Page 1

#3170

ASSEMBLY and MOUNTING

NSTRUCTIONS

WindeXL features a 23" Windex®wind vane for

boats over 40 feet (12 m). This large vane is easier to

see on a tall mast. WindeXL is 50% larger in linear

dimension than the popular Windex 15 (the choice of

most sailors worldwide).

WindeXL features a sapphire suspension bearing,

23" (58.4 cm) vane and adjustable tacking arms with

tabs. Vane and tabs feature reflectors for high visibility day and night. Uses same mounting thread pattern

as Windex 15 for easy upgrade or retrofit installation.

Stands 17.5" (44.5 cm) tall yet weighs just 8.3

ounces (233 g). May be fitted with optional Windex

Light #3200.

It is advisable to read through the entire set of

instructions before beginning assembly. Your

WindeXL is a precision instrument, and if not assembled properly might not hold together under the

strong vibration at the top of a mast. The mast top

environment is severe from a vibrational standpoint

and oscillates violently.

Note that you will find the diagram on the bottom of

the box helpful when adjusting the tab angle (step 6),

but these instructions should suffice if the box is no

longer in your possession.

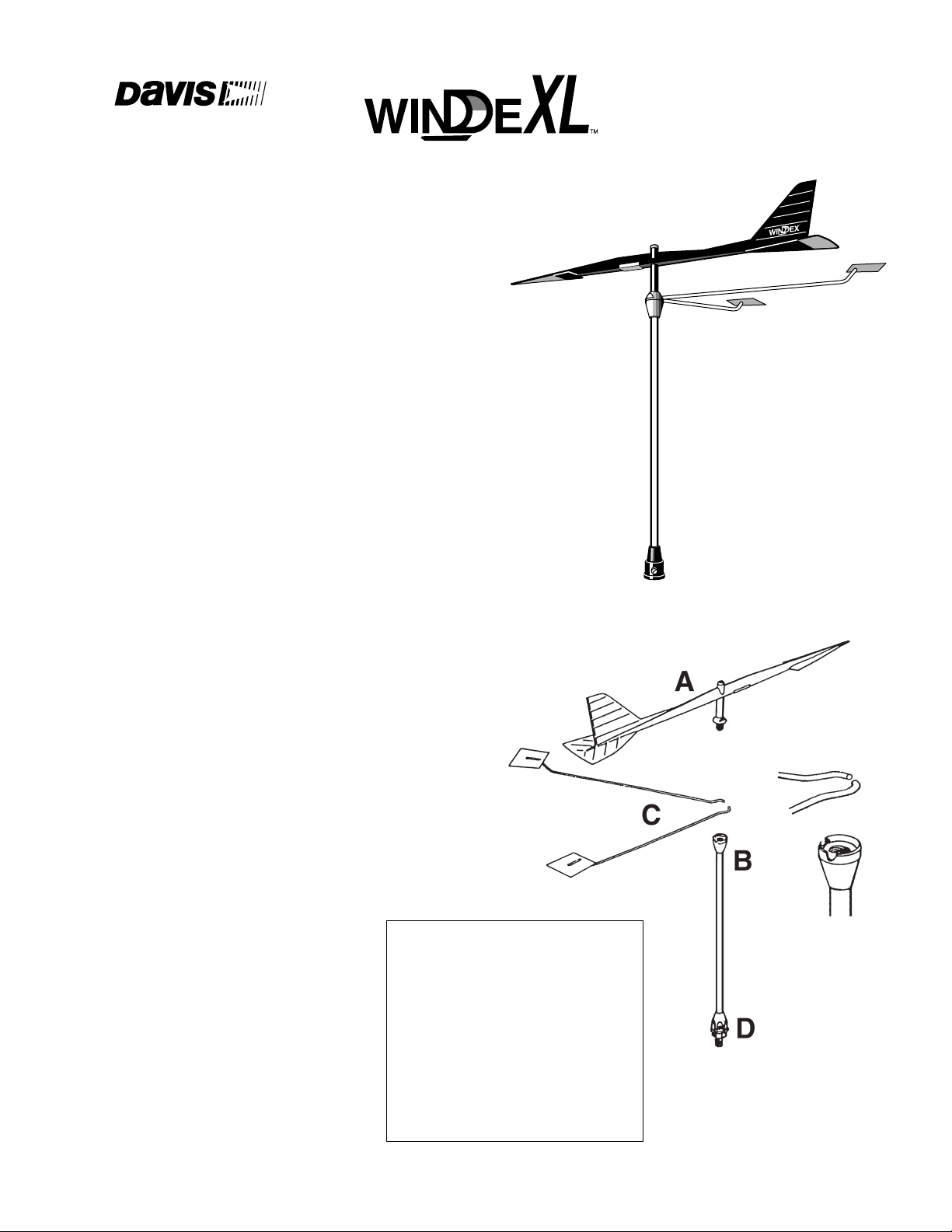

Box Contains:

(A) Vane assembly with jewel

bearing system and screw part.

