Page 1

Dell™ PowerEdge™ 1955 Systems

Hardware Owners Manual

www.dell.com | support.dell.com

Page 2

Notes, Notices, and Cautions

NOTE: A NOTE indicates important information that helps you make better use of your computer.

NOTICE: A NOTICE indicates either potential damage to hardware or loss of data and tells you how to avoid the

problem.

CAUTION: A CAUTION indicates a potential for property damage, personal injury, or death.

____________________

Information in this document is subject to change without notice.

© 2006 Dell Inc. All rights reserved.

Reproduction in any manner whatsoever without the written permission of Dell Inc. is strictly forbidden.

Trademarks used in this text: Dell, the DELL logo, Inspiron, Dell Precision, Dimension, OptiPlex, Latitude, PowerEdge, PowerVault,

PowerApp, and Dell OpenManage are trademarks of Dell Inc.; Intel, Pentium, Xeon, and Celer on are registered trademarks of Intel Corporation;

Microsoft and Windows are registered trademarks of Microsoft Corporation.

Other trademarks and trade names may be used in this document to refer to either the entities claiming the marks and names or their products.

Dell Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

January 2006

Page 3

Contents

1 About Your System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Other Information You May Need . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Overview

System Status Features

Server Module Features

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Using USB Diskette or USB CD Drives

Hard-Drive Features

Back-Panel Features

Power Supply Indicator

Fan Module Indicators

KVM Modules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Avocent Analog KVM Switch Module

Avocent Digital Access KVM Switch Module

DRAC/MC Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Important I/O Configuration Considerations

DRAC/MC Firmware Requirements

I/O Connectivity

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Guidelines for Installing Connectivity Modules

PowerConnect 5316M Ethernet Switch Module

Fibre Channel Pass-Through Module

Fibre Channel Switch Module

Infiniband Pass-through Module

. . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . 32

Gb Ethernet Pass-through Module

. . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . 33

Server Module Messages

Warning Messages

Diagnostics Messages

Alert Messages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Contents 3

Page 4

2 Using the System Setup Program . . . . . . . . . . . . . . . . . . 43

Entering the System Setup Program . . . . . . . . . . . . . . . . . . . . . . . 43

Responding to Error Messages

Using the System Setup Program

. . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . 44

System Setup Options

Main Screen

Memory Information Screen

CPU Information Screen

Integrated Devices Screen

Serial Communication Screen

System Security Screen

Exit Screen

System and Setup Password Features

Using the System Password

Using the Setup Password

Disabling a Forgotten Password

Acquiring the asset.com Utility

Baseboard Management Controller Configuration

Entering the BMC Setup Module

BMC Setup Module Options

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . 49

. . . . . . . . . . . . . . . . . . . . . . . . . . 49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . 55

3 Installing System Options . . . . . . . . . . . . . . . . . . . . . . . . 57

Power Supply Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

System Power Guidelines

Removing a Power Supply Module

Installing a Power Supply Module

. . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . 59

4 Contents

Fan Modules

DRAC/MC Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Removing a Fan

Installing a Fan

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Removing a DRAC/MC Module

Installing a DRAC/MC Module

. . . . . . . . . . . . . . . . . . . . . . . 62

Important I/O Configuration Considerations

DRAC/MC Firmware Requirements

. . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . 62

. . . . . . . . . . . . . . . . . . . . . 63

Page 5

KVM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing a KVM Module

Installing a KVM Module

. . . . . . . . . . . . . . . . . . . . . . . . . . 63

. . . . . . . . . . . . . . . . . . . . . . . . . . 63

Tiering an Avocent Analog KVM Switch or Avocent Digital

Access KVM Switch From a Analog KVM Switch

Tiering an Avocent Analog KVM Switch From a Dell Console Switch

. . . . . . . . . . . . . 65

. . . 68

Tiering an Avocent Digital Access KVM Switch From a Dell

Console Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Chassis I/O Module

I/O Module Placements

Installing an I/O Module

Server Modules

Removing a Server Module

Installing a Server Module

Opening the Server Module

Closing the Server Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . 72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . 76

Removing and Installing Server Module Components

Memory

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

General Memory Module Installation Guidelines

Memory Sparing

Memory Mirroring

Sample Memory Configurations

I/O Module Daughter Card

Activating the Integrated NIC TOE

Processors

Server Module Battery

Hard Drives

Removing a Hard Drive

Configuring the Boot Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . . . . . . . . 80

. . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . 84

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

. . . . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . 91

Removing a Hard Drive From a Hard-Drive Carrier

Installing a Hard Drive Into a Drive Carrier

. . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . 77

. . . . . . . . . . . . . 78

. . . . . . . . . . . . . 91

Back-Panel Module Cage Assembly (Service-Only Procedure)

Removing the Back-Panel Module Cage Assembly

Installing the Back-Panel Module Cage Assembly

Chassis Control Panel Assembly (Service-Only Procedure)

Removing the Chassis Control Panel

Installing the Chassis Control Panel

. . . . . . . . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . 92

. . . . . . . . . . . . . 93

. . . . . . . . . . 94

. . . . . . . . 92

Contents 5

Page 6

Server Module Control Panel Assembly (Service-Only Procedure) . . . . . . 96

Removing the Server Module Control Panel

Installing the Server Module Control Panel

. . . . . . . . . . . . . . . . 96

. . . . . . . . . . . . . . . . 97

System Board (Service-Only Procedure)

Removing the System Board

Installing the System Board

. . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . 99

4 Troubleshooting Your System . . . . . . . . . . . . . . . . . . . . 101

Safety First—For You and Your System . . . . . . . . . . . . . . . . . . . . 101

Start-Up Routine

Checking the Equipment

Troubleshooting External Connections

Troubleshooting the Video Subsystem

Troubleshooting the Keyboard

Troubleshooting the Mouse

Troubleshooting USB Devices

Responding to a Systems Management Alert Message

Troubleshooting a Wet System

Troubleshooting a Damaged System

Troubleshooting System Components

Troubleshooting Power Supply Modules

Troubleshooting Fan Modules

Troubleshooting the DRAC/MC Module

Troubleshooting a Network Switch Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . 104

. . . . . . . . . . . . . . . . . . . . . . 105

. . . . . . . . . . . . 105

. . . . . . . . . . . . . . . . . . . . . . . . . 106

. . . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . 110

6 Contents

Troubleshooting Server Module Components

Inside the Server Module

. . . . . . . . . . . . . . . . . . . . . . . . . 111

Troubleshooting Server Module Memory

Troubleshooting Hard Drives

Troubleshooting Microprocessors

. . . . . . . . . . . . . . . . . . . . . . . 113

. . . . . . . . . . . . . . . . . . . . 114

Troubleshooting the Server Module Board

Troubleshooting the Server Module Battery

. . . . . . . . . . . . . . . . . 110

. . . . . . . . . . . . . . . . 112

. . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . 115

Page 7

5 Running System Diagnostics. . . . . . . . . . . . . . . . . . . . . 117

Using Server Administrator Diagnostics . . . . . . . . . . . . . . . . . . . 117

System Diagnostics Features

When to Use the System Diagnostics

Running the System Diagnostics

From the Utility Partition

From a USB Flash Drive

System Diagnostics Testing Options

Using the Advanced Testing Options

Error Messages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

. . . . . . . . . . . . . . . . . . . . . . . . . 117

. . . . . . . . . . . . . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . 119

. . . . . . . . . . . . . . . . . . . . . 119

6 DIP Switch Settings and Connectors . . . . . . . . . . . . . . . 121

DIP Switch Settings—A General Explanation . . . . . . . . . . . . . . . . 121

DIP Switches

Server Module Board DIP Switch

Server Module Board Connectors

Disabling a Forgotten Password

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

. . . . . . . . . . . . . . . . . . . . . . . 122

. . . . . . . . . . . . . . . . . . . . . . . 123

. . . . . . . . . . . . . . . . . . . . . . . . 126

7 Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Online Services

AutoTech Service

Automated Order-Status Service

Technical Support Service

Dell Enterprise Training and Certification

Problems With Your Order

Product Information

Returning Items for Warranty Repair or Credit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

. . . . . . . . . . . . . . . . . . . . . 128

. . . . . . . . . . . . . . . . . . . . . . . . 128

. . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . 129

Contents 7

Page 8

Before You Call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Contacting Dell

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Index

8 Contents

Page 9

About Your System

Other Information You May Need

CAUTION: The Product Information Guide provides important safety and regulatory information. Warranty

information may be included within this document or as a separate document.

• The

• The

• The

• The

• The Dell Remote Access Controller/Modular Chassis User’s Guide provides detailed information

• CDs included with your system provide documentation and tools for configuring and managing

• Systems management software documentation describes the features, requirements, installation,

• Operating system documentation describes how to install (if necessary), configure, and use the

• Documentation for any components you purchased separately provides information to configure

• Updates are sometimes included with the system to describe changes to the system, software,

Rack Installation Guide

describes how to install your system into a rack.

Getting Started Guide

technical specifications.

Configuration Guide

other modular components in your system

Dell OpenManage Baseboard Management Controller User’s Guide

information on using the Baseboard Management Controller (BMC).

on using the remote management features of the system.

your system.

and basic operation of the software.

operating system software.

and install these options.

and/or documentation.

or

Rack Installation Instructions

provides an overview of system features, setting up your system, and

provides information

on initial configuration of the server modules and

.

included with your rack solution

provides detailed

NOTE: Always check for updates on support.dell.com and read the updates first because they often

supersede information in other documents.

• Release notes or readme files may be included to provide last-minute updates to the system or

documentation or advanced technical reference material intended for experienced users or

technicians.

About Your System 9

Page 10

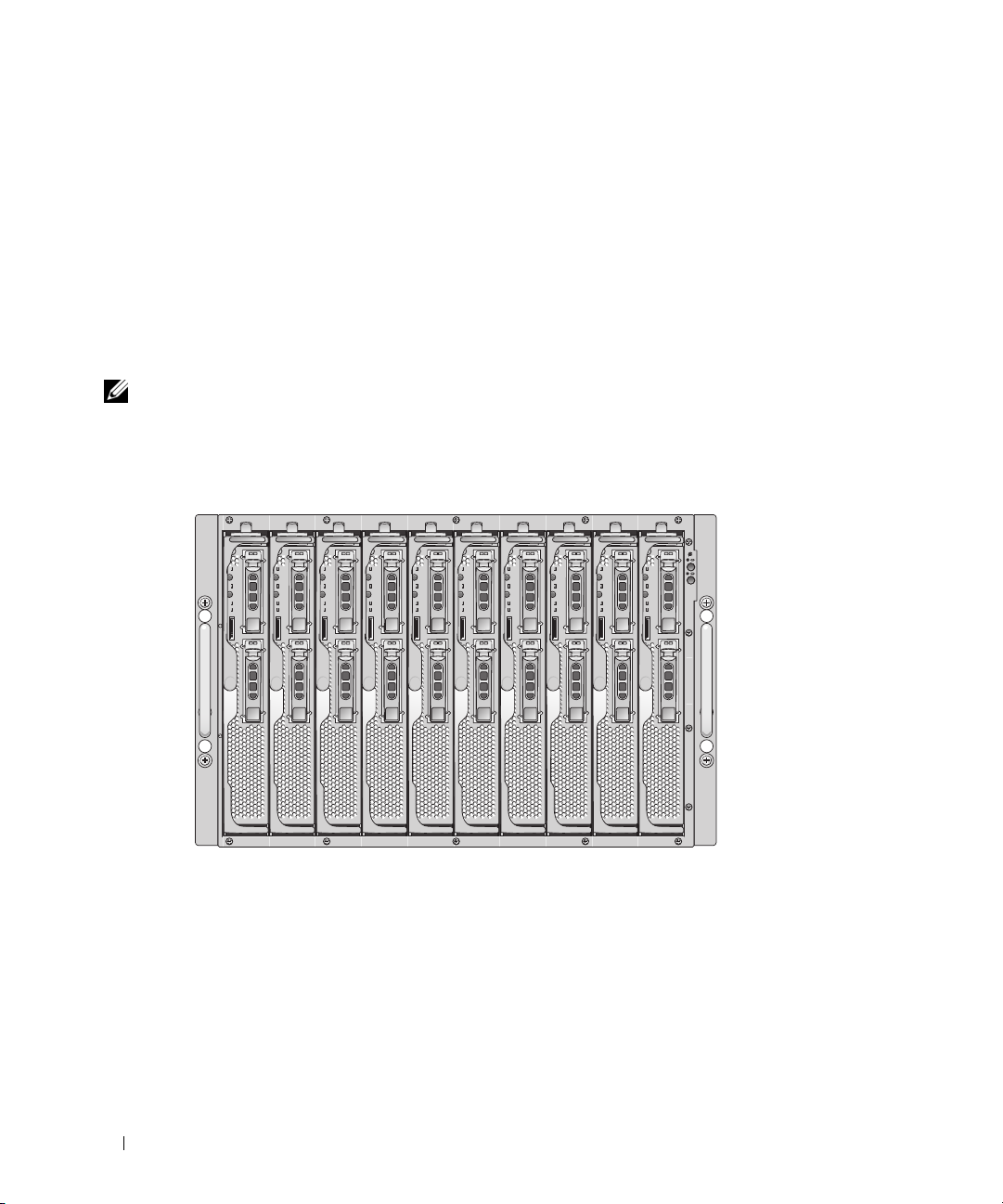

System Overview

Your system can include up to ten server modules (or blades) (see Figure 1-1). Each server module

functions as an individual server encompassing up to two microprocessors, up to two hot-pluggable hard

drives, and up to eight memory modules. To function as a system, a server module is inserted into a

chassis that supports power supplies, fan modules, a management module (Dell

Controller/Modular Chassis [DRAC/MC]), a KVM switch module, and at least one I/O module for

network connectivity. The power supplies, fans, DRAC/MC, and I/O modules are shared resources of the

server modules in the chassis. In addition, your system may also ship with an optional external USB

diskette drive and an optional external USB CD drive, which you can use to set up and configure the

server modules.

