Dell Data Domain DD9500, Data Domain DD9800 Hardware Overview And Installation Manual

Dell EMC Data Domain DD9500 and

DD9800 Systems

Version 6.1

Hardware Overview and Installation Guide

302-002-887

REV. 02

Copyright © 2016-2017 EMC Corporation All rights reserved.

Published June 2017

Dell believes the information in this publication is accurate as of its publication date. The information is subject to change without notice.

THE INFORMATION IN THIS PUBLICATION IS PROVIDED “AS-IS.“ DELL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND

WITH RESPECT TO THE INFORMATION IN THIS PUBLICATION, AND SPECIFICALLY DISCLAIMS IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. USE, COPYING, AND DISTRIBUTION OF ANY DELL SOFTWARE DESCRIBED

IN THIS PUBLICATION REQUIRES AN APPLICABLE SOFTWARE LICENSE.

Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other trademarks may be the property of their respective owners.

Published in the USA.

Dell EMC

Hopkinton, Massachusetts 01748-9103

1-508-435-1000 In North America 1-866-464-7381

www.DellEMC.com

2 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

CONTENTS

Figures

Tables

Chapter 1

Chapter 2

5

7

Revision history 9

Planning and Site Preparation 11

Tools and supplies needed...........................................................................12

Safety information...................................................................................... 12

Hardware Overview 15

System features..........................................................................................16

System specifications................................................................................. 16

DD9500/DD9800 front panel......................................................................18

Front LED indicators...................................................................... 18

Solid State Drives (SSD)................................................................21

Rear panel.................................................................................................. 22

Power supply units........................................................................ 23

Management module..................................................................... 23

Rear LED Indicators.......................................................................24

Available I/O modules.................................................................... 26

Ethernet I/O modules.................................................................... 27

Fibre Channel (FC) I/O modules.................................................... 27

SAS I/O modules........................................................................... 27

I/O module slot assignments...................................................................... 27

Slot Addition Rules........................................................................ 29

Internal System Components..................................................................... 30

DIMM Modules.............................................................................. 32

Cooling Fans.................................................................................. 32

Storage capacity........................................................................................ 33

Chapter 3

Chapter 4

Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide 3

Install the System in the Rack 37

Unpack the system.....................................................................................38

Install the rack brackets............................................................................. 38

Shelf brackets and cable management assembly........................... 38

Install rail brackets on the Data Domain racks (for square or round

hole racks).....................................................................................40

Install rail brackets using the adapter hardware (for threaded hole

racks)............................................................................................ 43

Install the DD9500/DD9800 system into a rack......................................... 45

Mount the cable management assembly..................................................... 47

Install the Data Domain cable management assembly (CMA).........47

Installing the expansion shelves into the racks............................................49

Connect Cables and Power on 51

Connecting the expansion shelves and the controllers............................... 52

CONTENTS

ES30 cable information.............................................................................. 52

Connecting multiple ES30 shelves to the DD9500 /DD9800 system......... 56

DD9500 /DD9800......................................................................... 56

DD9500 /DD9800 with HA (one rack).......................................... 58

DD9500 /DD9800 with HA (two racks).........................................60

DD9500 /DD9800 with DD Cloud Tier (Single node or HA)...........63

DD9500 /DD9800 with ERSO....................................................... 66

DS60 cable information.............................................................................. 69

Connecting multiple DS60 shelves to the DD9500 /DD9800 system......... 70

DD9500 /DD9800......................................................................... 70

DD9500 /DD9800 with HA............................................................ 73

DD9500 and DD9800 with DD Cloud Tier (Single node)................ 75

DD9500 and DD9800 with DD Cloud Tier (HA)............................. 76

DD9500 and DD9800 with ERSO.................................................. 80

Connecting the HA interconnect.................................................................81

Connect data cables on both nodes............................................................82

Power on the systems................................................................................ 83

Install the bezel.......................................................................................... 84

Chapter 5

Configure System For Use 85

Enable administrative communication.........................................................86

Accepting the End User License Agreement (EULA).................................. 88

Run the configuration wizard......................................................................88

Configuring the network................................................................88

Configuring additional system parameters..................................................90

Configure HA for new installations.............................................................. 91

4 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

FIGURES

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Warning about lifting the system.................................................................................13

Front panel components..............................................................................................18

Service LEDs...............................................................................................................19

Power button............................................................................................................. 20

Front LEDs................................................................................................................. 20

SSD drives.................................................................................................................. 21

Features on rear of chassis.........................................................................................22

Serial number tag location.......................................................................................... 22

Four power supplies....................................................................................................23

Management module.................................................................................................. 24

1000BaseT Ethernet ports..........................................................................................24

Rear LEDs.................................................................................................................. 25

Power supply LEDs.....................................................................................................25

Location of NVRAM and I/O modules......................................................................... 27

SP module ..................................................................................................................31

Releasing a memory riser ........................................................................................... 31

Open fan tray............................................................................................................. 32

Warning about lifting the system................................................................................ 38

Rail bracket inside...................................................................................................... 39

Rail bracket outside.................................................................................................... 39

Cable management assembly (CMA)..........................................................................40

Insert screw in the back.............................................................................................. 41

Insert screw in the front............................................................................................. 42

Attach bracket to front of rack...................................................................................42

Adapters.....................................................................................................................43

Attaching the front rail with the screw....................................................................... 44

Attach front rail adapter ............................................................................................ 45

Warning about lifting the system................................................................................ 45

System on a rack ....................................................................................................... 46

Location of serial number tag......................................................................................47

Data Domain CMA back ............................................................................................. 48

Data Domain cable management assembly back inside............................................... 48

Rear of the rack mount rail ........................................................................................ 49

Node 0 SAS I/O module to ES30 host port connector............................................... 53

Node 1 SAS I/O module to ES30 expansion port connector........................................54

Cables for ES30 to ES30 connections........................................................................55

Cabling for base DD9500 /DD9800 systems.............................................................. 58

Cabling for HA DD9500 /DD9800 systems in one rack...............................................60

Cabling for HA DD9500 /DD9800 systems in two racks.............................................63

Cabling for DD9500 /DD9800 systems with DD Cloud Tier (Single node or HA) .......66

Cabling for DD9500 /DD9800 systems with ERSO ................................................... 68

SAS I/O module to DS60 connector...........................................................................69

Cabling for base DD9500 and DD9800 systems..........................................................72

Cabling for HA DD9500 and DD9800systems............................................................. 74

Cabling for DD9500 and DD9800 systems with DD Cloud Tier................................... 76

Cabling for HA DD9500 and DD9800 systems with DD Cloud Tier..............................79

Cabling for DD9500 and DD9800 systems with ERSO................................................ 81

DD9500/DD9800 HA interconnect.............................................................................82

Power LED and power button..................................................................................... 87

Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide 5

FIGURES

6 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

TABLES

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Document revision history............................................................................................ 9

DD9500/DD9800 system features..............................................................................16

DD9500/DD9800 system specifications..................................................................... 16

Front panel LED status indicators............................................................................... 21

Rear LED status indicators......................................................................................... 25

Physical to logical port mapping example................................................................... 26

DD9500 and DD9800 I/O module slot assignments....................................................28

I/O module slot population rules................................................................................. 29

DD9500/DD9800 memory configurations.................................................................. 32

DD9500/DD9800 storage capacity............................................................................ 33

DD9500/DD9800 with ES30 SAS shelves.................................................................. 34

DD9500/DD9800 with DS60 shelves......................................................................... 35

Cables for node 0 to ES30 shelf loop..........................................................................53

Cables for node 1 to ES30 shelf loop.......................................................................... 54

ES30 to ES30 cable options....................................................................................... 55

Primary node cabling instructions...............................................................................59

