Page 1

INTEGRATED CIRCUITS

DATA SH EET

SAA5250

Interface for data acquisition and

control

(for multi-standard teletext

systems)

Product specification

File under Integrated Circuits, IC02

January 1987

Page 2

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

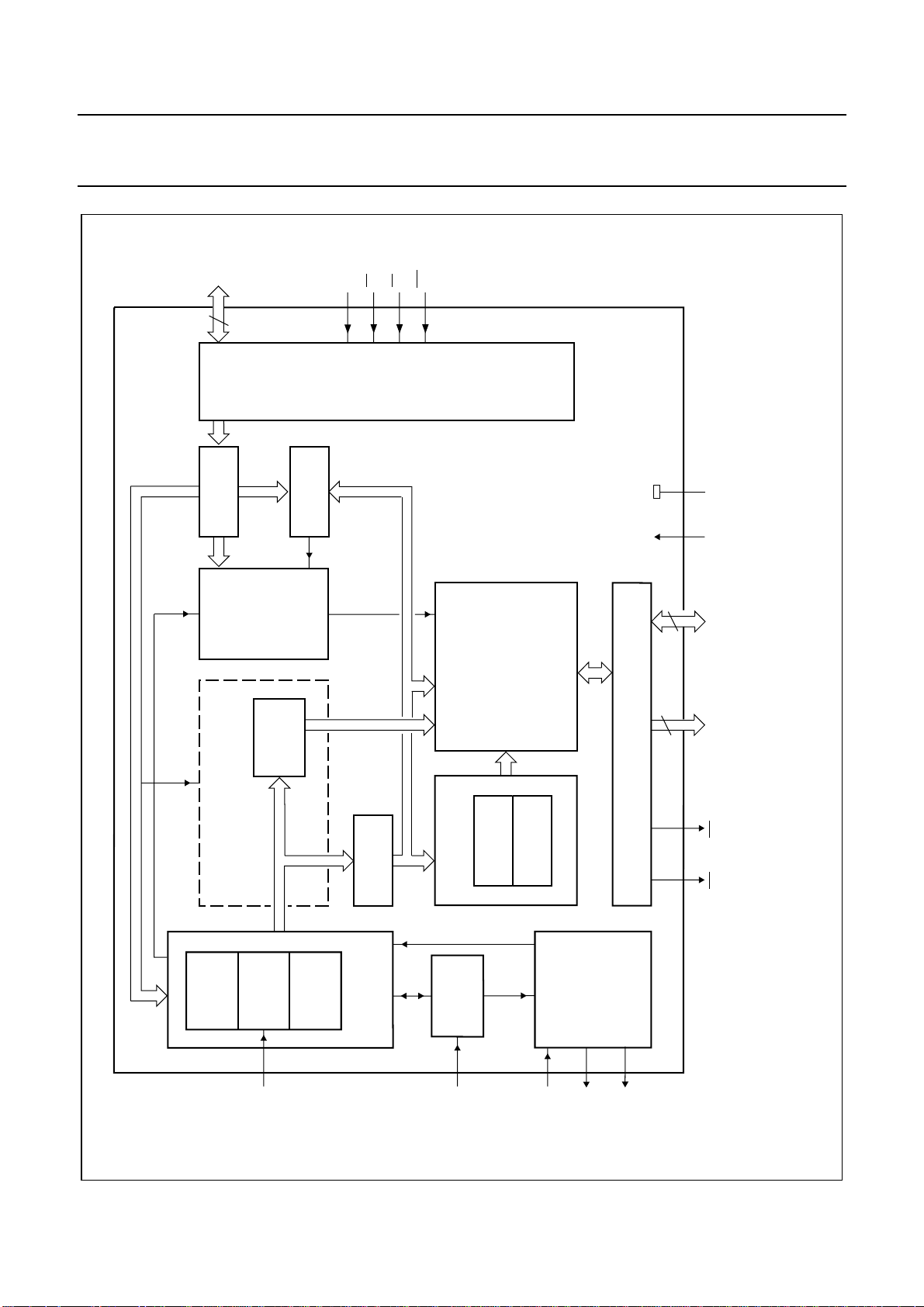

GENERAL DESCRIPTION

The SAA5250 is a CMOS Interface for Data Acquisition and Control (CIDAC) designed for use in conjunction with the

Video Input Processor (SAA5230) in a multi-standard teletext decoder. The device retrieves data from a user selected

channel (channel demultiplexer), as well as providing control signals and consecutive addressing space necessary to

drive a 2 K bytes buffer memory.

The system operates in accordance with the following transmission standards:

• French Didon Antiope specification D2 A4-2 (DIDON)

• North American Broadcast Teletext specification (NABTS)

• U.K. teletext (CEEFAX)

Features

• 7,5 MHz maximum conversion rate

• Three prefixes; DIDON, NABTS and U.K. teletext (CEEFAX)

• Mode without prefix

• Internal calculation of the validation (VAL) and colour burst blanking (CBB) signals, if programmed

• Programmable framing code and channel numbers

• Error parity calculation or not (odd parity)

• Hamming processing of the prefix byte

• Full channel or VBI reception

• Slow/fast mode (detection of page flags or not)

• Maximum/default format up to 63 bytes

• Addressing space of 2 K bytes of the static memory

• Multiplexed address/data information is compatible with Motorola or Intel microcontrollers

• CIDAC is ‘MOTEL’ compatible

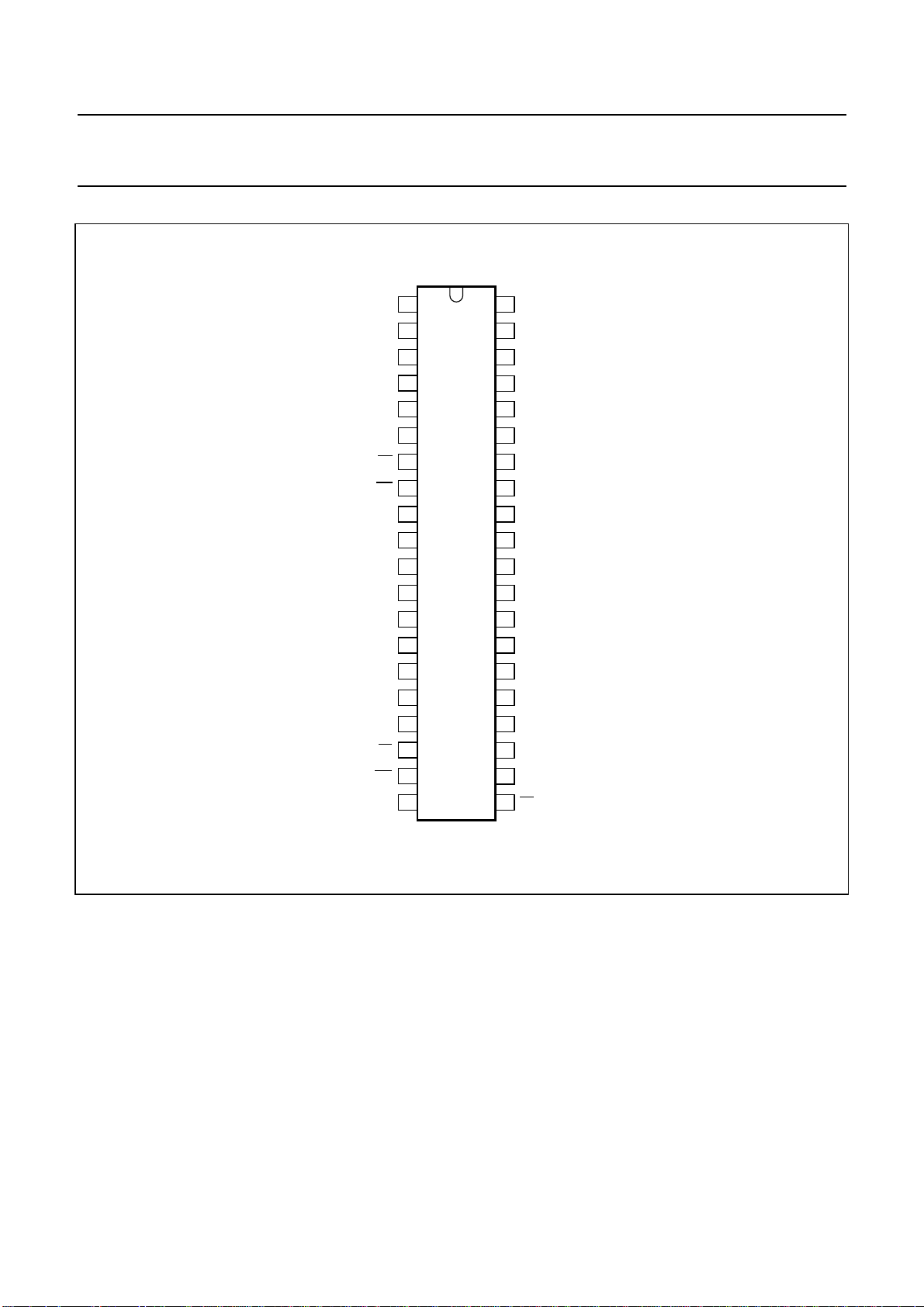

PACKAGE OUTLINES

SAA5250P: 40-lead DIL; plastic (SOT129); SOT129-1; 1996 December 02.

