dbx Pro 160A User Manual

MODEL 160A

COMPRESSOR

LIMITER

®

A Harman International Company

WARNING

FOR YOUR PROTECTION, PLEASE READ THE FOLLOWING:

WATER AND MOISTURE: Appliance should not be used near water (e.g. near a bath-

tub, washbowl, kitchen sink, laundry tub, in a wet basement, or near a swimming pool,

etc). Care should be taken so that objects do not fall and liquids are not spilled into the

enclosure through openings.

POWER SOURCES: The appliance should be connected to a power supply only of the

type described in the operating instructions or as marked on the appliance.

GROUNDING OR POLARIZATION: Precautions should be taken so that the grounding

or polarization means of an appliance is not defeated.

POWER CORD PROTECTION: Power supply cords should be routed so that they are

not likely to be walked on or pinched by items placed upon or against them, paying particular attention to cords at plugs, convenience receptacles, and the point where they

exit from the appliance.

SERVICING: To reduce the risk of fire or electric shock, the user should not attempt to

service the appliance beyond that described in the operating instructions. All other servicing should be referred to qualified service personnel.

FOR UNITS EQUIPPED WITH EXTERNALLY ACCESSIBLE FUSE RECEPTACLE:

Replace fuse with same type and rating only.

MULTIPLE-INPUT VOLTAGE: This equipment may require the use of a different line

cord, attachment plug, or both, depending on the available power source at installation.

Connect this equipment only to the power source indicated on the equipment rear

panel. To reduce the risk of fire or electric shock, refer servicing to qualified service

personnel or equivalent.

SAFETY INSTRUCTIONS

NOTICE FOR CUSTOMERS IF YOUR UNIT IS EQUIPPED WITH A POWER

CORD.

WARNING: THIS APPLIANCE MUST BE EARTHED.

The cores in the mains lead are coloured in accordance with the following code:

GREEN and YELLOW - Earth BLUE - Neutral BROWN - Live

As colours of the cores in the mains lead of this appliance may not correspond

with the coloured markings identifying the terminals in your plug, proceed as follows:

¥ The core which is coloured green and yellow must be connected to the

terminal in the plug marked with the letter E, or with the earth symbol, or

coloured green, or green and yellow.

¥ The core which is coloured blue must be connected to the terminal

marked N or coloured black.

¥ The core which is coloured brown must be connected to the terminal

marked L or coloured red.

This equipment may require the use of a different line cord, attachment plug, or

both, depending on the available power source at installation. If the attachment

plug needs to be changed, refer servicing to qualified service personnel who

should refer to the table below. The green/yellow wire shall be connected directly to the unit's chassis.

WARNING: If the ground is defeated, certain fault conditions in the unit or in the

system to which it is connected can result in full line voltage between chassis

and earth ground. Severe injury or death can then result if the chassis and earth

ground are touched simultaneously.

U.K. MAINS PLUG WARNING

A moulded mains plug that has been cut off from the cord is unsafe. Discard the

mains plug at a suitable disposal facility. NEVER UNDER ANY CIRCUM-

STANCES SHOULD YOU INSERT A DAMAGED OR CUT MAINS PLUG INTO

A 13 AMP POWER SOCKET. Do not use the mains plug without the fuse cover

in place. Replacement fuse covers can be obtained from your local retailer.

Replacement fuses are 13 amps and MUST be ASTA approved to BS1362.

The symbols shown above are internationally accepted symbols that warn of

potential hazards with electrical products. The lightning flash with arrowpoint in

an equilateral triangle means that there are dangerous voltages present within

the unit. The exclamation point in an equilateral triangle indicates that it is necessary for the user to refer to the ownerÕs manual.

These symbols warn that there are no user serviceable parts inside the unit. Do

not open the unit. Do not attempt to service the unit yourself. Refer all servicing

to qualified personnel. Opening the chassis for any reason will void the manufacturerÕs warranty. Do not get the unit wet. If liquid is spilled on the unit, shut it

off immediately and take it to a dealer for service. Disconnect the unit during

storms to prevent damage.