Standby node cabling instructions..............................................................................59

Primary node cabling instructions............................................................................... 61

Standby node cabling instructions...............................................................................61

Primary node cabling instructions...............................................................................64

Standby node cabling instructions.............................................................................. 64

Cables for node 0 and node 1 to DS60 shelf loop........................................................69

Primary node cabling instructions............................................................................... 73

Standby node cabling instructions.............................................................................. 73

Primary node cabling instructions............................................................................... 77

Standby node cabling instructions.............................................................................. 77

Communications settings........................................................................................... 86

Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide 7

TABLES

8 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

Revision history

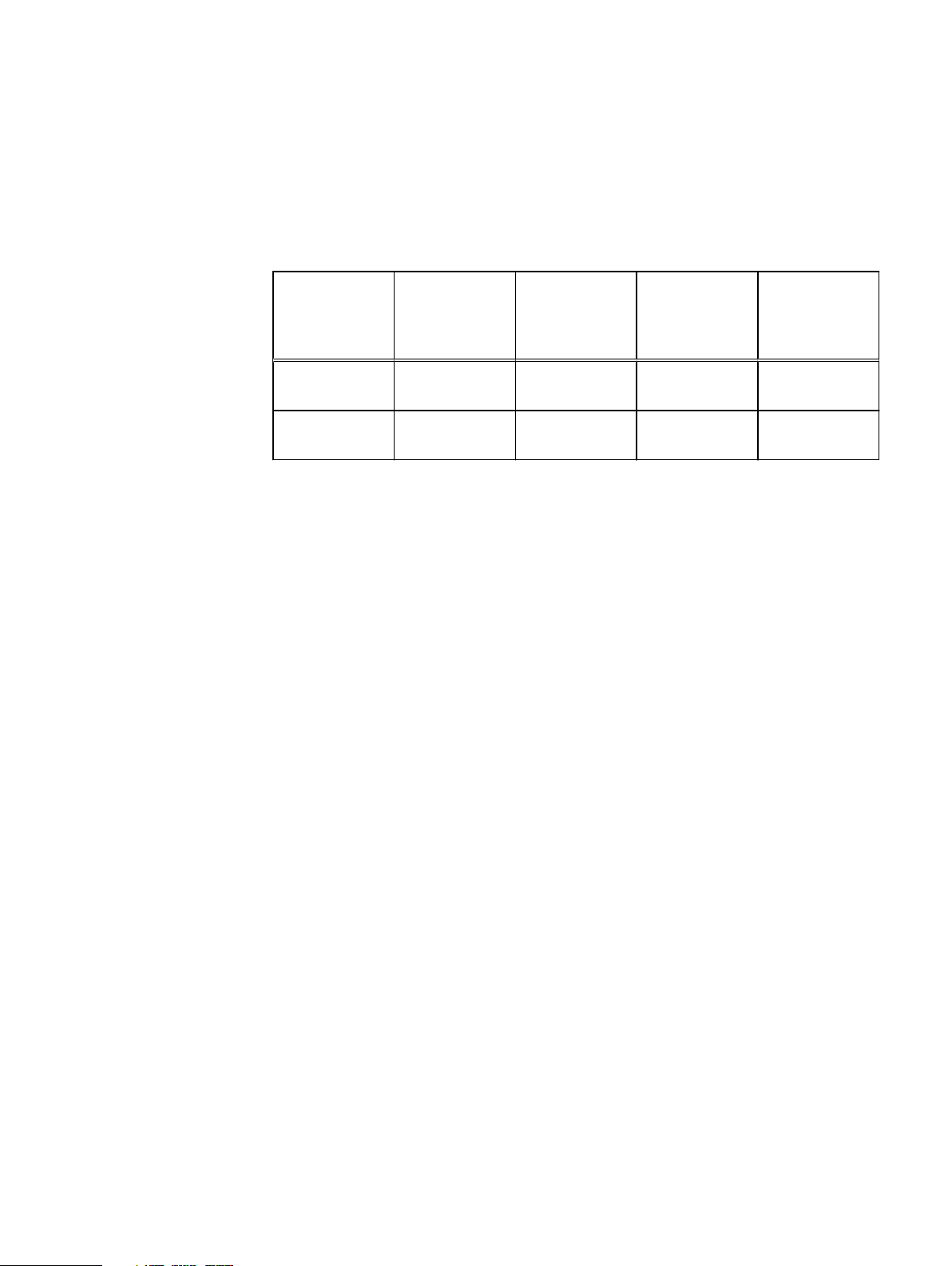

Table 1 Document revision history

Revision Date Document

part number/

Revision

Number

02 June 2017 302-002-887,

Rev. 01

01 October 2016 302-002-887,

Rev. 01

Software

version

6.1 Editorial

6.0 Initial publication

Description

revisions

Revision history 9

Revision history

10 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

CHAPTER 1

Planning and Site Preparation

l

Tools and supplies needed.................................................................................. 12

l

Safety information..............................................................................................12

Planning and Site Preparation 11

CAUTION

Planning and Site Preparation

Tools and supplies needed

These tools and supplies may be helpful for the installation and setup tasks for Data

Domain systems.

l

Null modem cable (DB-9 female to female), plus spare

l

USB-to-DB-9 serial (male connector) converter cable if the laptop does not have a

serial port, plus spare

l

Power adapter, C13 to NEMA 5–15 (if based in North America), or a power cord

for your laptop power adapter with a C13 plug, so that you can power your laptop

from a rack PDU

l

Antistatic wrist strap and conductive foam pad

l

Screwdrivers:

n

Phillips #2 with a 12 in. or longer blade

n

Phillips #2 (standard-length blade)

n

Phillips #1

n

Flat head 3/16 in.

n

Flat head 1/4 in.

n

Torx T10

l

Flashlight

l

Needle nose pliers

l

Diagonal wire cutters (for cutting tie wraps)

l

2 GB or greater USB flash memory drive

l

Tie wraps (4 in. and 8 in.)

l

(recommended) Roll of 5/8 inch Velcro cable tie material (3M Scotchmate

SJ-3401 or similar)

Safety information

12 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

l

If the system is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

l

The RJ45 sockets on the motherboard, PCI cards, or I/O modules are for

Ethernet connection only and must not be connected to a

telecommunications network.

Review this list of important safety recommendations.

l

All plug-in modules and blank plates are part of the fire enclosure and must be

removed only when a replacement can be added immediately. The system must

not be run without all parts in place.

l

A DD9500/DD9800 system must be operated only from a power supply input

voltage range of 200–240 VAC and 50–60 Hz. ES30 shelves use 100-240 VAC and

50–60 Hz. DS60 shelves use 200–240 VAC and 50–60 Hz.