SAA5250T: 40-lead mini-pack; plastic (VSO40); SOT158-1; 1996 December 02.

January 1987 2

Page 3

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

DB7toDB0

8

9-16

REGISTER

PROGRAM

17

CHANNEL

COMPARATOR

ALE

CS

RD

WR

18

21

19

INTERFACE

SAA5250

MGH075

SS

V

DD

SAA5250

, full pagewidth

PAGE DETECTION

CODE

FRAMING

DETECTION

SEQUENCE

CONTROLLER

REGISTER

SERIAL

REGISTER

PARALLEL

REGISTER

HAMMING

CORRECTOR

CONVERTER

SERIAL/PARALLEL

FORMAT

FORMAT

PROCESSOR

CLOCK

GENERATION

2 K BYTE

CONTROLLER

FIFO MEMORY

FORMAT

COUNTER

TRANSCODER

SIGNAL

VALIDATION

PROCESSING

29-22 40 20

8

1, 39-30

11

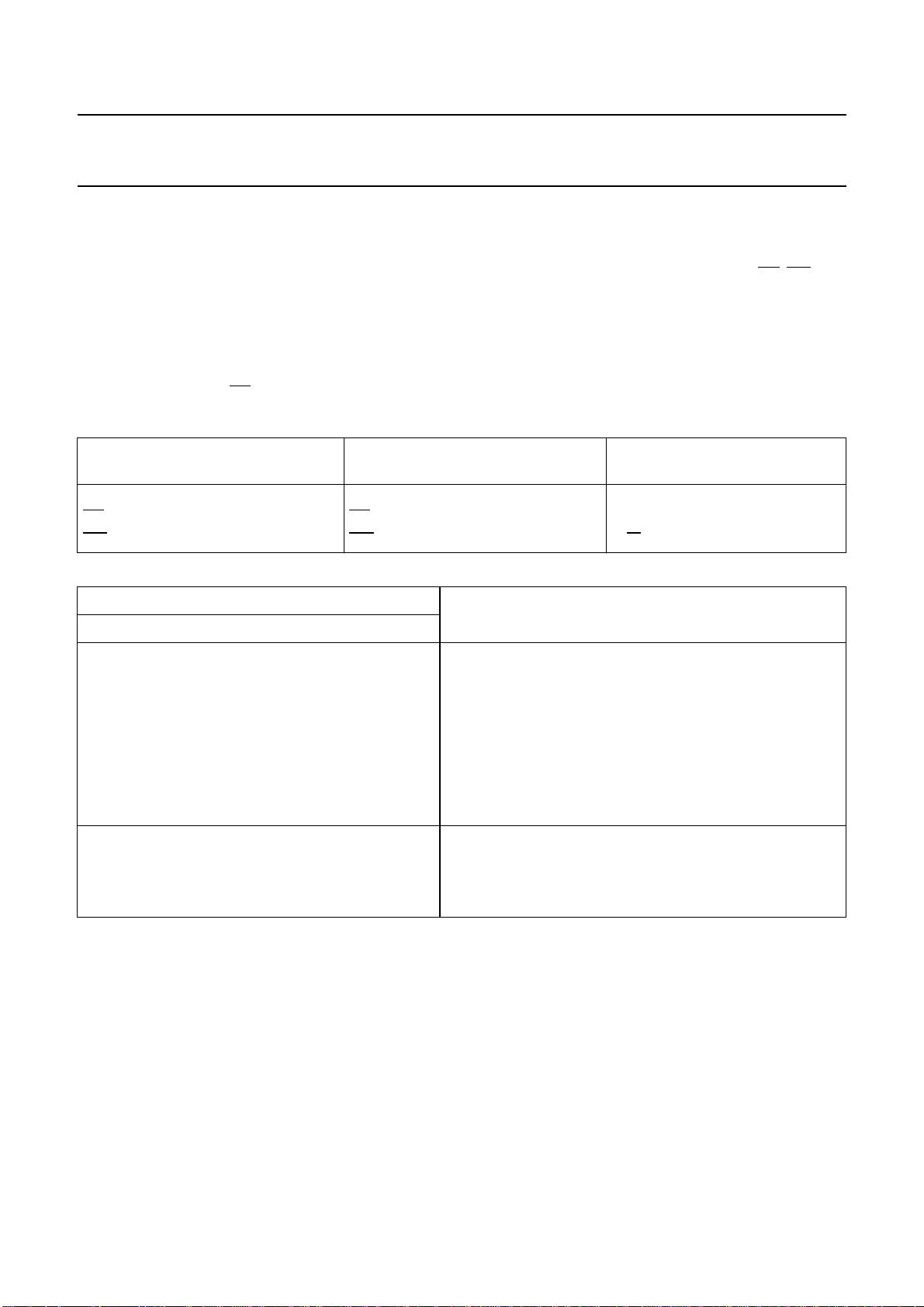

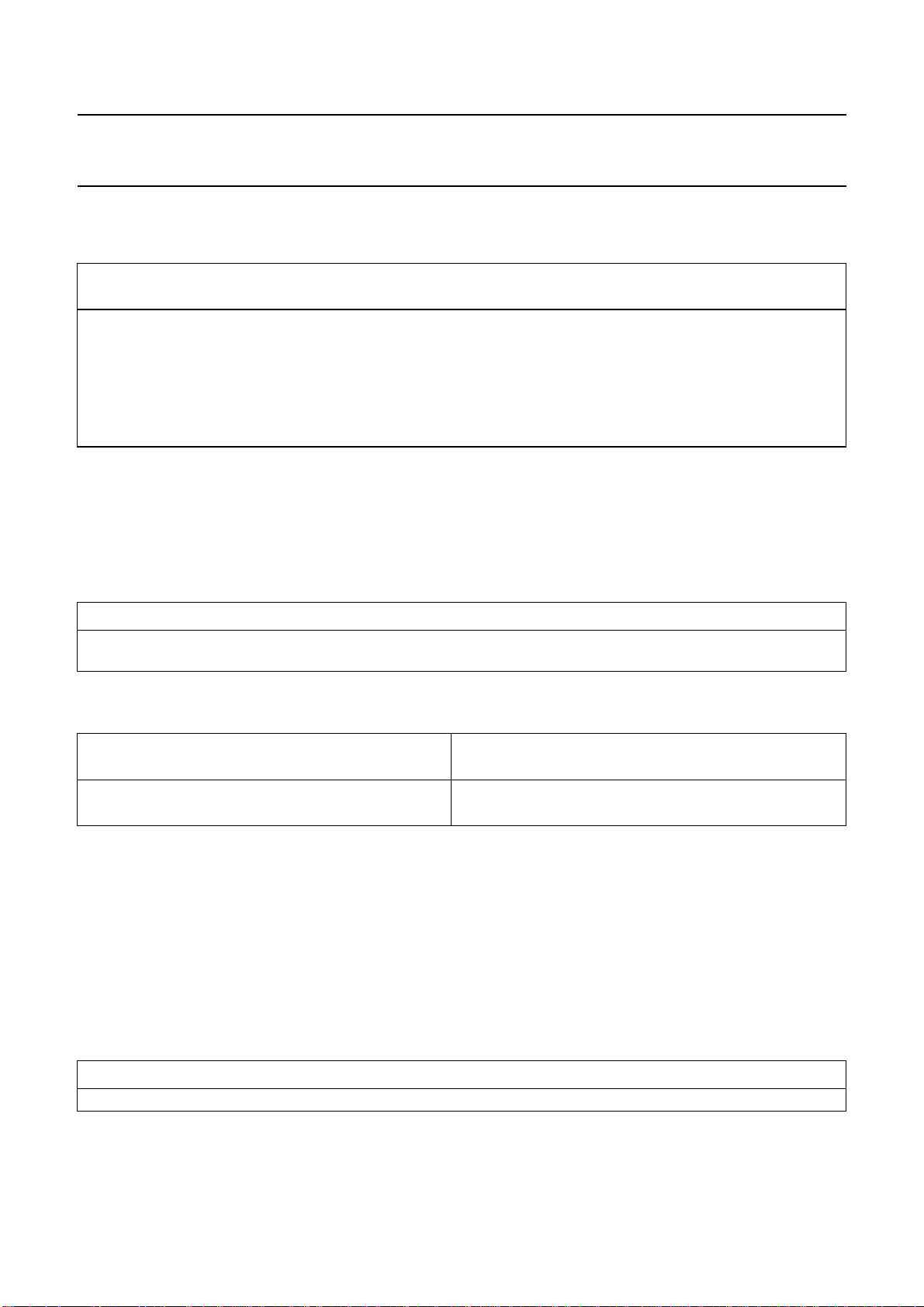

Fig.1 Block diagram.

