DE DIETRICH TWH 200E, TWH 300E, TWH 300EH User Manual

Export

C003182-B

KALIKO

Thermodynamic water heater

TWH 200E

TWH 300E

TWH 300EH

EN

Installation and

Service Manual

300026515-001-03

Declaration of conformity

The device complies with the standard type described in the EG

declaration of conformity. It was manufactured and commissioned in

accordance with European directives.

The original declaration of conformity is available from the

manufacturer.

Contents

1 Introduction ................................................................................................6

1.1 Symbols used .......................................................6

1.2 Abbreviations ........................................................6

1.3 General ..................................................................7

1.3.1 Manufacturer’s liability .............................................7

1.3.2 Installer’s liability .....................................................7

1.4 Homologations ......................................................7

1.4.1 Certifications ...........................................................7

1.4.2 Directive 97/23/EC ..................................................8

1.4.3 Factory test .............................................................8

2 Safety instructions and recommendations ..............................................9

2.1 Safety instructions ...............................................9

2.2 Recommendations ................................................9

2.3 Safety data sheet: R-134a refrigerant ...............10

2.3.1 Product identification .............................................10

2.3.2 Hazard identification ..............................................10

2.3.3 Composition / Information on the ingredients ........10

2.3.4 First aid .................................................................10

2.3.5 Fire prevention measures .....................................10

2.3.6 In the event of accidental spillage .........................11

2.3.7 Handling ................................................................11

2.3.8 Personal protection ...............................................11

2.3.9 Considerations on disposal ...................................12

2.3.10 Regulations ...........................................................12

3 Technical description ..............................................................................13

3.1 General description ............................................13

3.2 Main parts ............................................................14

3.3 Operating principle .............................................14

3.4 Technical specifications ....................................15

03/02/2014 - 300026515-001-03

3.4.1 Characteristics of the appliance ............................15

3.4.2 Heating time of the DHW tank depending on the air

temperature ...........................................................16

3.4.3 Max domestic hot water set point reached by the heat

pump depending on the air temperature ...............16

1

Contents

4 Installation ................................................................................................17

4.1 Regulations governing installation ...................17

4.2 Package list .........................................................17

4.2.1 Standard delivery ..................................................17

4.2.2 Accessories ...........................................................17

4.3 Storage and transport ........................................18

4.3.1 Transport ...............................................................18

4.4 Choice of the location ........................................19

4.4.1 Type plate .............................................................19

4.4.2 Positioning of the appliance ..................................19

4.4.3 Main dimensions ...................................................23

4.5 Positioning the appliance ..................................25

4.5.1 Unpacking the appliance .......................................25

4.5.2 Positioning the appliance ......................................25

4.5.3 Levelling ................................................................26

4.6 Hydraulic connections .......................................26

4.6.1 Connecting the calorifer to the domestic water circuit

(secondary circuit) .................................................26

4.6.2 Connection to a boiler (Version EH) ......................28

4.6.3 Connection to solar collectors (Version EH) .........30

4.7 Condensates discharge .....................................32

4.8 Installing the control system in the living

room .....................................................................32

4.8.1 Choose a location .................................................32

4.8.2 Operations to be carried out on the thermodynamic

DHW tank ..............................................................33

4.8.3 Installing the control system in the living

room ......................................................................34

4.9 Electrical connections ........................................35

4.9.1 Recommendations ................................................35

4.9.2 Connecting the hydraulic back-up (Version

EH) ........................................................................35

4.9.3 Access to the connection terminal HP/HC ............36

4.9.4 Connection with HP/HC signal connected ............37

4.9.5 Connection with timer programming .....................39

4.9.6 Connection with timer programming and photovoltaic

signal .....................................................................40

4.10 Electrical principle diagram ...............................41

4.11 Filling the thermodynamic DHW tank ...............42

5 Commissioning ........................................................................................43

5.1 Control panel .......................................................43

5.1.1 Description of the keys ..........................................43

5.1.2 Description of the display ......................................43

03/02/2014 - 300026515-001-03

2

5.1.3 Browsing in the menus ..........................................45

5.2 Check points before commissioning ................45

5.3 Putting the appliance into operation ................46

5.3.1 Commissioning ......................................................46

5.4 Checks and adjustments after

commissioning ...................................................46

5.5 Choosing the operating mode ...........................46

5.6 Reading out measured values ...........................47

5.6.1 Measurements menu ............................................47

5.6.2 Counters ................................................................47

5.7 Modifying the installer parameters ...................49

5.7.1 Access to parameters ...........................................49

5.7.2 List of the parameters ...........................................50

5.7.3 Control system sequence ......................................51

