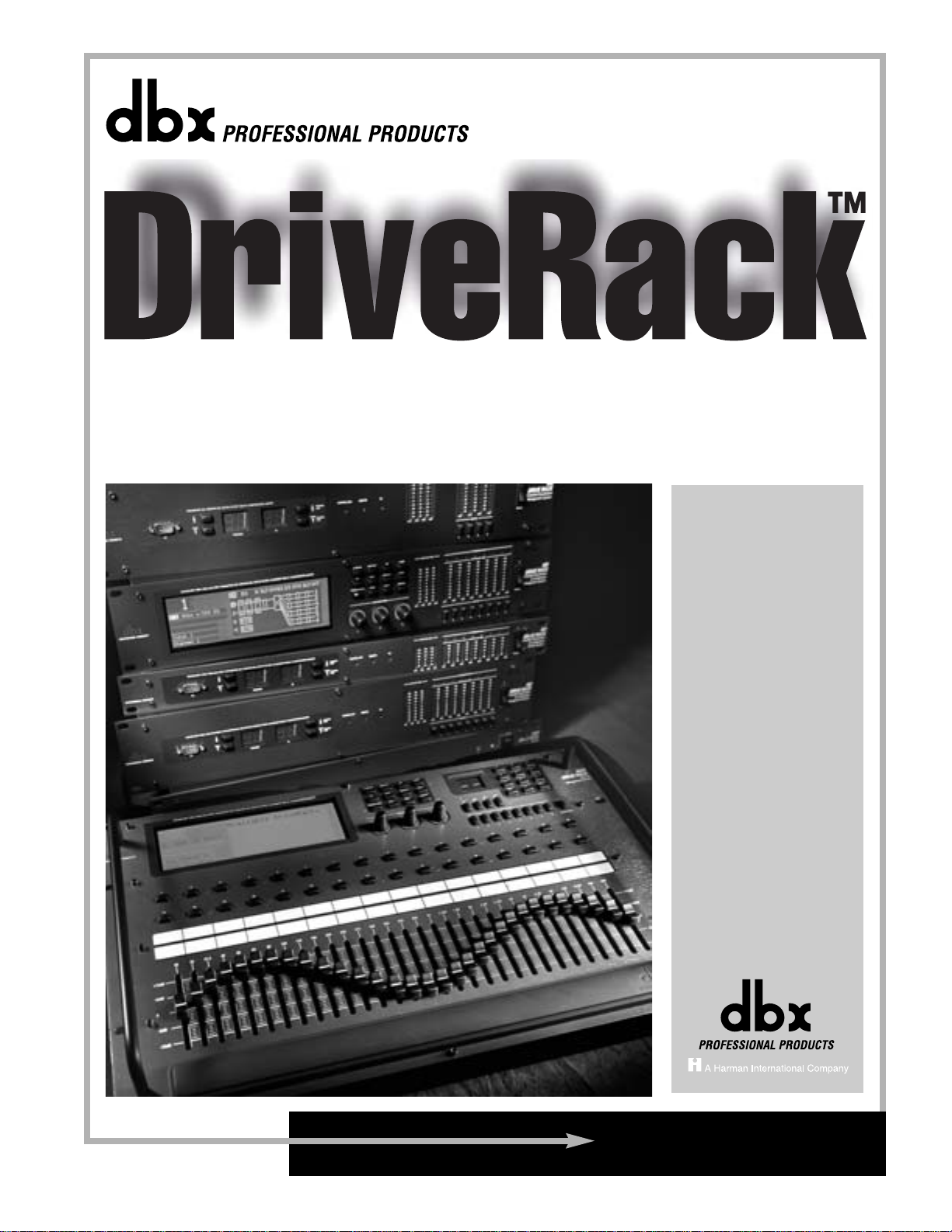

Page 1

User Manual

Complete Equalization & Loudspeaker Management System

442

480

481

482

480R

®

®

Page 2

WARNING FOR YOUR PROTECTION

PLEASE READ THE FOLLOWING:

KEEP THESE INSTRUCTIONS

HEED ALL WARNINGS

FOLLOW ALL INSTRUCTIONS

CLEAN ONLY WITH A DRY CLOTH.

DO NOT BLOCK ANY OF THE VENTILATION OPENINGS. INSTALL IN ACCORDANCE WITH THE

MANUFACTURER’S INSTRUCTIONS.

DO NOT INSTALL NEAR ANY HEAT SOURCES SUCH AS RADIATORS, HEAT REGISTERS, STOVES,

OR OTHER APP

ARATUS (INCLUDING AMPLIFIERS) THAT PRODUCE HEAT.

ONLY USE ATTACHMENTS/ACCESSORIES SPECIFIED BY THE MANUFACTURER.

UNPLUG THIS APPARATUS DURING LIGHTNING STORMS OR WHEN UNUSED FOR LONG PERIODS OF TIME.

GROUNDING PRONG: The wide blade or the thir

d prong are pr

ovided for your safety. If the

provided plug does not fit into your outlet, consult an electrician for replacement of the

obsolete outlet.

Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles, and the point wher

e they exit from the apparatus.

Use only with the cart stand, tripod bracket, or table specified by the manufactur

e, or sold

with the apparatus. When a cart is used, use caution when moving the cart/apparatus

combination to avoid injury from tip-over.

Refer all servicing to to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally, or has been dropped.

POWER ON/OFF SWITCH: The Power switch used in this piece of equipment DOES NOT break

the connection from the mains.

ALL-POLE MAINS SWITCH: An all-pole mains switch with a contact separation of at least

3mm in each pole shall be incorporated in the electrical installation of the rack or building.

FOR UNITS EQUIPPED WITH EXTERNALLY ACCESSIBLE FUSE RECEPTACLE: Replace fuse with

same type and rating only.

MULTIPLE-INPUT VOLTAGE: This equipment may require the use of a different line cord,

attachment plug, or both, depending on the available power source at installation. Connect

this equipment only to the power source indicated on the equipment rear panel. To reduce

the risk of fire or electric shock, refer servicing to qualified service personnel or

SAFETY INSTRUCTIONS

NOTICE FOR CUSTOMERS IF YOUR UNIT IS EQUIPPED WITH A POWER

CORD.

WARNING: THIS APPLIANCE MUST BE EARTHED.

CAUTION: EQUIPMENT IS NOT

DISCONNECTED FROM MAINS WHEN

SWITCH IS IN THE OFF POSITION

The cores in the mains lead are coloured in accordance with the following

code:

GREEN and YELLOW - Earth BLUE - Neutral BROWN - Live

As colours of the cores in the mains lead of this appliance may not correspond with the coloured markings identifying the terminals in your plug, proceed as follows:

• The core which is coloured green and yellow must be connected to the

terminal in the plug marked with the letter E, or with the earth symbol,

or coloured green, or green and yellow.

• The core which is coloured blue must be connected to the terminal

marked N or coloured black.

• The core which is coloured brown must be connected to the terminal

marked L or coloured red.

This equipment may require the use of a different line cord, attachment plug,

or both, depending on the available power source at installation. If the attachment plug needs to be changed, refer servicing to qualified service personnel

who should refer to the table below. The green/yellow wire shall be connected directly to the units chassis.

WARNING: If the ground is defeated, certain fault conditions in the unit or in

the system to which it is connected can result in full line voltage between

chassis and earth ground. Severe injury or death can then result if the chassis and earth ground are touched simultaneously.

The symbols shown above are internationally accepted symbols that

warn of potential hazards with electrical products. The lightning flash

with arrowpoint in an equilateral triangle means that there are dangerous

voltages present within the unit. The exclamation point in an equilateral

triangle indicates that it is necessary for the user to refer to the owner’s

manual.

These symbols warn that there are no user serviceable parts inside the

unit. Do not open the unit. Do not attempt to service the unit yourself.

Refer all servicing to qualified personnel. Opening the chassis for any

reason will void the manufacturer’s warranty. Do not get the unit wet. If

liquid is spilled on the unit, shut it off immediately and take it to a dealer for service. Disconnect the unit during storms to prevent damage.

IMPORTANT SAFETY INSTRUCTIONS

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

ATTENTION: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE

CONDUCTOR

L

N

E

LIVE

NEUTRAL

EARTH GND

WIRE COLOR

Normal Alt

BROWN

BLUE

GREEN/YEL

BLACK

WHITE

GREEN

Page 3

U.K. MAINS

PLUG WARNING

A molded mains plug that has been cut off from the cord is

unsafe. Discard the mains plug at a suitable disposal facility.

NEVER UNDER ANY CIRCUMSTANCES SHOULD YOU INSERT A

DAMAGED OR CUT MAINS PLUG INTO A 13 AMP POWER SOCKET. Do not use the mains plug without the fuse cover in place.

Replacement fuse covers can be obtained from your local retailer. Replacement fuses are 13 amps and MUST be ASTA approved

to BS1362.

LITHIUM BATTER

Y

WARNING

CAUTION!

This product may contain a lithium battery.There is danger of

explosion if the battery is incorrectly replaced. Replace only

with an Eveready CR 2032 or equivalent. Make sure the battery is installed with the correct polarity. Discard used batteries according to manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri - Eksplosjonsfare.Ved utskifting benyttes kun

batteri som anbefalt av apparatfabrikanten. Brukt batteri

returneres apparatleverandøren.

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri av samme fabrikat og

type. Levér det brugte batteri tilbage til leverandøren.

VAROITUS!

Paristo voi räjähtää, jos se on virheellisesti asennettu.Vaihda

paristo ainoastaan laitevalmistajan suosittelemaan tyyppin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

VARNING!

Explosionsfara vid felaktigt batteribyte.Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren. Kassera använt batteri enligt fabrikantens instruktion.

IMPORTANT SAFETY INSTRUCTIONS

ELECTROMAGNETIC

COMPATIBILITY

This unit conforms to the Product

Specifications noted on the Declaration of

Conformity. Operation is subject to the following two conditions:

• this device may not cause harmful inter-

ference, and

• this device must accept any interference

received, including interference that may

cause undesired operation.

Operation of this unit within significant electromagnetic fields should be avoided.

• use only shielded interconnecting cables.

DECLARATION OF

CONFORMITY

Manufacturer’s Name: dbx Professional Products

Manufacturer’s Address: 8760 S. Sandy Parkway

Sandy, Utah 84070, USA

declares that the product:

Product name: dbx Drive Rack 442,480,481,482

Note: Product name may be suffixed by the r, s, t, p and EU

Product option: None

conforms to the following Product Specifications:

Safety: IEC60065 (1998)

EN 60065 (1993)

CAN/CSA E60065-99

EMC: EN 55013 (1990)

EN 55020 (1991)

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage

Directive 72/23/EEC and the EMC Directive 89/336/EEC as amended by

Directive 93/68/EEC.

