Page 1

STW12NA50

N - CHANNEL ENHANCEMENT MODE

FAST POWER MOS TRANSISTOR

TYPE V

DSS

R

DS(on)

I

D

STW12NA50 500 V < 0.6 Ω 11.6 A

■ TYPICAL R

■ ± 30V GATE TO SOURCE VOLTAGE RATING

■ 100% AVALANCHE TESTED

■ REPETITIVE AVALANCHE DATA AT 100

■ LOW INTRINSIC CAPACITANCES

■ GATE GHARGE MINIMIZED

■ REDUCED THRESHOLD VOLTAGE SPREAD

DS(on)

= 0.5 Ω

o

C

DESCRIPTION

This series of POWER MOSFETS represents the

most advanced high voltage technology. The optimized cell layout coupled with a new proprietary

edge termination concur to give the device low

R

and gate charge, unequalled ruggedness

DS(on)

and superior switching performance.

APPLICATIONS

■ HIGH CURRENT, HIGH SPEED SWITCHING

■ SWITCH MODE POWERSUPPLIES (SMPS)

■ DC-AC CONVERTERS FOR WELDING

EQUIPMENT AND UNINTERRUPTIBLE

POWER SUPPLIES AND MOTOR DRIVE

3

2

1

TO-247

INTERNAL SCHEMATIC DIAGRAM

ABSOLUTE MAXIMUM RATINGS

Symb o l Paramet er Val u e Unit

V

V

V

I

DM

P

T

(•) Pulsewidth limited bysafe operating area

December 1995

Drain - s ource Voltage (VGS= 0) 500 V

DS

Drain- gate Voltage (RGS=20kΩ) 500 V

DGR

Gate-source Voltage ± 30 V

GS

Drain Current (continuous) at Tc=25oC11.6A

I

D

Drain Current (continuous) at Tc=100oC7.3A

I

D

(•) Drain Current (pulsed) 46.4 A

Total Di ssipation a t Tc=25oC 170 W

tot

Derat ing Factor 1.36 W/

St or a ge Tem perature -65 t o 150

stg

Max. Operating Jun ction T emperature 150

T

j

o

C

o

C

o

C

1/9

Page 2

STW12NA50

THERMAL DATA

R

thj-case

R

thj-amb

R

thj-amb

T

AVALANCHE CHARACTERISTICS

Symbol Parameter Max Valu e Uni t

I

AR

E

E

I

AR

Thermal Resistance Junction - cas e Max

Thermal Resistance Junction- ambient Max

Thermal Resistance Case-sink Typ

Maximum L ead Temperat ur e For Soldering Purpos e

l

Avalanc h e Cu rr ent , Repet itive or Not-Rep etitive

(pulse width limited by Tjmax, δ <1%)

Single Pul se Avalanche Ener gy

AS

(starti ng Tj=25oC, ID=IAR,VDD=50V)

Repetitive Avalanc he Energ y

AR

(pulse width limited by Tjmax, δ <1%)

Avalanc h e Cu rr ent , Repet itive or Not-Rep etitive

(Tc= 100oC, pulse width l imited by Tjmax, δ <1%)

0.73

30

0.1

300

11.6 A

670 mJ

26.5 mJ

7.3 A

o

C/W

o

C/W

o

C/W

o

C

ELECTRICAL CHARACTERISTICS (T

=25oC unless otherwisespecified)

case

OFF

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

(BR)DSS

Drain - s ource

ID=250µAVGS= 0 500 V

Break d own Volta ge

I

DSS

I

GSS

Zer o G at e V oltage

Drain Current (V

GS

Gat e- body Leakage

=0)

=MaxRating

V

DS

V

= Max Rating x 0.8 Tc=125oC

DS

25

250

VGS= ± 30 V ± 100 nA

Current (VDS=0)

ON (∗)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

GS(th)

R

DS(on)

Gate Threshold Voltage VDS=VGSID=250µA 2.25 3 3.75 V

St at ic Drain-s our ce O n

VGS=10V ID=6A 0.5 0.6 Ω

Resistance

I

D(on)