CAUTION

ELECTROMAGNETIC COMPATIBILITY

This unit conforms to the Product Specifications noted on the Declaration of

Conformity. Operation is subject to the following two conditions:

¥ this device may not cause harmful interference, and

¥ this device must accept any interference received, including interference

that may cause undesired operation.

Operation of this unit within significant electromagnetic fields should be avoided.

¥ use only shielded interconnecting cables.

DECLARATION OF CONFORMITY

ManufacturerÕs Name: dbx Professional Products

ManufacturerÕs Address: 8760 S. Sandy Parkway

Sandy, Utah 84070, USA

declares that the product:

dbx 160A

conforms to the following Product Specifications:

Safety: EN 60065 (1993)

IEC65 (1985) with Amendments 1, 2, 3

EMC: EN 55013 (1990)

EN 55020 (1991)

Supplementary Information:

The product herewith complies with the requirements of the

Low Voltage Directive 73/23/EEC and the EMC Directive

89/336/EEC as amended by Directive 93/68/EEC.

dbx Professional Products

Vice-President of Engineering

8760 S. Sandy Parkway

Sandy, Utah 84070, USA

July 28, 1998

European Contact: Your Local dbx Sales and Service Office or

International Sales Office

68 Sheila Lane

Valparaiso, Indiana

46383, USA

Tel: (219) 462-0938

Fax: (219) 462-4596

RISK OF ELECTRIC SHOCK

DO NOT OPEN

ATTENTION:

WARNING:

SHOCK DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE

RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR

TO REDUCE THE RISK OF FIRE OR ELECTRIC

CONDUCTOR

L

N

E

LIVE

NEUTRAL

EARTH GND

WIRE COLOR

Normal Alt

BROWN

BLUE

GREEN/YEL

BLACK

WHITE

GREEN

MANUAL CONTENTS

QUICK SET-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

I

NSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

I

NTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

A

PPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

O

PERATING CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

O

PERATING NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

C

ONNECTING THE 160A TO YOUR SYSTEM . . . . . . . . . . . . . . . . . . . . . . 10

I

NSTALLATION CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

T

ECHNICAL SUPPORT / FACTORY SERVICE . . . . . . . . . . . . . . . . . . . . . . 13

W

ARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

S

PECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

dbx 160A COMPRESSOR / LIMITER

1

QUICK SETUP

To get your unit up and running as quickly as possible, do the following steps. For more detailed information, refer to the

specified pages.

¥ Unpack and Inspect the 160A Package.

¥ Set Levels and Controls as Needed.

¥ Connect the 160A to Your System.

INSPECTION

Verify that the 160A package contains the following:

¥ 160A Unit

¥ AC Power Cord

¥ Operation Manual (including Registration Card)

INTRODUCTION

Congratulations on purchasing the dbx 160A Compressor/Limiter. We recommend you take a moment and read through

the manual as it provides information that will assist you from system installation to operation to special applications.

Features include:

¥ OverEasy¨/Hard Knee Selection -- allows selection between our famous OverEasy compression curve and the classic

ÒHard KneeÓ curve popularized by the original dbx 160, 161 and 162.

¥ True RMS Level Detectionª -- senses the power in the program in a musical manner, much as the ear does, giving

results superior to peak or average detection.

¥ Hardwire System Bypass Button -- allows the audio to pass even if the unit is unplugged, and is also useful for compar-

ing the processed and unprocessed signal.

¥ Front Panel SLAVE Button -- couples two 160As together for stereo operation at the push of a button. Note: a 160A

unit cannot be stereo-coupled with a dbx 160XT, 160X, 160, 161 or 162 unit.

¥ True Power Summing -- When two 160A units are slaved together, the RMS energy of the signal presented to the slave

unit is summed with the RMS energy of the signal presented to the master unit to prevent phase cancellation of the two

signals from causing unmusical compressor action.

¥ LED Displays -- 19-Segment LED Display for high resolution monitoring of True RMS INPUT and OUTPUT

LEVELs; 12-Segment LED Display for GAIN REDUCTION (up to 40dB).

¥ Meter Calibration -- Input/Output meter calibration, so the 160A can be used in a variety of situations where the Ò0Ó ref-

erence is not consistent.

