Page 1

INTEGRATED CIRCUITS

DATA SH EET

SAA4997H

VErtical Reconstruction IC (VERIC)

for PALplus

Preliminary specification

File under Integrated Circuits, IC02

1996 Oct 24

Page 2

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

SAA4997H

PALplus

FEATURES

• PALplus decoding

• Vertical reconstruction

• Quadrature mirror filter

• Luminance and chrominance processing

• Controlling.

QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. MAX. UNIT

V

DD

T

amb

ORDERING INFORMATION

TYPE

NUMBER

SAA4997H QFP64

supply voltage − 5.25 V

operating ambient temperature 0 70 °C

NAME DESCRIPTION VERSION

plastic quad flat package; 64 leads (lead length 1.95 mm); body 14 × 20 × 2.8 mm SOT319-2

GENERAL DESCRIPTION

The VErtical Reconstruction IC (VERIC) for PALplus

(VERIC) is especially designed for use in conjunction with

the Motion Adaptive Colour Plus And Control IC

(MACPACIC) to decode the transmitted PALplus video

signal in PALplus colour TV receivers. It provides the full

vertical resolution of a PALplus picture from the letter box

part and the decoded helper information.

PACKAGE

1996 Oct 24 2

Page 3

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

BLOCK DIAGRAMS

Y_VE_0 to 7

8

36

CLK_32B3

23

CLK_16B2

SAA4997H

UV

F/C

U/V_VE_0/1

4

FORMATTER

bypass

OE_FM2

RSTR_FM23

39

56

54

multi-PIP

OE_FM3

RE_FM2

40

55

TRSTN

TDO_VE

RE_FM3

30

29

BOUNDARY SCAN TEST

28 26 27

SAA4997H

MGE443

handbook, full pagewidth

mode select

F/C

LUMINANCE

(QM-FILTER)

PROCESSING

PIXEL

SELECT

8

multi-PIP

bypass

DELAY

COMPENSATOR

8

8

(LP-FILTER)

PROCESSING

CHROMINANCE

8

8

UV

REFORMATTER

PIXEL

SELECT

4

4

19

5

FM-control

UV-control

Y - UV - FM

Y-control

LINE COUNTER

CONTROL LOGIC

DECODER

PIXEL COUNTER

17

Fig.1 Block diagram.

EVEN_FIELD TDI TCK TMS

INTPOL

21 20 22

FILM

DECODER

Y_FM23_0 to 7

U/V_FM23_0/1

1996 Oct 24 3

VA_AI

HREF_MA

Page 4

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

Vertical

VERIC

Reconstruction IC

CLK_32B1

U_FM23_0,1

V_FM23_0,1

Y_FM23_0 to 7

4

8

8

4

FM2

TMS4C2970

V_VE_[0,1]

U_VE_[0,1]

8

4

V_VE_0,1

U_VE_0,1

Y_VE_0 to 7 Y_VE_[0 to 7]

8

4

FM3

TMS4C2970

TDO_VE

4

4

DD1-4

V

V

CLK_32B3

OE_FM3

OE_FM2

- Inverse QMF

reconstruction

SS1-4

CLK_16B2

CLK_32B3

RE_FM2

RE_FM3

RSTR_FM23

filter- Vertical

chrominance

FILM

VA_AI

HREF_MA

SRC- FM2/FM3

read control

TDI

TRSTN

INTPOL

EVEN_FIELD

TMS

3

TCK

SAA4997H

MGE444

11

NC

TEST1-3

ok, full pagewidth

CLK_16B1, 2, 3

3

3

MACPACIC

and Control IC

Motion Adaptive Colour Plus

Y_ADC_0 to 7

8

4

8

CLK_32B1, 2, 3

8

Y_FM1_0 to 7

8

TMS4C2970

8

4

U_MA_0,1

Y_MA_0 to 7

U_FM1_0,1

V_FM1_0,1

4

SRCK

FM1

SWCK

4

8

V_MA_0,1

U_ADC_0,1

4

CLK_16 CLK_16B1

(1)

(1)

Y_TO_FM1_0 to 7

U_TO_FM1_0

WE_FM2

U_TO_FM1_1

RSTW_FM23

- BB-decompanding

- Motion adaptive

V_ADC_0,1

5

5

SS1-5

DD1-5

V

V

CLK_16

CLK_32

(1)

WE_FM3

V_TO_FM1_1

V_TO_FM1_0

WE_FM1, RE_FM1

2

luminance/chrominance

separation

- Memory control

CLAMP

VA_FRONT

WE_FRONT

VA_AI

WE_FM4, RE_FM4

RST_FM14

2

- PALplus control

- Clock generation

SNERT_CL

SNERT_DA

SNERT_RST

HREF_MA

WE_MA

FILM

EVEN_FIELD

INTPOL

- Sync generation

- SNERT interface

3

TDI

TCK

TMS

TRSTN

TEST1-3

TDO_MA

4

V_FM4_0,1

U_FM4_0,1

4

V_TO_FM4_0,1

U_TO_FM4_0,1

(2)

VERIC_AV_N

CLK_16B1

FM4

TMS4C2970

Fig.2 Block diagram of the PALplus decoder module.

.

SS

Y_FRONT[0 to 7]

V_FRONT[0,1]

U_FRONT[0,1]

1996 Oct 24 4

(1) In case of stand alone MACPACIC the output signals are U_TO_FM1_1, V_TO_FM1_0 or V_TO_FM1_1; otherwise the output signals are WE_FM2, RSTW_FM23 or WE_FM3.

