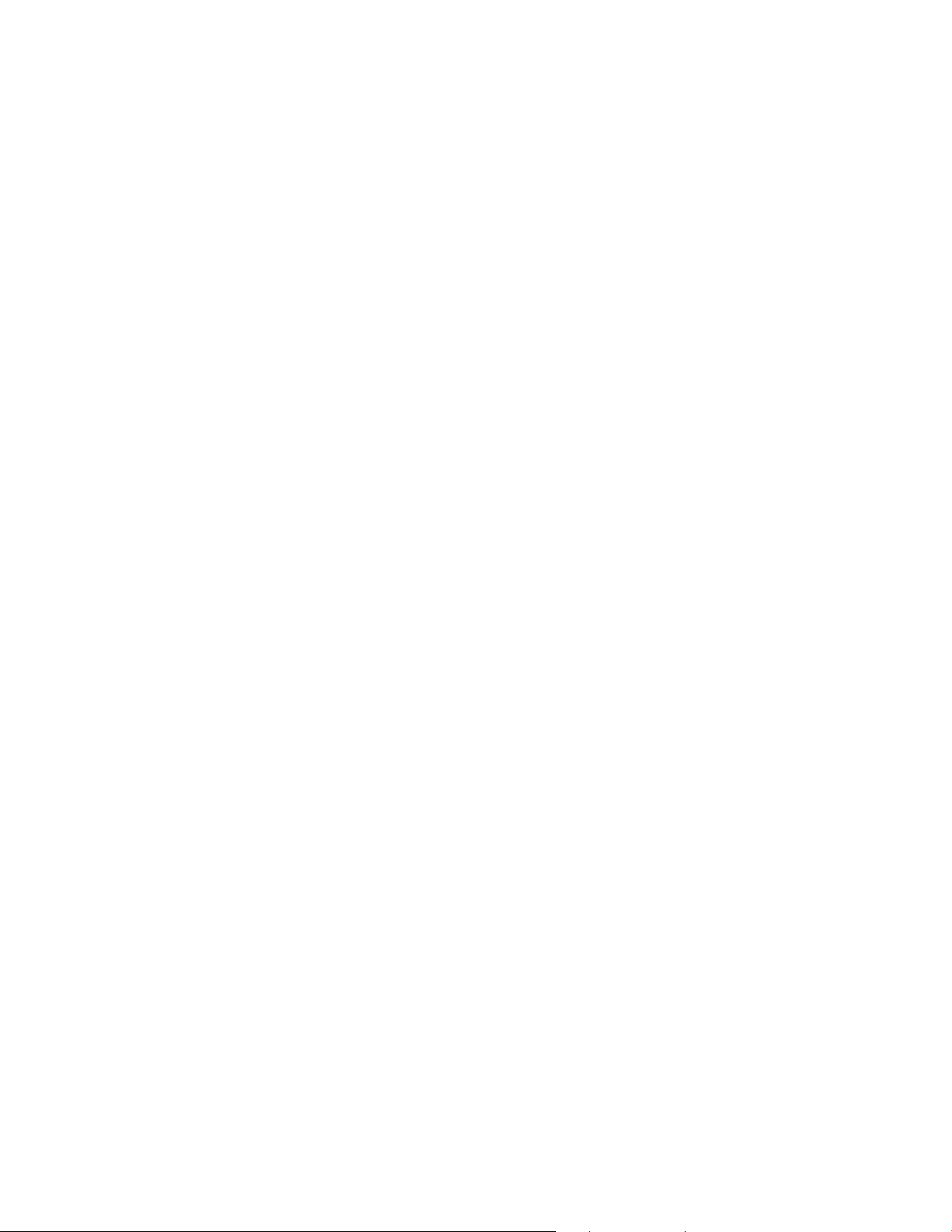

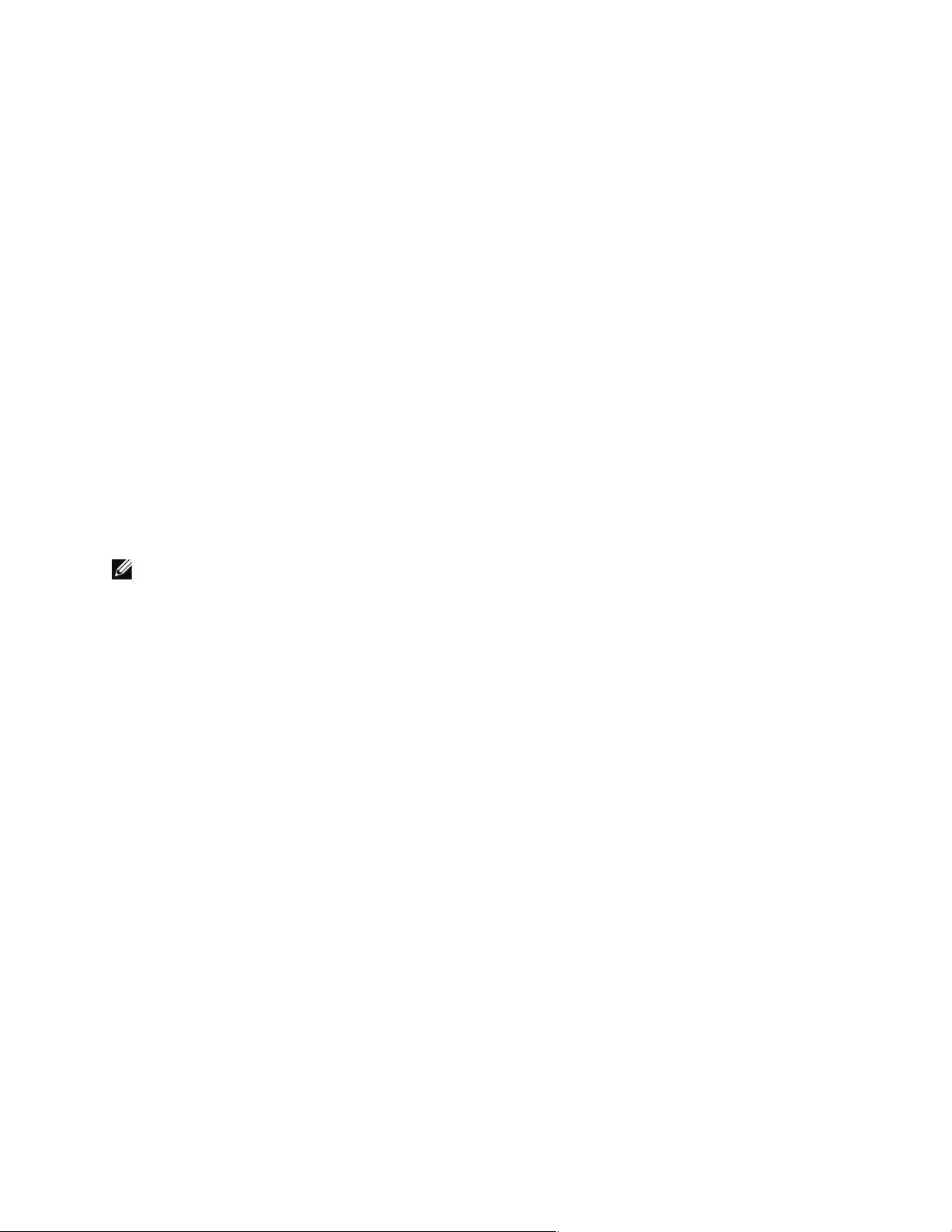

The rPDUs can be mounted vertically in several installation configurations and orientations to accommodate

different site needs. Either one or two rPDUs can be installed in each rPDU tray in the back of a rack enclosure,

providing a total of up to four rPDUs (see Figure 2).

NOTE:

When installing two rPDUs in a side-by-side configuration, you are not restricted to installing the same model.

See Figure 2.

Figure 2. One or Two rPDUs Installed in the rPDU Tray

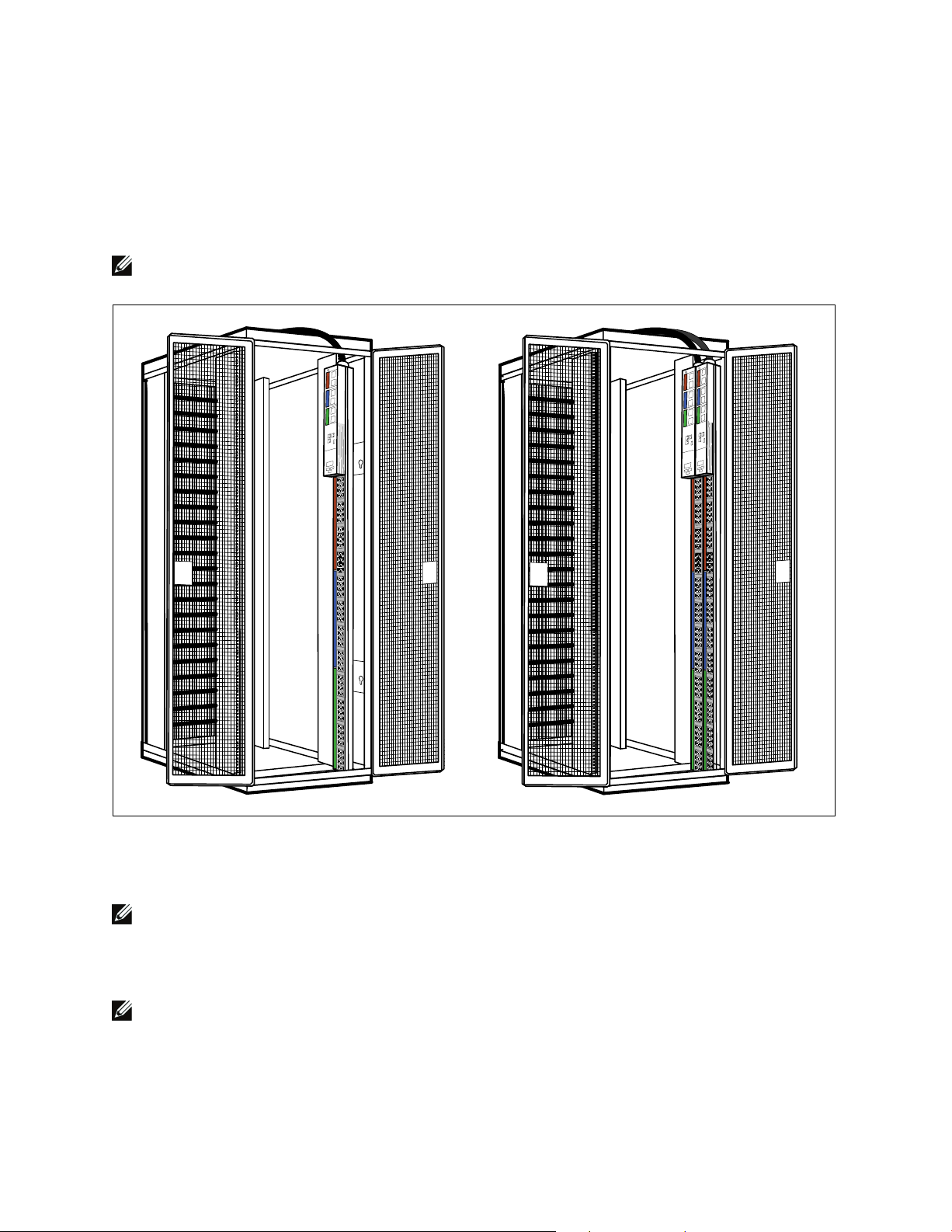

The standard mounting orientation for the rPDU is 180°. This is a snap-in, tooless installation. Two

factory-installed mounting pegs are inserted in mounting keyholes on the wall of the rPDU tray.

NOTE:

The 180° orientation means that the mounting surface (the back of the rPDU) is 180° in relation to the front

receptacles.

The rPDU can also be mounted in a 90° orientation. For this configuration, two deep mounting pegs (provided)

are user-installed before mounting the rPDU in the rPDU tray (see Figure 3).

NOTE:

The 90° orientation means that the mounting surface (the side of the rPDU) is 90° in relation to the front

receptacles.