dbx Professional Products

8760 S. Sandy Parkway

Sandy, Utah 84070, USA

March 15,2000

Revised: August 15,2001

European Contact: Your local dbx Sales and Service Office or

Harman Music Group

8760 South Sandy Parkway

Sandy, Utah

84070 USA

Ph: (801) 566-8800

Fax: (801) 568-7573

Page 4

Ta b le of Contents

DriveRack

™

Introduction

1.1 Defining the DriveRack™ System ...................ii

1.2 Service Contact Info........................................iv

1.3 Warranty...........................................................iv

Section 1 - Getting Started

1.1 Rear Panel Connections (480) .........................2

1.2 Front Panel (480) ............................................3

1.3 Rear Panel Connections (481) .........................4

1.4 Front Panel (481) ............................................5

1.5 Rear Panel Connections (482) .........................6

1.6 Front Panel (482) ............................................7

1.7 Rear Panel Connections (442) .........................9

1.8 Front Panel (442) ..........................................10

Section 2 - Editing Functions

2.1 Basic Navigation Modes.................................14

2.2 Button Array Overview..................................15

2.3 Parameter Knob Encoders Coarse/Fine ........16

2.4 (Horizontal-Vertical nav)................................16

2.5 Cut and Paste..................................................16

2.6 Navigating the EQ Sections ...........................17

2.7 Navigating the Crossover Section..................18

2.8 Navigating the RTA Section...........................19

2.9 Navigating the Delay Section ........................20

2.10 Navigating the Dynamics Section................21

2.11 Navigating the Other Section.......................22

2.12 Navigating the Utility Section ......................23

Section 3 - Configuring the

DriveRack

3.1 Program Definition.........................................26

3.2 Navigating Factory Programs.........................26

3.3 Editing Factory Programs...............................28

3.4 Saving Factory Program Changes..................28

3.5 Creating a User Configuration.......................30

3.6 Linking Modules .............................................32

3.7 Selecting and Moving Crossovers..................33

3.8 Saving Configuration Changes.......................34

Section 4 - Detailed Parameters

4.1 Input Routing..................................................36

4.2.1 Pre-Crossover EQ (31 Band Graphic)........36

4.2.2 Pre-Crossover EQ (31 Band Graphic)

Show and House ..................................................37

4.2.3 Pre-Crossover EQ (9-Band Parametric)......37

4.2.4 RTA...............................................................38

4.3 Notch Filter .....................................................39

4.4 Delay (Pre-Crossover) ....................................39

4.5 Crossovers.......................................................39

4.6 Post-Crossover Parametric EQ.......................39

4.7 Compressor/Limiter (Dynamics)....................44

4.8 Speaker Alignment Delay ..............................45

4.9 Output Routing...............................................46

Section 5 - Storing Changes

5.1 Saving Factory Program Changes..................48

5.2 Saving Configuration Changes.......................50

Section 6 - Utilities

6.1 Network ID.....................................................52

6.2 Security Levels ................................................52

6.3 Security Passwords .........................................53

6.4 Entering Security Password ...........................54

6.5 Program List....................................................55

6.6 Program Change Mode ..................................54

6.7 Contrast Adjustment .......................................57

6.8 PC COMM Mode ............................................57

6.9 Power-up (Mutes/Saved) ...............................58

6.10 MIDI Channels..............................................58

6.11 MIDI Program Dumps..................................58

6.12 SYSEX Dump ................................................59

6.13 Setup SYSEX ID............................................59

6.14 Mic Pre Set up ..............................................59

6.15 Redundancy Enable......................................60

Section 7 - Network Functions

7.1 Network Connections (Specs) .......................63

7.2 Network Connections (Applications)............64

7.3 Master/Slave Assignments..............................68

7.4 Redundancy ....................................................71

7.5 Network Trouble Shooting ............................72

7.6 PC GUI Install and basic operation ..............73

7.7 System Control................................................79

DriveRack™ User Manual

Table of Contents

®

Page 5

Ta b le of Contents

DriveRack

™

Section 8 - 480 Remote Controller

8.1 Rear Panel Connections .................................86

8.2 Front Panel Connections................................87

8.3 Rear Panel Connections (480P).....................88

8.4 Front Panel (480P) .........................................89

8.5 Using the RTA.................................................90

8.6 Hot Key Assignments.....................................91

8.7 Controlling Slave devices...............................91

8.8 480R Utility Menu...........................................92

8.9 480R System Control ......................................96

Section 9 - Application Guide

9.1 Four Way FOH .............................................100

9.2 Front of House w/Delay 3-Way Towers.....101

9.3 L-C-R + Sub + Rear.......................................102

9.4 Bi-Amp & In-Ear...........................................103

9.5 Dedicated FOH Crossover ...........................104

9.6 Stand-Alone Monitor EQ..............................105

Section 10 - Appendix

A.1 MIDI SYSEX..................................................108

A.2 Factory Reset ................................................111

A.3 Power up Quick Key Options ....................111

A.4 Flash Downloads .........................................112

A.5 Program List .................................................112

A.6 Specifications................................................113

A.7 Crossover Diagrams .....................................118

A.8 Gain Jumper Warning..................................123

A.9 Input and Output Section Diagrams...........124

A.10 “Pinking” a Room ......................................125

A.11 Wire Diagrams............................................126

DriveRack™ User Manual

Table of Contents

®

Page 6

Page 7

INTRO

CUSTOMER SERVICE INFO

Defining the

DriveRack

WARRANTY INFO

®

INTRODUCTION

DriveRack

™

Page 8

Introduction

DriveRack™ User Manual

ii

DriveRack

™

Congratulations on your purchase of the dbx DriveRack™ Complete Equalization and

Loudspeaker Management System! For over 30 years, dbx has been the industry leader in

dynamics processing. With the introduction of the DriveRack™ , dbx Professional Products has

redefined the standard by which all other loud speaker management systems will be based

This manual will be your guide to understanding the full functionality of the powerful 480, 481,

482, 442 and 480R DriveRack™ units. By combining the different components, the configuration possibilities are limitless. After you have become familiar with the unit, we encourage you

to experiment and find the most effective and efficient way to run your system by utilizing the

powerful processing of the DriveRack™.

The dbx DriveRack™ is the most effective way to manage all aspects of post mix processing

and signal routing. The following are just some of the features of the 480, 481, 482 and 480R.

480 DriveRack™ features:

•

4 Input and 8 Outputs with routing

•

31 band graphic or 9 band parametric equalizer on every input (pre-crossover)

•

Dual Real Time Audio Analyzers

•

Butterworth, Bessel or Linkwitz-Riley crossover filters

•

27 Different Crossover Configurations

•

Time Alignment and Transducer Alignment Delays

•

Compressor/Limiter on every output

•

Speaker Compensation EQ (post crossover)

•

Multi-level Security System

•

Separate House and Show EQ with individual lockouts

•

Triple redundant back up of all parameters when running network, 480R and PC GUI

•

TYPE IV™ Conversion System

•

Electronically balanced/RF filtered XLR Inputs and Outputs

•

Proprietary RS-485 Control Network

•

RS-232 PC Interface for computer display and configuration

481 DriveRack™ features:

•

4 Input and 8 Outputs with routing

•

31 band graphic or 9 band parametric equalizer on every input (pre-crossover)

•

Dual Real Time Audio Analyzers

•

Butterworth, Bessel or Linkwitz-Riley crossover filters

•

27 Different Crossover Configurations

1.1 Defining the DriveRack™ System

INTRODUCTION

®

Page 9

Introduction

DriveRack

™

DriveRack™ User Manual

•

Time Alignment and Transducer Alignment Delays

•

Compressor/Limiter on every output

•

Speaker Compensation EQ (post crossover)

•

Multi-level Security System

•

Separate House and Show EQ with individual lockouts

•

Triple redundant backup of all parameters when running network, 480R and PC GUI

•

TYPE IV™ Conversion System

•

Electronically balanced/RF filtered Euroblock Inputs and Outputs

•

Proprietary RS-485 Control Network

•

RS-232 PC Interface for computer display and configuration

482 DriveRack™ features:

•

4 Input and 8 Outputs with routing

•

31 band graphic or 9 band parametric equalizer on every input (pre-crossover)

•

Dual Real Time Audio Analyzers

•

Butterworth, Bessel or Linkwitz-Riley crossover filters

•

27 Different Crossover Configurations

•

Time Alignment and Transducer Alignment Delays

•

Compressor/Limiter on every output

•

Speaker Compensation EQ (post crossover)

•

Multi-level Security System

•

Separate House and Show EQ with individual lockouts

•

Triple redundant back up of all parameters when running network, 480R and GUI

•

TYPE IV™ Conversion System

•

Electronically balanced/RF filtered XLR Inputs and Outputs

•

Proprietary RS-485 Control Network

•

RS-232 PC Interface for computer display and configuration

442 DriveRack™ features:

•

4 Input and 4 Outputs

•

31 band graphic or 9 band parametric equalizer on every input

•

Time Alignment Delays

•

Compressor/Limiter on every output

•

Multi-level Security System

•

Separate House and Show EQ with individual lockouts

•

Triple redundant back up of all parameters when running network, 480R and GUI

•

TYPE IV™ Conversion System

•

Electronically balanced/RF filtered XLR Inputs and Outputs

•

Proprietary RS-485 Control Network

•

RS-232 PC Interface for computer display and configuration

iii

®

Page 10

Introduction

DriveRack™ User Manual

iv

DriveRack

™

480R DriveRack™ features:

•

Dedicated remote interface to control all 480, 481, 482 and 442 DriveRack™ units

•

31 Motorized faders for equalization control

•

32 assignable hot-keys with up to 64 different assignment capabilities

•

Built-in Real Time Audio Analyzer (with rear-panel XLR connector)

•

System Mute button

•

Proprietary RS-485 Control Network

•

RS-232 PC Interface for computer display and configuration

•

480P Power Supply Included

•

Responds to MIDI commands from mixing consoles including: Soundcraft™ SM20

and Series 5 and the Allen & Heath™ ML 4000 and ML5000

By including every form of processing necessary to drive the signal from the mixer to the power

amp, the DriveRack™ allows you to eliminate all other processing devices that are normally

found in large and cumbersome traditional DriveRack systems of the past.

The 480 DriveRack™ Loud Speaker Management System includes four balanced XLR inputs, as

well as eight balanced XLR outputs, which can be routed for any configuration. The 481 and

482 DriveRack™ feature the identical processing power of the 480 DriveRack, but utilize streamline front panel interfaces. In addition, the 481 utilizes euroblock connectors as opposed to the

XLR connectors found in the 480 and 482 DriveRack.

The 480, 481 and 482 DriveRacks™ include features such as: pre-crossover EQ, dual RTAs, notch

filters, speaker delays, multiple crossovers and compression/limiting, as well as numerous other

features. Dual RTA analyzers can be run simultaneously with RTA source inputs capable of

being remotely switched on the fly. The 480 DriveRack™ is fully programmable from the front

panel, and can control other devices in a network including the 481 and 482 slave units. In

addition, the entire system can be controlled via the 480R DriveRack™ remote controller or

through the included GUI interface.

The 442 DriveRack Equalization Management system is the perfect tool for monitor mixing

applications. The 442 offers four balanced XLR inputs and four XLR outputs, with four independent channels of effect processing. Each channel offers a 31-band graphic or parametric

equalizers, as well as digital delay and industry-standard, dbx dynamics processing.

If you require technical support, contact dbx Customer Service. Be prepared to accurately

describe the problem. Know the serial number of your unit - this is printed on a sticker attached

to the rear panel. If you have not already taken the time to fill out your warranty registration

card and send it in, please do so now.

1.2 Service Contact Info

®

Page 11

Before you return a product to the factory for service, we recommend you refer to the manual.

Make sure you have correctly followed installation steps and operation procedures. If you are still

unable to solve a problem, contact our Customer Service Department at (801) 568-7660 for consultation. If you need to return a product to the factory for service, you MUST contact Customer

Service to obtain a Return Authorization Number.

No returned products will be accepted at the factory without a Return Authorization Number.

Please refer to the Warranty below, which extends to the first end-user. After expiration of the warranty, a reasonable charge will be made for parts, labor, and packing if you choose to use the factory service facility. In all cases, you are responsible for transportation charges to the factory. dbx

will pay return shipping if the unit is still under warranty.

Use the original packing material if it is available. Mark the package with the name of the shipper

and with these words in red: DELICATE INSTRUMENT, FRAGILE! Insure the package properly.

Ship prepaid, not collect. Do not ship parcel post.

This warranty is valid only for the original purchaser and only in the United States.

1. The warranty registration card that accompanies this product must be mailed within 30 days

after purchase date to validate this warranty. Proof-of-purchase is considered to be the burden

of the consumer.

2. dbx warrants this product, when bought and used solely within the U.S., to be free from defects

in materials and workmanship under normal use and service.

3. dbx liability under this warranty is limited to repairing or, at our discretion, replacing defective

materials that show evidence of defect, provided the product is returned to dbx WITH RETURN

AUTHORIZATION from the factory, where all parts and labor will be covered up to a period of

two years. A Return Authorization number must be obtained from dbx by telephone. The company shall not be liable for any consequential damage as a result of the product's use in any

circuit or assembly.

4. dbx reserves the right to make changes in design or make additions to or improvements upon

this product without incurring any obligation to install the same additions or improvements on

products previously manufactured.

5. The foregoing is in lieu of all other warranties, expressed or implied, and dbx neither assumes

nor authorizes any person to assume on its behalf any obligation or liability in connection with

the sale of this product. In no event shall dbx or its dealers be liable for special or consequential damages or from any delay in the performance of this warranty due to causes beyond their

control.

1.3 Warranty

Introduction

Section i

DriveRack

™

DriveRack™ User Manual

v

®

Page 12

Introduction

DriveRack™ User Manual

vi

Section i

DriveRack

™

®

Page 13

Getting Started

Section 1

DriveRack

™

®

Page 14

Getting Started

DriveRack™ User Manual

2

Section 1

DriveRack

™

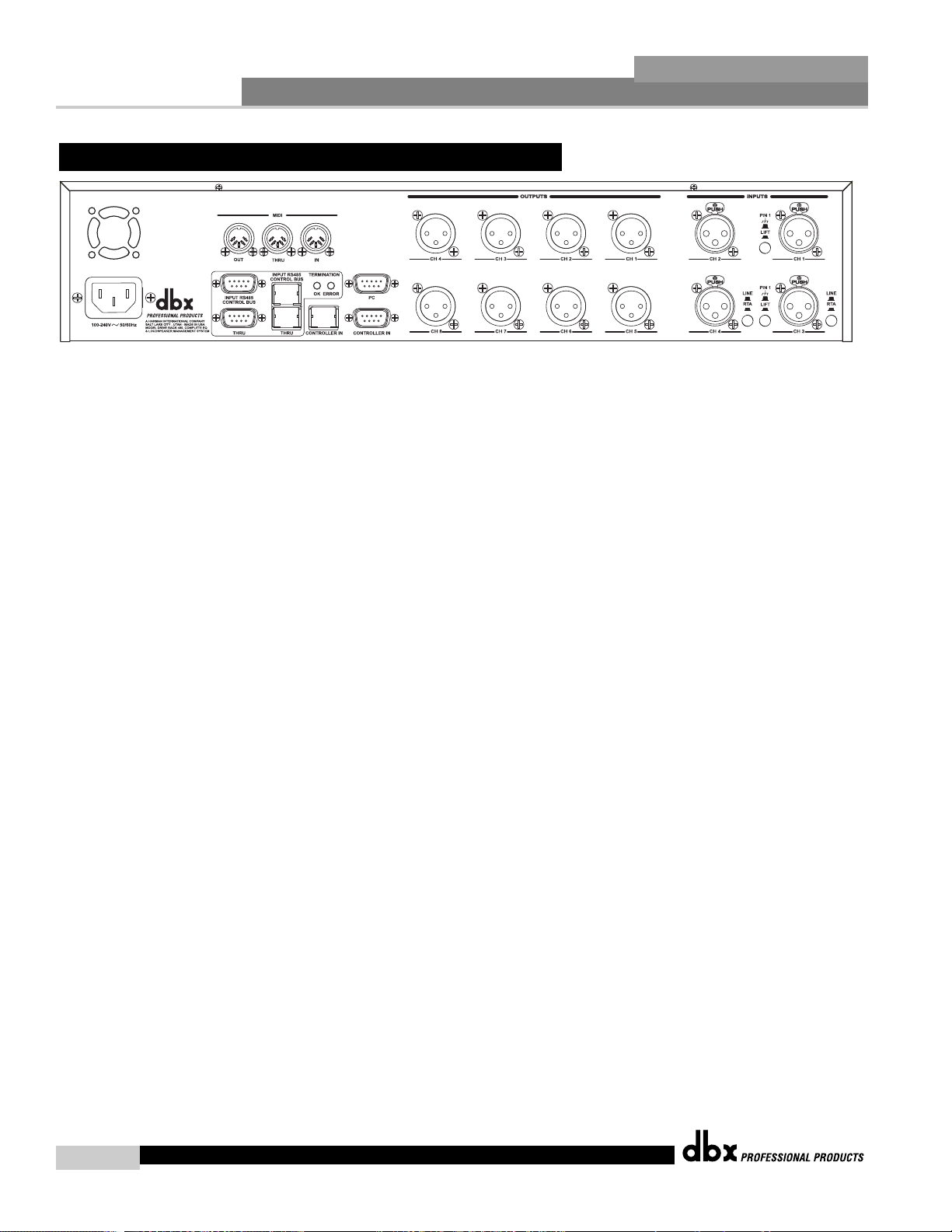

IEC Power Cord Receptacle

The 480 comes with an International power supply that will accept voltages ranging from 100V240V at frequencies from 50Hz-60Hz. An IEC cord is included.