(2) VERIC available: VERIC_AV_N is connected to V

Page 5

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

SAA4997H

PALplus

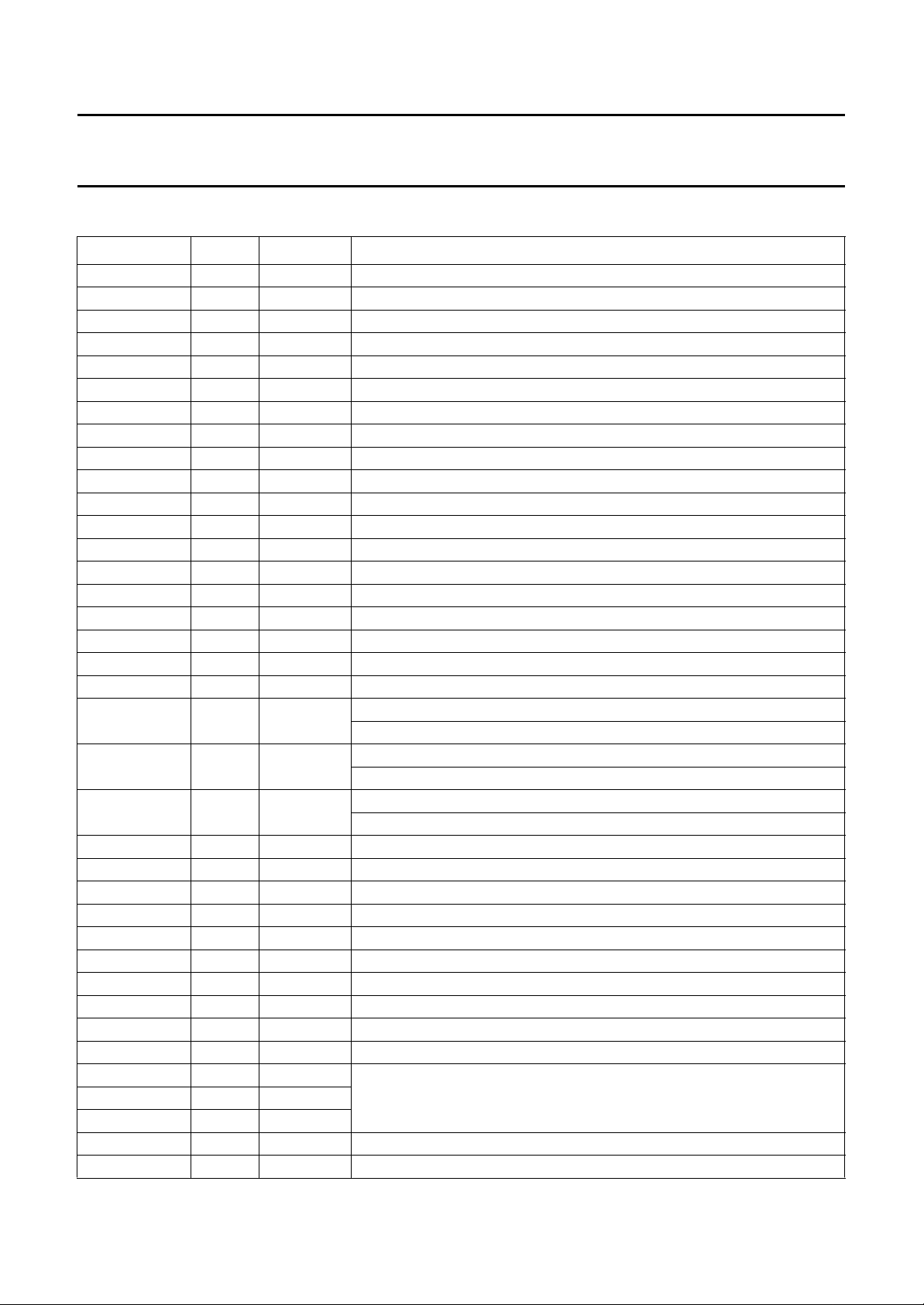

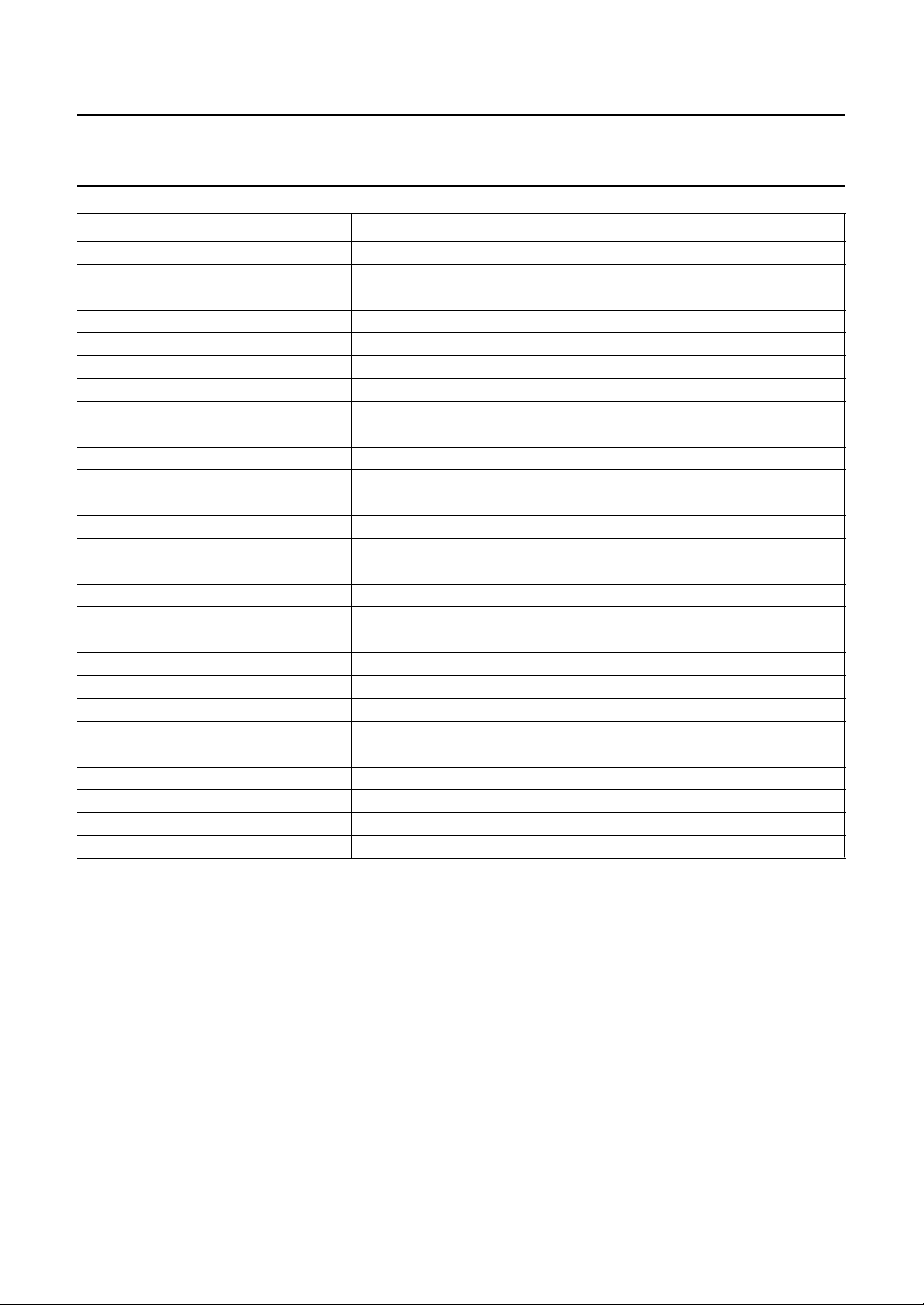

PINNING

SYMBOL PIN TYPE DESCRIPTION

Y_VE_1 1 output luminance output data bit 1

Y_VE_0 2 output luminance output data bit 0

U_VE_1 3 output chrominance output data bit 1 U-component

U_VE_0 4 output chrominance output data bit 0 U-component

V_VE_1 5 output chrominance output data bit 1 V-component

V_VE_0 6 output chrominance output data bit 0 V-component

V

SS1

V

DD1

n.c. 9 − not connected

n.c. 10 − not connected

n.c. 11 − not connected

n.c. 12 − not connected

n.c. 13 − not connected

n.c. 14 − not connected

n.c. 15 − not connected

n.c. 16 − not connected

HREF_MA 17 input horizontal reference

n.c. 18 − not connected

VA_AI 19 input vertical reference pulse related to output data

INTPOL 20 input INTPOL = 1: PALplus interpolation active

FILM 21 input FILM = 0: CAMERA mode

EVEN_FIELD 22 input EVEN_FIELD = 0: odd field related to MACPACIC input data

CLK_16B2 23 input buffered clock input (16 MHz)

V

SS2

V

DD2

TCK 26 input boundary scan test clock input

TMS 27 input boundary scan test mode select input

TDI 28 input boundary scan test data input

TDO_VE 29 output boundary scan test data output

TRSTN 30 input boundary scan test reset input

n.c. 31 − not connected

n.c. 32 − not connected

TEST1 33 tbf test pins

TEST2 34 tbf

TEST3 35 tbf

CLK_32B3 36 input buffered clock input (32 MHz)