Introduction

|

9

Page 10

rPDU installed using deep mounting pegs on the side (90°)rPDU installed using standard mounting pegs on the back (180°)

Figure 3. Standard 180° and 90° rPDU Installation

Strain Relief Brackets

You can install optional strain relief brackets on any rPDU model. Models with dense receptacle configurations

on the front panel have mounting holes for side-mounted relief brackets only. Models with spacing between

outlet groupings have mounting holes for both side- and front-mounted relief brackets.

The strain relief bracket kits include three brackets and mounting hardware. The side-mounted brackets can be

installed on either side of the rPDU. The front-mounted strain relief brackets are adjustable.

Ground Bonding Point

The external ground bonding point located on the rPDU front panel may be used to bond other conductive

metal components in the rack enclosure to a ground reference point for signaling or other functional purposes.

This bonding point can also be used to bond the rPDU to a known earthed reference terminal in the building.

Per international regulatory requirements, the primary Safety Earth Bond connection is contained in the rPDU

as an integral part of the branch circuit cabling and plug.

Delta and Wye Configurations

The rPDUs are configured in either Delta or Wye topology.

S The Delta configuration uses a four-wire input connector plug with three phase wires, a protective earth

(ground) wire, and no neutral wire. This is commonly expressed as 3W + PE (Delta).

S The Wye configuration uses a five-wire input connector plug with three phase wires, a protective earth

(ground) wire, and a neutral wire. This is commonly expressed as 3W + N + PE (Wye).

Table 1 on page 11 lists the Delta or Wye configuration for each model.

|

10

Introduction

Page 11

Attached Input Connections

All models use an IEC60309 input connector plug on a 3m (10 ft) cable attached to the rPDU. The type of input

connector plug varies by model to accommodate different amperage ratings and Delta or Wye configurations.

The input connector plugs have Ingress Protection (IP) ratings that specify the degree of environmental

protection for electrical equipment. All models use IEC60309 input connector plugs that are either splash

resistant (S) or waterproof (W).

NOTE:

Splash resistant plugs are IP-rated at IP 44, which means the plug is protected against solid objects less than

1.0 mm in diameter.

NOTE: Waterproof plugs are IP-rated at IP 67, which means the plugs are watertight, splashproof, and dust tight.

Standard IEC60309 reference codes provide a useful summary of the input connector plug specifications. The

code includes the number of pins, the maximum amperage rating, the type of connection, the alignment tab

clock position, and the protective classification.

Table 1 lists the standard IEC60309 reference codes for each model.

Table 1. Metered rPDU IEC60309 Codes

Model

DELLM0001 460P9W 4 60 P 9 W

DELLM001A 460P9W 4 60 P 9 W

DELLM0002 532P6S 5 32 P 6 S

DELLM0003 516P6S 5 16 P 6 S

DELLM0004 460P9W 4 60 P 9 W

DELLM004A 460P9W 4 60 P 9 W

DELLM0005 532P6S 5 32 P 6 S

DELLM0006 460P9W 4 60 P 9 W

DELLM0007 532P6S 5 32 P 6 S

IEC

Reference

Code

Delta 4-Pin Plug (4)

or

Wye 5-Pin Plug (5)

Maximum

Amperage (A)

Rating

Plug (P)

Receptacle/Socket

(R)

or Connector (C)

Clock

Position PE

(6 or 9)

Waterproof (W)

or

Splash Resistant (S)

Circuit Breakers

NOTE: The DELLM0003 model does not have circuit breakers.

There are six 20A circuit breakers on the rPDU (two circuit breakers per phase protecting the group of outlet

receptacles for that phase). Circuit breakers on the rPDU trip automatically when a power overload is detected.

Standard rPDU circuit breakers have Type C trip characteristics.

The rPDU monitoring firmware provides warnings that there is potential for overload and alarms if an overload

occurs. These thresholds are user-configurable. To reset the breakers after an overload, flip the breaker switch to

the ON position.

Circuit breakers and outlet receptacles are numbered and color-coded on the front panel to show the association

between breakers and the receptacles they protect. The phases (L1, L2, and L3) and protecting circuit breakers

(CB1 through CB6) are labeled on both circuit breaker groups and outlet receptacle groups (see Figure 4).

Introduction

|

11

Page 12

LCD Panel and Pushbutton Controls

The rPDU interface provides access to real-time performance monitoring and event notification data through

the LCD panel and pushbutton controls. This interface is also used to set user-configurable values, such as alarm

or warning thresholds. See Figure 4.

L1

L2

L3

Figure 4. LCD Front Panel

Phase 1: CB1 and CB2

Phase 2: CB3 and CB4

Phase 3: CB5 and CB6

Communication and Monitoring Ports

Two communication ports are provided. The rPDU has a serial port for an RJ-45 to DB-9 cable (provided) for

serial communication. The rPDU also has a 10/100 Base-T Ethernet port for network communication.

The network communication channel can be used to perform firmware upgrades (flash upgrades) over the

network. Upgrades can be performed for rPDUs installed in the rack enclosure while they are powered.

Two monitoring ports are provided. The following optional monitoring sensors can be installed:

S Dry contact sensor

S Temperature-only or combined temperature and humidity sensor

12

|

Introduction

Page 13

Finding Information

CAUTION: The Safety, Environmental, and Regulatory Information document provides important safety and regulatory

information.

What are You Looking For?

S Dell Metered Rack Power Distribution Unit (rPDU)

User's Guide

S Other rPDU documentation, such as Product Overview

documents

S Software updates Software updates can be found at:

Find It Here

Documentation can be found at:

support.dell.com/support/edocs/ACC/PDU/

support.dell.com

S How to install the rPDU

S rPDU specifications

S How to configure rPDU settings

S How to operate the rPDU

S Safety instructions

S Regulatory information

S Recycling information

S Warranty information

S Terms and Conditions (U.S. only)

S End User License Agreement

S Support information Dell Support Website — support.dell.com

Dell Metered rPDU User's Guide

The user's guide is available at:

support.dell.com/support/edocs/ACC/PDU/

Safety, Environmental, and Regulatory Information

Dell Warranty and Support Information

NOTE: Select your region or business segment to view the

appropriate support site.

Introduction

|

13

Page 14

Safety Warnings

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that you should follow during installation and operation of the Dell Metered Rack

Power Distribution Unit (rPDU). Please read all instructions before operating the equipment and save this manual for future

reference.

DANGER:

This rPDU contains LETHAL VOLTAGES. All repairs and service should be performed by AUTHORIZED SERVICE PERSONNEL

ONLY.

CAUTION:

S To reduce the risk of fire or electric shock, install this rPDU in a temperature and humidity controlled, indoor

environment, free of conductive contaminants. Ambient temperature must not exceed 50°C (122°F). Do not operate

near water or excessive humidity (95% maximum).

S To comply with international standards and wiring regulations, the total equipment connected to the output of this

rPDU must not have an earth leakage current greater than 3.5 milliamperes.

S For PLUGGABLE EQUIPMENT, a readily accessible disconnect device shall be incorporated in the building installation

wiring.

S For PLUGGABLE EQUIPMENT, the power outlet shall be installed near the equipment and shall be readily accessible.

2

14

|

Safety Warnings

Page 15

Installation

This section explains:

S Unpacking the Dell Metered Rack Power Distribution Unit (rPDU) equipment

S Equipment inspection

S Setup and installation

S Starting up and shutting down the rPDU

S Front panel diagrams

Unpacking the rPDU

CAUTION: Hazard of electric shock. Unpacking the cabinet in a low-temperature environment may cause condensation

to occur in and on the rPDU. Do not install the rPDU until the inside and outside are dry.

Use care when moving and opening the carton. Leave the components packaged until ready to install.

1 Remove the top from the carton(see Figure 5).

3

Figure 5. Unpacking the rPDU

2 Remove the rPDU, the accessory bag, and documentation from the carton:

Grasp the rPDU and the input connector plug and set them on a flat, stable surface.

Remove the Styrofoam shipping supports from the rPDU and the wrapper from the input connector plug.

Remove the documents and the accessory bag from the inside wall of the carton.

Installation

|

15

Page 16

3 Place the rPDU in a protected area that has adequate airflow and is free of humidity, flammable gas, and

corrosion.

4 Discard or recycle the packaging in a responsible manner, or store it for future use.

Inspecting the Equipment

If any equipment has been damaged during shipment, keep the shipping cartons and packing materials for the

carrier or place of purchase and file a claim for shipping damage. If you discover damage after acceptance, file a

claim for concealed damage.

To file a claim for shipping damage or concealed damage: 1) File with the carrier within 15 days of receipt of the

equipment; 2) Send a copy of the damage claim within 15 days to your service representative.

Checking the Accessory Bag

The rPDU accessory bag includes the following:

S (2) deep mounting pegs and (2) 8-32 5/8” mounting screws (for 90° installation)

S Grounding kit with:

- (1) silver 10-32

- (1) black, M5

- (1) ground wire

- (2) star washers

S Safety, Environmental, and Regulatory Information (SERI) document

S Quick Start Installation Sheet

S (1) RJ-45 Cable (RJ-45-to-DB9-female, 2.0m length, serial cable)

0.5” pan-head screw

12 pan-head screw

If you ordered the optional strain relief brackets (shipped separately), check that the following associated

hardware is included with the option.

For the side-mounted strain relief bracket:

S (3) strain relief brackets

S (8) M3 6 flat-head cross screws

For the front-mounted strain relief bracket:

S (3) strain relief brackets

S (4) 6-32 1/4” flat-head cross screws

|

16

Installation

Page 17

Preparing for Installation

Before installing the rPDUs in a rack enclosure, consider location and orientation. For most installations, the

selected location and orientation depends on the number of rPDUs that will be installed and the cable

management plan.

For example, suppose you plan to separate data and power cables on opposite sides of the rack enclosure. For this

configuration, install one or two rPDUs in the same tray. Route the data cables to the other rPDU tray (serving

as a cable channel) on the opposite side of the rack enclosure.

Another plan might be to balance the data and power cables on each side. For this configuration, install one

rPDU on each side of the rack enclosure. The remaining portion of each rPDU tray serves as a cable channel for

bundled and properly dressed data cables running beside the rPDU.

Other considerations include the orientation of the rPDU and the type of strain relief brackets mounted on the

rPDUs.

Installing Hardware for Options

Install the hardware that supports installation options before installing the rPDUs in the rack enclosure. This

includes the following:

S Strain relief brackets for cord management (optional kit)

S Deep mounting pegs for the 90° mounting option (supplied)

NOTE:

The factory-installed standard mounting pegs are secured to the chassis by two 8-32 3/7” mounting screws. The

user-installed deep mounting pegs are secured to the chassis by two 8-32 5/8” mounting screws.

Installing Strain Relief Brackets

To install the optional strain relief brackets:

1 Place the rPDU on a flat, stable surface.

2 Align the screw mounting holes on the rPDU with the screw mounting holes on the bracket (see Figure 6).

3 Secure the bracket with the supplied screws.

4 Are you installing deep mounting pegs for 90° installation?

If no, go to “Installing the rPDU in the Rack Enclosure” on page 19.

If yes, continue to the next section, “Installing Deep Mounting Pegs” on page 18.

