Page 1

Service Manual

19” LCD Monitor

DELL E193FPc

THESE DOCUMENTS ARE FOR REPAIR SERVICE INFORMATION ONLY.EVERY REASONABLE EFFOR T

HAS BEEN MADE TO ENSURE THE ACCURACY OF THIS MANUAL; WE CANNOT GUARANTEE THE

ACCURACY OFTHIS INFORMATION AFTER THE DATE OF PUBLICATION AND DISCLAIMS RELIABILITY FOR

CHANGES, ERRORS OR OMISSIONS.

Page 2

Dell E193FPc

Table of contents

Table of contents ---------------------------------------------------------------------------------------------------------------- 02

Revision List -----------------------------------------------------------------------------------------------------------------------------03

Important Safety Notice ------------------------------------------------------------------------------------------------------------04

1. Monitor Specifications ------------------------------------------------------------------------------------------------------05

2. LCD Monitor Description -------------------------------------------------------------------------------------------------- 05

3. Operation instructions-----------------------------------------------------------------------------------------------------------06

3.1 General Instructions---------------------------------------------------------------------------------------------------------06

3.2 Control buttons -----------------------------------------------------------------------------------------------------------------06

3.3 Adjusting the Picture --------------------------------------------------------------------------------------------------------07

4. Input/Output Specification ---------------------------------------------------------------------------------------------------10

4.1 Input Signal Connector -----------------------------------------------------------------------------------------------------10

4.2 Factory Preset Display Modes ----------------------------------------------------------------------------------------- 10

4.3 Power Supply Requirements ---------------------------------------------------------------------------------------- 11

4.4 Panel Specification ----------------------------------------------------------------------------------------------------- 11

5. Block Diagram ----------------------------------------------------------------------------------------------------------------14

5.1 Monitor Exploded View --------------------------------------------------------------------------------------------------------14

5.2 Software Flow Chart ----------------------------------------------------------------------------------------------------15

5.3 Electrical Block Diagram ----------------------------------------------------------------------------------------------17

6. Mechanical Instruction -----------------------------------------------------------------------------------------------------------19

7. Schematic --------------------------------------------------------------------------------------------------------------------------24

6.1 Main Board ---------------------------------------------------------------------------------------------------------------24

6.2 Power Board ---------------------------------------------------------------------------------------------------------------29

8. Layout ----------------------------------------------------------------------------------------------------------------------- 31

7.1 Main Board ---------------------------------------------------------------------------------------------------------------- 31

7.2 Power Board -------------------------------------------------------------------------------------------------------------- 34

7.3 Key Board ----------------------------------------------------------------------------------------------------------------- 35

9. Maintainability-------------------------------------------------------------------------------------------------------------------- 36

8.1 Equipments and Tools Requirement -------------------------------------------------------------------------------- 36

8.2 Trouble Shooting --------------------------------------------------------------------------------------------------------------- 37

8.2.1 Main Board----------------------------------------------------------------------------------------------------------------37

8.2.2 Power/Inverter Board -------------------------------------------------------------------------------------------- 40

8.2.3 Keypad Board ---------------------------------------------------------------------------------------------------- 42

10. White Balance Adjustment ---------------------------------------------------------------------------------------------- 43

11. EDID Content --------------------------------------------------------------------------------------------------------------- 44

12. ISP User Manual ---------------------------------------------------------------------------------------------------------- 45

11.1 Connect ISP Writer preparation action ---------------------------------------------------------------------- 45

11.2 To Use ISP Writer ------------------------------------------------------------------------------------------------ 46

11.3 Executing ISP -------------------------------------------------------------------------------------------------------------50

13. BOM List -----------------------------------------------------------------------------------------------------------------------------51

14. Definition Of Pixel Defects--------------------------------------------------------------------------------------------------------74

2

Page 3

Dell E193FPc

Revision List

Revision Date Revision History TPV model

A00 Mar-15-2004 Initial Release T980KLLHJ8DMN

Change the panel from LG (LPL 19" (B4KB)) to

A01 Jul-20-2005

A02 Nov-22-2005 Add “Important Safety Notice”

A03 Mar.-28-2006 Add “Definition Of Pixel Defects”

A04 April-25-2006

A05 Jun-28-2006

A06 Mar-02-2007 Add Mechanical Instruction in Item 6

SEC (SEC 19" EX1 (LOO))

Add ”Max Brightness measurement” on

Page43

Add new model in Item 13

T980KSLHM8DLN

T980KALHK8DLN

T980KSLHK8DLN

3

Page 4

Dell E193FPc

Important Safety Notice

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING

ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINGS

Important Safety Notice

Proper service and repair is important to the safe, reli able operatio n of all Dell Company** Equipment. The service

procedures recommended by Dell and described in this service manual are effective methods of performing

service operations. Some of these service operations require the use of tools specially designed for the purpose.

The special tools should be used when and as recomm ended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be carefully read

in order to minimize the risk of personal injury to service personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to unde rst and that the se CAUTIONS and NOTICE S ARE

NOT EXHAUSTIVE. Dell could not possibly know, evaluate and advise the service trade of all conceivable ways in

which service might be done or of the possible hazardous consequences of each way. Consequently, Dell has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not

recommended by Dell must first satisfy himself thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

* * Hereafter throughout this manual, Dell Comp any will be referred to as Dell.

WARNING

Use of substitute replacement parts, which do not have the same, specified safety characteristics may create

shock, fire, or other hazards.

Under no circumstances should the original desi gn be modified or altered with out written permissi on from Dell. Dell

assumes no liability, express or implied, arising out of any unauthorized modification of design. Servicer assumes

all liability.

FOR PRODUCTS CONTAINING LASER:

DANGER - Invisible laser radiation when open. AVOID DIRECT EXPOSURE TO BEAM.

CAUTION - Use of controls or adjustments or performance of procedure s othe r than those

CAUTION - The use of optical instruments with this product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY ORIGINAL

MANUFACT URER'S REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR PART

NUMBERS IN THE PARTS LIST SECTION OF THIS SERVICE MANUAL.

Take care during handling the LCD module with backlight unit

- Must mount the module using mounting holes arranged in four corners.

- Do not press on the panel, edge of the frame strongly or electric shock as this will result in damage to the

screen.

- Do not scratch or press on the panel with any sharp objects, such as pen cil or pen as this may result in

damage to the Panel.

- Protect the module from the ESD as it may damage the electronic circuit (C-MOS).

- Make certain that treatment person’s body is grounded throug h wristband.

specified herein may result in hazardous radiation exposure.

- Do not leave the module in high temperature and in areas of high humidity for a long time.

- Avoid contact with water as it may a short circuit within the module.

If the surface of panel becomes dirty, please wipe it off with a soft material. (Cleaning with a dirty or rough cloth

may damage the panel.)

4

Page 5

Dell E193FPc

1. Monitor Specifications

48 cm (19”) a-si TFT Active matrix LCD panel, 0.294mm dot pitch.

16 factory presets, 20 new modes

Vertical refre s h rate 55Hz to 75 Hz

Horizontal frequency 30kHz to 80kHz

Resolutions: 640 x 480 up to 1280 x 1024

Universal power supply designed for worldwide application

CE mark

TCO-99

VESA DPMS compliant

VESA DDC compliant

2. LCD Monitor Description

The LCD MONITOR will contain a main board, PWPC board, keypad board, which house the flat panel control

logic, brightness control logic and DDC.

The power board will provide AC to DC Inverter voltage to drive the backlight of panel and the main board chips

each voltage.

Monitor Block Diagram

CCFL Drive.

Flat Panel and

CCFL backlight

(Include adapter and Inverter

PWPC board

board)

AC-IN

100-240V

Main Board

Keyboard

5

RS232 Connector

For white balance

adjustment in factory

mode

Video signal, DDC

Host Computer

Page 6

Dell E193FPc

3. Operation instructions

3.1 General Instructions

Press the power button to turn the monitor on or off. The other control buttons are located at front pan el of the

monitor. By changing thes e settings, the picture can be adjusted to your personal preferences.

The power cord should be connected.

-

Connect the video cable from the monitor to the video card.

-

Press the power button to turn on the monitor, the power indicator will light up.

-

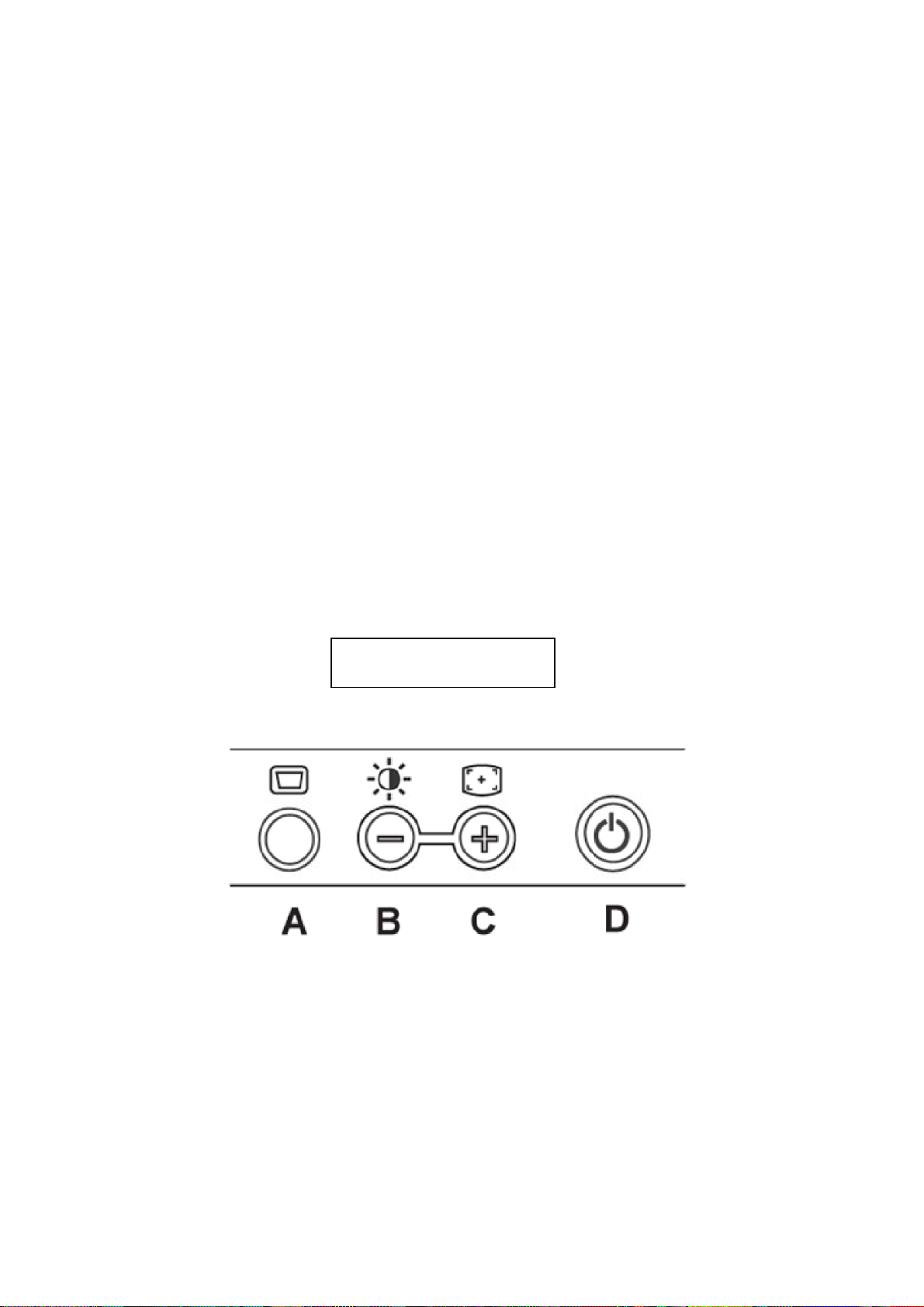

3.2 Control Buttons

Power Button: When pressed, the monitor enters the off mode, and the LED turns blank. Press again to

restore normal status.

Brightness Button: The Brightness Button is used to select the Brightness/Contrast adjust functions.

Press to switch functions or adjust settings.

Auto Adjust Key: The Auto Adjust Key is used to automatically set the H Position, V Position,

Clock and Phase.

Power Indicator:

Green — Power On mode.

Orange — Power Saving mode.

Blank — Power Off Mode.

Control Button

A. Buttons for the OSD menu (On-Screen-display)

B. Brightness Button

C. Auto Adjust Button

D. Power On/Off Button and indicator

6

Page 7

Dell E193FPc

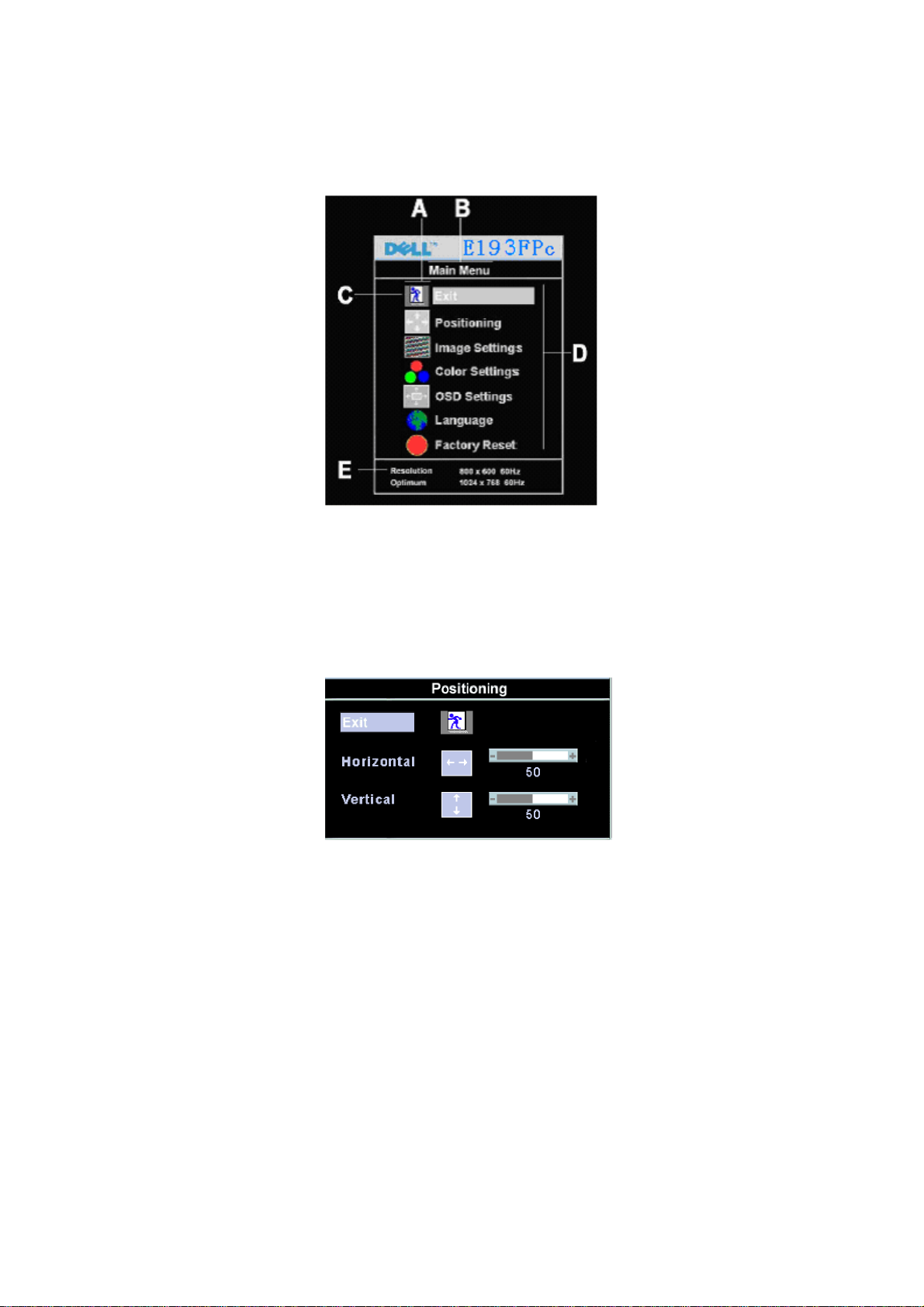

3.3 Adjusting the Picture

To set the OSD menu, perform the following steps:

Briefly press the SELCT / MENU button to activate the OSD menu.