V

SS3

7 input ground 1

8 input positive supply voltage 1 (+5 V)

INTPOL = 0: VERIC switched to bypass mode (standard signal)

FILM = 1: FILM mode

EVEN_FIELD = 1: even field related to MACPACIC input data

24 input ground 2

25 input positive supply voltage 2 (+5 V)

37 input ground 3

1996 Oct 24 5

Page 6

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

SYMBOL PIN TYPE DESCRIPTION

V

DD3

OE_FM3 39 output output enable field memory 3

RE_FM3 40 output read enable field memory 3

V_FM23_1 41 input chrominance input data bit 1 V-component

V_FM23_0 42 input chrominance input data bit 0 V-component

U_FM23_1 43 input chrominance input data bit 1 U-component

U_FM23_0 44 input chrominance input data bit 0 U-component

Y_FM23_7 45 input Y input data bit 7

Y_FM23_6 46 input Y input data bit 6

Y_FM23_5 47 input Y input data bit 5

Y_FM23_4 48 input Y input data bit 4

Y_FM23_3 49 input Y input data bit 3

n.c. 50 − not connected

Y_FM23_2 51 input Y input data bit 2

Y_FM23_1 52 input Y input data bit 1

Y_FM23_0 53 input Y input data bit 0

RSTR_FM23 54 output reset read field memory 2 and 3

RE_FM2 55 output read enable field memory 2

OE_FM2 56 output output enable field memory 2

V

DD4

V

SS4

Y_VE_7 59 output luminance output data bit 7

Y_VE_6 60 output luminance output data bit 6

Y_VE_5 61 output luminance output data bit 5

Y_VE_4 62 output luminance output data bit 4

Y_VE_3 63 output luminance output data bit 3

Y_VE_2 64 output luminance output data bit 2

38 input positive supply voltage 3 (+5 V)