On State Drain Current VDS>I

D(on)xRDS(on)max

12 A

VGS=10V

DYNAMIC

Symbol Parameter Test Conditions Min. Typ. Max. Unit

(∗)Forward

g

fs

Tr ansconductance

C

C

C

Input Capacitance

iss

Out put Capacitance

oss

Reverse Transfer

rss

Capacitance

VDS>I

D(on)xRDS(on)maxID

=6A 6 9 S

VDS=25V f=1MHz VGS= 0 1750

250

80

2500

370

130

µA

µA

pF

pF

pF

2/9

Page 3

STW12NA50

ELECTRICAL CHARACTERISTICS (continued)

SWITCHING ON

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

d(on)

(di/dt)

Q

Q

Q

Turn-on T ime

t

Rise Time

r

Turn-on Current S lope VDD=400V ID=12A

on

Total Gate Charge

g

Gat e- Source Charge

gs

Gate-Drain Charge

gd

SWITCHING OFF

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

r(Voff)

t

Off -voltage Rise Time

t

Fall Time

f

Cross-over Time

c

SOURCE DRAINDIODE

VDD=250V ID=6A

RG=4.7 Ω VGS=10V

20

32

(see test circuit, figure 3)

190 A/µs

RG=47 Ω VGS=10V

(see test circuit, figure 5)

VDD= 400 V ID=12A VGS=10V 80

12

37

VDD=400V ID=12A

RG=4.7 Ω VGS=10V

(see test circuit, figure 5)

16

12

30

28

45

110 nC

22

18

42

ns

ns

nC

nC

ns

ns

ns

Symbol Parameter Test Conditions Min. Typ. Max. Unit

I

I

SDM

SD

Source-drain C urrent

(•)

Source-drain C urrent

11.6

46.4

(pulsed)

V

(∗) Forward On Voltage ISD=12A VGS=0 1.6 V

SD

t

Reverse Recovery

rr

Time

Q

Reverse Recovery

rr

ISD= 12 A di/dt = 100 A/µs

VDD= 100 V Tj=150oC

(see test circuit, figure 5)