The main menu appears on the screen with icons for the setting functions.

The first symbol (Exit) is highlighted.

Necessary, press the - or + button to mark another icon (e.g. Positioning). Press the SELEC T/MENU button

to select the highlighted icon.

The corresponding setting window (here: Positioning) is displayed.

The first symbol (Exit) is highlighted.

If necessary, press the – or + button to mark the desired icon.

Press the SELECT/MENU button to select the highlighted function.

Press the – or + button to adjust the value for the selected function.

Press the SELECT/MENU button to exit the func tion .

Press the SELECT/MENU button to exit the sub-menu when “Exit” function is highlighted.

All changes are stored automatically.

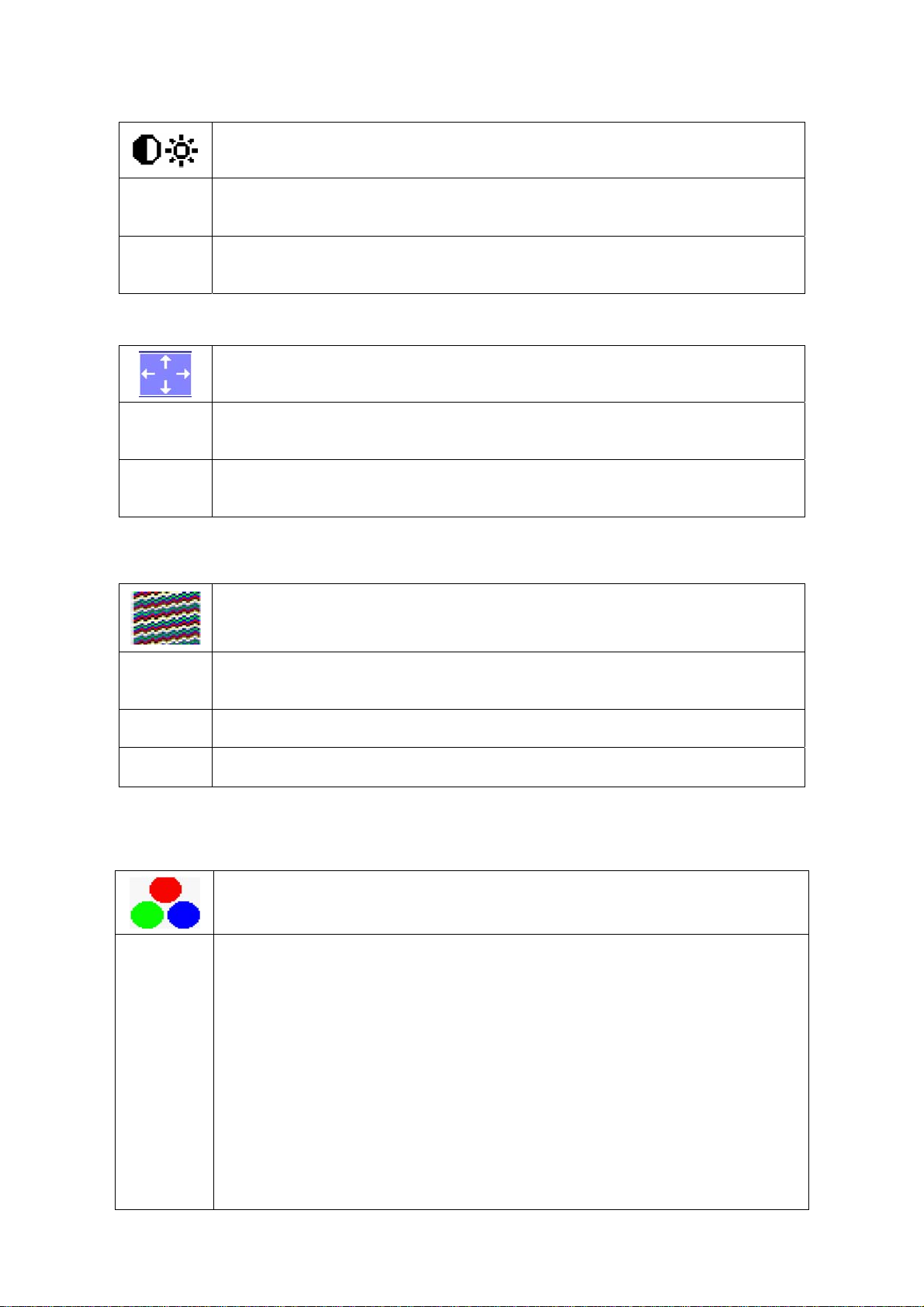

Adjusting the brightness and contrast

7

Page 8

Dell E193FPc

Calling the Brightness / Contrast setting window using Brightness button.

Brightness

Contrast

Setting the brightness of the display

With this function you change the brightness of the background lighting.

Setting the contrast of the display

With this function you modify the contrast o f bright color tones .

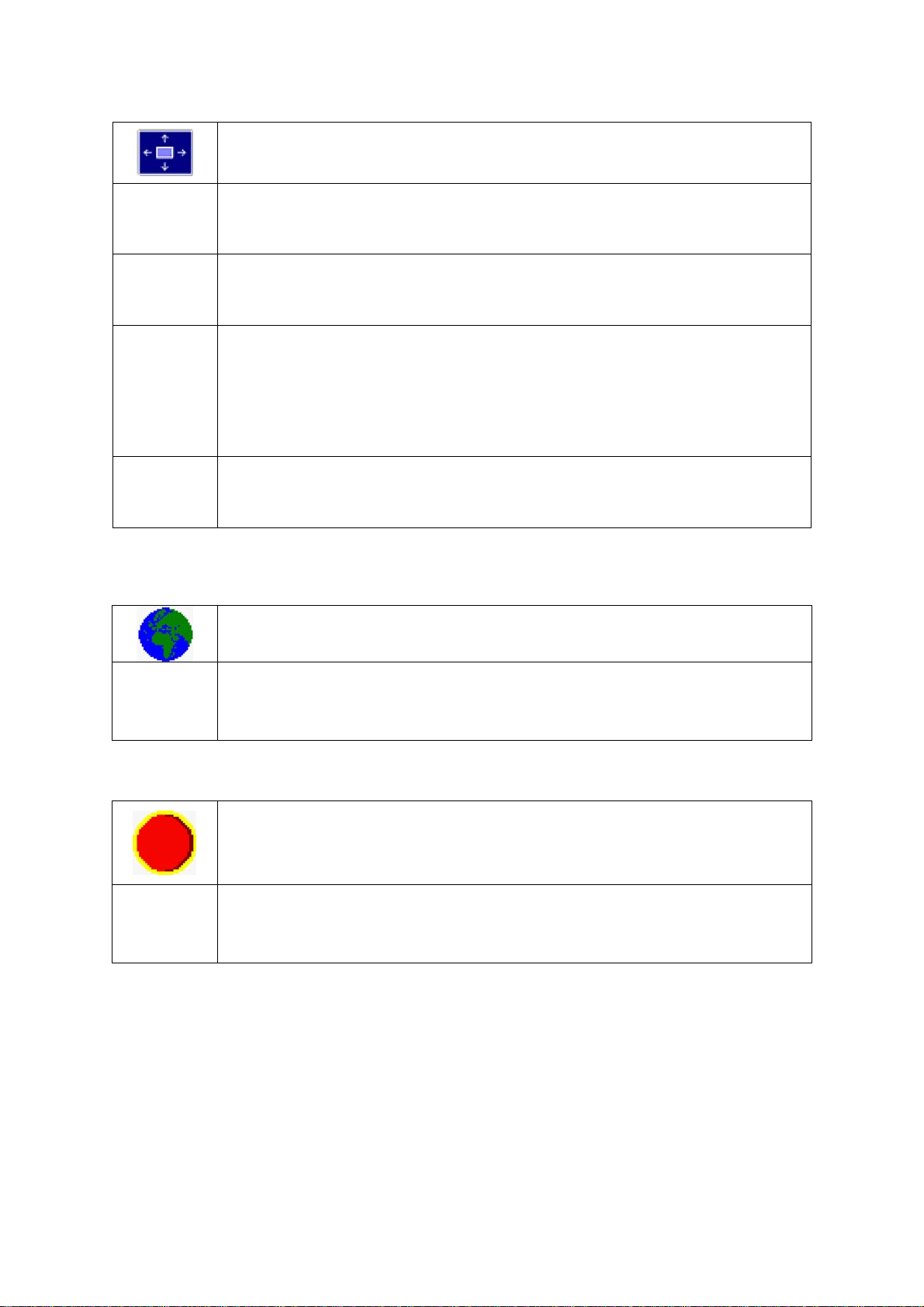

Adjusting size and position

H-Position

Calling the Positioning setting window

Adjusting the horizontal position

With this function you move the picture to the left or to the right.

V-Position

Adjusting the vertical position

With this function you move the picture up or down.

Setting Image

Calling the Image setting window

Auto

Adjust

Pixel clock Adjusting the pixel clock

Phase Adjusting the phase

Auto adjust will produce best image automatically, The information of “ Auto

Adjust In Progress” will show;

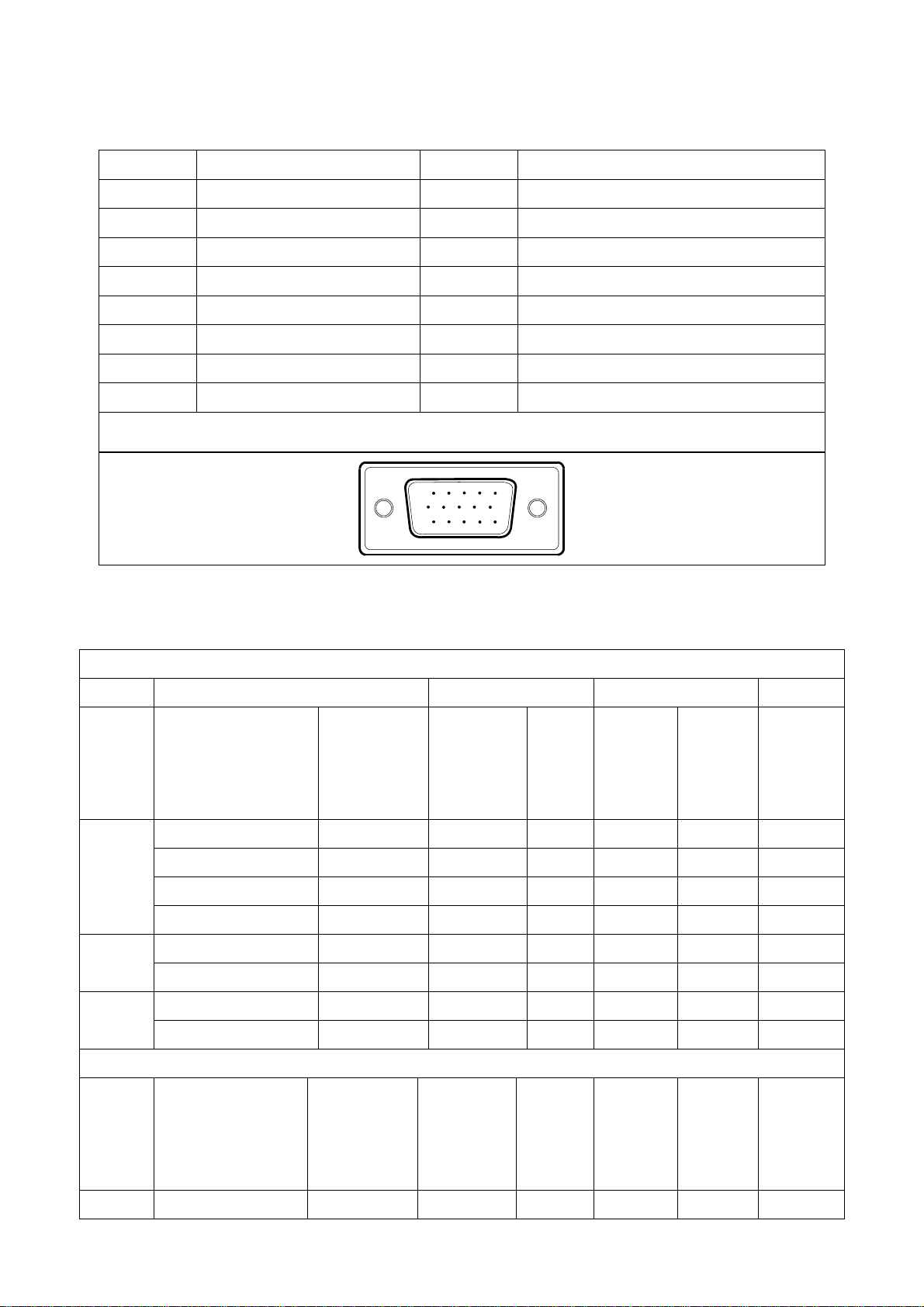

Setting color temperature and colors

Calling the Color setting window

Selecting the color temperature

The color temperature is measured in K (= Kelvin). You can select from Normal

Preset, Blue Preset, Red Preset to User Preset;

Normal preset = Original color of the LCD display , it’ s 6500K;

Blue preset =5700Kcolour of the LCD display , it’ s 9300K;

Red preset =9300K color of the LCD display, it’s 5700K;

User preset = Setting user-defined colors

In the user preset setting you can change the color ratios of the basic colors (red,

green, blue) as required.

8

Page 9

Dell E193FPc

Setting display of the OSD menu

Calling the OSD Set up setting window

Horizontal

Position

Vertical

Position

OSD

Hold

Time

OSD

Lock

Setting the horizontal position of the OSD menu

With this function you move the OSD menu to the left or to the right.

Setting the vertical position of the OSD menu

With this function you move the OSD menu up or down.

Setting the display duration of the OSD menu

With this function you select a value from 0 to 60 seconds.

If the set time expires without a setting being made, the OSD menu is automatically faded

out.

Setting the display of the OSD menu lock or unlock.

With this function you select Y es to lock OSD, NO to unlock it.

Setting Language

Calling the Language setting window

With this function you choose between English (default setting), French, German,

Spani sh and Japanese a s the language for the OSD menu.

Factory Reset

With this function all settings except Language of OSD are reset to the factory settings

without prompting for confirmation.

Activating the factory settings

9

Page 10

Dell E193FPc

4. Input/Output Specification

4.1 Input Signal Connector

Pin No. Description Pi N No. Description

1. Red Video 9. +5V

2. Green Video 10. Detector Pin

3. Blue Video 11. RXD

4. TXD 12. DDC-Serial Data

5. DDC-Return 13. H-Sync

6. R-Ground 14. V-Sync

7. G-Ground 15. DDC-Serial Clock

8. B-Ground

VGA Connector layout

15

6

11 15

10

4.2 Factory Preset Display Modes

Horizontal Vertical

Mode Resolution Total

640x480@60Hz 800 x 525 31.469 N 59.940 N 25.175

640x480@75Hz 840 x 500 37.500 N 75.00 N 31.500

VGA

800x600@60Hz 1056 x 628 37.879 P 60.317 P 40.000

800x600@75Hz 1056x625 46.875 P 75.000 P 49.500

1024x768@60Hz 1344x806 48.363 N 60.004 N 65.000

XGA

1024x768@75Hz 1312x800 60.023 P 75.029 P 78.750

VESA MODES

Nominal

Frequency

+/- 0.5kHz

Sync

Polarit

y

Nominal

Freq.