57 input positive supply voltage 4 (+5 V)

58 input ground 4

SAA4997H

1996 Oct 24 6

Page 7

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

handbook, full pagewidth

Y_VE_3

Y_VE_4

62

Y_VE_5

Y_VE_6

61

60

SAA4997H

Y_VE_1

Y_VE_0

U_VE_1

U_VE_0

V_VE_1

V_VE_0

V

SS1

V

DD1

n.c.

n.c.

n.c.

n.c.

n.c.

n.c.

n.c.

n.c

HREF_MA

n.c.

VA_AI

Y_VE_2

64

63

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

V

Y_VE_7

59

58

SS4

DD4

V

57

OE_FM2

RE_FM2

56

55

RSTR_FM23

Y_FM23_0

54

53

Y_FM23_1

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

Y_FM23_2

n.c.

Y_FM23_3

Y_FM23_4

Y_FM23_5

Y_FM23_6

Y_FM23_7

U_FM23_0

U_FM23_1

V_FM23_0

V_FM23_1

RE_FM3

OE_FM3

V

DD3

V

SS3

CLK_32B3

TEST3

TEST2

TEST1

SAA4997H

20

21

22

23

24

25

SS2

FILM

INTPOL

CLK_16B2

EVEN_FIELD

DD2

V

V

Fig.3 Pin configuration.

1996 Oct 24 7

26

TCK

27

TMS

28

TDI

29

30

TRSTN

TDO_VE

31

n.c.

32

n.c.

MGE442

Page 8

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

FUNCTIONAL DESCRIPTION

Introduction

As shown in Fig.2 the PALplus module consists of two

special integrated circuits:

• Motion Adaptive Colour Plus And Control IC

(MACPACIC)

• VErtical Reconstruction IC (VERIC)

and four field memories TMS4C2970.

The MACPACIC and the VERIC are intended to generate

digitally decoded 50 Hz YUV signals. The MACPACIC

performs the decompanding function for the helper lines

and the motion adaptive luminance/chrominance

separation. Furthermore, PALplus system controlling,

memory controlling and clock generation are carried out in

this circuit.

The function of the VERIC is to reconstruct the separated

2 × 72 helper lines and the 430 main lines into a standard

576 lines frame according the PALplus system description

“REV 2.0”

576 lines using a vertical sample rate converter.

The data of the VERIC are clocked out with 16 MHz.

The Y :U:V bandwidth ratio is 4:1:1.

The functional block diagram of the VERIC is shown in

Fig.1. The device consists of 3 main parts:

• Luminance processing

• Chrominance processing

• Controlling.

. Chrominance is converted from 430 lines to

SAA4997H

The luminance vertical conversion process in the decoder

is complementary to that of the encoder.

In the decoder the inverse QMF function is implemented to

recombine the two separated sub-bands and to generate

the original video signal with 576 active lines per frame.

Each output line is calculated from up to seven input lines

stored in line memories containing main or helper

information. The various lines are multiplied by switched

coefficients, changing every line within a sequence of four

lines, depending on the specific mode (CAMERA or FILM).

In case of standard PAL reception, the VERIC is switched

to bypass mode controlled by the signal INTPOL.

For multi-PIP processing the VERIC is also switched to

bypass mode, but controlling of FM2/3 is different (see

Fig.6). The total signal delay between the MACPACIC

input and the VERIC output is one line for this mode.

FM2/3 are driven with 32 MHz clock frequency.

The non-multiplexed input data are clocked out with

16 MHz.

Chrominance processing

The chrominance processing is carried out by the vertical

interpolation filter (poly phase filter).

In CAMERA and FILM mode, intra-field vertical sample

rate conversion is carried out.

One output line is calculated out of three or four lines in

CAMERA or FILM mode using different coefficients or

passed through in bypass mode.

The input data are delivered by the field memories FM2

and FM3, which include multiplexed first and second field

data processed by the MACPACIC. The luminance and

chrominance input data of the VERIC are clocked with

32 MHz (CLK_32B3). Internally the device operates at

32 or 16 MHz clock frequency.

Luminance processing

In the PALplus encoder the luminance signal is separated

vertically into two sub-bands by a special Quadrature

Mirror Filter (QMF).

A vertical low-pass sub-band consists of the 430 main

letter box lines per frame, and a vertical high-pass

sub-band includes the 144 helper lines per frame.

The used QMF technique has two advantages:

• Essentially loss-free data processing

• Cancellation of alias components in the main and helper

signal in the decoder.

1996 Oct 24 8

Control functions

The VERIC controller generates the necessary internal

control signals for the line memories, formatters,

reformatters, the selector signals for the multiplexers and

the read signals for the field memories FM2/3.

The system control input signals EVEN_FIELD, INTPOL

and FILM are derived from the control part of the

MACPACIC. The field selection information EVEN_FIELD

is related to the input data of the MACPACIC and is

adapted in the VERIC to its input data.

The control functions are described in Tables 1 and 2.