CAUTION

Planning and Site Preparation

l

Each component is intended to operate with all working power supplies installed.

l

Provide a suitable power source with electrical overload protection.

l

A safe electrical earth connection must be provided to each power cord. Check

the grounding of the power sources before applying power.

l

The plug on each power supply cord is used as the main device to disconnect

power from the system. Ensure that the socket outlets are located near the

equipment and are easily accessible.

l

Permanently unplug the unit if you think it is damaged in any way and before

moving the system. A DD9500/DD9800 system includes four power supplies. To

completely remove system power, you must disconnect all four power supplies.

l

The power connections must always be disconnected prior to removal or

replacement of a power supply module from any of the components in the system.

l

A faulty power supply module must be replaced within 24 hours.

l

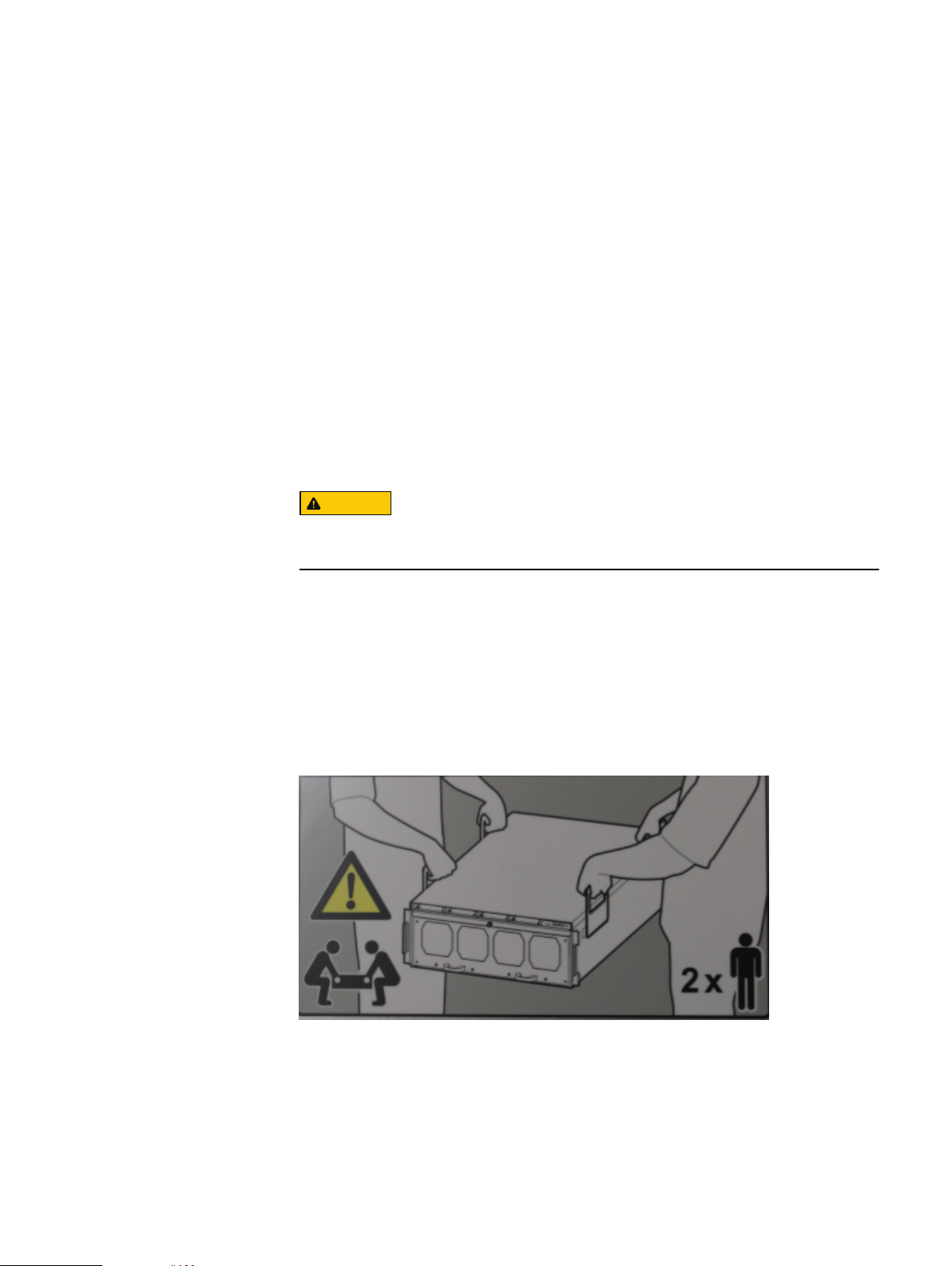

Do not lift system components by yourself. A DD9500/DD9800 system weighs up

to 117 lbs (53.2 kg), an ES30 expansion shelf weighs up to 68 lbs (30.8 kg), and a

DS60 shelf weighs up to 225 lbs (90.7 kg).

Data Domain systems are heavy. Use at least two people or a mechanical lift

to move any system.

l

Do not lift an expansion shelf by the handles on any modules. The handles are not

designed to support the weight of the populated shelf.

l

To comply with applicable safety, emission, and thermal requirements, covers

must not be removed and all bays must be fitted with plug-in modules.

l

Once removed from the shipping box, it is ok to lift the DD9500/DD9800 system

or the chassis with the four handles to place in a rack. You will need to remove the

handles from the sides before sliding the system in the rack. The four handles

should be saved for later use.

Figure 1

Warning about lifting the system

l

Load the rack with storage shelves beginning at the bottom and the DD9500

system in the designated location to prevent the rack from becoming top-heavy.

l

For ESD protection, Data Domain recommends that you wear a suitable antistatic

wrist or ankle strap. Observe all conventional ESD precautions when handling

plug-in modules and components.

Safety information 13

Planning and Site Preparation

l

Do not extend components on slide rails until you have loaded at least three or

more similarly weighted items in the rack, or unless the rack is bolted to the floor

or overhead structure to prevent tipping.

14 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

CHAPTER 2

Hardware Overview

l

System features................................................................................................. 16

l

System specifications.........................................................................................16

l

DD9500/DD9800 front panel............................................................................. 18

l

Rear panel..........................................................................................................22

l

I/O module slot assignments.............................................................................. 27

l

Internal System Components.............................................................................30

l

Storage capacity................................................................................................33

Hardware Overview 15

Hardware Overview

System features

Table 2 DD9500/DD9800 system features

Feature DD9500 DD9800

Rack Height 4U, supported in four-post racks only 4U, supported in four-post racks only

Power 4 hot-swappable power units, 2 pairs of 1 +1

redundant

4 hot-swappable power units, 2 pairs of 1 +1

redundant

Fans 8 hot-swappable fans, redundant 8 hot-swappable fans, redundant

Internal drives 4 x 400 GB (base 10) hot-swappable solid state

drives (SSD)

SSD cache Optional 1 x 8 drive SSD shelf or 1 x 15 drive SSD

shelf

l

Systems with 256 GB of memory have 8 SSDs.

l

Systems with 512 GB of memory have 15 SSDs.

4 x 400 GB (base 10) hot-swappable solid state

drives (SSD)

1 x 8 drive SSD shelf or 1 x 15 drive SSD shelf

l

Systems with 256 GB of memory have 8

SSDs.

l

Systems with 768 GB of memory have 15

SSDs.

NVRAM One 8-GB NVRAM module for data integrity during

a power outage

I/O Module slots 11 I/O module (Fibre Channel, Ethernet, and SAS)

slots. Replaceable I/O modules are not hotswappable. See I/O module slot assignments on

page 27

Memory

l

Base: 256 GB

l

Expanded 512 GB

512 GB is required for DD Cloud Tier and Extended

Retention. HA is supported with both memory

configurations.

One 8-GB NVRAM module for data integrity

during a power outage

11 I/O module (Fibre Channel, Ethernet, and SAS)

slots. Replaceable I/O modules are not hotswappable. See I/O module slot assignments on

page 27

l

Base: 256 GB

l

Expanded 768 GB

768 GB is required for DD Cloud Tier and

Extended Retention. HA is supported with both

memory configurations.

Rack mounting Rack mount kit included with each system.

Adjustable between 24 - 36 in. (60.9–76.2 cm).

Rack mount kit included with each system.

Adjustable between 24 - 36 in. (60.9–76.2 cm).

Processors 4 Intel EX processors. 4 Intel EX processors.

Voltage 200–240 V~. Frequency: 50 Hz to 60 Hz. 200–240 V~. Frequency: 50 Hz to 60 Hz.

