Page 1

SAP5S / SAP51

Revision C

DSTBn

LED1

OSC2

OSC1

P1

P0

D1

D0

P2

P3

D2

D3

PSTBn

LED2

PFAULT

UOUT

U5R

LTGN

CDC

LTGP

DSTBn

LED1

OSC2

OSC1

D1D0D2

D3

PSTBn

LED2

PFAULT

UOUT

U5R

LTGN

CDC

LTGP

Universal Actuator-Sensor Interface IC

Datasheet

Features

Universal application in AS-i Slave, Mas-

•

ter, Repeater and Bus-Monitor components

Support of AS-i Complete Specification

•

V3.0, including all optional features

Synchronous Data I/O Mode

-

-

4 Input / 4 Output operation in

Extended Address Mode

-

User write protection for

Extended ID-Code 1

-

Multiplexed Parameter Port

Full support of the AS-i “Safety at Work”

•

concept

On chip electronic inductor with current

•

drive capability of 55mA

LED outputs supporting all status indica-

•

tion modes defined by AS-i Complete

Specification V3.0

Data preprocessing functions: input filter-

•

ing and input inverting

Support of 5.33 / 16 MHz crystals by auto-

•

matic frequency detection

Clock Watchdog for high System Security

•

Communication Watchdog

•

Description

SAP5 is a monolithic CMOS integrated circuit

certified for AS-i (Actuator Sensor Interface)

networks. AS-i networks are used for industrial

automation.

AS-i is designed for easy and simple interconnection of binary sensors and actuators. It

uses a two-wire unshielded cable to transport

power and information.

Using the SAP5 safety-related AS-i slaves can

be realized according to the AS-i “Safety at

Work” concept. Slaves complying with category 4 of EN954-1 can be realized with a

minimum of external circuitry.

The device is available in SOP20 and SOP16

package.

Application Support

Configuration of the chip is handled through

programming of the on-chip E²PROM. ZMD

provides special tools to ease product evaluation and selection of different operation modes.

AS-Interface Programmer 2.0 USB

(Ordering Code: 3600100145)

SAP5 Evaluation Board 2.0

(Ordering Code: 3600100144)

Further application support is available through

e-mail hotline under asi@zmd.de

SAP5

Rev. 2.0 Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

SAP5

1/58

Page 2

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

Table of Contents

0 READ THIS FIRST ...........................................................................................................................................4

0.1 I

0.2 R

0.3 R

1 GENERAL DEVICE SPECIFICATION.............................................................................................................5

1.1 A

1.2 O

1.3 EMC B

1.4 Q

1.5 F

1.6 H

1.7 P

2 BASIC FUNCTIONAL DESCRIPTION ..........................................................................................................10

2.1 F

2.2 G

2.3 S

3 E²PROM .........................................................................................................................................................17

3.1 O

3.2 U

3.3 F

3.4 S

4 DETAILED FUNCTIONAL DESCRIPTION ...................................................................................................23

4.1 P

4.2 T

4.3 DC C

4.4 DC C

4.5 AS-I R

4.6 AS-I T

4.7 P

4.8 D

4.9 D

4.10

4.11

MPORTANT NOTICE

EFERENCES

EVISION HISTORY

BSOLUTE MAXIMUM RATINGS (NON OPERATING

PERATING CONDITIONS

UALITY STANDARDS

AILURE RATE

UMIDITY CLASS

ACKAGE PIN ASSIGNMENT

UNCTIONAL BLOCK DIAGRAM

ENERAL OPERATIONAL MODES

LAVE MODE

2.3.1 AS-i communication channel ...........................................................................................................12

2.3.2 Parameter Port Pins.........................................................................................................................12

2.3.3 Data Port Pins ..................................................................................................................................13

2.3.4 Data Input Inversion .........................................................................................................................13

2.3.5 Data Input Filtering...........................................................................................................................13

2.3.6 Synchronous Data I/O Mode............................................................................................................13

2.3.7 4 Input / 4 Output processing in Extended Address Mode ..............................................................13

2.3.8 AS-i Safety Mode .............................................................................................................................14

2.3.9 Enhanced LED Status Indication .....................................................................................................14

2.3.10 Communication Monitor/Watchdog ..................................................................................................14

2.3.11 Write protection of ID_Code_Extension_1 .......................................................................................14

2.3.12 Summary of Master Calls.................................................................................................................14

VERVIEW

SER AREA PROGRAMMING

IRMWARE AREA PROGRAMMING

AFETY AREA PROGRAMMING

OWER SUPPLY

4.1.1 Voltage Output Pins UOUT and U5R...............................................................................................23

4.1.2 Input Impedance (AS-i bus load) .....................................................................................................24

HERMAL PROTECTION

HARACTERISTICS

HARACTERISTICS

ECEIVER

RANSMITTER

ARAMETER PORT AND

ATA PORT AND

4.8.1 Timing of Data I/O and DSTBn ........................................................................................................28

4.8.2 Input Data Pre-Processing ...............................................................................................................29

4.8.3 Synchronous Data I/O Mode............................................................................................................30

4.8.4 Support of 4I/4O Signaling in Extended Address Mode ..................................................................31

4.8.5 Special function of DSTBn ...............................................................................................................33

ATA AND PARAMETER PORT CONFIGURATION

F

AULT INDICATION INPUT

LED

..............................................................................................................................................4

EHAVIOR

.............................................................................................................................................7

.............................................................................................................................................12

................................................................................................................................................17

..........................................................................................................................................26

OUTPUTS

.....................................................................................................................................4

......................................................................................................................................4

) ........................................................................................5

.............................................................................................................................6

..........................................................................................................................................6

..................................................................................................................................6

.........................................................................................................................................7

..........................................................................................................................8

....................................................................................................................10

................................................................................................................12

.......................................................................................................................17

...............................................................................................................20

....................................................................................................................21

........................................................................................................................................23

..............................................................................................................................24

– D

IGITAL INPUTS

– D

IGITAL OUTPUTS

....................................................................................................................................26

PSTBN.................................................................................................................27

DSTBN............................................................................................................................28

PFAULT .........................................................................................................34

.......................................................................................................................................34

...................................................................................................25

................................................................................................25

...........................................................................................33

Page

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

2/58

Page 3

Datasheet

4.11.1 Slave Mode ......................................................................................................................................34

4.11.2 Master/Repeater Mode ....................................................................................................................35

4.12

4.13

4.13.1 Power On Reset...............................................................................................................................36

4.13.2 Logic controlled Reset .....................................................................................................................37

4.13.3 External Reset .................................................................................................................................37

4.14

4.15

4.16

4.17

4.18

4.19

4.19.1 Master/ Repeater Mode Activation ..................................................................................................45

4.19.2 Pin Assignment ................................................................................................................................45

4.19.3 Functional Description .....................................................................................................................47

4.20

5 APPLICATION CIRCUITS .............................................................................................................................51

6 PACKAGE OUTLINES ..................................................................................................................................54

7 PACKAGE MARKING ...................................................................................................................................55

8 ORDERING INFORMATION..........................................................................................................................56

9 CONTACT INFORMATION ...........................................................................................................................57

9.1 ZMD S

9.2 ZMD D

9.3 AS-I

O

IC R

UART ...................................................................................................................................................39

M

S

C

S

M

W

SCILLATOR PINS

ESET

..............................................................................................................................................36

AIN STATE MACHINE

TATUS REGISTERS

OMMUNICATION MONITOR/WATCHDOG

AFETY MODE

ASTER- AND REPEATER MODE

RITE PROTECTION OF

ALES CONTACTS

ISTRIBUTION PARTNERS

NTERNATIONAL ASSOCIATION

.......................................................................................................................................41

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

OSC1, OSC2 ...........................................................................................................36

............................................................................................................................40

...............................................................................................................................40

.................................................................................................40

.............................................................................................................45

ID_C

ODE_EXTENSION

.............................................................................................................................57

..................................................................................................................57

..............................................................................................................57

_1 ...................................................................................49

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

3/58

Page 4

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

0 Read this First

0.1 Important Notice

Products sold by ZMD are covered exclusively by the warranty, patent indemnification and other provisions appearing in ZMD standard "Terms of Sale". ZMD makes no warranty (express, statutory, implied and/or by description), including without limitation any warranties of merchantability and/or fitness for a particular purpose,

regarding the information set forth in the Materials pertaining to ZMD products, or regarding the freedom of any

products described in the Materials from patent and/or other infringement. ZMD reserves the right to discontinue

production and change specifications and prices of its products at any time and without notice. ZMD products

are intended for use in commercial applications. Applications requiring extended temperature range, unusual

environmental requirements, or high reliability applications, such as military, medical life-support or lifesustaining equipment, are specifically not recommended without additional mutually agreed upon processing by

ZMD for such applications.

ZMD reserves the right to change the detail specifications as may be required to permit improvements in the

design of its products.

0.2 References

[1] AS-Interface Complete Specification Version 3.0, dated 16.09.2004

[2] Spezifikation der sicheren AS-i-Übertragung, Leuze electronic, 12.05.2000

0.3 Revision History

Revision Date Technical Changes Page in Datasheet

B September 2005 First marketed silicon version

C March 2007 Modified I

C March 2007 Modified Delay Mode activation through pa-

rameter port P1

C March 2007 Modified Synchronous Data I/O Mode activation

through parameter port P2

C March 2007 Modified Watchdog activation through parame-

ter port P0

C March 2007 Improved Burst protection filter and improved

ESD behavior

– current range for input low level Table 16 at Page 25

IL

Page 29

Page 30

Page 40

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

4/58

Page 5

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

1 General Device Specification

1.1 Absolute Maximum Ratings (Non Operating)

Table 1: Absolute Maximum Ratings

Symbol Parameter Min Max Unit Note

V

Voltage reference 0 0 V

LTGN

V

LTGP-LTGN

V

LTGP-LTGN_P

V

inputs1

Voltage difference between LTGP and LTGN (V

V

)

LTGN

Pulse voltage between LTGP and LTGN (V

LTGP

- V

-

LTGP

) 0 50 V

LTGN

Voltage at pin CDC, D0…D3, P0…P3, DSTBn, PSTBnBn,

0 40 V

-0.3 V

+ 0.3 V

UOUT

LED1, LED2, PFAULT, UOUT

V

Voltage at pins OSC1, OSC2, U5R -0.3 7 V

inputs2

Iin Input current into any pin except supply pins -50 50 mA

H Humidity non-condensing

V

Electrostatic discharge – Human Body Model (HBM2) 1500 V

HBM

V

Electrostatic discharge – Equipment Discharge Model

EDM

200 V

(EDM)