NOTE: To ensure proper operation and cooling, all bays must be populated at all times with either a server module

or with a blank.

Figure 1-1. Server Modules

12345678910

™

Remote Access

This section describes the major hardware and software features of your system and provides information

about the indicators on the system's front and back panels. It also provides information about other

documents you may need when setting up your system and how to obtain technical assistance.

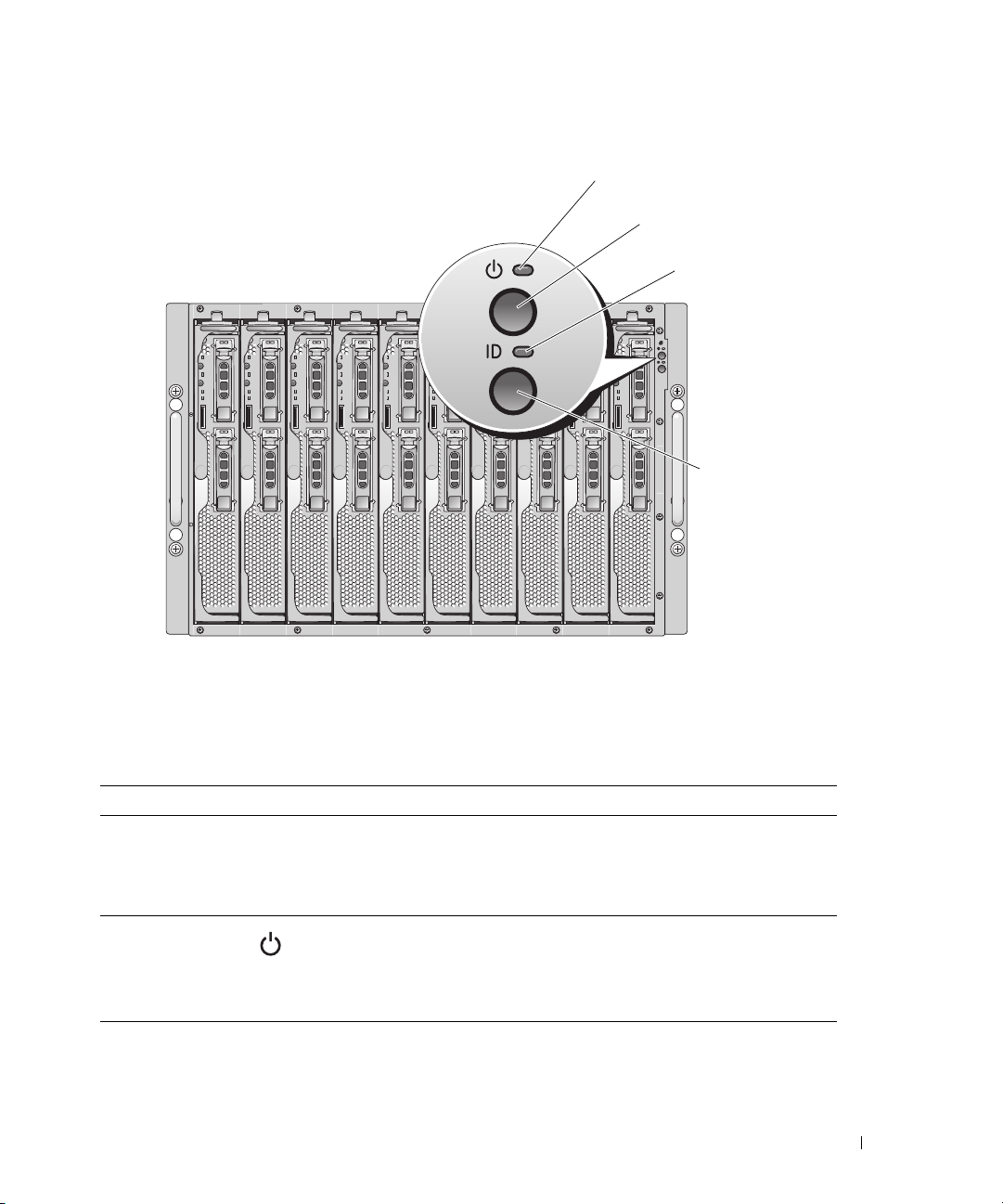

System Status Features

The chassis has front-panel control features including power and identification buttons and indicators

(see Figure 1-2). Press the power button to turn on the system; press and hold the power button to turn

off the system. Pressing the identification button activates the identification indicator on both the front

and back (on the KVM module) of the system. Table 1-1 shows the status features.

10 About Your System

Page 11

Figure 1-2. Front-Panel Control and Indicators

1

2

3

4

1 system power indicator 2 system power button 3 identification indicator

4 identification button

Table 1-1. System Status Features

Indicator Type Icon Indicator Indicator Code

System power

button

N/A None Turns the system on and off. Press to turn on the system.

Press and hold 10 seconds to turn off the system.

NOTE: The system power button controls power to all of the

server modules and I/O modules in the chassis.

System power

indicator

Identification

button

N/A None Turns on the identification indicators on both the front and

Off System does not have power.

Green System power is on.

Amber System is plugged in but is not turned on.

back (on the KVM switch module) of the chassis.

About Your System 11

Page 12

Table 1-1. System Status Features (continued)

Indicator Type Icon Indicator Indicator Code

Identification

indicator

Off Chassis is not being identified. This is the default.

Amber, slow

blinking

Amber, fast

blinking

Chassis is being identified. Either the front or back

identification button has been pressed. This indicator can

be turned off by pressing the identification button.

System error. Will stop blinking when the error is resolved.

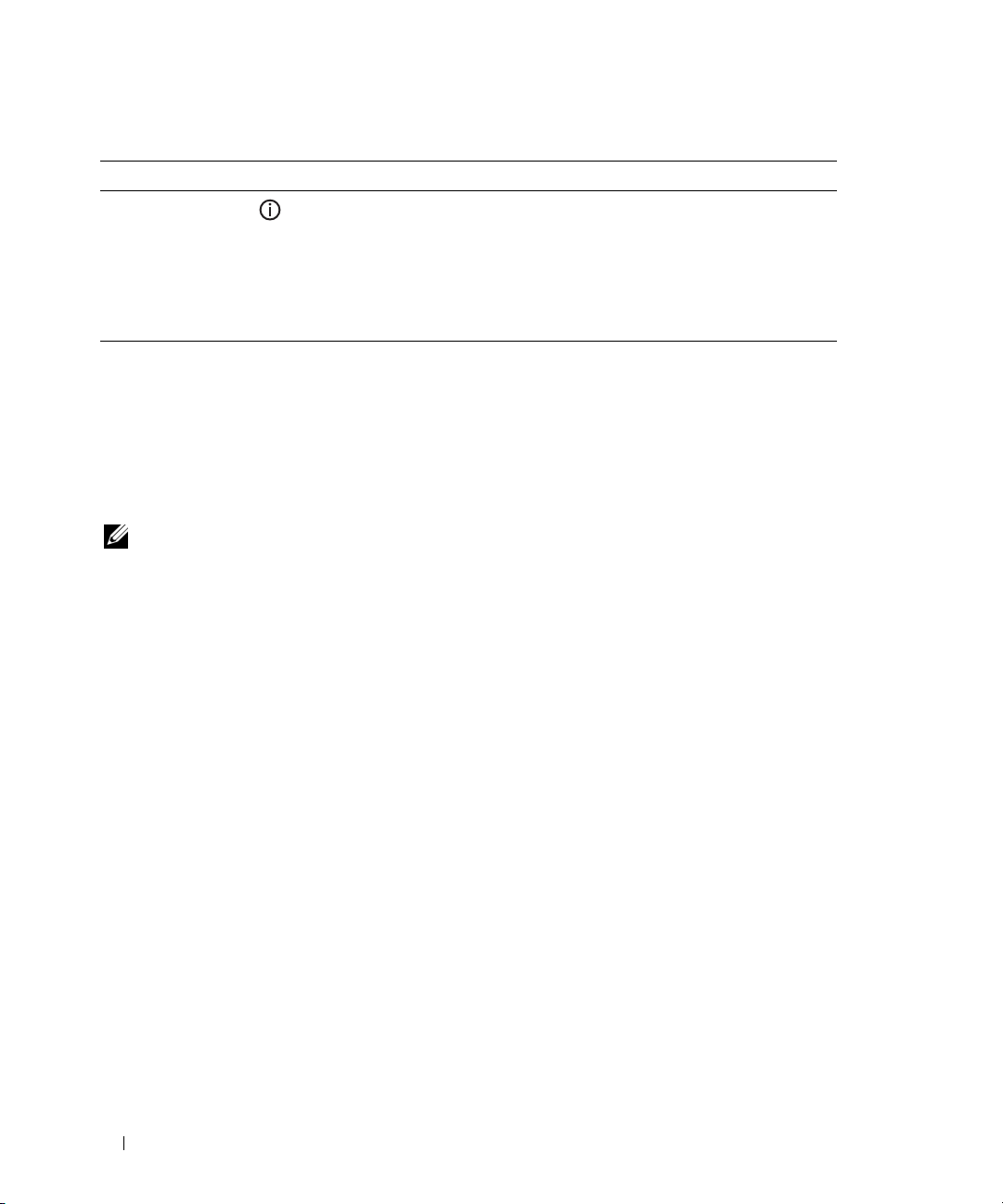

Server Module Features

Each server module has one power button and one KVM module selection button on the front (see

Figure 1-3). The indicators include a power indicator, network link indicators, and a KVM module

indicator. The server module also has a custom port on the front of the module. Use the custom cable

included with your system to connect this port to two USB devices (for example, USB diskette drive,

USB CD drive, USB mouse) and to video.

NOTE: The USB devices can only be connected by using the custom cable supplied with the system.

12 About Your System

Page 13

Figure 1-3. Server Module Indicators

1

2

3

4

5

6

7

1 server module power indicator 2 server module power button 3 KVM selection indicator

4 KVM selection button 5 daughter card status indicator 6 Ethernet network indicator

7 custom port (with custom

cable - USB [2] and video)

About Your System 13

Page 14

Table 1-2 provides information about the status indicators.

Table 1-2. Server Module Features and Indicators

Indicator Icon Activity Indicator Indicator Code

Server module

power indicator

Server module

power button

N/A None Turns server module power off and on.

Off Power is not available to the server module, the server

module is not turned on, or the server module is installed

incorrectly. For detailed information on installing a server

module, see "Server Modules" on page 73.

Green The module is turned on.

Green blinking fast The module power is on and there is a fault with the server

module.

Green blinking slowly The module power is on and the server module is being

remotely identified via the DRAC/MC.

Amber The module power is off, but the system power is on.

Amber blinking slowly The module power is off and the server module is being

remotely identified via the DRAC/MC.