MEMORY INTERFACE

WE A10 to A0 D7 to D0 V

78

MS

6

SD

January 1987 3

5

DCK

3

VAL IN/

SYNC

2

4

CBB

VAL OUT

Page 4

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

handbook, halfpage

VAL OUT

VAL IN/

A10

SYNC

CBB

DCK

SD

MS

WE

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

ALE

CS

WR

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

SAA5250

MGH074

SAA5250

40

V

DD

39

A9

38

A8

37

A7

36

A6

35

A5

34

A4

33

A3

32

A2

31

A1

30

A0

29

D7

28

D6

27

D5

26

D4

25

D3

24

D2

23

D1

22

D0

21

RD

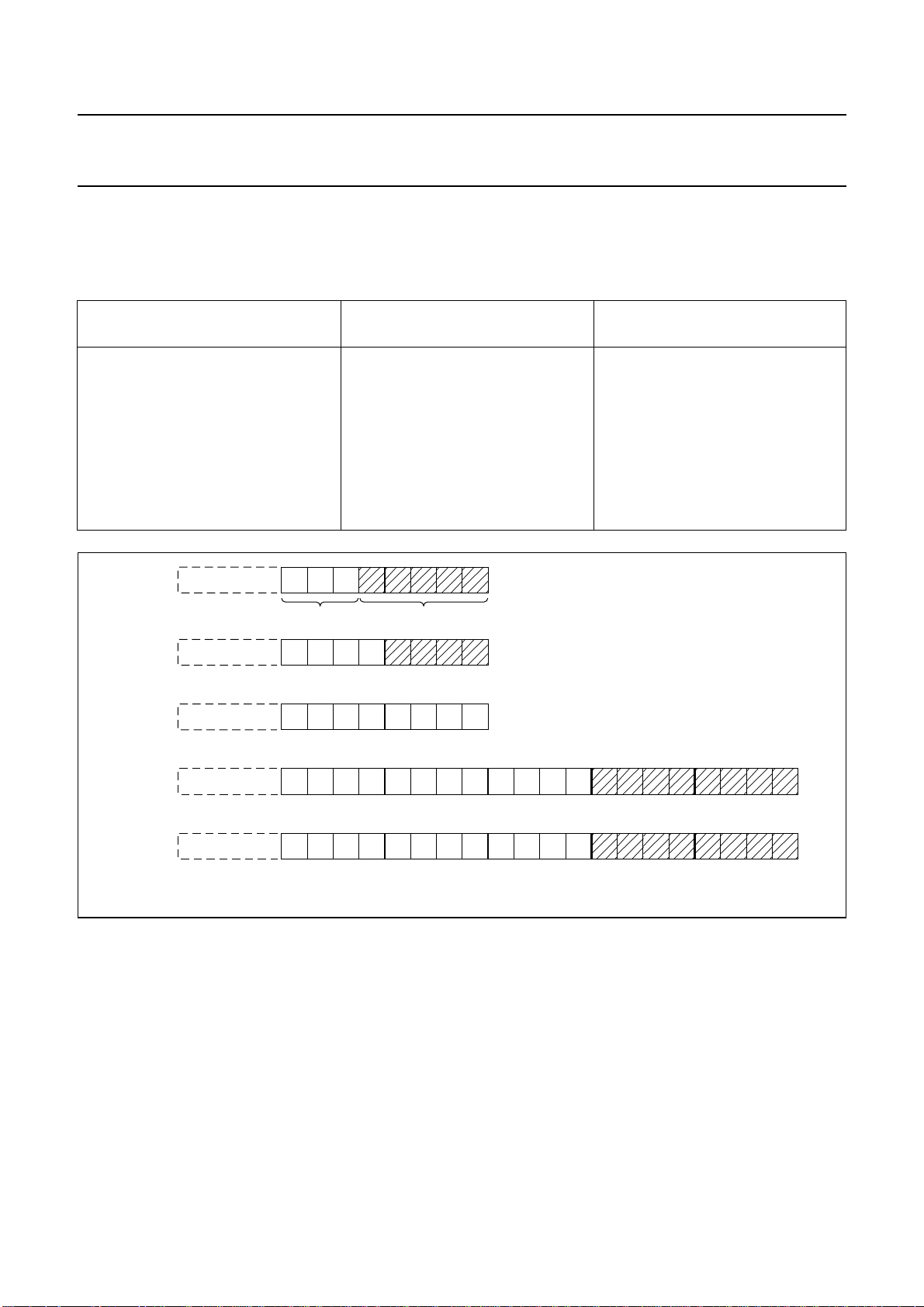

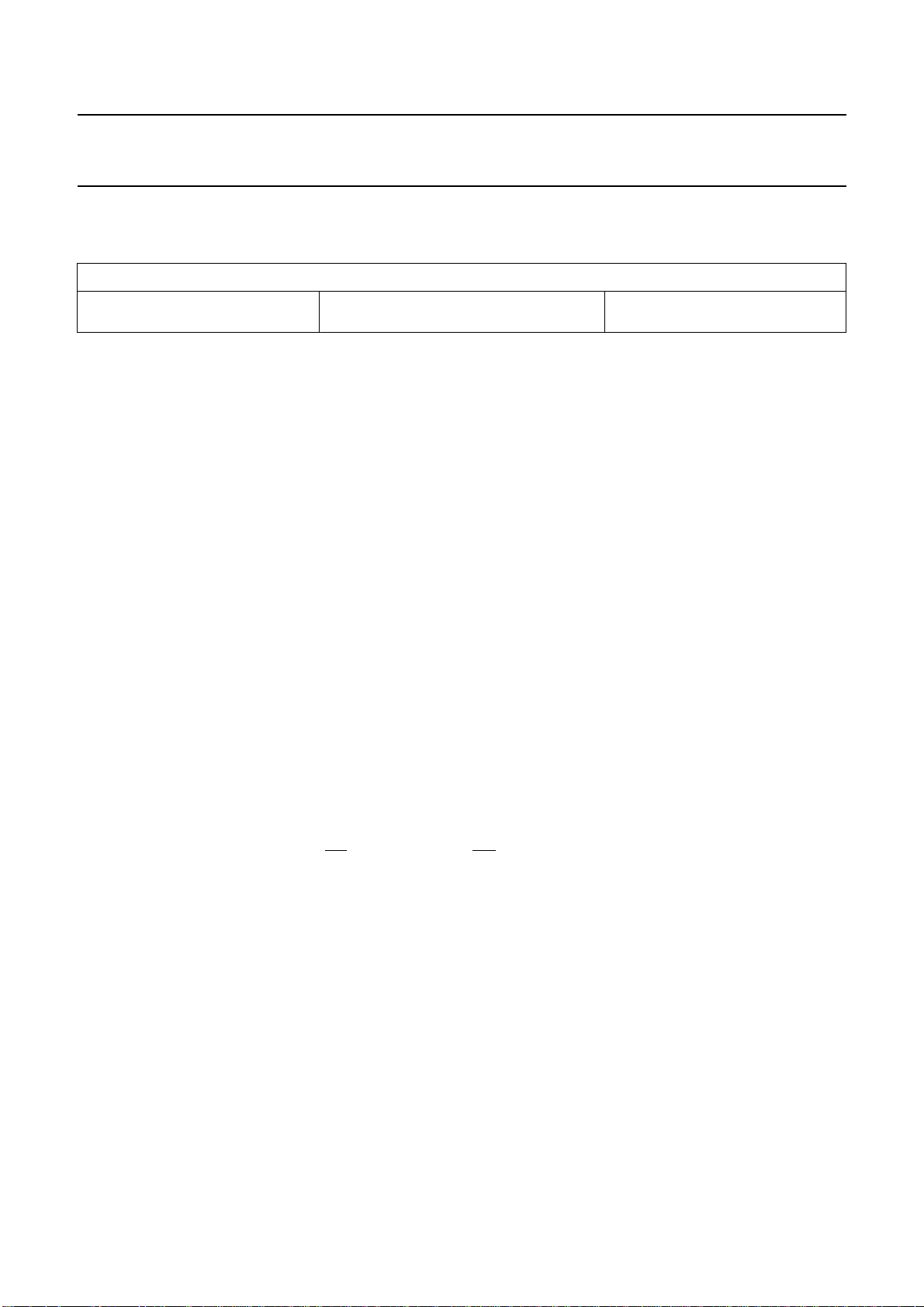

Fig.2 Pinning diagram.