MIDI In, Out and Thru Connectors

These connectors provide MIDI functionality to the 480 DriveRack™. The In, Out and Thru jacks

allow you to use the 480 DriveRack™ at any point in the MIDI chain.

RS485 Control Bus Input (DB-9 connector type)

This input network connection is used to receive information being sent from other units in the

DriveRack™ network link.

RS485 Control Thru Bus (DB-9 connector type)

This Thru network connection is used to pass information to other units in the DriveRack™ network link.

RS485 Control Bus Input (RJ-45 connector type)

This input network connection is used to receive information being sent from other units in the

DriveRack™ network link.

RS485 Control Thru Bus (RJ-45 connector type)

This Thru network connection is used to pass information to other units in the DriveRack™ network link.

Termination LEDs

These LEDS indicate when network is properly terminated. The Green LED indicates that the

network has been correctly terminated.

Remote Controller In Connection

This DB-9 type input connection is used to send and receive information from the 480R Remote

Control unit.

PC Connection

This DB-9 type connection is used to send and receive information to and from the GUI interface.

Outputs 1-8

The output section of the 480 DriveRack™ offers eight electronically balanced XLR connectors.

35 WATTS

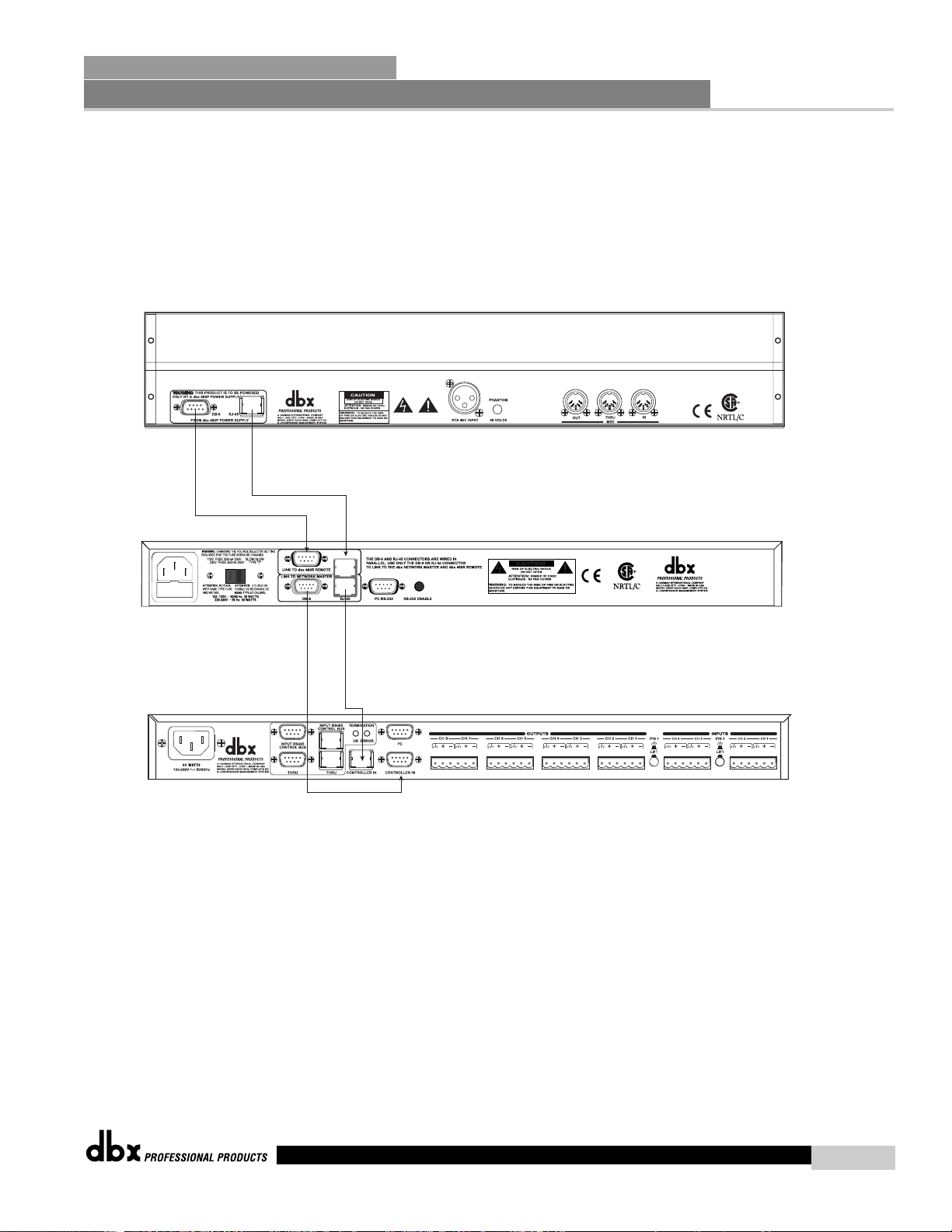

1.1 Rear Panel Connections (480)

®

Page 15

Inputs 1-4

The input section of the 480 DriveRack™ offers four electronically balanced XLR connectors.

Inputs 3 and 4 offer Line/RTA switches that allow you to run a real time audio analyzer microphone directly into the input of the 480 DriveRack™. The four XLR inputs of the 480

DriveRack™ also offer Pin 1 lift switches which lift the ground of the selected XLR input pair

when pressed.

WARNING - For proper operation of the RTA microphone, the RTA button must be depressed

and the ground /lift switch must be in the grounded position. When the RTA button on the back

panel is depressed, 48V phantom power is applied to pins 2 and 3 of the XLR connector. To

maintain a proper ground return for the phantom power, the ground/lift switch must be in the

grounded position. This will prevent the possibility of electrical shock.

LCD Display

The large LCD display of the 480 DriveRack™ provides the user with all of the vital processing

information of the DriveRack™ including: signal routing, configuration modes, effect block editing and RTA displays. The top left corner of the display indicates network device ID numbers.

The reverse background number indicates the number of the slave unit being controlled, while

Mst indicates that the unit is set to act as the master.

Function Buttons

The function buttons of the 480 DriveRack™ allow access to all editing and navigating functions

of the 480 DriveRack™.

Parameter Knobs

The parameter knobs of the 480 DriveRack™ allow the user to edit parameters of selected

effects of the 480 DriveRack™. The parameter knobs of the 480 and 480R DriveRack™ units

also incorporate light display Logicators™ which surround the knob itself and indicate levels of

parameter and effect activity. The parameter knobs of the 480 DriveRack™ also provide the

1.2 Front Panel (480)

Getting Started

Section 1

DriveRack

™

DriveRack™ User Manual

3

4063100 160 250 400 630 1.0k 1.5k 2.5k 4.0k 6.3k 10k 16k

F7 4-Way FOH w/RTA

Parameter 1

Parameter 2

Single RTA

Parameter 3

Channel 1

25

+14

+12

+10

+8

+6

+4

+2

0

-2

-4

-6

-8

-10

-12

-14

315080 125 200 315 500 800 1.3k 2.0k 3.2k 5.0k 8.0k 13k 20k

20

+24 +6

+18 +4

+12 +2

+8 0

0 -2

-8 -4

-12 -8

-18 -9

-24 -12

-30 -15

-40 -20

-50 -25

-60 -30

-70 -35

-80 -40

-90 -50

®

Page 16

Getting Started

DriveRack™ User Manual

4

Section 1

DriveRack

™

user with different modes of functionality including: coarse/fine encoding (successive presses

will toggle the knob between a fast and slow mode of operation) and horizontal-vertical navigators, which allow the parameter buttons (when used in program and configuration mode) to

navigate the program screen horizontally and vertically.

Input Meters

The 480 DriveRack™ provides the user with four independent 12 segment Lightpipe™ input meters that range from -30 to +22 dBu. Note:

These meters are calibrated for the +22dBu setting of the gain jumpers.

Threshold Meters

The threshold meters indicate that the threshold level has been

exceeded within the dynamics section (compressor/limiter), and gain

reduction is taking place within the specific output channel.

Output Meters

The 480 DriveRack™ provides the user with eight independent 12-segment Lightpipe™ output meters that range from -30 to +22 dBu. Note:

These meters are calibrated for the +22dBu setting of the gain jumpers.

Output Mutes

The eight output mute buttons are used for independently muting each

output on all eight outputs of the 480 DriveRack™.

Power Switch

Turns the 480 DriveRack™ on and off. Note: dbx Professional

Products recommends that power amps connected to the DriveRack™,

should be powered down prior to cycling the DriveRack™.

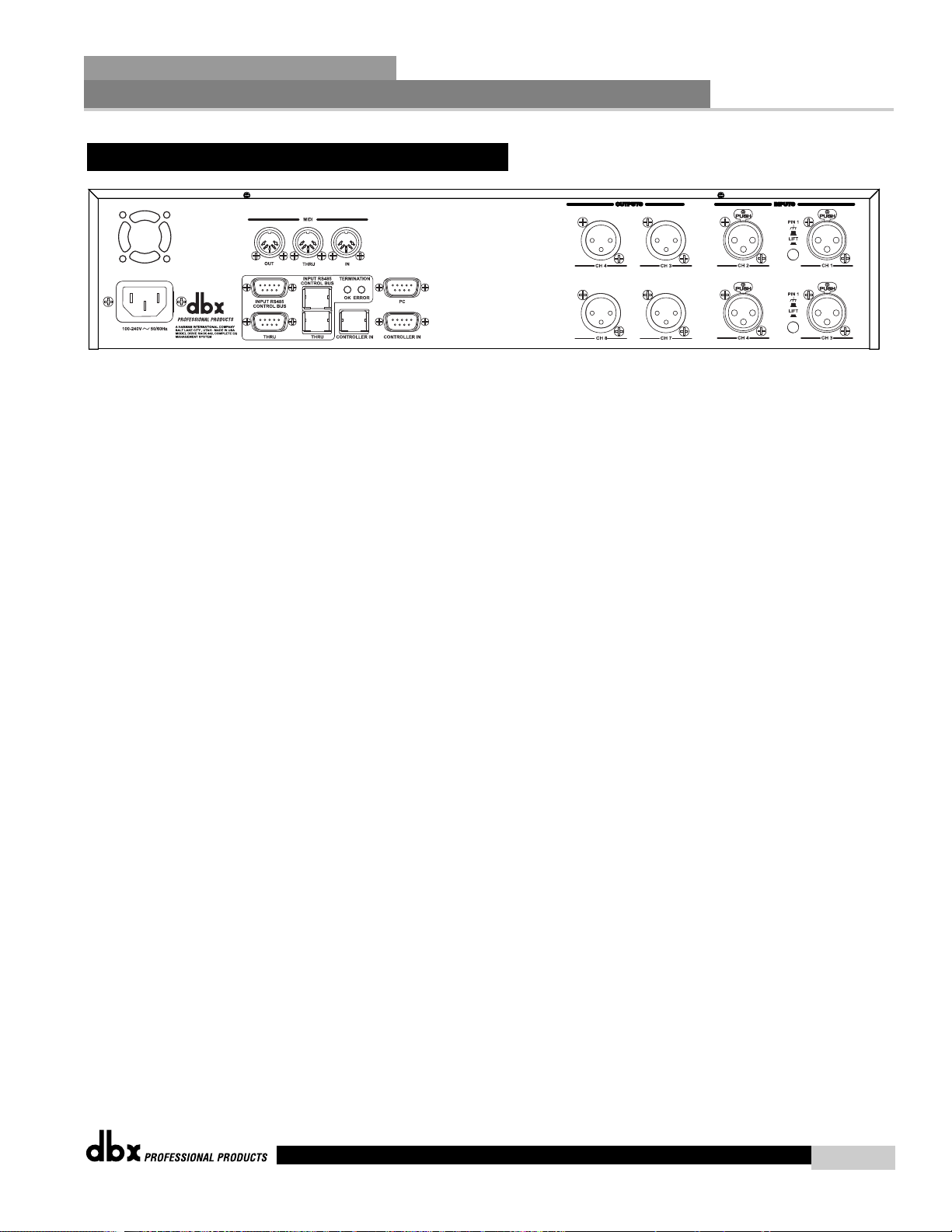

IEC Power Cord Receptacle

The 481 comes with an International power supply that will accept voltages ranging from 100V240V at frequencies from 50Hz-60Hz. An IEC cord is included.