Table 1 EVEN_FIELD

VALUE STATUS

EVEN_FIELD = 1 even field selected

EVEN_FIELD = 0 odd field selected

Page 9

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

Table 2 INTPOL and FILM

VALUE STATUS

INTPOL = 0 FILM = 0 bypass mode;

standard signals

INTPOL = 1 FILM = 0 interpolation active;

PALplus CAMERA mode

INTPOL = 0 FILM = 1 bypass mode; multi-PIP

INTPOL = 1 FILM = 1 interpolation active;

PALplus FILM mode

Modes and delays

The PALplus module can operate in two different

hardware configurations:

• Full PALplus configuration (MACPACIC and VERIC)

• Stand alone MACPACIC.

The vertical interpolation of the VERIC can be activated by

the signal INTPOL depending on the PALplus signalling

bits, transmitted in line 23 indicating the type of signal

being received.

However, the delay between input data of the MACPACIC

and output data of the VERIC always has to be 1.5 fields.

This is achieved with a suitable read timing of the field

memories FM2 and FM3 controlled by VA_AI which is

derived from the field length measurement in the

MACPACIC.

In case of INTPOL = LOW and additionally FILM = HIGH

(FILM mode), the VERIC is switched to multi-PIP mode.

In case the delay between input of the MACPACIC and

output of the VERIC is one line (1024 CLK_16 periods).

SAA4997H

Table 3 Delays

MODE FIELD VERIC I/O DELAY

FILM mode first 2 lines

second 3 lines

CAMERA mode first 3 lines

second 4 lines

Input/Output formats

NPUT FORMATS

I

The luminance input range of the main and helper signal

has the following values:

Main signal: black = 16, white = 191 (straight binary)

Helper signal: ±70, mid = 128 (straight binary)

Chrominance format: ±90, mid = 0 (two’s complement).

UTPUT FORMATS

O

Luminance format: black = 16, white = 191 (straight

binary)

Blanking: code 16

Chrominance format: ±90, mid = 0 (two’s complement)

Blanking: code 0.

Test activities

The pins TEST1, TEST2 and TEST3 are provided to

perform the IC test activities, such as scan test.

The pins TRSTN, TDI, TMS, TCK and TDO_VE are

intended for a boundary scan test.

The line and pixel timings of the VERIC are shown in

Figures 5 to 14.

1996 Oct 24 9

Page 10

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

SAA4997H

PALplus

DC CHARACTERISTICS

Tj= 0 to 125 °C

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

DD

I

DD

I

DD(q)

Inputs

V

IL

V

IH

I

LI

Outputs

V

OL

V

OH

I

OL

I

OH

supply voltage 4.75 5.0 5.25 V

supply current VDD=5V −− 80 mA

quiescent supply current all inputs to VDD or VSS−− 100 µA

LOW level input voltage −0.5 − +0.8 V

HIGH level input voltage 2.0 − V

DD

V

input leakage current −− 1.0 µA

LOW level output voltage IO=20µA −− 0.1 V

HIGH level output voltage IO=20µAV

− 0.1 −−V

DD

LOW level output current VO= 0.5 V 4.0 −−mA

HIGH level output current VO=VDD− 0.5 V 4.0 −−mA

AC CHARACTERISTICS

Tj= 0 to 125 °C

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Clock timing CLK_32B3 (see Fig.4)

T

CY(32)

t

H

t

L

t

r

t

f

∆f

clk

cycle time 28.1 31.25 − ns

HIGH time 9.2 −−ns

LOW time 9.2 −−ns

rise time 2.0 − 4.0 ns

fall time 2.0 − 4.0 ns

deviation of clock frequency −10 − +10 %

Clock timing CLK_16B2 (see Fig.4)

T

CY(16)

t

H

t

L

t

r

t

f

δ duty cycle 40 − 50 %

cycle time 56.2 −−ns

HIGH time 20.5 −−ns

LOW time 20.5 −−ns

rise time 2.0 − 4.0 ns

fall time 4.0 − 4.0 ns

t

H

δ

=

---- t

L

1996 Oct 24 10

Page 11

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

SAA4997H

PALplus

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Input data timing (CLK_32)

t

su

t

h(i)

Input control timing (CLK_16B2)

HREF_MA, VA_AI, FILM, EVEN_FIELD

t

su

t

h(i)

Output data timing (CLK_16B2)

AND UV_FM23

Y

t

h(o)

t

d(o)

Output control timing (CLK_32B3)

input data set-up time

CLK_16B2 −4.7 −−ns

Y and UV_FM23 −0.8 −−ns

input data hold time

CLK_16B2 5.1 −−ns

Y and UV_FM23 5.2 −−ns

AND INTPOL

input data set-up time 4.5 −−ns

input data hold time 0.1 −−ns

output data hold time CL=15pF 8 −−ns

output data delay time CL=15pF −− 27 ns

OE_FM2, OE_FM3, RE_FM2, RE_FM3

t

h(o)

t

d(o)

output data hold time CL=15pF 5 −−ns

output data delay time CL=15pF −− 20 ns

Delays

t

w(HREF)

t

d(RE)

HREF_MA pulse width − 60 × T

delay

RE_FM2/3 to HREF_MA

t

w(RE)

t

d(VE)(MA)

t

d(VE)

t

d(VE)

t

d(RSTR)

t

d(FM2)

RE_FM2/3 pulse width − 1680 × T

delay HREF_MA to YUV_VE − 80 × T

delay data input to output − 16 × T

delay data input to output multi-PIP − 2 × T

delay RSTR multi-PIP − 2016 × T

delay FM2 input to output multi-PIP − 2040 × T

AND RSTR_FM23

− 127 × T

CY(16)