5.7.4 Return to the factory settings ................................51

6 Switching off the appliance .....................................................................53

6.1 Installation shutdown .........................................53

6.2 Antifreeze protection ..........................................53

7 Checking and maintenance .....................................................................54

7.1 General instructions ...........................................54

7.2 Maintenance operations to be performed ........55

7.2.1 Refrigerant circuit ..................................................55

7.2.2 Hydraulic circuit .....................................................55

7.2.3 Aeraulics ...............................................................55

7.2.4 Impressed current anode ......................................55

7.2.5 Checking the safety valve or unit ..........................55

7.2.6 Descaling ..............................................................56

7.2.7 Cleaning the condensates discharge duct ............56

7.3 Accessing the bottom inspection trap .............57

7.4 Maintenance form ...............................................58

8 Troubleshooting .......................................................................................59

03/02/2014 - 300026515-001-03

8.1 Messages (Code type bxx or Exx) .....................59

8.1.1 Messages (type code bXX) ..............................59

8.1.2 Messages (type code EXX) ..............................61

8.2 Message and error history .................................62

8.2.1 Err error display ....................................................63

8.2.2 bL blockage display ...............................................63

8.2.3 Reset error and blockage history ..........................63

3

Contents

9 Spare parts ................................................................................................64

9.1 General ................................................................64

9.2 Spare parts ..........................................................64

9.2.1 Heat pump .............................................................64

9.2.2 DHW tank ..............................................................66

03/02/2014 - 300026515-001-03

4

03/02/2014 - 300026515-001-03

5

1. Introduction

1 Introduction

1.1 Symbols used

TWH 200E TWH 300E TWH 300EH

In these instructions, various danger levels are employed to draw the

user’s attention to particular information. In so doing, we wish to

safeguard the user’s safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

1.2 Abbreviations

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

Before installing and commissioning the device, read

carefully the instruction manuals provided.

4 HP: Heat pump

4 DHW: Domestic hot water

4 LP: Low pressure

4 HP: High pressure

4 CFC: Chlorofluorocarbon

4 Qpr: Static losses (Thermal losses from the DHW tank when it is

off for 24 hours)

4 COP: Performance coefficient

4 HP/HC: Peak hours / Off-peak hours

6

03/02/2014 - 300026515-001-03

TWH 200E TWH 300E TWH 300EH

1.3 General

1. Introduction

1.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.4 Homologations

1.3.2. Installer’s liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.4.1. Certifications

03/02/2014 - 300026515-001-03

Electrical compliance / Marking CE

n

This product complies to the requirements to the european directives

and following standards:

4 2006/95/EC Low Voltage Directive

Reference Standard: EN 60.335.1.

4 2004/108/EC Electromagnetic Compatibility Directive

7

1. Introduction TWH 200E TWH 300E TWH 300EH

Reference Standard: EN 50.081.1 / EN 50.082.1 / EN 55.014.

1.4.2. Directive 97/23/EC

This product conforms to the requirements of european directive 97 /

23 / EC, article 3, paragraph 3, on pressure equipment.

1.4.3. Factory test

Before leaving the factory, each appliance is tested for the following:

4 Water tightness

4 Air tightness

4 Electrical safety.

8

03/02/2014 - 300026515-001-03

TWH 200E TWH 300E TWH 300EH 2. Safety instructions and recommendations

2 Safety instructions and

recommendations

2.1 Safety instructions

DANGER

If smoke is released or in case of refrigerant leak:

1. Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches ( doorbell,

light, motor, lift, etc..).

2. Open the windows.

3. Switch the appliance off.

4. Avoid contact with the refrigerant. Danger of frost

injuries.

5. Trace possible leaks and seal them immediately.

2.2 Recommendations

WARNING

Depending on the settings of the appliance:

4 Do not touch the refrigeration connection pipes with

your bare hands while the appliance is running. Risk

of being burnt.

CAUTION

4 Do not neglect to service the appliance.

4 In order to limit the risk of being scalded, the

installation of a thermostatic mixing valve on the

domestic hot water flow piping is compulsory.

WARNING

Only certified professionals having received adequate

training are permitted to work on the appliance and the

installation.

03/02/2014 - 300026515-001-03

WARNING

Before any work, switch off the mains supply to the

appliance.

9

2. Safety instructions and recommendations

2.3 Safety data sheet: R-134a refrigerant

2.3.1. Product identification

4 Refrigerant name: R-134a

2.3.2. Hazard identification

4 Effects harmful to health:

- The vapours are heavier than air and may lead to asphyxia

owing to reduced oxygen levels.

- Liquefied gas: Contact with the liquid may cause serious frost

and eye injuries.

4 Product classification: This product is not classified as a

"hazardous preparation" according to European Union

regulations.

TWH 200E TWH 300E TWH 300EH

2.3.3. Composition / Information on the

ingredients

4 Chemical nature: 1,1,1,2-Tetrafluoroethane R-134a.

4 Ingredients that may lead to hazardous situations:

Substance name

1,1,1,2-Tetrafluoroethane R-134a 100 % 811-97-2 212-377-0

Concentration CAS number CE number Classification GWP

2.3.4. First aid

4 If inhaled: Evacuate the subject from the contaminated area and

take him into the open air.

If feeling unwell: Call a doctor.

4 In the event of contact with the skin: Treat frost injuries as

burns. Rinse in abundant water, do not remove clothing (risk of

adhesion to the skin).

If skin burns appear, call a doctor immediately.

4 In the event of contact with the eyes: Rinse immediately in

water, holding the eyelids well apart (at least 15 minutes).

Consult an ophthalmologist immediately.

1300

10

2.3.5. Fire prevention measures

4 Appropriate extinguishing agents: All extinguishing agents can be

used.

03/02/2014 - 300026515-001-03

TWH 200E TWH 300E TWH 300EH

2. Safety instructions and recommendations

4 Inappropriate extinguishing agents: None to our knowledge. In the

event of fire nearby, use the appropriate extinguishing agents.

4 Specific hazards:

- Rise in pressure.

In the presence of air, an inflammable mixture may form under

certain temperature and pressure conditions

- Toxic and corrosive vapours may be released by the effect of

the heat.