RS485 Control Bus Input (DB-9 connector type)

This input network connection is used to receive information being sent from other units in the

DriveRack™ network link.

RS485 Control Thru Bus (DB-9 connector type)

This Thru network connection is used to pass information to other units in the DriveRack™ network link.

RS485 Control Bus Input (RJ-45 connector type)

1.3 Rear Panel Connections (481)

®

Page 17

Getting Started

Section 1

DriveRack

™

5

This input network connection is used to receive information being sent from other units in the

DriveRack™ network link.

RS485 Control Thru Bus (RJ-45 connector type)

This Thru network connection is used to pass information to other units in the DriveRack™ network link.

Termination LEDs

These LEDS indicate when network is properly terminated. The Green LED indicates that the

network has been correctly terminated.

Remote Controller In Connection

This DB-9 type input connection is used to send and receive information from the 480 Remote

DriveRack™ Unit.

Outputs 1-8 (Euroblock Connectors)

The output section of the 481 DriveRack™ offers eight electronically balanced Euroblock connectors.

Inputs 1-4

The input section of the 481 DriveRack™ offers four electronically balanced Euroblock connectors.

Ground Lift Switch

This switch (when pressed in), is used to lift the Pin one ground on either inputs 1 and 2 or 3

and 4.

PC Connection

This DB-9 type connection is used to send and receive information to and from the GUI interface.

Program Up and Down

These program up and down buttons are used to scroll through the program menu of the 481.

Program Display

This program display is used to indicate the currently selected program of the 481.

ID Display

This ID display is used to indicate the current assigned identification of the 481. This identification is essential for unit recognition when the 481 is used in a network system.

Control Bus LED

1.4 Front Panel (481)

DriveRack™ User Manual

®

Page 18

Getting Started

6

Section 1

DriveRack

™

This LED (when lit), indicates that the 481 is connected to the control bus.

When it is flashing, the 481 is sending/receiving network information.

Remote LED

This LED (when lit), indicates that the 481 is connected to the 480R. When

it is flashing, the 481 is sending/receiving information from the 480R.

PC LED

This LED (when lit), indicates that the 481 is connected to the PC. When

it is flashing, the 481 is sending/receiving information from the PC.

Input Meters

The 481 DriveRack™ provides the user with four independent 6-segment

lightpipe™ input meters that range from -30 to +22 dBu. Note: These

meters are calibrated for the +22dBu setting of the gain jumpers.

Output Meters

The 481 DriveRack™ provides the user with eight independent 6-segment

lightpipe™ output meters that range from -30 to +22 dBu. Note: These

meters are calibrated for the +22dBu setting of the gain jumpers.

Power Switch

Turns the 481 DriveRack™ on and off. Note: dbx Professional Products recommends that power amps connected to the DriveRack™ should be powered down prior to cycling the DriveRack™.

IEC Power Cord Receptacle

The 482 comes with an International power supply that will accept voltages ranging from 100V-240V

at frequencies from 50Hz-60Hz. An IEC cord is included.

MIDI In, Out and Thru Connectors

These connectors provide MIDI functionality to the 482 DriveRack™. The In, Out and Thru jacks

allow you to use the 482 DriveRack™ at any point in the MIDI chain.

RS485 Control Bus Input (DB-9 connector type)

This input network connection is used to receive information being sent from other units in the

DriveRack™ network link.

1.5 Rear Panel Connections (482)

®

Page 19

RS485 Control Thru Bus (DB-9 connector type)

This Thru network connection is used to pass information to other units in the DriveRack™ network link.

RS485 Control Bus Input (RJ-45 connector type)

This input network connection is used to receive information being sent from other units in the

DriveRack™ network link.

RS485 Control Thru Bus (RJ-45 connector type)

This Thru network connection is used to pass information to other units in the DriveRack™ network link.

Termination LEDs

These LEDS indicate when network is properly terminated. The Green LED indicates that the network has been correctly terminated.

Remote Controller In Connection

This DB-9 type input connection is used to send and receive information from the 480 Remote

DriveRack™ Unit.

PC Connection

This DB-9 type connection is used to send and receive information to and from the GUI interface.

Outputs 1-8

The output section of the 482 DriveRack™ offers eight electronically balanced XLR connectors.

Inputs 1-4

The input section of the 482 DriveRack™ offers four electronically balanced XLR connectors.

Inputs 3 and 4 offer Line/RTA switches that allow you to run a real time audio analyzer microphone directly into the input of the 482 DriveRack™. The four XLR inputs of the 482 DriveRack™

also offer Pin 1 lift switches which lift the ground of the selected XLR input pair when pressed.

Warning - For proper operation of the RTA microphone, the RTA button must be depressed and

the ground /lift switch must be in the grounded position. When the RTA button on the back panel

is depressed, 48V phantom power is applied to pins 2 and 3 of the XLR connector. To maintain

a proper ground return for the phantom power, the ground/lift switch must be in the grounded

position. This will prevent the possibility of electrical shock.

1.6 Front Panel (482)

Getting Started

Section 1

DriveRack

™

7

®

Page 20

Getting Started

DriveRack™ User Manual

8

Section 1

DriveRack

™

PC Connection

This DB-9 type connection is used to send and receive information to and from the GUI interface.

Program Up and Down

These program up and down buttons are used to scroll through the program menu of the 482.

Program Display

This program display is used to indicate the currently selected program of the 482.

ID Display

This ID display is used to indicate the current assigned identification of the 482. This identification is essential for unit recognition when the 482 is used in a network system.

Control Bus LED

This LED (when lit), indicates that the 482 is connected to the control bus.

When it is flashing, the 482 is sending/receiving network information.

Remote LED

This LED (when lit), indicates that the 482 is connected to the 480R.

When it is flashing, the 482 is sending/receiving information from the

480R.

PC LED

This LED (when lit), indicates that the 482 is connected to the PC. When

it is flashing, the 482 is sending/receiving information from the PC.

Input Meters

The 482 provides the user with four independent 12 segment lightpipe™

input meters that range from -30 to +22 dBu. Note: These meters are

calibrated for the +22dBu setting of the gain jumpers.

Threshold Meters

The threshold meters indicate that the threshold level has been exceeded within the dynamics section (compressor/limiter), and gain reduction is taking place within the specific output channel.

Output Meters

The 482 DriveRack™ provides the user with eight independent 12-segment lightpipe™ output meters that range from -30 to +22 dBu. Note:

These meters are calibrated for the +22dBu setting of the gain jumpers.

Output Mutes

The eight output mute buttons are used for independently muting each

output of the 482 DriveRack™.

Power Switch

Turns the 482 DriveRack™ on and off. Note: dbx Professional Products

recommends that power amps connected to the DriveRack™ should be

powered down prior to cycling the DriveRack™.

®

Page 21

IEC Power Cord Receptacle

The 442 comes with an International power supply that will accept voltages ranging from 100V240V at frequencies from 50Hz-60Hz. An IEC cord is included.

MIDI In, Out and Thru Connectors

These connectors provide MIDI functionality to the 442 DriveRack™. The In, Out and Thru jacks

allow you to use the 442 DriveRack™ at any point in the MIDI chain.

RS485 Control Bus Input (DB-9 connector type)

This input network connection is used to receive information being sent from other units in the

DriveRack™ network link.

RS485 Control Thru Bus (DB-9 connector type)

This Thru network connection is used to pass information to other units in the DriveRack™ network link.

RS485 Control Bus Input (RJ-45 connector type)

This input network connection is used to receive information being sent from other units in the

DriveRack™ network link.

RS485 Control Thru Bus (RJ-45 connector type)

This Thru network connection is used to pass information to other units in the DriveRack™ network link.

Termination LEDs

These LEDS indicate when network is properly terminated. The Green LED indicates that the

network has been correctly terminated.

Remote Controller In Connection

This DB-9 type input connection is used to send and receive information from the 480 Remote

DriveRack™ Unit.

PC Connection

This DB-9 type connection is used to send and receive information to and from the GUI interface.

35 WATTS

1.7 Rear Panel Connections (442)

Getting Started

SECTION 1

DriveRack

™

9

DriveRack™ User Manual

®

Page 22

Getting Started

10

SECTION 1

DriveRack

™

Outputs 1-4

The output section of the 442 DriveRack™ offers four electronically balanced XLR connectors.

Inputs 1-4

The input section of the 442 DriveRack™ offers four electronically balanced XLR connectors.

The four XLR inputs of the 442 DriveRack™ also offer Pin 1 lift switches which lift the ground

of the selected XLR input pair when pressed.

PC Connection

This DB-9 type connection is used to send and receive information to and from the GUI interface.

Program Up and Down

These program up and down buttons are used to scroll through the

program menu of the 442.

Program Display

This program display is used to indicate the currently selected program of the 442.

ID Display

This ID display is used to indicate the current assigned identification of the 442. This identification is essential for unit recognition when the 442 is used in a network system.

Control Bus LED

This LED (when lit), indicates that the 442 is connected to the control

bus. When it is flashing, the 442 is sending/receiving network information.

Remote LED

This LED (when lit), indicates that the 442 is connected to the 480R.

When it is flashing, the 442 is sending/receiving information from the

480R.

PC LED

This LED (when lit), indicates that the 442 is connected to the PC.

When it is flashing, the 442 is sending/receiving information from the

PC.

1.8 Front Panel (442)

DriveRack™ User Manual

®

Page 23

Input Meters

The 442 provides the user with four independent 12 segment lightpipe™ input meters that range

from -30 to +22 dBu. Note: These meters are calibrated for the +22dBu setting of the gain

jumpers.

Threshold Meters

The threshold meters indicate that the threshold level has been exceeded within the dynamics

section (compressor/limiter), and gain reduction is taking place within the specific output channel.

Output Meters

The 442 DriveRack™ provides the user with four independent 12-segment lightpipe™ output

meters that range from -30 to +22 dBu. Note: These meters are calibrated for the +22dBu setting of the gain jumpers.

Output Mutes

The four output mute buttons are used for independently muting each output of the 442

DriveRack™.

Power Switch

Turns the 442 DriveRack™ on and off. Note: dbx Professional Products recommends that power

amps connected to the DriveRack™ should be powered down prior to cycling the DriveRack™.

Getting Started

SECTION 1

DriveRack

™

11

DriveRack™ User Manual

®

Page 24

Getting Started

12

SECTION 1

DriveRack

™

DriveRack™ User Manual

®

Page 25

EDITING

FUNCTIONS

®

Editing Functions

Section 2

DriveRack

™

Page 26

Editing Functions

14

Section 2

DriveRack

™

The 480 DriveRack™ has been carefully designed and engineered to ensure that all aspects of

operation are intuitive and logical. Simply stated, the 480 DriveRack™ operating system was

designed with user’s best interest in mind. Editing the 480 DriveRack™ can be done by utilizing key functions and tools. This section will provide you with detailed information on all of

the tools used to optimize the editing performance of your DriveRack™. This intuitive front

panel interface can also be used to control other units (481, 482 and 442) which are used within a a DriveRack™ network system.

Navigational aspects of the 480 DriveRack™ are clear, concise and more important: flexible.