θ

STG

θ

lead

θ

lead

R

Thermal resistance of SOIC 16 package 80 100 K/W

thj-16

R

Thermal resistance of SOIC 20 package 75 95 K/W

thj-20

1

reverse polarity protection has to be performed externally,

2

pulse with ≤ 50µs, repetition rate ≤ 0.5 Hz

3

V

LTGP-LTGN

4

Latch-up resistance, reference pin is 0V

5

Level 4 according to JEDEC-020A is guaranteed

6

HBM: C = 100pF charged to V

7

EDM: C = 200pF charged to V

8

Single layer board, P

Storage temperature -55 125 °C

JEDEC-J-STD-020C

Soldering temperature Sn/Pb

Soldering temperature 100%Sn

and V

LTGP-LTGN_P

tot

must not be violated

with resistor R = 1.5kΩ in series, valid for all pins except LTGP-LTGN

HBM2

with no resistor in series, valid for LTGP-LTGN only

EDM

= 0.5W; air velocity = 0m/s ⇒ max. value; air velocity = 2.5m/s ⇒ min. value

JEDEC-J-STD-020C

240

260

°C

°C

1

2

4

5

6

7

8

8

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

5/58

Page 6

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

1.2 Operating Conditions

Table 2: Operating Conditions

Symbol Parameter Min Max. Unit Note

V

Negative supply voltage 0 0 V

LTGN

V

DC voltage at LTGP relating to V

LTGP

I

Operating current at V

LTGP

I

Max. output sink current at pins D3...D0, DSTBn 10 mA

CL1

I

Max. output sink current at pins P0...P3, PSTBnBn 10 mA

CL2

θ

amb

1

Below V

Ambient temperature range, operating range -25 85 °C

the power supply block may not be able to provide the specified output currents at

LTGPmin

= 30V 6 mA

UIN

16 34 V

LTGN

UOUT and U5R.

2

Outside of these limits the send current shape and send current amplitude cannot be guaranteed.

3

fc = 16.000 MHz, no load at any pin, transmitter turned off, digital state machine is in idle state

Table 3: Crystal Frequency

1, 2

3

Symbol Parameter Nom. Unit Note

fc Crystal frequency 5.333/16.000 MHz

4

The IC automatically detects whether the crystal frequency is 5.333MHz or 16.000MHz and controls the

4

internal clock circuit accordingly.

1.3 EMC Behavior

The IC has to fulfill the requirements defined in AS-Interface Complete Specification V2.11 [1] and related test

requirements AS-Interface Slave ICs.

In addition to the AS-Interface Complete Specification and in combination with a reference component circuit the

IC has to achieve a communication failure rate less than 10% of the allowed failure rate according to the "Fast

Transient" test method specified in the related AS-Interface association test procedures.

The above specified behavior is correct by design and has to be proven while IC characterization.

1.4 Quality Standards

The quality of the IC will be ensured according to the ZMD quality standards. ZMD is a qualified supplier according to ISO/TS 16949:2002 and ISO 14001:1996.

The following reference documents apply for the development process:

• Management Regulation: 0410 Product Development procedure

• Process Specification: ZMD C7D 0.6µm Technology

Functional device parameters are valid for device operating conditions specified in chapter 1.2 at page 4. Production device tests are performed within the recommended ranges of V

and - 25°C on sample base only) unless otherwise stated.

LTGP

- V

, θamb = + 25°C (+ 85°C

LTGN

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

6/58

Page 7

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

1.5 Failure Rate

Symbol Parameter Max. Unit

AQL Acceptance Quality Level 0.1

%

F55 Failure Rate at 55°C 18 FIT

F70 Failure Rate at 70°C 60 FIT

F85 Failure Rate at 85°C 150 FIT

F125 Failure Rate at 125°C 1400 FIT

1.6 Humidity Class

Level 4 according to JEDEC-020A is guaranteed.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

7/58

Page 8

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

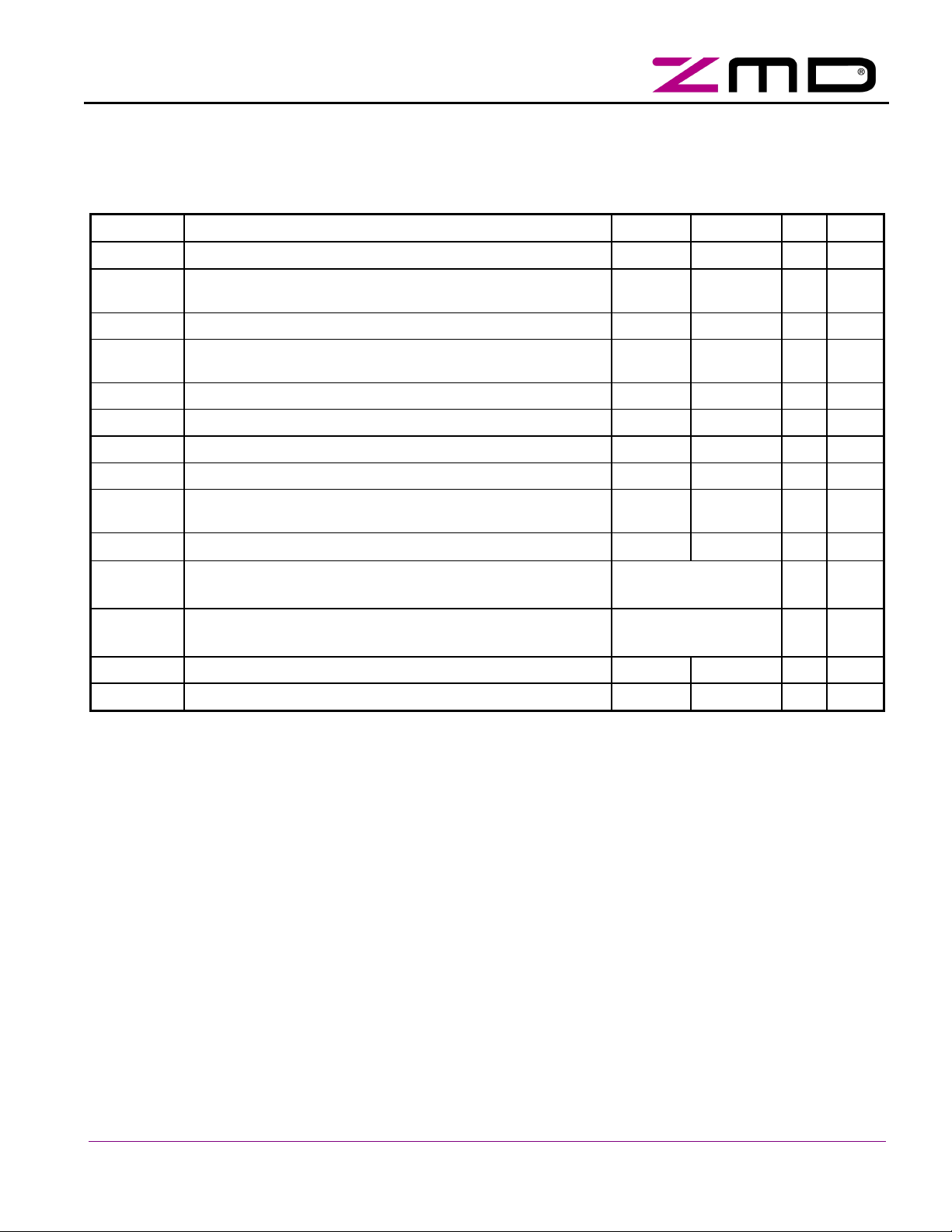

1.7 Package Pin Assignment

Table 4: SAP5 Pin List

SAP5S / SAP51

SOIC 20

Pin #

SOIC 16

pin #

Name Direction Type Description

1 - P1 I/O Pull-up/ Open Drain (*) Parameter port P1 / Data

input port 1 at IO-config = 7

2 - P0 I/O Pull-up/ Open Drain (*) Parameter port P0 / Data

input port 0 at IO-config = 7

3 1 D1 I/O Pull-up/ Open Drain Data port D2

4 2 D0 I/O Pull-up/ Open Drain Data port D0

5 3 DSTBn I/O Pull-up/ Open Drain Data Strobe output / Reset

input

6 4 LED1 OUT Open Drain LED 1 Status Indication

7 5 OSC2 OUT Analog (5V) Crystal oscillator

8 6 OSC1 IN Analog/ CMOS Crystal oscillator / External

clock input

9 7 U5R OUT Analog Regulated 5V power supply

10 8 LTGN IN Analog/Supply AS-i Transmitter/Receiver

output, to be connected to

AS-i-

11 9 LTGP IN Analog/Supply AS-i Transmitter/Receiver

input, to be connected to ASi+ via reverse polarity protection diode

12 10 CDC OUT Analog external buffer capacitor

13 11 UOUT OUT Analog decoupled actuator/sensor

power supply

14 12 PFAULT IN Pull-up Periphery Fault input (LOW =

Periphery Fault)

15 13 LED2 OUT Open Drain LED 2 status indication

16 14 PSTBnBn I/O Pull-up/ Open Drain Parameter Strobe output

17 15 D3 I/O Pull-up/ Open Drain Data port D3

18 16 D2 I/O Pull-up/ Open Drain Data port D2

19 - P3 I/O Pull-up/ Open Drain (*) Parameter port P3 / Data

input port 3 at IO-config = 7

20 - P2 I/O Pull-up/ Open Drain (*) Parameter port P2 / Data

input port 2 at IO-config = 7

All open drain outputs are NMOS based. Pull-up properties at input stages are achieved by current sources

referring to U5R.