4 Special intervention methods: Cool the volumes exposed to heat

with water spray.

4 Protection of the firemen:

- Full facepiece self-contained breathing apparatus

- Complete body protection.

2.3.6. In the event of accidental spillage

4 Individual precautions:

- Avoid contact with the skin and eyes

- Do not intervene without appropriate protective equipment

- Do not inhale the vapours

- Evacuate the hazardous area

- Stop the leakage

- Eradicate all sources of ignition

- Ventilate the spillage area mechanically (Risk of asphyxia).

4 Cleaning / Decontamination: Allow residual product to evaporate.

2.3.7. Handling

4 Technical measures: Ventilation.

4 Precautions to be taken:

- No smoking

- Prevent the accumulation of electrostatic charges

- Work in a well ventilated place.

2.3.8. Personal protection

4 Respiratory protection:

- If insufficient ventilation: AX type cartridge mask

- In confined spaces: Full facepiece self-contained breathing

apparatus.

4 Hand protection: Protective gloves in leather or nitrile rubber.

4 Eye protection: Safety glasses with side protection.

4 Skin protection: Clothing made mostly of cotton.

4 Industrial hygiene: Do not drink, eat or smoke at the place of work.

03/02/2014 - 300026515-001-03

11

2. Safety instructions and recommendations TWH 200E TWH 300E TWH 300EH

2.3.9. Considerations on disposal

4 Product waste: Consult the manufacturer or the supplier for

information on recovery or recycling.

4 Soiled packaging: Reuse or recycle after decontamination.

Destroy in authorised installations.

WARNING

Disposal must be done in compliance with prevailing local

and national regulations.

2.3.10. Regulations

4 EC Regulation 842/2006: Fluorinated greenhouse gases under

the Kyoto Protocol.

12

03/02/2014 - 300026515-001-03

TWH 200E TWH 300E TWH 300EH 3. Technical description

3 Technical description

3.1 General description

The DHW tanks in the TWH range have the following characteristics:

4 Floor-standing thermodynamic storage DHW tank

4 Thermodynamic unit extracting energy from unheated ambient air

or outside air

4 Control panel with display of the volume of water heated and

hourly programming

4 Heat exchanger for connection to a boiler or a solar circuit (Version

EH)

4 Steatite electrical resistor 2.4 kW

4 Enamelled tank protected by impressed current anode

4 Very thick insulation (0% CFCs)

The thermodynamic water heater is a hot water tank that can be

heated by:

4 The Heat Pump (up to 65°C)

4 The electric heating resistance (Electrical back-up - AUTO and

Boost mode) (up to 70°C)