Installation

|

17

Page 18

Side-Mounted Strain Relief Bracket

Front-Mounted Strain Relief Bracket

Figure 6. Strain Relief Bracket

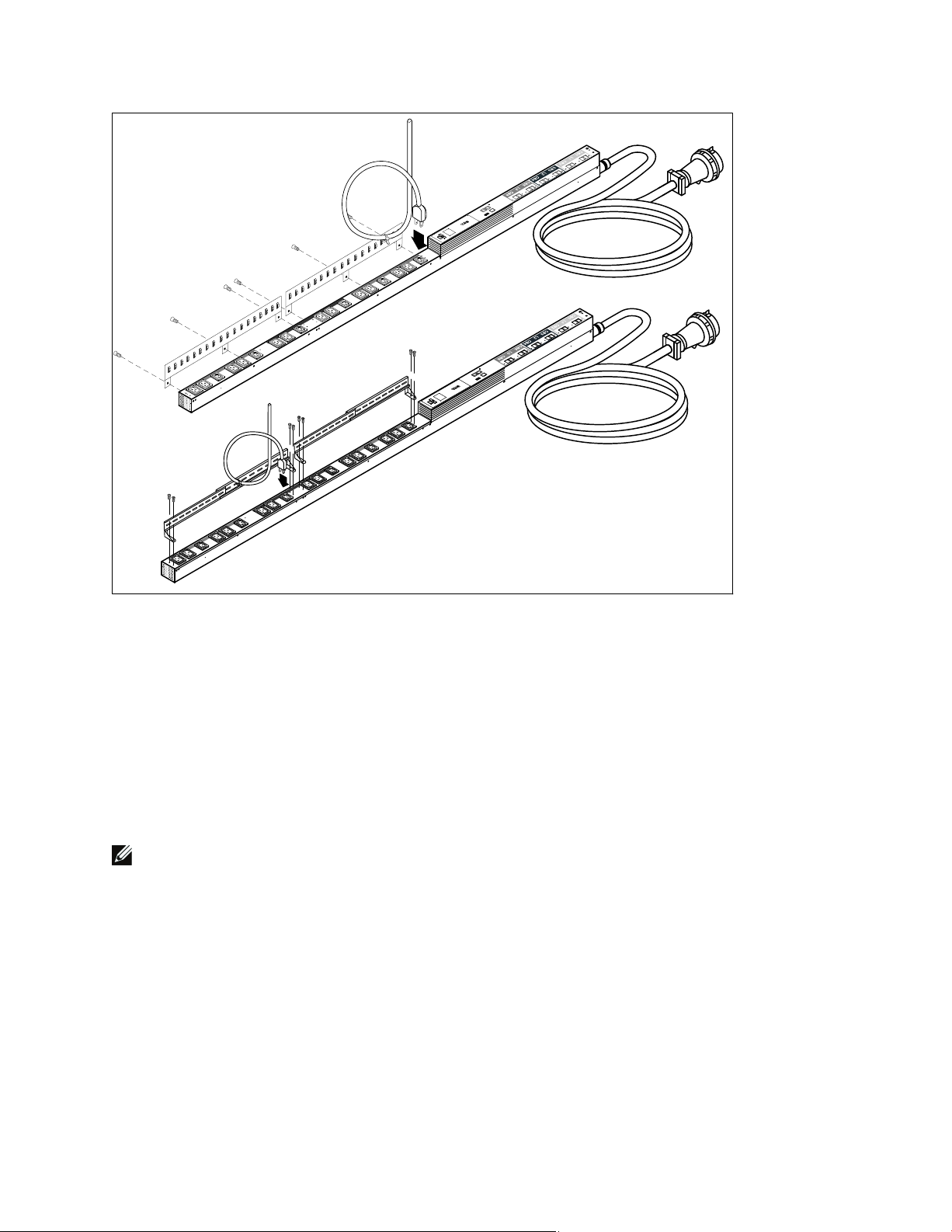

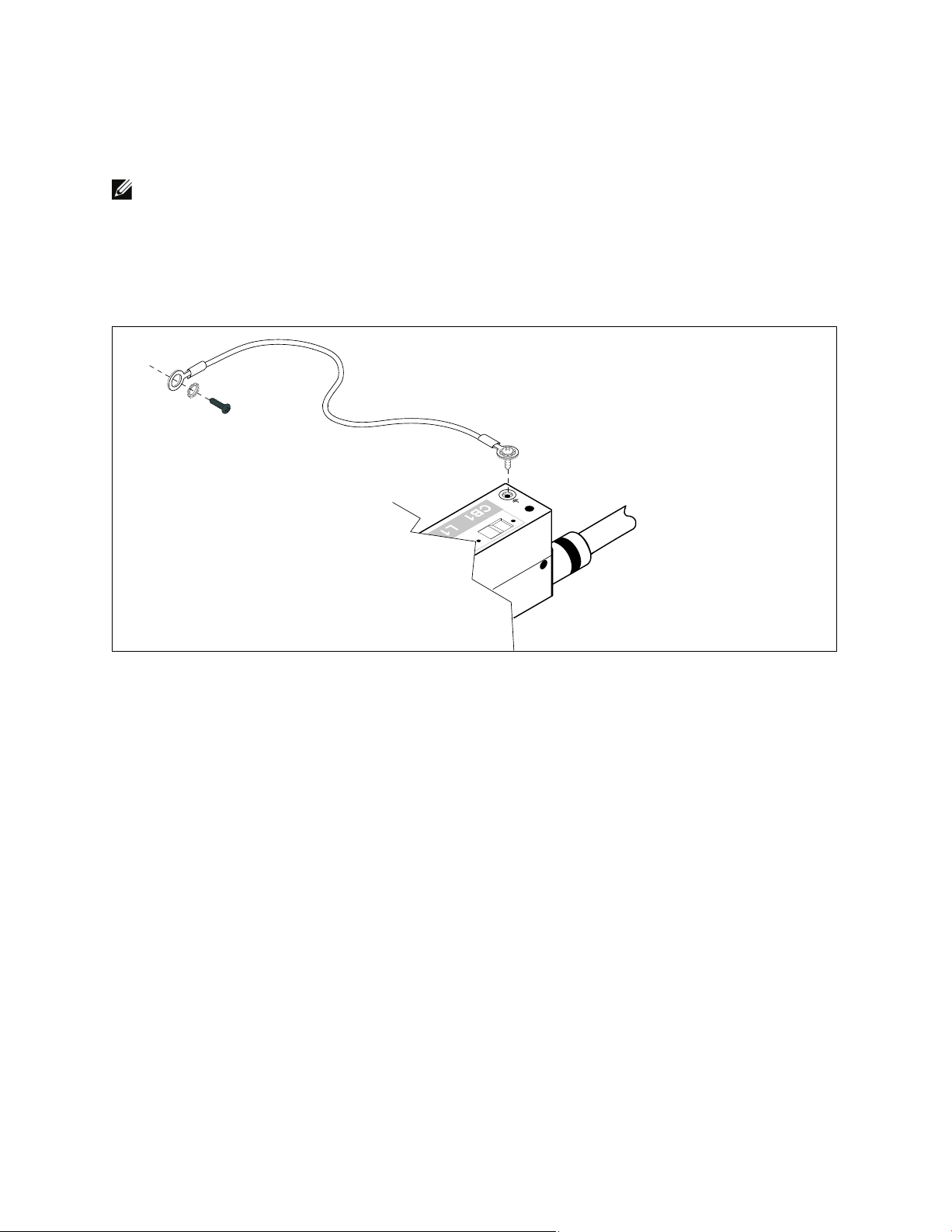

Installing Deep Mounting Pegs

To install the deep mounting pegs (supplied) on the side of the rPDU for 90° mounting installations:

1 Remove the two deep mounting pegs and two mounting screws from the accessory bag.

2 Locate the top and bottom peg mounting holes on the side of the rPDU (see Figure 7).

3 Align the peg mounting holes on the rPDU with the mounting hole in the center of the deep mounting

pegs.

4 Secure the top and bottom deep mounting peg with the provided screws (see Figure 7).

NOTE:

Dell recommends removing the standard mounting pegs on the rear of the rPDU if you install the deep mounting

pegs (provided in the accessory kit shipped with the rPDU). Retain the standard mounting pegs so the rPDU can be

reoriented later if needed.

|

18

Installation

Page 19

Figure 7. Installing the Deep Mounting Pegs

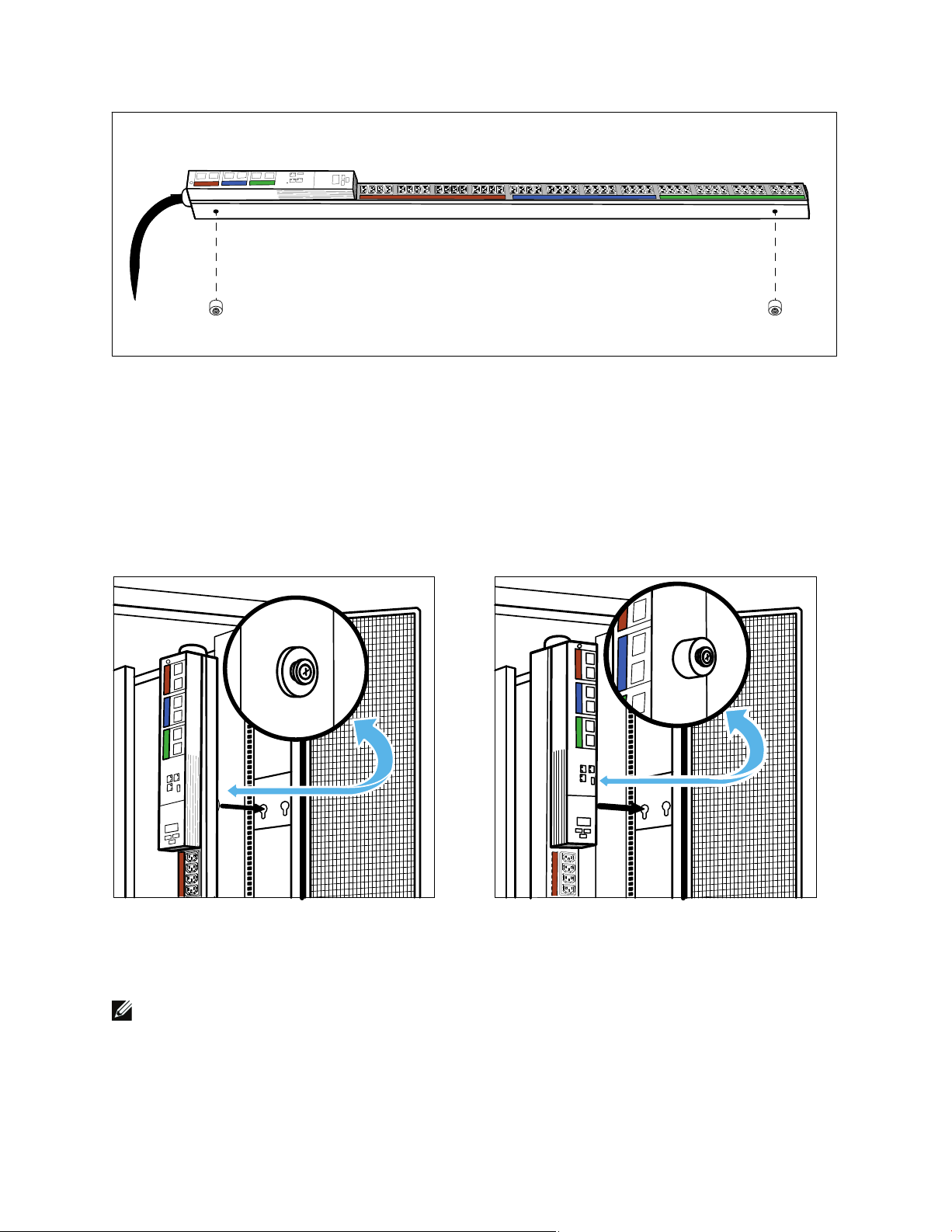

Installing the rPDU in the Rack Enclosure

To install the rPDU in a rack enclosure:

1 Move the rPDU into position at the rear of the rack enclosure.

2 Select the proper keyholes in the rPDU tray for mounting the rPDU.

3 Align the mounting pegs with the keyholes in wall of the rPDU tray (see Figure 8).

Figure 8. Aligning and Inserting the Standard or Deep Mounting Pegs (Top Mounting shown; Bottom Mounting not shown)

4 Fully insert both mounting pegs into the keyholes.

5 Push down to set the rPDU in place.

NOTE:

A second rPDU can be installed in the same tray. The procedure is the same. See Figure 9.

Installation

|

19

Page 20

Figure 9. Mounting Two rPDUs in the PDU Tray

6 Continue to “Attaching the Ground Wire” section on page 21.

20

|

Installation

Page 21

Attaching the Ground Wire

To attach the ground wire to the rack:

NOTE:

Dell recommends that you ground the rPDU to the rack frame with the ground wire provided in the Grounding Wire

Kit.