CY(16)

CY(32)

CY(32)

CY(16)

CY(16)

CY(32)

CY(32)

− ns

− ns

− ns

− ns

− ns

− ns

− ns

− ns

1996 Oct 24 11

Page 12

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

TIMING

90%

50%

10%

Dn

t

r

t

h(o)

handbook, full pagewidth

CLK

DATA/CONTROL

SAA4997H

t

f

t

H

XX

t

d(o)

t

L

D(n+1)

t

h(i)

t

su

MGE445

Data input: CLK =CLK_32B3

Data output: CLK =CLK_16B2

Control input: CLK =CLK_16B2

Control output: CLK =CLK_32B3

Fig.4 Data/control input/output set-up and hold timing.

1996 Oct 24 12

Page 13

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

SAA4997H

MGE446

handbook, full pagewidth

w(HREF)

t

w(RE)

t

d(RE)

t

CY(32)

1 × T

d(VE)

t

d(VE)(MA)

t

Fig.5 Pixel timing (except multi-PIP mode).

CLK_32B3

CLK_16B2

HREF_MA

1996 Oct 24 13

RE_FM2/3

Y(U/V)_FM23

Y(U/V)_VE

Page 14

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

3

3

1122

SAA4997H

MGE447

23

1

d(VE)

t

handbook, full pagewidth

d(RSTW)

t

d(RSTR)

t

d(FM2)

t

33

22

3

2

1

d(MA)

t

11

1024 pixels

Fig.6 Pixel timing multi-PIP mode (MACPACIC input to VERIC output).

VA_AI

CLK_16B2

CLK_32B3

RSTW_FM2

RSTR_FM2

1996 Oct 24 14

YUV_ADC

YUV_MA

YUV_FM2

YUV_VE

WE_FM2 and RE_FM2 are constant HIGH; YUV_MA =MACPACIC input.

Page 15

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

B

Y839

U1

836B

U0

836B

V1

836B

V0

SAA4997H

MGE448

836B

handbook, full pagewidth

Y0A Y0B Y1A Y1B Y2A Y2B Y3A Y3B Y4A Y4B Y5A Y5B Y6A Y6B Y7A Y7B Y8A Y8B

U70A U50A U30A U10A U70B U50B U30B U10B U74A U54A U34A U14A U74B U54B U34B U14B U78A U58A

U60A U40A U20A U00A U60B U40B U20B U00B U64A U44A U24A U04A U64B U44B U24B U04B U68A U48A

V70A V50A V30A V10A V70B V50B V30B V10B V74A V54A V34A V14A V74B V54B V34B V14B V78A V58A

V60A V40A V20A V00A V60B V40B V20B V00B V64A V44A V24A V04A V64B V44B V24B V04B V68A V48A

field

V 6 0 A

input signal

Fig.7 Input data timing (except multi-PIP mode).

word

bit

CLK_32B3

RE_FM2/3

Y_FM23(0-7)

1996 Oct 24 15

U_FM23_1

U_FM23_0

V_FM23_1

V_FM23_0

Page 16

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

16

Y

839

0

U1

836

SAA4997H

MGE449

0

U0

836

0

V1

836

0

V0

836

handbook, full pagewidth

Fig.8 Output data timing.

Y0 Y1 Y2 Y3 Y4 Y5 Y6 Y7 Y8

16

U70 U50 U30 U10 U74 U54 U34 U14 U78

0

U60 U40 U20 U00 U64 U44 U24 U04 U68

0

V70 V50 V30 V10 V74 V54 V34 V14 V78

0

V60 V40 V20 V00 V64 V44 V24 V04 V68

0

word

V 6 0

input signal

bit

CLK_16B2

Y_VE(0-7)

U_VE_1

1996 Oct 24 16

U_VE_0

V_VE_1

V_VE_0

Page 17

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

311/623

145 lines

SAA4997H

MGE450

handbook, full pagewidth

20 lines

166/478 167/479

146 lines

multiplexed active lines from FM23

21/333

166 167 311

24232221 25 26 27

Fig.9 Line read timing FM2/3 bypass mode standard signal, first field.

VA_AI

YUV_FM23(0-7)

OE_FM2

1996 Oct 24 17

RE_FM2

OE_FM3

RE_FM3

Y/UV_VE

Page 18

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

311/623

145 lines

SAA4997H

MGE451

handbook, full pagewidth

19 lines field B

166/478 167/479

146 lines

multiplexed active lines from FM23

21/333

478 479 623

336335334333 337 338 339

Fig.10 Line read timing FM2/3 bypass mode standard signal, second field.

VA_AI

YUV_FM23(0-7)

OE_FM2

1996 Oct 24 18

RE_FM2

OE_FM3

RE_FM3

Y/UV_VE

Page 19

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

SAA4997H

MGE452

ll pagewidth

21 22 23 24 25 26 27 161 162 163 164 165 166 167 302 303 304 305 306 307 308 309 310

VERIC

line counter

M11,10

(1)

H3,4

M3,2 M5,4H1,2 M7,6 M9,8

Y_FM23

UV11,10

UV3,2 UV5,4 UV7,6 UV9,8

U/V_FM23

OE_FM3

RE_FM3

OE_FM2

RE_FM2

161 162 163 164 165 166 167 302 303 304 305 306 307 308 309 310

Fig.11 Line read timing FM2/3 CAMERA mode, first field.