+/- 1 Hz

Sync

Polarity

Nominal

Pixel

Clock

(MHz)

SXGA

Mode Resolution Total

DOS 720x400@70Hz 900 x 449 31.469 N 70.087 P 28.322

1280x1024@60Hz 1688x1066 64.000 P 60.000 P 108.00

1280x1024@75Hz 1688x1066 79.976 P 75.025 P 135.00

IBM MODES

Nominal

Frequency

+/- 0.5kHz

10

Sync

Polarity

Nominal

Sync

Freq.

Polarity

+/- 1 Hz

Nominal

Pixel

Clock

(MHz)

Page 11

Dell E193FPc

4.3 Power Supply Requirements

A/C Line voltage range 100 V ~ 240 V± 10 %

A/C Line frequency range 50 ± 3Hz, 60 ± 3Hz

Input Voltage transients 280 volts AC for 10 sec @40℃

Current 0.6A max. at 100V, 0.35A max. at 240 V

< 60A peak at 240 VAC and cold starting

Peak surge current

< 30A peak a t 120VAC and cold starting

Leakage current < 3.5mA

No advance effects (no loss of information or defect)

Power line surge

with a maximum of 1 half-wave missing per second

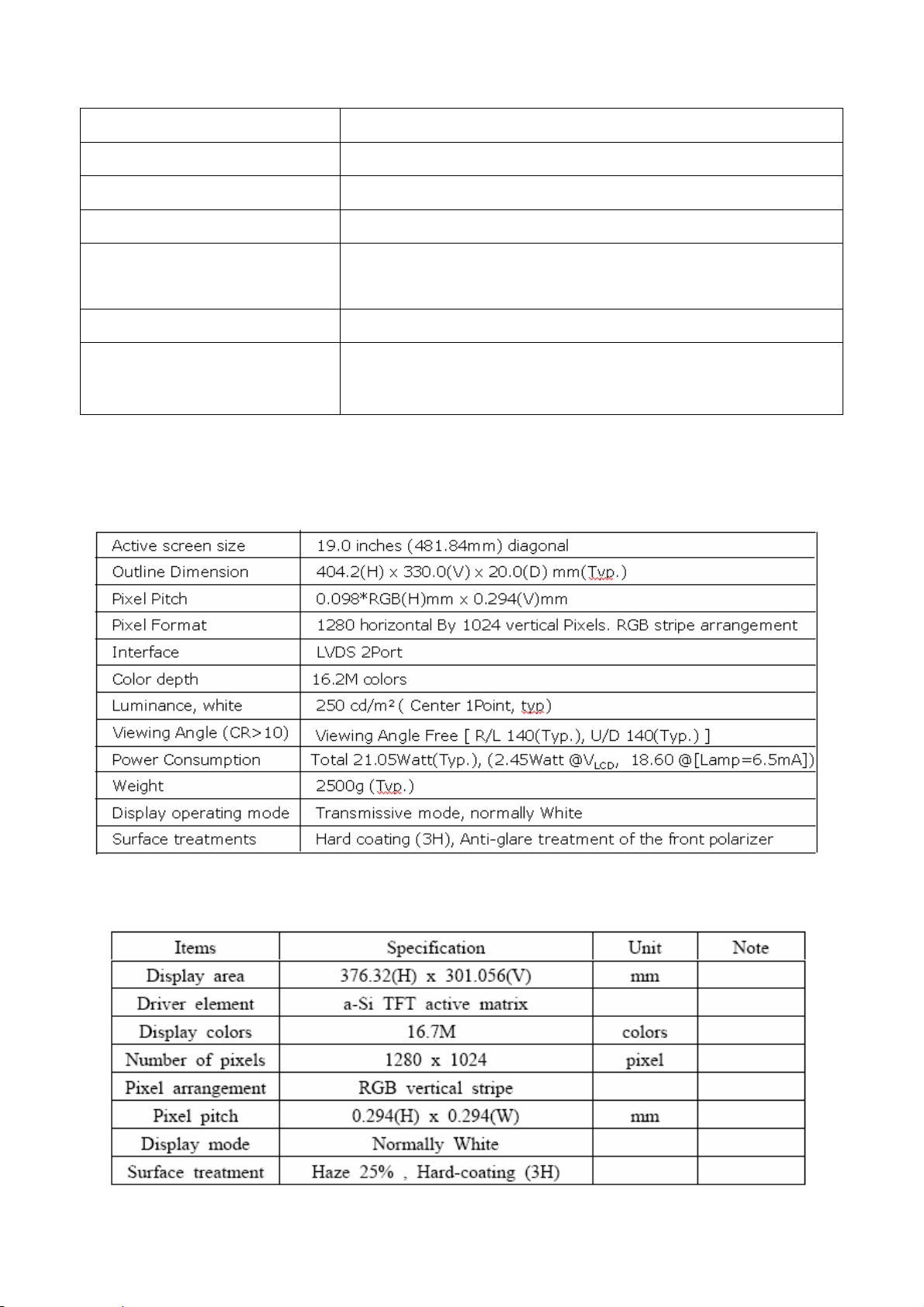

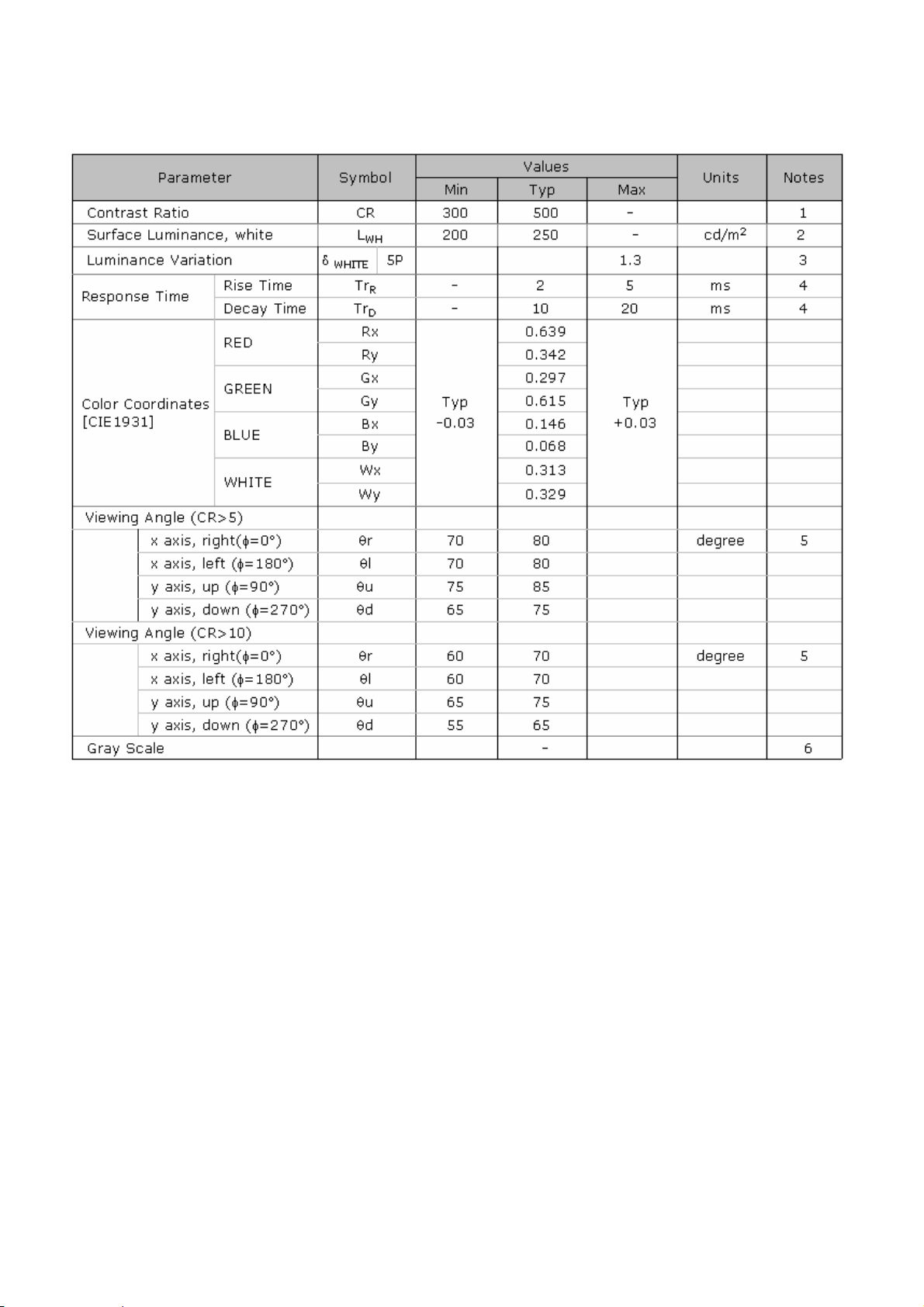

4.4 Panel Specification

4.4.1 Display Characteristics

For LM190E03-B4 model

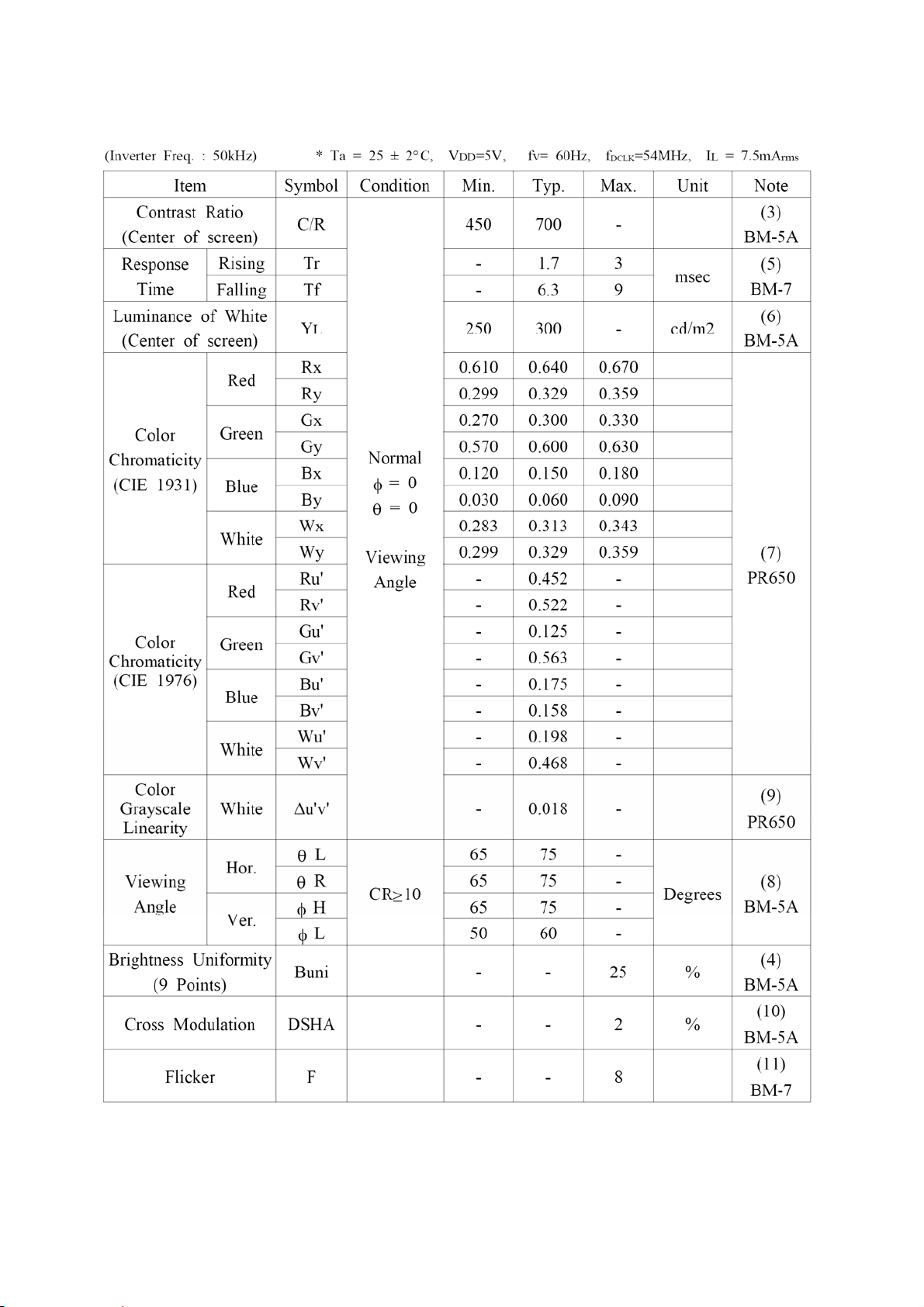

For LTM190EX-L01 model

11

Page 12

Dell E193FPc

4.4.2 Optical Characteristics

For LM190E03-B4 model

Ta= 25°C, V

=5.0V, fV=60Hz Dclk=54MHz,

LCD

12

Page 13

Dell E193FPc

For LTM190EX-L01 model

The optical characteristics are measured under stable conditions as follows:

13

Page 14

Dell E193FPc

5. Block Diagram

5.1 Monitor Exploded View

14

Page 15

Dell E193FPc

5.2 Software Flow Chart

1

2

4

Y

3

N

5

Y

6

7

9

10

Y

N

12

N

N

Y

N

11

13

8

N

18

N

14

19

Y

Y

Y

15

Y

17

15

N

16

Page 16

Dell E193FPc

1) MCU Initializes.

2) Is the EEprom blank?

3) Program the EEprom by default values.

4) Get the PWM value of brightness from EEprom.

5) Is the power key pressed?

6) Clear all global flags.

7) Are the AUTO and SELECT keys pressed?

8) Enter factory mode.

9) Save the power key status into EEprom.

Turn on the LED and set it to green color. Scalar

initializes.

10) In standby mode?

11) Update the lifetime of back light.

12) Check the analog port, are there any signals coming?

13) Does the scalar send out an interrupt request?

14) Wake up the scalar.

15) Are there any signals coming from analog port?

16) Display "No connection Check Signal Cable" message. And go into standby mode after the message

disappears.

17) Program the scalar to be able to show the coming mode.

18) Process the OSD display.

19) Read the keyboard. Is the power key pressed?