(B) Supporting rod with tab arm

holder.

(C) Two reference tab arms, port

and starboard.

(D) Mast fitting with lock screw,

mounting screw, nut, and

washer

NOTE: WindeXL was

discontinued in 2006.

Page 2

Assembling your WindeXL:

1.Put some silicone or other sealant on the threads

of the screw part of the vane assembly (A).

2.Place the screw part against the tab arm holder

(B) and turn the screw by hand 2 full turns into the

thread, leaving a slot for insertion of the tab arms

(C).

3.Insert the curved ends of the tab arms (C) so that

the black surfaces of the tabs point upwards

(reflective side down). The tab arms should protrude through the cut-outs in the tab arm holder

(B.)

4.Now rotate the screw part of the vane assembly

(A) by hand, checking that the curved ends of the

tab arms lie flat in the recess of the tab arm holder. This procedure is easier with the tabs resting

on a flat surface. When you are satisfied with the

positioning of the tab arm ends in the recess and

how they lie in the cut-outs, check again that the

black surface of the tabs point upwards (reflecting

side down).

5.Take a well-fitting wrench or spanner and, holding

the assembly with your fingers around both tab

arms and the central rod, tighten the screw part

securely. With your hand, flex the tab arms a little

to finally seat them in position, then tighten again.

The tab arms should now be rigidly attached.

6.Use the angle indication on the underside of the

box to adjust the angle between the tab arms to

suit your yacht’s windward performance. The three

different angles could represent:

Heavy displacement cruising yachts

65°

Cruising yachts in general

60°

High-pointing racing yachts

55°

Adjust the tab arms carefully, a little bit at a time,

bending them close to the attachment point. The

angles suggested are based on experience, but

many individual variations exist, with rig types and

keels also having an influence. The recommended

tab angles are simply a convenience that allow

the index tabs to be approximately centered in

relation to the vane’s position when sailing closehauled.

Attaching WindeXL to the Mast Fitting:

1.Select a place for your WindeXL where the vane

and tab arms can be seen comfortably from deck

and there are no obstructions to the vane swinging freely.

2.The mounting of the mast fitting (D) is easiest

done with the mast on the ground.

3.There are two alternatives for mounting the mast

fitting. Whichever method is used, apply structural

adhesive (2-component epoxy or similar) under

the mast fitting to further secure it, itself, from

rotating.

Alternative I. On a horizontal part of the masthead with an 5/16" (8 mm) diameter throughhole. Insert mast fitting into hole. Slide on washer

and nut supplied. Use a strong screwdriver to

screw the bottom screw into the nut. The screw is

very strong and must be tightened with considerable force to prevent it and the mast fitting from

turning under sea conditions and vibration. Finally,

tighten the nut with a wrench, holding the screw

with the screwdriver. Again it must be emphasized

that the desired result depends on very forceful

tightening.

Alternative II. In a blind hole in an aluminum or

titanium masthead. Use a 5/16" UNC tap to cut

threads in a 1/4" diameter hole (FULL thread min.

3/4" deep). Then use structural adhesive on the

threads and under the mast fitting, and tighten

with considerable force as in Alternative I.

4. It is important that the two tab arms (C) are lined

up pointing symmetrically aft in relation to the

yacht’s centerline. For reference, use the spreaders (with the mast on the ground) or the aft stay

when the mast is stepped. When you are satisfied

with the symmetry of the tab arms, and with the

central shaft pressed all the way down (locking

screw unscrewed) into the mast socket (D), tighten the locking screw so that the sharp tip makes

an impression onto the aluminum shaft. This mark,

which should be deepened slightly using the

sharp point of a knife or similar tool, will help you

to accurately reposition your WindeXL. This

depression is also what keeps the WindeXL from

turning out of position.

Page 3

3465 Diablo Avenue, Hayward, CA 94545, U.S.A.

Phone (510) 732-9229 • Fax (510) 732-9188

info@davisnet.com • www.davisnet.com

3170_Ins.pdf June 2008

If you exercise reasonable care and take down your

WindeXL before you unstep your mast, it will give you

many years of excellent service without any form of

maintenance.

Replacement Parts

Spare parts for WindeXL are no longer available.

Manufactured and distributed by

The Complete Windex®Line…

Windex, the famous wind direction indicator for sailboats, is the standard on most mastheads

around the world. Models available for every sailor’s needs:

#3120 Windex 10.sport — 10" (25 cm) vane. . . for small boats and dinghies

#3150 Windex 15 — 15" (38 cm) vane . . . . . . the choice for most sailors

#3160 Windex AV — 15" (38 cm) vane . . . . . . for mounting on whip antennas,

combining two installations in one

Loading...

Loading...