Amber blinking fast The module power is off and there is a fault with the server

module.

• If you turn off the module using the power button and

the module is running an ACPI-compliant operating

system, the module can perform an orderly shutdown

before the power is turned off.

• If the module is not running an ACPI-compliant

operating system, power is turned off immediately after

the power button is pressed.

• Press and hold the button to turn off the server module

immediately.

The button is enabled in the System Setup program. When

disabled, you can only use the button to turn on the server

module.

14 About Your System

Page 15

Table 1-2. Server Module Features and Indicators (continued)

Indicator Icon Activity Indicator Indicator Code

KVM selection

indicator

KVM selection

button

Daughter card

status indicator

(Infiniband card

installed)

Daughter card

status indicator

(Fibre channel

daughter card

installed)

Daughter card

status indicator

(Gb Ethernet

daughter card

installed)

Daughter card

status indicator

(TOE NIC

daughter card

installed)

N/A None Selects the server module for use with the KVM located on

I/O Off Daughter card is not installed.

I/O Off Daughter card is not installed.

I/O Off Daughter card is not installed.

I/O Off Daughter card is not installed.

Off The server module is not selected by the KVM.

Green The server module is selected for the KVM.

Amber blinking The server module is not selected by the KVM and a power

fault exists.

Green/amber blinking The server module is selected for the KVM and a power fault

exists.

the back of the system. See "Avocent Analog KVM Switch

Module" on page 22 for information on selecting a server

module by using the keyboard.

Green Infiniband daughter card is installed, but no traffic is

detected.

Green blinking Infiniband daughter card is present and data transfers are

occurring.

Green A link exists.

Green blinking Fibre channel daughter-card data transfers are occurring.

Green A link exists.

Green blinking Gb Ethernet daughter-card data transfers are occurring.

Green A link exists.

Green blinking TOE NIC daughter card is installed and data transfers are

occurring.

About Your System 15

Page 16

Table 1-2. Server Module Features and Indicators (continued)

Indicator Icon Activity Indicator Indicator Code

Network indicators Off Indicates that the server module does not have a link to the

Ethernet switch or pass-through module.

Green on Indicates that the server module has a valid link to the

network switch module.

Green blinking Indicates network activity between the server module and

the network switch module.

NOTE: External network activity is not reported by this

indicator.

NOTE: This network indicator may also blink green due to

systems management activity if you use the integrated NIC to

remotely access your system’s Baseboard Management

Controller (BMC). See "Baseboard Management Controller

Configuration" on page 54.

USB/video

connector

None Use the custom cable to connect external USB devices and

video to the server module.

Using USB Diskette or USB CD Drives

Each server module has a USB port on the front of the server module which allows you to connect a

custom cable for a diskette drive or USB CD drive. The USB drives are used to configure the server

module.

NOTICE: The system supports only Dell-branded USB 1.1 or USB 2.0 drives. The drive must be horizontal and level

to operate properly.

NOTE: If the drive must be designated as the boot drive, connect the USB drive, restart the system, then enter the

System Setup Program and set the drive as first in the boot sequence (see "Using the System Setup Program" on

page 43). The USB device will be displayed in the boot order setup screen only if it is attached to the system before

you run the System Setup program.

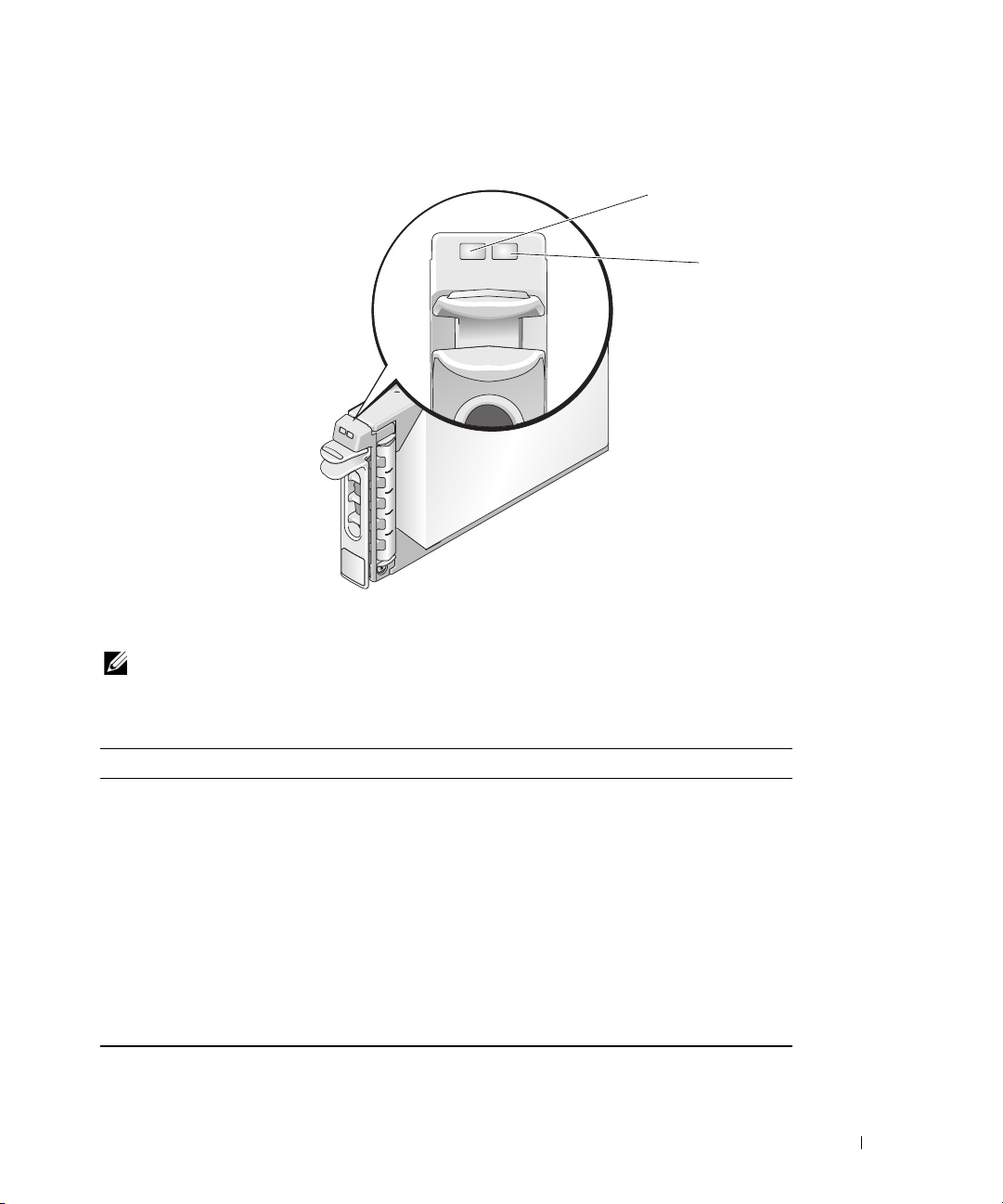

Hard-Drive Features

Each server module supports one or two hot-pluggable SAS hard drives, or one or two hot-pluggable

SATA hard drives. See Figure 1-4 and Table 1-3 for information on the hard-drive indicators. Different

patterns are displayed as drive events occur in the system.

NOTICE: Each server module must have a hard drive or a hard-drive blank installed in each hard-drive bay.

NOTICE: You cannot install a SAS drive and a SATA drive within a given server module (blade). However, you can

install server modules (blades) with SAS drives and server modules with SATA drives in the same server enclosure.

16 About Your System

Page 17

Figure 1-4. Hard-Drive Features and Indicators

1 drive activity indicator 2 drive status indicator

NOTE: The hard-drive status indicator is only functional for RAID hard drive configurations.

For non-RAID configurations, only the drive-activity indicator is active.

1

2

Table 1-3. Hard-Drive Status Indicator Patterns (RAID Configurations Only)

Status Indicator State Indicator Code

Off

Green Drive is online.

Green, blinking slowly Drive is rebuilding.

Green, blinking quickly Drive is being identified.

Amber Drive has failed or has an error. See "Troubleshooting Hard

Amber blinking slowly,

green blinking slowly, then off

• Drive is ready for removal.

• Drive bay is empty.

• Power is off to the server module.

Drives" on page 113.

The drive has reported a predictive failure event, and should

be replaced.