¥ XLR-type Input and Output Jacks -- because the 3-pin XLR connector has been recognized as the most durable and

widely used connector for professional applications. (An optional output transformer is available.)

¥ Input and Output Jacks -- with the output capable of driving its own additional 600½ load (single-ended) in addition to

any load on the XLR output.

¥ Input Ground Lift Switch -- internally disconnects pin 1 of the input XLR jack from 160A chassis ground to eliminate

any ground loop hum problems that may arise.

¥ Detector Input -- useful for special applications including frequency conscious compression in which an external equal-

izer is used.

¥ DC-controlled Parameters -- the signal does not pass through any of the parameter controls. Instead a DC voltage con-

trols all functions; this eliminates any possibility of potentiometer noise developing over time.

2

®

PROFESSIONAL PRODUCTS

dbx 160A COMPRESSOR / LIMITER

APPLICATIONS

The dbx 160A is capable of handling a wide range of applications. In the studio, the 160A can be used on everything

from vocals to percussion. In live sound reinforcement, the 160A can allow the engineer to get that Òfat studio soundÓ

out of the drum kit or provide protection limiting for the speakers. It is also an excellent line driver, perfect for sending

signals down long cables to power amp stacks or from remote broadcast trucks. In radio or television broadcast, the

160A will produce stable voice levels, even with non-professional subjects.

OPERATING CONTROLS

Front Panel

BYPASS Button and LED:

Depress this button to create aÓhard-wire bypassÓ of the 160A's circuitry (i.e., unaltered input signal will pass through

the unit even if it is unplugged).

In Bypass mode, the input is sent directly to the output, bypassing the 160A's processing and controls and presenting

unaltered input signal at the 160A's OUTPUT. Bypass mode is especially useful for making comparisons between

processed and unprocessed signals.

The BYPASS LED turns On in Bypass mode if the 160A is being provided with AC power.

SLAVE Button and LED:

When two 160As are connected via their rear panel STEREO STRAPPING jacks, depressing the SLAVE button on one

160A of the stereo pair determines that the other 160A will be the Master (i.e., the controlling unit).

Note: When two 160As are strapped together and the SLAVE buttons on both units are NOT depressed, the 160As DO NOT operate independently

because the “ring” of the strapping cable still sums the audio of each unit. The strapping cable must be removed for proper single-channel operation. If

both SLAVE buttons are depressed, both units will be bypassed (i.e., fixed at unity gain).

The LED above the SLAVE button turns On when the 160A is in Slave mode, indicating that the front panel functions

(with the exception of BYPASS and LEVEL display) are deactivated and under control of the Master 160A.

THRESHOLD Control:

Adjust this knob to set the threshold of compression -40dBu (7.8mVRMS) to +20dBu (7.8VRMS).

OverEasy Button:

Depress this button to select the OverEasy¨ compression characteristic. The amber THRESHOLD LED turns On when

the signal is in the OverEasy region. When this button is out, the 160A operates as a hard knee compressor/limiter.