(*) The pull-up current source on these parameter ports is switched off if the slave device is programmed with

I/O configuration code 7 and a DEXG master call is processed.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

8/58

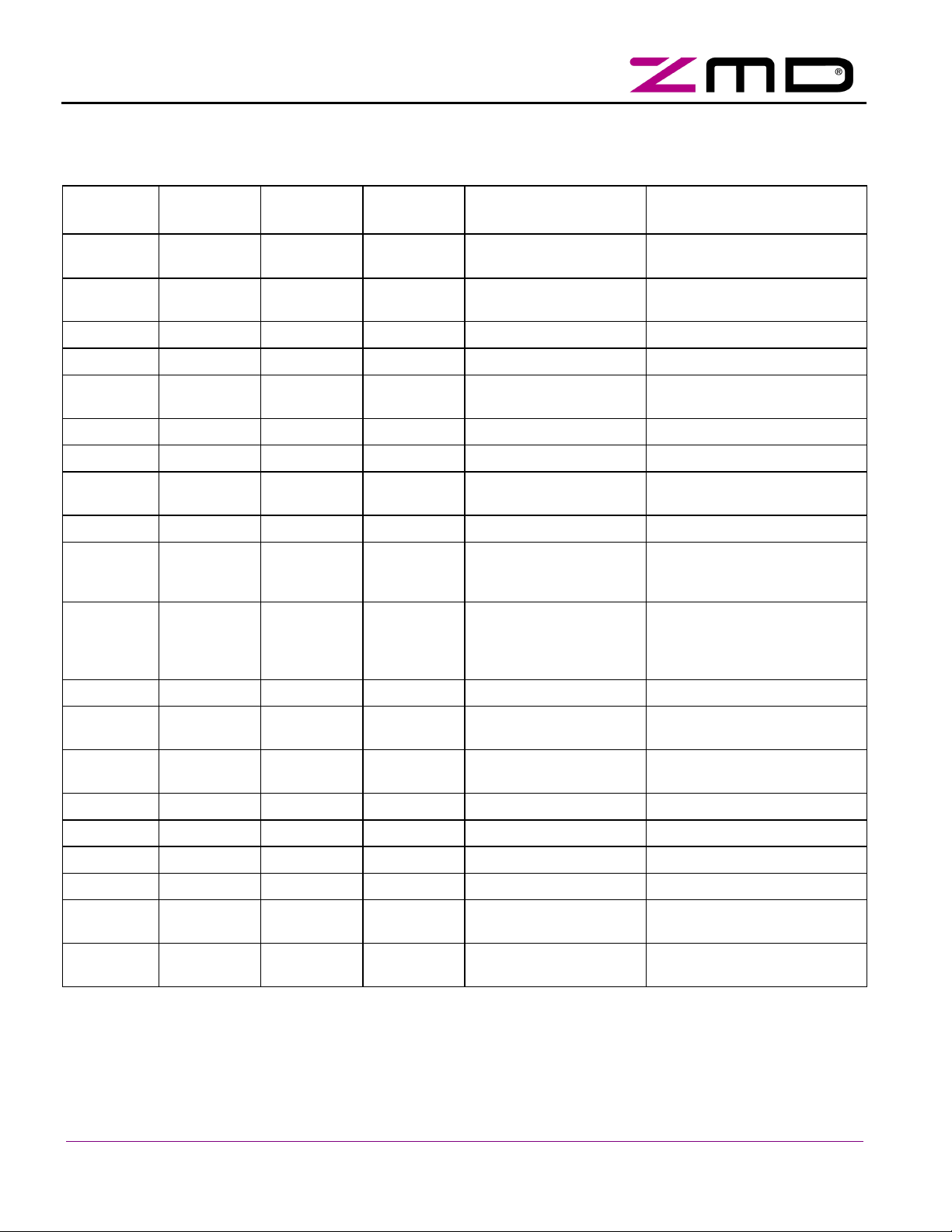

Page 9

DSTBn

LED1

OSC2

OSC1

P1

P0

D1

D0

P2

P3

D2

D3

PSTBn

LED2

PFAULT

UOUT

U5R

LTGN

CDC

LTGP

Pin 1

DSTBn

LED1

OSC2

OSC1

D1D0D2

D3

PSTBn

LED2

PFAULT

UOUT

U5R

LTGN

LTGP

Pin1

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

SAP5

Figure 1: SAP5 Package Pin Assignment for the 20 pin version

SAP5

Figure 2: SAP5 Package Pin Assignment for the 16 pin version

CDC

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

9/58

Page 10

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

2 Basic Functional Description

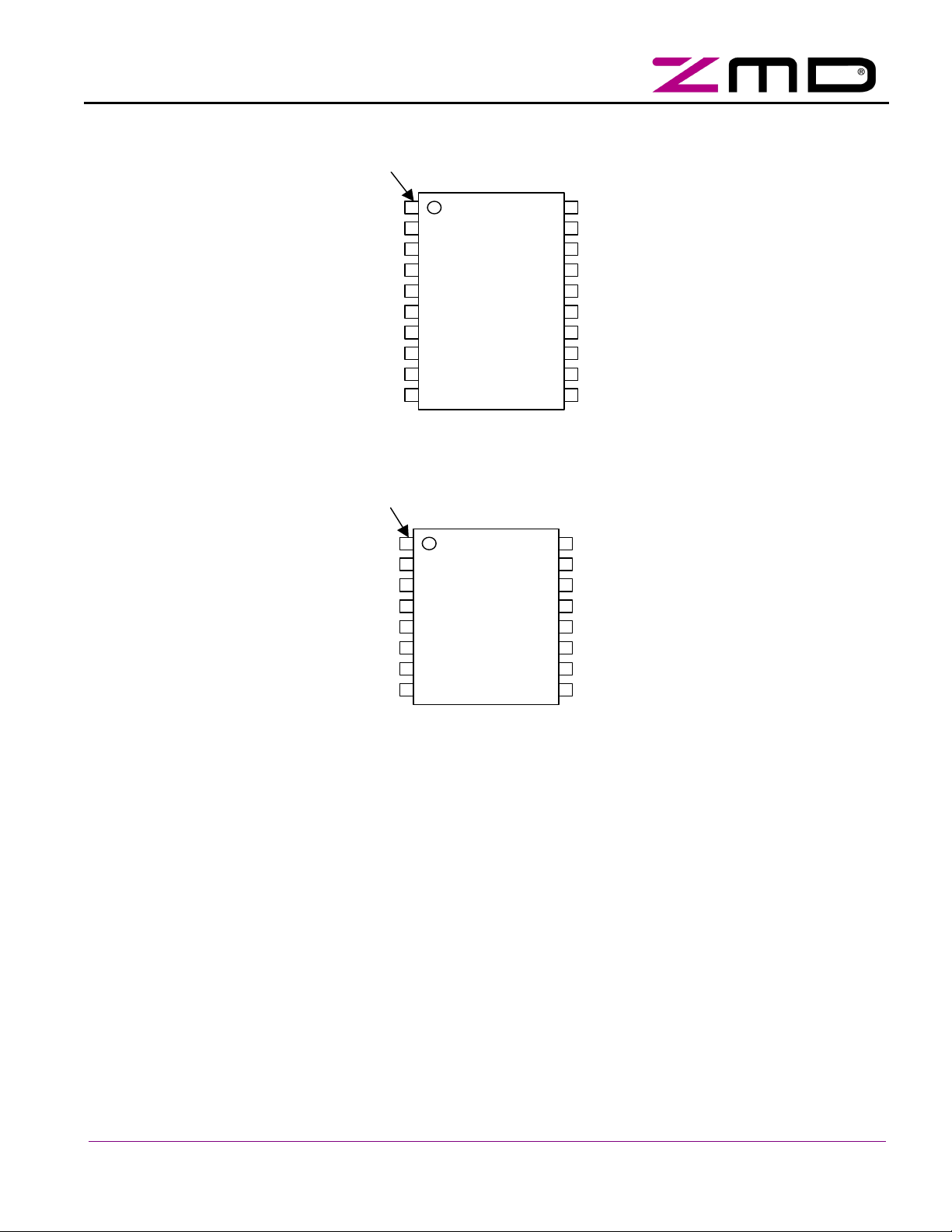

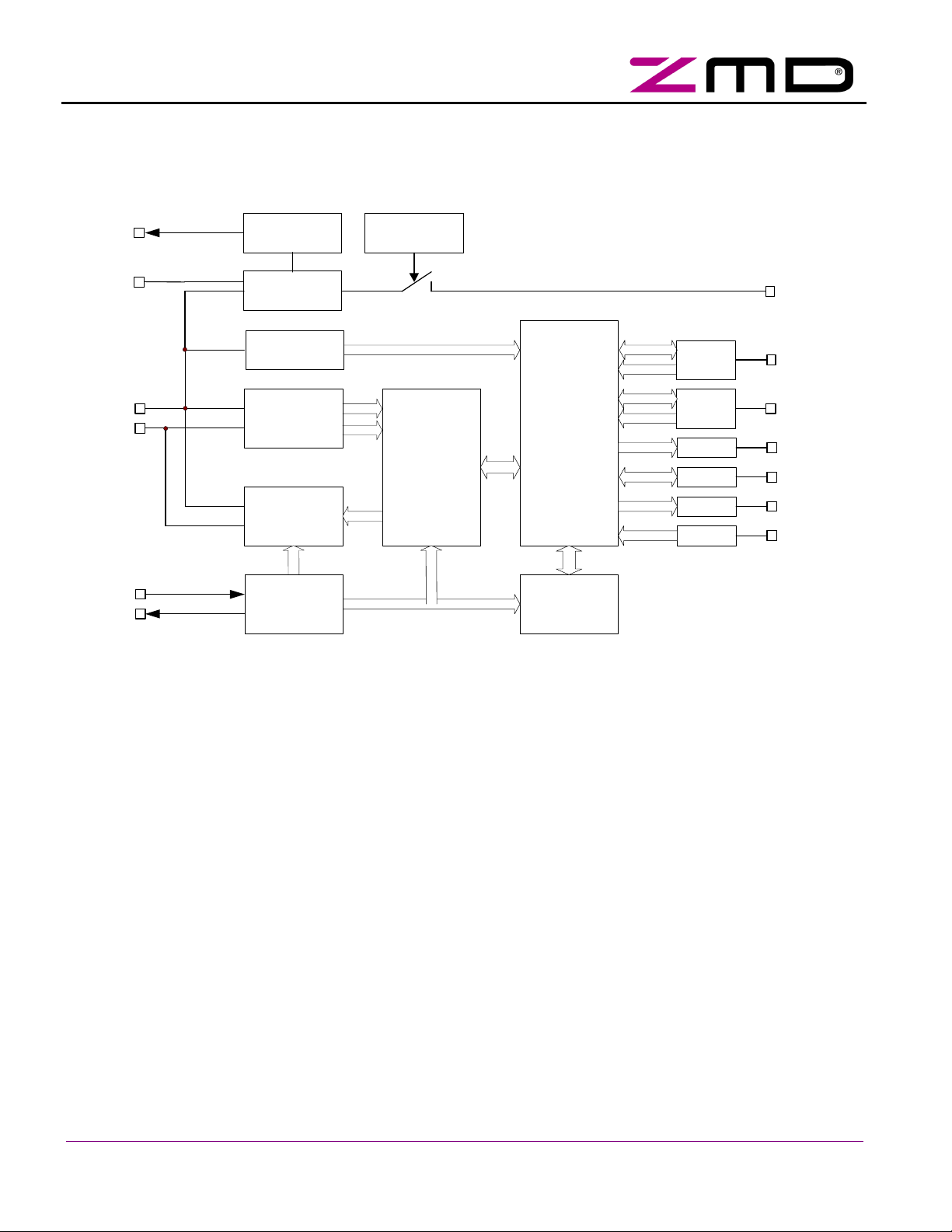

2.1 Functional Block Diagram

U5R

CDC

LTGP

LTGN

OSC1

OSC2

Power

Supply

Electronic

Inductor

Power

Fail Detector

Receiver

Transmitter

c

l

k

OSCILLATOR

PLL

Thermal

Protection

APF

pos

neg

MAN

clk

UART

c

l

k

Main

State

Machine

EEPROM

Figure 3: Functional Block Diagram

Param

Offset

Data

Offset

LED

DSTB

PSTB

PFAULT

UOUT

I / O

I / O

Output LED2, LED1

I / O DSTBn

Output PSTBn

Input PFAULT

P3 ... P0

D3 ... D0

Following device functions are associated with the different blocks of the IC:

RECEIVER

The receive block converts the analog telegram waveform from the AS-i bus to a digital

pulse coded signal that can be processed further by a digital UART circuit.