January 1987 4

Page 5

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

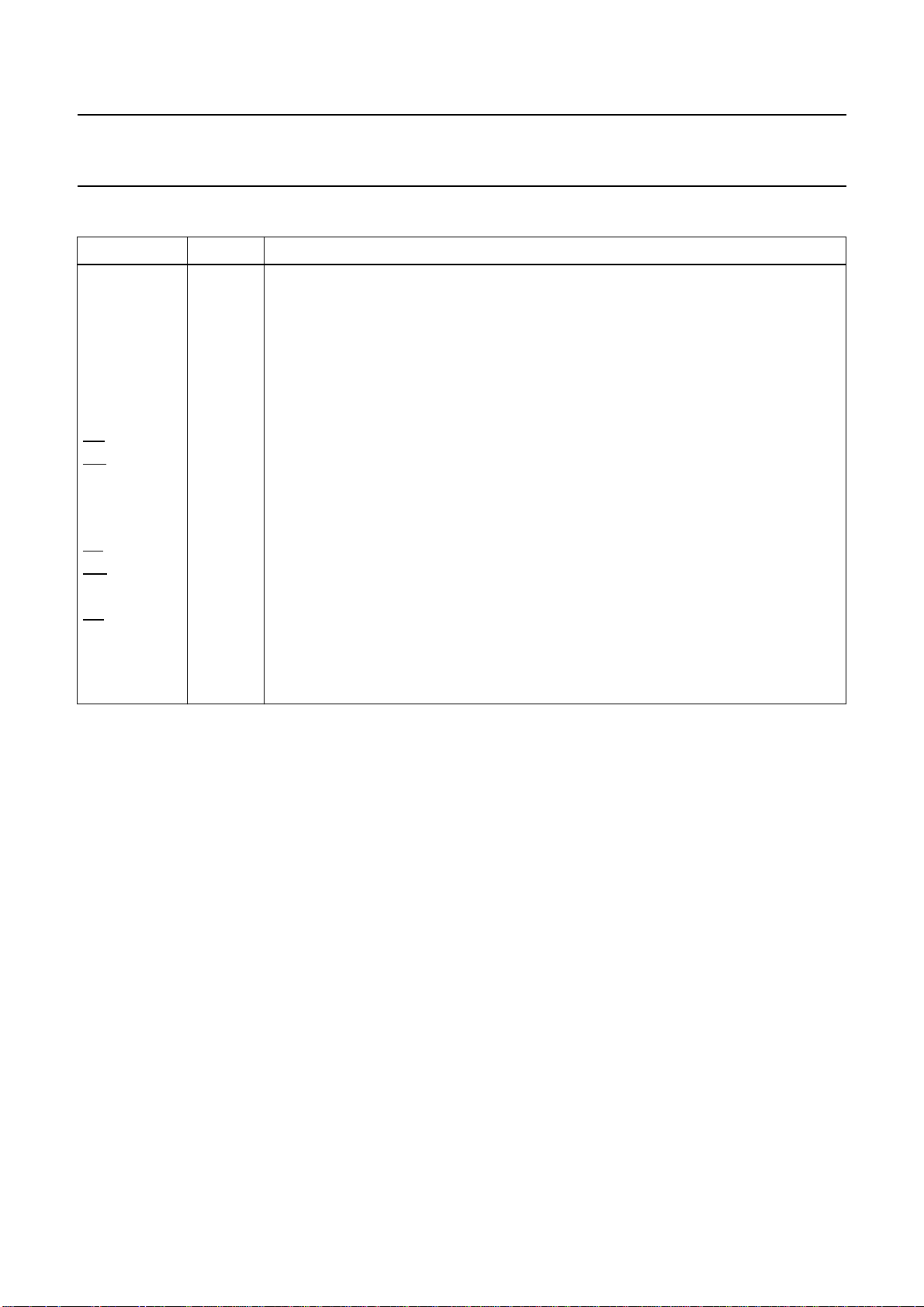

PINNING FUNCTION

MNEMONIC PIN NO. FUNCTION

A10 and

A0 to A9

VAL OUT 2 Validation output signal used to control the location of the window for the framing code.

VAL IN/SYNC 3 Validation input signal (line signal) used to give or calculate a window for the framing

CBB 4 Colour burst blanking output signal used by the SAA5230 as a data slicer reset pulse

DCK 5 Data clock input, in synchronization with the serial data signal

SD 6 Serial data input, arriving from the demodulator

MS 7 Chip enable output signal for buffer memory selection

WE 8 Write command output for the buffer memory

DB7 to DB0 9 to 16 8-bit three state input/output data/address bus used to transfer commands, data and

ALE 17 Demultiplexing input signal for the CPU data bus

CE 18 Chip enable input for the SAA5250

WR 19 Write command input (when LOW)

V

SS

RD 21 Read command input (when LOW)

D0 to D7 22 to 29 8-bit three state input/output data bus used to transfer data between CIDAC and the

V

DD

1 and

30 to 39

20 ground

40 +5 V power supply

Memory address outputs used by CIDAC to address a 2 K byte buffer memory

code detection

status between the CIDAC registers and the CPU

buffer memory

January 1987 5

Page 6

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

FUNCTIONAL DESCRIPTION

Microcontroller interface

The microcontroller interface communicates with the CPU via the handshake signals DB7 − DB0, ALE, CS,

microcontroller interface produces control commands as well as programming the registers to write their contents or read

incoming status/data information from the buffer memory. The details of the codes used to address the registers are

given in Table 2.

The CIDAC is ‘MOTEL’ compatible (MOTEL compatible means it is compatible with standard Motorola or Intel

microcontrollers). It automatically recognizes the microcontroller type (such as the 6801 or 8501) by using the ALE signal

to latch the state of the RD input. No external logic is required.

Table 1 Recognition signals

8049/8051

CIDAC

ALE ALE AS

RD RD DS, E, Φ 2

WR WR R/W

Table 2 CIDAC register addressing

TIMING 1

6801/6805

TIMING 2

RD,WR. The

CODES

FUNCTIONR W CS DB2 DB1 DB0

100000write register R0

100001write register R1

100010write register R2

100011write register R3

100100write register R4

100101write register R5

100110write command register R6 (initialization command)

100111write register R7

010000read status

010001read data register

010010test (not used)

010011test (not used)

January 1987 6

Page 7

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

Register organization

R0 register

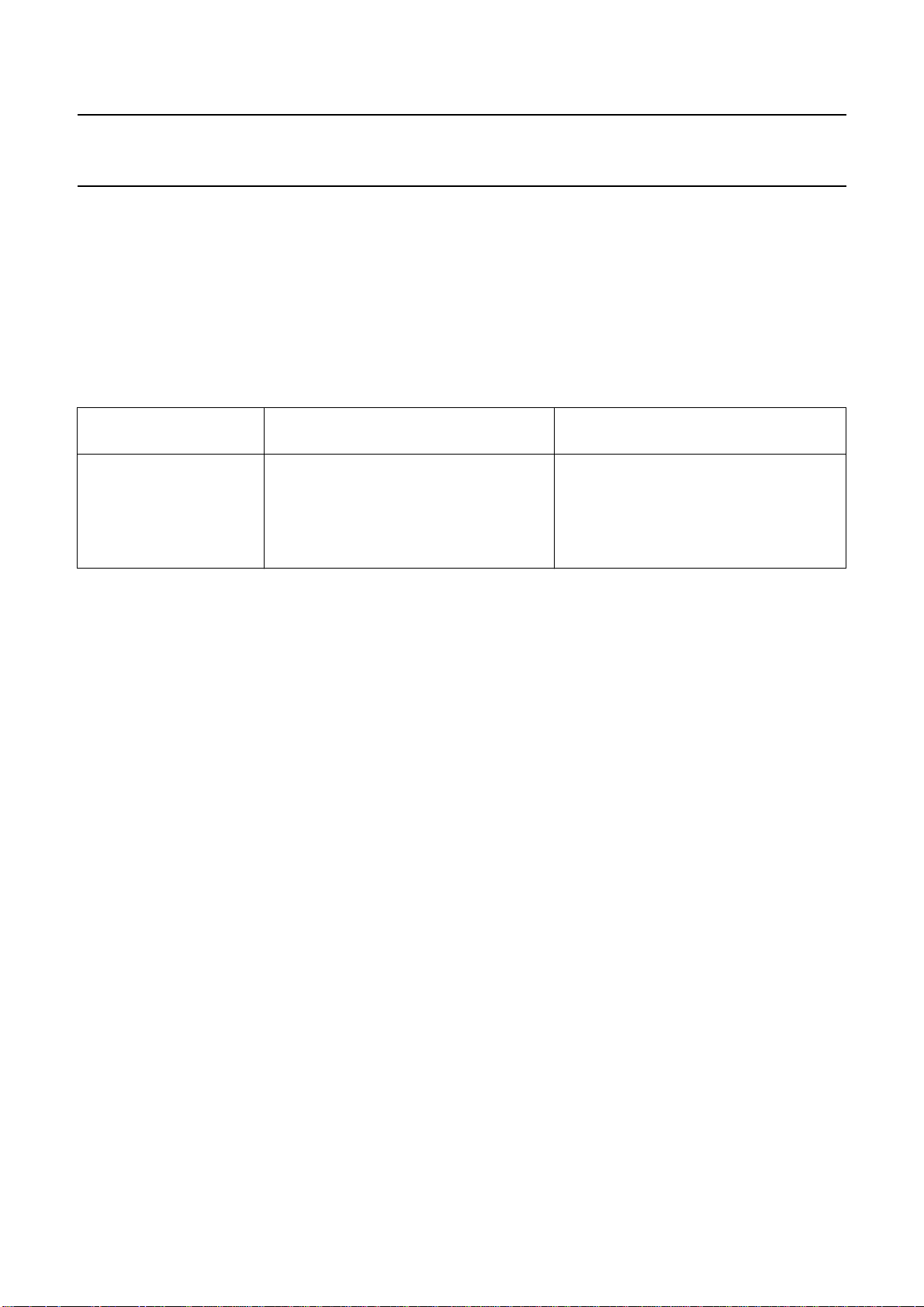

Table 3 R0 Register contents

R04

SLOW/FAST MODE

0 = slow mode 0 = no parity control 000 = DIDON long

1 = fast mode 1 = odd parity 001 = DIDON medium

handbook, full pagewidth

FCCEEFAX

R03

PARITY

SAA5250

R02 TO R00

USED PREFIXES

010 = DIDON short

011 = not used

100 = U.K. teletext

101 = NABTS

110 = without prefix

111 = without prefix

magazine and row address group

MRAG

format

A2

A2

A2

A3

A3

CI

CI

format

PS

MGH077

DIDON

short

DIDON

medium

DIDON

long

NABTS

A

FC

A1

FC

A1

FC

A1

FC

Fig.3 Five prefixes.