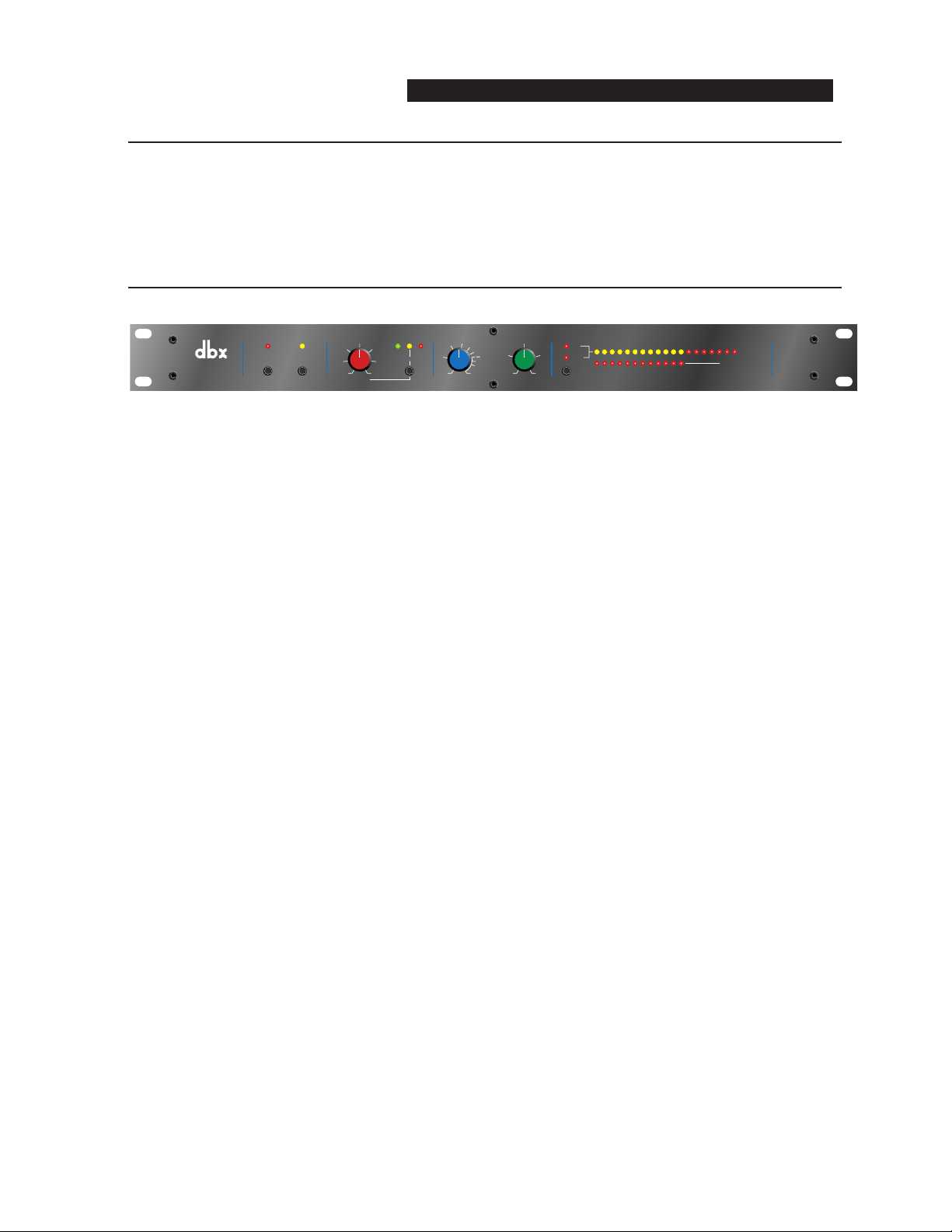

In Hard Knee mode, the threshold of compression is defined as that point above which the output level no longer

changes on a 1:1 basis with changes in the input level. See Figure 1.

In OverEasy mode, the threshold of compression is defined as the middle of the OverEasy threshold region, that is,

Òhalf-wayÓ into compression, as shown in Figure 2.

THRESHOLD LEDs:

These three LEDs indicate the relationship of the input signal level to the threshold of compression. The green

ÒBELOWÓ LED is On when the signal is below threshold and the red ÒABOVEÓ LED is On when the signal is above

threshold. When the 160A is switched to OverEasy mode, the amber LED is On when the signal is in the OverEasy

region (See Figure 2).

COMPRESSION RATIO Control:

Rotate this control clockwise to increase the amount of compression from 1:1 (no compression) up to infinity:1 (no

increase in output level, regardless of input level increases above threshold); further clockwise rotation increases compression into the INFINITY+ region, up to a maximum of 1:1 (i.e., a 1dB increase in input level above threshold causes

a 1dB decrease in output level). In the INFINITY+ region, the 160A inverts the program dynamics for special effects.

dbx 160A COMPRESSOR / LIMITER

3

160A

BYPASS SLAVE OVEREASY

-20

-30

-40dBu -1:1

THRESHOLD COMPRESSION

-10

0

BELOW ABOVE

+10

+20dBu

4:1

3:1

6:1

10:1

2:1

-5:1

-2:1

1:1 +20dB

RATIO

0

-10

:1

-20dB

OUTPUT

GAIN

INPUT

+10

-40302015108654321012461020+

OUTPUT

COMPRESSOR/LIMITER

DISPLAY

GAIN REDUCTION

LEVEL

OUTPUT GAIN Control:

Adjust this control to vary the amount of fixed gain (up to +20dB) in the 160A's output amplifier stage. The OUTPUT

GAIN control does not interact with the threshold of compression.