The RECEIVE block is directly connected to the AS-i line pins LTGP and LTGN. It converts

the differential AS-i telegram to a single ended signal and removes the DC offset by high

pass filtering. To adapt quickly on changing signal amplitudes in telegrams from different

network users, the amplitude of the first telegram pulse is measured by a 3 bit flash ADC

and the threshold of a positive and a negative comparator is set accordingly to about 50% of

the measured level. The comparators generate the P-Pulse and N-Pulse signals.

TRANSMITTER

The transmit block transforms a digital response signal to a correctly shaped send current

signal which is applied to the AS-i bus. Due to the inductive network behavior of the network

the changing send current induces voltage pulses on the network line that overlay the DC

operating voltage. The voltage pulses shall have sin²-wave shapes. Hence, the send current

shape must follow the integral of the sin²-wave function.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

10/58

Page 11

Datasheet

UART /

MAIN STATE

MACHINE /

EEPROM

ELECTRONIC

INDUCTOR

POWER

SUPPLY

OSCILLATOR /

PLL

THERMAL

PROTECTION

POWER FAIL

DETECTOR

INPUT STAGE

OUTPUT

STAGE

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

E²PROM write access and other I/O operations of the Main State Machine are supported in

Slave Mode only (see description of general IC operational modes below). In Master Mode

the IC is basically equivalent to a physical layer transceiver.

If Slave Mode is activated, the UART demodulates the received telegrams, verifies telegram

syntax and timing and controls a register interface to the Main State Machine. After reception of a correct telegram, the UART generates appropriate Receive Strobe signals, that tell

the Main State Machine to start further processing. The Main State Machine decodes the

telegram information and starts respective I/O processes or E²PROM access. A second

register interface is used to send data back to the UART for construction of a telegram response. The UART modulates the response data into a Manchester-II-coded bit stream that

is used to control the TRANSMITTER unit.

The electronic inductor is basically a gyrator circuit. It provides an inductive behavior between the IC pins LTGP and UOUT while the inductance is controlled by the capacitor on

pin CDC. The inductor decouples the power regulator of the IC as well as the external load

circuit from the AS-i bus and hence prevent cross talk or switching noise from disturbing the

telegram communication on the bus.

The AS-i Complete Specification describes the input impedance behavior of a slave module

by an equivalent circuit that consists of R, L and C in parallel. For example, a slave module

in Extended Address Mode shall have R > 13.5 kOhm, L > 13.5 mH and C < 50pF. The

electronic inductor of the SAP5 delivers values that are well within the required ranges for

output currents up to 55mA (Uin>24V). More detailed parameters can be found in chapter

4.1.

The electronic inductor requires an external capacitor of 10µF at pin UOUT for stability.

The power supply block consists of a bandgap referenced 5V-regulator as well as other

reverence voltage and bias current generators for internal use. The 5V regulator requires an

external capacitor at pin U5R of at least 100nF for stability. It can source up to 4mA for external use, however the power dissipation and the resulting device heating become a major

concern, if too much current is drawn from the regulator. See chapter 4.1.

The oscillator supports direct connection of 5.33 MHz or 16.000 MHz crystals with a dedicated load capacity of 12pF and parasitic pin capacities of up to 8pF. The IC automatically

detects the oscillation frequency of the connected crystal and controls the internal clock

generator circuit accordingly.

After power-on reset the IC is set to 16.000 MHz operation by default. After about 200µs it

will either switch to 5.333 MHz operation or remain in the 16.000 MHz mode. The frequency

detection is active until the first AS-i telegram was successfully received in order to make

sure the IC found the correct clock frequency setting. The detection result is locked thereafter to increase resistance against burst or other interferences.

The oscillator unit also contains a clock watch dog circuit that can generate an unconditioned IC reset if there was no clock oscillation for more than about 20µs. This is to prevent

the IC from unpredicted behavior if no clock signal is available anymore.

The IC is self protected against thermal overload. If the silicon die temperature rises above

around 140°C for more than 2 seconds, the IC detects thermal overheating, switches off the

electronic inductor, performs an IC reset and sets all analog blocks to power down mode.

The 5V-regulator is of course also turned off in this state, however, there will still remain a

voltage of about 3 … 3.5V available at U5R that is derived from the internal start circuitry. If

the overheat condition is left the IC resumes operation and performs an initialization.

The Power Fail Detector observes the voltage at the AS-i-line. It signals at pin PSTBn/APF

when the voltage drops below about 22.5V. Active in Master Mode only.

All digital inputs, except of the oscillator pins, have high voltage capabilities and pull-up

features. For more details see chapters 1.7, 4.3, 4.7, and 4.8.

All digital output stages, except of the oscillator pins, have high voltage capabilities and are

implemented as NMOS open drain buffers. Each pin can sink up to 10mA of current. See

chapter 4.4.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

11/58

Page 12

ASI+

-

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

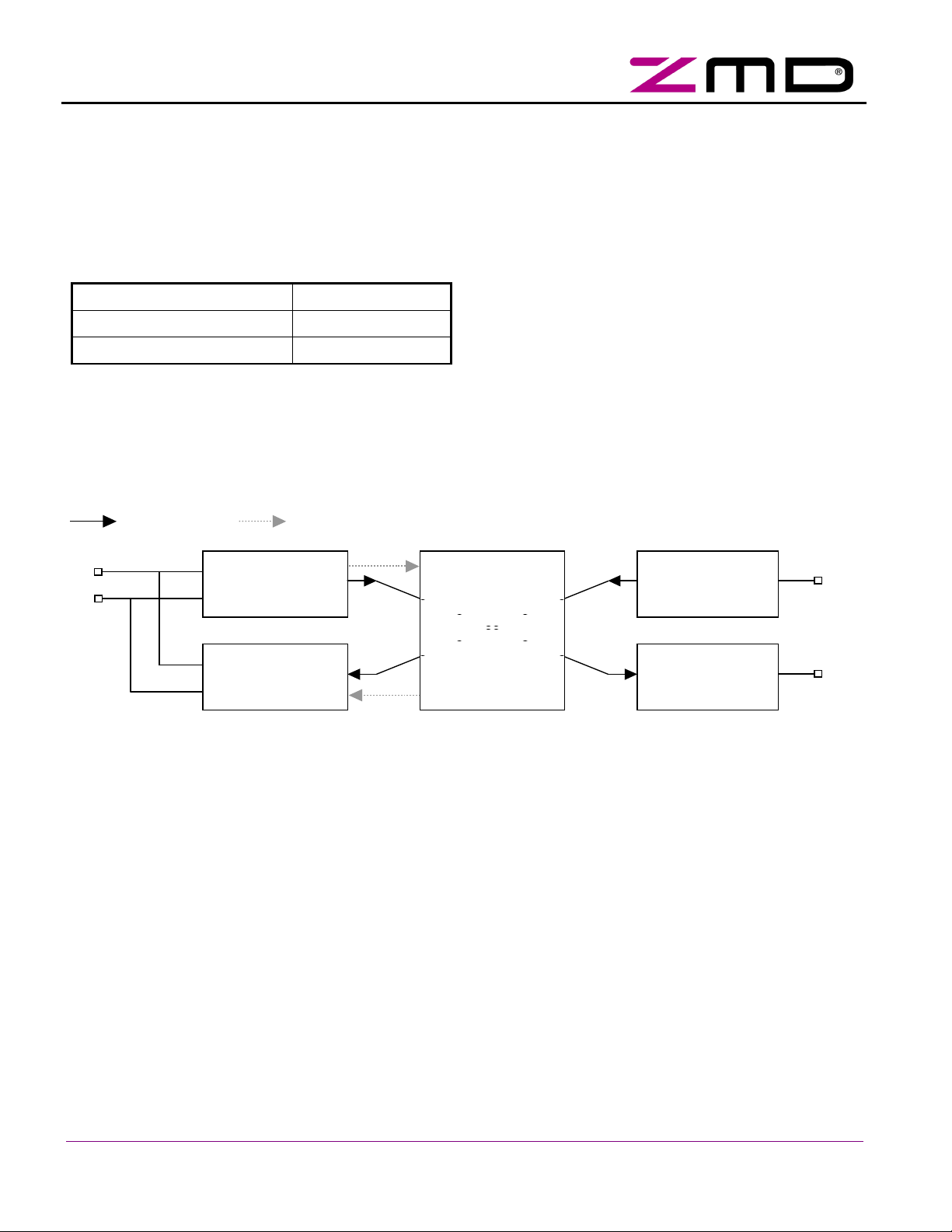

2.2 General Operational Modes

The SAP5 provides two operational modes: Slave Mode and Master/Repeater Mode. A definition of which operational mode becomes active is made by programming the flag Master_Mode in the Firmware Area of the

E²PROM (see also Table 9 on page 19). The E²PROM is read out at every initialization of the IC. Online mode

switching is not provided. The following configurations apply:

Table 5: Assignment of operational modes

Selected Operational Mode Master Mode Flag

Slave Mode 0

Master/Repeater Mode 1

In Slave Mode the SAP5 operates as fully featured AS-i Slave IC according to AS-i Complete Specification v3.0.

In Master/Repeater Mode the SAP5 it acts as physical layer transceiver. It translates a digital output signal from

the master control logic (etc. PLC, µP, …) to a correctly shaped, analog AS-i pulse sequence and vice versa.

Every AS-i telegram received is checked for consistency with the AS-i communication protocol specifications

and if no errors were found, an appropriate receive strobe signal is generated.

The following figure shows the different data path configurations.

Master Mode Slave Mode, ASI-Channel

ASI

ASI- Receiver

UART

ASI- Transmitter

Figure 4: Data path in Master-, Repeater- and Monitor-Mode

More detailed signal descriptions can be found in chapters 4.19 Master- and Repeater Mode as well as 4.14

UART.

CMOS Input

LED Output

D0

(TX)

LED1

(RX)

2.3 Slave Mode

The Slave Mode is the most complex operational mode of the IC. The SAP5 does not only support all mandatory AS-i Slave functions but also a variety of additional features that eases the design of AS-i Slave modules.

2.3.1 AS-i communication channel

The AS-i channel is directly connected to AS-i Bus via the pins LTGP and LTGN. A receiver and a transmitter

unit are connected in parallel to the pins that allow fully bi-directional communication through LTGP and LTGN.