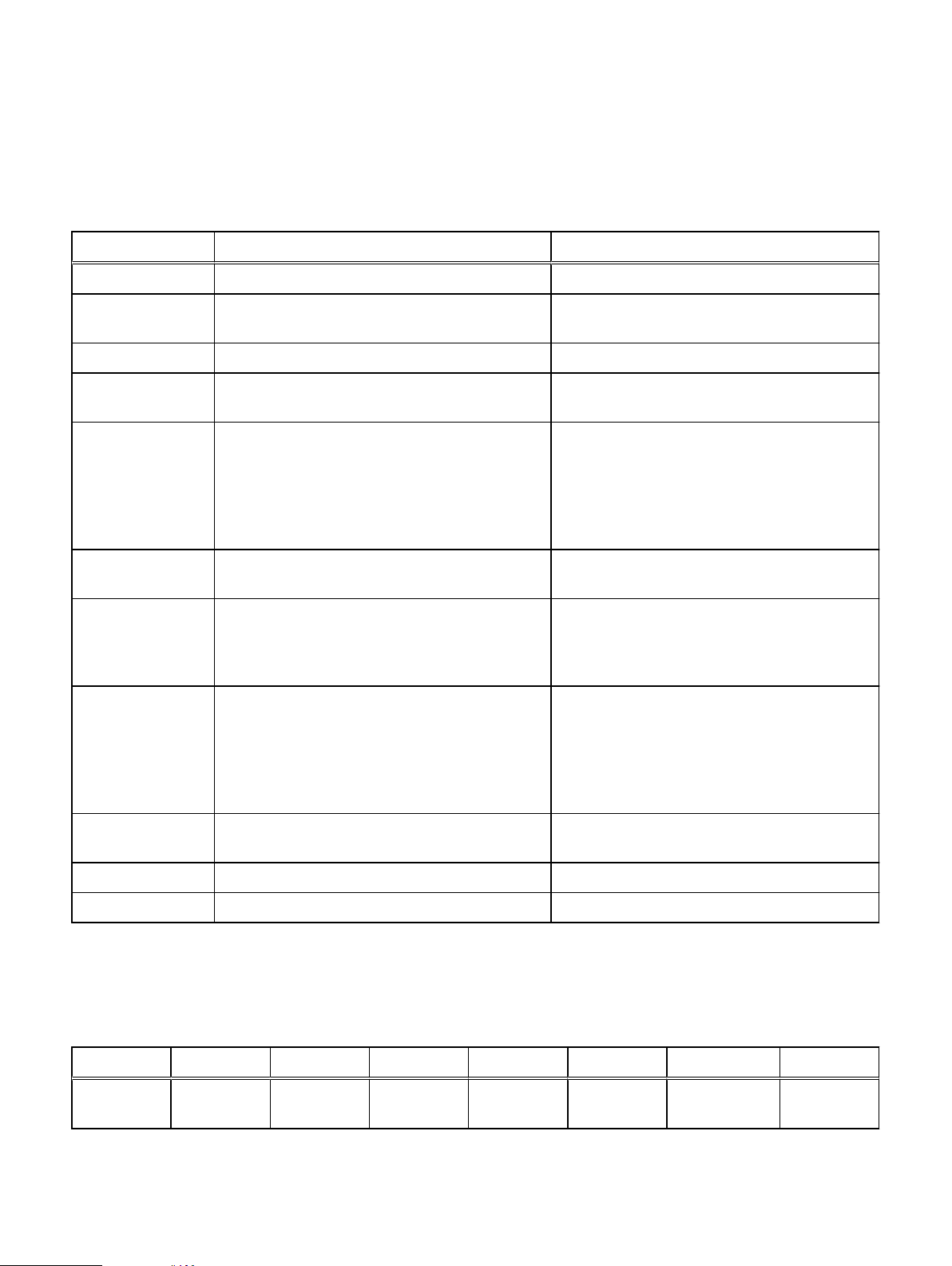

System specifications

Table 3

Model Watts BTU/hr Power (VA) Weight Width Depth Height

DD9500/

DD9800

16 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

1887 6444 1981 117 lb / 53.2kg19 in / 48.3cm29.5 in / 74.9cm7 in / 17.8 cm

DD9500/DD9800 system specifications

Hardware Overview

l

Operating temperature: 50° to 95° F (10° to 35° C), derate 1.1° C per 1000 feet,

above 7500 feet up to 10,000 feet

l

Operating humidity: 20% to 80%, non-condensing

l

Non-operating temperature: -40° to +149° F (-40° to +65° C)

l

Operating acoustic noise: Sound power, LWAd, is 7.7 bels.

System specifications 17

Note

Hardware Overview

DD9500/DD9800 front panel

The four solid state drives (SSDs), the storage processor (SP), and the fans are

accessed from the front of the system. The SP must be pulled out to provide access

to the DIMMs. The fans are accessed without pulling or removing the SP and they are

hot-swappable. The photo shows the interfaces on the front of the system.

Figure 2 Front panel components

Front LED indicators

On the front panel to the right of SSD #4 (in Slot 3) are 3 LEDs that show high level

system status. The System Power LED glows blue to show the system is powered on.

The system can have power (be plugged in) but the blue LEDs are off if the system is

powered off.

The SP Service LED is normally off, but glows amber whenever the storage processor

(SP) requires service. The Enclosure Service LED is normally off, but glows amber

whenever the SP or other replaceable parts require service. The System Power and

Enclosure Service LEDs are visible through the front bezel.

1. SSD slot 0

2. SSD slot 1

3. SSD slot 2

4. SSD slot 3

5. Front LEDs

6. USB ports

7. Power button

8. Fan tray thumbscrew (left)

9. SP module thumbscrew to secure the ejector handle

10. Fan tray thumbscrew (right)

18 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

Figure 3 Service LEDs

Hardware Overview

1. SP service LED — Amber light indicates that the SP or one of its components

needs service.

2. Enclosure Service LED — This is normally off, but amber light indicates that the

enclosure or something within the enclosure— the fans, SP, I/O modules,

management module etc—requires service.

3. System power LED — Blue light indicates system running

Front LED indicators 19

Hardware Overview

The power button shown in the picture is used when a system needs to be powered up

after a shut down using the system poweroff command. Once power is restored

the system power LED light turns blue.

Figure 4 Power button

1. System power LED — Blue light indicates system running

2. Power button

The LEDs in the front are shown in the following figure.

Figure 5

Front LEDs

1. SSD LED in slot 0

2. SSD LED in slot 1

3. SSD LED in slot 2

4. SSD LED in slot 3

5. System power LED — Blue light indicates system running

20 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

Table 4 Front panel LED status indicators

Part Description or Location State

Hardware Overview

System, SP fault Exclamation point within a

System, chassis fault Exclamation point within a

SSD Top LED Solid blue, disk ready, blinks

SSD Bottom LED Dark indicates healthy. Solid

Solid State Drives (SSD)

A system contains 4 hot-swappable 2.5 in. 400 GB SSD drives located in the front.

There are four drive bays numbered 0-3 from left to right. A dual drive failure allows

the DD9500/DD9800 system to operate without disruption.

Each drive has a blue colored power LED and an amber fault LED.

Figure 6

SSD drives

triangle

triangle

Dark indicates normal

operation. Amber indicates

failure.

Dark indicates normal

operation. Amber indicates a

fault condition.

while busy.

amber indicates disk fail.