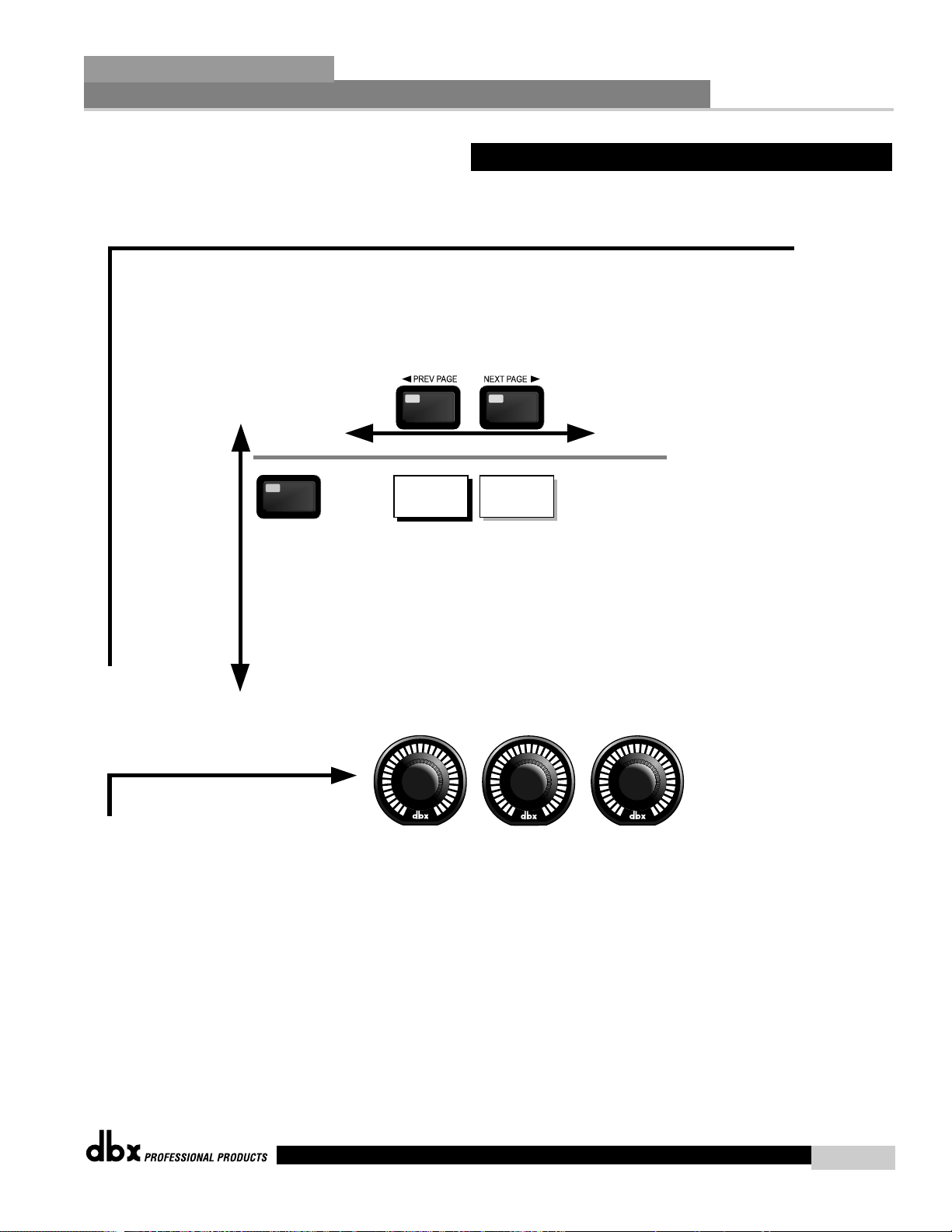

The DriveRack™ provides you with essentially three different modes of navigation when performing programming edits. 1. FX buttons - This array of 12 FX buttons is your primary mode

of accessing any effect module. 2. NEXTPG & PREVPG page buttons - Successive presses

of the NEXTPG or PREVPG page buttons will move the user from one page to the next in

an effect block. 3. PARAMETER KNOBS - In addition to editing parameter values with the

PARAMETER knobs, the PARAMETER 2 & 3 knobs (when used in program mode) will move

the cursor throughout the display horizontally and vertically. For more information on this

unique feature, please see section 2.4.

The following sections will provide you with detailed information for accurate navigation of the

FX button section of the 480 DriveRack™. Each diagram indicates the functionality of each FX

button and its ability to guide the user through each operational menu.

2.2 FX Button Array Overview

2.1 Basic Navigation Modes

Editing

Functions

DriveRack™ User Manual

®

Page 27

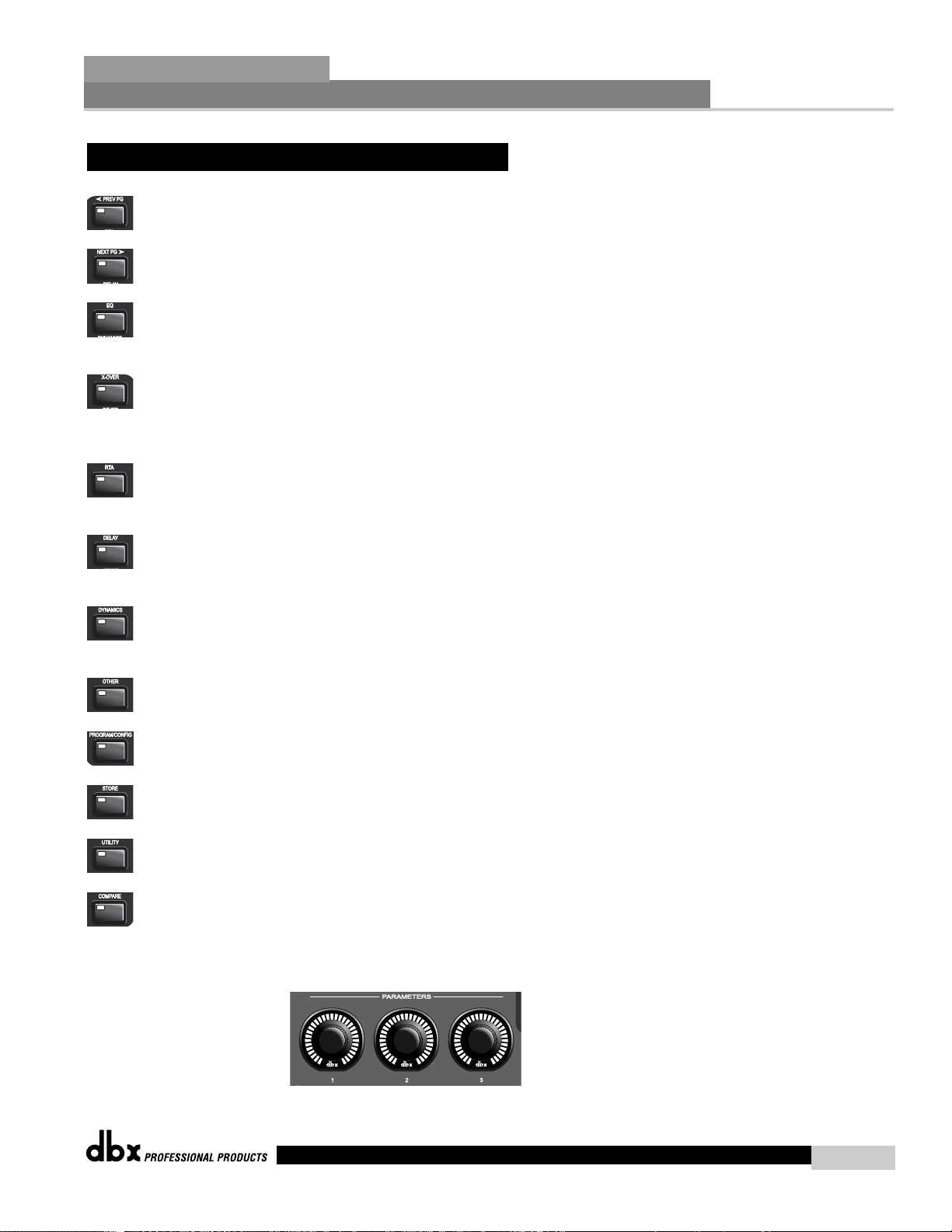

PREVIOUS PAGE - Moves to the previous page in the currently selected effect menu.

NEXT PAGE - Moves to the next page in the currently selected effect menu.

EQ - Selects the EQ effect menu. Successive presses will rotate through the various

EQ modules.

XOVER - Selects the Cross over menu. Successive presses will toggle between the

various crossovers. Note: when used as a controller for the 442, pressing

the X-over button will access the notch filter section of the 442.

RTA - Enters the RTA mode of the DriveRack. Successive presses will toggle between

the RTA modules.

DELAY - Selects the DELAY effect menu. Successive presses will toggle between the

various delay modules.

DYNAMICS - Selects the Compressor/Limiter effect menu. Successive presses will

move through the dynamics modules.

OTHER - Selects the Input and Output editing sections of the DriveRack™.

PROGRAM/CONFIG - This button will load a selected program, loads the Program

mode or enters the Configuration edit mode when pressed and held.

STORE - The STORE button is used to store program edits.

UTILITY - Selects the Utility edit menu of the DriveRack.

COMPARE - The Compare button is used to compare program edits to the original

(unedited) program.

PARAMETER KNOBS - The parameter knobs perform various functions including: program

changes (parameter 1), parameter value edits and cursor navigation utilizing the parameter

knobs 2 and 3.

2.2 FX Button Array Overview (cont.)

Editing Functions

Section 2

DriveRack

™

15

DriveRack™ User Manual

®

Page 28

Editing Functions

16

Section 2

DriveRack

™

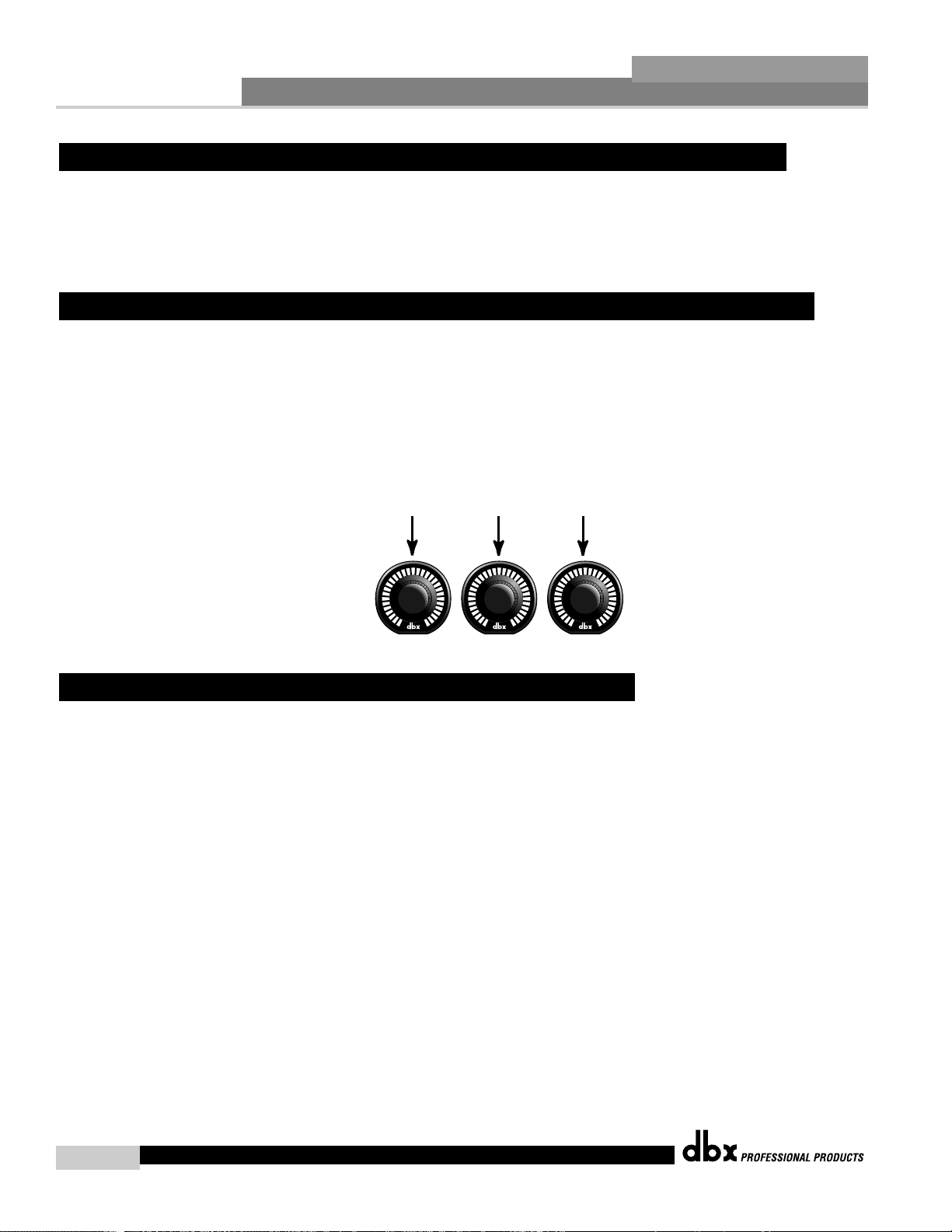

The parameter knob encoders of the 480 and 480R DriveRack™ Remote provide the user with

the option of coarse or fine performance modes. This means that the parameter knobs can be

set to either move or change values at a rapid (coarse) or slower (fine) rate. This option can

be selected in any mode by simply pressing the selected parameter knob. Successive presses

will toggle between coarse and fine mode.

The 480 DriveRack™ offers the horizontal-vertical navigation feature which helps streamline

navigation and editing of the unit. The Horizontal-Vertical Navigation mode allows the user to

use the parameter knobs (2&3) to quickly navigate through the program/configuration menu of

any DriveRack™ unit. This feature can be used to navigate the display screen in program or

configuration mode. To utilize this feature, simply select the high-lighted cursor, then use the

PARAMETER 2 knob to move the cursor left and right, and use the PARAMETER 3 knob to

move the cursor up and down while the unit is in Program or Configuration mode.

The front panel of the 480 and 480R allow you to copy and paste the parameter value settings

for entire effect module blocks, and then paste them into another block. Note that the information from one module must be pasted into a similar module, ie; from one dynamic module

to another. This function can be performed in a single unit, or to any unit in a network setup.

The procedure for cut and paste is as follows:

• From program mode, use the PARAMETER knobs to navigate to the desired module.

• Once the desired module has been selected, press and hold the PREVIOUS PAGE button

until the display reads: COPY.

• The information is now held in what is commonly known as the “pasteboard.”

• At this point, navigate to the unit that you wish to paste the information into using the

PARAMETERS knobs.

• If you are pasting into a unit within the network, either enter in the device id# (key pad on

the 480R, or from the Utility page in the 480).

• Once the desired module has been selected, press and hold the NEXT PAGE button and

the display will read: PASTE.