2.3.2 Parameter Port Pins

In the 20-pin package the SAP5 features a 4-bit wide parameter port and a related parameter strobe signal pin

PSTBn. AS-i Complete Specification V3.0 newly defines a bidirectional mode for parameter data. The SAP5

supports this feature, that can be activated by special E²PROM setting (IO_Code, see chapter 4.9).

There is a defined phase relation between a parameter output event, the parameter input sampling and the activation of the PSTBn signal. Thus it can be used to trigger external logic or a micro controller to process the received parameter data or to provide new input data for the AS-i slave response.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

12/58

Page 13

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

See chapter 4.7 for further details.

2.3.3 Data Port Pins

The SAP5 provides a 4-bit wide data port. The outputs work independently from each other allowing a maximum

of 4 output devices to be connected to the SAP5. The direction of the Data Port pins are set through the

IO_Code, see chapter 4.9.

The data port is accompanied by the data strobe signal DSTBn. There is a defined phase relation between a

data output event, the input data sampling and the activation of the DSTBn signal. Thus, it can be used to trigger external logic or a micro controller to process the received data or to provide new input data for the AS-i

slave response. See chapter 4.8 for further details.

2.3.4 Data Input Inversion

By default the logic signal (HIGH / LOW) that is present at the data input pins during the input sampling phase is

transferred without modification to the send register, which is interfaced by the UART. By that, the signal becomes directly part of the slave response.

Some applications work with inverted logic levels. To avoid additional external inverters, the input signal can be

inverted by the SAP5 before transferring it to the send register. The inversion of the input signals can be done

jointly for all data input pins. See chapter 4.8.

2.3.5 Data Input Filtering

To prevent input signal bouncing from being transferred to the AS-i Master, the data input signals can be digitally filtered. Activation of the filter is done jointly either by E²PROM configuration or by the logic state of parameter port pin P2. For more detailed information refer to chapter 4.8.

2.3.6 Synchronous Data I/O Mode

AS-i Complete Specification V3.0 newly defines a synchronous data I/O feature, that allows a number of slaves

in the network to switch their outputs at the same time and to have their inputs sampled simultaneously. This

feature is especially useful if more than 4-bit wide data is to be provided synchronously to an application.

The synchronization point was defined to the data exchange event of the slave with the lowest address in the

network. This definition relies on the cyclical slave polling with increasing slave addresses per cycle that is one

of the basic communication principles of AS-i. The IC always monitors the data communication and detects the

change from a higher to a lower slave address. If such a change was recognized, the IC assumes that the slave

with the lower address has the lowest address in the network.

There are some special procedures that become active during the start of synchronous I/O mode operation and

if more than three consecutive telegrams were sent to the same slave address. This is described in more detail

in chapter 4.8.3.

2.3.7 4 Input / 4 Output processing in Extended Address Mode

A new feature of AS-i Complete Specification v3.0 is also support of 4-bit wide output data in Extended Address

Mode. In Extended Address Mode it was, up to Complete Specification v2.11, only possible to send three data

output bits from the master to the slave because telegram bit I3 is used to select between A- and B- slave type

for extended slave addressing (up to 62 slaves per network). In normal address mode I3 carries output data for

pin D3.

The new definition introduces a multiplexed data transfer, so that all 4-bits of the data output port can be used

again. A first AS-i cycle transfers the data for a 2-bit output nibble only, while the second AS-i cycle transfers the

data for the contrary 2-bit nibble. Nibble selection is done by the remaining third bit. To ensure continuous alternation of bit information I2 and thus continued data transfer to both nibbles, a special watchdog was implemented that observes the state of I2 bit. The watchdog can be activated or deactivated by E²RPOM setting. It

provides a watchdog filter time of about 327ms.

The multiplexed transfer of course increases the refresh time per output by a factor of two, however, some applications can tolerate this increase for the benefit of less external circuitry and better slave address efficiency.

The sampling cycle of the data inputs remains unchanged since the meaning of I3 bit was not changed in the

slave response with the definition of the Extended Address Mode.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

13/58

Page 14

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

More detailed information is described in chapter 4.8.4.

2.3.8 AS-i Safety Mode

Using the SAP5 Safety Mode makes it easy to implement a safety-related AS-i slave according to the AS-i

Safety at Work concept. Slaves complying with the control category 4 according to EN 954 –1 can be implemented even with a minimum of external circuitry.

In Safety Mode the respond of the SAP5 IC on a Data_Exchange master call (DEXG) is different. Instead of

responding the regular input data provided at the data ports, a 4-bit data word from a specific 8*4 bit code table

is transmitted to the master. Cycling the code table is used to transmit another data word with each DEXG master call. The data transmission is supervised by a Safety Monitor.

In Safety Mode the use of the enhanced data input features described above is disabled. In this case the safety

mode related inputs act as 3-level inputs. See chapter 4.18 for further details.

2.3.9 Enhanced LED Status Indication

The SAP5 IC supports status indication by two LED outputs. More detailed information on the signaling scheme

can be found in chapter 4.11.

2.3.10 Communication Monitor/Watchdog

Data and Parameter communication are continuously observed by a communication monitor. If neither

Data_Exchange nor Write_Parameter calls were addressed to and received by the IC within a time frame of

about 41ms, a so called No Data/Parameter Exchange status is detected and signaled at LED1.

If the respective flags are set in the E²PROM the communication monitor can also act as communication watchdog, that initiates a complete IC reset after expiring of the watchdog timer. The watchdog mode can also be

activated and deactivated by a signal at parameter port pin P0. For more detailed information see chapter 4.17.

2.3.11 Write protection of ID_Code_Extension_1

As defined in AS-i Complete Specification v3.0 the SAP5 also supports write protection for ID_Code_Extension_1. The feature allows the activation of new manufacturer protected slave profiles and is enabled by

E²PROM setting. It is described in more detail in chapter 4.20.

2.3.12 Summary of Master Calls

In Table 6 and Table 7 on the following pages show the complete set of master calls that are decoded by the

SAP5 in Slave Mode. The master calls in Table 7 are intended for programming of the IC by the slave manufacturer only. They become deactivated as soon as the Lock_EE_PRG and Safety_Program_Mode_Disable flag

are set in the Firmware Area of the E²PROM.

AS-i Complete Specification compliance note:

In order to achieve full compliance to the AS-i Complete Specification, the Program_Mode_Disable flag must be

set by the manufacturer of AS-i slave modules during the final manufacturing and configuration process and

before an AS-i slave device is delivered to field application users.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

14/58

Page 15

Code_1

1

Configuration

0

0

0

0

1

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

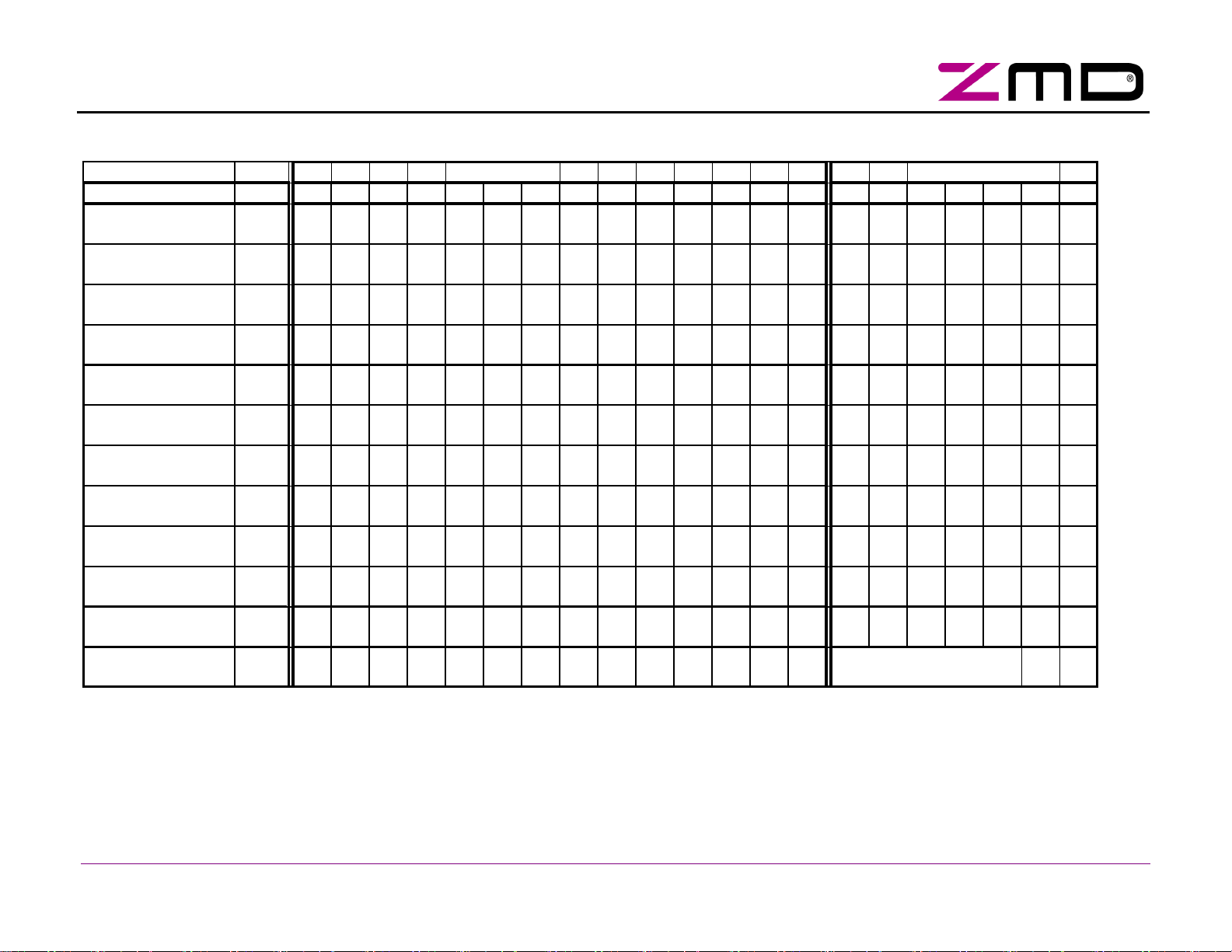

Table 6: SAP5 Master Calls and Related Slave Responses

Master Request Slave Response

Instruction MNE ST CB A4 A3 A2 A1 A0 I4 I3 I2 I1 I0 PB EB SB I3 I2 I1 I0 PB EB

Data Exchange

Write Parameter

DEXG 0 0 A4 A3 A2 A1 A0 0

WPAR 0 0 A4 A3 A2 A1 A0 1

D3

D2 D1 D0 PB 1 0 D3 D2 D1 D0 PB 1

~Sel

P3

P2 P1 P0 PB 1 0 P3 P2 P1 P0 PB 1

~Sel

Address Assignment

Write Extented ID

Delete Address

Reset Slave

Read IO

Read ID Code

Read ID Code_1

Read ID Code_2

Read Status

Broadcast (Reset)