About Your System 17

Page 18

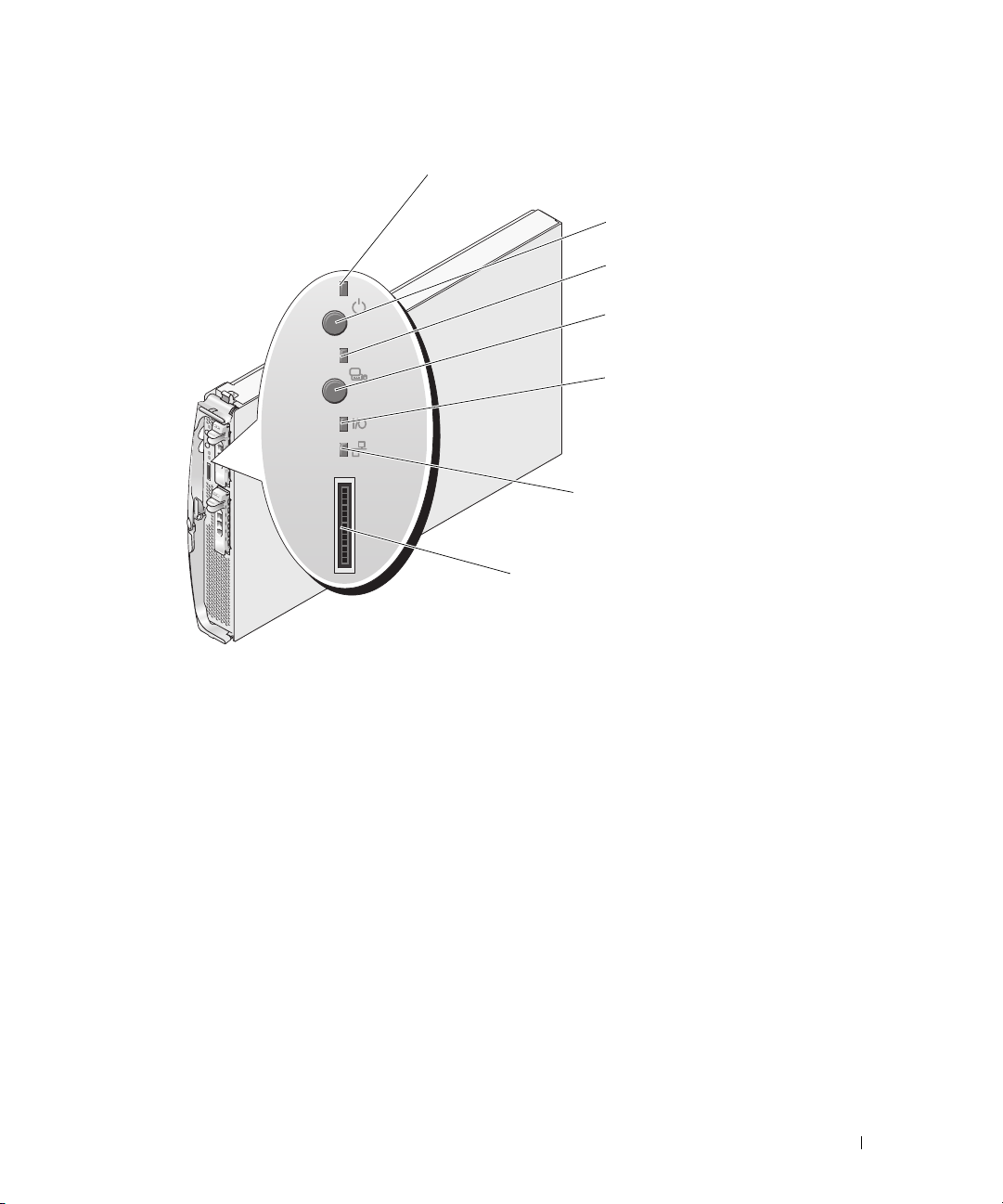

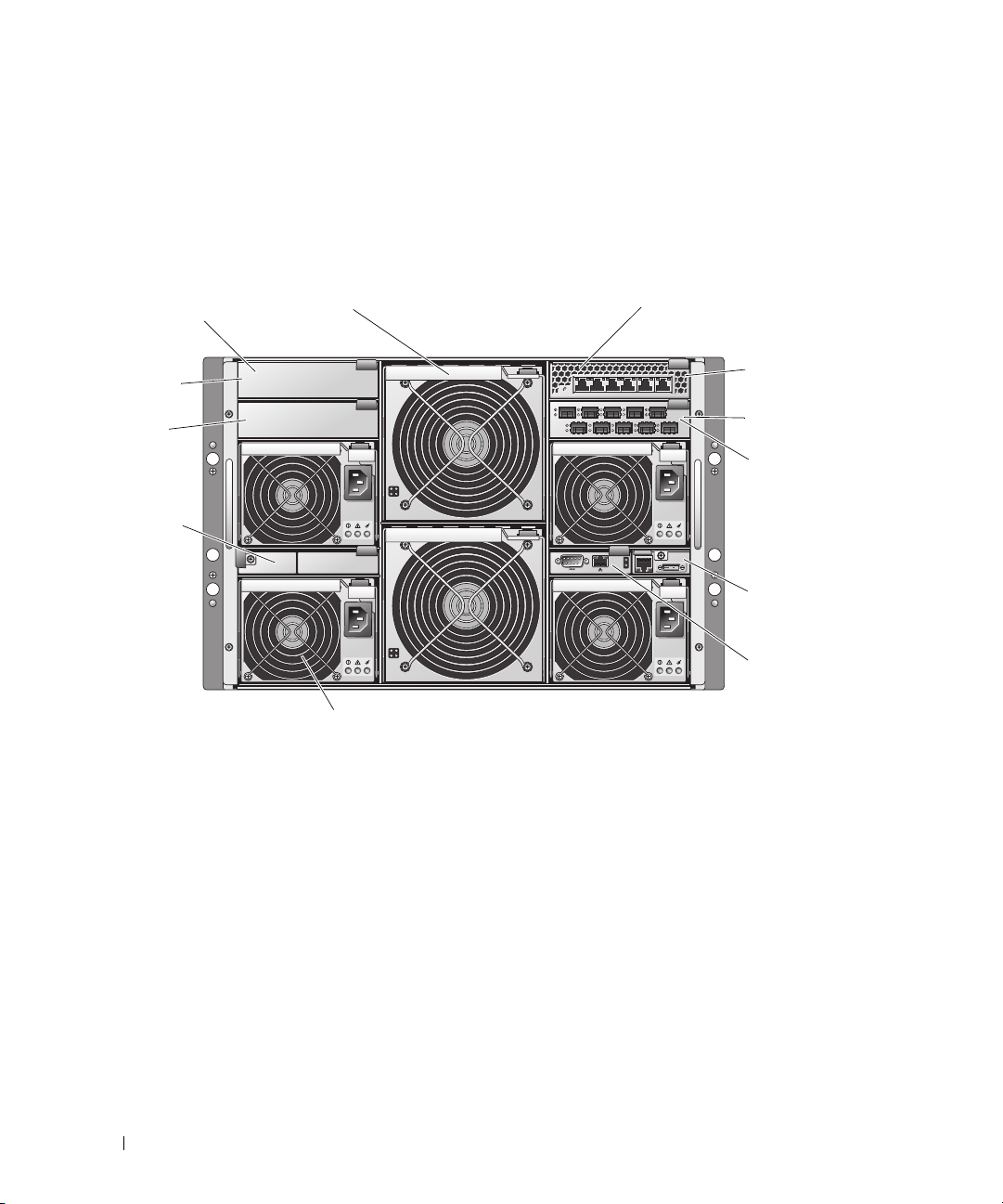

Back-Panel Features

The back of the chassis supports four I/O module bays, the DRAC/MC, fan modules, and power supply

modules. Figure 1-5 shows a sample configuration and the numbering for the bays. Table 1-4 provides

information about the back-panel features.

Figure 1-5. Back-Panel Features

1

12

11

10

1 I/O bay 2 2 fan modules (2) 3 PowerConnect 5316M

4 I/O bay 1 5 Fibre Channel pass-through

7 KVM module 8 DRAC/MC module 9 power supply modules (4)

10 blanks (2) 11 I/O bay 4 12 blanks (2)

2

9

module

3

34

12

Ethernet switch module

6 I/O bay 3

4

5

6

7

8

18 About Your System

Page 19

Table 1-4. Back-Panel Features and Indicators

Component Indicator Description

Power supply modules Provide information about power status (see "Power Supply Indicator Codes" on

page 20).

Fan modules Provide information about status of the system fans (see "Fan Module Indicators"

on page 21).

KVM module Provides information about the KVM module (see "KVM Modules" on page 22).

DRAC/MC module Provides information about system status, system management status, and port

status (see "DRAC/MC Module" on page 26).

PowerConnect™ 5316M

Ethernet switch module

Fibre Channel pass-through

module

Fibre Channel switch module Provides information about the Fibre Channel network status (see "Fibre

Infiniband pass-through

module

Gb pass-through module Provides information about the network status (see "Gb Ethernet Pass-through

Provides information about the 10/100/1000 BASE-T network status (see

"PowerConnect 5316M Ethernet Switch Module" on page 29).

Provides information about the Fibre Channel network status (see "Fibre

Channel Pass-Through Module" on page 31).

Channel Switch Module" on page 32).

Provides information about the Infiniband network status (see "Infiniband Passthrough Module" on page 32).

Module" on page 33).

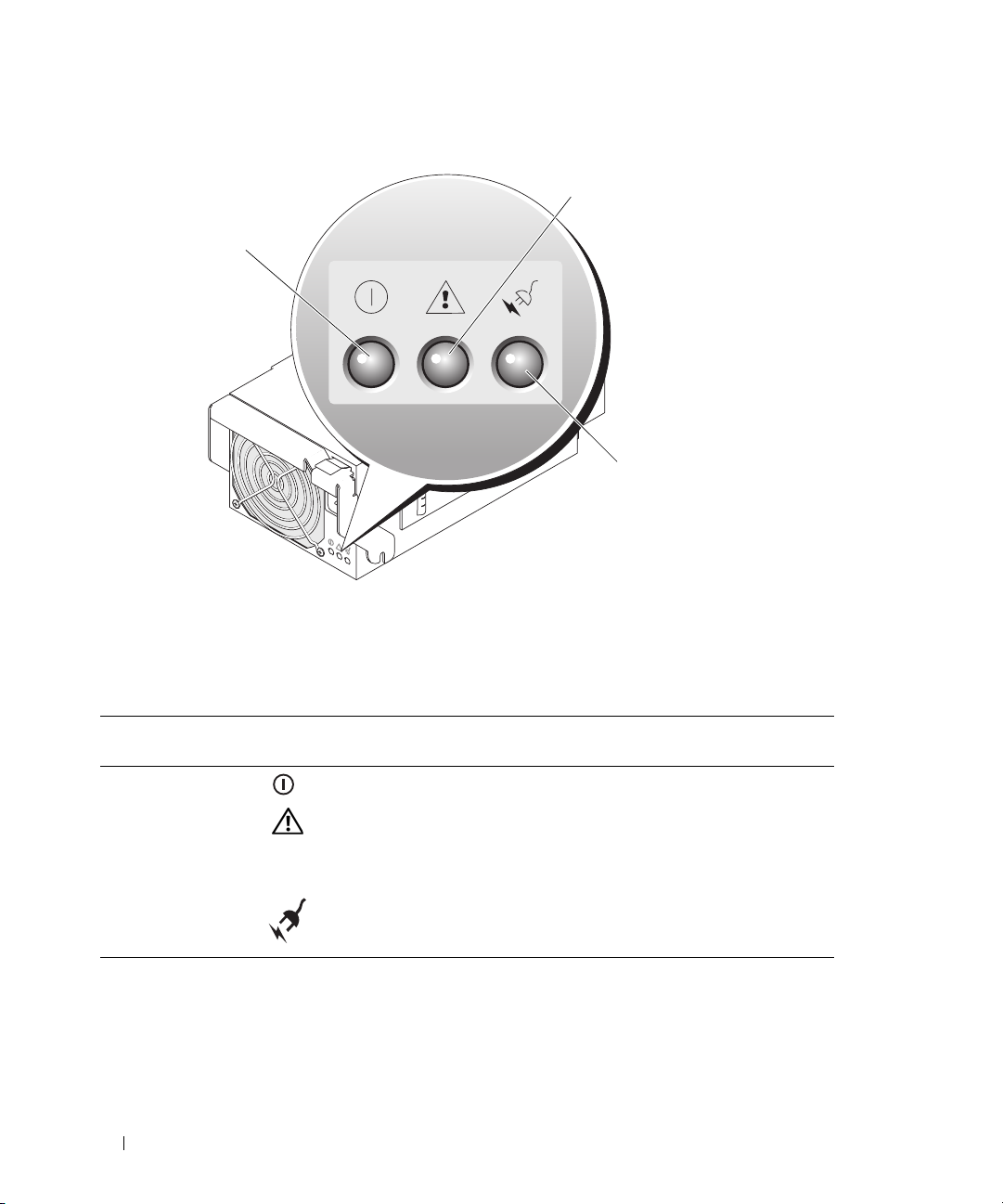

Power Supply Indicator

Each hot-pluggable power supply has indicators that provide information about power status, fault, and

the presence of AC power (see Figure 1-6). Table 1-5 lists the power supply indicator codes.

NOTE: Only 2100-W power supply modules are supported on your system. The 2100-W power supply modules

require 180–240 V input from a PDU capable of providing AC current up to 29.2 A at 180 V input. If the power supply

modules are plugged into 110-V electrical outlets, the system will not power up.

About Your System 19

Page 20

Figure 1-6. Power Supply Indicators

1

3

2

1 fault indicator 2 AC power present indicator 3 DC power indicator

Table 1-5. Power Supply Indicator Codes

Indicator Icon Activity

Indicator

DC power indicator Green The power supply is operational.

Fault indicator Amber The power supply is in a fault condition. The fault

AC power present

indicator

Green AC power is present at the power supply and the system

Indicator Code

condition can result from either a failed power supply

or a failed fan within the power supply. See "Power

Supply Modules" on page 58.

is connected to an AC power source.

20 About Your System

Page 21

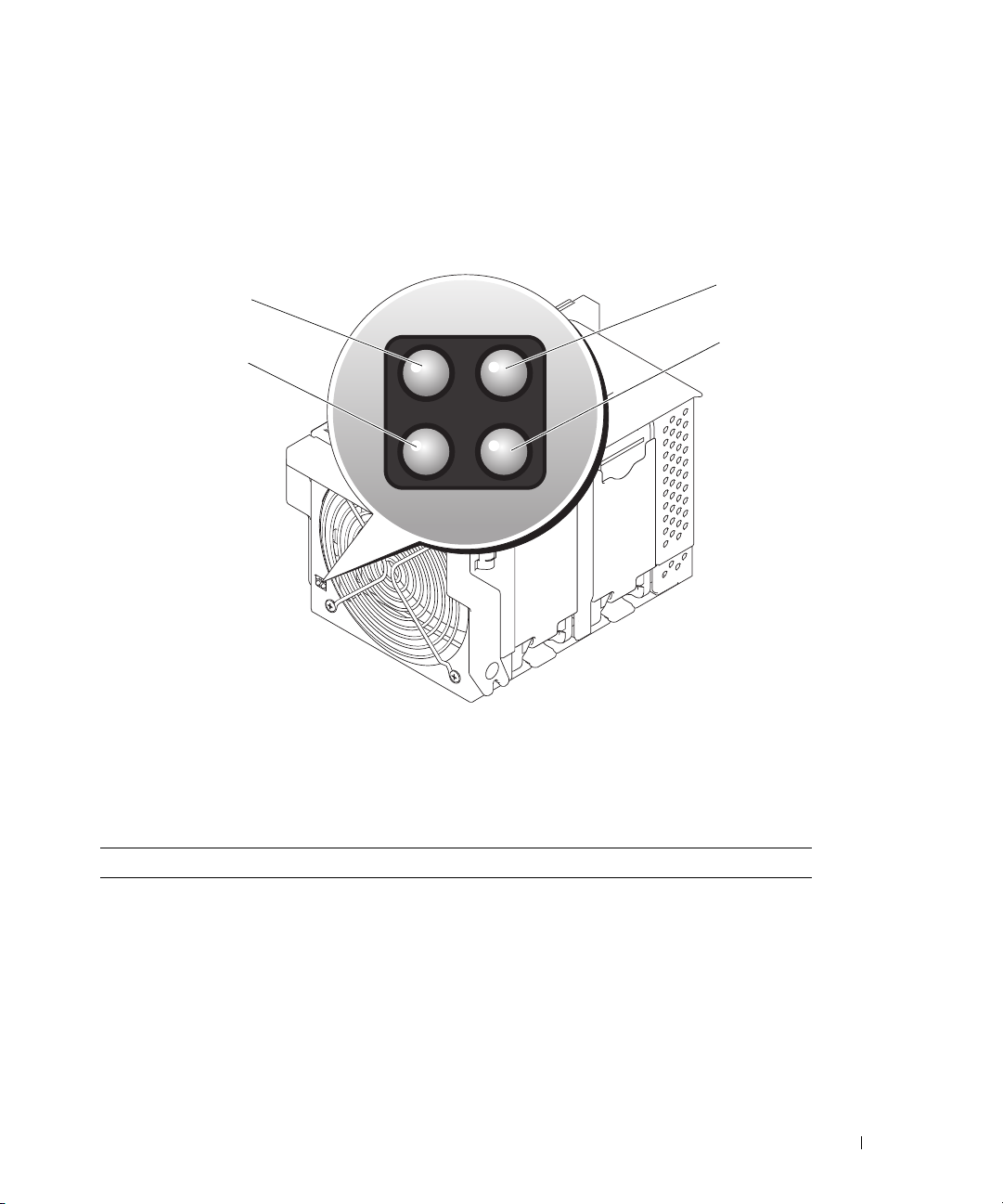

Fan Module Indicators

Each hot-pluggable fan module contains two redundant fans (see Figure 1-7). Table 1-6 lists the fan

indicator codes.