4 The additional heat exchanger (Version EH)

03/02/2014 - 300026515-001-03

13

C003185-F

5

6

10

2

1

3

4

15

16

13

12

14

17

11

19

18

8

7

9

3. Technical description

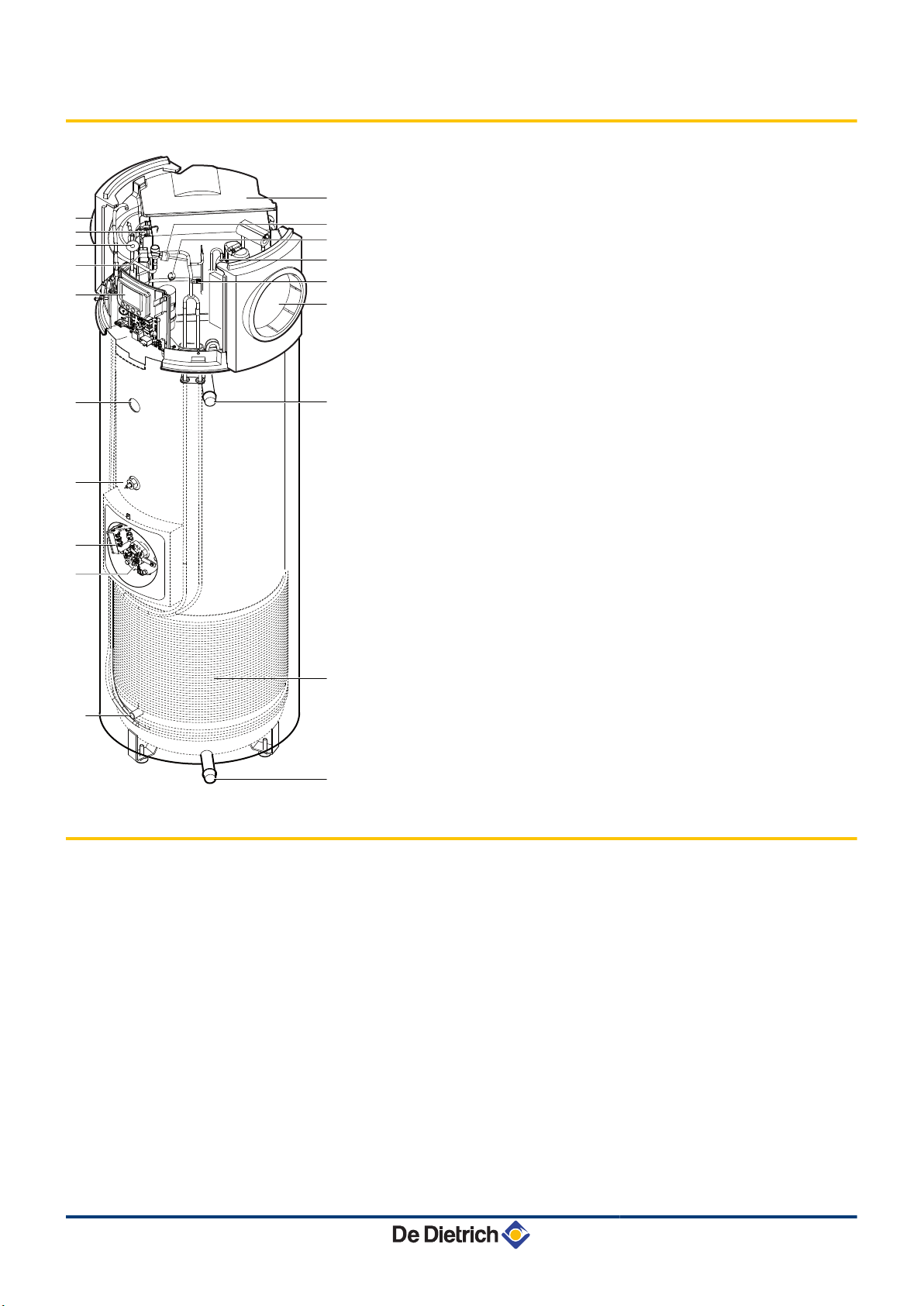

3.2 Main parts

TWH 200E TWH 300E TWH 300EH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Fan

Evaporator

Expansion valve

Solenoid valve for defrosting

Regulation

temperature sensor

Impressed current anode

Safety thermostat

Steatite electrical resistor

temperature sensor

Air conduits

High pressure (HP) pressure switch

Low pressure (LP) pressure switch

Compressor

Pressure measurement point - High pressure (HP)

Ventilation grid

Domestic hot water outlet

18

19

Condenser

Cold water inlet

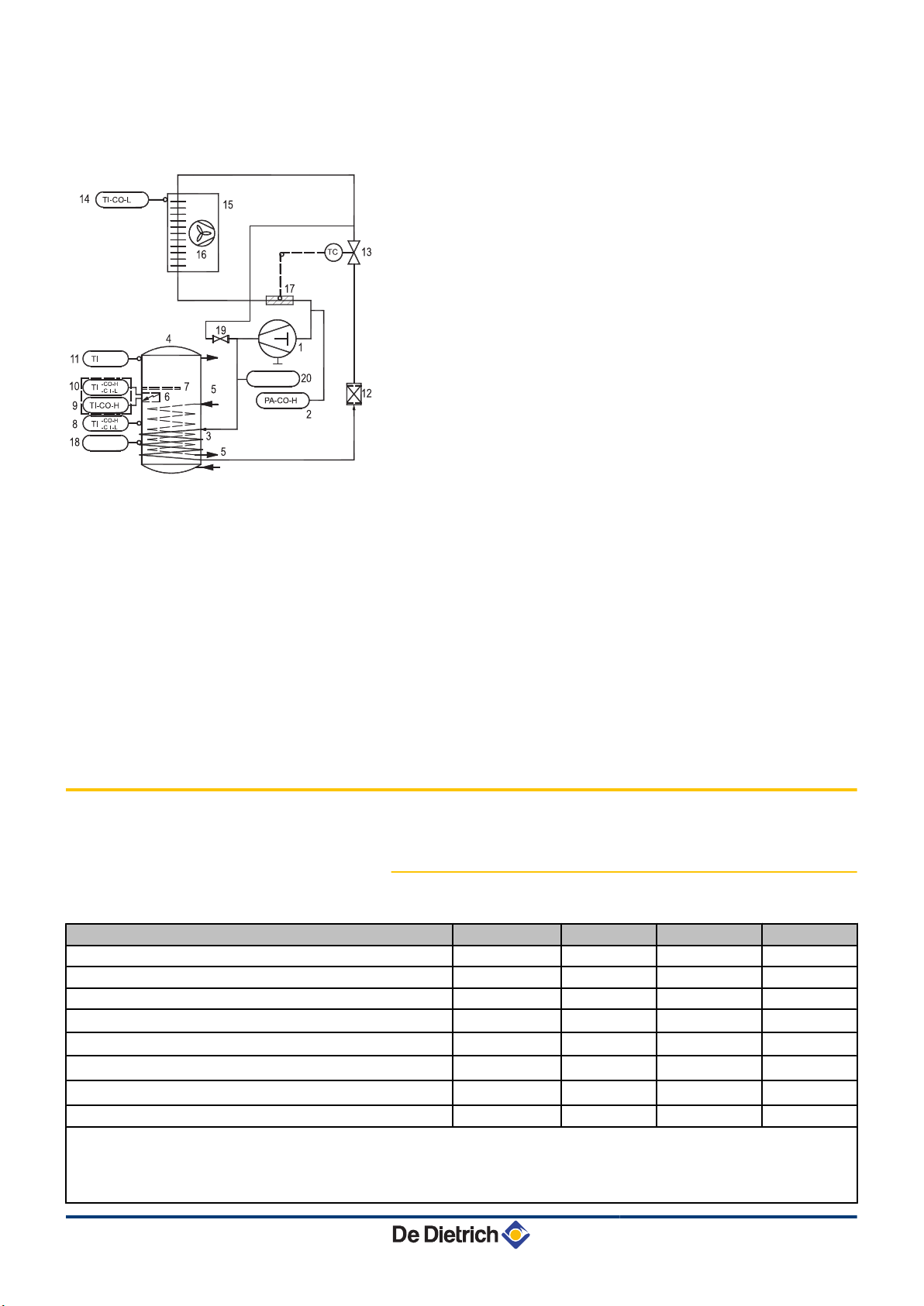

3.3 Operating principle

The thermodynamic DHW tank uses unheated ambient air or outside

air to prepare DHW.