ADRA 0 0 0 0 0 0 0 A4 A3 A2 A1 A0 PB 1 0 0 1 1 0 0 1

WID1 0 1 0 0 0 0 0 0 ID3 ID2 ID1 ID0 PB 1 0 0 0 0 0 0 1

DELA 0 1 A4 A3 A2 A1 A0 0 0 Sel 0 0 0 PB 1 0 0 0 0 0 0 1

RES 0 1 A4 A3 A2 A1 A0 1

RDIO 0 1 A4 A3 A2 A1 A0 1

RDID 0 1 A4 A3 A2 A1 A0 1

RID1 0 1 A4 A3 A2 A1 A0 1

RID2 0 1 A4 A3 A2 A1 A0 1

RDST 0 1 A4 A3 A2 A1 A0 1

~Sel

~Sel

1 0 0 PB 1 0 0 1 1 0 0 1

0 0 0 PB 1 0 IO3 IO2 IO1 IO0 PB 1

Sel

0 0 1 PB 1 0 ID3 ID2 ID1 ID0 PB 1

Sel

0 1 0 PB 1 0 ID3 ID2 ID1 ID0 PB 1

Sel

0 1 1 PB 1 0 ID3 ID2 ID1 ID0 PB 1

Sel

1 1 0 PB 1 0 S3 S2 S1 S0 PB 1

BR01 0 1 1 1 1 1 1 1 0 1 0 1 1 1 --- no slave response ---

NOTE: In extended address mode the "Select Bit" defines whether the A-Slave or B-Slave is being addressed. Dependent on the type of master call the I3 bit carries

the select bit information (Sel) or the inverted select bit information (~Sel). The extended address mode can

Lock_EE_PRG

is at logic LOW level. Refer to chapter 3.3 on page 20 for programming the

Lock_EE_PRG

flag.

not

be activated, as long as the E²PROM flag

Rev 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

15/58

Page 16

Enter Program Mode

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

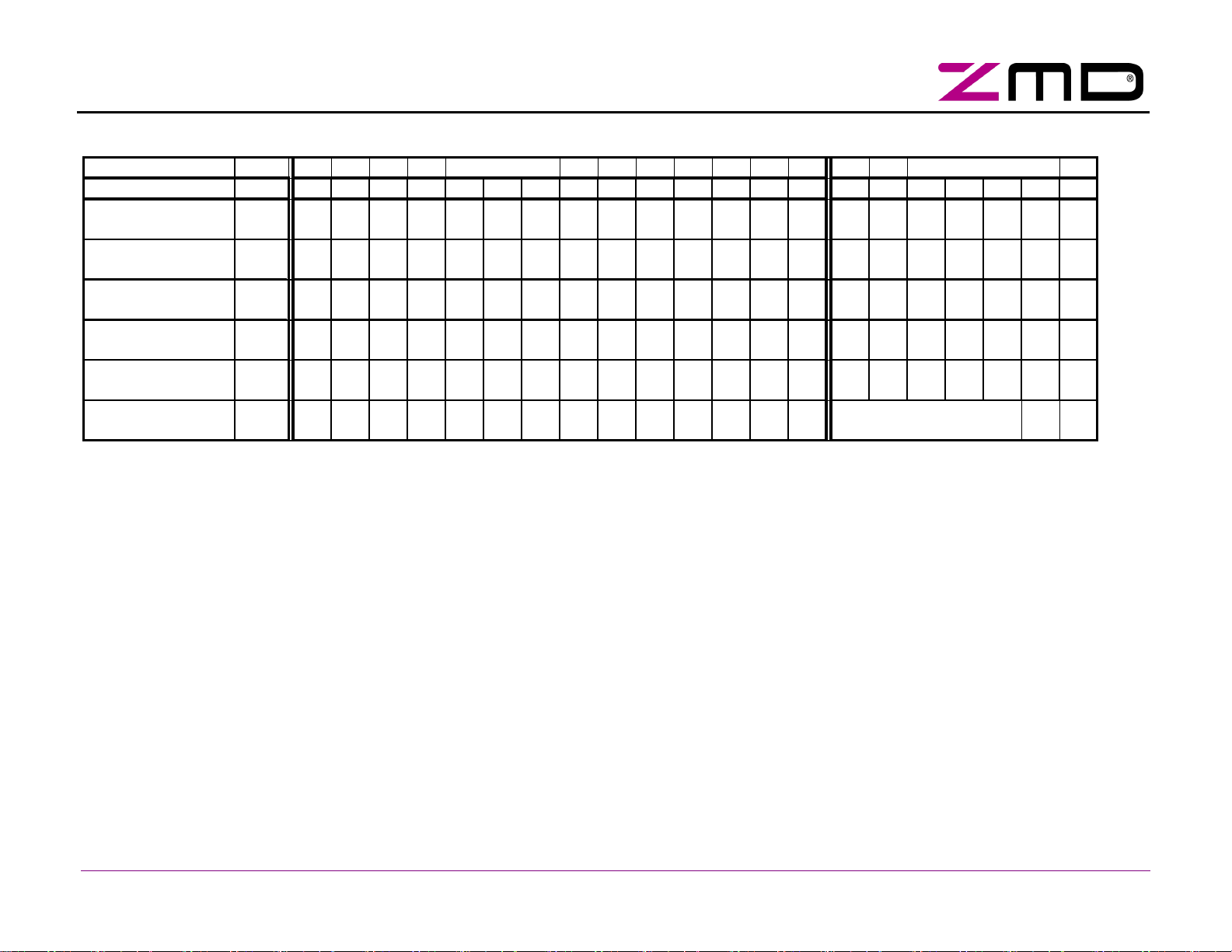

Table 7: SAP5 Additional Master Calls for Slave Configuration

Master Request Slave Response

Instruction MNE ST CB A4 A3 A2 A1 A0 I4 I3 I2 I1 I0 PB EB SB I3 I2 I1 I0 PB EB

Set ID Code

Set IO Config

Set ID Code 2

Set Control Code

Set Control Code 2

Safety

(RDIO) 0 1 A4 A3 A2 A1 A0 1 1 0 0 0 PB 1 0 0 1 1 0 0 1

(RDID) 0 1 A4 A3 A2 A1 A0 1 1 0 0 1 PB 1 0 0 1 1 0 0 1

(RID1) 0 1 A4 A3 A2 A1 A0 1 1 0 1 0 PB 1 0 0 1 1 0 0 1

(RID2) 0 1 A4 A3 A2 A1 A0 1 1 0 1 1 PB 1 0 0 1 1 0 0 1

(RES) 0 1 A4 A3 A2 A1 A0 1 0 1 0 0 PB 1 0 0 1 1 0 0 1

PRGM 0 1 0 0 0 0 0 1 1 1 0 1 1 1 --- no slave response ---

Rev. 2.0 Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

16/58

Page 17

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

3 E²PROM

3.1 Overview

The SAP5 provides an on-chip E²PROM with typical write and read times according to Table 8.

Table 8: E²PROM Read and Write Times

Symbol Parameter Min Max. Unit Note

t

Initialization readout time 50.0

read_init

t

wrt_adra1

t

wrt_adra2

t

wrt_wid1u

Write time after ADRA master request

Write time after ADRA master request

Write time after WID1 master request

38.0 ms

12.5 ms

38.0 ms

s

µ

(user access)

t

wrt_wid1m

Write time after WID1 master request

25.0 ms

(manufacturer access)

t

1

Single cell write time 12.5 ms

wrt_prgm

Time includes readout of the configuration block. Running in Safety Mode, the User/Firmware Area and the

Safety Area will be read out in parallel.

2

the Lock_EE_PRG flag is set

3

the Lock_EE_PRG flag is not yet set

4

concerns the programming of data in both Firmware Area and Safety Area

For security reasons the memory area is structured in three independent data blocks and a single configuration

block containing the Security_Flag. The data blocks are named User Area, Firmware Area and Safety Area.

The Firmware Area contains all manufacturing related configuration data (i.e. selection of optional features, ID

codes, …). It can be protected against undesired data modification by setting the Lock_EE_PRG flag to ‘1’.

The User Area contains only such data that is relevant for changes at the final application (i.e. field installation

of slave module). Because the environment where modifications of the user data may become necessary can

sometimes be rough and unpredictable, additional security was added to the programming of the User Area,

ensuring a write access cannot result in an undetected corruption of E²PROM data.

The Safety Area contains the cryptographic code table for the Safety Mode.

The E²PROM cells in User Area, Firmware Area and Safety Area have a word width of 6 bit. The sixth bit is not

shown in Table 9 and Table 11. The sixth bit of each cell represents the odd parity of the respective data word,

providing an additional data security mechanism. The programming of the parity bit is performed automatically

during the E²PROM write process and cannot be influenced by the user. Each E²PROM read process – particularly during initialization of the SAP5 – involves an evaluation of the parity bits. In case a wrong parity bit was

found in the User Area, the entire User Area data is treated as corrupted. The IC returns to Slave Address “0”

and the ID_Code as well as the IO_Code are set to 0xF. In case a false parity bit was found in one or more cells

of the Firmware Area or the Safety Area, the status register bit S1 will be set (=’1’), signaling the same state as

the input PFAULT would be set (refer to chapter 4.16 page 40).

1

2

3

2

3

4

3.2 User Area Programming

User Area data can be written by an ADRA or WID1 master request (refer to Table 6). Any such write access is

accompanied by two write steps to the Security_Flag, one before and one after the actual modification of user

data.

The following procedure is executed when writing to the User Area of the E²PROM:

1. The Security_Flag is programmed to ‘1’.

2. The content of the Security_Flag is read back, verifying it was programmed to ‘1’.

3. The user data is modified.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

17/58

Page 18

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

4. A read back of the written data is performed.

5. If the read back has proven successful programming of the user data, the Security_Flag

is programmed back to ‘0’.

6. The content of the Security_Flag is read back, verifying it was programmed to ‘0’.

Successful execution of the E²PROM write procedure may be observed at the status register contents. If bit S0

is set (logic HIGH) the write process is not finished yet and the programming data is still volatile. If bit S3 (equals

the Security_Flag) is set, the write procedure did not successfully complete either because the write cycle was

interrupted or due to an internal error. In order to program the data correctly the write request should be repeated. The status register can be read using the AS-i Master call Read_Status (RDST).

In addition to a read out of the data areas, the Security_Flag of the E²PROM is also read and evaluated during

IC initialization. In case the value of the Security_Flag equals ‘1’ (i.e. due to an undesired interruption of a User

Area write access), the entire User Area data is treated as corrupted. The IC returns to Slave Address “0” and

the ID_Code as well as the IO_Code are set to 0xF. Consequently, the programming of the User Area data can

be repeated.