1. Slot 0

2. Slot 1

3. Slot 2

4. Slot 3

Solid State Drives (SSD) 21

Hardware Overview

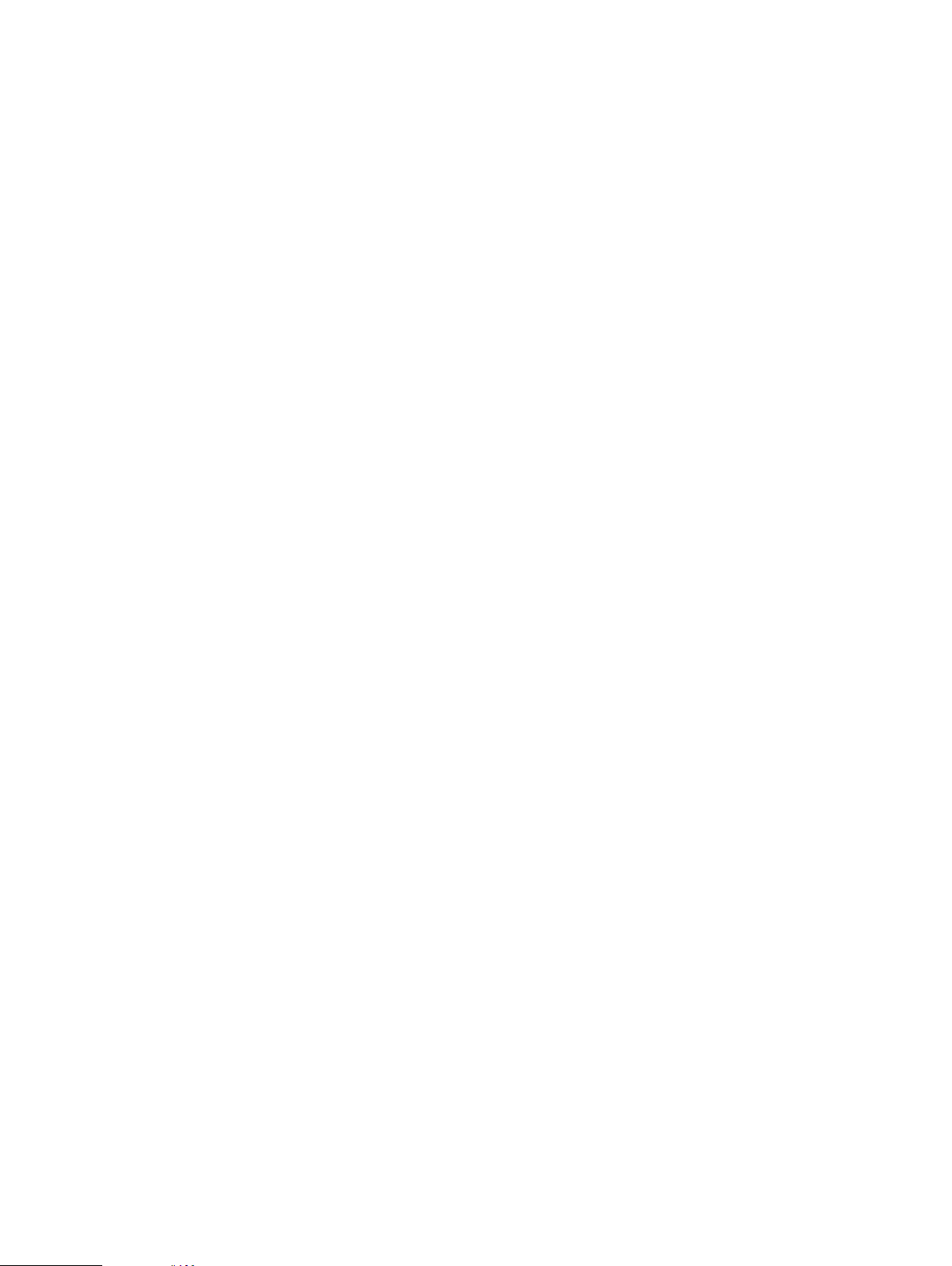

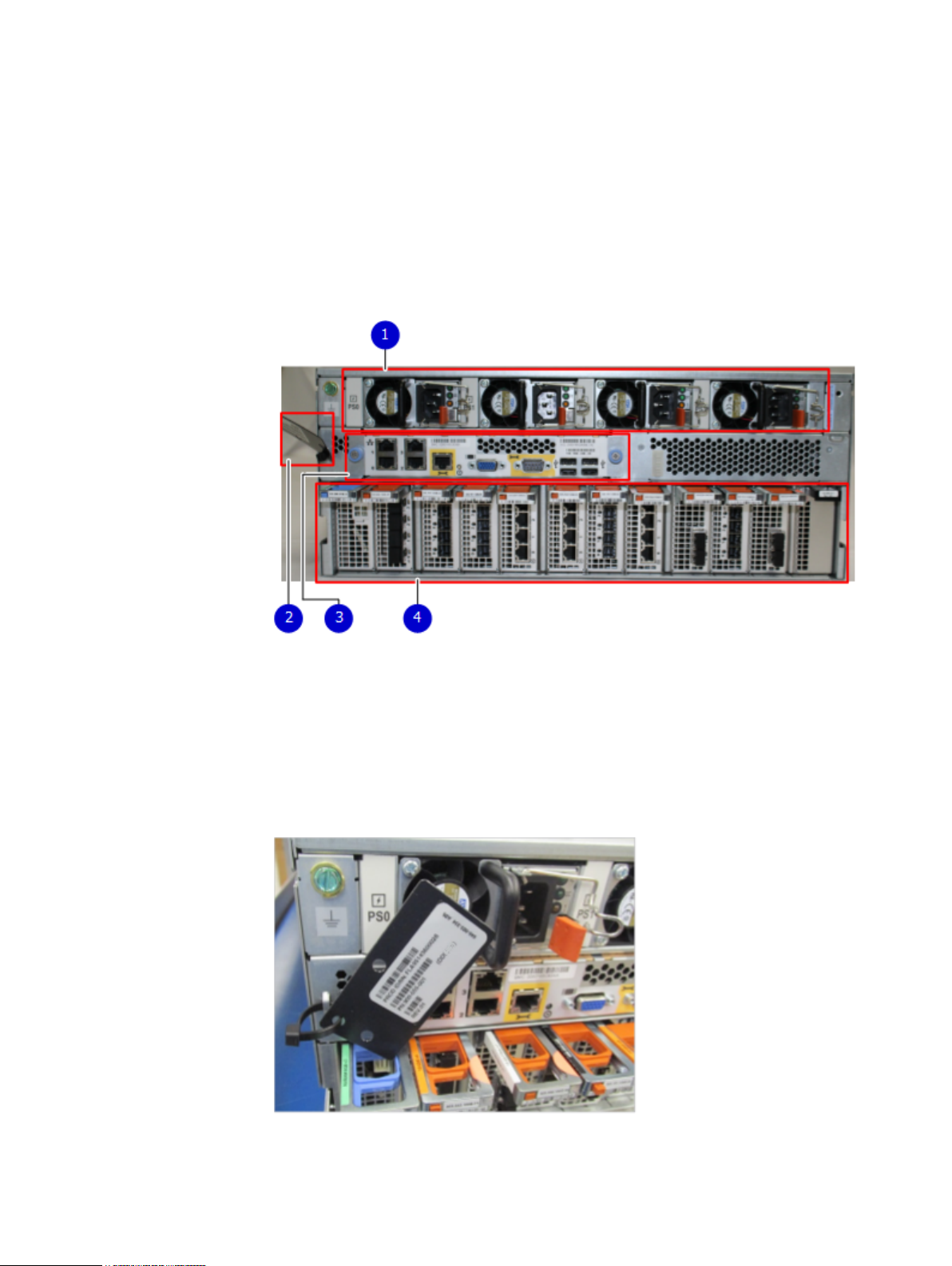

Rear panel

In the rear of the system, the top section contains the 4 power supply units. In the

middle of the section, on the left, is serial number tag location. To the right of the

serial number tag location is the management module. The lower section contains the

NVRAM and the I/O modules numbered 0 through 11 from left to right. The photo

shows the hardware features and interfaces on the rear of the system.