2.5 Copy/Paste Functionality

Up-DownLeft-Right

Select

1

2

3

2.4 Parameter Knobs (Horizontal-Vertical Navigation Mode)

2.3 Parameter Knob Encoders Coarse/Fine Operation

DriveRack™ User Manual

®

Page 29

2.6 Navigating the EQ Sections

Editing Functions

Section 2

DriveRack

™

17

DriveRack™ User Manual

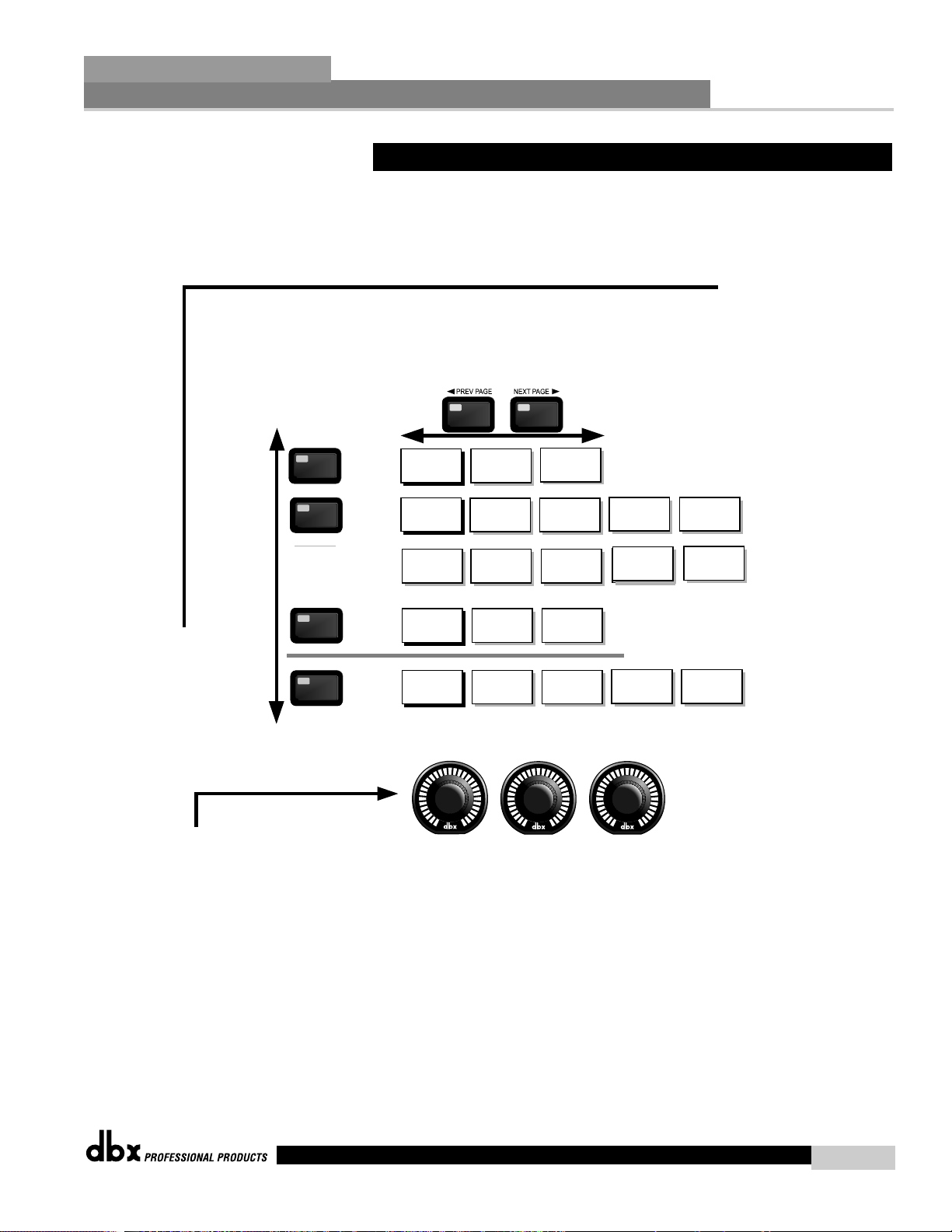

Navigating the "EQ and Notch Filter Sections"

To edit the parameters of the EQs and Notch Filters used in a selected program, simply use the following procedure. From progra m mode,

either press the EQ button or use the Parameter 2 or 3 knobs to move to EQ module to be edited. Once you have reached the desired EQ,

press the Parameter 2 or 3 knob. Successive presses of the EQ button will move through each channel (input or output) that utilizes an EQ module.

Navigate throughthe Pages of the selected EQ section by pressing "Next Page" or "Prev Page" successively until arriving at the desired Page.

The EQ button

toggles through

the EQs or notch

filters used in

each channel of

the selected

program

menu.

EQ

EQ

EQ

GEQ

PEQ

EQ On/Off

Flat Set/Undo

EQ On/Off

Type

Flat Set/Undo

Band 5 Freq

Q

Level

Frequency

Level

Band 1 Freq

Slope

Level

Band 6 Freq

Q

Level

Boom

Zizz

Band 2 Freq

Q

Level

Band 7 Freq

Q

Level

Band 3 Freq

Q

Level

Band 8 Freq

Band 9 Freq

Q

Slope

Level

Level

Band 4 Freq

Q

Level

Band 9 Freq

Slope

Level

NOTCH

EQ

PEQ

The PARAMETER knobs are used

to edit parameter values

Notch On/Off

EQ On/Off

Type

Flat Set/Undo

1

Notch1 Freq

Q Adjust

Level

Band 1 Freq

Q Adjust

Level

Notch 2 Freq

Q Adjust

Level

Post XOVER

Band 2 Freq

Q Adjust

Level

2 3

Band 3 Freq

Q Adjust

Level

Band 4 Freq

Q Adjust

Level

®

Page 30

Editing Functions

18

Section 2

DriveRack

™

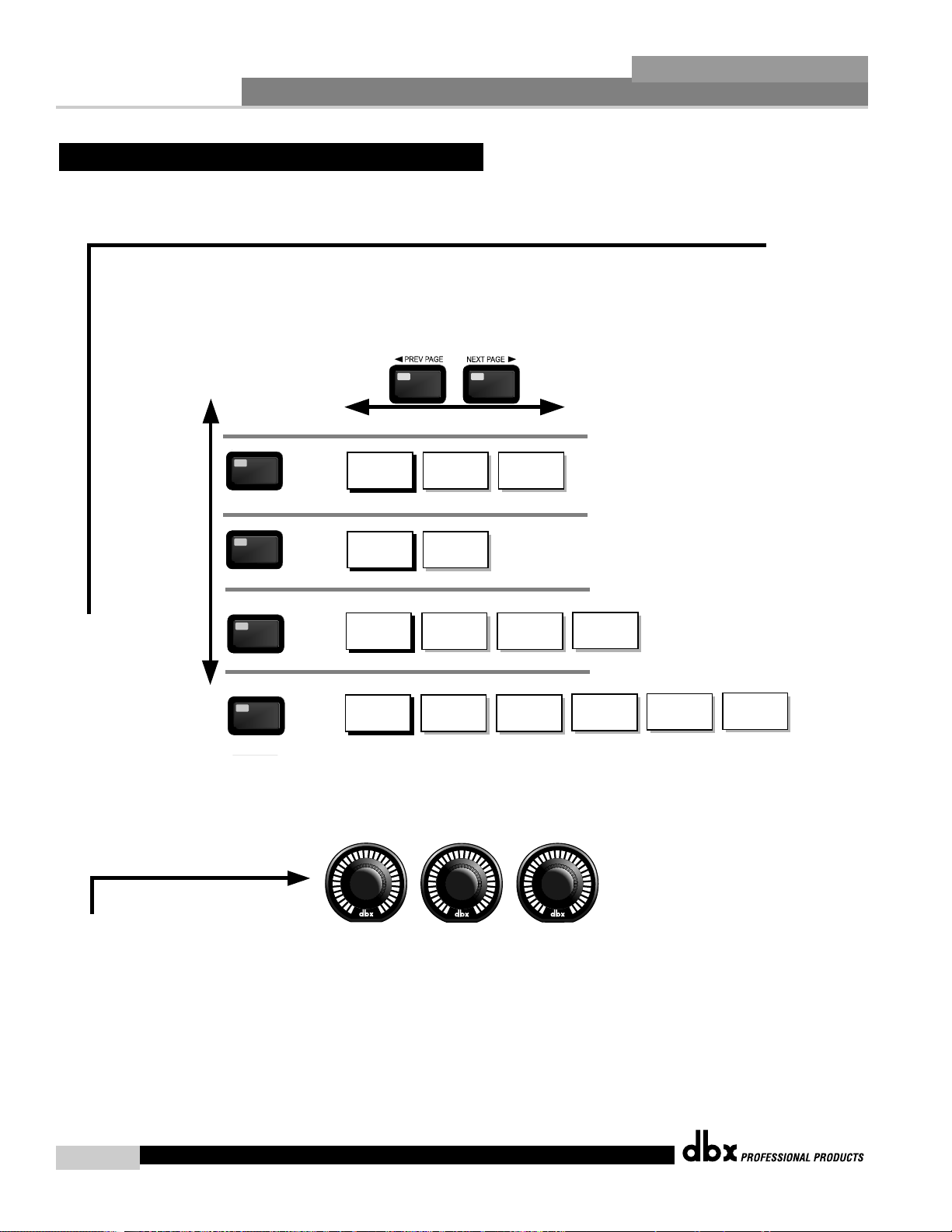

Navigating the "X-OVER Section"

The PARAMETER knobs are used

to edit parameter values

1

2 3

The X-OVER button

toggles through

the Crossover

modules used in

each channel of

the selected

program.

X-OVER

X-OVER

Low Fc

Center Fc

High Fc

X-OVER

X-OVER

Type

Low Slope

High Slope

1X2... X-OVER

X-OVER

Filter Type

X-OVER

Lowpass

Highpass

Low Slope

High Slope

Filter - Dual Filter

1X3... X-OVER

Low1 Fc

Center1 Fc

High1 Fc

Type

Low1 Slope

High1 Slope

Low2 Fc

Center2 Fc

High2 Fc

Type

Low2 Slope

High2 Slope

X-OVER

X-OVER

1X4... X-OVER

Low1 Fc

Center1 Fc

High1 Fc

Type

Low1 Slope

High1 Slope

Low2 Fc

Center2 Fc

High2 Fc

Type

Low2 Slope

High2 Slope

Low3 Fc

Center3 Fc

High3 Fc

Type

Low3 Slope

High3 Slope

To edit the parameters of the Crossover used in a selected program, simply use the following procedure. From program mode,

either press the X-OVER button or use the Parameter 2 or 3 knobs to move to Crossover module. Once you have reached the Crossover module,

press the Parameter 2 or 3 buttons to access the editing pages of the module. Navigate through the Pages of the selected Crossover

module by pressing the "Next Page" or "Prev Page" buttons successively until arriving at the desired Page.

2.7 Navigating the XOVER

DriveRack™ User Manual

®

Page 31

2.8 Navigating the RTA

Editing Functions

Section 2

DriveRack

™

19

DriveRack™ User Manual

Navigating the "RTA" Section

To edit the parameters of the Real Time Audio Analyzer used in a selected program, simply use the following procedure. From program mode,

either press the RTA button or use the Parameter 2 or 3 knobs to move to RTA module. Navigate through the Pages

of the selected RTA module by pressing the "Next Page" or "Prev Page" buttons successively until arriving at the desired Page.

The RTA button

toggles through

the RTA

modules used in

each channel of

the selected

program.

Note that you

must be in a

that uses an

RTA module

to utilize

this feature.

RTA

RTA

Input

RTA Gain

Mic Sens.

Rate

Scale

Display

RTA

The PARAMETER knobs are used

to edit parameter values

®

1

2 3

Page 32

Editing Functions

20

Section 2

DriveRack

™

Navigating the "Delay" Section

The PARAMETER knobs are used

to edit parameter values

1

2 3

The DELAY button

toggles through

the Delay

modules used in

each channel of

the selected

program

menu.

DLY

DLY

Speaker Alignment Delay (Post X-OVER)

To edit the parameters of the Delay and Speaker Alignment Delay used in a selected program, simply use the following procedure.

From program mode, either press the DELAY button or use the Parameter 2 or 3 knobs to move to Delay module to be edited.

Navigate through the Pages of the selected Delay module by depressing the "Next Page" or "Prev Page"

buttons successively until arriving at the desired Page.

Delay On/Off

Type

Length

DELAY

DELAY

Delay On/Off

Type

Length

2.9 Navigating the Delay

DriveRack™ User Manual

®

Page 33

2.10 Navigating the Dynamics Section

Editing Functions

Section 2

DriveRack

™

21

DriveRack™ User Manual

Navigating the "Dynamics" Section

To edit the parameters of the Dynamics module used in a selected program, simply use the following procedure. From program mode,

either press the X-OVER button or use the Parameter 2 or 3 knobs to move to the Dynamics module. Once you have reached the Crossover module,

through each channel that utilizes a Dynamics module. Navigate through the Pages of the selected Dynamics module by pressing the

The DYNAMICS button

toggles through

the Dynamics

modules used in

each channel of

the selected

program.

press either Parameter button to enter the module. Successive presses of DYNAMICS button will move

"Next Page" or "Prev Page" buttons successively until you arrive at the desired Page.