Rev. 2. 0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

18/58

Page 19

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

Table 9: SAP5 E²PROM - User and Firmware Area Content

Internal

E²PROM

Address

Bit

Position

0 4 … 0

1 2 … 0

3

4

2 3 … 0

4

3 4 … 0

4

3 … 0

5

4

3 … 0

6

4

E²PROM Cell Content Description

A4 … A0

Slave address

ID1_Bit2 … ID1_Bit0 ID_Code_Extension_1 (user configurable)

ID1_Bit3 ID_Code_Extension_1, A/B slave selection in extended

address mode

Not implemented

ID1_Bit3 … ID1_Bit0 ID_Code_Extension_1 (manufacturer configurable)

Synchronous_Data_IO

Not implemented

Not implemented

Synchronized Data I/O mode 4

ID_Bit3 … ID_Bit0 ID_Code

Inhibit_Write_ID1

ID_Code_Extension_1 is manufacturer configurable,

refer to page 41

ID2_Bit3 … ID2_Bit0 ID_Code_Extension_2

P1_Delay_Activation

If flag is set, the logic value at the parameter pin P1

determines whether the Delay_Mode function is active

or inactive, refer to Table 22

7

8

9

10

11

0 … 3

4

3

2

1

0

4

3

2

1

0

IO_Bit3 … IO_Bit0 IO_Code

Lock_EE_PRG

Delay_Mode activates the Delay_Mode function, refer to Table 22

Invert_Data_In

Inhibit_BR01 If flag is set, the master call BR01 is not executed.

Inhibit_Watchdog If flag is set, the watchdog is not activated.

P2_Sync_Activation

Ext_Addr_4I/4O_Mode

Parallel_Out_4I/4O

Master_Mode

P0_Watchdog_Activation

4 … 0 Analogue circuitry trim information

User Area Firmware Area

Programming of the E²PROM Firmware region is possible as long as this flag is not set (logic LOW).

All Data Port inputs are inverted.

The Synchronized Data I/O mode may be activated by

Parameter bit P2 as described in Table 23 on page 30.

4 Input/ 4 Output Mode in Extended Address Mode

enables the parallel data output option in Extended

Address 4I/4O Mode

Master/Repeater Mode Flag

The watchdog can be enabled/disabled by the logic

value at the parameter pin P0.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

19/58

Page 20

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

3.3 Firmware Area Programming

In order to program one of the 5-bit cells of the Firmware Area (address 4…8) a special master call according to

Table 10 must be applied, followed by a DEXG or WPAR call immediately. Write access to the Firmware Area is

possible as long as the Lock_EE_PRG flag is not set. The write procedure is started after receipt of the

DEXG/WPAR call. Finish of write procedure may be observed at the status register S0 as described above.

The analogue circuitry trim information (address 9…11) can be written by special test mode operation only.

There is no possibility to read out the E²PROM data directly. However, AS-i-related configuration data like

ID_Code may be read by the respective Read_ID_Code master request.

Table 10: SAP5 E²PROM - User and Firmware Area Programming

Internal

E²PROM Cell Content Programming Master Calls

E²PROM

Address

0

1

2

A4 … A0 ADRA Master Call

ID1_Bit3 … ID1_Bit0

WID1 Master Call

ID1_Bit3 … ID1_Bit0

3 Not implemented

Synchronous_Data_IO

I4 4

Set ID Code (RDIO) 1 + DEXG/WPAR 2

ID_Bit3 … ID_Bit0 I3 … I0

7

Inhibit_Write_ID1

ID2_Bit3 … ID2_Bit0

P1_Delay_Activation

IO_Bit3 … IO_Bit0

Lock_EE_PRG

Delay_Mode

Invert_Data_In

Inhibit_BR01

I4 5

I3 … I0

I4 6

I3 … I0

I4

I3

I2

I1

Set ID Code 2 (RID1) 1 + DEXG/WPAR 2

Set IO Config (RDID) 1 + DEXG/WPAR 2

Set Control Code (RID2) 1 +

DEXG/WPAR 2

Inhibit_Watchdog I0

8

9

P2_Sync_Activation

Ext_Addr_4I/4O_Mode

Parallel_Out_4I/4O

Master_Mode

P0_Watchdog_Activation

Analogue circuitry trim information Accessible by ZMD only

I4

I3

I2

I1

I0

Set Control Code 2 (RES) 1 +

DEXG/WPAR 2

10

11

1

according to Table 7

2

according to Table 6 with information bits corresponding to the left-hand column; DEXG if I4=’0’, WPAR if

I4=‘1’. Note: Differing from regular WPAR/DEXG calls, the slave always returns the received data bits I3…I0.

User Area Firmware Area

Rev. 2. 0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

20/58

Page 21

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

3.4 Safety Area Programming

The Safety Area contains the cryptographic code table which consists of 8 data words and one swap-flag each

(refer to chapter 4.18 on page 41 for an explanation of the SAP5 Safety Mode). Similar to the Firmware Area it

can be protected against undesired data modification by setting the Safety_Program_Mode_Disable flag to ‘1’,

see Table 11.

: Once the Safety_Program_Mode_Disable flag is set, the Safety Area of the E²PROM is

NOTE

locked, i.e. write access to the Safety Area as described in chapter 3.4 is possible only as long as the

Safety_Program_Mode_Disable is set to ‘0’.

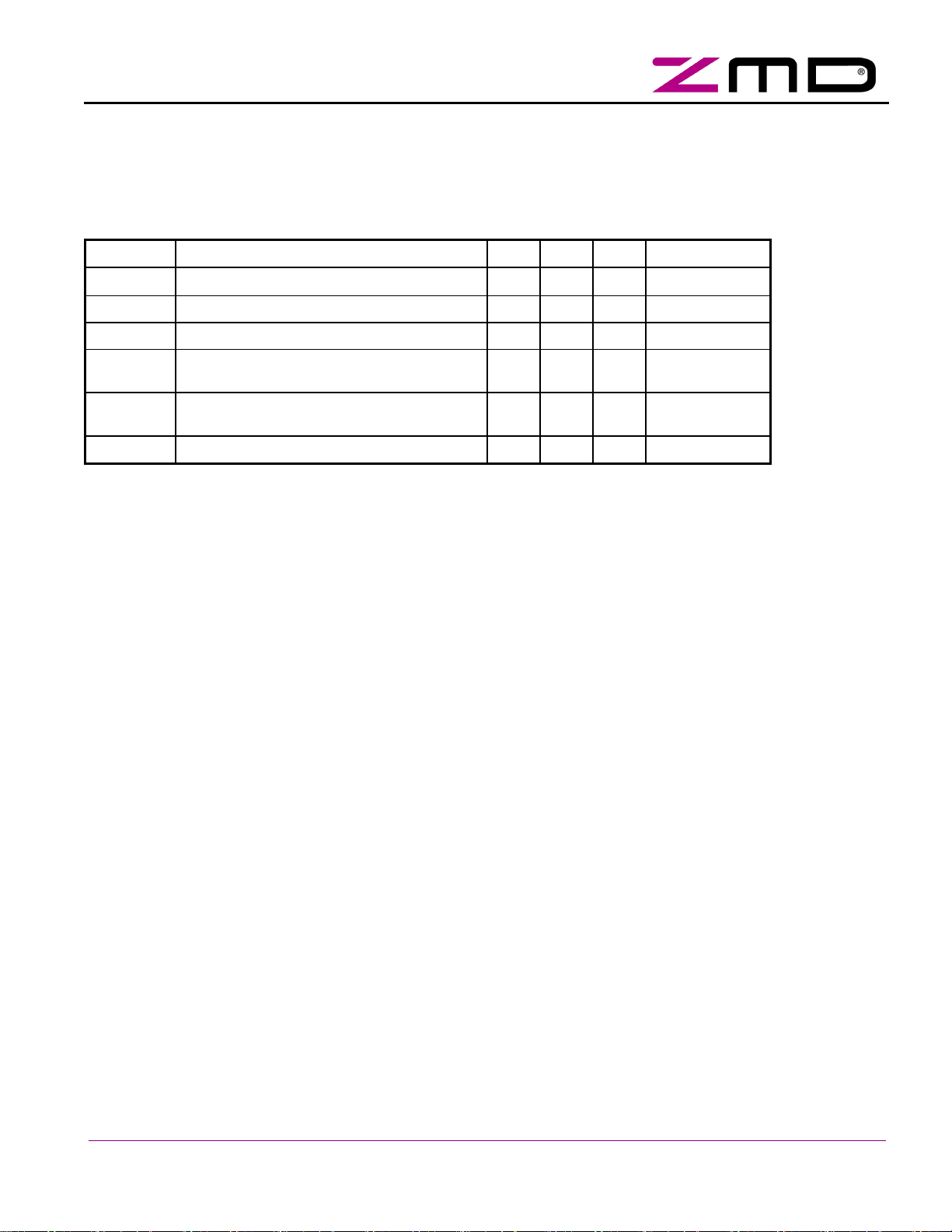

Table 11: SAP5 E²PROM - Safety Area Content

permanently

Logical

E²PROM

Address

Bit

E²PROM Cell Content Description

Position

4

3 … 0

4

3 … 0

4

3 … 0

4

3 … 0

4

3 … 0

4

S_flag 0

DI_S0 3 … 0

S_flag 1

DI_S1 3 … 0

S_flag 2

DI_S2 3 … 0

S_flag 3

DI_S3 3 … 0

S_flag 4

DI_S4 3 … 0

S_flag 5

swap flag 0 1

Data Input word 0 from Safety Code Table

swap flag 1 2

Data Input word 1 from Safety Code Table

swap flag 2 3

Data Input word 2 from Safety Code Table

swap flag 3 4

Data Input word 3 from Safety Code Table

swap flag 4 5

Data Input word 4 from Safety Code Table

swap flag 5 6

3 … 0 DI_S5 3 … 0 Data Input word 5 from Safety Code Table

4 S_flag 6 swap flag 6 7

3 … 0

4

DI_S6 3 … 0

S_flag 7

Data Input word 6 from Safety Code Table

swap flag 7 8

3 … 0

1

0

DI_S7 3 … 0

Safety_Mode_Enable

Safety_Program_Mode_Disable

Data Input word 7 from Safety Code Table

If set, Safety Mode can be enabled 31

If set, Safety Area is protected against overriding

Similar to the Firmware Area programming, Safety Area programming is intended to be used only during production set-up of a slave component at the manufacturer’s site. Write Access to the Safety Area of the E²PROM

is feasible in the so called Safety Program Mode. It can be entered only if the Safety_Program_Mode_Disable

flag is not yet set and if the slave address was set to 0x0. In the case that the slave address equals zero, the

reception of the Enter_Program_Mode_Safety (PRGM) call sets the SAP5 device into the Safety Program

Mode. It should be noted that no response is generated to the Enter_Program_Mode_Safety call (refer to AS-i

Complete Specification).