Figure 1-7. Fan Module Indicators

1

4

1 fan 1 fault indicator 2 fan 1 present indicator 3 fan 2 present indicator

4 fan 2 fault indicator

2

3

Table 1-6. Fan Module Indicator Codes

Indicator Activity Indicator Indicator Code

Fan 1 present indicator Off Fan 1 is not installed.

Green Fan 1 is installed.

Fan 1 fault indicator Off Fan 1 is operating normally.

Amber Fan 1 has failed. See "Fan Modules" on page 59.

Fan 2 present indicator Off Fan 2 is not installed.

Green Fan 2 is installed.

About Your System 21

Page 22

Table 1-6. Fan Module Indicator Codes (continued)

Indicator Activity Indicator Indicator Code

Fan 2 fault indicator Off Fan 2 is operating normally.

Amber Fan 2 has failed. See "Fan Modules" on page 59.

KVM Modules

Your system includes one of the KVM modules described in this section:

• Avocent Analog KVM switch module (standard)

• Avocent Digital Access KVM switch module (optional)

NOTE: Earlier versions of KVM modules are not supported on your system.

Avocent Analog KVM Switch Module

The Avocent Analog KVM switch module provides a custom connection for a keyboard, video (monitor),

and mouse to monitor a server module. (You must use the custom cable provided with your system to

connect the KVM to the external devices.)

NOTE: Your system has two custom cables—one that connects to the front of the server module to connect two

USB devices and video, and a second cable that connects to the KVM to provide two PS/2 connections and a video

connection. The cables are not interchangeable. It is recommended that you keep these custom cables available.

The switch module also provides an Analog Console Interface (ACI) port, which allows you to connect a

server module via Cat5 cabling to an external device such as the Dell 2161DS Digital console switch or

Dell 180AS/2160AS analog console switches, without the need for a Server Interface Pod (SIP.)

NOTE: Although the ACI port is an RJ-45 connector and uses Cat5 cabling, it is not an Ethernet network interface

port. It is only used for connection to external KVM switches with Analog Rack Interface (ARI) ports.

NOTE: The ACI port can only be used to connect to ARI ports on Dell console switches. To connect to other types or

brands of switches, including Avocent switches, you must connect to the switch’s PS2 and video ports using the

proprietary dongle provided with that switch.

22 About Your System

Page 23

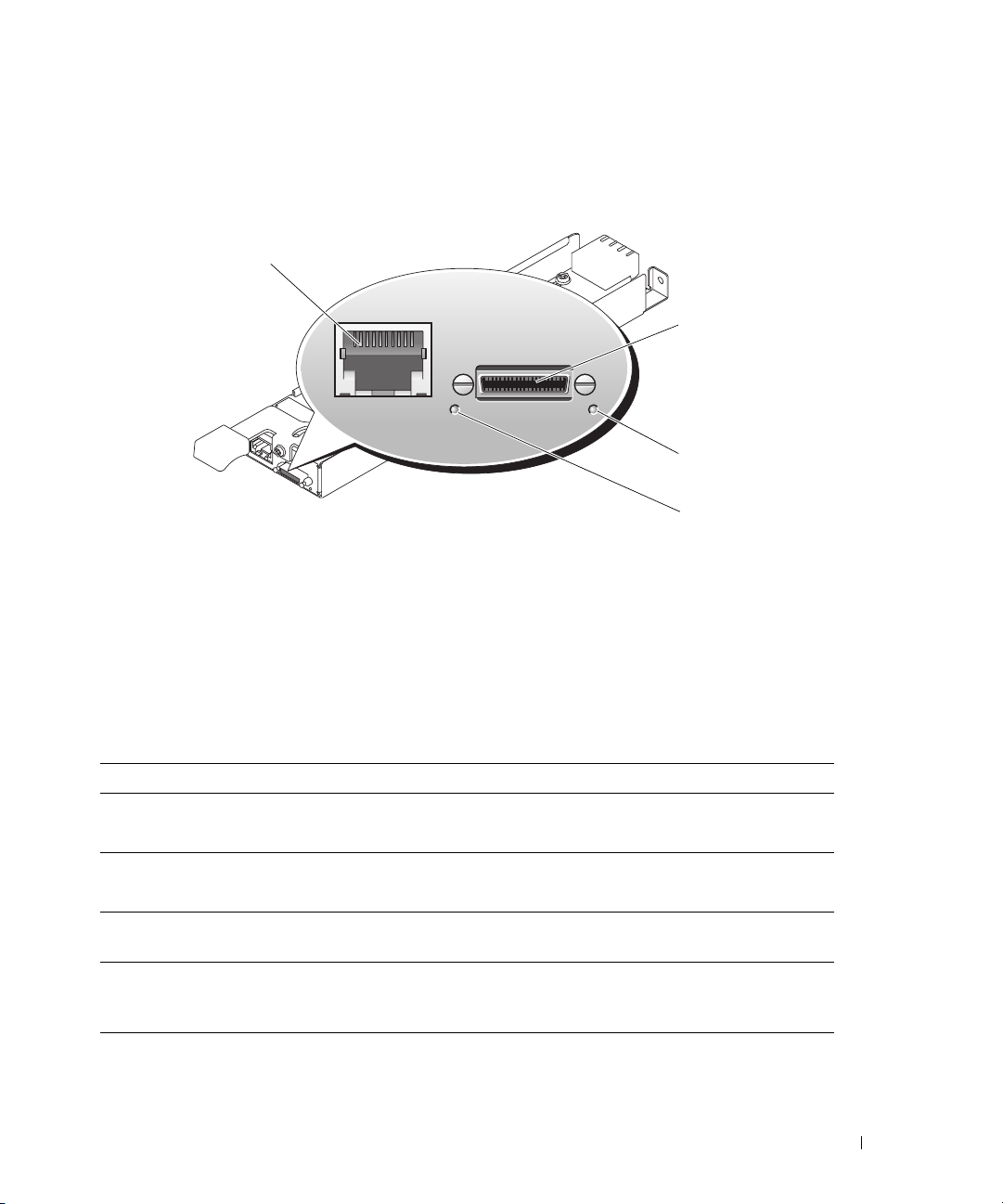

Figure 1-8 shows the external features on the Avocent Analog KVM switch module.

Figure 1-8. Avocent Analog KVM Switch Module

1

2

3

4

1 ACI port 2 custom connector for custom

cable (PS/2 [2] and video)

4 power indicator

3 identification indicator

The Avocent Analog KVM switch module also includes an identification indicator (see Figure 1-8).

Table 1-7 describes the indicators and features on this switch module.

Table 1-7. Avocent Analog KVM Switch Module Indicators and Features

Feature Activity Indicator Indicator Code

Identification

indicator

Power indicator Off KVM switch does not have power.

Custom

connector

ACI port None Allows connection of one or more servers to a Dell console

Off Chassis is not being identified.

Amber blinking Chassis is being identified.

Green KVM switch has power.

None Allows two PS/2 and one video device to be connected to the

system.

switch with an Analog Rack Interface (ARI) port, such as a

digital or analog console switch.

About Your System 23

Page 24

Avocent Digital Access KVM Switch Module

The optional Avocent Digital Access KVM switch module allows you to configure and manage the server

modules through a single keyboard, monitor and mouse. You select server modules using the On-Screen

Configuration and Reporting (OSCAR) graphical user interface (GUI).

The Avocent Digital Access KVM switch module includes the following features:

• Analog KVM switching

This switch can be used as an Analog switch, allowing local KVM switching through direct connection

of a keyboard, monitor and mouse; or tiered into external analog KVM switches. This switch uses the

same OSCAR interface as the Avocent Analog KVM switch to switch between server modules.

The Digital Access KVM switch provides a custom connector which brings out PS2/video ports. These

ports can be directly connected to a keyboard, monitor, and mouse, or tiered into an external analog

KVM switch with KVM ports. If you are connecting the Digital Access KVM switch to an external

KVM switch using Cat5 connectors/ACI ports, that switch’s dongle (PS2/video to Cat5) is required.

NOTE: The Avocent Digital Access KVM module differs from the Avocent Analog KVM module in that the

Digital Access KVM switch module does not have an ACI port; it has an Ethernet network interface.

• Remote control of Virtual Media and virtual KVM

After connecting to your network using the switch’s Ethernet connection, use the system’s DRAC/MC

GUI to select Media and/or console and which server module to connect to.

NOTE: You must connect the switch’s Ethernet port into the same network as the DRAC/MC port.

You can then use the switch’s Virtual Media and virtual KVM features:

– Virtual Media – Using this feature, you can remotely map local drives on a management

workstation to the server module, or boot a server module to a remote diskette, optical drive, or

USB key. For example, you can remotely perform operating system installation, operating system

recovery, BIOS updates, and other functions.

– Virtual KVM – You can remotely control the server modules from any location, using the digital

KVM and an OS-independent graphical console.

24 About Your System

Page 25

Figure 1-9 shows the external features of the Avocent Digital Access KVM switch module.