1 Connect one end of the ground wire to the ground bonding point location on the front panel of the rPDU

using the silver, 10-32

2 Connect the other end of the ground wire to a hole in the rack frame using the black, M5 12 pan-head

screw and star washer (supplied). See Figure 10.

0.5” pan-head screw and star washer (supplied).

Frame Connection

M5

12 Pan-head Screw (Black)

Star Washer

Figure 10. Ground Bonding Point and Frame Connections

3 Continue to “Connecting Protected Equipment” on page 22.

Ground Bonding Point Connection

10-32

0.5” Pan-head Screw (Silver)

Star Washer

Installation

|

21

Page 22

Connecting the Protected Equipment

CAUTION: For PLUGGABLE EQUIPMENT, the power outlet shall be installed near the equipment and shall be readily

accessible.

CAUTION: The rPDU output receptacles for each phase are protected by two 20A circuit breakers on the front panel.

Confirm that the equipment connected to the rPDU does not exceed the rPDU's capacity.

NOTE: The DELLM0003 model does not have circuit breakers.

To install the plug-receptacles:

1 Plug the equipment power cords into the rPDU outlet receptacles.

2 If an optional strain relief bracket is installed, attach the power cords to the bracket by looping the cords

and securing them with tie wraps.

NOTE:

Secure the power cords in the bracket so you can unplug them without removing the tie wrap.

3 Plug the rPDU power cord into a power outlet.

4 Ensure that each circuit breaker is in the ON position.

NOTE:

If power to the rPDU is interrupted, check each circuit breaker and reset if necessary.

Starting the rPDU

To start the rPDU:

1 Plug the rPDU power cord into the power outlet.

2 Turn each circuit breaker to the ON position.

3 If power to the rPDU is interrupted, check each circuit breaker and reset if necessary.

NOTE:

During startup, the Dell Startup screen displays for five seconds and then defaults to the Input Status screen.

Shutting Down the rPDU

NOTE: The protected equipment may be turned off at the equipment or, for models with circuit breakers, at the circuit

breakers on the rPDU.

To shut down the rPDU:

1 Shut down the protected equipment according to the manufacturer's recommended shutdown sequence.

2 Models with circuit breakers only. Turn each circuit breaker to the OFF position.

3 To remove power from the rPDU completely, disconnect the rPDU input connector at the source.

22

|

Installation

Page 23

Front Panels

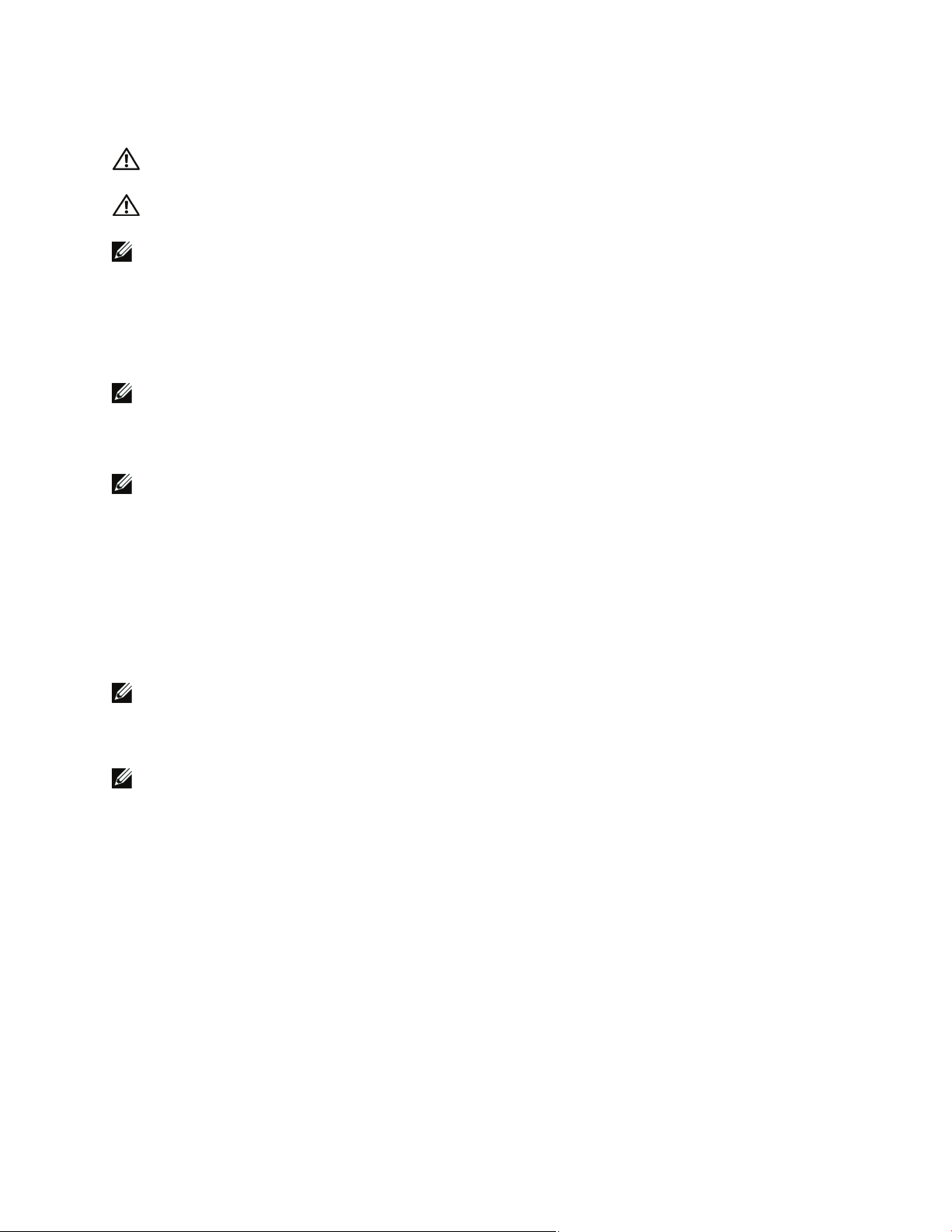

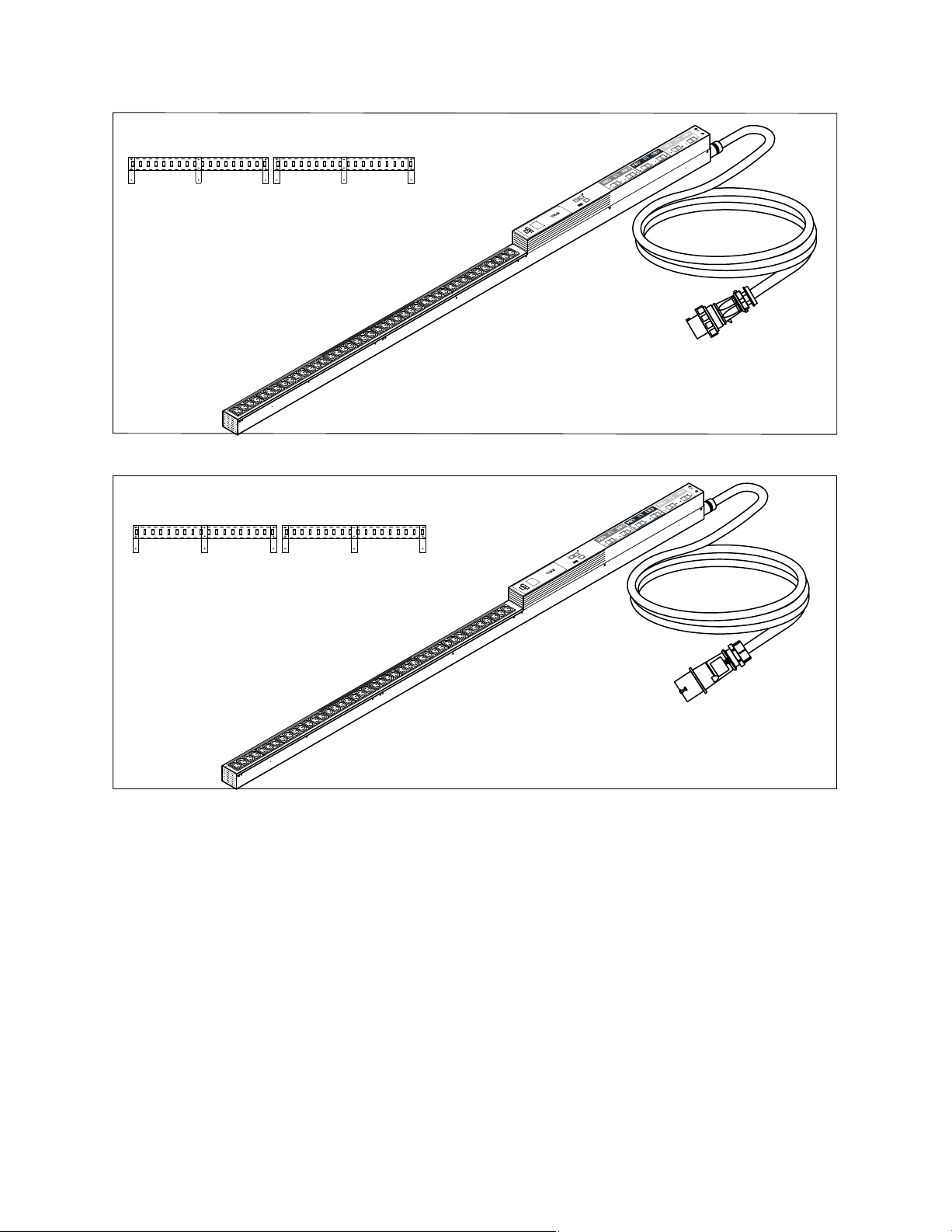

This section shows the front panels of the rPDU models.

rPDU Model Number See Figure On Page

DELLM0001 Figure 11 23

DELLM001A Figure 11 23

DELLM0002 Figure 12 24

DELLM0003 Figure 13 24

DELLM0004 Figure 14 25

DELLM004A Figure 14 25

DELLM0005 Figure 15 25

DELLM0006 Figure 16 26

DELLM0007 Figure 17 26

(6) 20A Circuit Breakers

Side-Mounted or Front-Mounted

Strain Relief Bracket (Optional)

Figure 11. DELLM0001 and DELLM001A

42U

Output Receptacles

(6) IEC 320-C13; 10A

(12) IEC320-C19; 16A

IEC60309-60A

(Waterproof - IP 67)