Being in the Safety Program Mode, the Write_Parameter (WPAR) and Data_Exchange (DEXG) calls are used

to transfer data words to the E²PROM similar to the Firmware Area write procedure described above. However,

the address bits A4...A0 of the master telegrams are used to address one of the memory locations of the

E²PROM (refer to Table 11). The information bits I4...I0 (normally used for output data) carry the data which

shall be stored.

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

21/58

Page 22

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

Any WPAR or DEXG call initializes an autonomous write process within the IC. The status of the write process

can be monitored by evaluating the status register of the IC the same way described above. Since the IC is still

in Safety Program Mode, the address within the Read_Status master call doesn’t care. In order to execute as

many write procedures as desired, the Safety Program Mode must not be left. However, the SAP5 will leave the

Safety Program Mode and start it’s initialization procedure if it receives a Reset_Slave (RES) master call to any

desired slave address.

Any attempt to access one of the not available E²PROM address locations (0, 9 … 30) through a

Write_Parameter (WPAR) or Data_Exchange (DEXG) command will be ignored.

There is no direct read access to the Safety Area data in Safety Program Mode.

An E²PROM verification procedure should be carried out e.g. by performing one complete AS-i safety cycle (8

DEXG calls in minimum 250µs intervals) in Safety Mode operation.

Rev. 2. 0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

22/58

Page 23

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

4 Detailed Functional Description

4.1 Power Supply

The power supply block provides a sensor supply, which is inductively decoupled from the AS-i bus voltage, at

pin UOUT. The decoupling is realized by a Electronic Inductor circuit, which basically consists of a current

source and a controlling low pass. The time constant of the low pass that has influence to the resulting input

impedance at pin UIN, can be adjusted by an external capacitor at pin CDC.

A second function of the power supply block is to generate a regulated 5V supply for operation of the internal

logic and some analog circuitry. The voltage is provided at pin U5R an can be used to supply external circuitry

as well, as long as the current requirements stay within in the specified limits (Table 2 at page 6). Because the

5V supply is generated out of the decoupled sensor supply at UOUT, the current drawn at U5R has to be subtracted from the total available load current at UOUT.

The power supply dissipates the major amount of power:

Ptot = V

In total, the power dissipation shall not exceed the specified values of chapter 1.1.

To cope with fast internal and external load changes (spikes) external capacitors at UOUT and U5R are required. The LTGN pin defines the ground reference voltage for both UOUT and U5R.

4.1.1 Voltage Output Pins UOUT and U5R

Table 12: Properties of voltage output pins UOUT and U5R

Drop

* (I

UOUT

+ I5V) + (V

UOUT

-5V) * I5V

Symbol Parameter Min Max Unit

V

Positive supply voltage for IC opera-

UIN

16 34 V

tion

V

Voltage drop from pin LTGP to pin

DROP

5.2 7.8 V V

UOUT

V

UOUT output supply voltage V

UOUT

V

UOUT output voltage pulse deviation 1.5 V

UOUTp

t

UOUT output voltage pulse deviation

UOUTp

UIN

- V

DROPmax

V

UIN

- V

DROPmin

2 ms

V I

width

V

5V supply voltage 4.75 5.25 V

U5R

I

UOUT output supply current 0 55 mA I

UOUT

I5V U5R output supply current 0 4 mA

Io Total output current I

C

C

1

Parameter copied from Table 2 at page 6

2

3

Blocking capacitance at UOUT 10 470 µF

BUOUT

Blocking capacitance at U5R 100 nF

B5V

The actual voltage drop increases with increasing load current at Uout

C

= 10µF, output current switches from 0 to I

UOUT

+ I5V 60 mA

UOUT

UOUTmax

and vice versa

Note

1

> 22V

UIN

2

UOUTmax

3

3

= 0

U5R

Uin>24V

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

23/58

Page 24

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

4.1.2 Input Impedance (AS-i bus load)

Table 13: AS-i Bus Load Properties

Symbol Parameter Min Max Unit Note

R

Equivalent resistor of the IC 13,5

IN1

L

Equivalent inductor of the IC 13,5 mH

IN1

C

Equivalent capacitor of the IC 30 pF

IN1

R

Equivalent resistor of the IC 13,5

IN2

L

Equivalent inductor of the IC 12 13,5 mH

IN2

C

Equivalent capacitor of the IC 15 + (L-12mH)*10pF/mH pF

IN2

C

Parasitic capacitance of the external

Zener

20 pF

kΩ

kΩ

over-voltage protection diode (Zener

diode)

1

The equivalent circuit of a slave, which is calculated from the impedance of the IC and the paralleled external

over-voltage protection diode (Zener diode), has to satisfy the requirements of the AS-i Complete Specification

for Extended Address Mode slaves.

2

Subtracting the maximum parasitic capacitance of the external over voltage protection diode (20pF) either the

triple R

IN1

, L

and C

IN1

or the triple R

IN1

IN2

, L

and C

IN2

has to be reached by the IC to fulfill the AS-i Complete

IN2

Specification.

1,2

1,2

1,2

1,2

1,2

1,2

1

Table 14: CDC pin parameters

Symbol Parameter Min Typ Max Unit Note

V

C

Input voltage range -0.3 V

CDC_IN

External decoupling capacitor 100 nF

CDC

V

U5R

Note: A decoupling capacitor defines internal low-pass filter time constant; lower values decrease the imped-

ance but improve the turn-on time. Higher values do not improve the impedance but do increase the turnon time. The turn-on time also depends on the load capacitor at UOUT. After connecting the slave to the

power the capacitor is charged with the maximum current I

voltage allows the analog circuitry to fully operate.

. The impedance will increase when the

UOUT

4.2 Thermal Protection

The IC continuously observes its silicon die temperature. If the temperature rises above around 140°C for more

than 2 seconds the IC will cut off the UOUT output from the internal voltage reference. Thus the current consumption of the IC will drop down to its operating current (refer to Table 2). In order to prevent an undesired

drawing of transmit current the transmitter is also disabled in case the over temperature cut off condition is true.

After over temperature cut off, the output voltage at UOUT will be restored and the IC performs an initialization if

the die temperature has cooled down by 10 … 20°C with an additional time delay of 1s.

Table 15: Cut Off Temperature

Symbol Parameter Min Max Unit Note

T

Chip temperature for over temperature cut off 125 160 °C

CutOff

Rev. 2. 0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

24/58

Page 25

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

4.3 DC Characteristics – Digital Inputs

The following pins contain digital high voltage input stages:

-

Input-only pin: PFAULT

-

I/O pins: P1, P3, D1, D3, DSTBn, PSTBn 1, LED1 1

-

3-level I/O pins: P0, P2, D0, D2 3

Table 16: DC Characteristics of digital high voltage input pins

Symbol Parameter Min Max Unit Note

V

Voltage range for input ”offset_low” level 0 1.0 V

OFL

V

Voltage range for input ”offset_high” level 1.6 V

OFH

V

Voltage range for input ”low” level 0 2.5 V

IL2

VIH Voltage range for input ”high” level 3.5 V

V

UOUT

V

UOUT

IIL Current range for input ”low” level -12 -3 µA VIN = 1V

3,4

3,4

4

2

IIH Current range for input ”high” level -10 10 µA

CDL Capacitance at pin DSTBn 10 pF

1

PSTBn and LED1 are inputs for test purposes only.

2

The pull-up current is driven by a current source connected to U5R. It stays almost constant for input voltages

V0 ≥ V

5

U5R

ranging from 0 to 3.8V.

3

Pins P0, P2, D0 and D2 are used as 3-level inputs - i.e. inputs with offset detection - in Safety Mode only, con-

figuration beyond depends on the slave profile (refer to Table 26 on page 34)

4

The 3-level input pads contain independent comparators for the detection of regular input data level and offset.

Refer to Figure 12 on page 44 for constraints to the externally applied voltages in Safety Mode.

5

The internal pull-up current is sufficient to avoid accidental triggering of an IC reset if the DSTBn pin remains

unconnected. For external loads at DSTBn a sufficient pull up resistor is required to ensure V

≥ 3.5V in less

IH

than 90ms after the beginning of a DSTBn = Low pulse.

4.4 DC Characteristics – Digital Outputs

The following pins contain digital high voltage open drain output stages:

-

Output-only pin: LED2

-

I/O pins: D0 … D3, P0 … P3, DSTBn, PSTBn1, LED11

Table 17: DC Characteristics of digital high voltage output pins

Symbol Parameter Min Max. Unit Note

V

Voltage range for output ”low” level 0 1 V I

OL1

V

Voltage range for output ”low” level 0 0.4 V I

OL2

IOH Output leakage current -10 10 µA

1

PSTBn and LED1 are inputs for test purposes only.

A slew rate limitation is provided to each digital high voltage output driver which limits the rise and fall times for

both High/Low and Low/High transitions to 40…50ns.

NOTE: The rise time for a Low/High transition is mainly influenced by the external pull-up resistor.

= 10mA

OL1

= 2mA

OL2

V0H ≥ V

U5R

Rev. 2.0, Copyright © 2007, ZMD AG

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

25/58

Page 26

V

V

V

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

SAP5S / SAP51

4.5 AS-i Receiver

The receiver detects (telegram) signals at the AS-i line, converts them to digital pulses and forwards them to the

UART for further processing. The receiver is internally connected between the LTGP and LTGN pins.

Functional, the receiver removes the DC value of the input signal, band-pass filters the AC signal and extracts

the digital output signals from the sin2-shaped input pulses by a set of comparators. The amplitude of the first

pulse determines the threshold level for all following pulses. This amplitude is digitally filtered to guarantee stable conditions and to suppress burst spikes. This approach combines a fast adaptation to changing signal amplitudes with a high detection safety. The comparators are reset after every detection of a telegram pause at the

AS-i line.

When the receiver is turned on, the transmitter is turned off to reduce the power consumption.

Table 18: Receiver Parameters

Symbol Parameter Min Max Unit Note

V

AC signal peak-peak amplitude (between LTGP and LTGN) 3 8 V

SIG

V

Receiver comparator threshold level (refer to Figure 5) 45 55 % Related to

LSIGon

amplitude of

1st pulse

DC level

The IC determines the

amplitude of the first

negative pulse of the

LSIGon

= (0.45 ... 0.55) * V

LSIGon

SIG

/ 2

/ 2

SIG

AS-i telegram. This

amplitude is asserted

to be V

SIG

/ 2.

First negative

pulse of the

AS-i telegram

Figure 5: Receiver comparator threshold set-up in principle

4.6 AS-i Transmitter

The transmitter draws a modulated current between LTGP and LTGN to generate the communication signals.

The shape of the current corresponds to the integral of a sin2-function. The transmitter comprises a current DAC