DYNAMICS

DYNAMICS

Compressor

Peakstop

Over Easy

Threshold

Ratio

Gain

Dynamics (Mono Compressor)

The PARAMETER knobs are used

to edit parameter values

®

1

2 3

Page 34

Editing Functions

22

Section 2

DriveRack

™

Navigating the Other (Input and Output) Sections

The OTHER button

toggles through

the Input and

Output modules used

in each channel of

the selected

program.

OTHER

OTHER

Level

High Pass On/Off

OTHER

OTHER

Pink Noise On/Off

Noise Level

Input Channels 1-4

Output Channels 1-8

Level/Shift

Out Level

Phase Shift

To edit the parameters of the Input and Ouptuts used in a selected program, simply use the following procedure. From program mode,

either press the OTHER button or use the Parameter 2 or 3 knobs to move to Input or Output modules. Once you have reached the

Input and Output modules, press the next pg and prev pg buttons to access the editing pages of the module. Successive presses

will move through each of the Input and Output editing modules. Navigate through the Pages of the

selected Input or Output module by pressing the "Next Page" or "Prev Page" buttons

successively until arriving at the desired Page.

1

2 3

The PARAMETER buttons are used

to edit parameter values

2.11 Navigating the Other Section

DriveRack™ User Manual

®

Page 35

2.12 Navigating the Utility Section

Editing Functions

Section 2

DriveRack

™

23

DriveRack™ User Manual

Navigating the "Utility" Section

Navigate through the Pages by depressing the "Next Page" or "Prev Page"

Page 1

Limiter

Device ID

Target ID

The PARAMETER buttons are used

to edit parameter values

buttons successively until arriving at the desired Page

Page 2

Limiter

Item

Level

Page 3 Page 5

Limiter

Edit High Passw

Edit Med Passw

Security

Page 4 Page 6 Page 7 Page 8 Page 9

Limiter

List size

List Index

Prg Num

Limiter Limiter Limiter Limiter Limiter

Prg Mode

1

Contrast

PC Comm

PUP Mute

Page 10

Mic Pre Ch 3

Mic Pre Ch 4

Mic In

2 3

MIDI CH

SYSEX ID

MIDI DUMP

SEND

Limiter

MIDI BULK

DUMP

SEND

Page 11

Limiter

REDUNDANCY

CUE AFL

®

Page 36

Page 37

CONFIGURATION

FUNCTIONS

®

SOFTWARE

Section 3

DriveRack

™

Page 38

Configuring the DriveRack™

26

Section 3

DriveRack

™

DriveRack™ User Manual

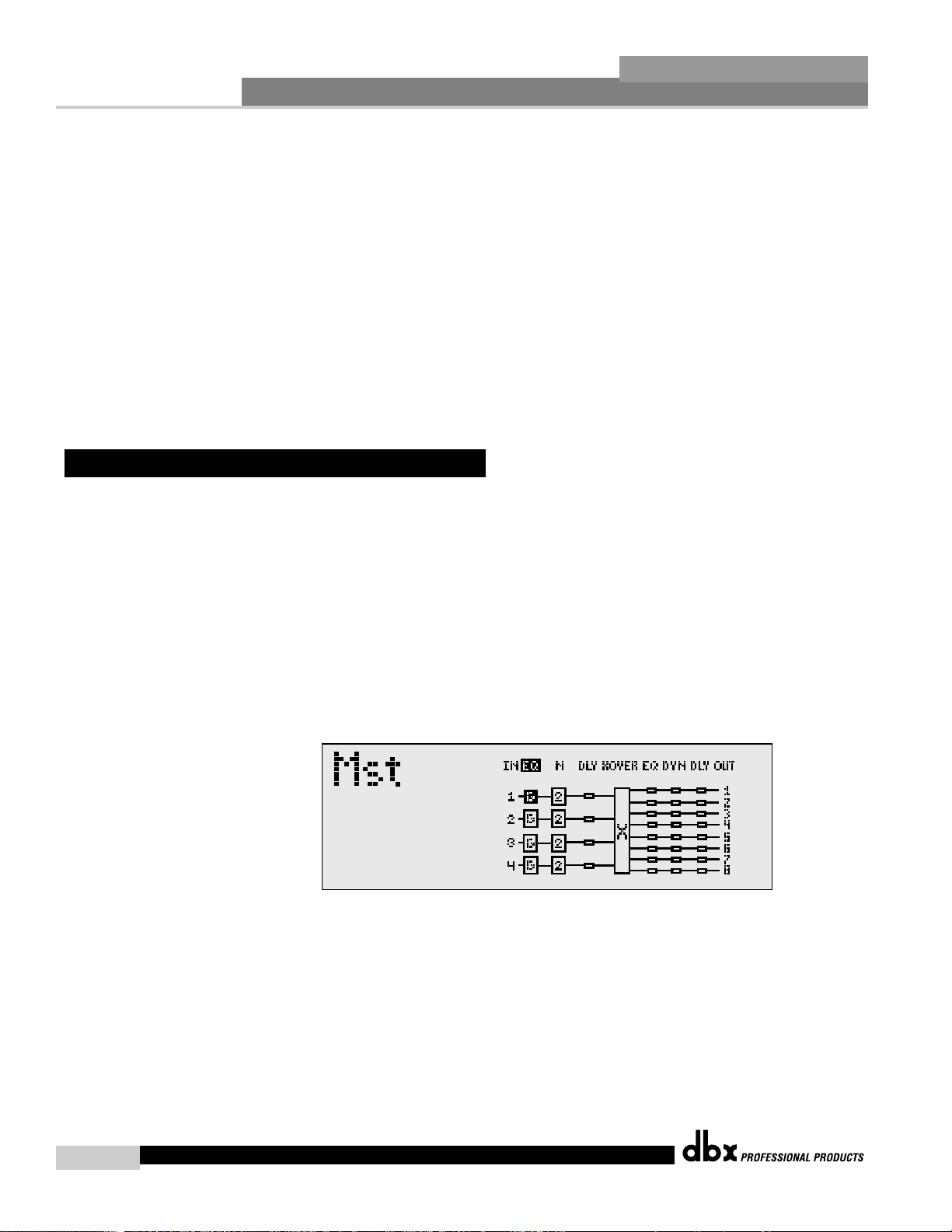

The Configuring section of the 480, 481, 442 and 482 DriveRack™ units will be your key to

successful navigation of the configuration functions of the DriveRack™. The following information provides, descriptions about program functions and in depth configuration options of

the 480, 481 and 482 DriveRack™ units.

The first step in understanding the complex programming capabilities of the DriveRack™ is to

understand the elements involved that combined, define a complete “program.” Within an individual program, there are several levels of editing that make up the complete program. When

initially entering a program, you will be at the “program” mode level. This level supplies the

user with current program information such as: current signal path, effect usage, and program

name. From this point, the 480, 481, 442 and 482 DriveRack™ units give you the option of

entering subsequent levels of operation that are dedicated to program editing. The levels

include: Configuration mode and Effect Edit mode. The key element to remember is that all of

these components combined, make up the conventional “program”, and that they are all unique

to each individual program. The utility menu mode and Network setup and management and

setup are accessed via the utility menu, and are not part of the program.

From the factory, the 480, 481, 442 and 482 DriveRack™ units are shipped with 20 factory programs that utilize carefully constructed routing configurations that have been designed to

accommodate virtually any sound reinforcement and installation application. These configurations are laid out in an intuitive straight forward manner on the 480. The 480 display shows

the entire signal route from the input section to the output section.

Selecting Programs:

The quickest mode for getting up and running with the DriveRack™ is to simply use any one

of the factory programs that are available in the box. To select a factory program, (from program mode), use the PARAMETER 1 knob to scroll through the various factory programs. This

is an ideal method of selection because when each factory program is scrolled to, the display

will clearly indicate the routing matrix, as well as all of the effects that are being used for the

selected program. Once a program is selected, press the PROGRAM/CONFIG button to load

the program. The display will appear something like this:

25

4063100 160 250 400 630 1.0k 1.5k 2.5k 4.0k 6.3k 10k 16k

20

315080 125 200 315 500 800 1.3k 2.0k 3.2k 5.0k 8.0k 13k 20k

+24 +6

+18 +4

+12 +2

+8 0

0 -2

-8 -4

-12 -8

-18 -9

-24 -12

-60 -30

-30 -15

-40 -20

-50 -25

-70 -35

-80 -40

-90 -50

+14

+12

+10

+8

+6

+4

+2

0

-2

-10

-4

-6

-8

-12

-14

Parameter 1

Parameter 2

Parameter 3

Single RTA

Channel 1

F7 4-Way FOH w/RTA

3.2 Navigating Factory Programs

3.1 Program Definition

®

Page 39

Configuring the DriveRack™

Section 3

DriveRack

™

27

DriveRack™ User Manual

Navigation Modes

Once you have selected a program that utilizes a configuration that accommodates your application, the DriveRack™ offers different modes of navigation to access and edit effect types within the selected configuration.

To instantly

access an effect module, simply press the corresponding button in the button array

for the desired module. The following buttons will access the following modules: EQ = PEQ,

GEQ and Notch filters (successive presses will you move through each input and output which

utilizes an EQ type module). X-OVER = Crossover(s) and filters, RTA = Real Time Audio

Analyzer, DELAY = Delay and Driver Alignment Delay (successive presses will you move

through each input and output which utilizes the Delay type module). DYNAMICS =

Compressor/Limiter (successive presses will you move through each output compressor module. OTHER = Input and Output modules (successive presses will you move through each

input and output channel).

To roam through a program configuration, simply use the PARAMETER 2 knob to move from

left or Right within the configuration, and use the PARAMETER 3 knob to move Up and Down

within the configuration. Once you have reached the module to be edited, press either the

PARAMETER 2 or 3 knob to access the editing parameters of the modules.

Parameter 2

Parameter 3

®

Page 40

Configuring the DriveRack™

28

Section 3

DriveRack

™

DriveRack™ User Manual

Once you have reached the module that you wish to edit, simply use the

PREV PG and NEXT PG buttons to move through the pages within the module. The PARAMETER knobs are used to edit parameter values. The following illustration shows an exam-

ple of the Compressor/Limiter module in edit mode:

Once you are satisfied with the changes that have been made to a factory or user program, the

DriveRack™ allows you to save these changes to the program as a custom USER program by

simply pressing the STORE button, and the display will appear something like this:

Rotate the Parameter 2 knob to move the cursor position. Rotate the Parameter 1 knob to

select the desired character. Push the PARAMETER 2 knob to toggle between upper and

lower case characters.

STORE

Whl1: Cursor Position

Whl2: Character Selec

Btn2: Character Shift

NAME:

4 2Way Monitors

3.4 Saving Factory Programs Changes

Compressor

Parameter 1

Parameter 2

Parameter 3

Channel 1 Output 1

Mono Comp. p1:2

Compressr ON

PKStop+ ON

Over Easy 1

GR

THRESH

- 0 +

3.3 Editing Factory Programs

®

Page 41

Configuring the DriveRack™

Section 3

DriveRack

™

29

DriveRack™ User Manual

• Once you are satisfied with the selected name, press the STORE button again and the

screen will appear something like this:

• If you wish to replace an existing User program, press the PARAMETER 1 knob and the

display will appear as follows:

• Use the Parameter 3 knob to select the USER program to be replaced. Once the pro-

gram to be replaced has been selected, press the STORE button once again and the

program will then be replaced.

• To store a program as a new USER program, press the STORE button and then press

the Parameter 2 knob to store as new and the display will appear as follows:

• At this point, use the Parameter 2 knob to select the position where the new USER program will be stored.

STORE

Choose Place In The

USER PROGRAM LIBRARY

To Insert The New

Program.

Press <STORE> To Save

Program.

4-Way FOH w/RTA

1 Replace Old

Parameter 3

STORE

Choose Program To Be

Replaced.

Press <STORE> To Save

Program.

4-Way FOH w/RTA

4-Way FOH w/RTA

Replacing:

Parameter 1

Parameter 2

STORE

1 Replace Old

2 Store New

®

Page 42

Configuring the DriveRack™

30

Section 3

DriveRack

™

User Configuration creation is an ideal feature available in the DriveRack™ line. Even with the

versatility of the Factory configurations within the DriveRack™, there may be an application that

requires a unique “custom” program. The DriveRack™ gives you the ability to create a custom

routing configuration by selecting and modifying the modules including: Inputs (naming), precrossover EQ, Notch Filter, Crossovers and Output Naming. The procedure for this process is

as follows:

• From Program mode, press and hold the PROGRAM/CONFIG button until the top left side

of the display reads:

CONFIGURATION

MODE: Select FX

• At this point, you can navigate the signal route to move to the module that you wish to edit

by using the PARAMETER 2 knob to move the cursor left and right, and use the

PARAMETER 3 knob to move the cursor up and down.

• Once you have reached the module that you wish to edit and the module has been high lighted, simply use the PARAMETER 1 knob to select the various options for the selected mod-

ule. The following illustration and sub sections offer information about each section of the

signal path within the DriveRack™ unit.

3.5- A Input Routing

From the Configuration creation mode, the DriveRack™ gives you the option of routing any

physical analog input to any digital input. This means that a connection can be made at any

one of the four inputs on the rear panel of the unit and then routed to any one of the four

digital input sections within the unit. This routing feature will also allow you to number the

A

B

C

D E F

G

H

I

3.5 Creating a User Configuration

DriveRack™ User Manual

®

Page 43

Configuring the DriveRack™

Section 3

DriveRack

™

31

Input in a manner that will accommodate your application. The inputs of the DriveRack™ units

can also mix audio from any one, or all of the analog inputs. Options for selecting and numbering Inputs include: Input names 1-4 and M.