The refrigerant circuit is a closed circuit in which the R-134a

refrigerant plays the role of an energy carrier.

The heat from the intake air is transferred to the refrigerant in the

finned heat exchanger at a low evaporation temperature.

The refrigerant is sucked in by a compressor in vapour form, which

raises it to a higher pressure and temperature and sends it to the

condenser. In the condenser, the heat extracted in the evaporator and

some of the energy absorbed by the compressor are released into

the water.

14

03/02/2014 - 300026515-001-03

C003625-D

TWH 200E TWH 300E TWH 300EH 3. Technical description

The refrigerant is depressurised in the thermostatic expansion valve

and is cooled. The refrigerant can again extract the heat contained in

the inlet air into the evaporator.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Compressor

Low pressure (LP) pressure switch

Condenser

Domestic hot water tank

Heat exchanger (Version EH)

Steatite electrical resistor

Impressed current anode

Temperature regulator (HP)

Limiting thermostat

Temperature regulator (Electric heating

resistance)

Sensor tube

Filter-drier

Thermostatic expansion valve

Ambient air thermostat

Evaporator

Fan

17

18

19

20

Expansion valve bulb

Sensor tube

Solenoid valve for defrosting

High pressure (HP) pressure switch

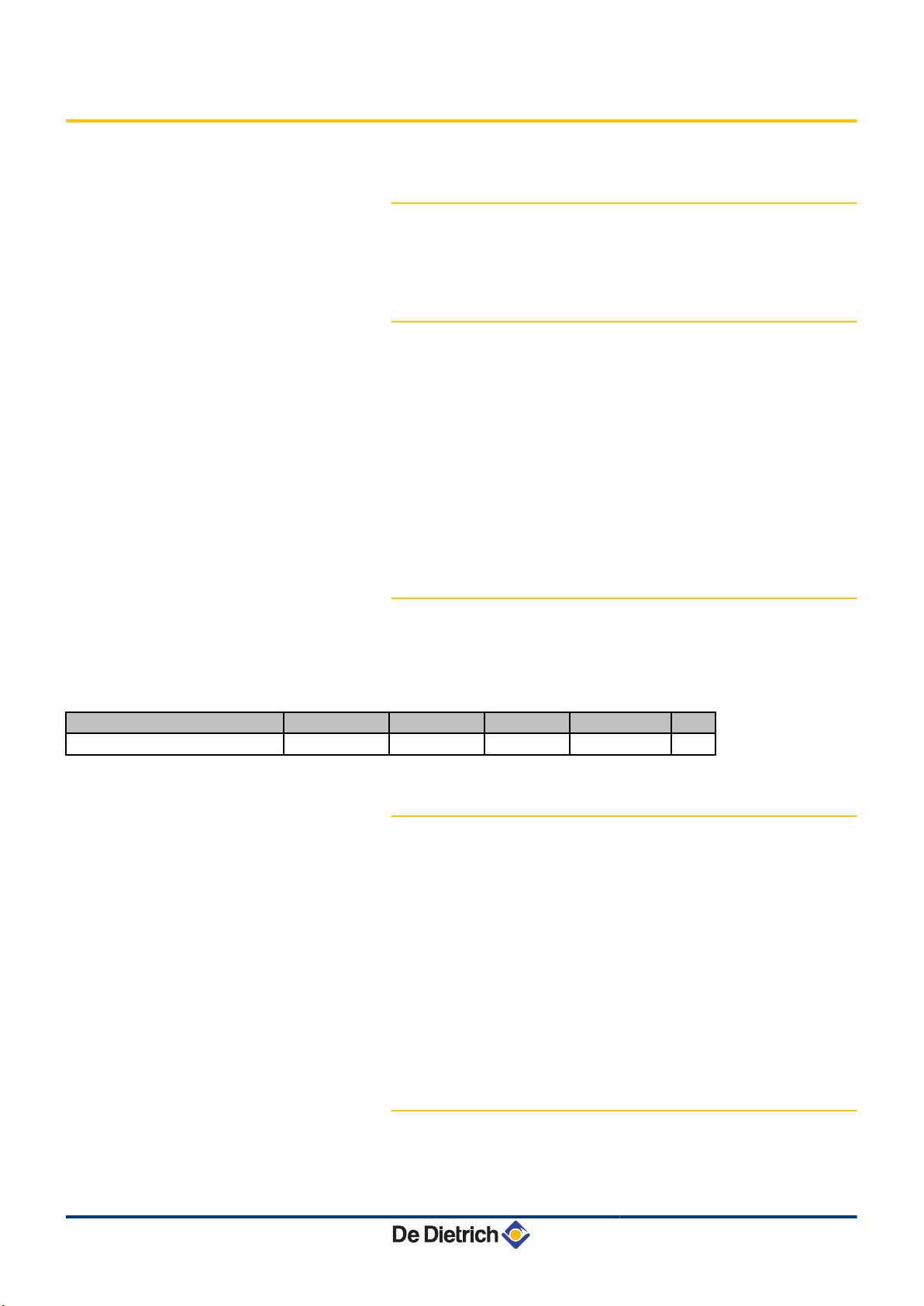

3.4 Technical specifications

3.4.1. Characteristics of the appliance

Model

Capacity litres 270 265 215

Output (HP) -Air temperature = 15°C W 1700 1700 1700

Absorbed electrical power (HP) W 500 500 500

(1)

COP

(2)

COP

Air flow rate - maximum

Nominal air flow rate (DP = 25 Pa)

Electrical resistor output W 2400 2400 2400

(1) Value obtained at an air temperature of 15°C and a relative humidity of 70%. Water inlet temperature at 15°C in accordance with EN255-3.