Figure 1-9. Avocent Digital Access KVM Switch Module

1

2

1 RJ-45 connector (Ethernet

interface)

2 custom connector (for custom

KVM cable - PS/2 [2] and

video)

About Your System 25

Page 26

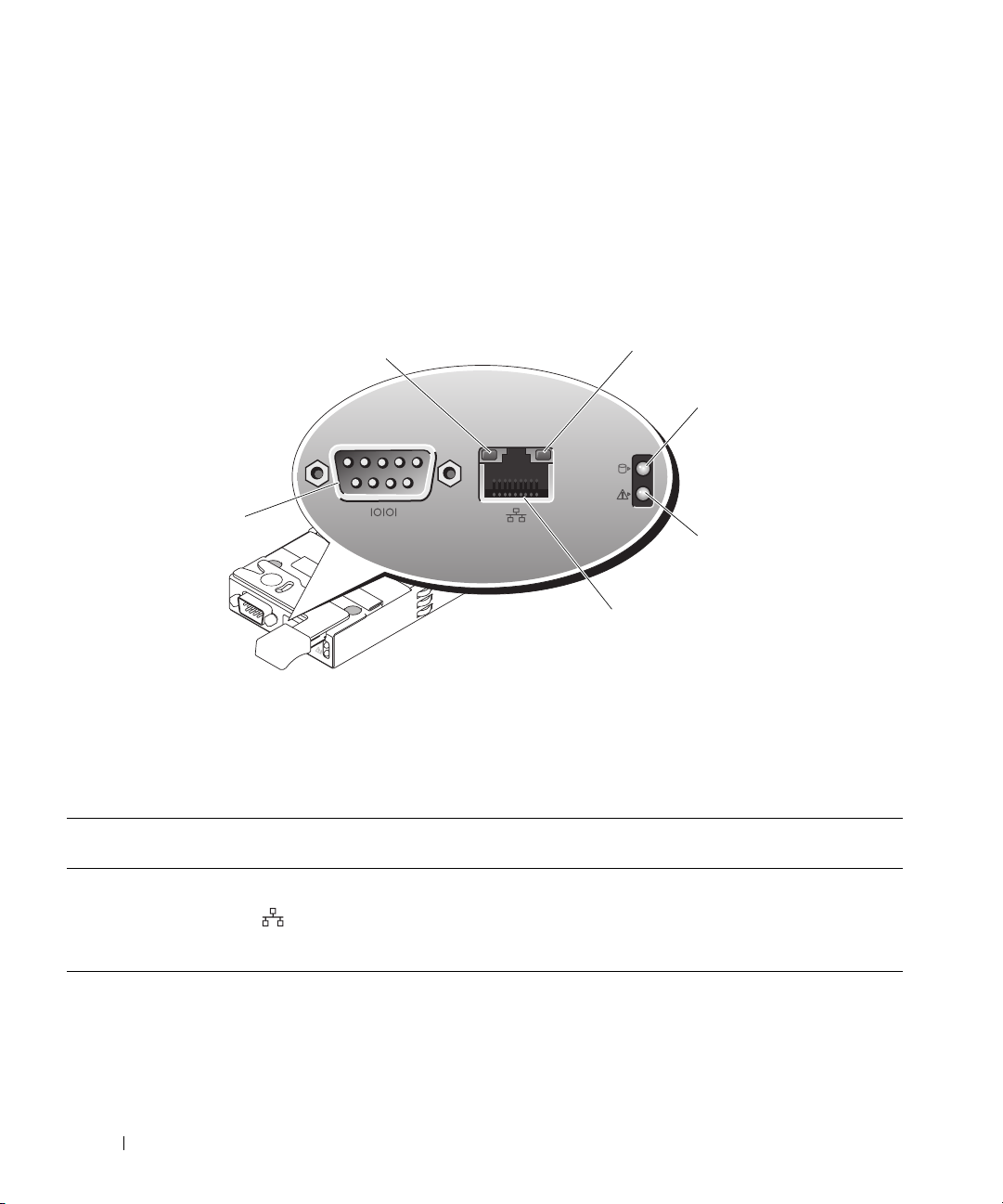

DRAC/MC Module

2

The DRAC/MC provides serial and Ethernet management ports, a status indicator when redundant

DRAC/MCs are installed (when available), and status indicators for the DRAC/MC and for the link to

the system's onboard network interface controller (see Figure 1-10). See the documentation for the

DRAC/MC module for specific information on serial port redirection of server modules and switches.

Table 1-8 provides information about the status indicators.

Figure 1-10. DRAC/MC Module Features

1

3

6

4

5

1 link indicator 2 activity indicator 3 primary/secondary indicator

4 fault indicator 5 network interface controller 6 serial connector

Table 1-8. DRAC/MC Module Indicators

Indicator Type Icon Activity

Indicator

Network interface

controller link

indicator

Network interface

controller activity

indicator

Off LAN is not linked.

Green LAN is linked.

Off LAN is not active.

Amber blinking Indicates that the system DRAC/MC and the LAN are

26 About Your System

Indicator Code

communicating.

Page 27

Table 1-8. DRAC/MC Module Indicators (continued)

Indicator Type Icon Activity

Indicator

Primary/secondary

indicator

Fault indicator Off The DRAC/MC is operating normally.

Serial connector None Used for a serial connection with a null modem cable.

Off The DRAC/MC is a backup for the master DRAC/MC.

Green The DRAC/MC is active for system management.

Green blinking The DRAC/MC is in special or manufacturing mode.

Amber In a single (nonredundant) configuration, this DRAC/MC failed.

Amber blinking In a dual (redundant) configuration (when available), this

Indicator Code

NOTE: For information on availability of dual (redundant)

configurations for the DRAC/MC, see www.dell.com.

See "DRAC/MC Module" on page 61.

DRAC/MC failed. See "DRAC/MC Module" on page 61.

Important I/O Configuration Considerations

Insure that you read the DRAC/MC module’s readme.txt file. It contains updated information, including

system indicator behavior in certain conditions.

CAUTION: Data loss can result if you perform certain actions on a system in which the I/O bays have not been

configured correctly. Specifically, bay 2 should have an I/O module installed only if a module of the same fabric

type is present in bay 1, and bay 4 should have an I/O module installed only if a module of the same fabric type is

present in bay 3. Except in these cases (or in a case where you temporarily need to swap a failed I/O module in

bay 1 or 3), bays 2 and 4 should be unoccupied.

Unless your system is configured according to these guidelines, do not perform any of the following actions:

•

Upgrade DRAC/MC firmware

•

Issue a software reset command for a DRAC/MC, such as racadm racreset

•

Reseat a DRAC/MC module

•

Cause a DRAC/MC failover event, such as removing the network cable from the primary DRAC/MC, or rebooting

a switch that the DRAC/MC cable is connected to

Performing any of these actions will power off and stop traffic on the bay 2 or bay 4 I/O module, resulting in data loss.

When initiated, the DRAC/MC firmware algorithm must find a module in bay 1 before bay 2 and a

module in bay 3 before bay 4. Otherwise, the module in bay 2 or bay 4 will be powered off if you perform

a firmware upgrade procedure on the DRAC/MC, cause a DRAC/MC failover, or reset the DRAC/MC.

See the current Dell Remote Access Controller/Modular Chassis User's Guide at support.dell.com for

more information about configuring your DRAC/MC system.

About Your System 27

Page 28

DRAC/MC Firmware Requirements

The minimum DRAC/MC firmware requirement for your system is version 1.3 or later. If you are adding

a second DRAC/MC module with version 1.0 to support redundancy, you must upgrade the module’s

firmware to version 1.1, then upgrade the firmware to version 1.3 (or later).

NOTE: A DRAC/MC module’s firmware version is displayed on its web-based GUI or by typing the command

getsysinfo or racadm getsysinfo.

See the latest Dell Remote Access Controller/Modular Chassis User's Guide at support.dell.com for more

information about firmware updates and installing redundant DRAC/MC modules. This guide also

provides complete instructions on how to set up and operate that version of the module.

I/O Connectivity

The system offers several options for connectivity through a combination of embedded Ethernet

controllers, optional I/O daughter cards on the server module, and chassis I/O modules in the rear of the

chassis. An I/O module's green system/diagnostic indicator is off when the module is properly operating

or is off and blinks when the module is not properly operating.

Guidelines for Installing Connectivity Modules

The following guidelines must be used when populating I/O modules. See Figure 1-5 for I/O bay

locations.

• Insert a connectivity module into I/O bay 1 before installing a connectivity module into I/O bay 2.

Ensure that the connectivity modules installed in I/O bays 1 and 2 are of the same fabric type.

• Insert a connectivity module into I/O bay 3 before installing a connectivity module into I/O bay 4.

Ensure that the connectivity modules installed in I/O bays 3 and 4 are of the same fabric type.

• I/O bay 3 connects to port 1 on the daughter card (optional) installed in the server module.

– This bay must be populated if there is a daughter card installed in the server module.

– The type of I/O module installed in this bay must match the type of daughter card installed in the

server module. For example, a Fibre Channel I/O module requires that a Fibre Channel daughter

card be installed in the server module.

28 About Your System

Page 29

Table 1-9 lists the valid I/O module configurations. See Figure 1-5 for I/O bay locations.

Table 1-9. Valid I/O Module Configurations

Network Controller Bay IO/1 Bay IO/2 Bay IO/3 Bay IO/4

Server Module

Embedded NIC 1

Server Module

Embedded NIC 2

Fibre Channel

Daughter Card Port 1

Fibre Channel

Daughter Card Port 2

Gb Ethernet Daughter

Card Port 1

Gb Ethernet Daughter

Card Port 2

Infiniband Daughter

Card

Ethernet switch

module or passthrough module

N/A Ethernet switch

N/A N/A Fibre channel

N/A N/A N/A Fibre channel

N/A N/A Ethernet switch

N/A N/A Ethernet switch

N/A N/A Infiniband module

N/A N/A N/A

N/A N/A

module or passthrough module

N/A

switch or passthrough module

switch or pass-

through module

module or passthrough module

module or pass-

through module

Infiniband module

(either or both

bays)

(either or both

bays)

PowerConnect 5316M Ethernet Switch Module

The PowerConnect 5316M Ethernet switch module is a 16-port switch with 6 uplinks and 10 downlinks

(see Figure 1-11). The uplinks connect to the external Ethernet network and operate at 1/2/4 Gb. The

downlinks connect to the embedded Ethernet controller on the server module and operate at 1 Gb only.

The PowerConnect 5316M Ethernet switch module is hot-pluggable. To provide connectivity into

separate Ethernet networks, two switch modules can be installed in bays I/O 1 and I/O 2 (see Figure 1-5).

I/O bays 3 and 4 require that you install a Gb Ethernet daughter card in the server module. If redundancy

is not required, the switch module must be installed in I/O 1 bay. The switch module has an internal

serial port that communicates with the DRAC/MC module. Table 1-10 lists the indicators on each switch

module. For additional information about the PowerConnect 5316M Ethernet switch module, see the

documentation that shipped with the module.

About Your System 29

Page 30

Figure 1-11. PowerConnect 5316M Ethernet Switch Module Indicators and Features

1

3

1 speed/link activity indicator 2 duplex mode indicator 3 system/diagnostic indicator

Table 1-10. PowerConnect 5316M Ethernet Switch Module Indicators

Indicator Type Activity

Indicator

Speed/link activity

indicator (bicolor)

Off Not connected.

Green The port is connected to a valid link partner on the network.

Green blinking Network data is being sent or received at 1 Gb.

Amber The port is connected to a valid link partner on the network.

Amber blinking Network data is being sent or received at 10 Mb or 100 Mb.

Indicator Code

2

161514131211

Duplex mode

indicator

System/diagnostic

indicator

Green The port is operating at full duplex mode.

Off The port is operating at half duplex mode.

Green blinking Module is being powered down by the DRAC/MC controller

Off Module is operating normally.

30 About Your System

due to an I/O module mismatch. See "Guidelines for Installing

Connectivity Modules" on page 28.

Page 31

Fibre Channel Pass-Through Module

The Fibre Channel pass-through module provides a bypass connection between the Fibre Channel

daughter card in the server module and optical transceivers for direct connection into a Fibre Channel

switch or a storage array. (see Figure 1-12). The Fibre Channel pass-through modules are hot-pluggable.

The Fibre Channel pass-through module in I/O bay 3 connects to port 1 on the optional Fibre Channel

daughter card installed in a server module. The Fibre Channel pass-through module in I/O bay 4

connects to port 2 on the optional Fibre Channel daughter card installed in a server module. To provide

redundancy, both I/O bay 3 and I/O bay 4 must have Fibre Channel pass-through modules installed.

Table 1-11 lists the functionality of the Fibre Channel pass-through module indicators. For additional

information on installing this module, see "Chassis I/O Module" on page 70.

NOTE: The Fibre Channel pass-through module includes Short Wave Small Form Factor Pluggable (SFP) optical

transceivers. To ensure proper functionality, use only the SFPs provided with this module.

Figure 1-12. Fibre Channel Pass-through Module Indicators and Features

1

2

3

13579

246810

1 SFP Fibre Channel connector 2 green indicator 3 amber indicator

About Your System 31

Page 32

Table 1-11. Fibre Channel Pass-Through Module Indicators

Indicator Type Activity

Indicator

Fibre Channel

indicator

(green/amber)

Off Power is off to the system.

Green/amber System has power.

Green/off Fibre Channel connection is online.

Off/amber The port is connected to a valid link partner on the network.

Off/flashing (twice

per second)

Indicator Code

Connection has lost synchronization.

Fibre Channel Switch Module

You can install one or two hot-pluggable Fibre Channel switch modules in I/O bay 3 and I/O bay 4,

beginning with I/O bay 3. You must also install a Fibre Channel HBA daughter card in the server module.

The Fibre Channel switch module includes four external autosensing Fibre Channel ports numbered 10

through 13, 10 internal ports, and one Ethernet port with an RJ-45 connector. All the external ports operate

at 1 Gb/sec, 2 Gb/sec, or 4 Gb/sec.

See the documentation for your particular Fibre Channel switch module for the functionality and

location of the switch module indicators. For general information on installing this module, see "Chassis

I/O Module" on page 70.