3.5- B Pre Crossover EQ

At the pre crossover section of the signal path, the DriveRack™ units give you the option of utilizing either a 31 band graphic or 9 band parametric EQ on each channel of the selected input.

The DriveRack™ will also accommodate a dual 31 band graphic EQ, dual (Show and House)

31 band graphic, or 9 band graphic EQs on each input. Enter the Configuration creation section of the DriveRack™ by pressing and holding the PROGRAM/CONFIG button. Now use

the PARAMETER 2 and 3 knobs to move to the selected input of the pre-crossover EQ section. Once you are there, use the PARAMETER 1 knob to select either the 31 band graphic

(G), Show/House (SH) 31 band, or the 9 band parametric (P) equalizer. In addition to the

equalizers available in this section, inputs 3 and 4 offer real time audio analyzers which can be

selected by using the same procedure.

3.5- C Notch Filter

At the Notch filter section of the signal path, the DriveRack™ units give you the ability to use

a 1-5 band notch filter on any input within the section, while not exceeding 10 bands within

the unit. The notch filter is the perfect tool for removing unwanted frequencies from the signal path. Enter the Configuration creation section of the DriveRack™ by pressing and holding

the PROGRAM/CONFIG button. Now use the PARAMETER 2 and 3 knobs to move to the

selected input of Notch filter section. Once you are there, use the PARAMETER 1 knob to

select the desired Notch filter.

3.5- D Delay Section

The DriveRack™ units offer two unique delay sections within the signal path. The first Delay

section can be used for setting overall room delay settings. Enter the Configuration creation

section of the DriveRack™ by pressing and holding the PROGRAM/CONFIG button. Now

use the PARAMETER 2 and 3 knobs to move to the selected input of Delay section.

3.5- E Crossover

The Crossover section of the DriveRack™ unit offers 27 different crossover options that can

accommodate any audio application. Enter the Configuration creation section of the DriveRack

by pressing and holding the PROGRAM/CONFIG button. Now use the PARAMETER 2 and

3 knobs to move to the Crossover section. Once you are there, use the PARAMETER 1 knob

to select the desired Crossover module. Section 3.7 provides you with in-depth information for

selecting and moving crossover types.

3.5- F Post Crossover Parametric EQ

After the Crossover section, the DriveRack™ units offer an additional 4 band Parametric EQ

module. This EQ is often used to compensate for non-lineararities in speaker response. Enter

the Configuration creation section of the DriveRack™ by pressing and holding the PRO-

GRAM/CONFIG button. Now use the PARAMETER 2 and 3 knobs to move to the selected

output EQ section.

3.5- G Dynamics (Compressor/Limiter)

The Dynamics section of the DriveRack™ signal path provides you with compression/limiting

on any one (or all) of the eight outputs of the signal path. Enter the Configuration creation section of the DriveRack™ by pressing and holding the PROGRAM/CONFIG button. Now use

the PARAMETER 2 and 3 knobs to move to the selected output Dynamics section.

DriveRack™ User Manual

®

Page 44

Configuring the DriveRack™

32

Section 3

DriveRack

™

3.5- H Driver Alignment Delay

The second Delay section of the DriveRack™ units is used to fine tune delay times within an

enclosed speaker or an array of speakers. Enter the Configuration creation section of the

DriveRack™ by pressing and holding the PROGRAM/CONFIG button. Now use the PARA-

METER 2 and 3 knobs to move to the selected output Delay section.

3.5- I Output Routing and Phase Compensation

From the Configuration creation mode, the DriveRack™ gives you the option of routing any digital output to any of the eight analog outputs of the DriveRack™ unit. This means that the digital output signal can be routed to any one of the eight physical outputs. Options for numbering Outputs names include: 1-8 . This means that two signals that are sent to the same output,

will be summed to one output that shares the same name. In addition to output routing, each

output section of the DriveRack™ unit offers phase compensation within the selected output

module.

The DriveRack™ provides the user with an option to link like modules together (ie; four 31

band Graphic EQs and so on) so that when a change is made in a selected program to one

module, the change will affect all of the like modules. This linking feature can be applied to

every module used in any single configuration. The following procedure will illustrate how to

perform this feature.

• While you are in Configuration mode, use the PARAMETER 2 and 3 to scroll to the mod-

ule section that you wish to link. For this example, we will use the Graphic (G) EQ modules. Once a single Graphic EQ module has been selected, you can select all of the Graphic

EQ modules by pressing the PARAMETER 3 knob, and the display will appear something

like this:

• At this point, rotate the PARAMETER 3 knob to select all four Graphic EQ modules, then

press the PARAMETER 2 knob to link the modules together. Once this has been done,

Parameter 1

Parameter 2

Parameter 3

CONFIGURATION

MODE:Link/Unlink

Graphic EQ

Pre EQ

Channel 1

3.6 Linking Modules

DriveRack™ User Manual

®

Page 45

Configuring the DriveRack™

Section 3

DriveRack

™

33

the display will appear something like this:

Note: Linking modules past the crossover section will be dictated by the selected crossover

type. For example, if a two-way crossover is used, you will be limited to linking the

effect modules past the crossover to highs and lows.

The user has the ability to select and position the desired crossover within the crossover module section. You also have the ability to change the crossover output route while you are selecting and moving crossovers. The procedure is as follows:

• From Program mode, press and hold the PROGRAM/CONFIG button until you are in

Configuration mode. The display will appear as follows:

• At this point use the Parameter 2 and 3 knobs to move to the crossover section.

• Once the crossover section has been selected, use the PARAMETER 1 knob to select

the desired crossover type.

• If you wish to move a crossover type, simply rotate the PARAMETER 1 knob counter

clockwise until the display appears something like this:

• Now use the PARAMETER 3 knob to move the crossover module to the desired posi-

tion.

Parameter 1

Parameter 2

Parameter 3

CONFIGURATION

Input 1

Input

Channel 1

3 MODE:Select FX

Parameter 1

Parameter 2

Parameter 3

CONFIGURATION

Input 1

Input

Channel 1

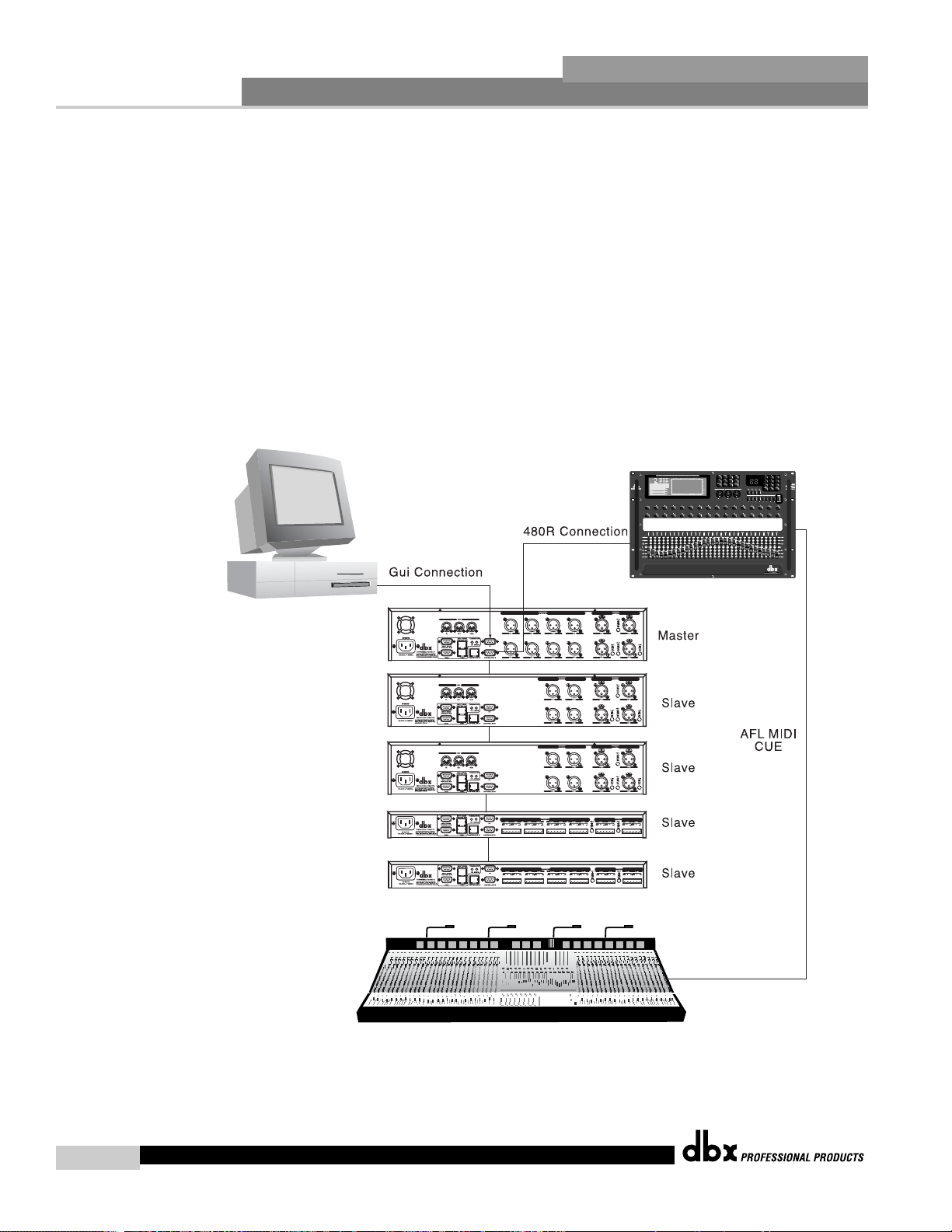

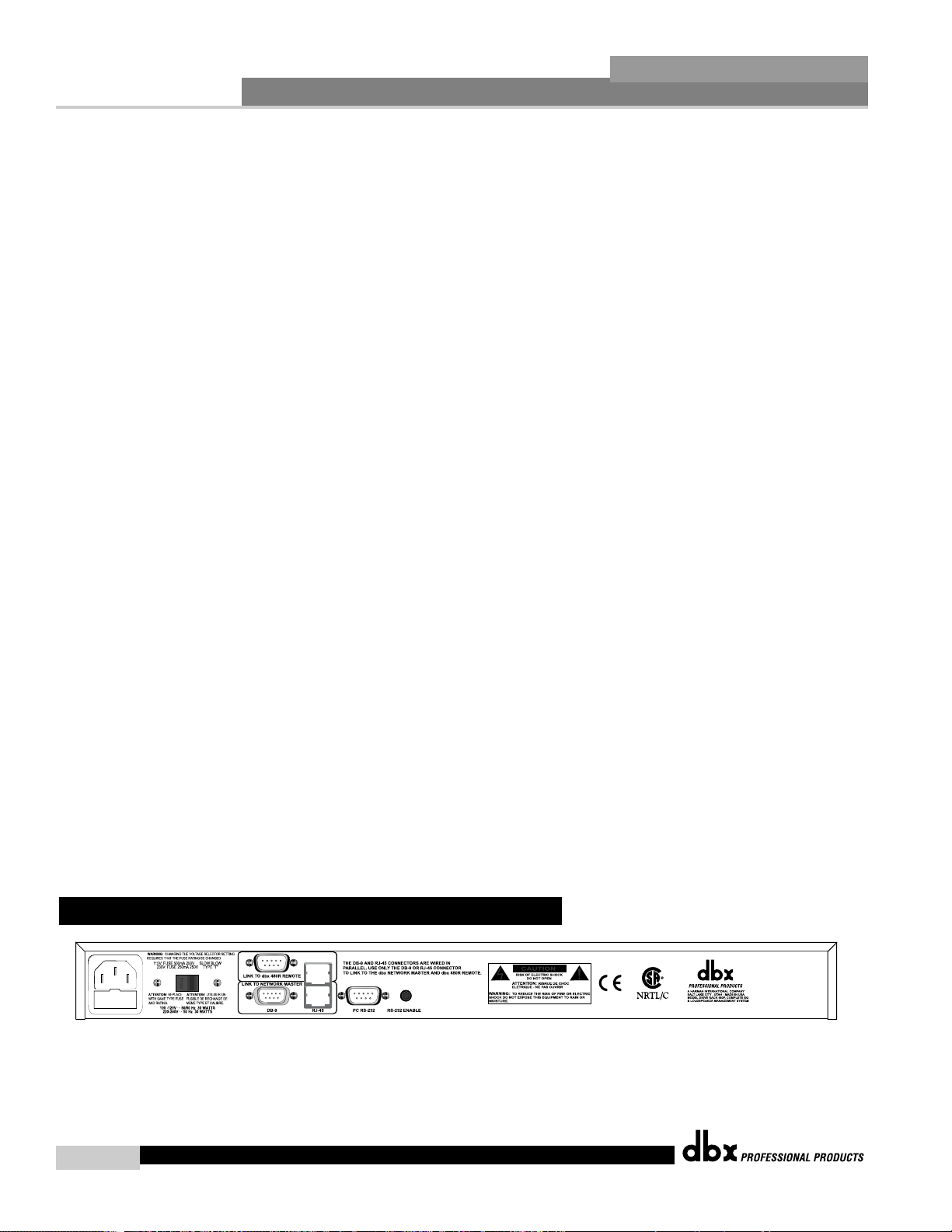

3 MODE:Select FX