(2) Value obtained with an air temperature of 7 and a water inlet at 10 °C, as per EN16147 based on Specification LCIE N°103-15/B:2011

(3) Domestic cold water input at 10°C - Primary inlet temperature at 80°C

(4) Output: 34.1 kW

(5) The installation of suction and backflow conduits on the heat pump lessens its performance

(2)

m3/h

m3/h

TWH 300 E TWH 300 EH TWH 200 E

3.7 3.6 3.5

2.94 2.75 2.90

385 385 385

320 320 320

03/02/2014 - 300026515-001-03

15

0

2

4

6

8

10

12

14

16

18

20

-5 0 5 10 15 20 25 30 35

Y

X

B

A

C003447-A

C003483-B

51°

-5 0 5 7 10 X

55°

65°

Y

3. Technical description TWH 200E TWH 300E TWH 300EH

Model

TWH 300 E TWH 300 EH TWH 200 E

Operating pressure bar (MPa) 10 10 10

Power supply voltage V 230 230 230

Circuit breaker A 16 16 16

Exchanger surface

Continuous output DT = 35 K

Flow rate over 10 minutes with DT = 30 K

Heating time (15-51 °C)

(1)

Qpr

(1)

V40

(2)

Vmax

(2)

Pes

(3) (4)

(3)

(1)

Maximum length of the air connection Diameter 160 mm

(5)

2

m

- 1.00 -

litres per hour - 955.6 -

l/10 mm - 420 -

Hours 7 7 5

kWh/24h 0.67 0.75 0.73

litres 357 358 240

litres 388 383 281.9

W 34 36 30

m 25 25 25

R134a refrigerant kg 1.45 1.45 1.45

Weight (empty) kg 105 123 92

(1) Value obtained at an air temperature of 15°C and a relative humidity of 70%. Water inlet temperature at 15°C in accordance with EN255-3.

(2) Value obtained with an air temperature of 7 and a water inlet at 10 °C, as per EN16147 based on Specification LCIE N°103-15/B:2011

(3) Domestic cold water input at 10°C - Primary inlet temperature at 80°C

(4) Output: 34.1 kW

(5) The installation of suction and backflow conduits on the heat pump lessens its performance

3.4.2. Heating time of the DHW tank depending on

the air temperature

Scenario for complete heating of the DHW tank

A

B

Y

X

Heating time for a set point of 51°C

Heating time for a set point of 62°C

Heating time (Hours)

Air temperature (°C)

3.4.3. Max domestic hot water set point reached

by the heat pump depending on the air

temperature

Y

Max domestic hot water temperature (°C)

16

X

Air temperature (°C)

03/02/2014 - 300026515-001-03

TWH 200E TWH 300E TWH 300EH 4. Installation

4 Installation

4.1 Regulations governing installation

CAUTION

Installation and maintenance of the appliance must be

done by a qualified professional in accordance with

prevailing statutory texts and codes of practice.

4.2 Package list

4.2.1. Standard delivery

The delivery includes:

4 The thermodynamic DHW tank x1

4 Dielectric connection (delivered in the instructions bag for the

DHW tank) (2x)

4 Lip gasket (2x)

4 Condensate evacuation hose (1x)

4 Instructions + Kyoto Protocol sticker (1x)

4 Hose holding clip (1x)

4 The user instructions

4 The installation and maintenance instructions

4.2.2. Accessories

Accessories

Galvanised 90° elbow (Diameter 160 mm) EH 77

Adapter sleeve (Diameter 160 mm) EH 205

Insulated flexible duct (Diameter 160 mm - Length 3 m) EH 206

Set of 2 retaining clamps (Diameter 160 mm) EH 207

Passing through walls (Diameter 160 mm) + Closing plate EH 208

Outside grid (Diameter 160 mm) (aluminium) EH 209

PPE duct (Diameter 160 mm - Length 2x1 m) + 2 sleeves EH 272

290° elbows (PPE) (Diameter 160 mm) + 2 sleeves EH 273

2 sleeves PPE (Diameter 160 mm) EH 274

Roof outlet Black (Diameter 160 mm) EH 275

Tightness bed plate for flat roof (Diameter 160 mm) EH 276

package

03/02/2014 - 300026515-001-03

17

C003496-B

4. Installation TWH 200E TWH 300E TWH 300EH

Accessories package

Tightness bed plate for sloping roof 25 to 45° (Diameter 160

mm)

Reduced elbow kit EH 434

Connection kit for safety unit ER 208

EH 277

4.3 Storage and transport

CAUTION

4 Have 2 people available.

4 Use a 3-wheel hand truck.

4 Handle the appliance with gloves.

4 The appliance cover cannot be used for transport

operations. The cover is not capable of withstanding

heavy weights.