All of the bytes (see Fig.3) are Hamming protected. The hatched bytes are always stored in the memory in order to be

processed by the CPU (see section ‘Prefix processing’). In the mode without prefix all of the bytes which follow the

framing code are stored in the memory until the end of the data packet, the format is then determined by the contents of

the R3 register.

If R03 = 0; no parity control is carried out and the 8-bits of the incoming data bytes are stored in the fifo memory.

If R03 = 1; the 8th bit of the bytes following the prefix (data bytes) represents the result of the odd parity control.

If R04 = 0; the device operates in the slow mode. The CIDAC retrieves data from the user selected magazine (see

section ‘R1 and R2’) and without searching for a start to a page stores the data into the FIFO memory.

January 1987 7

Page 8

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

If R04 = 1; the device operates in the fast mode. Prior to writing into the FIFO memory, the CIDAC searches for a start

to a page which is variable due to the different prefixes:

• DIDON (long, medium and short): using the redundant bytes, SOH RS, X RS and SOH X (where X is a bit affected by

a parity error)

• NABTS, the least significant bit of the PS byte is set to 1

• U.K. teletext, ROW = 0

R1 register

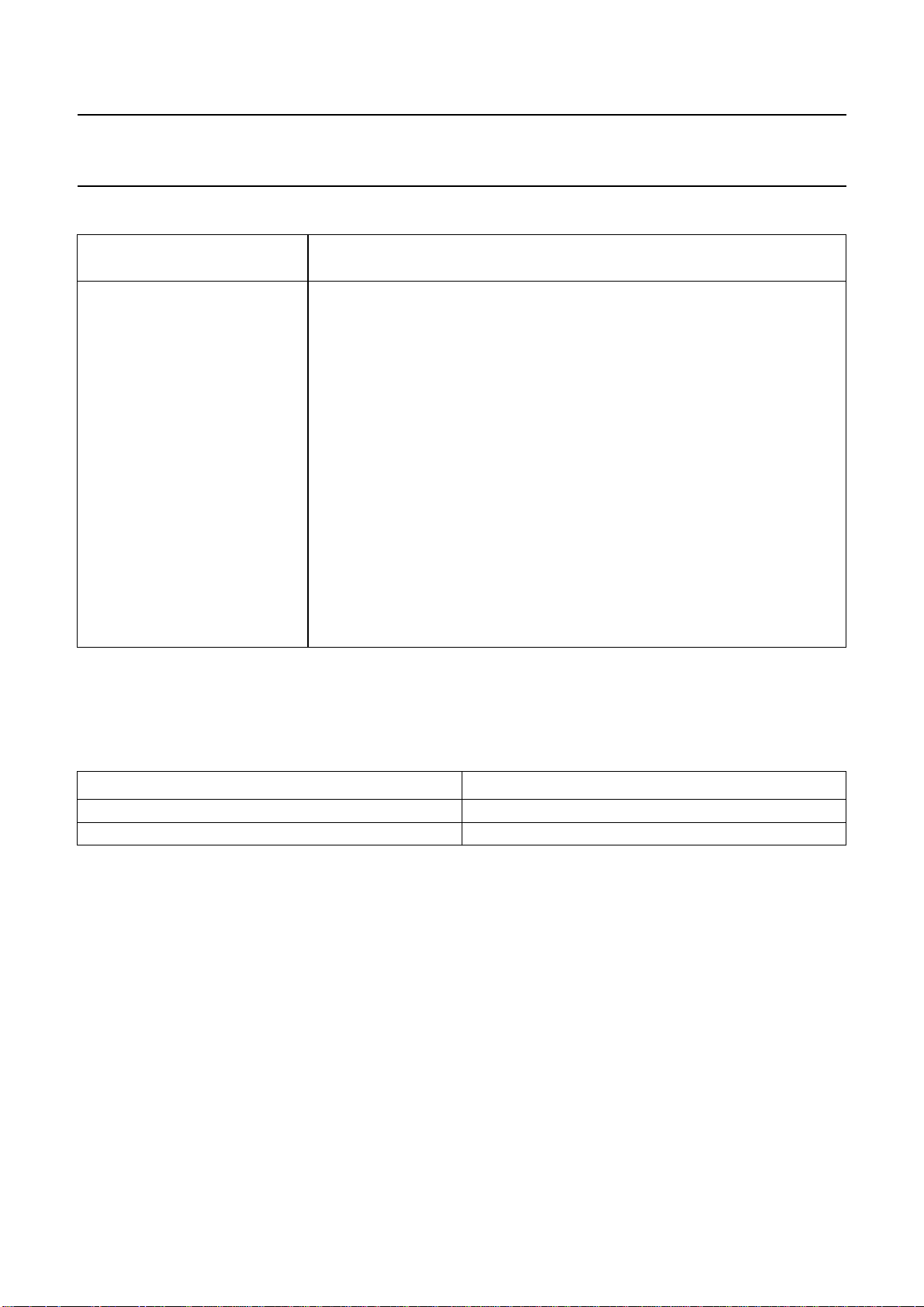

Table 4 R1 Register contents

R17

VAL IN/SYNC

1 = VAL 000 = list 1 first digit hexadecimal value

0 = SYNC 001 = list 2

Note

1. X = don’t care

R16 TO R14

FORMAT TABLE

010 = list 3

011 = list 4

1XX = maximum/default value used (R3)

(1)

R13 TO R10

CHANNEL NUMBERS (FIRST DIGIT)

If VAL IN/SYNC = 1; the line signal immediately produces a validation signal for the framing code detection.

If VAL OUT = 0; the line signal is used as a starting signal for an internally processed validation signal (see Fig.15). The

framing code window width is fixed at 13 clock periods and the delay is determined by the contents of the R5 register

(R56 to R50).

At any moment the user is able to ensure that the framing code window is correctly located. This is accomplished by the

VAL OUT pin reflecting the internal validation signal. A CBB signal with programmable width (see section ‘R7 register’)

can also be generated, this is used as a data slicer reset pulse by the SAA5230. The line signal is used as the starting

point of the internal CBB signal width fixed by the contents of the R7 register.

If R16 = 0; then bits R15 and R14 provide the format table number using DIDON long and short prefixes (see Table 6).

If R16 = 1; then the format is determined by the contents of the R3 register.

The bits R13 to R10 represent the first channel number to be checked in the prefix. In U.K. teletext mode only 3 bits are

required, so R13 = X.

January 1987 8

Page 9

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

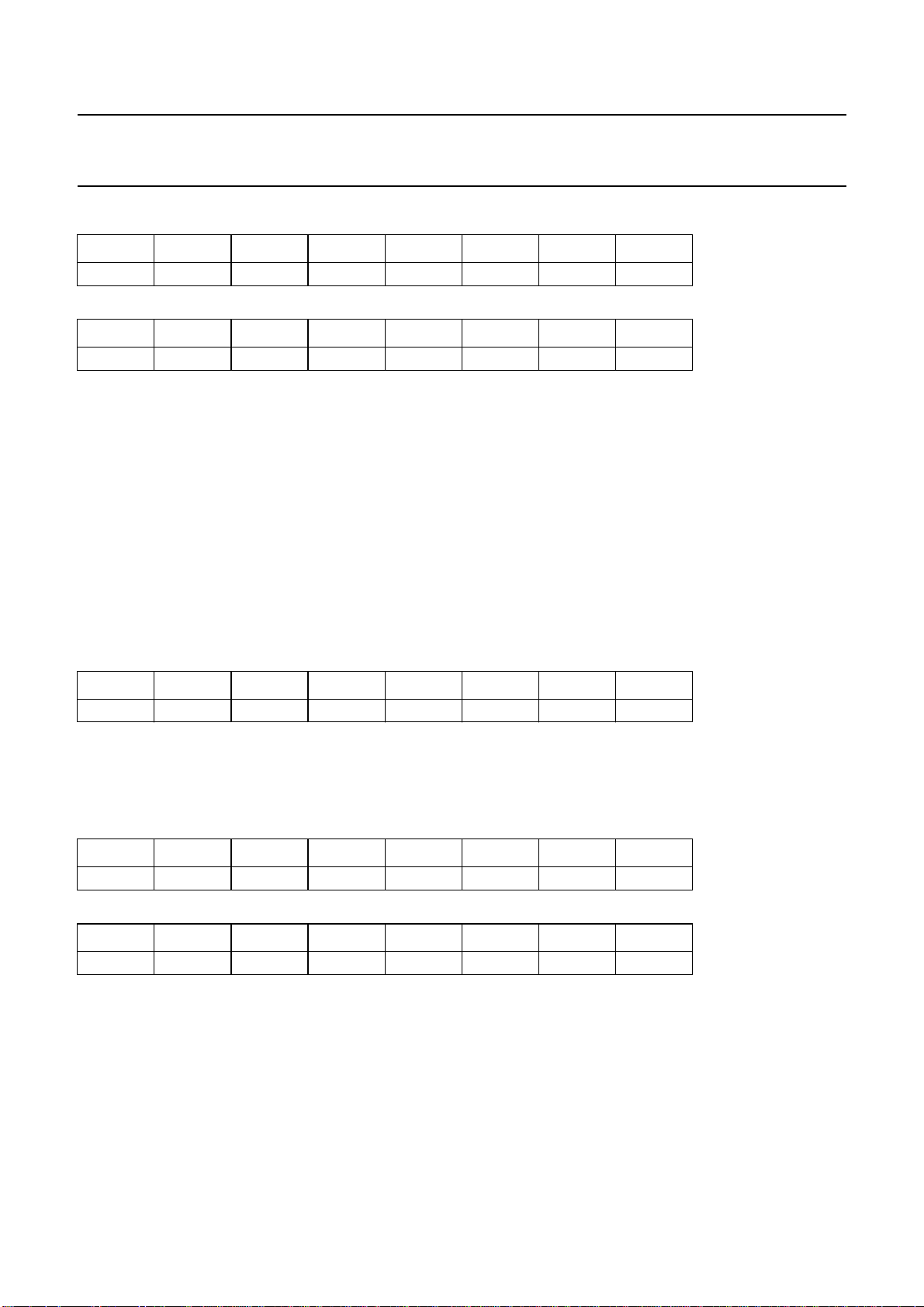

Table 5 Format table

FORMAT BYTE

B8, B6, B4 AND B2

0000 0 0 0 0

0001 1 1 1 1

0010 2 2 2 2

0011 3 3 3 3

0100 4 5 6 7

0101 8 9 10 11

0110 12 13 14 15

0111 16 17 18 19

1000 20 21 22 23

1001 24 25 26 27

1010 28 29 30 31

1011 3233 3435

1100 36 37 38 39

1101 40 41 42 43

1110 44 45 46 47

1111 48 49 50 51

(1)