NOTE: The Fibre Channel switch module includes Short Wave Small Form Factor Pluggable (SFP) optical

transceivers. To ensure proper functionality, use only SFPs provided with this module.

Infiniband Pass-through Module

The Infiniband pass-through module provides a bypass connection between an optional Infiniband Host

Channel Adapter (HCA) daughter card in the server module and 4x Infiniband Transceivers for direct

connection to an Infiniband switch. The Infiniband pass-through modules are hot-pluggable. To provide

redundancy, both I/O bay 3 and I/O bay 4 must have Infiniband pass-through modules installed. In this

configuration, the module in I/O bay 3 connects to port 1 on the Infiniband HCA daughter card; the

Infiniband pass-through module in I/O bay 4 connects to port 2 on the Infiniband HCA daughter card.

NOTE: The Infiniband pass-through module uses small form factor 4x Infiniband connectors. To ensure proper

functionality, use only cables provided with the module.

NOTE: If you require service, technical support, or parts replacement for your Topspin Infiniband product, contact

Topspin Support Services directly at 1-800-499-1473 or through www.topspin.com.

32 About Your System

Page 33

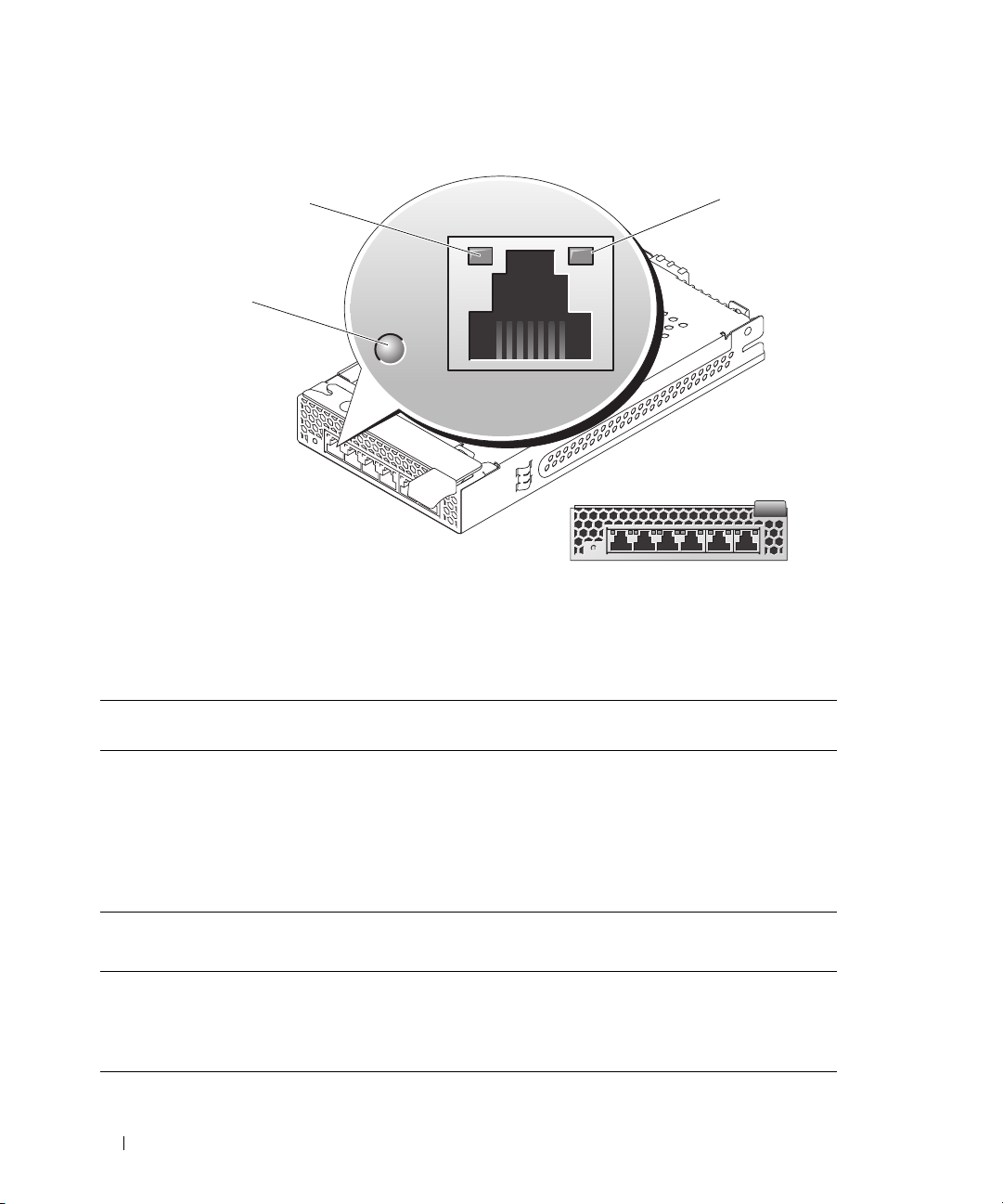

Gb Ethernet Pass-through Module

The Gb Ethernet pass-through module has 10 RJ45 ports. When installed in I/O 1 bay or I/O 2 bay, the

Gb Ethernet pass-through module provides a connection between the server module and an external Gb

Ethernet device. When installed in the I/O 3 bay or I/O 4 bay, the Gb Ethernet pass-through module

provides a connection between the optional internal Gb Ethernet daughter card in the server module,

providing a direct connection into an external Gb Ethernet device (see Figure 1-13). The Gb Ethernet

pass-through modules are hot-pluggable. The Gb Ethernet pass-through module in I/O bay 3 connects to

the optional Gb Ethernet daughter card installed in a server module. The Gb Ethernet pass-through

module in I/O bay 4 connects to port 2 on the optional Gb Ethernet daughter card installed in a server

module. Table 1-12 lists the functionality of the Gb Ethernet pass-through module indicators. For

additional information on installing this module, see "Chassis I/O Module" on page 70.

NOTE: Only connect the Gb Ethernet module to 1000-Mb external switch ports. Do not use this module with 10-Mb

or 100-Mb external switch ports.

Figure 1-13. Gb Pass-through Module Indicators and Features

1

5

4

1 activity indicator 2 link indicator 3 status indicator

4 link indicator 5 activity indicator

NOTE: Connectors on the Gb pass-through module correspond directly to the server module number. For example,

server module 5 is connected to port 5 on the Gb pass-through module.

2

3

13579

246810

About Your System 33

Page 34

Table 1-12. Gb Pass-through Module Indicators

Indicator Type Activity

Indicator

Link

indicator/activity

indicator

Status indicator Green Module is operating correctly.

Green/amber

blinking

Green/off The Gb Ethernet connector is linked to the server module

Off/amber blinking The Gb Ethernet connector is not linked to the server

Off/off The Gb Ethernet connector is not linked to the server

Green blinking Module is being powered down by the DRAC/MC controller

Indicator Code

The Gb Ethernet connector is linked to the server module

and there is network activity

and there is no network activity.

module and there is network activity.

module and there is no network activity.

due to an I/O module mismatch. See "Guidelines for

Installing Connectivity Modules" on page 28.

Server Module Messages

System messages appear on the screen to notify you of a possible problem with the system. Table 1-13

lists the system messages that can occur and the probable cause and corrective action for each message.

CAUTION: Many repairs may only be done by a certified service technician. You should only perform

troubleshooting and simple repairs as authorized in your product documentation, or as directed by the online or

telephone service and support team. Damage due to servicing that is not authorized by Dell is not covered by your

warranty. Read and follow the safety instructions that came with the product.

NOTE: If you receive a system message that is not listed in Table 1-13, check the documentation for the application

that is running when the message appears or the operating system's documentation for an explanation of the

message and recommended action.

34 About Your System

Page 35

Table 1-13. Server Module Messages

Message Causes Corrective Actions

Alert: DIMM_

must be populated with a

matched set of DIMMs if

more than 1 DIMM is

present. The following

memory DIMMs have been

disabled:

Alert! Redundant memory

disabled!. Memory

configuration does not

support redundant memory

Alert! Unsupported memory,

incomplete sets, or

unmatched sets. The

following memory DIMMs

have been disabled:

Caution! NVRAM_CLR jumper

is installed on system

board.

CPUs with different cache

sizes detected.

Decreasing available

memory

DIMMs should be installed

in pairs. Pairs must be

matched in size, speed,

and technology.

n

and DIMM_n

Ensure that the memory modules are

installed in matched pairs. See "General

Memory Module Installation

Guidelines" on page 78.

The installed memory configuration

does not support redundant memory.

The installed memory configuration is

invalid.

NVRAM_CLR switch is set to "on." Set the NVRAM_CLR switch to "off."

Mismatched processors are installed. Install a correct version of the

Faulty or improperly installed memory

modules.

Mismatched or unmatched DIMMs

installed; faulty or improperly

installed memory modules. The

system will operate in a degraded

mode with reduced ECC protection.

Only memory installed in channel 0

will be accessible.

Install a memory configuration that

supports redundant memory. See

"General Memory Module Installation

Guidelines" on page 78.

Disable the Redundant Memory option

in the System Setup program. See

"Using the System Setup Program" on

page 43.

Add, move, or remove memory modules

to achieve a configuration supported by

the system. See "General Memory

Module Installation Guidelines" on

page 78.

See Figure 6-2 for the jumper location.

microprocessor so that both

microprocessors have the same cache

size. See "Processors" on page 84.

Ensure that all memory modules are

properly installed. See "Troubleshooting

Server Module Memory" on page 112.

Ensure that all pairs of memory modules

are of the same type and size and that

they are properly installed. See "General

Memory Module Installation

Guidelines" on page 78. If the problem

persists, see "Troubleshooting Server

Module Memory" on page 112.

About Your System 35

Page 36

Table 1-13. Server Module Messages (continued)

Message Causes Corrective Actions

DIMMs must be populated in

sequential order beginning

with slot 1. The following

DIMM is electrically

x

isolated: DIMM

DIMM pairs must be matched

in size, speed, and

technology. The following

DIMM pair is mismatched:

x

DIMM

Diskette drive

failure

Diskette read failure Faulty or improperly inserted diskette. Replace the diskette.

Diskette subsystem reset

failed

Drive not ready Diskette missing or improperly

Error: Incorrect memory

configuration. DIMMs must

be installed in pairs of

matched memory size,

speed, and technology.

and DIMM

.

y.

n

seek

The specified DIMM is inaccessible to

the system due to its location.

DIMMs must be populated in

sequential order, beginning with

slot 1.

Mismatched or unmatched DIMMs

installed; faulty or improperly seated

memory modules.

Incorrect configuration settings in

System Setup program.

Faulty or improperly connected

diskette or optical drive to the custom

cable.

Faulty diskette drive or optical drive

controller.

inserted in diskette drive.

Mismatched or unmatched DIMMs

installed; faulty or improperly seated

memory modules.

Populate two, four, or eight DIMMs

sequentially beginning with slot 1.

Ensure that all pairs of memory modules

are of the same type and size, and that

they are properly installed. See "General

Memory Module Installation

Guidelines" on page 78. See

"Troubleshooting Server Module

Memory" on page 112.

Run the System Setup program to

correct the settings. See "Using the

System Setup Program" on page 43.

Replace the diskette. Ensure that the

diskette drive and optical drive cables are

properly connected. See

"Troubleshooting USB Devices" on

page 105.

Ensure that the diskette drive and

optical drive cables are properly

connected to the custom cable. See

"Troubleshooting USB Devices" on

page 105. If the problem persists, see

"Getting Help" on page 127.

Reinsert or replace the diskette.

Ensure that all pairs of memory modules

are of the same type and size, and that

they are properly installed. See "General

Memory Module Installation

Guidelines" on page 78. If the problem

persists, see "Troubleshooting Server

Module Memory" on page 112.

36 About Your System

Page 37

Table 1-13. Server Module Messages (continued)

Message Causes Corrective Actions

Error: Memory failure

detected. Memory size

reduced. Replace the

faulty DIMM as soon as

possible.

Error: Remote Access

Controller initialization

failure.

FBD training error: The

following branch has been

x

disabled: Branch

Gate A20 failure Faulty keyboard controller (faulty

General failure Operating system corrupted or

Keyboard controller

failure

Keyboard data line failure

Keyboard failure

Keyboard stuck key failure

Manufacturing mode

detected

.