16

Page 17

Dell E193FPc

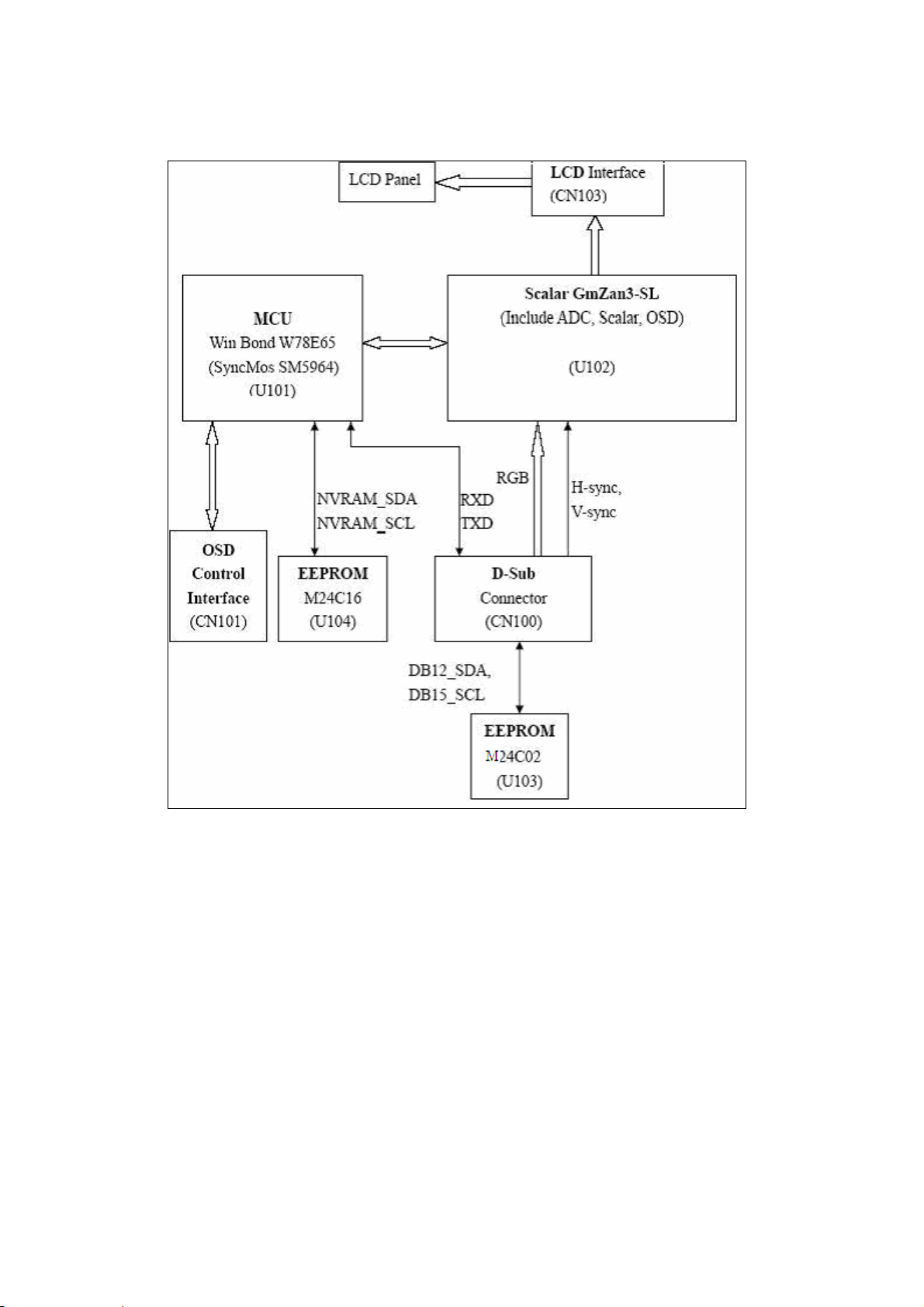

5.3 Electrical Block Diagram

5.3.1 Main Board

17

Page 18

Dell E193FPc

5.3.2 Inverter/Power Board

18

Page 19

Dell E193FPc

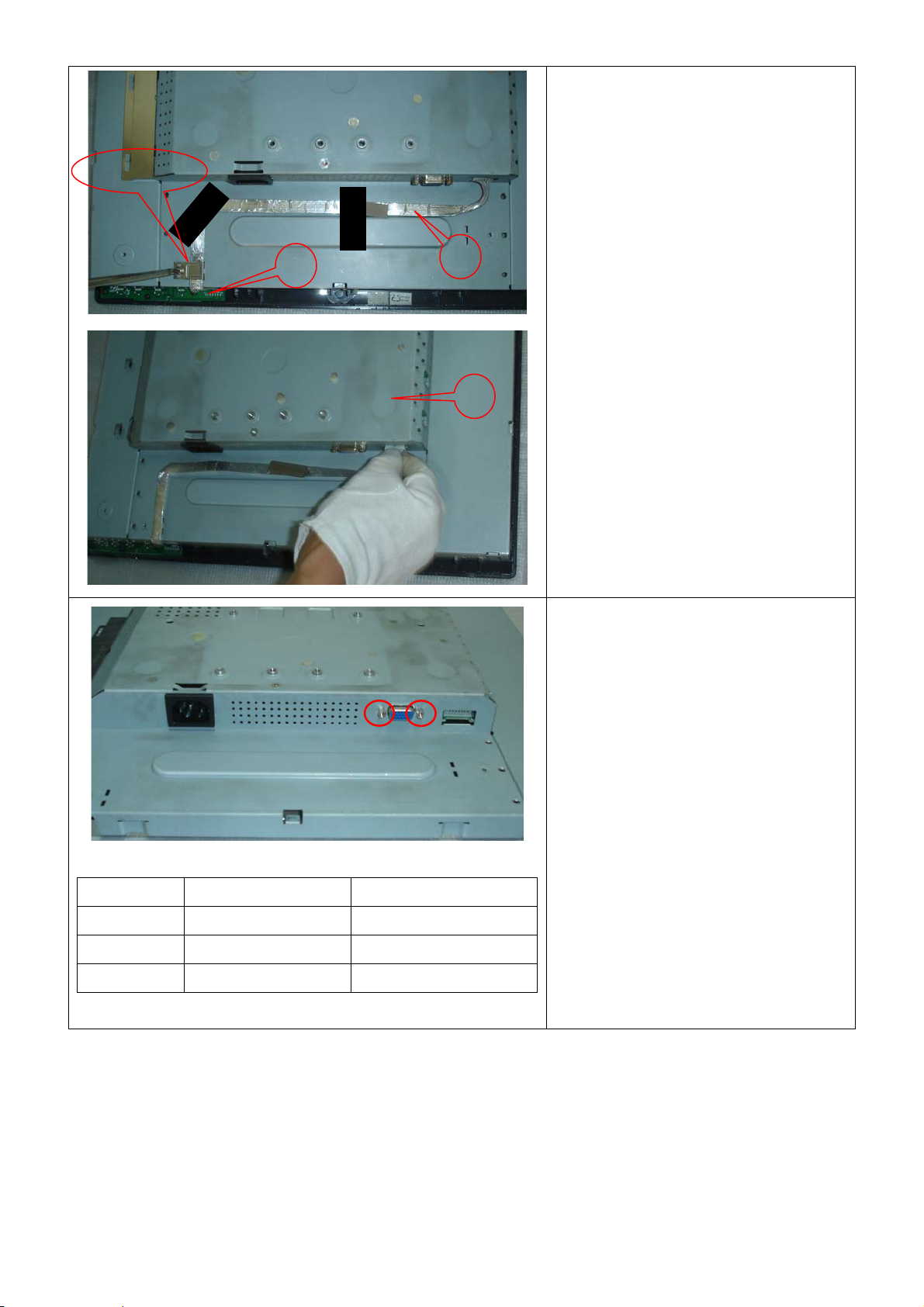

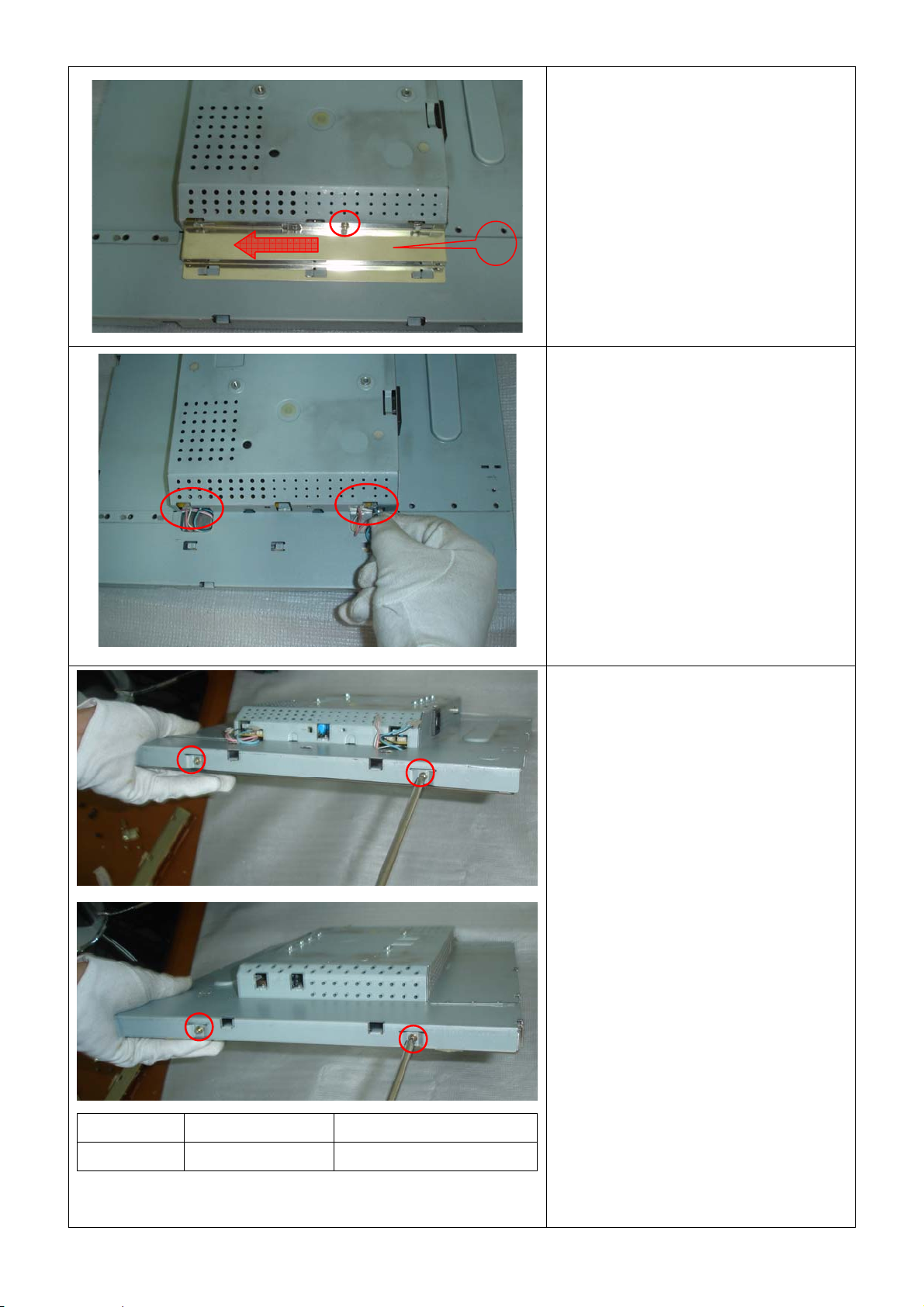

6. Mechanical Instruction

Tools: 2 Power screwdrivers (φ=5mm,L=60mm); 1 small cross screwdriver; turnbuckle driver;

Setting: Power screwdriver torque A=11 kgF. Cm; torque B=6 kgF. Cm

Fig Remark

1

Remove stand: Remove the 4 screws

and remove the stand ass’y by torque A

2

3

Remove the rear cover

Pry the monitor up then find out the hooks’

position, use the tool (like the picture or

other card) to insert into the gap of bezel

and rear cover.

Turn over the monitor as the Fig and take

off the rear cover

19

Page 20

Dell E193FPc

Cable hook

5

4

6

Remove bezel:

Disconnect the Key board connector and

remove the bezel

Note: When installing monitor fixes the

cable use Black Ad hesive Tape and screw

the cable hook.

Symbol TPV Part Number Description

4 095G8014 8 21 wire harness

5 KEPC980KED1 Key Board

6 015G8140 2 Main Frame

Remove the small shield:

Remove the screws by Torque B

20

Page 21

Dell E193FPc

Remove the screw and push the small

shield as the arrowhead direction by

7

Torque B or by manual

Remove the main frame:

Disconnect the back light connectors

Symbol TPV Part Number Description

7 085G 673 1 SHIELD-INVERTER

Remove the four screws and remove the

main frame by manual or torque =

3kgF.Cm

21

Page 22

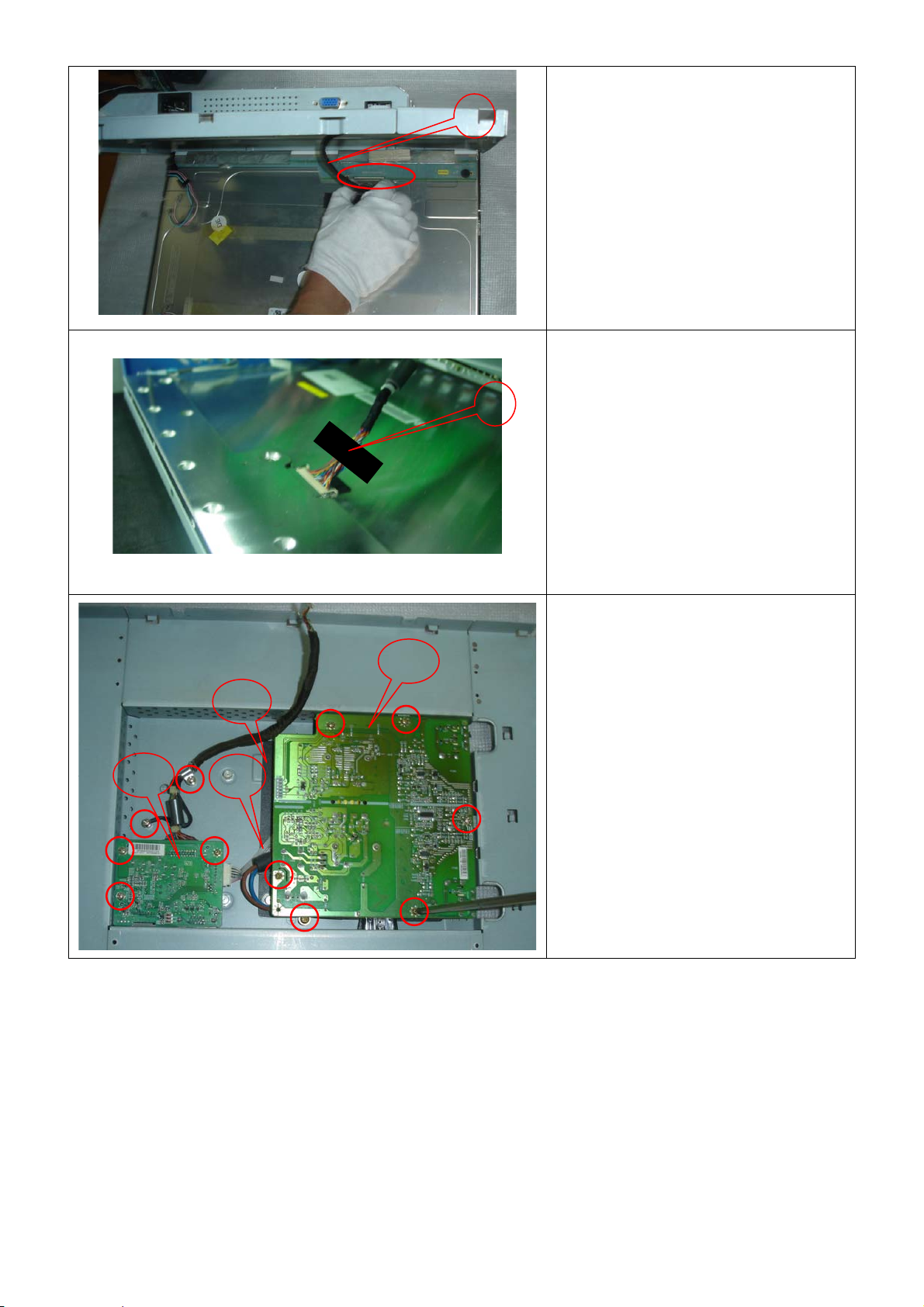

Dell E193FPc

8

Remove the main frame and at the same

time disconnect the LVDS connector

11

13

10

9

When installing monitor. Fix the LVDS by

Black Adhe sive T ape. 10mm should be

kept between the tape and the connect

end.

12

Remove the Power board and main

board:

Remove the eight screws by Torque B

And take off the Power board and main

board.

22

Page 23

Dell E193FPc

Installing the LVDS cable:

Connect the LVDS cable with MB, and

then fix the cable by screwing the cable

A

Ground

B

D

C

Ground

hook, and the ground end to the

mainframe. Make sure the ground line is

below signal lines.

Line C is power supply for the MB.

Connect the PB and MB directly; the

cable must not touch the pillar of screw.

The end

The angle between CCFL line and vertical

direction should be 30-40 degree.