460P9W

Installation

|

23

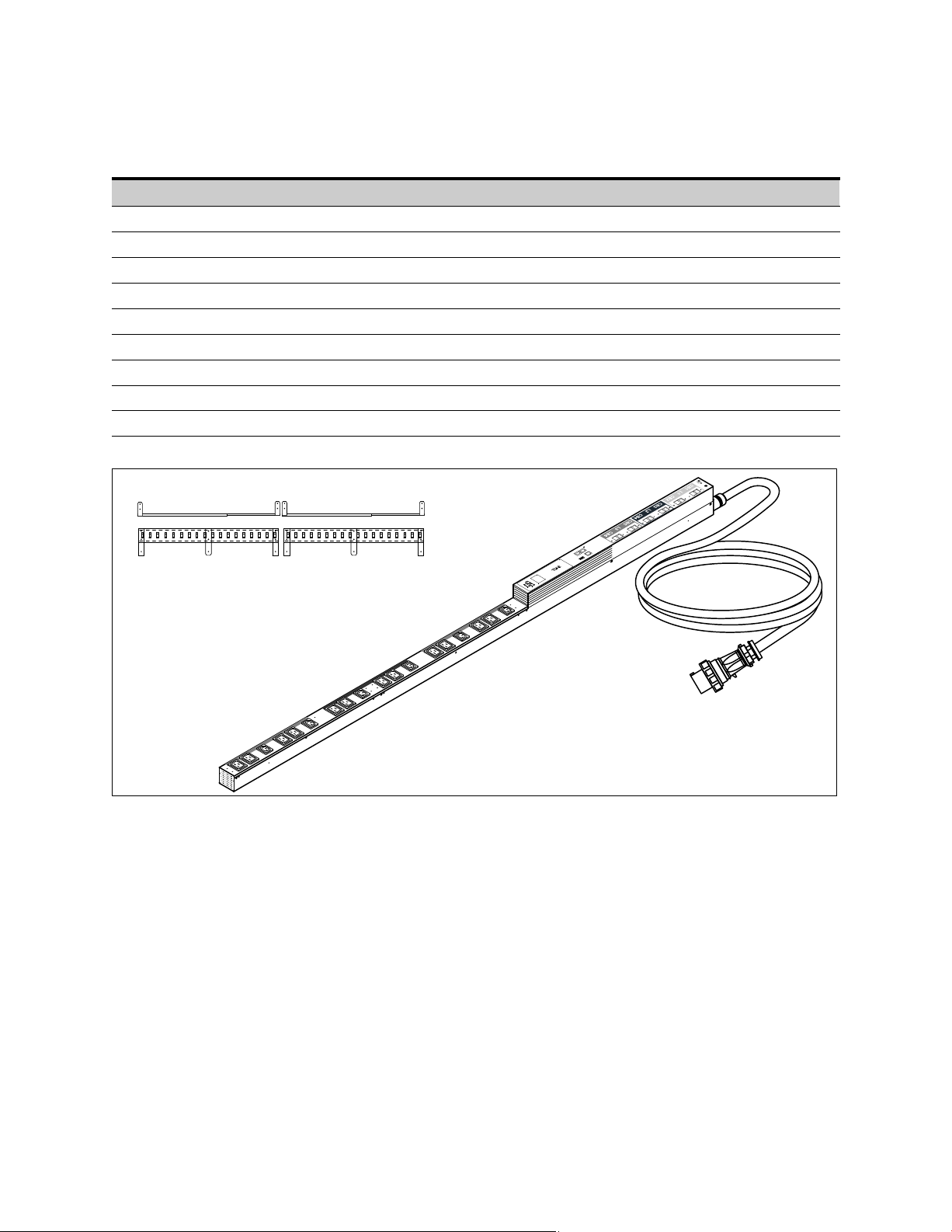

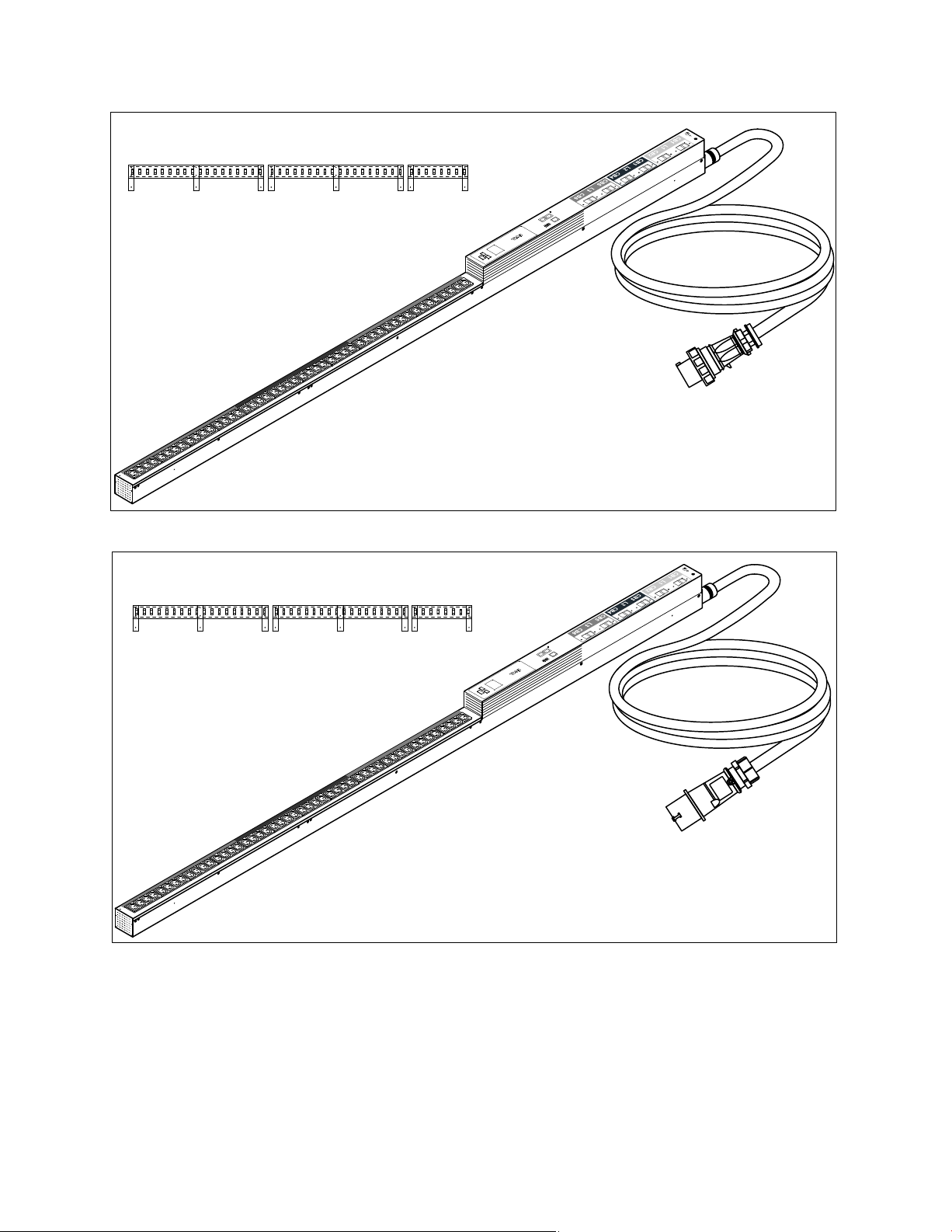

Page 24

Side-Mounted or Front-Mounted

Strain Relief Bracket (Optional)

Figure 12. DELLM0002

Side-Mounted or Front-Mounted

Strain Relief Bracket (Optional)

42U

42U

(6) 20A Circuit Breakers

Output Receptacles

(18) IEC 320-C13; 10A

(12) IEC320-C19; 16A

IEC60309-32A

(Splash resistant - IP 44)

532P6S

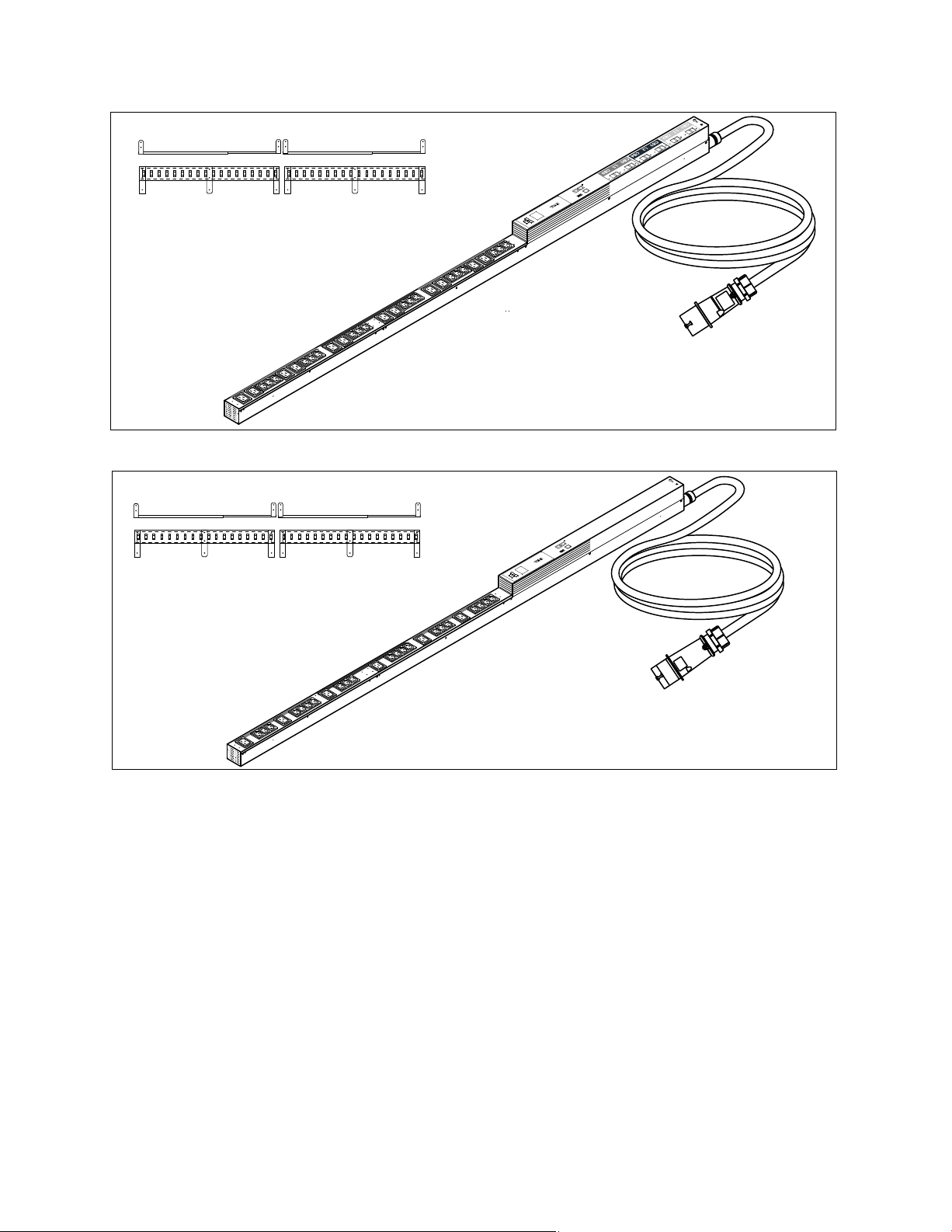

Figure 13. DELLM0003

Output Receptacles

(21) IEC 320-C13; 10A

(6) IEC320-C19; 16A

IEC60309-16A

(Splash resistant - IP 44)

516P6S

24

|

Installation

Page 25

Side-Mounted Strain Relief Bracket (Optional)

Figure 14. DELLM0004 and DELLM004A

Side-Mounted Strain Relief Bracket (Optional)

(6) 20A Circuit Breakers

42U

Output Receptacles

(42) IEC 320-C13; 10A

IEC60309-60A

(Waterproof - IP 67)

460P9W

(6) 20A Circuit Breakers

Figure 15. DELLM0005

42U

Output Receptacles

(42) IEC 320-C13; 10A

IEC60309-32A

(Splash resistant - IP 44)

532P6S

Installation

|

25

Page 26

Side-Mounted Strain Relief Bracket (Optional)

Figure 16. DELLM0006

48U

Output Receptacles

(48) IEC 320-C13; 10A

(6) 20A Circuit Breakers

IEC60309-60A

(Waterproof - IP 67)

460P9W

(6) 20A Circuit Breakers

Side-Mounted Strain Relief Bracket (Optional)

Figure 17. DELLM0007

48U

Output Receptacles

(48) IEC 320-C13; 10A

IEC60309-32A

(Splash resistant - IP 44)