Figure 7 Features on rear of chassis

1. Power supply units

2. Serial number tag

3. Management module

4. NVRAM and IO modules (slots 0-11)

The figure shows the location of the serial number tag on the left of the management

module.

Figure 8

Serial number tag location

22 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

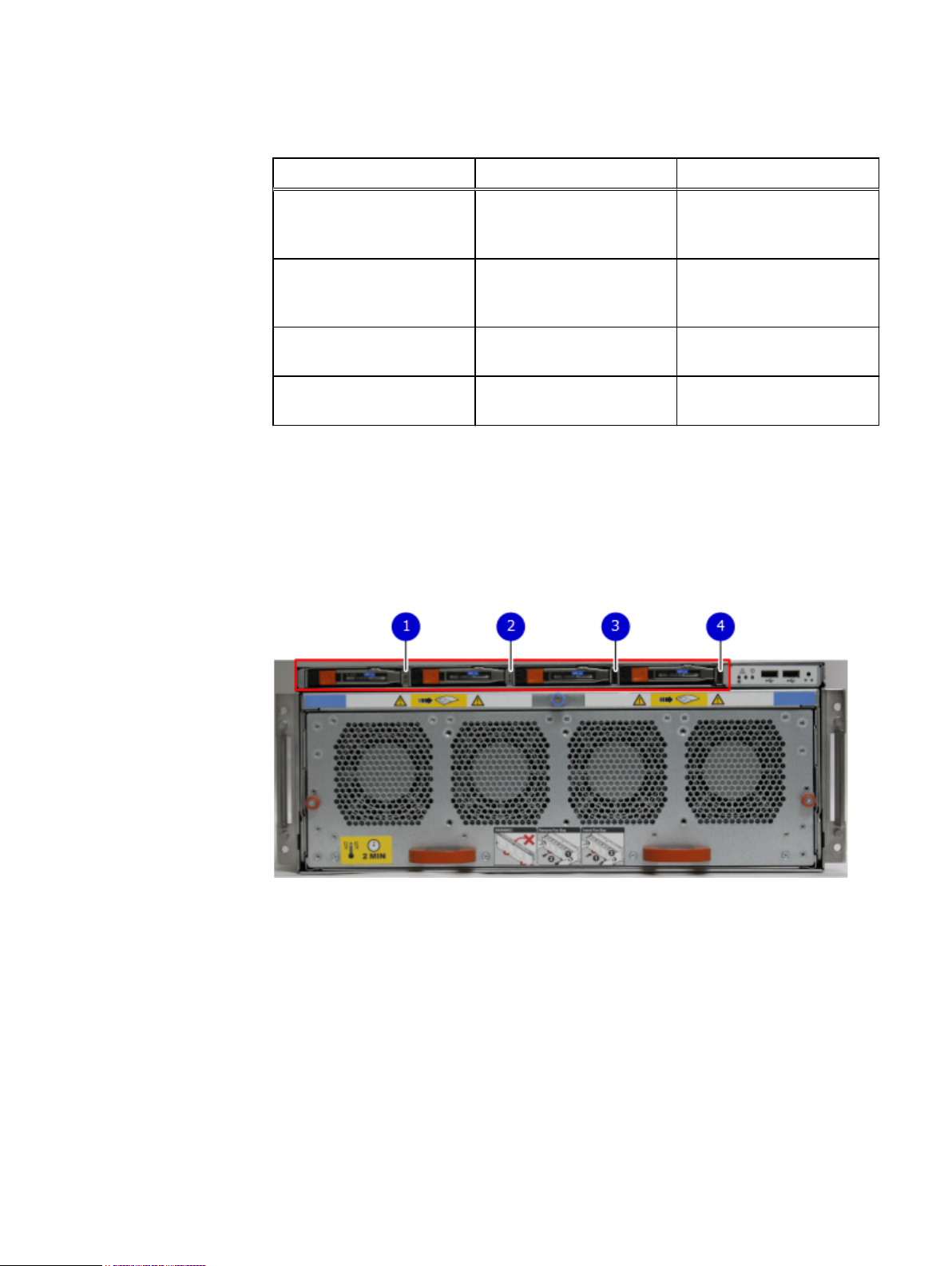

Power supply units

Note

Hardware Overview

A DD9500/DD9800 system has four power supply units, numbered PSU0, PSU1,

PSU2, and PSU3 from left to right. Each power supply has its own integral cooling

fan.

The DD9500/DD9800 system should be powered from redundant AC sources. This

allows one AC source to fail or be serviced without impacting system operation. PSU0

and PSU1 should be attached to one AC source. PSU2 and PSU3 should be attached

to the other AC source.

The AC power plugs are located to the right of each power supply. The wire clips for

the AC cords hold the cords in place. The wire clips must be disengaged before

disconnecting the AC power to each power supply.