Symbol TPV Part Number Description Symbol TPV Part Number Description

8 95G8018 30590/95G801 8 30632

95G8018 30576

095G8018 30594

9 052G 1150 C Black

10 095G8014 6 19 Wire

LVDS 11 CBPC980KLLDR

CBPC980KSLDR

CBPC980KALDR

12 PWPC1942LGD1

Adhesive

Tape

13 052G6025 11772 Mylar

Harness

PWPC1942SED1

PWPC1942AUD1

Main Board

Power

Board

23

Page 24

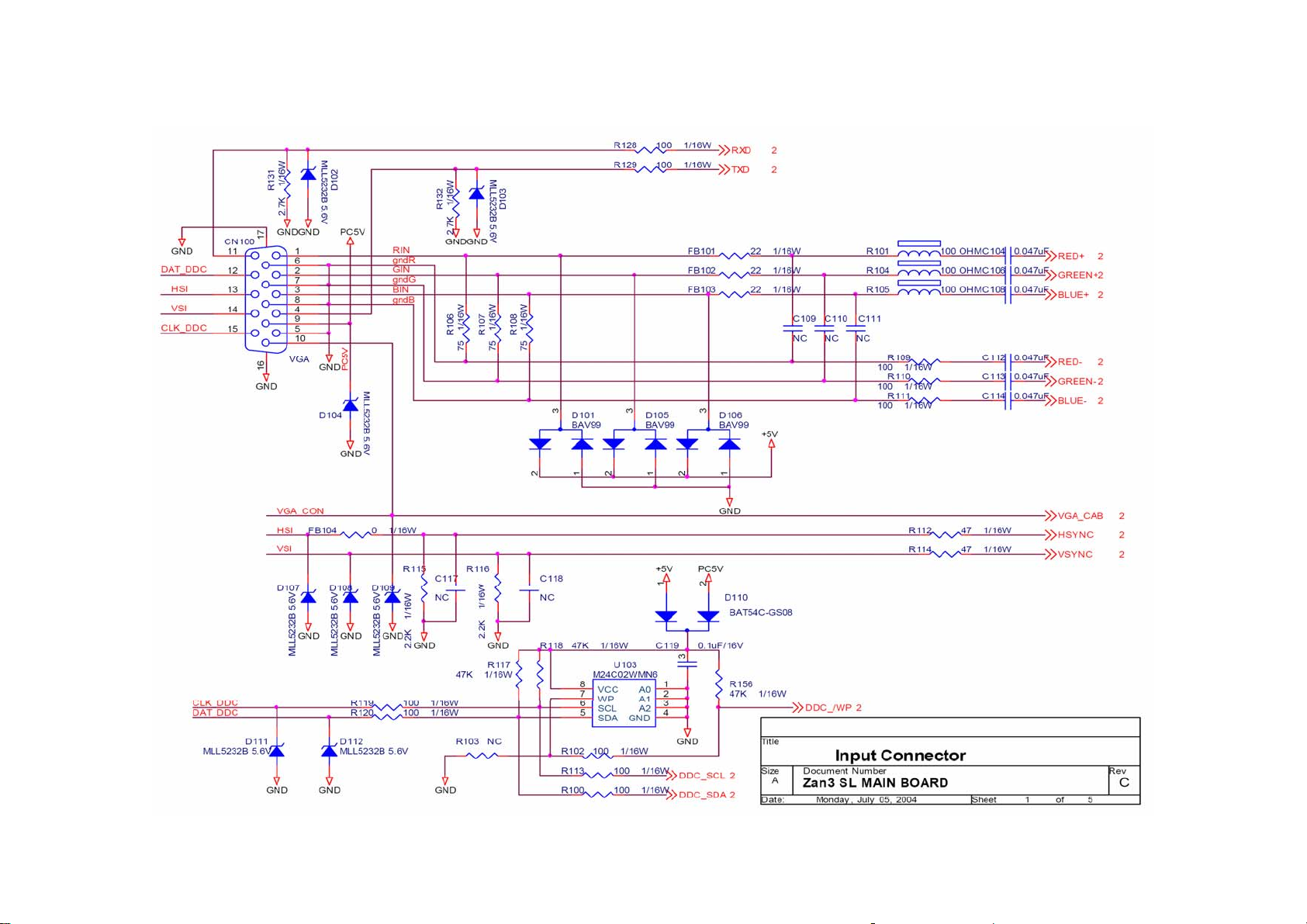

Dell E193FPc

7. Schematic

7.1 Main Board

24

Page 25

Dell E193FPc

25

Page 26

Dell E193FPc

26

Page 27

Dell E193FPc

27

Page 28

Dell E193FPc

28

Page 29

Dell E193FPc

7.2 Power Board

29

Page 30

Dell E193FPc

30

Page 31

8. PCB Layout

8.1 Main Board

Dell E193FPc

31

Page 32

Dell E193FPc

32

Page 33

Dell E193FPc

33

Page 34

8.2 Inverter/Power Board

Dell E193FPc

34

Page 35

8.3 Key Board

Dell E193FPc

35

Page 36

9. Maintainability

9.1 Equipments and Tools Requirement

1. Voltage meter

2. Oscilloscope

3. Pattern Generator

4. LCD Color Analyzer

5. Service Manual

Dell E193FPc

6. User Manual

36

Page 37

9.2 Trouble shooting

9.2.1 Main Board

No display

Measured CN104 pin5 = 5 V?

Measured U101 pin 44= 5V?

Measured U105 pin 2= 3.3V?

OK

Disconnected the Signal cable (Loose the

Signal cable), Is the screen show Block

WRGB color bars?

NG

OK

Dell E193FPc

Check Power board, is there DC level output?

Check U105 pin3=5V, U105 pin2=3.3V?

Is there any shortage or cold solder?

Connected the Signal cable again,

check LED status.

Green

NG

Connected the Signal

cable again Check LED

status.

Green

Check the Wire-Harness from CN101

OK, Wire tight

Check Panel-Power Circuit Block

Check U102 Data-output Block

OK, Panel Power OK

OK, U104 data OK

Orange

OK, Keyboard no stuck

enough

Check Power switch is in Power-on

status, and check if Power switch had

been stuck?

Measured RGB (R112, R114,)

H/V Input at U102 pin 95,96,

Was there have signal?

OK

Measured Crystal X102

OK

Orange

ReplaceU102

Scalar IC

Check

Correspondent

component

short/open

(Protection Diode)

NG

Replace Inverter board and Check

Inverter control relative circuit

Replace U102 (ZAN3XL)

Re-do White balance adjust

OK

Note: 1. If replace “Main-Board”, Please re-do “DDC-content” programmed & “White-Balance”.

2. If replace “Power Board” only , Please re-do “ White-Balance”

37

Page 38

Panel Power Circuit

Check R171 should have response from

0V to 5V when we switch the power

switch from on to off

OK

NG

Dell E193FPc

Check the PPWR panel power relative circuit,

Q105, Q104 In normal operation,

when LED =green, R171 should =5V

If PPWR no-response when the power switch

Turn on and turn off, replace the U102

Measured the Q104 pin 3= 5V?

OK

Inverter Control Relative Circuit

Measured the inverter connector CN104

Pin1 on/off control=3.3V (on)

Pin2 PWM signal control dim 0V-5V

NG, still no screen

NG

Check U102 pin30

OK

NG

Check the BKlt-On relative circuit,

R162, in normal operation, when LED=green,

R162 BKlt-On should=3.3V, If BKlt-On

no-reponse when the power switch turn

on-off, Replace U102

Replace Inverter board to new-one

And check the screen is normal?

NG

Check NO SCREEN APPEAR block

OK

38

Page 39

U102-date Output

Measured DCLK (pin 57 from U102)

DVS, DHS (pin 54,55 from U102)

Is the waveform ok?

DCLK around 48 MHZ, DVS=60.09Hz, DHS around 80

KHz? (Refer to input signal=640x480@60 Hz, and LED is

Green)

Dell E193FPc

NG

Replace ZAN3XL (U102) or

replace Main board.

OK

Check ZAN3/XL (U102)

Signal output (PIN5-14, 106-113,17-26)

NG

If Main Board being replaced, please

do the DDC – content reprogrammed

Is the waveform ok?

OK

OK

39

Page 40

9.2.2 Inverter/Power Board

No Power

Check to CN102 Pin12=12V

Dell E193FPc

Check AC line volt 110V or 220V

Check the voltage of C904(+)

Check start voltage for the pin3 of IC901

OK

OK

OK

OK

NG

NG

Check Interface board

Check AC line

NG

Check F901, bridge rectified circuit

NG

Check R906, R907, IC901

Check the auxiliary voltage Is between 10V-16V

NG

OK

Check D910, D911, ZD904

1) Check IC902, IC903

2) Check Q901, Q902 OVP circuit

40

Page 41

No Backlight

Dell E193FPc

Check C201 (+) =12V

Check U201 pin9=12V voltage of C905(+)

Check the pin1 of U201 have saw tooth wave

OK

Check ON/OFF signal

OK

OK

OK

NG

NG

NG

Change F902

Check D201/Q209/Q210/D202/Q211/Q212

Check Interface board

NG

Change Q201 or Q202

Change U201

Check D201(-), D202(-) have the output of square wave at short time.

NG

OK

Check the resonant wave of pin2 & pin5 for PT201/ PT202

NG

OK

Check the output of PT201/PT202

NG

OK

Check connecter & lamp

CheckQ205/Q207/Q203/Q201 or

/Q206/Q208/Q204/D202

Check Q209/Q210/C213 or Q211/C212/C214

Change PT201/PT202

41

Page 42

9.2.3 Key Board

OSD is unstable or not working

Dell E193FPc

Is Keypad board connecting normally?

OK

Is Button Switch normally?

OK

Is Keypad board normally?

OK

Check main board

NG

Connect Keypad Board

NG

Replace Button Switch

NG

Replace Keypad Board

42

Page 43

Dell E193FPc

10.White balance, Luminance adjustment

Approximately 2 Hours should be allowed for warm up before proceeding White-Balance

adjustment.

Before started adjust white balance, please setting the Chroma-7120 MEM. Channel 3 to 65000K colors, MEM.

Channel 4 to 9300

±20 cd/m

2

, 6500 parameter is x = 313 ±28, y = 329 ±28, Y = 180 ±20 cd/m2, and 5700 parameter is x = 328 ±28, y =

344 ±28, Y = 180 ±20 cd/m

How to setting MEM.channel you can reference to chroma 7120 user guide or simple use “ SC” key and “ NEXT”

key to modify xyY value and use “ID” key to modify the TEXT description Following is the procedure to do

white-balance adjust

Press MENU and AUT O-ADJUST button during press Power button will activate the factory mode,

0

K colors, MEM. Channel 9 to 57000K (our 9300 parameter is x = 283 ±28 y =297±28, Y =175

2

)

Gain adjustment:

Move cursor to “-Factory Setting-” and press MENU key to enter this sub-menu;

Move cursor to “ Factory” and press MENU key;

Move cursor to “ Auto Level” and press MENU key to adjust Gain and Of fs et autom atically;

0

a. Adjust sRGB (6500

K) color-temperature

1. Switch the chroma-7120 to RGB-mode (with press “MODE” button)

2. Switch the MEM.channel to Channel 3 (with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x = 313 ±28, y = 329 ±28, Y = 180 ±20 cd/m

4. Adjust the RED on OSD window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN on OSD, until chroma 7120 indicator reached G=100

6. Adjust the BLUE on OSD, until chroma 7120 indicator reached B=100

7. Repeat above procedure (item 5,6,7) until chroma 7120 RGB value meet the tolerance =100±2

0

b. Adjust Color1 (9300

K) color-temperature

8. Switch the chroma-7120 to RGB-mode (with press “MODE” button)

2

9. Switch the MEM.channel to Channel 4 ( with up or down arrow on chroma 7120 )

10. The LCD-indicator on chroma 7120 will show x = 283 ±28 y =297±28, Y = 175 ±20 cd/m

1 1. Adjust the RED on OSD window until chroma 7120 indicator reached the value R=100

12. Adjust the GREEN on OSD, until chroma 7120 indicator reached G=100

13. Adjust the BLUE on OSD, until chroma 7120 indicator reached B=100

14. Repeat above procedure (item 5,6,7) until chroma 7120 RGB value meet the tolerance =100±2

0

c. Adjust Color2 (5700

K) color-temperature

15. Switch the chroma-7120 to RGB-mode (with press “MODE” button)

16. Switch the MEM.channel to Channel 9 (with up or down arrow on chroma 7120)

17. The LCD-indicator on chroma 7120 will show x = 328 ±28, y = 344 ±28, Y = 180 ±20 cd/m

18. Adjust the RED on OS D window until chroma 7120 indicator reached the value R=100

19. Adjust the GREEN on OSD, until chroma 7120 indicator reached G=100

20. Adjust the BLUE on OS D, until chroma 7120 indicator reached B=100

43

2

2

Page 44

Dell E193FPc

21. Repeat above procedure (item 5,6,7) until chroma 7120 RGB value meet the tolerance =100±2

22. Move cursor to “ Exit/Save” sub-menu and press MENU key to save adjust value and exit.

Turn the POWER-button off to on to quit from factory mode.

Max Brightness measurement:

a. Switch to the full white pattern, in user mode main menu:

1. Set <Color Settings> Red, Green, and Blue to the max.

2. Set <Brightness> Brightness, Contrast to the max.

b. The Minimum brightness is 200cd/m2 ±20.

11. EDID Content

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

0: 00 FF FF FF FF FF FF 00 10 AC 0E 70 34 33 32 31

16: 2E 0E 01 03 68 26 1E 78 2E CE 50 A3 54 4C 99 26

32: 0F 50 54 A5 4B 00 71 4F 81 80 01 01 01 01 01 01

48: 01 01 01 01 01 01 30 2A 00 98 51 00 2A 40 30 70

64: 13 00 78 2D 11 00 00 1E 00 00 00 FF 00 36 34 31

80: 38 30 33 39 46 31 32 33 34 0A 00 00 00 FC 00 44

96: 45 4C 4C 20 45 31 39 33 46 50 63 0A 00 00 00 FD

112: 00 38 4C 1E 51 0E 00 0A 20 20 20 20 20 20 00 3B

Note: Byte 0C, 0D, 0E, 0F means Serial No. Byte 10, 11 means manufacture time. Byte

7F means checksum

44

Page 45

Dell E193FPc

12. ISP (In System Program) User Manual

12.1 Connect ISP Writer preparation action

Connect RXD and TXD of PC to RXD (P3.0) and TXD (P3.1) of CPU through RS-232.

a. There are two ways to entering Reboot Mode. The settings for Reboot Mode is as follow

z Both P2.6 P2.7 are LOW and RESET pin is HIGHT.

z P4.3 is LOW and RESET pin is HIGHT.

45

Page 46

Dell E193FPc

12.2 To Use ISP WRITER (take E153FP for example)

Press the “–“ key at front bezel and plug the AC power cord in, then the MCU enter ISP mode;

a. You will enter the window as follow after executing the ispwriter.exe file.

46

Page 47

Dell E193FPc

b. Click the “Select Chip” button, and choose the type you’re going to program.

47

Page 48

Dell E193FPc

c. Click the “Select Bank0” button and selecting a file which a binary Format required.

48

Page 49

d. Select the communication Setting: Port Name

e. Click the “ConNect” button.

Dell E193FPc

49

Page 50

f. Click “Program all” to start programming.

12.3. Executing ISP

Dell E193FPc

a. “Program All” button that will execute erase and program and verify. Then you can get the window as

follow, and cli ck “OK” to complete ISP process.

b. Complete the ISP process, click“exit LD”button to reset monitor.