532P6S

26

|

Installation

Page 27

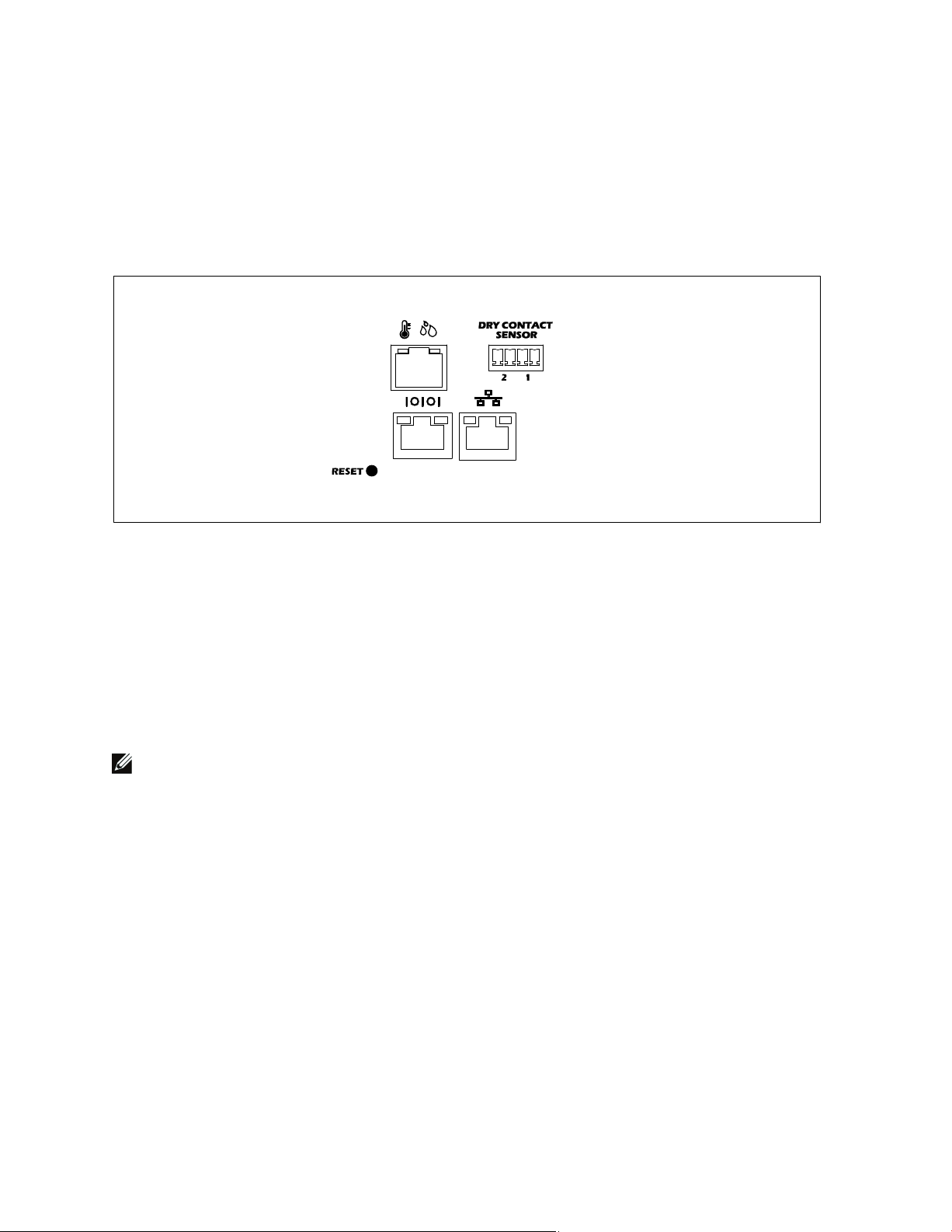

External Signaling Ports

Two types of external signaling ports are provided on the rPDU front panel (see Figure 18):

S Communication ports

S Monitoring ports

4

Temperature/Humidity

Sensor Port

Serial Port

NMC Reset Button

Figure 18. Communication and Environmental Ports

Dry Contact Sensor Port

Ethernet Port

Communication Ports

The rPDU provides both a serial and an Ethernet (10/100 Base-T) communication port for external controls.

These communication ports are used to access external controls for upgrading, monitoring, or managing the

rPDU.

Firmware upgrades (flash upgrades) update the rPDU firmware and the internal Dell Network Management

Card (NMC). Upgrades can be performed either using a command line interface (CLI) upgrade utility or a

Web-based graphical user interface.

NOTE:

The RESET button on the front panel resets the internal NMC.

Flash upgrades are transparent and do not affect rPDU operation. However, the front panel buttons and LCD

operation are disabled during the upgrade. Unique model identification information prevents an incorrect

firmware load from being installed on an rPDU during a flash upgrade.

During the flash upgrade, the LCD provides a “Flash Update In Process” message and provides a progress bar. If

the upgrade is interrupted, recovery processes allow the upgrade to restart. If the upgrade fails, the LCD displays

a “Flash Error” message and the backlight changes to amber text with a dark red background.

The rPDUs can be monitored and settings modified using a graphical Web interface. The settings correspond to

the Settings menu (see Settings menu on page 43). This requires a PC connected through the Ethernet port.

External Signaling Ports

|

27

Page 28

Serial Port

The serial port provides RS-232 serial communication between the rPDUs and a computer using an RJ-45 to

DB-9 serial cable (supplied). Use the serial port to connect to a PC and perform the following using a CLI:

S Configure the internal NMC at startup

S Upgrade the internal NMC and rPDU firmware using a flash update utility program

S Connect to a Dell KVM that supports rPDU communication

To create a serial connection between the rPDU and a PC:

1 Locate the RJ-45 to DB-9 serial cable provided in the accessory bag.

2 Connect the RJ-45 serial cable connector to the rPDU serial communication port (see Figure 18).

3 Connect the serial cable console connector to the RS-232 serial connection port (COM port) on the PC.

NOTE:

Use HyperTerminal® or an equivalent terminal emulation application for the CLI.

The cable pins for the RS-232 serial connection (DB-9 female connector) are identified in Figure 19.

3

16245

879

Figure 19. DB-9 Female Connector

Table 2 provides RS-232 serial connector port pin assignments.

Table 2. Serial Communication RS-232 Port Pin Assignment

Pin

1 Unused —

2 RXD Receive Data In

3 TXD Transmit Data Out

4 Unused —

5 GND Ground —

6 Unused —

7 Unused —

8 Unused —

9 Unused —

Signal Name Function Direction from the rPDU

NOTE: Unused pins must be left free on all models. The pins labeled “Unused” are not to be pulled high or tied to ground.

28

|

External Signaling Ports

Page 29

Table 3 provides RJ-45 serial connector port pin assignments.

Table 3. Serial Communication RJ-45 Port Pin Assignment

Pin

1 Unused —

2 Unused —

3 Unused —

4 RXD Receive Data In

5 TXD Transmit Data Out

6 GND Ground —

7 Unused —

8 Unused —

Signal Name Function Direction from the rPDU

Ethernet Port

The rPDU provides an Ethernet (10/100 Base-T) port connection in order to use the internal NMC to monitor

and manage rPDUs.

The rPDU defaults to using DHCP when delivered. If you are unable to connect to the rPDU through the

network connection with this default address, change the IP address using the serial interface before using any of

the network interfaces. See “Serial Interface Operation” on page 50 for more information.

Once connected, you can access the graphical Web interface over the network and verify that the rPDU's

internal NMC is operational and recognized by the Web interface so the rPDU can be monitored and managed.

NOTE:

The rPDU is defaulted to use DHCP, but additional NMC configuration can be done through the serial connection

using a CLI.

To create an Ethernet connection between the rPDU and the network:

1 Locate the Ethernet cable to use for this network connection (not provided).

2 Ensure the network cable is connected to the network server or router connection.

3 Connect the Ethernet cable to the Ethernet connection port on the rPDU (see Figure 18).

Monitoring Ports

Monitoring ports are used to collect readings from connected sensors. There are two types of environmental

monitoring device (EMD) ports on the rPDU. One port is provided for a either a temperature-only or a

combined temperature and humidity sensor. A dry contact sensor port is also provided.

Temperature and Humidity Sensor (Optional)

Temperature-only or combined temperature and humidity sensors provide readings of the ambient conditions where

the sensor is installed. If a temperature or humidity reading crosses the high or low threshold setting, an alarm

displays in the LCD. (See the Settings menu on page 43.) If the sensor is not installed, or not connected to the rPDU,

the LCD displays dashes.

NOTE:

An environment alarm does not affect rPDU system operation. The alarm only reports an environmental condition.

Install and set up the sensor as instructed in the installation documentation on www.dell.com. Connect the

appropriate end of the temperature-only or combined temperature and humidity sensor cable to the

temperature/humidity sensor port on the rPDU (see Figure 18).

External Signaling Ports

|

29

Page 30

NOTE: Temperature readings are measured in Kelvin (K), then converted and reported as °C on the LCD panel.

Dry Contact Sensor (Optional)

Two dry contacts on the front panel can be configured as either normally open or normally closed when dry

contacts are installed. When configured as normally open, the dry contact becomes active when the pins are

shorted. When configured as normally closed, the dry contact becomes active when the pins are open. (See the

Settings menu on page 43.)

NOTE:

When the dry contact is active, an alarm displays. The alarm is cleared by restoring the hardware connection to

the state before the dry contact became active.

Install and set up the dry contact sensor as instructed in the installation documentation on www.dell.com.

Connect the dry contact sensor to the appropriate port on the rPDU (see Figure 18).

30

|

External Signaling Ports

Page 31

LCD Operation

This chapter contains information on how to use the Dell Metered Rack Power Distribution Unit (rPDU),

including:

S LCD panel and control button functions

S Menu selections

The LCD panel language is not configurable. Only English is provided.

NOTE:

LCD Panel and Control Buttons

The rPDU has a three-button, graphical LCD panel (see Figure 20). Use the control buttons to change the

screen display and retrieve specific performance data or change configuration values.

The display view can also change automatically. For example, the display changes to show active alarms as they

occur, or particular displays update due to a change in operating state.

Inactivity can cause a screen change as well. For example, the display returns to the rPDU Input Status screen

automatically when no button has been pressed for 15 min.

5

Figure 20. LCD Panel

LCD Operation

|

31

Page 32

Table 4 describes the elements that comprise the LCD panel.

Table 4. LCD Panel Elements

LCD Panel Element Description

Scroll up to go back to previous options or menu levels

Selects a menu or option

Scroll down to see the next option or menu level

A standard backlight is continually lit so the white text and a blue background is

clearly visible.

When an rPDU alarm is active, the text changes to amber and the backlight

becomes dark.

Table 5 describes the LCD control button functions.

Table 5. LCD Control Button Functions

Control Button

Operator Action Response

Press for less than one second Scroll up, moving back to the previous menu.

Press for longer than one second Return/exit back one menu layer without initiating a command or

changing a setting.

Press for less than one second Select the menu or option to be changed.

Press for longer than one second Save the setting being edited.

Press for less than one second Scroll down, moving forward to the next menu option.

NOTE: The display automatically returns to the Input Status screen when no button has been pressed for 15 minutes and

no other screen has been locked by a user. To return to the Main Menu, press any control button.

32

|

LCD Operation

Page 33

Locking a Screen

To lock a screen, press the button. The screen view stays locked and does not automatically return to the

default screen after time-out. When the screen is locked, the image of a key appears at the top of locked screen.

Pressing any control button unlocks the screen, removes the lock symbol, and returns the normal control button

functions to the operator (see Figure 21).

Figure 21. Locked Screen

Automatic Alarm Notification

When an alarm occurs, the LCD display automatically changes to the active alarm display except under the

following circumstances:

S Screen lock is activated

S You are in the Settings menu

S You selected a control button in the last five seconds

NOTE:

An active alarm is presented as amber text on a dark background to distinguish it from the standard LCD display.

Input Status Screen

Five seconds after rPDU startup, the Input Status screen automatically replaces the Dell startup screen. The Input Status

screen provides a summary of rPDU input measurements (see Figure 22).

Figure 22. Dell Startup and Input Status Screens

LCD Operation

|

33

Page 34

Table 6 describes the values on the Input Status screen display.

Table 6. Input Status Screen

Status Description

Input Voltage (V) Present average of the total input voltage for all three rPDU phases, reported in Volts (V).

NOTE: If any phase fails to report voltage, the voltage for the remaining phases is averaged.

Input Wattage (W) Calculated value of the overall input wattage of the rPDU, reported in Watts (W). This is also

called active power.

Input Volt-amperes (VA) Calculated value of the overall input volt-amperes (VA) of the rPDU. This is also called

apparent power.