600

10.2

Charge

I

RRM

Reverse Recovery

34

Current

(∗) Pulsed:Pulse duration = 300 µs, dutycycle 1.5 %

(•) Pulse widthlimited by safeoperating area

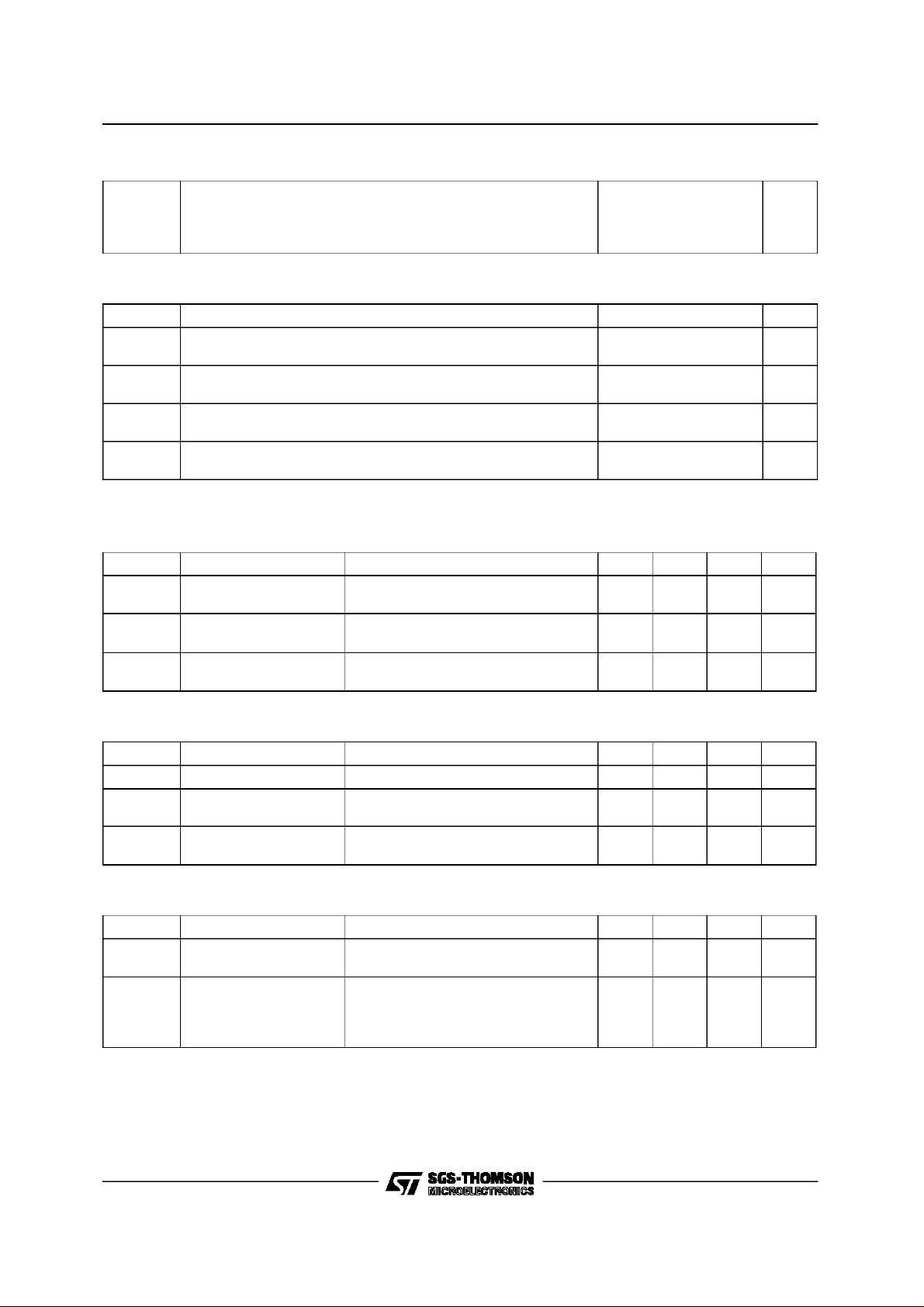

Safe Operating Areas Thermal Impedance

A

A

ns

µC

A

3/9

Page 4

STW12NA50

Derating Curve

Transfer Characteristics

Output Characteristics

Transconductance

Static Drain-source On Resistance

4/9

Gate Charge vs Gate-source Voltage

Page 5

STW12NA50

Capacitance Variations Normalized Gate Threshold Voltage vs

Temperature

Normalized On Resistance vs Temperature Turn-on Current Slope

Cross-over TimeTurn-off Drain-source Voltage Slope

5/9

Page 6

STW12NA50

Switching SafeOperating Area Accidental Overload Area

Source-drain Diode Forward Characteristics

Fig. 1: Unclamped Inductive Load Test Circuits Fig. 2: Unclamped Inductive Waveforms

6/9

Page 7

STW12NA50

Fig. 3: Switching Times Test Circuits For

Resistive Load

Fig. 5: Test Circuit For Inductive Load Switching

And Diode Recovery Times

Fig. 4: Gate Charge Test Circuit

7/9

Page 8

STW12NA50

TO-247 MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 4.7 5.3 0.185 0.208

A1 2.87 0.113

A2 1.5 2.5 0.059 0.098

b 1 1.4 0.039 0.055

b1 2.25 0.088

b2 3.05 3.43 0.120 0.135

C 0.4 0.8 0.015 0.031

D 20.4 21.18 0.803 0.833

e 5.43 5.47 0.213 0.215

E 15.3 15.95 0.602 0.628

L 15.57 0.613

L1 3.7 4.3 0.145 0.169

Q 5.3 5.84 0.208 0.230

ØP 3.5 3.71 0.137 0.146

mm inch

8/9

C

A

b1

A1

b

e

b2

A2

Q

D

L1

L

ø

E

Page 9

STW12NA50

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsability for the

consequences of use of such information nor for any infringement of patents or other rightsof third parties which mayresults fromits use. No

licenseis granted by implication or otherwise under any patentor patent rights of SGS-THOMSON Microelectronics. Specifications mentioned

in thispublication are subject to change withoutnotice. Thispublication supersedes andreplacesall information previously supplied.

SGS-THOMSONMicroelectronics products are not authorizedfor use ascriticalcomponents in lifesupport devices or systems withoutexpress

writtenapproval ofSGS-THOMSONMicroelectonics.

1996 SGS-THOMSON Microelectronics -Printed in Italy- AllRightsReserved

Australia- Brazil -Canada -China - France- Germany - HongKong- Italy - Japan- Korea- Malaysia - Malta- Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland-Taiwan - Thailand- UnitedKingdom - U.S.A

SGS-THOMSONMicroelectronics GROUPOF COMPANIES

.

9/9

Loading...

Loading...