LIST 1 LIST 2 LIST 3 LIST 4

SAA5250

Note

1. B8 = MSB and B2 = LSB.

R2 register

Table 6 R2 Register contents

R27 TO R24 R23 TO R20

channel number, third digit channel number, second digit

(hexadecimal value, third digit) (hexadecimal value, second digit

Note

1. R27 and R23 = MSB and R24 and R20 = LSB

The R2 register provides the other two parts of the channel number (depending on the prefix) that require checking.

January 1987 9

Page 10

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

R3 register

Table 7 R3 register contents

R35 TO R30

6-BIT FORMAT MAXIMUM/DEFAULT VALUE

000000 = 0

000001 = 1

−

−

−

111111 = 63

This 6-bit byte gives:

• In the DIDON long and short mode, a maximum format in case of corrupted transmission (multiple errors on the

Hamming corrector)

• A possible 63-bit format for all types of prefix

R4 register

Table 8 R4 register contents

R47 TO R40

8-bit register used for storing the framing code value which will be compared with the third byte of each data

line

R5 register

Table 9 R5 register contents

R57

NEGATIVE/POSITIVE

0 = negative edge for sync signal 7-bit sync delay, giving a maximum

1 = positive edge for sync signal delay of (2

Note

1. F = data clock acquisition frequency (DCK).

Using R57 it is possible to start the internal synchronization delay (t

R6 write command register

This is a fictitious register. Only the address code (see Table 2) is required to reset the CIDAC. See Table 11 for the

status of the FIFO memory on receipt of this command.

R7 register

Table 10 R7 register contents

R56 TO R50

SYNCHRONIZATION DELAY

7

− 1) × 106µs/F (Hz)

) on the positive or negative edge.

DVAL

R75 TO R70

6-bit register used to give a maximum colour burst blanking signal of: (26− 1) × 106µs/F (Hz)

Note

1. F = data clock acquisition frequency.

January 1987 10

Page 11

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

Fifo status register (

Table 11 Fifo register contents

DB2 TO DB0

DB2 = 1

memory empty

Once the relevant prefix and the right working modes have been given by the corresponding registers, a write command

to the R6 register enables the CIDAC to accept and process serial data.

Channel comparator

This is a four bit comparator which compares the three user hexadecimal defined values in R1 and R2 to corresponding

bytes of the prefix coming from the Hamming corrector. If the three bytes match, the internal process of the prefix

continues. If they do not match the CIDAC returns to a wait state until the next broadcast data package is received.

FIFO memory controller

The FIFO memory contains all the necessary functions required for the control of the 11-bit address memory (2 K byte).

The functions contained in the FIFO memory are as follows:

• write address register (11-bits)

• read address register (11-bits)

• memory pointer (11-bits)

• address multiplexer (11-bits)

• write data register (8-bits)

• read data register (8-bits)

• data multiplexer

• control logic

read R0 register)

DB1 = 1, data not present in the

read data register

DB0 = 0

memory not full

The FIFO memory provides the memory interface with the following:

• 11-bit address bus (A10 to A0)

• 8-bit data bus (D7 to D0)

• two control signals, memory select (MS) and write enable (WE)

January 1987 11

Page 12

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

Operation

The CIDAC uses the same clock signal for data acquisition and internal processing, this allows the CIDAC to have a write

and a read cycle during each character period (see Fig.13). The first half of the character period is a write cycle and the

second half is a read cycle. Consequently, for an 8 MHz bit rate the maximum memory cycle time is 500 ns.

When the first data byte is written into the FIFO memory, thus transferred into the read register, the FIFO memory enters

the status shown in Table 12.

Table 12 FIFO status

DB2 TO DB0

DB2 = 1

memory empty

When the FIFO memory is full two events occur:

• the write address register points to the next address after the last written address

• when new data is to be written, the memory select signal output ceases

Memory interface

DB1 = 0

data available

DB0 = 0

memory not full

The memory interface contains all the buffers for the memory signals mentioned in the section ‘FIFO memory controller’.

Page detection

This part of the CIDAC contains a parallel register with logic which detects (only in fast mode) a start of a page or data

group (see section ‘R0 register’).

Hamming correction (see Tables 13 and 14) The Hamming correction provides (see section ‘Prefix processing’):

• hexadecimal value of the Hamming code

• accept/reject code signal

• parity information

January 1987 12

Page 13

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

Table 13 Hamming correction (coding)

HEXADECIMAL

NOTATION

0 00010101

1 00000010

2 01001001

3 01011110

4 01100100

5 01110011

6 00111000

7 00101111

8 11010000

9 11000111

A 10001100

B 10011011

C 10100001

D 10110110

E 11111101

F 11101010

B8 B7 B6 B5 B4 B3 B2 B1

SAA5250

Note

1. B7 = B8 ⊕ B6 ⊕ B4

B5 = B6 ⊕ B4 ⊕ B2

B3 = B4 ⊕ B2 ⊕ B8

B1 = B2 ⊕ B8 ⊕ B6

⊕ = exclusive OR gate function

B8, B6, B4 and B2 = data bits

B7, B5, B3 and B1 = redundancy bits

January 1987 13

Page 14

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

Table 14 Hamming correction (decoding)

ABCDINTERPRETATION INFORMATION

1111no error accepted

0010error on B8 corrected

1110error on B7 accepted

0100error on B6 corrected

1100error on B5 accepted

1000error on B4 corrected

1010error on B3 accepted

0000error on B2 corrected

0110error on B1 accepted

A.B.C = 0 1 multiple errors rejected

Note

1. A = B8 ⊕ B6 ⊕ B2 ⊕ B1

B = B8 ⊕ B4 ⊕ B3 ⊕ B2

C = B6 ⊕ B5 ⊕ B4 ⊕ B2

D = B8 ⊕ B7 ⊕ B6 ⊕ B5 ⊕ B4 ⊕ B3 ⊕ B2 ⊕ B1

⊕ = exclusive OR gate function

SAA5250

Format processing

The format processing consist of two parts:

part 1

A format transcoder produces a 6-bit code (up to 63) and uses the following as inputs:

• DIDON long and short prefixes;

hamming corrected code (4-bits)

accept/reject code condition

table number (see section ‘R1 register’, bits R15 and R14)

• Other prefixes (R16 = 1)

• 6-bit maximum/default format (see section ‘R3 register’)

part 2

A format counter operating at the character clock frequency which receives the 6-bit code from the format transcoder and

is used to check the data packet length following the prefix.

Serial/parallel converter

The serial/parallel converter consists of three parts:

• An 8-bit shift register which receives the SD input and operates at the bit frequency (DCK).

• An 8-bit parallel register used for storage.

• A framing code detection circuit. This logic circuit compares the 8-bits of the R4 register with that of the serial register.

If seven bits out of eight match (in coincidence with a validation window), it produces a start signal for a new teletext

data line to the sequence controller.

January 1987 14

Page 15

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

Clock generation

The clock generator does the following:

• acts as a buffer for the DCK clock

• generates the character clock

As soon as a framing code has been detected, a divide by 8 counter is initialized and the character clock is started. The

clock drives the following:

• sequence controller

• parallel registers

• format counter

Processing of VAL and CBB signals

The circuit has one input (VAL IN/SYNC) and two outputs (VAL OUT and CBB). The circuit consists of:

• 7-bit counter operating at DCK frequency which produces the framing code validation pulse delay

• 7-bit comparator which compares the contents of the R5 register (bits R56 to R50) to the bit counter

• a 6-bit counter operating at DCK frequency which produces the CBB pulse width

• 6-bit comparator which compares the contents of the R7 register (bits R75 to R70) to the bit counter

• control logic required to provide the start condition for the VAL signal and the CBB pulse width (on the negative or

positive edge of the sync signal)

The CBB signal useful occurs when the associated video processor:

• has no sandcastle pulse to send back to the demodulator

• carries out the synchronization of the time base clock. In this event the CBB acts as a data slicer reset pulse

The VAL OUT is a control signal which reflects the internal framing code window.

Prefix processing (see Table 21)

Figs 4 to 9 show the acquisition flow charts for each prefix type coded in the R0 register (bits R02 to R00).