2423 25 26 27

Y/UV_VE

1996 Oct 24 19

(1) M = main line and H = helper line.

Page 20

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

SAA4997H

MGE453

handbook, full pagewidth

20 21 22 23 24 25 26 160 161 162 163 164 165 166 301 302 303 304 305 306 307 308 309 310

VERIC

line counter

H3,4

M11,10

M3,2 M5,4 H1,2 M7,6 M9,8

(1)

Y_FM23(0-7)

3,2 5,4 7,6 9,8 11,12

OE_FM3

U/V_FM23(0-1)

RE_FM3

OE_FM2

RE_FM2

476 477 478 479 480 481 482 614 615 616 617 618 619 620 621 622 623

Fig.12 Line read timing FM2/3 CAMERA mode, second field.

336 337 338 339

Y/UV_VE

1996 Oct 24 20

(1) M = main line and H = helper line.

Page 21

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

SAA4997H

MGE454

handbook, full pagewidth

M11,10

(1)

H3,4

M5,4

H1,2 M7,6 M9,8

M3,2

Y_FM23

UV11,10

UV3,2 UV5,4 UV7,6 UV9,8

U/V_FM23

OE_FM3

RE_FM3

OE_FM2

RE_FM2

162 163 164 165 166 167 168 303 304 305 306 307 308 309 310

Fig.13 Line read timing FM2/3 FILM mode, first field.

252423 26 27 28

Y/UV_VE

1996 Oct 24 21

(1) M = main line and H = helper line.

Page 22

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

SAA4997H

MGE455

handbook, full pagewidth

M11,10

H3,4

M7,6 M9,8

H1,2

M3,2 M5,4

(1)

Y_FM23(0-7)

OE_FM3

RE_FM3

OE_FM2

RE_FM2

474 475 476 477 478 479 480 615 616 617 618 619 620 621 622 623

Fig.14 Line read timing FM2/3 FILM mode, second field.

336 337 338 339 340

Y/UV_VE

1996 Oct 24 22

(1) M = main line and H = helper line.

Page 23

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

PACKAGE OUTLINE

QFP64: plastic quad flat package; 64 leads (lead length 1.95 mm); body 14 x 20 x 2.8 mm

c

y

X

51 33

52

32

Z

A

E

SAA4997H

SOT319-2

pin 1 index

64

1

w M

b

e

DIMENSIONS (mm are the original dimensions)

mm

A

max.

3.20

0.25

0.05

2.90

2.65

0.25

UNIT A1A2A3b

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

p

D

H

D

cE

0.25

0.14

D

20.1

19.9

p

0.50

0.35

0 5 10 mm

(1)

(1) (1)(1)

14.1

13.9

19

Z

D

scale

eH

H

24.2

1

23.6

20

D

B

e

H

E

w M

b

p

v M

A

v M

B

LLpQZywv θ

E

18.2

17.6

1.0

0.6

A

2

A

E

1.4

1.2

A

1

detail X

0.2 0.10.21.95

Q

(A )

3

θ

L

p

L

Z

E

D

1.2

0.8

o

7

o

0

1.2

0.8

OUTLINE

VERSION

SOT319-2

IEC JEDEC EIAJ

REFERENCES

1996 Oct 24 23

EUROPEAN

PROJECTION

ISSUE DATE

92-11-17

95-02-04

Page 24

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook”

Reflow soldering

Reflow soldering techniques are suitable for all QFP

packages.

The choice of heating method may be influenced by larger

plastic QFP packages (44 leads, or more). If infrared or

vapour phase heating is used and the large packages are

not absolutely dry (less than 0.1% moisture content by

weight), vaporization of the small amount of moisture in

them can cause cracking of the plastic body. For more

information, refer to the Drypack chapter in our

Reference Handbook”

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

(order code 9398 652 90011).

“Quality

(order code 9398 510 63011).

SAA4997H

If wave soldering cannot be avoided, the following

conditions must be observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave)

soldering technique should be used.

• The footprint must be at an angle of 45° to the board

direction and must incorporate solder thieves

downstream and at the side corners.

Even with these conditions, do not consider wave

soldering the following packages: QFP52 (SOT379-1),

QFP100 (SOT317-1), QFP100 (SOT317-2),

QFP100 (SOT382-1) or QFP160 (SOT322-1).

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Repairing soldered joints

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

Wave soldering

Wave soldering is not recommended for QFP packages.

This is because of the likelihood of solder bridging due to

closely-spaced leads and the possibility of incomplete

solder penetration in multi-lead devices.

1996 Oct 24 24

Page 25

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

SAA4997H

PALplus

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

1996 Oct 24 25

Page 26

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

NOTES

SAA4997H

1996 Oct 24 26

Page 27

Philips Semiconductors Preliminary specification

VErtical Reconstruction IC (VERIC) for

PALplus

NOTES

SAA4997H

1996 Oct 24 27

Page 28

Philips Semiconductors – a worldwide company

Argentina: see South America

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. +612 98054455, Fax.+61 29805 4466

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box213,

Tel. +431 60101, Fax.+43 160 1011210

Belarus: Hotel Minsk Business Center, Bld. 3, r.1211, Volodarski Str.6,

220050 MINSK, Tel.+375 172200 733,Fax. +375172 200773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15th floor,

51 JamesBourchier Blvd., 1407SOFIA,

Tel. +3592 689211, Fax.+359 2689 102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1800 2347381