50

Page 51

13. BOM List

T980KLLHJ8DMN

Location Part NO Description

M1L 330 4128 SCREW M3X4

CBPC980KLLDR CONVERSION BOARD

KEPC980KED1 KEY BOARD

PWPC1942LGD1 POWER BOARD

11L6036 1 SPACER SUPPORT SCC-24

12L 394 1 FOOT PORON

15G8140 2 MAINFRAME LG

15L5689 3 A GROUND CLAMP

23L3178700 1A LOGO

26G 800700 5B BARCODE

33L4669 GV C POWER BUTTON

33L4817 GV T KEYPAD BUTTON

Dell E193FPc

34L1495AY2 T BEZEL

34L1496 Y2 T REAR COVER

40G 191700 1 ID LABEL

40G 581700 3A CARTON LABEL

44L3231 15507 EVA WASHER

44L3923 1 EPS

44L3923 2 EPS

44L3923 3EPE EPE

44L3923700 1A CARTON

45L 88626DE3 PE BAG FOR MONITOR

52L 1186 SMALL TAPE

52L 1207 A ALUMINIUM TAPE

52L6022 1500 SMALL TAPE

52L6025 11828 MYLAR

85L 673 1 SHIELD-INVERTER

85L6096 1 DIP-EMI

89L1738GAA 16 SIGNAL CABLE

89L401A18NHRA POWER CORD

95G8018 30594 WIRE HARNESS (TD1?

M1G2940 10225 SCREW

M1L 130 6225 SCREW M3X6

M1L1730 6128 SCREW M3x6

M1L1740 6128 SCREW

Q1L 330 8 47 SCREW 3X8mm

705L 980 87DL2 CN901 ASS'Y

51

Page 52

705L980KB34083 19" COVER ASS'Y

750LLG90E03 4 LPL 19" (B4KB) PANEL

40L 457624 1B CPU LABEL

AIC980KSLDR MAIN BOARD

40L 45762412B CBPC LABEL

C122 67L309V220 3 22UF +-20% 16V

C129 67L309V220 3 22UF +-20% 16V

C136 67L309V220 3 22UF +-20% 16V

C140 67L309V220 3 22UF +-20% 16V

C143 67L309V220 3 22UF +-20% 16V

C158 67L309V101 3 100UF 16V

C162 67L309V101 3 100UF 16V

C165 67L309V470 3 47UF 16V 85C

C166 67L309V470 3 47UF 16V 85C

C169 67L309V229 7 2.2UF +-20% 50V

Dell E193FPc

C171 67L309V470 3 47UF 16V 85C

C172 67L309V220 3 22UF +-20% 16V

CN100 88L 35315F H D-SUB 15PIN

CN101 33L3802 8H WAFER 8P RIGHT ANGLE PI

CN103 33L8027 24 H CONN W TO B12P*2 P*2.0

CN104 33L8013 6 H 6P PLUG R/A

U101A 56L1125137LD5 W78E65P-40 BY WINBOND

X101 93G 22 53 H 14.31818MHZ/30PF/49US

X102 93G 22 53 H 14.31818MHZ/30PF/49US

715L1280 E PCB

C104 65L0603473 32 CHIP 0.047UF 50V X7R

C106 65L0603473 32 CHIP 0.047UF 50V X7R

C108 65L0603473 32 CHIP 0.047UF 50V X7R

C112 65L0603473 32 CHIP 0.047UF 50V X7R

C113 65L0603473 32 CHIP 0.047UF 50V X7R

C114 65L0603473 32 CHIP 0.047UF 50V X7R

C119 65L0603104 12 0.1UF +-10% 16V X7R

C123 65L0603104 12 0.1UF +-10% 16V X7R

C124 65L0603104 12 0.1UF +-10% 16V X7R

C125 65L0603104 12 0.1UF +-10% 16V X7R

C126 65L0603104 12 0.1UF +-10% 16V X7R

C127 65L0603104 12 0.1UF +-10% 16V X7R

C128 65L0603104 12 0.1UF +-10% 16V X7R

C130 65L0603104 12 0.1UF +-10% 16V X7R

C131 65L0603104 12 0.1UF +-10% 16V X7R

52

Page 53

Dell E193FPc

C132 65L0603104 12 0.1UF +-10% 16V X7R

C133 65L0603104 12 0.1UF +-10% 16V X7R

C134 65L0603104 12 0.1UF +-10% 16V X7R

C135 65L0603104 12 0.1UF +-10% 16V X7R

C137 65L0603104 12 0.1UF +-10% 16V X7R

C138 65L0603104 12 0.1UF +-10% 16V X7R

C139 65L0603104 12 0.1UF +-10% 16V X7R

C141 65L0603104 12 0.1UF +-10% 16V X7R

C142 65L0603104 12 0.1UF +-10% 16V X7R

C144 65L0603104 12 0.1UF +-10% 16V X7R

C145 65L0603104 12 0.1UF +-10% 16V X7R

C147 65L0603220 31 CHIP 22PF 50V NPO

C148 65L0603220 31 CHIP 22PF 50V NPO

C149 65L0603104 12 0.1UF +-10% 16V X7R

C150 65L0603104 12 0.1UF +-10% 16V X7R

C152 65L0603102 32 1000PF +-10% 50V X7R

C153 65L0603102 32 1000PF +-10% 50V X7R

C154 65L0603102 32 1000PF +-10% 50V X7R

C155 65L0603102 32 1000PF +-10% 50V X7R

C156 65L0603102 32 1000PF +-10% 50V X7R

C157 65L0603102 32 1000PF +-10% 50V X7R

C159 65L0603104 12 0.1UF +-10% 16V X7R

C163 65L0603104 12 0.1UF +-10% 16V X7R

C164 65L0603104 12 0.1UF +-10% 16V X7R

C167 65L0603104 12 0.1UF +-10% 16V X7R

C168 65L0603104 12 0.1UF +-10% 16V X7R

C173 65L0603104 12 0.1UF +-10% 16V X7R

C174 65L0603104 12 0.1UF +-10% 16V X7R

C175 65L0603104 12 0.1UF +-10% 16V X7R

C176 65L0603220 31 CHIP 22PF 50V NPO

C177 65L0603220 31 CHIP 22PF 50V NPO

D101 93G 6433P BAV99

D102 93L 39146 LL5232B SMT

D103 93L 39146 LL5232B SMT

D104 93L 39146 LL5232B SMT

D105 93G 6433P BAV99

D106 93G 6433P BAV99

D107 93L 39146 LL5232B SMT

D108 93L 39146 LL5232B SMT

D109 93L 39146 LL5232B SMT

53

Page 54

Dell E193FPc

D110 93L 64 42 P BAV70 SOT-23

D111 93L 39146 LL5232B SMT

D112 93L 39146 LL5232B SMT

FB101 61L0603220 CHIPR 22 OHM+-5% 1/10W

FB102 61L0603220 CHIPR 22 OHM+-5% 1/10W

FB103 61L0603220 CHIPR 22 OHM+-5% 1/10W

FB104 61L0603000 CHIPR 0OHM +-5% 1/10W

FB105 71L 56K121 M CHIP BEAD

L101 71L 56K121 M CHIP BEAD

L102 71L 56K121 M CHIP BEAD

L103 71L 56K121 M CHIP BEAD

L104 71L 56K121 M CHIP BEAD

L105 71L 56K121 M CHIP BEAD

L106 71L 56K121 M CHIP BEAD

Q101 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q102 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q104 57L 763 1 A03401 SOT23 BY AOS(A1)

Q105 57G 417 4 PMBS3904/PHILIPS-SMT(04

R101 71L 59Q101 CHIP BEAD 100 OHM

R102 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R104 71L 59Q101 CHIP BEAD 100 OHM

R105 71L 59Q101 CHIP BEAD 100 OHM

R106 61L0603750 9F 75OHM 1% 1/10W

R107 61L0603750 9F 75OHM 1% 1/10W

R108 61L0603750 9F 75OHM 1% 1/10W

R109 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R110 61L0603101 CHIPR 100 OHM +-5% 1/10

R111 61L0603101 CHIPR 100 OHM +-5% 1/10

R112 61L0603470 CHIPR 47 OHM +-5% 1/10W

R114 61L0603470 CHIPR 47 OHM +-5% 1/10W

R115 61L0603222 CHIPR 2.2K OHM+-5% 1/10

R116 61L0603222 CHIPR 2.2K OHM+-5% 1/10

R117 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R118 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R119 61L0603101 CHIPR 100 OHM +-5% 1/10

R120 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R122 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R123 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R125 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R126 61L0603101 CHIPR 1 00 OHM +-5% 1/10

54

Page 55

Dell E193FPc

R127 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R128 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R129 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R130 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R131 61L0603272 CHIP 2.7K OHM 1/10W

R132 61L0603272 CHIP 2.7K OHM 1/10W

R133 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R134 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R135 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R137 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R139 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R141 61L0603101 CHIPR 1 00 OHM +-5% 1/10

R142 61L0603000 CHIPR 0OHM +-5% 1/10W

R143 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R144 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R146 61L0603000 CHIPR 0OHM +-5% 1/10W

R147 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R148 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R154 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R155 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R156 61L0603473 CHIP 47K OHM 1/10W

R157 61L0603221 CHIPR 220 OHM+-5% 1/10W

R158 61L0603221 CHIPR 220 OHM+-5% 1/10W

R159 61L0603221 CHIPR 220 OHM+-5% 1/10W

R160 61L0603221 CHIPR 220 OHM+-5% 1/10W

R161 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R162 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R163 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R164 61L0603102 CHIPR 1K O HM +-5% 1/10W

R165 61L0603102 CHIPR 1K O HM +-5% 1/10W

R168 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R169 61L0603000 CHIPR 0OHM +-5% 1/10W

R171 61L0603104 CHIPR 100K OHM +-5% 1/1

R172 61L1206331 CHIP 330OHM 5% 1/4W

R173 61L0603472 CHIPR 4.7K OHM +-5% 1/1

RP103 61L 125472 8 CHIP AR 8P4R 4.7K OHM+-

U101 87L 202 44 PLCC SMT CONN PD41C-441

U102 56L 562 58 GMZAN3/SL (AC)

U103 56L1133 34 M24C02-WMN6T SMT

U104 56L1133 56 M24C16-WMN6T/W SO-8

55

Page 56

Dell E193FPc

U105 56L 585 4 AIC1117-33CY

U106 56G 563 27 AIC1117A-18CY SOT -223

715L1408 1 PCB

CN101 95G8014 8 21 WIRE HARNESS

LED1 81L 12 1A GP LED

R101 61L 60210152T 100OHM +- 5% 1/6W

SW101 77L 600 4 HJ TACT SWITCH TSPE-1

SW102 77L 600 4 HJ TACT SWITCH TSPE-1

SW103 77L 600 4 HJ TACT SWITCH TSPE-1

SW104 77L 600 4 HJ TACT SWITCH TSPE-1

PW1942LGD1SMT POWER BOARD FOR SMT

40L 45762420A ID LABEL

71L 55 2 A FERRITE BEAD 6.5*5*1.7

705L 560 57 DL D910/D911 ASS'Y

705L 560 61 06 R903 ASS'Y

705L 780 57 DL Q903 ASS'Y

705L 780 61 07 R917 ASS'Y

705L1742 HL BD901/C903/IC901 ASS'Y

C213 63L210J1842A2 PMS 0.18UF 250V

C214 63L210J1842A2 PMS 0.18UF 250V

C226 65L 3J2206ET 22PF 5% 3KV TDK

C227 65L 3J2206ET 22PF 5% 3KV TDK

C228 65L 3J2206ET 22PF 5% 3KV TDK

C229 65L 3J2206ET 22PF 5% 3KV TDK

C901 65L305M2222EM 2200PF+-20% 250VAC/400V

C902 65L305M2222EM 2200PF+-20% 250VAC/400V

C904 67L215S10115K 100UF 450V

C913 65L306M3322F2 3300PF +-20% 400VAC Y1

C922 67L215L102 4N KY25VB1000M-L 12.5*20

C923 67L215C102 3H EC LESR 1000UF16V HERME

CN901 33G8029 4A PLUG

CON102 95G8014 6 19 WIRE HARNESS

CON201 33L8021 2D AC CONN.2P R/A 87210-0236

CON202 33L8021 2D AC CONN.2P R/A 87210-0236

CON203 33L8021 2D AC CONN.2P R/A 87210-0236

CON204 33L8021 2D AC CONN.2P R/A 87210-0236

IC902 56L 139 3B PC123 Y82

L201 73G 253139 HA CHOKE COIL

L202 73G 253139 HA CHOKE COIL

L203 73L 174 30YSA FILTER

56

Page 57

Dell E193FPc

L204 73L 174 30YSA FILTER

L902 73L 174 40 LS LINE FILTER

L903 73L 253 91 LS CHOKE BY LI SHIN

L904 73L 253 91 LS CHOKE BY LI SHIN

NR901 61L 58120 WT NTCR 12OHM 20% 2A SCK-1

PT201 80LL15T 7YSG X'FMR

PT202 80LL15T 7YSG X'FMR

Q209 57G 761 6 2SC5706-P-E

Q210 57G 761 6 2SC5706-P-E

Q211 57G 761 6 2SC5706-P-E

Q212 57G 761 6 2SC5706-P-E

T901 80LL17T 2 T X'FMR

PW1942LGD1AI POWER BOARD FOR AI

C202 65L0805104 22 0.1UF +-10% 25V X7R 080

C203 65L0805105 22 CHIP 1UF 25V X7R 0805

C204 65L0805104 22 0.1UF +-10% 25V X7R 080

C205 65L0805104 22 0.1UF +-10% 25V X7R 080

C206 65L0805104 22 0.1UF +-10% 25V X7R 080

C208 65L0805331 31 CHIP 330pF 50V NPO

C209 65L0805105 22 CHIP 1UF 25V X7R 0805

C210 65L0805105 22 CHIP 1UF 25V X7R 0805

C211 65L0805105 22 CHIP 1UF 25V X7R 0805

C212 65L0805105 22 CHIP 1UF 25V X7R 0805

C219 65L0805105 22 CHIP 1UF 25V X7R 0805

C220 65L0805105 22 CHIP 1UF 25V X7R 0805

C221 65L0805474 22 CHIP 0.47UF 25V X7R 080

C222 65L0805474 22 CHIP 0.47UF 25V X7R 080

C230 65L0805102 32 CHIP 1000P 50VX7R 0805

C231 65L0805102 32 CHIP 1000P 50VX7R 0805

C907 65L0805104 32 CHIP 0.1UF 50V X7R

C908 65L0805104 32 CHIP 0.1UF 50V X7R

C909 65L0805104 32 CHIP 0.1UF 50V X7R

C910 65L0805102 32 CHIP 1000P 50VX7R 0805

C911 65L0805471 21 CHIP 470PF 25V NPO

C926 65L0805104 32 CHIP 0.1UF 50V X7R

C927 65L0805104 32 CHIP 0.1UF 50V X7R

C930 65L0805102 32 CHIP 1000P 50VX7R 0805

C931 65L0805102 32 CHIP 1000P 50VX7R 0805

D201 93G3004 2 SR34 PAN JIT

D202 93G2004 2A SM240A DO-214AC

57

Page 58

Dell E193FPc

D203 93G 39S 3 T BZT52-C11

D204 93G 39S 3 T BZT52-C11

F201 61L1206000 CHIPR 0 OHM +-5% 1/4W

Q201 57G 760 5B PDTC144WK SOT346

Q202 57G 760 4B PDTA144WK SOT346

Q203 57L 763 3 AO4411 SO-8 BY AOS SMT

Q204 57L 763 3 AO4411 SO-8 BY AOS SMT

Q205 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q206 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q207 57G 417 6 PMBS3906/PHILIPS-SMT(06

Q208 57G 417 6 PMBS3906/PHILIPS-SMT(06

R202 61L0603512 CHIP 5.1K OHM 1/10W

R203 61L0603512 CHIP 5.1K OHM 1/10W

R204 61L0603103 CHIPR 10K OHM +-5% 1/10

R205 61L0603683 CHIP 68K OHM 1/10W

R206 61L0603683 CHIP 68K OHM 1/10W

R208 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R209 61L0603472 CHIPR 4.7K OHM +-5% 1/1