Main Menu Selections

The rPDU menu selection hierarchy provides useful performance information, alarms, events, identification, and

configuration settings.

Make a selection from the rPDU

Main Menu to retrieve performance monitoring data, review operation log

information, retrieve system identification information, or enter a configuration settings (see

Figure 23. Main Menu Selections

Figure 23).

34

|

LCD Operation

Page 35

Table 7 provides descriptions of Main Menu selections.

Table 7. Main Menu Selections

Main Menu Description

Performance Selections on the Performance Menu display data that represent the real-time operating status

of the system.

S The L1, L2, or L3 submenus provide voltage, frequency, or current data for each phase.

S The Power submenu provides present readings for power (VA) and wattage (W) data.

S The Environment menu displays present temperature and humidity readings (if sensors are

installed and connected).

Alarms Alarm screens are only visible when alarms are active. Selecting the Alarm menu displays the

message “No active alarm” if no alarms are active.

Event Log Scroll through the Event Log to review the most recent events (50 events maximum).

NOTE: Events do not automatically display when they occur the way alarms display. Events are

shown only in the event log.

System Info The System Info menu provides rPDU identification information, such as model serial

number and firmware version identification.

Settings The Settings menu provides configuration options for customizing performance monitoring

thresholds and configuring the user interface.

NOTE: For Delta models, L1 represents L1-L3 data, L2 represents L1-L2 data, and L3 represents L2-L3 data.

Selecting a Menu

To select a menu:

1 From the Main menu, use the or button to navigate to any menu.

2 Press and release the button to select the menu.

3 To exit any menu screen and return to the previous menu level, press the button for longer than one

second.

Performance Menu

Selections on the Performance menu display data that represents the real-time operating status of the system.

The Performance menu contains the following submenus:

S The L1, L2, or L3 menus provide voltage, current, and frequency data for each phase.

S The Power menu provides present readings for power (VA) and wattage (W) data.

S The Environment menu displays the present temperature (°C) and humidity (%) readings (if sensors are

installed and connected).

NOTE:

For Delta models, L1 represents L1-L3 data, L2 represents L1-L2 data, and L3 represents L2-L3 data.

LCD Operation

|

35

Page 36

Retrieving Performance Information

To select an option and retrieve rPDU performance information:

1 From the Main menu, use the or buttons to navigate to the Performance menu.

2 Press and release the button to select the Performance menu.

3 Use the or buttons to navigate to a submenu.

4 Press and release the button to select the submenu.

5 Use the or buttons to toggle the available options within a submenu.

NOTE:

When scrolling through the selections, the up-to-date data displays for each selection.

6 To exit any screen and return to the previous menu level, press the button for longer than one second.

Figure 24. Example Performance Displays

Table 8 provides descriptions of Performance menu selections.

|

36

LCD Operation

Page 37

Table 8. Performance Menu Selections

Performance

Option Description

Submenu

L1 Menu

L1 Voltage Present voltage reading for phase 1 (L1), displayed in

Volts (V)

L1 Frequency Present frequency reading for phase 1 (L1), displayed in

Hertz (Hz)

L1 Current Present current reading for phase 1 (L1), displayed in

Amps (A)

L2 Menu

L2 Voltage Present voltage reading for phase 2 (L2), displayed in

Volts (V)

L2 Frequency Present frequency reading for phase 2 (L2), displayed in

Hertz (Hz)

L2 Current Present current reading for phase 2 (L2), displayed in

Amps (A)

L3 Menu

L3 Voltage Present voltage reading for phase 3 (L3), displayed in

Volts (V)

L3 Frequency Present frequency reading for phase 3 (L3), displayed in

Hertz (Hz)

L3 Current Present current reading for phase 3 (L3), displayed in

Amps (A)

NOTE: For Delta models, L1 represents L1-L3 data, L2 represents L1-L2 data, and L3 represents L2-L3 data.

LCD Operation

|

37

Page 38

Table 8. Performance Menu Selections (Fortsetzung)

Option DescriptionPerformance

Submenu

Power

Environment

Active Power Provides the calculated value of the overall input,

displayed in watts (W)

Apparent Power Provides the calculated value of the overall input,

displayed in Volt-amperes (VA)

Instantaneous Headroom Watts Provides the watts capacity remaining

NOTE: When the rPDU is in an overload state, this value

is always 0.

Peak Headroom Watts Provides the remaining watts available to support the

load at peak demand

Peak Consumption Watts Provides the peak power demand on the rPDU with time

and date stamp of the most recent data update

Cumulative kWh Consumption Provides the total kWh usage with time and date stamp

of the most recent data update

NOTE: This value accumulates. If this value reaches the

maximum value for a 32-bit number, do not reset.

No sensors connected Displays dashes on both Temperature and Humidity

screens.

Only Temperature sensor connected Displays the temperature in °C on the Temperature

screen. Displays dashes on the Humidity screen.

Temperature and Humidity sensors

connected

Displays the temperature in °C on the Temperature

screen. Displays the humidity percentage on the

Humidity screen.

Measured and Calculated Meters

The rPDU operating status information provided by the Performance menu selections is derived from a series of

measured and calculated meters. See Table 9 for descriptions of measured and calculated meters.

Table 9. Measured and Calculated Meters

Meter Unit Description

Input Voltage

Input Frequency Hertz (Hz) Present frequency measured at the input of the rPDU

Input Current Amps (A) Present current measured at 3 f input of the rPDU

Input Watts Watts (W) Calculated value of the overall input W of the rPDU (active power)

Input Volt-amperes Volt-amperes (VA) Calculated value of the overall input VA of the rPDU (apparent power)

Instantaneous Headroom

Watts

Peak Headroom Watts

(with time stamp)

|

38

LCD Operation

Volts (V) Present voltage measured at the 3 f input of the rPDU

Watts (W) Present W capacity remaining for the rPDU

NOTE: This value is an absolute value calculated from the W rating of

rPDU deducted from the W being consumed.

Watts (W) Remaining W available to support the load at peak demand

NOTE: This value is based on the lowest value set for that Instantaneous

Headroom Watts. The value can be reset from the LCD or the internal

Dell Network Management Card (NMC).

Page 39

Table 9. Measured and Calculated Meters (Fortsetzung)

DescriptionMeter Unit

Peak Consumption

Watts (with time stamp)

Cumulative Kilowatt per

hour (with time stamp)

Temperature Kelvin (K) Two high temperature thresholds from an environmental thermal-only

Humidity Percent (%) Two low humidity thresholds reported from an environmental thermal

Real Time Clock MM/DD/YYYY Current time and date reading from the network interface card real-time

Watts (W) Peak power demand on the rPDU with time and date stamp of the most

recent data update

Kilowatt per hour

(kWh)

Total kWh usage

NOTE: This 32-bit meter value is derived by retrieving the current kWh

consumption meter once each hour and adding it to the previous value.

This value accumulates until it is reset from the LCD or network

interface card.

or thermal and humidity sensor, measured in K and reported as °C

and humidity sensor, reported as a percentage (%)

clock

Alarms Menu

Selecting the Alarms menu allows you to review all active alarms in the order of occurrence. If there are no active

notices or alarms, a “No Active Alarm” message appears (see Figure 25).

In addition to displaying in the Alarms menu alarms and notices are logged in the Event Log.

NOTE:

Events are not shown in rPDU alarm status screens. Events appear only in the Event Log.

Retrieving Active Alarms

To retrieve active alarms:

1 From the Main menu, use the or buttons to navigate to the Alarms menu.

2 Press and release the button to select the Alarms menu.

3 Use the or buttons to navigate forward or back to review the active alarms.

4 To exit any screen and return to the previous menu level, press the button for longer than one second.

Figure 25. Example Alarms Menu Display

Table 10 provides descriptions of status alarms, notices, and events.

NOTE:

For Delta models, L1 represents L1-L3 data, L2 represents L1-L2 data, and L3 represents L2-L3 data.

LCD Operation

|

39

Page 40

Table 10. Alarms , Notices, and Events

Name

L1 Over Current Warning The Phase 1 input current amperage (A) reading is

L2 Over Current Warning The Phase 2 input current amperage (A) reading is

L3 Over Current Warning The Phase 3 input current amperage (A) reading is

L1 Over Current Alarm The Phase 1 input current amperage (A) reading is

L2 Over Current Alarm The Phase 2 input current amperage (A) reading is

L3 Over Current Alarm The Phase 3 input current amperage (A) reading is

L1 Low Current Warning The Phase 1 input current amperage (A) reading is less

L2 Low Current Warning The Phase 2 input current amperage (A) reading is less

L3 Low Current Warning The Phase 3 input current amperage (A) reading is less

Description Type

greater than the value configured as the over current

warning threshold. This warning indicates that the

current A reading is approaching the value set for the

over current alarm.

Generates an alarm and is logged in the Event Log.

greater than the value configured as the over current

warning threshold. This warning indicates that the

current A reading is approaching the value set for the

over current alarm.

Generates an alarm and is logged in the Event Log.

greater than the value configured as the over current

warning threshold. This warning indicates that the

current A reading is approaching the value set for the

over current alarm.

Generates an alarm and is logged in the Event Log.

greater than the value configured as the over current

alarm threshold.

Generates an alarm and is logged in the Event Log.

greater than the value configured as the over current

alarm threshold.

Generates an alarm and is logged in the Event Log.

greater than the value configured as the over current

alarm threshold.

Generates an alarm and is logged in the Event Log.

than the value configured as the low current warning

threshold. This warning indicates that the current A

reading is approaching the value set for the low current

alarm.

Generates an alarm and is logged in the Event Log.

than the value configured as the low current warning

threshold. This warning indicates that the current A

reading is approaching the value set for the low current

alarm.

Generates an alarm and is logged in the Event Log.

than the value configured as the low current warning

threshold. This warning indicates that the current A

reading is approaching the value set for the low current

alarm.

Generates an alarm and is logged in the Event Log.

Notice

Notice

Notice

Alarm

Alarm

Alarm

Notice

Notice

Notice

40

|

LCD Operation

Page 41

Table 10. Alarms , Notices, and Events (Fortsetzung)

Name TypeDescription

Overload Warning The total watts (W) reading for all three phases is

greater than the value configured as the overload

warning threshold. This warning indicates that the

current W reading is approaching the value set for the

overload alarm.

Generates an alarm and is logged in the Event Log.

Overload Alarm The total watts (W) reading for all three phases is

greater than the value configured as the overload alarm

threshold.

Generates an alarm and is logged in the Event Log.

Low Load Warning The total watts (W) reading for all three phases is less

than the value configured as the low load warning

threshold. This warning indicates that the W reading is

approaching the value set for the low load alarm.

Generates an alarm and is logged in the Event Log.

Over Temperature Alarm The temperature level reading is greater than the

maximum temperature threshold value. This alarm

clears when the temperature drops 5°C below the

Temperature High Alarm Level value setting.

Generates an alarm and is logged in the Event Log.

Over Temperature Warning The temperature level reading is greater than the

warning temperature threshold value. This alarm clears

when the temperature drops 5°C below the Temperature

High Warning Level value setting.

Generates an alarm and is logged in the Event Log.

Low Humidity Warning The humidity level reading is less than the value

configured as the warning humidity threshold. This

alarm clears when the humidity rises 5% above the

Humidity Low Warning Level value setting.

Generates an alarm and is logged in the Event Log.

Low Humidity Alarm The humidity level reading is less than the minimum

humidity threshold. This alarm clears when the

humidity rises 5% above the Humidity Low Alarm Level

value setting.

Generates an alarm and is logged in the Event Log.

Contact 1 Active The signal for Dry Contact 1 is active.

Generates an alarm and is logged in the Event Log.

Contact 2 Active The signal for Dry Contact 2 is active.

Generates an alarm and is logged in the Event Log.

Meter IC Fault Communication is lost.

Generates an alarm and is logged in the Event Log.