DISPLAY Button and LED:

Depress this button to make the upper LED array display the INPUT LEVEL to the 160A. With the button out, the

OUTPUT LEVEL is displayed. A pair of LEDs immediately above the DISPLAY button indicates the selected display.

INPUT/OUTPUT LEVEL and GAIN REDUCTION Displays:

The upper row of 19 LEDs displays either the INPUT or OUTPUT LEVEL, as selected with the DISPLAY button. This

display is factory set so that 0dB is equivalent to +4dBu input or output level (1.23VRMS), but may be reset with the

rear panel METER CALIBRATION trimmer. (See following pages.)

The lower row of 12 LEDs displays up to 40dB of GAIN REDUCTION (although the 160A is actually capable of delivering up to 60dB of gain reduction). Note that fixed gain changes due to the OUTPUT GAIN control are not displayed

by the GAIN REDUCTION LEDs but are reflected in the OUTPUT LEVEL display.

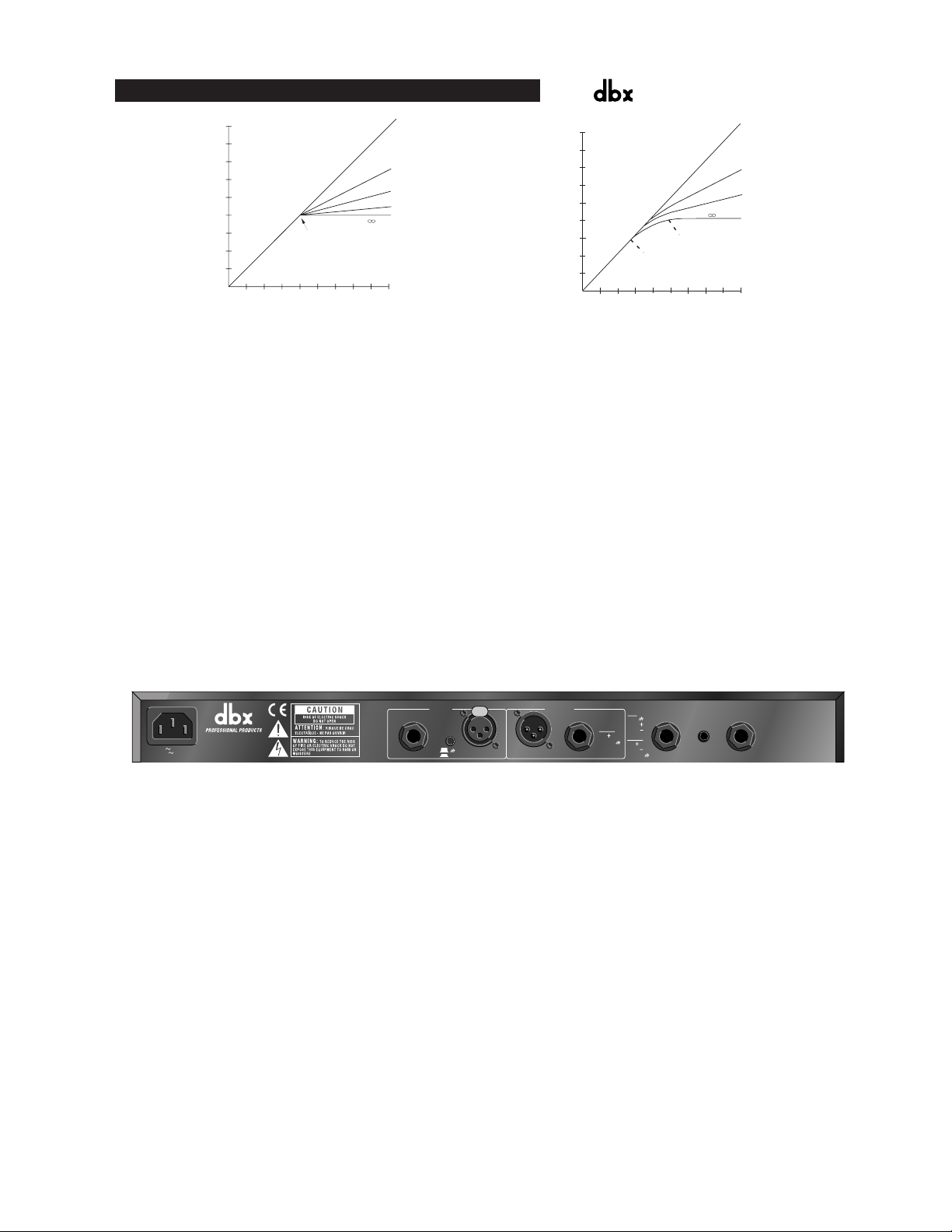

Rear Panel

INPUT (BALANCED) Jacks:

The Tip/Ring/Sleeve phone jack and XLR-type jack are wired in parallel; either INPUT will accept an audio signal for

processing by the 160A. The phone jack accepts a standard TRS 1/4Ó phone plug for a balanced input source, or a 2-circuit (Tip/Sleeve) 1/4Ó phone plug for an unbalanced source. The XLR-type jack is wired pin 2 HOT (+), pin 3 COLD (-)

and pin 1 GROUND.

OUTPUT (BALANCED) Jack:

The 160A's OUTPUT (BALANCED) jack is driven by a floating active-balanced amplifier that simulates a true transformer output. This allows for the load at the OUTPUT to be either balanced with respect to ground, or single-ended to

ground (unbalanced) with very little difference (less than 0.5dB) in output level. For proper unbalanced operation, the

unused pin (either pin 2 or 3) MUST be grounded.