Figure 9 Four power supplies

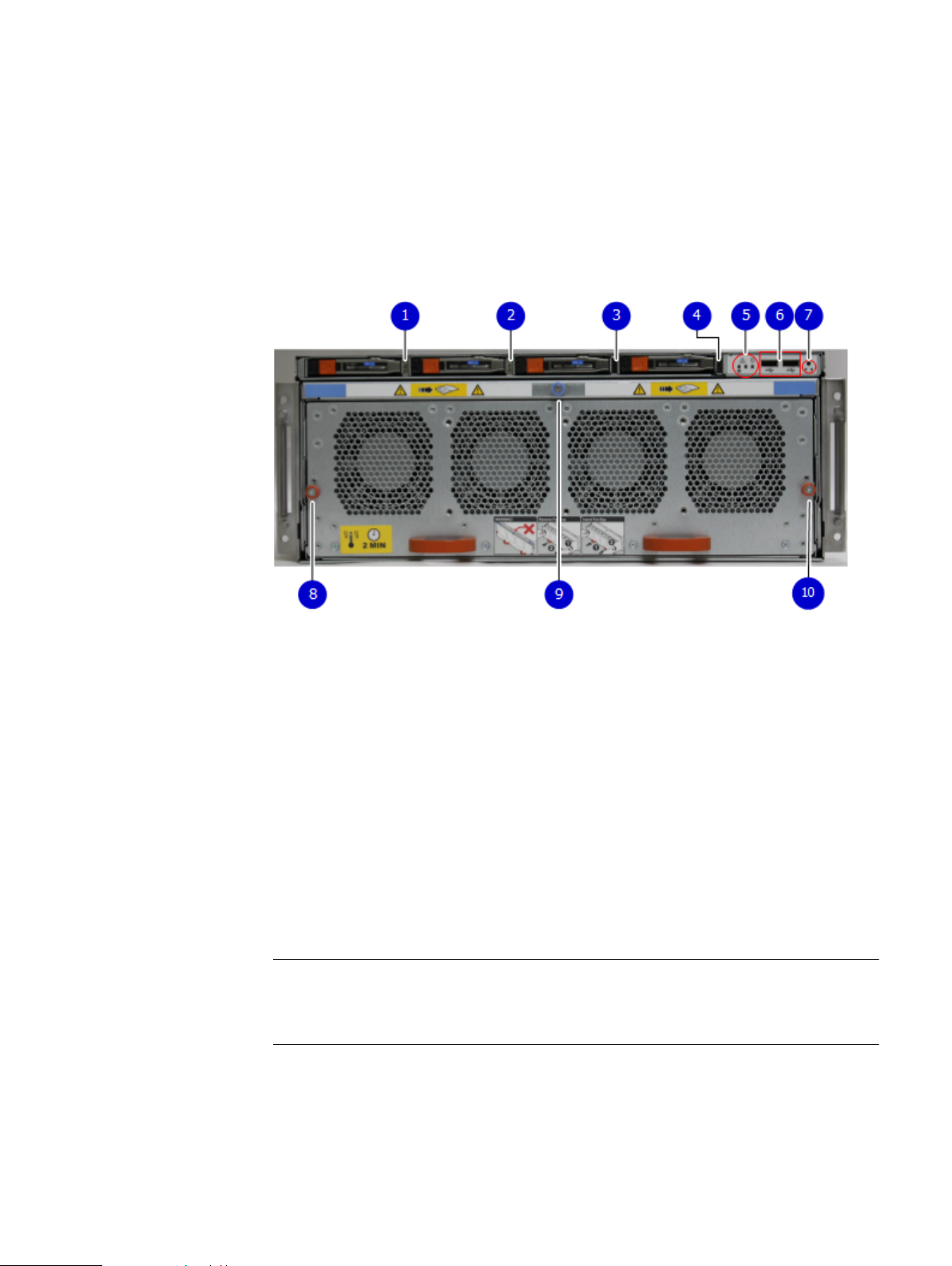

Management module

The following figure shows the location of the DD9500/DD9800 management module

on the rear of the system and identifies the interfaces.

Power supply units 23

Hardware Overview

Figure 10 Management module

1. Left blue thumbscrew to loosen the management module

2. 4 x 1000BaseT Ethernet ports (For details, see the picture - 1000BaseT Ethernet

ports)

3. Service network port (IPMI, 1000BaseT Ethernet port)

4. Service LED

5. VGA port

6. Serial port

7. Four USB ports

8. Right blue thumbscrew to loosen the management module

Rear LED Indicators

Figure 11

1000BaseT Ethernet ports

- Lower left port: physical #0, logical ethMa

- Top left port: physical #1, logical ethMb

- Lower right port: physical #2, logical ethMc

- Top right port: physical #3, logical ethMd

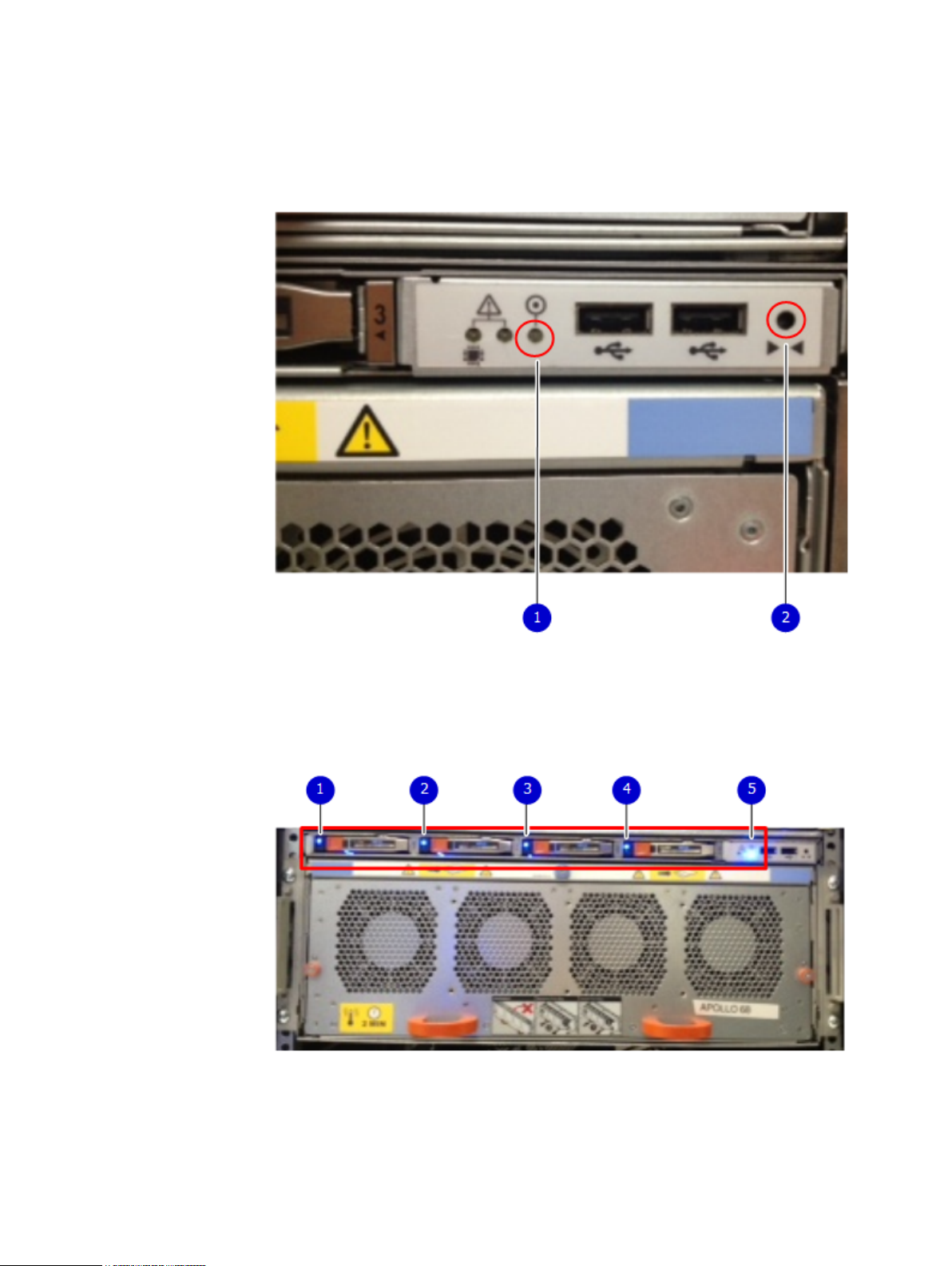

The rear elements containing LEDs include each power supply, each I/O module, and

the management module.

24 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

The figure shows the rear LEDS.

Figure 12 Rear LEDs

1. Management module service LEDs

2. Power supply LEDs

3. NVRAM LEDs

4. IO Module LEDS

Hardware Overview

The power supply LEDs include:

l

AC LED on top

l

DC LED in the middle

l

Service Required LED on the bottom

Figure 13

Table 5 Rear LED status indicators

Power supply LEDs

Part Description or Location State

Power supply AC LED Steady green indicates normal

AC input power.

Rear LED Indicators 25

Hardware Overview

Table 5 Rear LED status indicators (continued)

Part Description or Location State

Power supply DC LED Steady green indicates normal

DC output power.

Power supply Service LED Solid amber indicates a failed

power supply.

I/O module I/O module handle Solid green, I/O module

functioning normally; amber

indicates a fault condition.

Each IO module also has per

port LEDs. These are blue on

the FC, and SAS I/O modules.

They light when the port is

active.

Management module Bicolor LED Solid green, management

module functioning normally;

amber indicates the

management module requires

service.

Available I/O modules

I/O modules may include:

l

l

l

l

l

I/O module port physical mapping

I/O module ports are numbered starting with 0. When the I/O modules are inserted

vertically into the system chassis, port 0 is on the bottom.

I/O module port logical mapping

The numerical port labels on the I/O modules are identified logically in the DD OS

software by the following descriptions:

l

l

l

The following example is based on a four-port Ethernet I/O module installed in slot 1 of

the system chassis.