4 Model 300 : Allow a minimum room height of

approximately 2.15 m

Model 200 : Allow a minimum room height of

approximately 1.84 m.

4 The thermodynamic DHW tank must be stored and transported in

its packaging and not filled with water.

4 Ambient transport and storage temperatures admissible: from

-20 to +60°C.

4.3.1. Transport

We recommend shipping the appliance vertically.

It is possible to ship the appliance horizontally over short

distances but only on its back.

CAUTION

The appliance must never be stacked or laid on another

side; it may otherwise malfunction or break down.

18

03/02/2014 - 300026515-001-03

C003192-D

TWH 200E TWH 300E TWH 300EH

4.4 Choice of the location

4. Installation

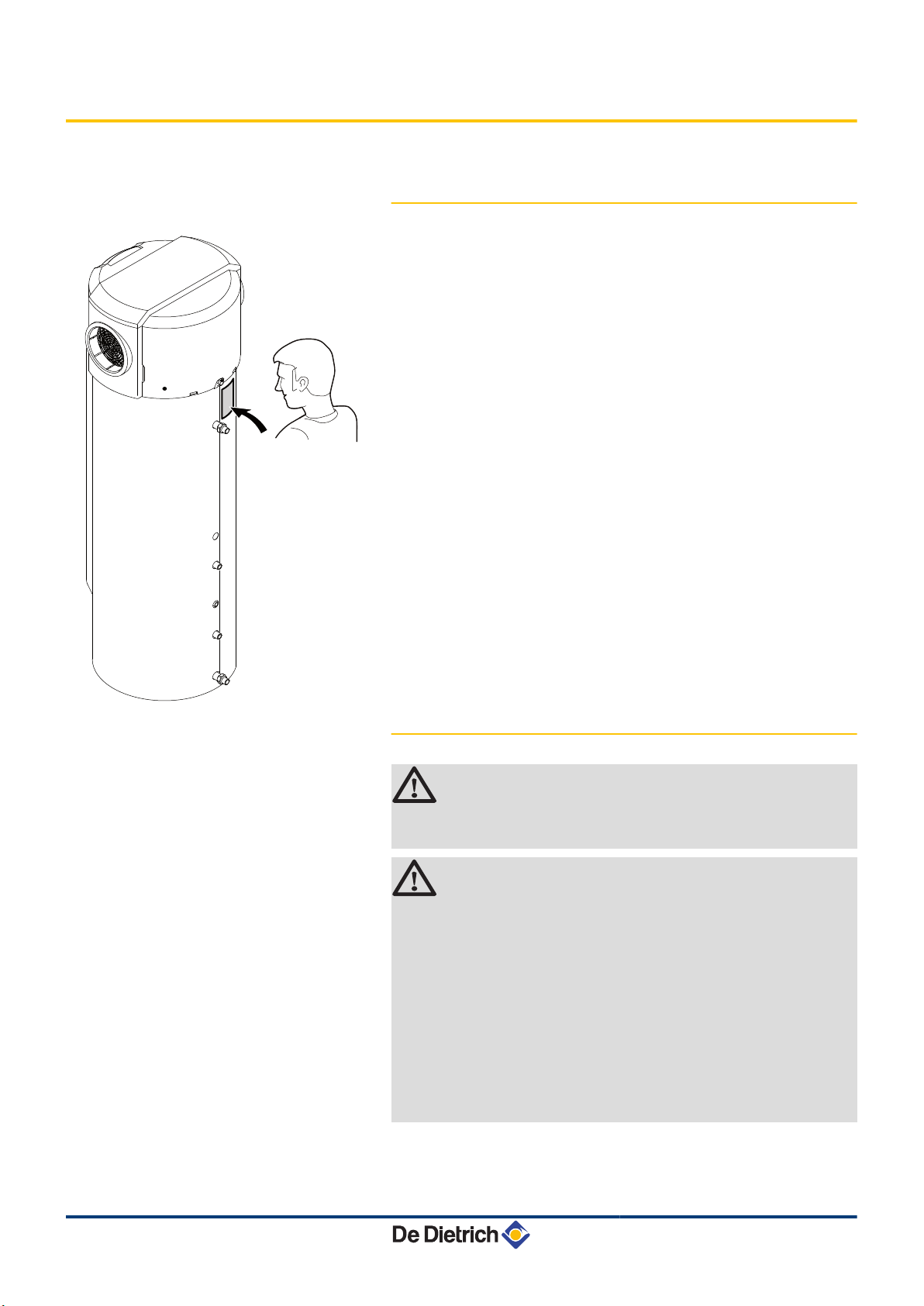

4.4.1. Type plate

4 The type plate must be accessible at all times.

4 The type plate identifies the product and provides the following

information:

- Appliance type

- Manufacturing date (Year - Week)

- Serial number.

4.4.2. Positioning of the appliance

CAUTION

When installing the appliance, respect the IP21

environmental rating.

CAUTION

4 Do not install the thermodynamic water heater in

premises exposed to gas, vapours or dust. Do not

install the thermodynamic DHW tank in an

atmosphere which is chlorinated (swimming pool) or

fluorinated (aerosols, detergents, solvents, etc.).

4 The air taken in must in no event be dusty.

4 Adequate thermal insulation in relation to adjacent

living spaces is recommended.