Nominal output signal level is +4dBu into 600½, and typical maximum output level is +25dBu into 600½. This jack

accepts XLR-type connectors, wired pin 2 HOT (+), pin 3 COLD (-), and pin 1 chassis ground.

For applications which require a ÒtrueÓ transformer output, an optional output transformer can be installed. Contact our

Customer Service Department at the phone number listed on the back cover for details. If outside the United States, contact your dbx distributor.

OUTPUT (UNBAL) Jack:

The 160A has a separate single-ended (unbalanced) output amplifier capable of driving a 600½ (or greater) load to

4

®

PROFESSIONAL PRODUCTS

dbx 160A COMPRESSOR / LIMITER

)

Figure 1: Hard Knee Compression Curve

and threshold LEDs

Figure 2: OverEasy® Compression Curve

and threshold LEDs

1:1 Unity

+20

+15

+10

+5

0

-5

OUTPUT LEVEL (dB)

-10

-15

-15

RED

Above Threshold

Rotation Point T hreshold

GREEN

Below Threshold

-10-50

INPUT LEVEL (dB)

+5 +15

+10

2:1

4:1

20:1

:1

+20

+20

+15

+10

+5

0

-

5

OUTPUT LEVEL (dB)

-

10

-

15

-

15

R

BE

M

A

YELLOW

N

OverEasy Range

E

RE

G

Below Threshold

-

-

50+5

10

INPUT LEVEL (dB

RED

Above Threshold

+15

+10

1:1

2:1

4:1

:1

+20

15 WATTS

100V 50/60Hz

120V 60Hz

A HARMAN INTERNATIONAL

COMPANY

SALT LAKE CITY, UTAH

MADE IN USA

MODEL 160A

COMPRESSOR/LIMITER

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS 4,234,804 4,316,107 4,329,598 4,331,931 4,377,792 4,403,199 4,409,500 4,425,551 4,434,380 4,454,433 4,471,324 4,473,793 OTHER PATENTS PENDING

INPUTS OUTPUTS

XLR

GND

LIFT

BALANCED BALANCED

LIFT

UNBALANCEDBAL / UNBAL

PHONE:

TIP

SLEEVE

XLR:

PIN 1

PIN 2

PIN 3

PHONE:

TIP

RING

SLEEVE

DETECTOR

INPUT

METER

CALIBRATION

STEREO

STRAPPING

TRS 160A ONLY

Loading...

Loading...