Quad port Ethernet 10GBase-SR Optical with LC connectors

Quad port Ethernet 10GBase-CX1 Direct Attach Copper with SPF+ module

Quad port Ethernet 10GBase-T Copper

Dual port 16 Gbps Fibre Channel

Quad port 6 Gbps SAS

I/O module type

I/O module slot

Alphabetic character corresponding to the physical port number

Table 6

Physical to logical port mapping example

Physical port Logical identifier

0 eth1a

26 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

Table 6 Physical to logical port mapping example (continued)

Physical port Logical identifier

1 eth1b

2 eth1c

3 eth1d

Ethernet I/O modules

A system can have up to a maximum of four Ethernet I/O modules of any type. The

four Ethernet I/O module limit applies to any combination of the different types of

Ethernet I/O modules. In other words two 10GBaseT and two fiber optic Ethernet I/O

modules are allowed. But three of each is not allowed. The available Ethernet I/O

modules are listed in the Available I/O modules on page 26.

Fibre Channel (FC) I/O modules

An FC I/O module is a dual-port Fibre Channel module. Up to four FC I/O modules

may be installed. The optional virtual tape library (VTL) feature requires at least one

FC I/O module. Boost over Fibre Channel is an optional feature and requires at least

one FC I/O module. A maximum of four FC I/O modules may be installed in a system

using either VTL or the Boost protocol or a combination of both protocols.

Hardware Overview

SAS I/O modules

DD9500/DD9800 systems have three quad-port SAS I/O modules installed in slots 2,

3 and 6. DD9500/DD9800 systems configured with DD Extended Retention (ER) or

DD Cloud Tier software options require an additional SAS I/O module in slot 9.

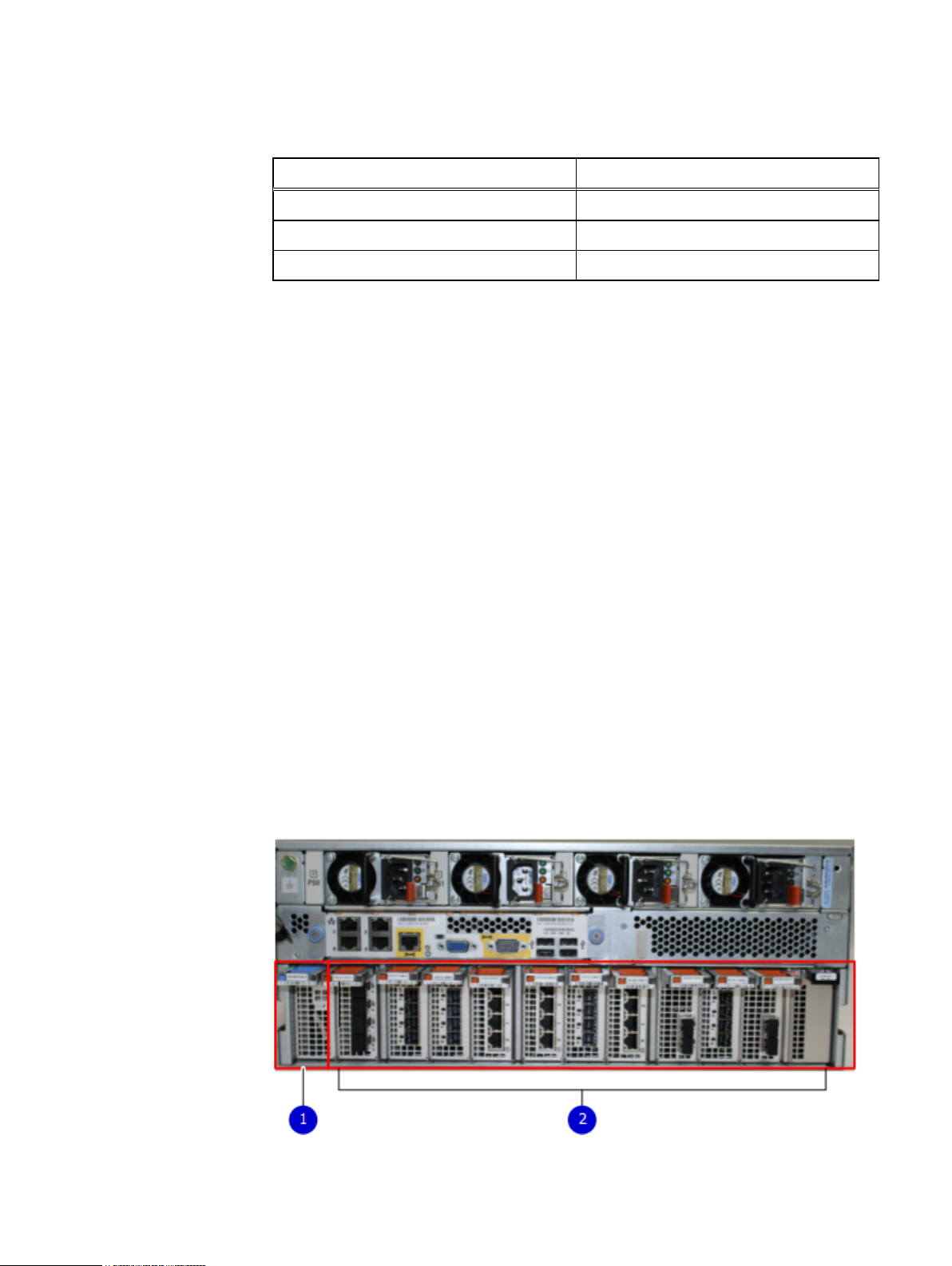

I/O module slot assignments

The following figure shows the location of the NVRAM and I/O modules.

Figure 14

Location of NVRAM and I/O modules

1. NVRAM module—slot 0

Ethernet I/O modules 27

Note

Note

Hardware Overview

Figure 14 Location of NVRAM and I/O modules (continued)

2. I/O modules—slots 1 to 11 (See the I/O module slot assignments table.)

Slots 2, 3, and 6 (three I/O slots) are used for SAS I/O modules for systems without

Extended Retention (ER).

Slots 2, 3, 6, and 9 (four I/O slots) are for SAS I/O modules for systems with ER or

DD Cloud Tier software.

The table shows the I/O module slot assignments for the DD9500 and DD9800

systems. Each type of I/O module is restricted to certain slots.

The I/O module slot assignments for the DD9500 and DD9800 systems are the same.

Table 7 DD9500 and DD9800 I/O module slot assignments

Slot Base

configuratio

HA ER or DD Cloud

Tier

DD Cloud Tier

and HA

n

0 NVRAM NVRAM NVRAM NVRAM

1 Fibre Channel

(FC), Ethernet

or empty

2 SAS SAS SAS SAS

3 SAS SAS SAS SAS

4 FC, Ethernet or

empty

5 FC, Ethernet or

empty

6 SAS SAS SAS SAS

7 FC, Ethernet or

empty

8 FC, Ethernet or

empty

9 Not available

(contains a

filler)

Fibre Channel

(FC), Ethernet

or empty

FC, Ethernet or

empty

FC, Ethernet or

empty

FC, Ethernet or

empty

FC, Ethernet or

empty

Not available

(contains a

filler)

Fibre Channel (FC),

Ethernet or empty

FC, Ethernet or

empty

FC, Ethernet or

empty

FC, Ethernet or

empty

FC, Ethernet or

empty

SAS SAS

Fibre Channel (FC),

Ethernet or empty

FC, Ethernet or

empty

FC, Ethernet or

empty

FC, Ethernet or

empty

FC, Ethernet or

empty

10 FC, Ethernet or

empty

11 FC, Ethernet or

empty

28 Data Domain DD9500 and DD9800 Systems 6.1 Hardware Overview and Installation Guide

FC, Ethernet or

empty

10 Gb optical

Ethernet for

interconnect

between the

FC, Ethernet or

empty

FC, Ethernet or

empty

FC, Ethernet or

empty

10 Gb optical

Ethernet for

interconnect

between the

Loading...

Loading...