R210 61L0603123 CHIP 12K OHM 1/10W

R211 61L0603123 CHIP 12K OHM 1/10W

R212 61L0603392 CHIP 3.9K OHM 1/10W

R213 61L0603392 CHIP 3.9K OHM 1/10W

R214 61L0603392 CHIP 3.9K OHM 1/10W

R215 61L0603392 CHIP 3.9K OHM 1/10W

R216 61L0603221 CHIPR 220 OHM+-5% 1/10W

R217 61L0603221 CHIPR 220 OHM+-5% 1/10W

R218 61L0603471 CHIPR 470 OHM+-5% 1/10W

R219 61L0603471 CHIPR 470 OHM+-5% 1/10W

R220 61L0603153 CHIPR 1 5KOHM+-5% 1/10W

R221 61L0603153 CHIPR 1 5KOHM+-5% 1/10W

R222 61L0603123 CHIP 12K OHM 1/10W

R223 61L0603123 CHIP 12K OHM 1/10W

R234 61L0603621 CHIPR 620 OHM+-5% 1/10W

R235 61L0603621 CHIPR 620 OHM+-5% 1/10W

R236 61L0603471 CHIPR 470 OHM+-5% 1/10W

R237 61L0603471 CHIPR 470 OHM+-5% 1/10W

R238 61L0603123 CHIP 12K OHM 1/10W

R239 61L0603123 CHIP 12K OHM 1/10W

R240 61L0603513 CHIP 51K OHM 1/10W

R241 61L0603513 CHIP 51K OHM 1/10W

58

Page 59

Dell E193FPc

R901 61L1206105 CHIP 1MOHM 5% 1/4W

R902 61L1206105 CHIP 1MOHM 5% 1/4W

R908 61L1206519 CHIPR 5.1 OHM +-5% 1/4W

R909 61L1206472 CHIP 4.7KOHM 5% 1/4W

R910 61L1206472 CHIP 4.7KOHM 5% 1/4W

R911 61L1206472 CHIP 4.7KOHM 5% 1/4W

R912 61L1206101 CHIP 100 OHM 5% 1/4W

R913 61L1206103 CHIP 10KOHM 5% 1/4W

R914 61L1206243 CHIP 24K OHM 5% 1/4W

R928 61L1206102 CHIP 1K OHM 5% 1/4W

U201 56L 608 1 TL1451ACD

ZD901 93G 39S 23 T GLZ22B

ZD904 93L 39S 19 T PTZ7.5B

715L1283 4 PCB

C201 67L215C1514HT LOW ESR 150UF 25V 8*7MM

C207 67L 305330 7T

C213 6L 31502 1.5MM RIVET

C214 6L 31502 1.5MM RIVET

C223 67L215C1514HT LOW ESR 150UF 25V 8*7MM

C904 6L 31502 1.5MM RIVET

C905 65L 2K152 1T6921 1.5NF/2KV Y5P +-10%

C906 67L 305220 7T 22UF +-20% 50V

C920 65L517K102 5T 1000PF 10% Y5P 500V

C921 65L517K102 5T 1000PF 10% Y5P 500V

C924 67L215B4713HT 470UF 16V LTR471M1CF11V

C925 67L215B4713HT 470UF 16V LTR471M1CF11V

C929 64L700J1040AT 0.1UF 50V PEN

CN901 6L 31500 EYELET

D205 93L 64 1152T 1N4148

D206 93L 64 1152T 1N4148

D207 93L 64 1152T 1N4148

33UF 105

D208 93L 64 1152T 1N4148

D209 93L 64 1152T 1N4148

D210 93L 64 1152T 1N4148

D901 93G 6026T52T RECTIFIER DIODE FR107

D902 93L 6038P52T PS102R

D903 93L 64 1152T 1N4148

F901 84G 56 1 FUSE 2A 250V WICKMANN

FB901 71L 55 29 FERRITE BEAD

IC903 56L 158 4 T A H431BA

59

Page 60

Dell E193FPc

J002 61L 60222152T CFR 220 OHM +-5% 1/6W

L902 6L 31502 1.5MM RIVET

PT201 6L 31502 1.5MM RIVET

PT202 6L 31502 1.5MM RIVET

Q901 57L 420 PP T 2PA733P

Q902 57L 419 PP T 2PC945P

R201 61L 60224352T 24K OHM 5% 1/6W

R224 61L 17210252T 1K OHM 5% 1/4W

R225 61L 17210252T 1K OHM 5% 1/4W

R226 61L 17210252T 1K OHM 5% 1/4W

R227 61L 17210252T 1K OHM 5% 1/4W

R228 61L 17210252T 1K OHM 5% 1/4W

R229 61L 17210252T 1K OHM 5% 1/4W

R230 61L 17210252T 1K OHM 5% 1/4W

R231 61L 17210252T 1K OHM 5% 1/4W

R232 61L 17210252T 1K OHM 5% 1/4W

R233 61L 17210252T 1K OHM 5% 1/4W

R904 61L214Y10552T 1M,1/4W

R905 61L214Y10552T 1M,1/4W

R906 61L214Y10552T 1M,1/4W

R907 61L214Y10552T 1M,1/4W

R915 61L 17210052T 100HM 5% 1/4W

R916 61L 17210352T CFR 10KOHM +-5% 1/4W

R920 61L175L47052T 47OHM +-5% 1/2W

R921 61L175L47052T 47OHM +-5% 1/2W

R922 61G 20033352T 33KOHM 1% 1/4W

R923 61G 20036252T 3.6KOHM 1% 1/4W

R924 61G 20024252T 2.4KOHM 1% 1/4W

R925 61L 17210252T 1K OHM 5% 1/4W

R926 61L 17210252T 1K OHM 5% 1/4W

R929 61L 17210152T 100 OHM 5% 1/4W

T901 6L 31502 1.5MM RIVET

ZD902 93L 39 5452T ZENER HZ12B2

ZD903 93G 39 7752T HZ5C1-E

90L6064 1 HEAT SINK

M1L1730 8128 SCREW M3x8

D910 93G 60245 SP10150

D911 93G 60217 FMB-29L

96L 29 6 SHRINK TUBE UL/CSA

R903 61L152M10458F 100K OHM 5% 2W

60

Page 61

90L6064 1 HEAT SINK

M1L1730 8128 SCREW M3x8

Q903 57L 667 15 FQPF7N80 TO-220F

96L 29 6 SHRINK TUBE UL/CSA

R917 61L 2J39858F 0.390OHM 5% 2W

BD901 93G 50460502 KBP206G

IC901 56G 379 32 SG6841DZ DIP-8

71L 100509 FERRITE CORD

87L 501 14 RF AC SOCKET

95G8021 2520 WIRE HARNESS

95L 900567 HARNESS

96L 29 6 SHRINK TUBE UL/CSA

15L8144 1 BRACKET BASE

20L 023 1 BRACKET RISER

34L1497 Y2 T BASE

Dell E193FPc

34L1499 Y2 T RISER FRONT

34L1500 Y2 T RISER REAR

34L1501 Y2 T VESA COVER

37L 522 1 HINGE ASSY

M1L 130 8225 SCREW

M1L 140 8225 SCREW

Q1L 130 8 47 SCREW

Q1L 330 8 47 SCREW 3X8mm

Q1L 330 8 47 SCREW 3X8mm

61

Page 62

Dell E193FPc

T980KSLHK8DLN

Location Part No. Description

011G6036 1 SPACER SUPPORT SCC-24

012G 394600 FOOT FORON

015G5689502 1 GND LUG (AL)

015G8142 1 MAIN FRAME

023G3178700 1A LOGO

026G 800700 5B BARCODE LABEL

033G4669 GV C POWER BUTTON

033G4817 GV T keypad button

034G1495AY2 T BEZEL

034G1496 Y2 T REAR COVER

040G 191700 2E ID LABEL

040G 581700 3A6813 CARTON LABEL

041G7800700 5A QSU

044G3231 9 EVA WASHER

044G3935 1 EPS(L)

044G3935 2 EPS(R)

044G3935 3EPE EPE

044G3935700 1A CARTON

044G6000700 1A SPACE BOX

044G6000700 2A SPACE BOX

044G600260811A PAPER BOARD

044G9003 90 CORNER PAPER

044G9003115 CORNER PAPER

044G9003132 CORNER PAPER

044GSLIP100 1A PLASTIC SLIP SHEET

044GSLIP100 2A PLASTIC SLIP SHEET

045G 88626DE3 PE BAG FOR MONITOR

052G 1186 SMALL TAPE

052G 1211516 ALUMINUM TAPE

052G6022 1500 SMALL TAPE

052G6025 11772 MYLAR

052G6025 11932 MYLAR

070G1900700 2B CD MANUAL

085G 673 1 SHIELD-INVERTER

E089B 089G1738LAA 16 SIGNAL CABLE

E089A 089G402A18NISD POWER CORD

E095 095G8018 30576 LVDS CABLE(JAE)

62

Page 63

Dell E193FPc

0M1G 330 4128 SCREW M3X4

0M1G1730 6128 SCREW M3x6

0M1G1730 6128 SCREW M3x6

0M1G1730 6128 SCREW M3x6

0M1G1740 6128 SCREW

0M1G2940 10225 SCREW

0Q1G 330 8 47 SCREW 3X8mm

705L 980 87DL1 CN901 ASS'Y

705L980KB34083 19" COVER ASS'Y

750LLS90EX1 ZB SEC 19" EX1 PANEL(LOO) ZB

CBPC980KSLDR CONVERSION BOARD

KEPC980KED1 KEY BOARD

PWPC1942SED1 POWER BOARD

071G 100509 FERRITE CORD

087G 501 14 RF AC SOCKET

095G 900567 WIRE HARNESS

095G8021 2520 WIRE HARNESS

096G 29 6 H.S. TUBE

015G8144 1 BRACKET BASE

020G 023 1 BRACKET RISER

034G1497 Y2 B BASE

034G1499 Y2 B RISER FRONT

034G1500 Y2 B RISER REAR

034G1501 Y2 T VESA COVER

0M1G 130 8225 SCREW

0M1G 140 8225 SCREW M3X8

0Q1G 130 8 47 SCREW

0Q1G 330 8 47 SCREW 3X8mm

0Q1G 330 8 47 SCREW 3X8mm

M037 S37G5221 19" DELL LCD HINGE ASS'Y

CN101 033G3802 8H WAFER 8P RIGHT ANGLE PITCH 2.0

CN104 033G8013 6 H 6P PLUG R/A

CN103 033G8027 24 H CONN W TO B12P*2 P*2.0 4505-2

040G 45762412B CBPC LABEL

CN100 088G 35315F HJ SOC SUBD H 15P F

X101 093G 22 53 H 14.31818MHZ/30PF/49US

X102 093G 22 53 H 14.31818MHZ/30PF/49US

AIC980KSLDD MAIN BOARD

R101 061G 60210152T 100OHM +- 5% 1/6W

63

Page 64

Dell E193FPc

SW104 077G 600 4 HJ TACT SWITCH

SW103 077G 600 4 HJ TACT SWITCH

SW102 077G 600 4 HJ TACT SWITCH

SW101 077G 600 4 HJ TACT SWITCH

LED1 081G 12 1A GP LED

CN101 095G8014 8 21 wire harness

715L1408 1A KEY BOARD

CON201 033G8021 2D AC CONN.2P R/A 87210-0236 DIP BY

CON202 033G8021 2D AC CONN.2P R/A 87210-0236 DIP BY

CON203 033G8021 2D AC CONN.2P R/A 87210-0236 DIP BY

CON204 033G8021 2D AC CONN.2P R/A 87210-0236 DIP BY

CN901 033G8029 4A PLUG

040G 45762420A LABEL 25x6mm

IC902 056G 139 3B PC123 Y82FZ0F

Q209 057G 761 6 2SC5706-P-E

Q210 057G 761 6 2SC5706-P-E

Q211 057G 761 6 2SC5706-P-E

Q212 057G 761 6 2SC5706-P-E

NR901 061G 58120 WT NTCR 12OHM 20% 2A SCK-122

C213 063G210J1842A2 PMS 0.18UF 250V

C214 063G210J1842A2 PMS 0.18UF 250V

C229 065G 3J2206ET 22PF 5% SL 3KV TDK

C227 065G 3J2206ET 22PF 5% SL 3KV TDK

C228 065G 3J2206ET 22PF 5% SL 3KV TDK

C226 065G 3J2206ET 22PF 5% SL 3KV TDK

C901 065G305M2222BP 2200PF +-20%

C902 065G305M2222BP 2200PF +-20%

C913 065G306M3322F2 3300PF +-20% 400VAC Y1

C912 065G306M4722BP 4700PF +-20% 400VAC

C923 067G215L102 3R LOW E.S.R 1000UF +/-20% 16V

C922 067G215L102 4N KY25VB1000M-L 12.5*20

C904 067G215S10115K 100UF 450V

071G 55 2 FERRITE BEAD 6.5*5*1.7

L903 073G 253 91 LS CHOKE BY LI SHIN

L904 073G 253 91 LS CHOKE BY LI SHIN

L202 073G 253139 HA CHOKE COIL

L201 073G 253139 HA CHOKE COIL

L902 073L 174 40LSG LINE FILTER

PT202 080LL15T 7YSG X'FMR

64

Page 65

Dell E193FPc

PT201 080LL15T 7YSG X'FMR

T901 080LL17T 2 TG X'FMR

CON102 095G8014 6 19 WIRE HARNESS

705L 560 57 DL D910/D911 ASS'Y

705L 560 61 06 R903 ASS'Y

705L 780 57 DL Q903 ASS'Y

705L 780 61 07 R917 ASS'Y

705L1742 HL BD901/C903/IC901 ASS'Y

PW1942SED1SMT POWER BOARD FOR SMT

002F0605100 SCREW NUTS M6.0*P1.0

004F0612052 00 METAL WASHER

004F061210M 00 METAL WASHERS12.0*6.03*4.70H

004F061210T 00 METAL WASHERS12.0*8.00*1.6H

004F061210T 01 METAL WASHERS12.0*4.72*1.0T

015F 522110 BRACKET

015F 522130 BRACKET

019F20173L0 WASHER

019F20173R0 WASHER

028F0623090 SHAFT

040G 457624 1B LABEL-CPU

U106 056G 56327A IC AP1117E18LA SOT223-3L ANACHIP

U105 056G 585 4A AP1117E33LA

U101 056G1125137 X W78E065A40PL PLCC44

U103 056G1133 34 M24C02-WMN6TP

U104 056G1133 56 M24C16-WMN6TP

U102 056L 562 58 GMZAN3/SL (AC)

Q101 057G 417 4 PMBS3904/PHILIPS-SMT(04)

Q102 057G 417 4 PMBS3904/PHILIPS-SMT(04)

Q105 057G 417 4 PMBS3904/PHILIPS-SMT(04)

Q104 057G 763 1 A03401 SOT23 BY AOS(A1)