China/Hong Kong: 501 HongKong Industrial Technology Centre,

72 TatChee Avenue, Kowloon Tong, HONG KONG,

Tel. +8522319 7888,Fax. +8522319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Prags Boulevard80, PB 1919, DK-2300COPENHAGEN S,

Tel. +4532 882636, Fax.+45 3157 1949

Finland: Sinikalliontie 3, FIN-02630ESPOO,

Tel. +3589 615800,Fax. +3589 61580/xxx

France: 4 Ruedu Port-aux-Vins, BP317, 92156SURESNES Cedex,

Tel. +331 4099 6161,Fax. +331 4099 6427

Germany: Hammerbrookstraße 69, D-20097HAMBURG,

Tel. +4940 2353 60,Fax. +4940 23536 300

Greece: No. 15,25th MarchStreet, GR 17778TAVROS/ATHENS,

Tel. +301 4894339/239, Fax.+30 14814 240

Hungary: see Austria

India: Philips INDIA Ltd, Shivsagar Estate, A Block, Dr. Annie Besant Rd.

Worli, MUMBAI 400018, Tel. +9122 4938541, Fax.+91 224938 722

Indonesia: see Singapore

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +3531 7640000, Fax.+353 17640 200

Israel: RAPAC Electronics, 7Kehilat SalonikiSt, TEL AVIV61180,

Tel. +9723 6450444, Fax.+972 3649 1007

Italy: PHILIPS SEMICONDUCTORS, Piazza IVNovembre 3,

20124 MILANO, Tel.+39 26752 2531,Fax. +392 67522557

Japan: Philips Bldg13-37, Kohnan 2-chome, Minato-ku, TOKYO108,

Tel. +813 37405130, Fax.+81 33740 5077

Korea: Philips House, 260-199Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +822 7091412, Fax.+82 2709 1415

Malaysia: No. 76Jalan Universiti, 46200PETALING JAYA, SELANGOR,

Tel. +60 3750 5214,Fax. +603 7574880

Mexico: 5900 GatewayEast, Suite 200, ELPASO, TEXAS 79905,

Tel. +9-5800 2347381

Middle East: see Italy

Netherlands: Postbus 90050, 5600PB EINDHOVEN, Bldg.VB,

Tel. +3140 2782785, Fax.+31 4027 88399

New Zealand: 2 WagenerPlace, C.P.O. Box1041, AUCKLAND,

Tel. +649 8494160, Fax.+64 9849 7811

Norway: Box 1, Manglerud0612, OSLO,

Tel. +4722 748000, Fax.+47 2274 8341

Philippines: Philips Semiconductors Philippines Inc.,

106 ValeroSt. SalcedoVillage, P.O. Box2108 MCC,MAKATI,

Metro MANILA, Tel.+63 2816 6380,Fax. +632 8173474

Poland: Ul. Lukiska10, PL 04-123WARSZAWA,

Tel. +4822 6122831, Fax.+48 22612 2327

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva35A, 119048 MOSCOW,

Tel. +7095 2479145, Fax.+7 095247 9144

Singapore: Lorong 1, ToaPayoh, SINGAPORE 1231,

Tel. +65350 2538,Fax. +65251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 MainRoad Martindale,

2092 JOHANNESBURG, P.O.Box 7430 Johannesburg2000,

Tel. +2711 4705911, Fax.+27 11470 5494

South America: Rua doRocio 220, 5thfloor, Suite 51,

04552-903 SãoPaulo, SÃO PAULO- SP, Brazil,

Tel. +5511 8212333, Fax.+55 11829 1849

Spain: Balmes 22, 08007BARCELONA,

Tel. +343 3016312, Fax.+34 3301 4107

Sweden: Kottbygatan 7, Akalla, S-16485STOCKHOLM,

Tel. +468 6322000, Fax.+46 8632 2745

Switzerland: Allmendstrasse 140, CH-8027ZÜRICH,

Tel. +411 4882686, Fax.+41 1481 7730

Taiwan: PHILIPS TAIWAN Ltd., 23-30F, 66,

Chung HsiaoWest Road,Sec. 1, P.O.Box 22978,

TAIPEI 100,Tel. +8862 3824443, Fax.+886 2382 4444

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-BangnaRoad Prakanong, BANGKOK10260,

Tel. +662 7454090, Fax.+66 2398 0793

Turkey: Talatpasa Cad. No. 5, 80640GÜLTEPE/ISTANBUL,

Tel. +90212 2792770, Fax.+90 212282 6707

Ukraine: PHILIPS UKRAINE, 4 PatriceLumumba str., Building B, Floor7,

252042 KIEV, Tel.+380 44264 2776, Fax. +38044 2680461

United Kingdom: Philips Semiconductors Ltd., 276 BathRoad, Hayes,

MIDDLESEX UB35BX, Tel. +44181 7305000, Fax.+44 181754 8421

United States: 811 EastArques Avenue, SUNNYVALE, CA94088-3409,

Tel. +1800 2347381

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica5/v, 11000 BEOGRAD,

Tel. +38111 625344, Fax.+38111 635777

For all other countries apply to: Philips Semiconductors, Marketing &Sales Communications,

Building BE-p, P.O.Box 218, 5600MD EINDHOVEN, TheNetherlands, Fax.+31 4027 24825

© Philips Electronics N.V. 1996 SCA52

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Internet: http://www.semiconductors.philips.com

Printed in The Netherlands 537021/1200/01/pp28 Date of release: 1996 Oct 24 Document order number: 9397 750 01423

Loading...

Loading...