As soon as an initialization command is received by the CIDAC, a write command to the R6 register (only the address is

significant), is ready to receive data from a dedicated channel number and store the data in the FIFO memory (explained

in the following paragraphs, each paragraph being dedicated to an individual type of prefix).

DIDON long (see Fig.4) In this mode, the continuity index, format and data bytes are written into the FIFO memory. (In fast mode, information

can be written into the FIFO memory only after a page detection.)

January 1987 15

Page 16

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

Table 15 Continuity index processing result

D7 D6 D5 D4 D3 D2 D1 D0

A/R X X X CI3 CI2 CI1 CI0

Table 16 Format processing result

D7 D6 D5 D4 D3 D2 D1 D0

A/RX F5F4F3F2F1F0

Note

1. A/R = 0, if rejected

2. A/R = 1, if accepted

3. X = don’t care

DIDON mediun (see Fig.5) Only data bytes are written into the FIFO memory. (In fast mode, information can be written into the FIFO memory only

after a page detection.)

DIDON short (see Fig.6) In this mode, format and data bytes are written into the FIFO memory. (In fast mode, information can be written into the

FIFIFO memory only after a page detection.)

Table 17 Format processing result

D7 D6 D5 D4 D3 D2 D1 D0

A/RX F5F4F3F2F1F0

NABTS (see Fig.7) In this mode, the continuity index, packet structure and data bytes are written into the FIFO memory. (In fast mode,

information can be written into the FIFO memory only after a page detection.)

Table 18 Continuity index processing result

D7 D6 D5 D4 D3 D2 D1 D0

A/R X X X CI3 CI2 CI1 CI0

Table 19 Packet structure processing result

D7 D6 D5 D4 D3 D2 D1 D0

A/R X X X PS3 PS2 PS1 PS0

U.K. teletext (see Fig.8) In this mode, the magazine and row address group (two bytes) and data bytes are written into the FIFO memory. (In fast

mode, information can be written into the FIFO memory only after a flag detection.)

January 1987 16

Page 17

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

Table 20 Magazine and row address group processing results

D7 D6 D5 D4 D3 D2 D1 D0

A/R X X RW4 RW3 RW2 RW1 RW0

Without prefix

All the data following the framing code are stored in the FIFO memory.

Table 21 Prefix processing

CONSTRUCTION

PREFIXES

DIDON

long

OF PREFIXES

A1, A2, A3,

CI, F and D CI, F and D CI

DIDON

medium A1, A2 and D D D

DIDON

short A1, F and D F and D F

NABTS A1, A2, A3

CI, PS and D CI, PS and D CI

U.K.

teletext MRAG and D MRAG and D MRAG

without

prefix

BYTES STORED IN FIFO

MEMORY DURING SLOW MODE

BYTES STORED IN FIFO

MEMORY DURING FAST MODE

(1)

(1)

(1)

(1)

all bytes of the data packet following the framing code are written into the

FIFO memory

(1)

, F

and D

, PS

(1)

and D

(1)

(1)

and D

and D

SAA5250

(1)

(1)

(1)

Note

1. after page/flag detection

2. A1, A2, A3 are channel numbers

CI = continuity index

F = format

PS = packet structure

D = data

MRAG = magazine and row address group

January 1987 17

Page 18

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

SAA5250

Fig.4 DIDON (long) acquisition flow chart.

January 1987 18

Page 19

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

handbook, full pagewidth

INITIALIZE CIDAC

FRAMING

CODE DETECT

1

A1 O.K.

1

A2 O.K.

1

LOAD FORMAT COUNTER

WITH EXPLICIT VALUE

SAA5250

0

0

0

PAGE IN

PROGRESS

0

DECREMENT FORMAT COUNTER

1

0

SET PAGE IN PROGRESS FLAG

START OF

PAGE DETECT

1

FORMAT

COUNTER = 0

0

FAST

DECREMENT FORMAT COUNTER.

WRITE DATA BYTES INTO FIFO

SLOW/FAST

MODE

SLOW

1

MGH084

Fig.5 DIDON (medium) acquisition flow chart.

January 1987 19

Page 20

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

handbook, full pagewidth

INITIALIZE CIDAC

FRAMING

CODE DETECT

A O.K.

LOAD FORMAT COUNTER

WITH INCOMING VALUE

FAST

SLOW/FAST

MODE

SAA5250

0

1

0

1

PAGE IN

PROGRESS

0

1

DECREMENT FORMAT COUNTER

SET PAGE IN PROGRESS FLAG

FORMAT

COUNTER = 0

0

START OF

PAGE DETECT

1

1

0

SLOW

WRITE FORMAT INTO FIFO

FORMAT

COUNTER = 0

0

DECREMENT FORMAT COUNTER.

WRITE DATA BYTES INTO FIFO

1

Fig.6 DIDON (short) acquisition flow chart.

January 1987 20

MGH083

Page 21

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

handbook, full pagewidth

INITIALIZE CIDAC

FRAMING

CODE DETECT

1

A1 O.K.

1

A2 O.K.

1

A3 O.K.

1

SAVE CI BYTES

SAA5250

0

0

0

0

DATA GROUP IN

PROGRESS

0

SYNCHRONIZING

PACKET

SET DATA GROUP IN

PROGRESS FLAG

LOAD FORMAT COUNTER

WITH IMPLICIT FORMAT

FAST

1

0

1

DECREMENT FORMAT COUNTER.

SLOW/FAST

MODE

SLOW

WRITE CI BYTE INTO FIFO

WRITE PS BYTE INTO FIFO

FORMAT

COUNTER = 0

0

WRITE DATA BYTES INTO FIFO

1

MGH082

Fig.7 NABTS acquisition flow chart.

January 1987 21

Page 22

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

handbook, full pagewidth

INITIALIZE CIDAC

FRAMING

CODE DETECT

1

MAG O.K.

1

SLOW/FAST

MODE

SAA5250

0

0

PAGE IN

PROGRESS

0

0

SET PAGE IN PROGRESS FLAG

ROW 0

1

SLOW

WRITE ROW NUMBER INTO FIFO

LOAD FORMAT COUNTER

WITH IMPLICIT FORMAT

FORMAT

COUNTER = 0

DECREMENT FORMAT COUNTER.

WRITE DATA BYTES INTO FIFO

MGH081

Fig.8 U.K. teletext acquisition flow chart.

January 1987 22

Page 23

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

handbook, halfpage

INITIALIZE CIDAC

FRAMING

CODE DETECT

1

LOAD FORMAT COUNTER

WITH EXPLICIT FORMAT

FORMAT

COUNTER = 0

0

DECREMENT FORMAT COUNTER.

WRITE DATA BYTES INTO FIFO

SAA5250

0

1

handbook, full pagewidth

DCK

SD

MGH080

Fig.9 Without prefix acquisition chart.

5

D

6

D

CBI

D = clamping diodes

CBI = clamping pulse, the pulse width

is given by the R7 register

clock input to

data acquisition

circuit

data input to

data acquisition

circuit

MGH076

Fig.10 SD and DCK input circuitry.

January 1987 23

Page 24

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

RATINGS

Limiting values in accordance with the Absolute Maximum System (IEC 134)

PARAMETER CONDITIONS SYMBOL MIN. MAX. UNIT

Supply voltage range V

Input voltage range V

Total power dissipation P

Operating ambient temperature range T

Storage temperature range T

DD

I

tot

amb

stg

D.C. CHARACTERISTICS (except SD and DCK)

= 5 V±10%; VSS = 0 V; T

V

DD

= 0 to 70 °C, unless otherwise specified

amb

PARAMETER CONDITIONS SYMBOL MIN. TYP. MAX. UNIT

Supply voltage range V

Input voltage HIGH V

Input voltage LOW V

Input leakage current I

Output voltage HIGH I

Output voltage LOW I

= 1 mA V

load

= 4 mA,

load

DD

IH

IL

I

OH

4,5 5,0 5,5 V

2 − V

−−0,8 V

−−1,0 µA

VDD−0,4 −−V

at pins 9 to 16

and 22 to 29 V

I

= 1 mA all

load

other outputs V

OL

OL

−−0,4 V

−−0,4 V

Power dissipation P − 5 − mW

Input capacitance C

I

−−7,5 pF

−0,3 6,5 V

−0,3 VDD+0,3 V

− 400 mW

070°C

−20 +125 °C

DD

V

January 1987 24

Page 25

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

SD and DCK D.C. CHARACTERISTICS (see Fig.10)

= 5 V; VSS = 0 V; T

V

DD

PARAMETER CONDITIONS SYMBOL MIN. TYP. MAX. UNIT

DCK

Input voltage range

(peak-to-peak value)

Input current V

Input capacitance C

External coupling capacitor C

SD

D.C. input voltage range HIGH note 1 V

D.C. input voltage range LOW note 2 V

A.C. input voltage

(peak-to-peak value)

Input leakage current V

Input capacitance C

External coupling capacitor C

= 0 to 70 °C, unless otherwise specified

amb

V

I(p-p)

= 0 to V

I

= 0 to V

I

DD

DD

I

V

I

I

I

text

IH

IL

I(p-p)