4 Temperature of the ambient air or of the air taken in

by the heat pump for optimum running: from 10 to

35°C.

Install the appliance in a dry, frost-free room at a minimum

4

temperature of 7°C.

4 Install the appliance on a flat, solid surface.

03/02/2014 - 300026515-001-03

19

C004021-A

C004020-A

C004019-A

A

C004022-A

C004023-A

B

4. Installation TWH 200E TWH 300E TWH 300EH

4 Install the appliance on a base frame. The base frame must at all

times present sufficient resistance to the load.

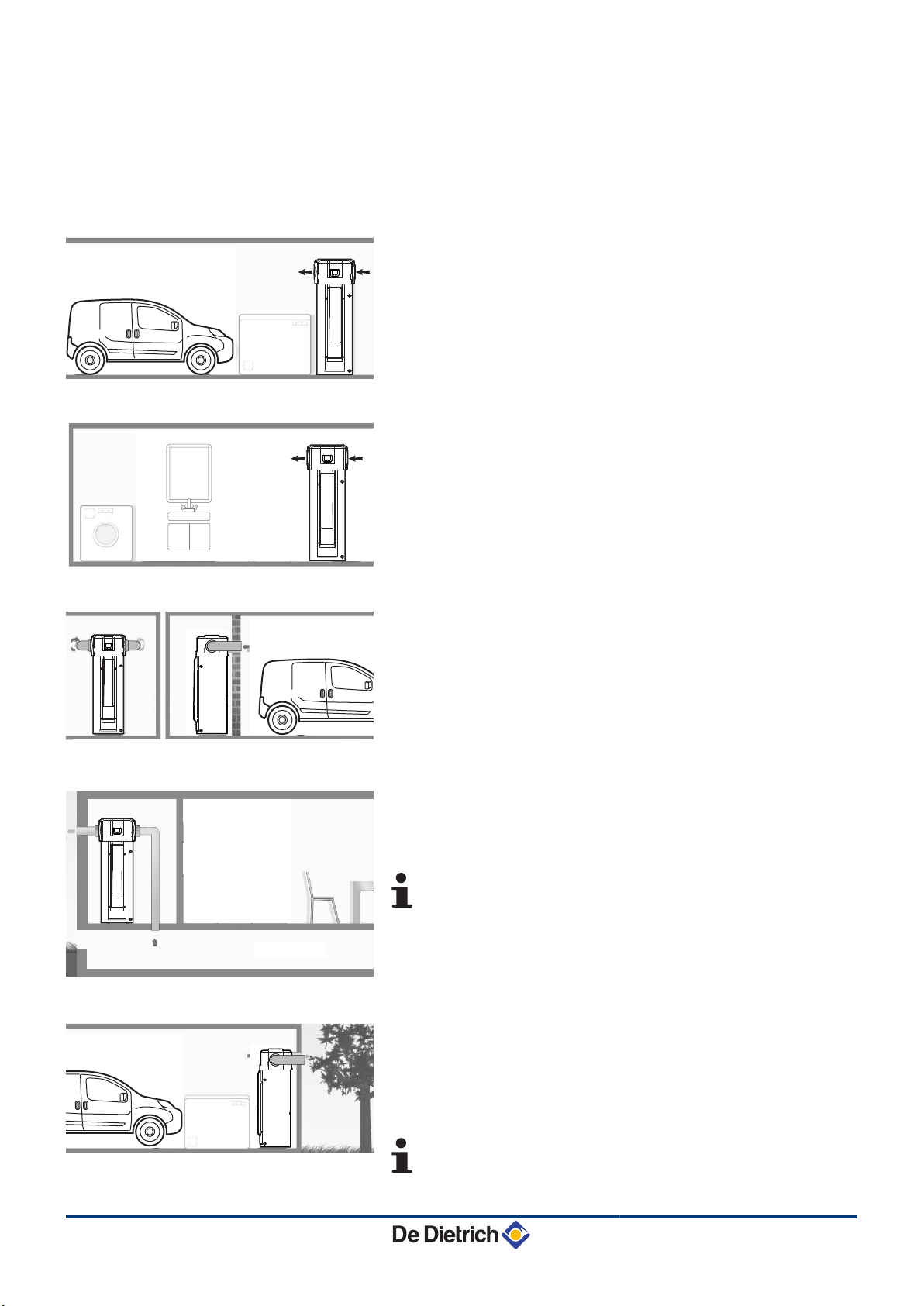

Advised positions

n

Garage:

4 Unheated room.

4 Enables recovery of the free energy released by your vehicle’s

engine when switched off after use or by household appliances in

operation.

Laundry room:

4 Unheated room.

4 Enables the dehumidification of the room and recovery of the

energy wasted by washing and drying machines.

Habitable room:

4 Can obtain free heat from the garage.

Via crawl space:

4 Connection to the crawl space is possible if the volume is greater

than 30 m3.

4 The crawl space must be frost-free (temperature > 1°C).

If the crawl space is poorly insulated, thermal losses from

the home will be greater.

Via outside air:

4 Connection to the outside air may lead to overconsumption of

electricity if the outside air temperature falls outside the operating

range.

4 Minimum distance to be observed for the ducts if intake and

backflow are done on the same façade: 700 mm.

20

Risk of discomfort in the Eco operating mode.

03/02/2014 - 300026515-001-03

Loading...

Loading...