Faulty or improperly seated memory

modules.

Faulty or improperly installed

DRAC/MC module.

The specified branch (channel pair)

contains DIMMs that are

incompatible with each other.

server module board).

improperly installed.

Faulty keyboard controller (faulty

server module board).

Loose or improperly connected

keyboard cable; faulty keyboard to the

custom cable; faulty keyboard

controller.

System is incorrectly configured. Set the NVRAM_CLR switch to "on"

See "Troubleshooting Server Module

Memory" on page 112.

Reinstall the DRAC/MC module. See

"DRAC/MC Module" on page 26.

If the problem persists, replace the

DRAC/MC module.

Ensure that only Dell qualified memory

is used. Dell recommends purchasing

memory upgrade kits directly from

http://www.dell.com or your Dell sales

agent to ensure compatibility.

See "Getting Help" on page 127.

Reinstall the operating system.

See "Getting Help" on page 127.

Ensure that the keyboard is properly

connected. If the problem persists,

replace the keyboard.

If the message still appears, the keyboard

controller is faulty. See "Getting Help"

on page 127.

and reboot the server module. See

Figure 6-2 for switch location.

About Your System 37

Page 38

Table 1-13. Server Module Messages (continued)

Message Causes Corrective Actions

Memory address line

failure at

value

expecting

Memory double word logic

failure at

value

expecting

Memory odd/even logic

failure at

to

end address

Memory write/read failure

address

at

expecting

Memory mirroring enabled Memory mirroring enabled Information only.

Memory tests terminated by

keystroke

No boot device available Faulty or missing diskette drive,

No boot sector on

hard-disk drive

No timer tick interrupt Faulty server module board. See "Getting Help" on page 127.

Not a boot diskette Not a bootable diskette. Use a bootable diskette.

PCI BIOS failed to install Faulty or improperly installed. Reseat the daughter card. See "I/O

address

address

start address

, read

value

, read

value

, read

value

value

Faulty or improperly installed memory

modules, or faulty server module

board.

The spacebar was pressed during

POST to terminate the memory test.

optical drive, or hard drive.

An operating system is not on the

hard drive.

Ensure that all memory modules are

properly installed. See "Troubleshooting

Server Module Memory" on page 112. If

the problem persists, see "Getting Help"

on page 127.

Information only.

Check the Integrated Devices

configuration settings in the System

Setup program and ensure that the

controller for the boot device is enabled.

See "Using the System Setup Program"

on page 43. Ensure that the controller

for the boot device is enabled.

If the problem persists, replace the drive.

See "Hard Drives" on page 89.

Check the hard-drive configuration

settings in the System Setup program.

See "Using the System Setup Program"

on page 43.

Module Daughter Card" on page 82. If

the problem persists, see "Getting Help"

on page 127.

38 About Your System

Page 39

Table 1-13. Server Module Messages (continued)

Message Causes Corrective Actions

Plug & Play Configuration

Error

Read fault Faulty diskette, diskette drive, optical

Remote Configuration

update attempt failed

Sector not found

Seek error

Seek operation failed

Shutdown failure Shutdown test failure. Ensure that all memory modules are

Spare bank enabled Memory sparing enabled. Information only.

The amount of system

memory has changed.

Time-of-day clock stopped Faulty battery; faulty server module

Time-of-day not set please run SETUP program

Timer chip counter 2

failed

Error encountered in initializing PCI

device; faulty server module board.

drive, or hard drive.

Server module could not implement

Remote Configuration request.

Faulty diskette or hard drive. Replace the diskette. If the problem

Faulty memory module. See "Troubleshooting Server Module

Information only, if you have changed

the memory configuration.

board.

Incorrect Time or Date settings; faulty

server module board battery.

Faulty server module board. See "Getting Help" on page 127.

Set the NVRAM_CLR switch to "on"

and reboot the server module. See

Figure 6-2 for switch location.

Check for a BIOS update. If the problem

persists, see "Getting Help" on page 127.

Replace the diskette. Ensure that the

custom cable is properly connected. See

"Troubleshooting USB Devices" on

page 105 or "Troubleshooting Hard

Drives" on page 113. for the appropriate

drive(s) installed in your system.

Retry Remote Configuration.

persists, see "Troubleshooting Hard

Drives" on page 113 for the appropriate

drive installed in your system.

properly installed. See "Troubleshooting

Server Module Memory" on page 112. If

the problem persists, see "Getting Help"

on page 127.

Memory" on page 112. If the problem

persists, see "Getting Help" on page 127.

See "Troubleshooting Server Module

Memory" on page 112. If the problem

persists, see "Getting Help" on page 127.

Check the Time and Date settings. See

"Using the System Setup Program" on

page 43. If the problem persists, see

"Troubleshooting the Server Module

Battery" on page 115.

About Your System 39

Page 40

Table 1-13. Server Module Messages (continued)

Message Causes Corrective Actions

Unsupported CPU

combination

Unsupported CPU stepping

detected

Warning! No microcode

update loaded for

processor

Warning: The current

memory configuration is

not validated. Change it

to the recommended memory

configuration or press any

key to continue.

Write fault

Write fault on selected

drive

n

Mismatched processors are installed.

Processor is not supported by the

server module.

Processor is not supported by the

server module.

Unsupported processor. Update the BIOS firmware using the

There is no memory configuration

error, but the memory configuration is

not recommended by Dell.

Faulty diskette, diskette drive, optical

drive, hard drive.

Replace a microprocessor so that both

microprocessors match. See "Processors"

on page 84.

Check for a BIOS update using the Dell

Support website at support.dell.com.

Check for a BIOS update using the Dell

Support website at support.dell.com. If

the problem persists, install a supported

processor. See "Processors" on page 84.

Dell Support website at

support.dell.com.

See "General Memory Module

Installation Guidelines" on page 78.

Replace the diskette. Ensure that the

custom cable is properly connected. See

"Troubleshooting USB Devices" on

page 105 or "Troubleshooting Hard

Drives" on page 113 for the appropriate

drive(s) installed in your system.

Warning Messages

A warning message alerts you to a possible problem and prompts you to respond before the system

continues a task. For example, before you format a diskette, a message will warn you that you may lose all

data on the diskette. Warning messages usually interrupt the task and require you to respond by typing

(yes) or

n (no).

NOTE: Warning messages are generated by either the application or the operating system. For more information,

see the documentation that accompanied the operating system or application.

Diagnostics Messages

When you run system diagnostics, an error message may result. Diagnostic error messages are not

covered in this section. Record the message on a copy of the Diagnostics Checklist in "Getting Help,"

then follow the instructions in that section for obtaining technical assistance.

40 About Your System

y

Page 41

Alert Messages

Systems management software generates alert messages for your system. Alert messages include

information, status, warning, and failure messages for drive, temperature, fan, and power conditions. For

more information, see the systems management software documentation.

About Your System 41

Page 42

42 About Your System

Page 43

Using the System Setup Program

After you set up your system, run the System Setup program to familiarize yourself with your system

configuration and optional settings. Record the information for future reference.

You can use the System Setup program to:

• Change the system configuration stored in NVRAM after you add, change, or remove hardware

• Set or change user-selectable options—for example, the time or date

• Enable or disable integrated devices

• Correct discrepancies between the installed hardware and configuration settings

NOTE: When a server module is inserted into a chassis, the server module functions as a system. Each server

module has a System Setup program to allow configuration of the server module and features such as

password protection.

Entering the System Setup Program

1

Turn on or restart your system.

2

Press <F2> immediately after you see the following message:

<F2> = Setup

If your operating system begins to load before you press <F2>, allow the system to finish booting,

and then restart your system and try again.

NOTE: To ensure an orderly system shutdown, see the documentation that accompanied your operating

system.

Responding to Error Messages

You can enter the System Setup program by responding to certain error messages. If an error message

appears while the system is booting, make a note of the message. Before entering the System Setup

program, "Server Module Messages" on page 34 and "Warning Messages" on page 40 for an

explanation of the message and suggestions for correcting errors.

NOTE: After installing a memory upgrade, it is normal for your system to send a message the first time you

start your system.

Using the System Setup Program 43

Page 44

Using the System Setup Program

Table 2-1 lists the keys that you use to view or change information on the System Setup program screens

and to exit the program.

Table 2-1. System Setup Program Navigation Keys

Keys Action

Up arrow or <Shift><Tab> Moves to the previous field.

Down arrow or <Tab> Moves to the next field.

Spacebar, <+>, <

right arrows

<Esc> Exits the System Setup program and restarts the

<F1> Displays the System Setup program

NOTE: For most of the options, any changes that you make are recorded but do not take effect until you restart the

system.

–>, left and

Cycles through the settings in a field. In some fields,

you can also type the appropriate value.

system if any changes were made.

's help file.

System Setup Options

Main Screen

When you enter the System Setup program, the main System Setup program screen appears (see

Figure 2-1).

44 Using the System Setup Program

Page 45

Figure 2-1. Main System Setup Program Screen

Table 2-2 lists the options and descriptions for the information fields that appear on the main System

Setup program screen.

NOTE: The options for the System Setup program change based on the system configuration.

NOTE: The System Setup program defaults are listed under their respective options, where applicable.

Table 2-2. System Setup Program Options

Option Description

Asset Tag Displays the customer-programmable asset tag number for the system if

an asset tag number has been assigned. To enter an asset tag number of

up to 10 characters into NVRAM, see "Acquiring the asset.com Utility"

on page 54.

System Time Resets the time on the system's internal clock.

System Date Resets the date on the system's internal calendar.

Memory Information See "Memory Information Screen" on page 47.

CPU Information See "CPU Information Screen" on page 47.

Using the System Setup Program 45

Page 46

Table 2-2. System Setup Program Options (continued)

Option Description

Boot Sequence Determines the order in which the system searches for boot devices

during system startup. Available options can include the USB diskette

drive, USB CD drive, hard drives, and USB flash drive.

NOTE: A USB device will be displayed in the boot order screen only if it is

attached to the system before the system enters BIOS.

Hard-Disk Drive

Sequence

USB Flash Drive

Emulation Type

(Auto default)

Integrated Devices See "Integrated Devices Screen" on page 48.

PCI IRQ Assignment Displays a screen to change the IRQ assigned to each of the integrated

Serial Communication See "Serial Communication Screen" on page 49.

System Security Displays a screen to configure the system password and setup password

Keyboard NumLock

(On default)

Report Keyboard Errors

(Report default)

Determines the order in which the system searches the hard drives during

system startup. The selections depend on the hard drives installed in your

system.

Determines the emulation type for a USB flash drive. Hard disk allows

the USB flash drive to act as a hard drive. Floppy allows the USB flash

drive to act as a removable diskette drive. Auto automatically chooses an

emulation type.

devices on the PCI bus, and any installed expansion cards that require an

IRQ.

features. See "Using the System Password" on page 51 and "Using the

Setup Password" on page 53 for more information.

Determines whether your system starts up with the NumLock mode

activated on 101- or 102-key keyboards (does not apply to 84-key

keyboards).

Enables or disables reporting of keyboard errors during the POST. Select

Report for host systems that have keyboards attached. Select Do Not

Report to suppress all error messages relating to the keyboard or keyboard

controller during POST. This setting does not affect the operation of the

keyboard itself if a keyboard is attached to the system.

46 Using the System Setup Program

Page 47

Memory Information Screen

Table 2-3 lists the options and descriptions for the information fields that appear on the Memory

Information screen.

Table 2-3. Memory Information Screen

Option Description

System Memory Size Displays the amount of main memory. (If memory mirroring or

spare memory is enabled, this value will be less than the amount of

physical memory installed in the server module.) This field does

not have user-selectable settings.

System Memory Type Displays the type of system memory. This field does not have user-

selectable settings.

System Memory Speed Displays the system memory clock frequency. This field does not

have user-selectable settings.

Video Memory Displays the amount of video memory. This field does not have

user-selectable settings.

System Memory Testing

(Enabled default)

Redundant Memory If a valid memory configuration is installed, you can enable memory

Determines if memory is being tested during POST. Setting this

value to Enabled will affect the duration of system POST.

mirroring or spare memory. Options are Mirror Mode, Spare Mode,

and Disabled. See "Memory" on page 77.

CPU Information Screen

Table 2-4 lists the options and descriptions for the information fields that appear on the CPU

Information screen.

Table 2-4. CPU Information Screen

Option Description

64-bit Displays the processor register width.