RP103 061L 125472 8 CHIP AR 8P4R 4.7K OHM+-5%1/16W

R146 061L0603000 RST SM 0603 JUMP MAX 0R05 R

R169 061L0603000 RST SM 0603 JUMP MAX 0R05 R

R142 061L0603000 RST SM 0603 JUMP MAX 0R05 R

FB104 061L0603000 RST SM 0603 JUMP MAX 0R05 R

R141 061L0603101 CHIPR 100 OHM +-5% 1/16W

R139 061L0603101 CHIPR 100 OHM +-5% 1/16W

R137 061L0603101 CHIPR 100 OHM +-5% 1/16W

R130 061L0603101 CHIPR 100 OHM +-5% 1/16W

65

Page 66

Dell E193FPc

R129 061L0603101 CHIPR 100 OHM +-5% 1/16W

R128 061L0603101 CHIPR 100 OHM +-5% 1/16W

R126 061L0603101 CHIPR 100 OHM +-5% 1/16W

R125 061L0603101 CHIPR 100 OHM +-5% 1/16W

R120 061L0603101 CHIPR 100 OHM +-5% 1/16W

R119 061L0603101 CHIPR 100 OHM +-5% 1/16W

R111 061L0603101 CHIPR 100 OHM +-5% 1/16W

R110 061L0603101 CHIPR 100 OHM +-5% 1/16W

R109 061L0603101 CHIPR 100 OHM +-5% 1/16W

R102 061L0603101 CHIPR 100 OHM +-5% 1/16W

R164 061L0603102 CHIPR 1K OHM +-5% 1/16W

R165 061L0603102 CHIPR 1K OHM +-5% 1/16W

R171 061L0603104 RST SM 0603 RC0603 100K PM5 R

FB103 061L0603220 CHIPR 22 OHM+-5% 1/16W

FB102 061L0603220 CHIPR 22 OHM+-5% 1/16W

FB101 061L0603220 CHIPR 22 OHM+-5% 1/16W

R157 061L0603221 CHIPR 220 OHM+-5% 1/16W

R158 061L0603221 CHIPR 220 OHM+-5% 1/16W

R159 061L0603221 CHIPR 220 OHM+-5% 1/16W

R160 061L0603221 CHIPR 220 OHM+-5% 1/16W

R115 061L0603222 CHIPR 2.2K OHM+-5% 1/16W

R116 061L0603222 CHIPR 2.2K OHM+-5% 1/16W

R132 061L0603272 RST SM 0603 RC22H 2K7 PM1 R

R131 061L0603272 RST SM 0603 RC22H 2K7 PM1 R

R112 061L0603470 CHIPR 47 OHM +-5% 1/16W

R114 061L0603470 CHIPR 47 OHM +-5% 1/16W

R144 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R147 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R148 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R154 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R155 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R161 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R162 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R163 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R173 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R168 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R143 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R117 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R118 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

66

Page 67

Dell E193FPc

R122 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R123 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R127 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R133 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R134 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R135 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R156 061L0603473 RST SM 0603 RC0603 47K PM5 R

R106 061L0603750 9F 75OHM 1% 1/10W

R107 061L0603750 9F 75OHM 1% 1/10W

R108 061L0603750 9F 75OHM 1% 1/10W

R172 061L1206331 CHIP 330OHM 5% 1/4W

C154 065G0603102 31 CHIP 1000PF 50V NPO

C156 065G0603102 31 CHIP 1000PF 50V NPO

C155 065G0603102 32 1000PF +-10% 50V X7R

C153 065G0603102 32 1000PF +-10% 50V X7R

C157 065G0603102 32 1000PF +-10% 50V X7R

C152 065G0603102 32 1000PF +-10% 50V X7R

C174 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C123 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C125 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C127 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C130 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C132 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C134 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C137 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C139 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C142 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C145 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C150 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C163 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C167 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C173 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C175 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C124 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C144 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C133 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C168 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C128 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C138 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

67

Page 68

Dell E193FPc

C159 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C164 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C149 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C141 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C135 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C131 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C126 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C119 065G0603104 12 CER2 0603 X7R 16V 100N PM10 R

C147 065G0603220 31 CER1 0603 NP0 50V 22P PM5 R

C176 065G0603220 31 CER1 0603 NP0 50V 22P PM5 R

C148 065G0603220 31 CER1 0603 NP0 50V 22P PM5 R

C177 065G0603220 31 CER1 0603 NP0 50V 22P PM5 R

C113 065G0603473 32 CHIP 0.047UF 50V X7R

C106 065G0603473 32 CHIP 0.047UF 50V X7R

C114 065G0603473 32 CHIP 0.047UF 50V X7R

C112 065G0603473 32 CHIP 0.047UF 50V X7R

C104 065G0603473 32 CHIP 0.047UF 50V X7R

C108 065G0603473 32 CHIP 0.047UF 50V X7R

L106 071G 56K121 M CHIP BEAD

L105 071G 56K121 M CHIP BEAD

L104 071G 56K121 M CHIP BEAD

L103 071G 56K121 M CHIP BEAD

L102 071G 56K121 M CHIP BEAD

L101 071G 56K121 M CHIP BEAD

FB105 071G 56K121 M CHIP BEAD

R101 071G 59Q101 Y CHIP BEAD 0603 100ohm TAIYO YUDEN

R104 071G 59Q101 Y CHIP BEAD 0603 100ohm TAIYO YUDEN

R105 071G 59Q101 Y CHIP BEAD 0603 100ohm TAIYO YUDEN

D112 093G 39147SEM ZMM5V6ST

D111 093G 39147SEM ZMM5V6ST

D109 093G 39147SEM ZMM5V6ST

D108 093G 39147SEM ZMM5V6ST

D107 093G 39147SEM ZMM5V6ST

D104 093G 39147SEM ZMM5V6ST

D103 093G 39147SEM ZMM5V6ST

D102 093G 39147SEM ZMM5V6ST

D110 093G 64 42 P BAV70 SOT-23

D101 093G 6433P BAV99

D105 093G 6433P BAV99

68

Page 69

Dell E193FPc

D106 093G 6433P BAV99

715L1280 E main board

090G6064 1 HEAT SINK

D911 093G 60217 FMB29L 10A 100V SANKEN

D910 093G 60245 SP10150

0M1G1730 8128 SCREW M3x8

R903 061G152M10458F 100K OHM 5% 2W

096G 29 6 H.S. TUBE

Q903 057G 667 22 FQPF8N80C

090G6064 1 HEAT SINK

0M1G1730 8128 SCREW M3x8

R917 061G 2J39858F 0.390OHM 5% 2W

096G 29 6 H.S. TUBE

IC901 056G 379 32 SG6841DZ DIP-8

BD901 093G 50460502 KBP206G

U201 056G 608 1 TL1451ACD

Q205 057G 417 4 PMBS3904/PHILIPS-SMT(04)

Q206 057G 417 4 PMBS3904/PHILIPS-SMT(04)

Q207 057G 417 6 PMBS3906/PHILIPS-SMT(06)

Q208 057G 417 6 PMBS3906/PHILIPS-SMT(06)

Q202 057G 760 4B PDTA144WK SOT346

Q201 057G 760 5B PDTC144WK SOT346

Q204 057G 763 3 AO4411 SO-8

Q203 057G 763 3 AO4411 SO-8

R204 061L0603103 CHIPR 10K OHM +-5% 1/16W

R239 061L0603123 CHIP 12K OHM 1/16W

R238 061L0603123 CHIP 12K OHM 1/16W

R223 061L0603123 CHIP 12K OHM 1/16W

R222 061L0603123 CHIP 12K OHM 1/16W

R211 061L0603123 CHIP 12K OHM 1/16W

R210 061L0603123 CHIP 12K OHM 1/16W

R220 061L0603153 CHIPR 15KOHM+-5% 1/10W

R221 061L0603153 CHIPR 15KOHM+-5% 1/10W

R217 061L0603221 CHIPR 220 OHM+-5% 1/16W

R216 061L0603221 CHIPR 220 OHM+-5% 1/16W

R212 061L0603392 CHIP 3.9K OHM 1/16W

R213 061L0603392 CHIP 3.9K OHM 1/16W

R214 061L0603392 CHIP 3.9K OHM 1/16W

R215 061L0603392 CHIP 3.9K OHM 1/16W

69

Page 70

Dell E193FPc

R237 061L0603471 CHIPR 470 OHM+-5% 1/16W

R236 061L0603471 CHIPR 470 OHM+-5% 1/16W

R219 061L0603471 CHIPR 470 OHM+-5% 1/16W

R218 061L0603471 CHIPR 470 OHM+-5% 1/16W

R209 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R208 061L0603472 CHIPR 4.7K OHM +-5% 1/16W

R202 061L0603512 CHIP 5.1K OHM 1/16W

R203 061L0603512 CHIP 5.1K OHM 1/16W

R241 061L0603513 CHIP 51K OHM

R240 061L0603513 CHIP 51K OHM

R206 061L0603683 CHIP 68K OHM 1/16W

R205 061L0603683 CHIP 68K OHM 1/16W

R235 061L0603821 RST SM 0603 RC22H 820R PM1 R

R234 061L0603821 RST SM 0603 RC22H 820R PM1 R

F201 061L1206000 CHIPR 0 OHM +-5% 1/8W

R912 061L1206101 CHIP 100 OHM 5% 1/8W

R928 061L1206102 CHIP 1K OHM 5% 1/8W

R913 061L1206103 CHIP 10KOHM 5% 1/4W

R901 061L1206105 CHIP 1MOHM 5% 1/4W

R902 061L1206105 CHIP 1MOHM 5% 1/4W

R914 061L1206240 2F CHIP 24KOHM1% 1/4W

R909 061L1206472 CHIP 4.7KOHM 5% 1/4W

R910 061L1206472 CHIP 4.7KOHM 5% 1/4W

R911 061L1206472 CHIP 4.7KOHM 5% 1/4W

R908 061L1206519 CHIPR 5.1OHM +-5% 1/4W

C230 065G0805102 32 CHIP 1000P 50VX7R 0805

C931 065G0805102 32 CHIP 1000P 50VX7R 0805

C910 065G0805102 32 CHIP 1000P 50VX7R 0805

C930 065G0805102 32 CHIP 1000P 50VX7R 0805

C231 065G0805102 32 CHIP 1000P 50VX7R 0805

C206 065G0805104 22 0.1UF +-10% 25V X7R 080

C204 065G0805104 22 0.1UF +-10% 25V X7R 080

C205 065G0805104 22 0.1UF +-10% 25V X7R 080

C202 065G0805104 22 0.1UF +-10% 25V X7R 080

C907 065G0805104 32 CHIP 0.1U 50V X7R

C908 065G0805104 32 CHIP 0.1U 50V X7R

C909 065G0805104 32 CHIP 0.1U 50V X7R

C926 065G0805104 32 CHIP 0.1U 50V X7R

C927 065G0805104 32 CHIP 0.1U 50V X7R

70

Page 71

Dell E193FPc

C212 065G0805105 22 CHIP 1UF 25V X7R 0805

C203 065G0805105 22 CHIP 1UF 25V X7R 0805

C210 065G0805105 22 CHIP 1UF 25V X7R 0805

C220 065G0805105 22 CHIP 1UF 25V X7R 0805

C211 065G0805105 22 CHIP 1UF 25V X7R 0805

C209 065G0805105 22 CHIP 1UF 25V X7R 0805

C219 065G0805105 22 CHIP 1UF 25V X7R 0805

C208 065G0805331 31 CHIP 330pF 50V NPO

C911 065G0805471 21 CHIP 470PF 25V NPO

C221 065G0805474 22 CHIP 0.47UF 25V X7R 0805

C222 065G0805474 22 CHIP 0.47UF 25V X7R 0805

D203 093G 39S 3 T BZT52-C11

D204 093G 39S 3 T BZT52-C11

ZD904 093G 39S 19 T PTZ7.5B

ZD901 093G 39S 23 T GLZ22B

D202 093G2004 2A SM240A DO-214AC

D201 093G3004 2 SR34 PAN JIT

PW1942SED1AI POWER BOARD FOR AI

CN901 006G 31500 EYELET

C904 006G 31502 1.5MM RIVET

C214 006G 31502 1.5MM RIVET

C213 006G 31502 1.5MM RIVET

T901 006G 31502 1.5MM RIVET

PT201 006G 31502 1.5MM RIVET

PT202 006G 31502 1.5MM RIVET

L902 006G 31502 1.5MM RIVET

715L1283 5 PCB

R915 061G 17210052T 100HM 5% 1/4W

R929 061G 17210152T 100 OHM 5% 1/4W

R926 061G 17210252T 1K OHM 5% 1/4W

R925 061G 17210252T 1K OHM 5% 1/4W

R233 061G 17210252T 1K OHM 5% 1/4W

R232 061G 17210252T 1K OHM 5% 1/4W

R231 061G 17210252T 1K OHM 5% 1/4W

R230 061G 17210252T 1K OHM 5% 1/4W

R229 061G 17210252T 1K OHM 5% 1/4W

R228 061G 17210252T 1K OHM 5% 1/4W

R227 061G 17210252T 1K OHM 5% 1/4W

R226 061G 17210252T 1K OHM 5% 1/4W

71

Page 72

Dell E193FPc

R225 061G 17210252T 1K OHM 5% 1/4W

R224 061G 17210252T 1K OHM 5% 1/4W

R916 061G 17210352T CFR 10KOHM +-5% 1/4W

R924 061G 20024252T 2.4KOHM 1% 1/4W

R922 061G 20033352T 33KOHM 1% 1/4W

R923 061G 20036252T 3.6KOHM 1% 1/4W

J002 061G 60222152T CFR 220OHM +-5% 1/6W

R201 061G 60224352T 24K OHM 5% 1/6W

R920 061G175L47052T 47OHM +-5% 1/2W

R921 061G175L47052T 47OHM +-5% 1/2W

R907 061L214Y10552T 1M,1/4W

R904 061L214Y10552T 1M,1/4W

R905 061L214Y10552T 1M,1/4W

R906 061L214Y10552T 1M,1/4W

FB901 071G 55 29 FERRITE BEAD

ZD902 093G 39 5452T HZ12B2-E

ZD903 093G 39 7752T HZ5C1-E

D901 093G 6026T52T RECTIFIER DIODE FR107

D902 093G 6038P52T PS102R

D903 093G 64 1152T 1N4148

D210 093G 64 1152T 1N4148

D209 093G 64 1152T 1N4148

D208 093G 64 1152T 1N4148

D207 093G 64 1152T 1N4148

D206 093G 64 1152T 1N4148

D205 093G 64 1152T 1N4148

IC903 056G 158 10 T IC AZ431AZ-AE1 TO-92 BY AAC

Q902 057G 419 PP T 2PC945P

Q901 057G 420 PP T 2PA733P

C929 064G700J1040AT 0.1UF 50V PEN

C905 065G 2K152 1T6921 1.5NF/2KV Y5P +-10%

C921 065G517K102 5T 1000PF 10% Y5P 500V

C920 065G517K102 5T 1000PF 10% Y5P 500V

C925 067G215B4713HT 470UF 16V LTR471M1CF11VR 8*11m

C924 067G215B4713HT 470UF 16V LTR471M1CF11VR 8*11m

C201 067G215C1514HT LOW ESR 150UF 25V 8*7MM

C223 067G215C1514HT LOW ESR 150UF 25V 8*7MM

F901 084G 56 1 FUSE 2A 250V WICKMANN

72

Page 73

Dell E193FPc

Diversity of T980KALHK8DLN compared with T980KSLHK8DLN

Location Part No. for TPV Description

015G8142 2 MAIN FRAME

E089B 089G1738GAA 16 SIGNAL CABLE

095G8018 30590 WIRE HARNESS

750GLU90N04 2Z AU 19" V2D ZBD PANEL

CBPC980KALDR CONVERSION BOARD

PWPC1942AUD1 POWER BOARD

CN100 088G 35315F H D-SUB 15PIN

AIC980KALDR MAIN BOARD

L201 073G 253139 SA CHOKE COIL

L202 073G 253139 SA CHOKE COIL

PW1942AUD1SMT POWER BOARD FOR SMT

R234 061L0603621 CHIPR 620 OHM+-5% 1/16W

R235 061L0603621 CHIPR 620 OHM+-5% 1/16W

PW1942AUD1AI POWER BOARD FOR AI

73

Page 74

14. Definition Of Pixel Defects

Type 1. LM190E03

Dot Defect

Bright Dot

Dark Dot

Dell E193FPc

Total amount of Dot Defects -------------------------5 Max(Combination)

Polarizer Defects

74

Page 75

Foreign Material

Line Defect

Bezel Appearance

Dell E193FPc

Others

Type 2. LTM190EX-L01

75

Page 76

Dell E193FPc

76

Page 77

Dell E193FPc

77

Page 78

Dell E193FPc

78

Loading...

Loading...