I

I

ext

SAA5250

2,0 −−V

5 − 200 µA

−−30 pF

10 −−nF

2,0 −−V

−−0,8 V

2,0 −−V

−−10 µA

−−30 pF

10 −−nF

January 1987 25

Page 26

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

A.C. CHARACTERISTICS

= 5 V ± 10%; Reference levels for all inputs and outputs, VIH = 2 V; VIL = 0,8 V; VOH = 2,4 V; VOL = 0,4 V;

V

DD

= 50 pF on DB7 to DB0; T

C

L

PARAMETER CONDITIONS SYMBOL MIN. TYP. MAX. UNIT

Microcontroller

interface

Cycle time t

Address pulse width t

RD HIGH or WR to ALE HIGH Fig.11 t

DS LOW to AS HIGH Fig.12 t

ALE LOW to

RD

LOW or WR LOW

AS LOW to DS HIGH Fig.12 t

Write pulse width t

Address and chip select

set-up time

Address and chip select hold

time

Read to data out period t

Data hold after

R/

W to DS set-up time Fig.12 t

R/

W to DS hold time Fig.12 t

RD t

Data set-up time write cycle t

Data hold time write cycle t

Read pulse width note 3 t

= 0 to 70 = C, unless otherwise specified

amb

Figs 11 and 12

CY

LHLL

AHRD

AHRD

Fig.11 t

ALRD

ALRD

WL

t

ASL

t

AHL

RD

DR

RWS

RWH

DW

WD

RL

400 −−ns

50 −−ns

0 −−ns

0 −−ns

30 −−ns

30 −−ns

120 −−ns

10 −−ns

20 −−ns

−−130 ns

10 − 100 ns

40 −−ns

10 −−ns

50 −−ns

10 −−ns

150 or

DCK + 50

−−ns

SAA5250

Memory interface

WE LOW to DCK falling edge t

WE HIGH to DCK falling edge t

MS LOW to DCK rising edge t

MS HIGH to DCK rising edge t

Address output from DCK

Fig.13

WEL

WEH

MSL

MSH

t

AV

rising edge

Data output from

WE falling

t

DWL

edge

Data hold from

Address set-up time to data note 4 t

WE pulse width note 5 t

MS pulse width note 6 t

WE rising edge t

DWH

AD

WEW

MSW

January 1987 26

10 − 80 ns

10 − 80 ns

10 − 80 ns

10 − 85 ns

10 − 120 ns

0 − 10 ns

0 −−ns

−−3×DCK

−110 ns

3 × DCK −−ns

2 × DCK −−ns

Page 27

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

PARAMETER CONDITIONS SYMBOL MIN. TYP. MAX. UNIT

Demodulator interface

(see SD and DCK D.C.

CHARACTERISTICS) Fig.14

DCK LOW conversion

rate < 7,5 MHz t

DCKL

DCK HIGH conversion

rate < 7,5 MHz t

Serial data set-up time t

Serial data hold time t

Validation signal set-up time t

Validation signal hold time t

Other I/O signals

Fig.15

DCKH

SSD

HSD

SVALI

HVALI

User definable width as a

multiple of DCK period t

Validation signal width note 7 t

WCBB

WVAL

User definable delay as a

multiple of DCK period t

DVAL

Notes to the characteristics

1. Unless R7 = 00 the value given is unacceptable.

2. When CBI signal is maintained at 0 V (R7 = 00) and if SD input signal is correctly referenced to ground, no coupling

capacitor is required.

3. DCK + 50 is the DCK period plus 50 ns.

4. 3 × DCK − 110 is 3 × DCK period − 110 ns.

5. 3 × DCK is 3 × DCK period.

6. 2 × DCK is 2 × DCK period.

7. X = irrelevant.

55 −−ns

55 −−ns

0 −−ns

30 −−ns

50 −−ns

50 −−ns

0 − 63 DCK

X 12 X DCK

0 − 127 DCK

January 1987 27

Page 28

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

handbook, full pagewidth

READ CYCLE

ALE

RD

WR

CS

t

AHRD

t

LHLL

t

ASL

t

ALRD

t

AHL

t

RD

t

t

CY

RL

SAA5250

t

DR

BUS

WRITE CYCLE

ALE

WR

RD

CS

BUS

t

AHRD

t

AHRD

ADDRESS D OUT

t

CY

t

LHLL

t

ASL

ADDRESS D IN

t

ALRD

t

AHL

t

WL

t

DW

t

WD

MGH087

Fig.11 Timing diagram for microcontroller interface (Intel).

January 1987 28

Page 29

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

AHRD

t

RWH

t

t

WD

t

DW

D IN

t

DR

SAA5250

MGH085

D OUT

CY

t

ALRD

t

AHRD

t

DS

(pin RD)

handbook, full pagewidth

LHLL

t

(1)

AS

(pin ALE)

RD

t

ALE, CS, RD, WR and DB7 to DB0

(1)

AHL

t

RWS

t

ASL

t

AHL

t

ASL

t

(1)

Fig.12 Timing diagram for microcontroller interface (Motorola).

BUS

read cycle

R/W

(pin WR)

BUS

CS

write cycle

January 1987 29

Page 30

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

WRITE ADDRESS

SAA5250

MGH086

DATA OUTDATA IN

handbook, full pagewidth

character

period

DCK

WEH

t

WEL

t

WEW

t

WE

MSH

t

MSW

t

MS

MSL

t

MSL

t

READ ADDRESS

AV

t

WRITE ADDRESS

AV

t

A10 to A0

t

DWH

t

DWL

t

AD

Fig.13 Timing diagram for memory interface.

DATA OUT

D7 to D0

January 1987 30

Page 31

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

t

handbook, full pagewidth

DCK

SD

VAL IN/

SYNC

Fig.14 Timing diagram for demodulator interface.

DCKL

t

SSD

t

SVALI

t

DCKH

t

HSD

t

HVALI

SAA5250

MGH079

handbook, full pagewidth

DCK

VAL IN /

SYNC

SD

VAL OUT

CBB

VAL, CBB

t

WCBB

CLOCK SYNCHRONIZATION

t

DVAL

BITS

FRAMING

CODE

PREFIX AND DATA BYTES

t

WVAL

Fig.15 Timing diagram for all other I/O signals.

MGH078

January 1987 31

Page 32

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

PACKAGE OUTLINES

DIP40: plastic dual in-line package; 40 leads (600 mil)

D

seating plane

L

Z

40

e

b

SAA5250

SOT129-1

M

E

A

2

A

A

1

w M

b

1

21

c

(e )

1

M

H

pin 1 index

1

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

A

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

max.

mm

1 2

min.

max.

b

1.70

1.14

0.067

0.045

b

0.53

0.38

0.021

0.015

cD E e M

1

0.36

0.23

0.014

0.009

52.50

51.50

2.067

2.028

14.1

13.7

0.56

0.54

E

20

(1)(1)

e

L

1

3.60

3.05

0.14

0.12

M

15.80

15.24

0.62

0.60

E

17.42

15.90

0.69

0.63

H

w

0.2542.54 15.24

0.010.10 0.60

max.

2.254.7 0.51 4.0

0.089 0.19 0.020 0.16

(1)

Z

OUTLINE

VERSION

SOT129-1

IEC JEDEC EIAJ

051G08 MO-015AJ

REFERENCES

January 1987 32

EUROPEAN

PROJECTION

ISSUE DATE

92-11-17

95-01-14

Page 33

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

VSO40: plastic very small outline package; 40 leads

D

y

Z

40

SAA5250

SOT158-1

E

c

H

E

21

A

X

v M

A

pin 1 index

1

e

0 5 10 mm

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

A

max.

2.70

0.11

0.3

0.1

0.012

0.004

2.45

2.25

0.096

0.089

3

0.25

0.010

b

0.42

0.30

0.017

0.012

p

0.22

0.14

0.0087

0.0055

UNIT A1A2A

inches

Notes

1. Plastic or metal protrusions of 0.4 mm maximum per side are not included.

2. Plastic interlead protrusions of 0.25 mm maximum per side are not included.

(1)E(2)

cD

15.6

15.2

0.61

0.60

20

w M

b

p

scale

eHELLpQywv θ

7.6

0.762 2.25

7.5

0.30

0.03 0.089

0.29

12.3

11.8

0.48

0.46

Q

A

2

A

1

1.7

1.5

0.067

0.059

detail X

1.15

0.2

1.05

0.045

0.008 0.004

0.041

L

p

L

0.1 0.1

0.004

(A )

A

3

θ

(1)

Z

0.6

0.3

0.024

0.012

o

7

o

0

OUTLINE

VERSION

SOT158-1

IEC JEDEC EIAJ

REFERENCES

January 1987 33

EUROPEAN

PROJECTION

ISSUE DATE

92-11-17

95-01-24

Page 34

Philips Semiconductors Product specification

Interface for data acquisition and control

(for multi-standard teletext systems)

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

“IC Package Databook”

our

DIP

SOLDERING BY DIPPING OR BY WAVE

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

SO and VSO

REFLOW SOLDERING

Reflow soldering techniques are suitable for all SO and

VSO packages.

(order code 9398 652 90011).

). If the

stg max

SAA5250

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

AVE SOLDERING

W

Wave soldering techniques can be used for all SO and

VSO packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

EPAIRING SOLDERED JOINTS

R

Fix the component by first soldering two diagonally-

opposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

January 1987 34

Page 35

Philips Semiconductors Product specification

Interface for data acquisition and control

SAA5250

(for multi-standard teletext systems)

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

January 1987 35

Loading...

Loading...