Notice

Alarm

Notice

Alarm

Notice

Notice

Alarm

Alarm

Alarm

Alarm

LCD Operation

|

41

Page 42

Table 10. Alarms , Notices, and Events (Fortsetzung)

Name TypeDescription

Fatal EEPROM Fault This alarm occurs when the EEPROM experiences a

Range Check Failure alarm, an incorrect EEPROM

model map alarm, or an EEPROM Checksum Failure

alarm.

Generates an alarm and is logged in the Event Log.

PDU Control Power ON The rPDU processor is powered on.

Logged in the Event Log only.

Alarm

Event

Event Log

The Event Log holds up to 50 alarms, events, and most notices. They are logged when they occur. You can scroll

through the event screens, beginning with the most recent event.

The first row of each event screen contains the date (MM/DD/YYYY) and time (hh:mm:ss) at which the event

occurred. The second row contains the type of event and code. The event description begins on the third row

and may continue to the fourth row.

The bottom right corner of the event screen displays two numbers—an ordering number of the event in the log,

followed by the total number of events in the log.

If there are no events in the log, the screen displays “No events in log.”

Retrieving the Event Log

To retrieve the logged events:

1 From the Main menu, use the or buttons to navigate to the Events Log menu.

2 Press the button for longer than one second to see the logged events.

3 Use the or buttons to navigate forward or back to review the events, notices, and alarms in the order

they occurred.

4 To exit any screen and return to the previous menu level, press the button for longer than one second.

Figure 26. Example Event Log Displays

42

|

LCD Operation

Page 43

System Info

The System Info menu screens display the following rPDU identification information:

S Type and model

S rPDU part number

S Serial number

S NMC firmware version

S NMC IP address

S NMC MAC address

S rPDU firmware

Retrieving System Identification Information

To retrieve rPDU system identification information:

1 From the Main menu, use the or buttons to navigate to the System Info menu.

2 Press and release the button to select the System Info menu.

3 Use the or buttons to toggle the available options within the menu.

4 To exit any screen and return to the previous menu level, press the button for longer than one second.

Figure 27. Example Identification Displays

Settings

The Settings menu provides user configuration options (see Figure 28). Only the available options display.

User settings are not protected by default. You can enable the password through the Password setting.

NOTE:

Retrieving or Changing Configuration Settings in the Settings Menu

1 From the Main menu, use the or buttons to navigate to the Settings menu.

2 Press and release the button to select the Settings menu.

3 Use the or buttons to navigate to a submenu.

4 Press and release the button to select the submenu.

5 Use the or buttons to toggle the available configuration options within a submenu.

When scrolling through the selections, the present setting displays for each selection.

NOTE:

6 Press and release the button to select the configuration option you want to change.

LCD Operation

|

43

Page 44

7 Use the or buttons to toggle to the value you want to set.

8 Set a new value by pressing the button again for longer than one second.

9 To exit any screen and return to the previous menu level, press the button for longer than one second.

Figure 28. Example Settings Displays

Table 11 provides descriptions of Settings menu selections.

|

44

LCD Operation

Page 45

Table 11. Settings

Settings

Setting Option Available Settings Default Setting

Submenu

Cumulative

Reset Peak Watts [No] [Yes]

No

If No, no action.

If Yes, the Peak Consumption Watts value is

cleared and the date and time stamp for this

statistic is set to the present date and time.

Reset Peak Headroom Watts [No] [Yes]

No

If No, no action.

If Yes, the Peak Headroom Watts value is

cleared and the date and time stamp for this

statistic is set to the present date and time.

Reset Cumulative kWh [No] [Yes]

No

If No, no action.

If Yes, the Cumulative Consumption kWh

value is cleared and the date and time stamp for

this statistic is set to the present date and time.

L1 Settings

L1 Over Current Warning Level [0.0A]...[48.0A] *

[0.0A]...[32.0A] **

[0.0A]...[16.0A] ***

38.4A

25.6A

12.8A

An input current amperage (A) reading greater

than this value causes a warning to generate.

This warning indicates that the current A

reading has risen to an unacceptable level.

L1 Over Current Alarm Level [0.0A]...[48.0A] *

[0.0A]...[32.0A] **

[0.0A]...[16.0A] ***

48.0A

32.0A

16.0A

An input current amperage (A) reading greater

than this value causes an over current alarm to

generate.

L1 Low Current Warning Level [0.0A]...[48.0A] *

[0.0A]...[32.0A] **

[0.0A]...[16.0A] ***

0.0A

0.0A

0.0A

An input current amperage (A) reading less

than this value causes a warning to generate.

This warning indicates that the current A

reading is reduced to an unacceptable level.

* DELLM0001, DELLM001A, DELLM0004, DELLM004A, DELLM0006

** DELLM0002, DELLM0005, DELLM0007

*** DELLM0003

NOTE: For Delta models, L1 represents L1-L3 data, L2 represents L1-L2 data, and L3 represents L2-L3 data.

LCD Operation

|

45

Page 46

Table 11. Settings (Continued)

Settings

Setting Option Default SettingAvailable Settings

Submenu

L2 Settings

L2 Over Current Warning Level [0.0A]...[48.0A] *

[0.0A]...[32.0A] **

[0.0A]...[16.0A] ***

38.4A

25.6A

12.8A

An input current amperage (A) reading greater

than this value causes a warning to generate.

This warning indicates that the current A

reading has risen to an unacceptable level.

L2 Over Current Alarm Level [0.0A]...[48.0A] *

[0.0A]...[32.0A] **

[0.0A]...[16.0A] ***

48.0A

32.0A

16.0A

An input current amperage (A) reading greater

than this value causes a over current alarm to

generate.

L2 Low Current Warning Level [0.0A]...[48.0A] *

[0.0A]...[32.0A] **

[0.0A]...[16.0A] ***

0.0A

0.0A

0.0A

An input current amperage (A) reading less

than this value causes a warning to generate.

This warning indicates that the current A

reading is reduced to an unacceptable level.

L3 Settings

L3 Over Current Warning Level [0.0A]...[48.0A] *

[0.0A]...[32.0A] **

[0.0A]...[16.0A] ***

38.4A

25.6A

12.8A

An input current amperage (A) reading greater

than this value causes a warning to generate.

This warning indicates that the current A

reading has risen to an unacceptable level.

L3 Over Current Alarm Level

[0.0A]...[48.0A] *

[0.0A]...[32.0A] **

[0.0A]...[16.0A] ***

48.0A

32.0A

16.0A

An input current amperage (A) reading greater

than this value causes an over current alarm to

generate.

L3 Low Current Warning Level [0.0A]...[48.0A] *

[0.0A]...[32.0A] **

[0.0A]...[16.0A] ***

0.0A

0.0A

0.0A

An input current amperage (A) reading less

than this value causes a warning to generate.

This warning indicates that the current A

reading is reduced to an unacceptable level.

* DELLM0001, DELLM001A, DELLM0004, DELLM004A, DELLM0006

** DELLM0002, DELLM0005, DELLM0007

*** DELLM0003

NOTE: For Delta models, L1 represents L1-L3 data, L2 represents L1-L2 data, and L3 represents L2-L3 data.

46

|

LCD Operation

Page 47

Table 11. Settings (Continued)

Settings

Setting Option Default SettingAvailable Settings

Submenu

Power Limits

Near Overload Warning Level [0kW]...[17.3kW] *

[0kW]...[22.0kW] **

[0kW]...[11.0kW] ***

13.8kW

17.6kW

8.8kW

An input wattage (kW) reading in excess of this

value causes an overload warning to generate.

This warning indicates that the current kW

reading has risen nearly to the overload alarm

level value.

Overload Alarm Level [0kW]...[17.3kW] *

[0kW]...[22.0kW] **

[0kW]...[11.0kW] ***

17.3kW

22.0kW

11.0kW

An input wattage (kW) reading in excess of this

value causes an overload alarm to generate.

Low Load Warning Level [0.0kW]...[17.3kW] *

[0.0kW]...[22.0kW] **

[0.0kW]...[11.0kW] ***

0.0kW

0.0kW

0.0kW

An input wattage (kW) reading less than this

value causes a low load warning to generate as a

reminder to share the load for this phase.

Environments

Temperature High Warning

Level

[0 degree C]...[65 degree C]

A high temperature warning threshold is

59 degree C

exceeded when a value greater than this setting

is detected by the environmental temperature

sensor. A high temperature warning generates.

Temperature High Alarm Level [0 degree C]...[65 degree C]

60 degree C

A high temperature alarm threshold is exceeded

when a value greater than this setting is

detected by the environmental temperature

sensor. A high temperature alarm generates.

Humidity Low Warning Level [0%]...[95%]

10%

A low humidity warning threshold is exceeded

when a value less than this setting is detected

by the environmental humidity sensor. A low

humidity warning generates.

Humidity Low Alarm Level [0%]...[95%]

0%

A low humidity alarm threshold is exceeded

when a value less than this setting is detected

by the environmental humidity sensor. A low

humidity alarm generates.

* DELLM0001, DELLM001A, DELLM0004, DELLM004A, DELLM0006

** DELLM0002, DELLM0005, DELLM0007

*** DELLM0003

NOTE: For Delta models, L1 represents L1-L3 data, L2 represents L1-L2 data, and L3 represents L2-L3 data.

LCD Operation

|

47

Page 48

Table 11. Settings (Continued)

Settings

Setting Option Default SettingAvailable Settings

Submenu

Contact config.

Contact 1 [Normally open], [Normally closed]

Normally open

When set to normally open, the dry contact will

be active when the pins are shorted. When set

to normally closed, the dry contact will be

active when the pins are open.

Contact 2 [Normally open], [Normally closed]

Normally open

When set to normally open, the dry contact will

be active when the pins are shorted. When set

to normally closed, the dry contact will be

active when the pins are open.

Password Password [Enabled] [Disabled]

Disabled

If Enabled, the default password is USER. and

all settings are password-protected.

NOTE: If you enter an incorrect password, the

message “Incorrect Password” appears. Press

any button to return to the password screen and

retry the password.

Factory setting Restore Factory Defaults [No], [Yes]

No

If No, no action.

If Yes, all configurable settings are restored to

factory default values.

NOTE: When you select [Yes] and press the

select button, a “Factory setting restored”

message displays. You are prompted to “Press

any key to continue.”

Clear event log Clear Event Log [No], [Yes]

No

If No, no action.

If Yes, all events in the log are cleared and the

Total Events value returns to 0.

* DELLM0001, DELLM001A, DELLM0004, DELLM004A, DELLM0006

** DELLM0002, DELLM0005, DELLM0007

*** DELLM0003

NOTE: For Delta models, L1 represents L1-L3 data, L2 represents L1-L2 data, and L3 represents L2-L3 data.

48

|

LCD Operation

Page 49

Table 11. Settings (Continued)

Settings

Setting Option Default SettingAvailable Settings

Submenu

LCD display

LCD Contrast [-5], [-4], [-3], [-2], [-1], [+0], [+1], [+2],

[+0]

[+3], [+4], [+5]

The LCD contrast is adjustable from -5 to +5.

This range covers the maximum adjustment for

contrasting the background with the text in the

visual display of the control panel.

NOTE: The contrast on the LCD display screen

adjusts immediately as the Up and Down

buttons are pressed. Once you reach the

optimal contrast, press and hold the Select

button for one second to set the new contrast.

LCD Orientation [0 degree], [180 degree]

[0 degree]

The LCD orientation is adjustable to

accommodate both horizontal (0 degree

setting) and vertical (180 degree setting) views.

* DELLM0001, DELLM001A, DELLM0004, DELLM004A, DELLM0006

** DELLM0002, DELLM0005, DELLM0007

*** DELLM0003

NOTE: For Delta models, L1 represents L1-L3 data, L2 represents L1-L2 data, and L3 represents L2-L3 data.

LCD Operation

|

49

Page 50

Serial Interface Operation

This section describes remotely configuring and monitoring a Dell Metered Rack Power Distribution Unit

(rPDU) through the serial interface connection between the rPDU internal Dell Network Management Card

(NMC) and a laptop or workstation.

Access to a command line interface (CLI) using an Avocent protocol is provided through a terminal emulation

program, such as HyperTerminal or Telnet.

NOTE: