Page 1

The SA828 PWM generator has been designed to provide

waveforms for the control of variable speed AC machines,

uninterruptible power supplies and other forms of power

electronic devices which require pulse width modulation as a

means of efficient power control.

The six TTL level PWM outputs (Fig. 2) control the six

switches in a three-phase inverter bridge. This is usually via an

external isolation and amplification stage.

The SA828 is fabricated in CMOS for low power

consumption.

Information contained within the pulse width modulated

sequences controls the shape, power frequency, amplitude,

and rotational direction (as defined by the red-yellow-blue

phase sequence) of the output waveform. Parameters such as

the carrier frequency, minimum pulse width, and pulse delay

time may be defined during the initialisation of the device. The

pulse delay time (underlap) controls the delay between turning

on and off the two power switches in each output phase of the

inverter bridge, in order to accommodate variations in the turnon and turn-off times of families of power devices.

The SA828 is easily controlled by a microprocessor and its

fully-digital generation of PWM waveforms gives unprecedented

accuracy and temperature stability. Precision pulse shaping

capability allows optimum efficiency with any power circuitry.

The device operates as a stand-alone microprocessor

peripheral, reading the power waveform directly from an

internal ROM and requiring microprocessor intervention only

when operating parameters need to be changed.

An 8-bit multiplexed data bus is used to receive addresses and

data from the microprocessor/controller. This is a standard

MOTEL

TM

bus, compatible with most microprocessors/controllers.

Rotational frequency is defined to 12 bits for high accuracy

and a zero setting is included in order to implement DC

injection braking with no software overhead.

This family is pin and functionally compatible with the

MA828 PWM generator . Two standard wave shapes are

available to cover most applications. In addition, any

symmetrical wave shape can be integrated on-chip to order.

FEATURES

■ Fully Digital Operation

■ Interfaces with Most Microprocessors

■ Wide Power-Frequency Range

■ 12-Bit Speed Control Accuracy

■ Carrier Frequency Selectable up to 24kHz

■ Waveform Stored in Internal ROM

■ Double Edged Regular Sampling

■ Selectable Minimum Pulse Width and Underlap Time

■ DC Injection Braking

DP28

MP28

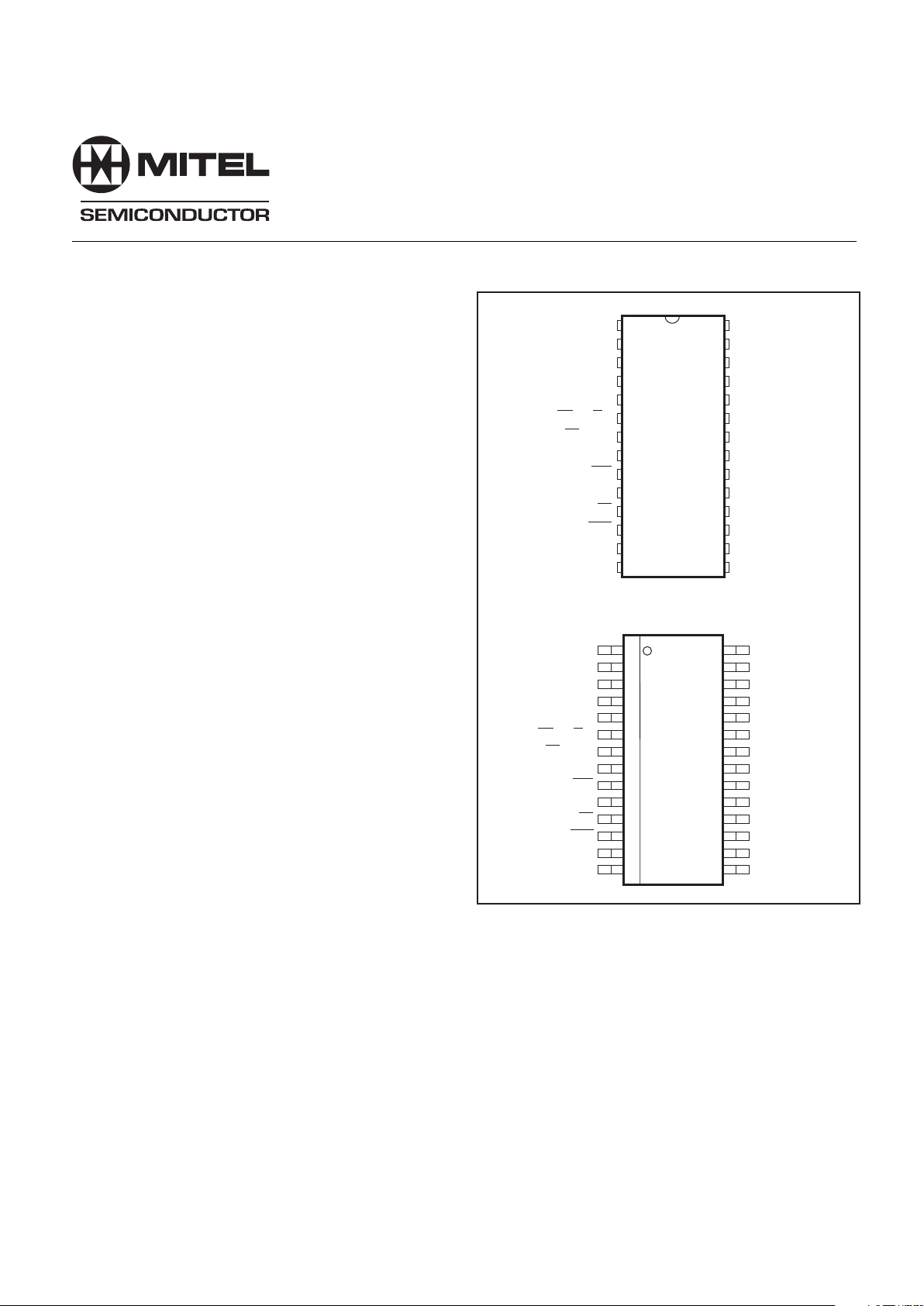

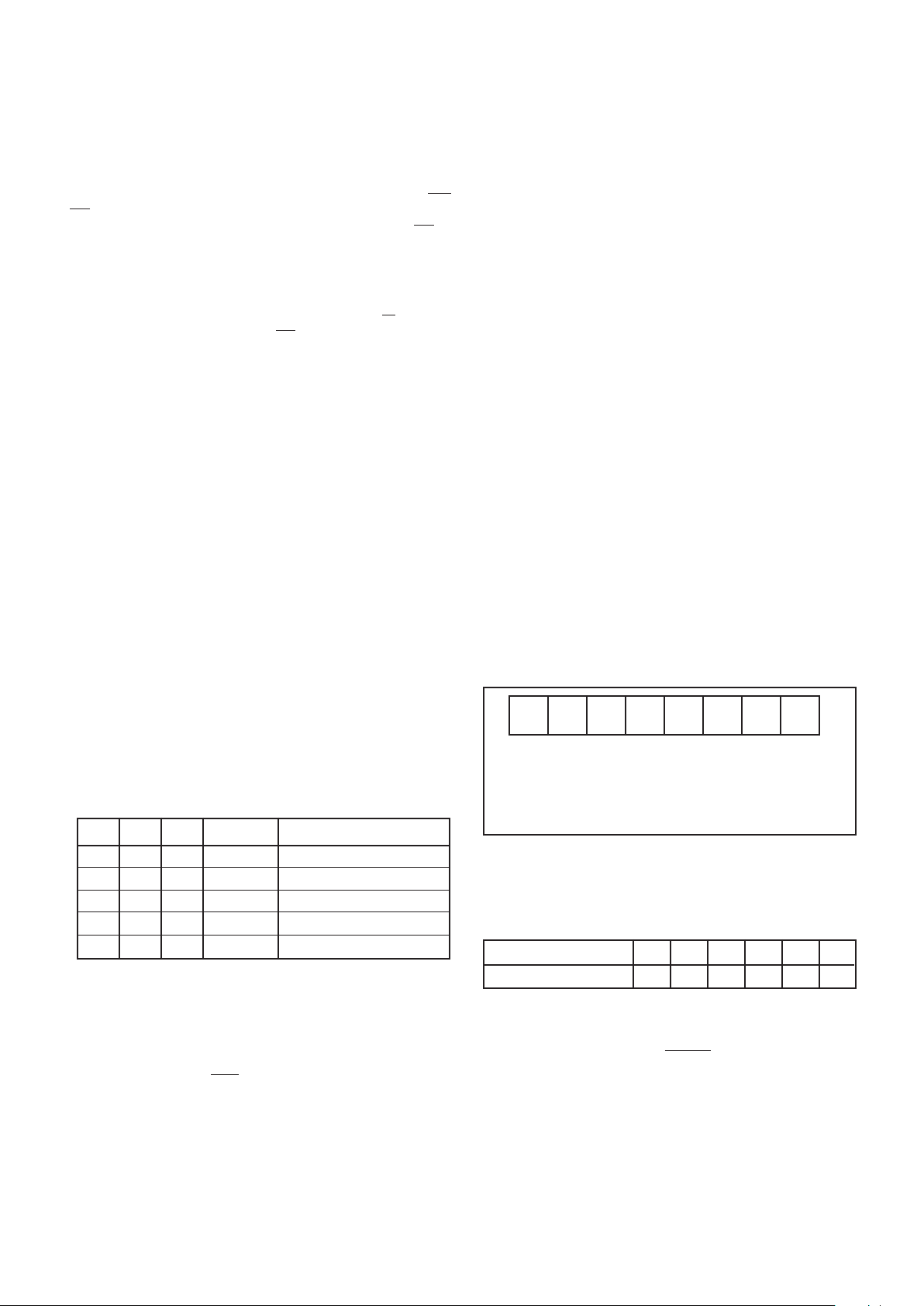

Fig. 1 Pin connections – top view (not to scale)

MOTEL is a registered Trademark of Intel Corp. and Motorola Corp.

AD

2

AD

1

AD

0

VDD

ZPPB

ZPPY

ZPPR

WSS

RPHT

SET TRIP

YPHT

BPHT

V

SS

BPHB

AD

3

AD

4

AD

5

AD

6

AD

7

WR* (R/W†)

RD* (DS†)

ALE* (AS†)

RST

CLK

CS

TRIP

RPHB

YPHB

* = Intel bus format

† = Motorola bus format

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

SA828

SA828

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AD

2

AD

1

AD

0

VDD

ZPPB

ZPPY

ZPPR

WSS

RPHT

SET TRIP

YPHT

BPHT

V

SS

BPHB

AD

3

AD

4

AD

5

AD

6

AD

7

WR* (R/W†)

RD* (DS†)

ALE* (AS†)

RST

CLK

CS

TRIP

RPHB

YPHB

ORDERING INFORMATION

SA8281/IG/DP1S (28-lead DIL, sine + third harmonic

waveform)

SA8282/IG/DP1S (28-lead DIL, sine waveform)

SA8281/IG/MP1S (28-lead SOIC, Sine + third

harmonic waveform)

SA8382/IG/MP1S (28-lead SOIC, sine waveform)

SA828 Family

Three-Phase PWM Waveform Generator

DS4226 - 2.0 November 1996

Page 2

SA828

2

>4·5

<0·2

<10

5·0

Input high voltage

Input low voltage

Input leakage current

Output high voltage

Output low voltage

Supply current (static)

Supply current (dynamic)

Supply voltage

V

IN

= VSS or V

DD

IOH = – 12mA

I

OL

= 12mA

All outputs open circuit

f

CLK

= 10MHz

V

IH

V

IL

I

IN

V

OH

V

OL

I

DD (static)

I

DD (dynamic)

V

DD

2

4·0

4·5

0·8

10

0·4

100

20

5·5

Typ. Max.Min.

Value

Characteristic Symbol

ConditionsUnits

ELECTRICAL CHARACTERISTICS

These characteristics are guaranteed over the following conditions (unless otherwise stated):

VDD = +5V ±5%, T

AMB

= +25°C

DC Characteristics

V

V

µA

V

V

µA

mA

V

-

2/f

CLK

2/f

CLK

Clock frequency

Clock duty cycle

SET TRIP = 1 → outputs tripped

→

TRIP = 0

M : S ratio = 1 : 1 ±20%

f

CLK

in MHz

f

CLK

in MHz

f

CLK

D

CLK

t

TRIP

12·5

60

3/f

CLK

3/f

CLK

MHz

%

µs

µs

NOTE 1. For microprocessor interface timings, see Intel and Motorola bus timings (Tables 1 and 2).

Conditions

Typ. Max.

Characteristic Symbol Units

Value

AC Characteristics

ABSOLUTE MAXIMUM RATINGS

Supply voltage, V

DD

Voltage on any pin

Current through any I/O pin

Storage temperature

Operating temperature range

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

Name

AD

3

AD

4

AD

5

AD

6

AD

7

Intel: WR

Motorola: R/

W

Intel: RD

Motorola: DS

Intel: ALE

Motorola: AS

RST

CLK

CS

TRIP

Type

I

I

I

I

I

I

I

I

I

I

I

O

Function

Multiplexed Address/Data

Multiplexed Address/Data

Multiplexed Address/Data

Multiplexed Address/Data

Multiplexed Address/Data(MSB)

Intel bus control:

Write Strobe

Motorola bus control: Read/

Write

select

Intel bus control: Read Strobe

Motorola bus control: Data Strobe

Intel bus control: Address Latch

Enable

Motorola bus control: Address

Strobe

Reset internal counters, active low

Clock input

Chip Select input, active low

Output trip status; low = output tripped

Name

RPHB

YPHB

BPHB

V

SS

BPHT

YPHT

SET TRIP

RPHT

WSS

ZPPR

ZPPY

ZPPB

V

DD

AD

0

AD

1

AD

2

Pin

No.

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Type

O

O

O

P

O

O

I

O

O

O

O

O

P

I

I

I

Function

Red Phase, Bottom power switch

Yellow Phase, Bottom power switch

Blue Phase, Bottom power switch

Negative power supply (0V)

Blue Phase, Top power switch

Yellow Phase, Top power switch

Set output trip. 120kΩ internal

pull-up resistor

Red Phase, Top power switch

Waveform Sampling Synchronisation

Zero Phase Pulse, Red phase

Zero Phase Pulse, Yellow phase

Zero Phase Pulse, Blue phase

Positive power supply

Multiplexed Address/Data (LSB)

Multiplexed Address/Data

Multiplexed Address/Data

PIN DESCRIPTIONS

The temperature ranges quoted apply to all package types.

Many package types are available and extended temperature

7V

V

SS

–0·3V to VDD +0·3V

±10mA

–65°C to +125°C

–40°C to +85°C

40

ranges can be offered for some. Further information is available

on request.

Stresses above those listed in the Absolute Maximum

Ratings may cause permanent damage to the device. These

are stress ratings only and functional operation of the device at

these conditions, or at any other condition above those indicated

in the operations section of this specification, is not implied.

Exposure to Absolute Maximum Rating conditions for extended

periods may affect device reliability.

Page 3

3

SA828

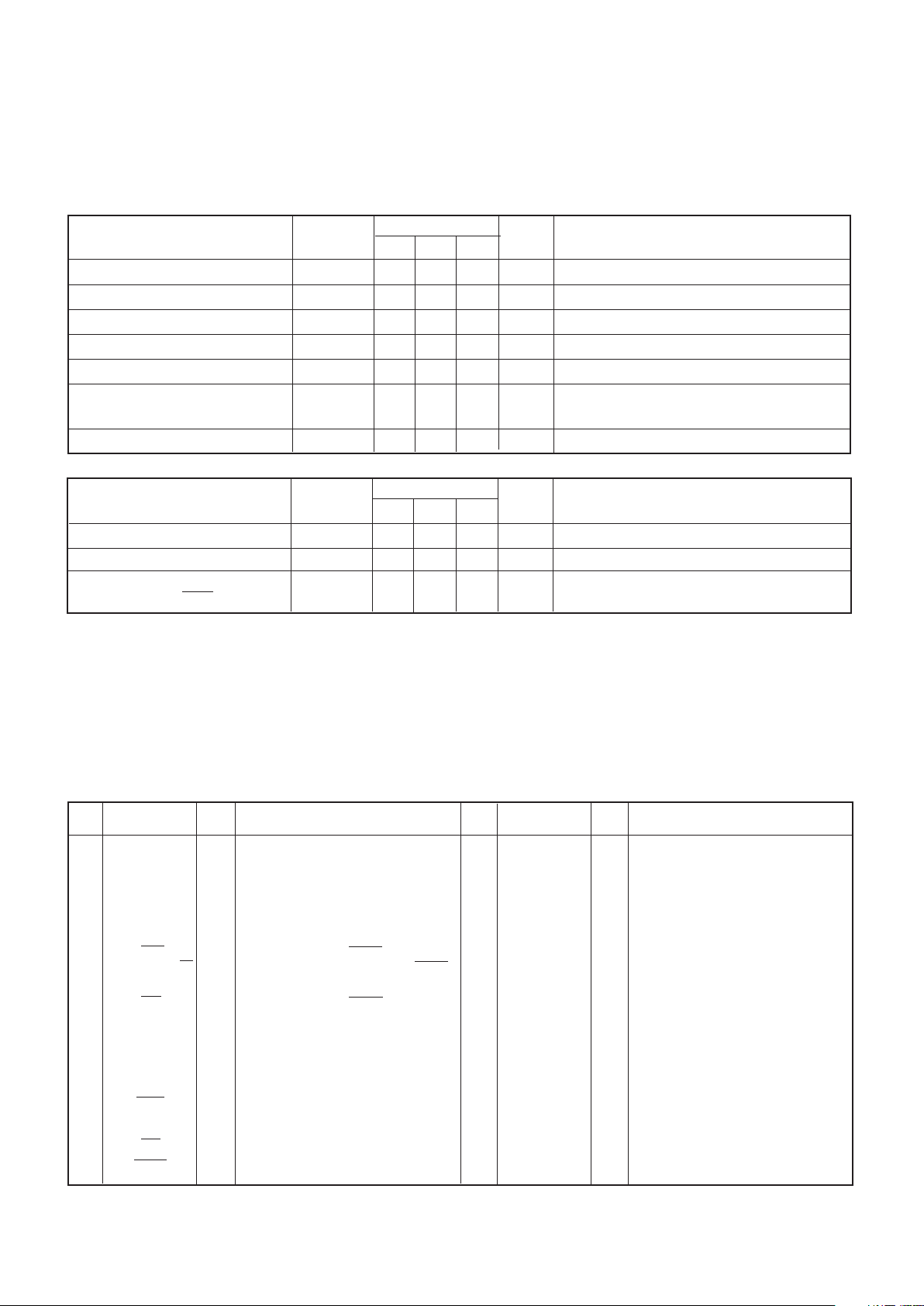

Fig. 2 SA828 internal block diagram

PULSE

DELETION

PULSE

DELAY

CIRCUIT

RPHT

RPHB

PULSE

DELETION

PULSE

DELAY

CIRCUIT

YPHT

YPHB

PULSE

DELETION

PULSE

DELAY

CIRCUIT

BPHT

BPHB

RED PHASE

YELLOW PHASE

BLUE PHASE

PHASING

AND

CONTROL

LOGIC

WAVEFORM

ROM

TRIP

LATCH

ADDRESS

GENERATOR

24-BIT

INITIALISATION

REGISTER

24-BIT

CONTROL

REGISTER

R0

R1

R2

R3

R4

BUS

DEMULTIPLEXER

BUS

CONTROL

CLOCK

DIVIDER

RST

MOTEL

INTERFACE

SYSTEM

BUS

AD

0

-AD

7

8

SET

TRIP

TRIP

CS

CLOCK

ZPP

O/Ps

WSS

FUNCTIONAL DESCRIPTION

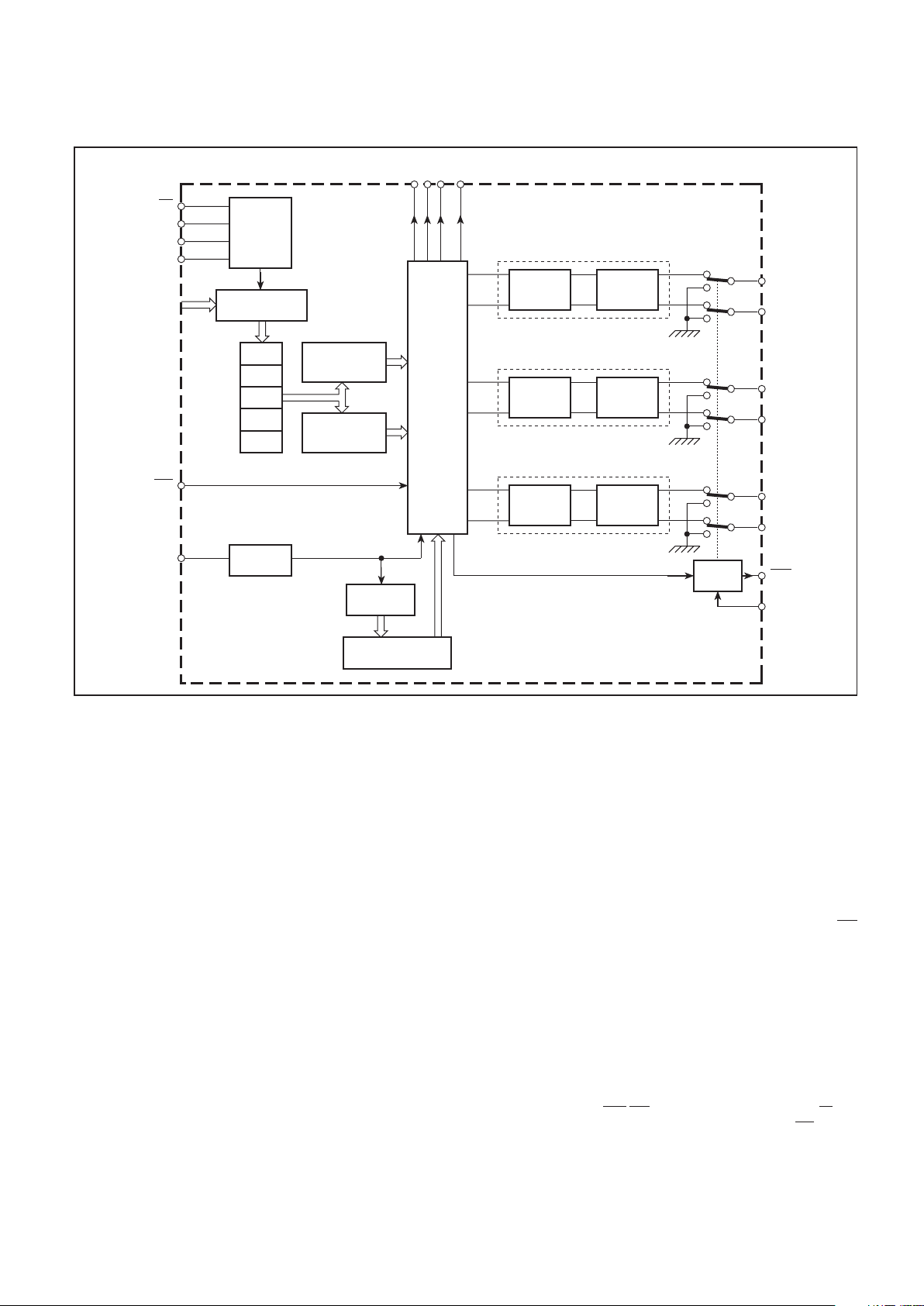

An asynchronous method of PWM generation is used with

uniform or ‘double-edged’ regular sampling of the waveform

stored in the internal ROM as illustrated in Fig. 3.

The triangle carrier wave frequency is selectable up to 24kHz

(assuming the maximum clock frequency of 12.5MHz is used),

enabling ultrasonic operation for noise critical applications. With

12.5MHz clock, power frequency ranges of up to 4kHz are

possible, with the actual output frequency resolved to 12-bit

accuracy within the chosen range in order to give precise motor

speed control and smooth frequency changing. The output phase

sequence of the PWM outputs can also be changed to allow both

forward and reverse motor operation.

PWM output pulses can be ‘tailored’ to the inverter

characteristics by defining the minimum allowable pulse width

(the SA828 will delete all shorter pulses from the ‘pure’ PWM pulse

train) and the pulse delay (underlap) time, without the need for

external circuitry. This gives cost advantages in both component

savings and in allowing the same PWM circuitry to be used for

control of a number of different motor drive circuits simply by

changing the microprocessor software.

Power frequency amplitude control is also provided with an

overmodulation option to assist in rapid motor braking. Alternatively,

braking may be implemented by setting the rotational speed to

0Hz. This is termed ‘DC injection braking’, in which the rotation of

the motor is opposed by allowing DC to flow in the windings.

A trip input allows the PWM outputs to be shut down immediately,

overriding the microprocessor control in the event of an emergency.

The Waveform Sampling Synchronisation (WSS) output may

be used in conjunction with the ZPP signals to provide feedback

of the actual rotational speed from the rotor. This is of particular

use in slip compensated systems.

Other possible SA828 applications are as a 3-phase waveform

generator as part of a switched-mode power supply (SMPS) or of

an uninterruptible power supply (UPS). In such applications the

high carrier frequency allows a very small switching transformer

to be used.

MICROPROCESSOR INTERFACE

The SA828 interfaces to the controlling microprocessor by

means of a multiplexed bus of the MOTEL format. This interface

bus has the ability to adapt itself automatically to the format and

timing of both MOTorola and IntEL interface buses (hence MOTEL).

Internally, the detection circuitry latches the status of the DS/

RD

line when AS/ALE goes high. If the result is high then the Intel

mode is used; if the result is low then the Motorola mode is used.

This procedure is carried out each time that AS/ALE goes high. In

practice this mode selection is transparent to the user. For bus

connection and timing information refer to the description relevant

to the microprocessor/controller being used.

Industry standard microprocessors such as the 8085, 8088,

etc. and microcontrollers such as the 8051, 8052 and 6805 are all

compatible with the interface on the SA828. This interface consists

of 8 data lines, AD

0

- AD7 (write-only in this instance), which are

multiplexed to carry both the address and data information, 3 bus

control lines, labelled

WR,RD and ALE in Intel mode and R/W, DS

and AS in Motorola mode, and a Chip Select input,

CS, which

allows the SA828 to share the same bus as other microprocessor

peripherals. It should be noted that all bus timings are derived from

the microprocessor and are independent of the SA828 clock

input.

Page 4

SA828

4

Fig. 3 Asynchronous PWM generation with‘double-edged’ regular sampling as used by the SA828

t

1

ALE

t

4

t

3

t

2

t

8

t

10

t

11

t

9

t

12

RD

WR

AD

0

-AD

7

CS

LATCH ADDRESS LATCH DATA

t

15

t

4

t

3

t

8

t

10

t

11

t

9

t

12

DS

R/W

AD

0

-AD

7

CS

LATCH ADDRESS

LATCH DATA

t

1

AS

t

2

t

5

t

6

t

7

t

15

+1

– 1

+1

– 1

RESULTING

PWM

WAVEFORM

0

0

PWM SWITCHING

INSTANTS

TRIANGLE WAVE AT

CARRIER FREQUENCY,

SAMPLING ON +VE AND – VE PEAKS

POWER WAVEFORM

AS READ FROM

INTERNAL ROM

Fig. 5 Motorola bus timing definitions

Parameter

AS high period

Delay time, as low to DS high

DS high period

Delay time, DS low to AS high

DS low period

DS high to R/

W low setup time

R/W hold time

CS setup time

CS hold time

Address setup time

Address hold time

Write data setup time

Write data hold time

Symbol

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

15

t

11

t

12

Min.

90

40

210

40

200

10

10

20

0

30

30

110

30

Table 2 Motorola bus timings at VDD = 5V, T

AMB

= +25°C

Units

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Fig. 4 Intel bus timing definitions

Parameter

ALE high period

Delay time, ALE to

WR

WR low period

Delay time,

WR high to ALE high

CS setup time

CS hold time

Address setup time

Address hold time

Data setup time

Data hold time

Symbol

t

1

t

2

t

3

t

4

t

8

t

9

t

10

t

15

t

11

t

12

Min.

70

40

200

40

20

0

30

30

100

25

Table 1 Intel bus timings at VDD = 5V, T

AMB

=

+

25°C

Units

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Page 5

5

SA828

Register

R0

R1

R2

R3

R4

Comment

Temporary register R0

Temporary register R1

Temporary register R2

Transfers control data

Transfers initialisation data

AD

1

0

0

1

1

0

Power frequency range

This sets the maximum power frequency that can be carried

within the PWM output waveforms. This would normally be set

to a value to prevent the motor system being operated outside

its design parameters.

Pulse delay time ('underlap')

For each phase of the PWM cycle there are two control

signals, one for the top switch connected to the positive

inverter DC supply and one for the bottom switch connected to

the negative inverter DC supply. In theory, the states of these

two switches are always complementary. However, due to the

finite and non-equal turn-on and turn- off times of power

devices, it is desirable when changing the state of the output

pair, to provide a short delay time during which both outputs

are off in order to avoid a short circuit through the switching

elements.

Pulse deletion time

A pure PWM sequence produces pulses which can vary in

width between 0% and 100% of the duty cycle. Therefore, in

theory, pulse widths can become infinitesimally narrow. In

practice this causes problems in the power switches due to

storage effects and therefore a minimum pulse width time is

required. All pulses shorter than the minimum specified are

deleted.

Counter reset

This facility allows the internal power frequency counter of

the SA828 to be set to zero, disabling the normal frequency

control and giving a 50% output duty cycle.

Initialisation Register Programming

The initialisation register data is loaded in 8-bit segments into

the three 8-bit temporary registers R0-R2. When all the initialisation

data has been loaded into these registers it is transferred into the

24-bit initialisation register by writing to the dummy register R4.

AD

2

0

0

0

0

1

AD

0

0

1

0

1

0

Table 3 SA828 register addressing

Initialisation Register Function

The 24-bit initialisation register contains parameters which,

under normal operation, will be defined during the power-up

sequence. These parameters are particular to the drive circuitry

used, and therefore changing these parameters during a PWM

cycle is not recommended. Information in this register should

only be modified while

RST is active (i.e. low) so that the PWM

outputs are inhibited (low) during the updating process.

The parameters set in the initialisation register are as follows:

Carrier frequency

Low carrier frequencies reduce switching losses whereas

high carrier frequencies increase waveform resolution and can

allow ultrasonic operation.

Carrier frequency selection

The carrier frequency is a function of the externally applied

clock frequency and a division ratio

n

, determined by the 3-bit

CFS word set during initialisation. The values of

n

are selected

as shown in Table 4.

The carrier frequency,

f

CARR

,

is then given by:

CFS word

Value of n

000

1

001

2

010

4

011

8

100

16

101

32

Table 4 Values of clock division ratio n

FRS2FRS1FRS0X X CFS2CFS2CFS

2

FREQUENCY

RANGE

SELECT WORD

FRS

2

= MSB

FRS0 = LSB

DON’T

CARE

CARRIER

FREQUENCY

SELECT WORD

CFS

2

= MSB

CFS0 = LSB

Fig. 6 Temporary register R1

where k = clock frequency and n = 1, 2, 4, 8, 16 or 32 (as set

by CFS)

Power frequency range selection

The power frequency range selected here defines the maximum

limit of the power frequency. The operating power frequency is

controlled by the 12-bit Power Frequency Select (PFS) word in

the control register but may not exceed the value set here.

k

512 x

n

f

CARR

=

MICROPROCESSOR BUS TIMING

Intel Mode (Fig. 4 and Table 1)

The address is latched by the falling edge of ALE. Data is

written from the bus into the SA828 on the rising edge of

WR.

RD is not used in this mode because the registers in the SA828

are write only. However, this pin must be connected to RD (or

tied high) to enable the SA828 to select the correct interface

format.

Motorola Mode (Fig. 5 and Table 2)

The address is latched on the falling edge of the AS line. Data

is written from the bus into the SA828 (only when R/

W is low) on

the falling edge of DS (providing

CS is low).

CONTROLLING THE SA828

The SA828 is controlled by loading data into two 24-bit

registers via the microprocessor interface. These registers are

the initialisation register and the control register.

The initialisation register would normally be loaded before

motor operation (i.e., prior to the PWM outputs being activated)

and sets up the basic operating parameters associated with the

motor and inverter. This data would not normally be updated

during motor operation.

The control register is used to control the PWM outputs (and

hence the motor) during operation e.g., stop/start, speed,

forward/reverse etc. and would normally be loaded and changed

only after the initialisation register has been loaded.

As the MOTEL bus interface is restricted to an 8-bit wide

format, data to be loaded into either of the 24-bit registers is first

written to three 8-bit temporary registers R0, R1 and R2 before

being transferred to the desired 24-bit register. The data is

accepted (and acted upon) only when transferred to one of the

24-bit registers.

Transfer of data from the temporary registers to either the

initialisation register or the control register is achieved by a write

instruction to a dummy register. Writing to dummy register R3

results in data transfer from R0, R1 and R2 to the control

register, while writing to dummy register R4 transfers data from

R0, R1 and R2 to the initialisation register. It does not matter

what data is written to the dummy registers R3 and R4 as they

are not real registers. It is merely the write instruction to either

of these registers which is acted upon in order to load the

initialisation and control registers.

Page 6

SA828

6

pdy

f

CARR

x 512

Counter reset

When the CR bit is active (i.e., Iow) the internal power

frequency phase counter is set to 0 degrees for the red

phase. It will remain at 0 degrees until the CR bit is released

(i.e., high).

Control Register Function

This 24-bit register contains the parameters that would

normally be modified during PWM cycles in order to control

the operation of the motor.

The parameters set in the control register are as follows:

Power frequency (speed)

Allows the power frequency of the PWM outputs to be

adjusted within the range specified in the initialisation register

Forward/reverse

Allows the direction of rotation of the AC motor to be

changed by changing the phase sequence of the PWM

outputs.

Power frequency amplitude

By altering the widths of the PWM output pulses while

maintaining their relative widths, the amplitude of the power

waveform is effectively altered whilst maintaining the same

power frequency.

Overmodulation

Allows the output waveform amplitude to be doubled so

that a quasi-squarewave is produced. A combination of

overmodulation and a lower power frequency can be used to

achieve rapid braking in AC motors.

Output inhibit

Allows the outputs to be set to the low state while the PWM

generation continues internally. Useful for temporarily

inhibiting the outputs without having to to change other

register contents.

The power frequency range is a function of the carrier

waveform frequency (

f

CARR

) and a multiplication factor m,

determined by the 3-bit FRS word. The value of

m

is determined

as shown in Table 5.

FRS word

Value of m

000

1

001

2

010

4

011

8

100

16

101

32

Table 5 Values of carrier frequency multiplicaion factor m

110

64

The power frequency range,

f

RANGE

, is then given by:

where

f

CARR

= carrier frequency and m = 1, 2, 4, 8, 16, 32 or 64

(as set by FRS).

f

CARR

384

f

RANGE

= x

m

X X PDY5PDY4PDY3PDY2PDY1PDY

0

DON’T

CARE

PULSE

DELAY

SELECT WORD

PDY

5

= MSB

PDY0 = LSB

Fig. 7 Temporary register R2

PDY word

Value of pdy

000000

64

...etc...

...etc...

111110

2

Table 6 Values of pdy

111111

1

The pulse delay time,

t

pdy

, is then given by:

where

pdy

= 1- 64 (as set by PDY) and

f

CARR

= carrier

frequency.

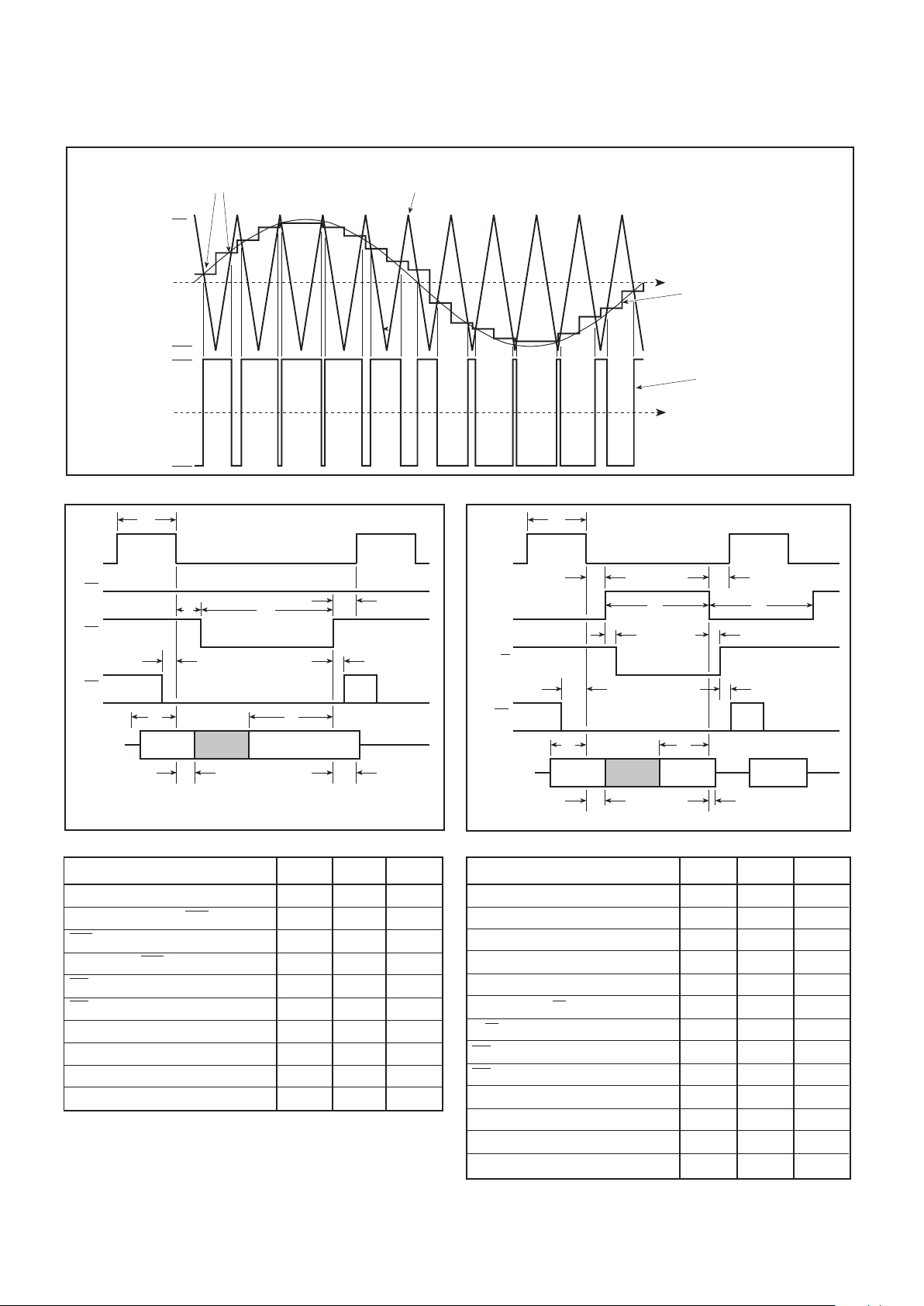

Fig 8 shows the eftect of the pulse delay circuit.

It should be noted that as the pulse delay circuit follows the

pulse deletion circuit (see Fig. 2), the minimum pulse width

seen at the PWM outputs will be shorter than the pulse deletion

time set in the initialisation register. The actual shortest pulse

generated is given by

t

pd

–

t

pdy

.

Pulse delay time

The pulse delay time affects all six PWM outputs by delaying

the rising edges of each of the outputs by an equal amount.

The pulse delay time is a function of the carrier waveform

frequency and

pdy

, defined by the 6-bit pulse delay time select

word (PDY). The value of

pdy

is selected as shown in Table 6.

Fig. 8 Effect of pulse delay on PWM pulse train

PWM SIGNAL

REQUIRED AT

INVERTER OUTPUT

t

pdy

t

pdy

t

pdy

t

pdy

OUTPUT SIGNAL TO

DRIVE TOP SWITCH

INVERTER ARM

OUTPUT SIGNAL TO

DRIVE BOTTOM SWITCH

INVERTER ARM

t

pdy

= PULSE DELAY TIME

t

pdy

=

CR PDT6PDT5PDT4PDT3PDT2PDT1PDT

0

COUNTER

RESET

PULSE DELETION

TIME

SELECT WORD

PDT

6

= MSB

PDT0 = LSB

Fig. 9 Temporary register R0

Pulse deletion time

To eliminate short pulses the true PWM pulse train is passed

through a pulse deletion circuit. The pulse deletion circuit

compares pulse widths with the pulse deletion time set in the

initialisation register. lf a pulse (either positive or negative) is

greater than or equal in duration to the pulse deletion time, it is

passed through unaltered, otherwise the pulse is deleted.

The pulse deletion time,

t

pd

, is a function of the carrier wave

frequency and

pdt

, defined by the 7-bit pulse deletion time word

(PDT). The value of

pdt

is selected as shown in Table 7.

PDT word

Value of pdt

0000000

128

...etc...

...etc...

1111110

2

Table 7 Values of pdt

1111111

1

The pulse deletion time,

t

pd

, is then given by:

where

pdt

= 1-128 (as set by PDT) and

f

CARR

= carrier frequency.

Fig. 10 shows the effect of pulse deletion on a pure PWM

waveform.

t

pd

=

pdt

f

CARR

x 512

Page 7

7

SA828

Fig. 10 The effect of the pulse deletion circuit

PWM SIGNAL

BEFORE

PULSE DELETION

<t

pd

>t

pd

tpd = PULSE DELETION TIME

<t

pd

>tpd>t

pd

>t

pd

>t

pd

>t

pd

>t

pd

>t

pd

PWM SIGNAL

AFTER

PULSE DELETION

PULSE

DELETED

PULSE

DELETED

where

pfs

= decimal value of the 12-bit PFS word and

f

RANGE

=

power frequency range set in the initialisation register.

PFS7PFS6PFS5PFS4PFS3PFS2PFS1PFS

0

POWER

FREQUENCY

SELECT WORD

BITS 0-7

PFS

0

= LSB

Fig. 11 Temporary register R0

F/R OM INH X PFS11PFS10PFS9PFS

8

POWER

FREQUENCY

SELECT WORD

BITS 8-11

PFS

11

= MSB

DON’T

CARE

OVERMOD-

ULATION

BIT

0 = DISABLED

1 = ACTIVE

OUTPUT

INHIBIT BIT

0 = OUTPUTS DISABLED

1 = OUTPUTS ACTIVE

FORWARD/

REVERSE BIT

0 = FORWARD

1 = REVERSE

Fig. 12 Temporary register R1

Power frequency selection

The power frequency is selected as a proportion of the power

frequency range (defined in the initialisation register) by the 12bit power frequency select word, PFS, allowing the power

frequency to be defined in 4096 equal steps. As the PFS word

spans the two temporary registers R0 and R1 it is therefore

essential, when changing the power frequency, that both these

registers are updated before writing to R3.

The power frequency (

f

POWER

) is given by:

Control Register Programming

The control register should only be programmed once the

initialisation register contains the basic operating parameters of

the SA828.

As with the initialisation register, control register data is

loaded into the three 8-bit temporary registers R0 - R2. When all

the data has been loaded into these registers it is transferred

into the 24-bit control register by writing to the dummy register

R3. It is recommended that all three temporary registers are

updated before writing to R3 in order to ensure that a conformal

set of data is transferred to the control register for execution.

f

RANGE

4096

f

POWER

=

x pfs

OVERMODULATION BIT NOT SET

(100% MODULATION)

OVERMODULATION BIT SET

(200% MODULATION)

V

V

0

0

t

t

Fig. 13 Current waveforms as seen at the motor terminals,

showing the effect of setting the overmodulation bit

Forward/ reverse selection

The phase sequence of the three-phase PWM output

waveforms is controlled by the Forward/Reverse bit F/R. The

actual effect of changing this bit from 0 (forward) to 1 (reverse)

is to reverse the power frequency phase counter from

incrementing the phase angle to decrementing it. The required

output waveforms are all continuous with time during a forward/

reverse change.

In the forward mode the output phase sequence is redyellow-blue and in the reverse mode the sequence is blueyellow-red.

Output inhibit selection

When active (i.e., Iow) the output inhibit bit INH sets all the

PWM outputs to the off (low) state. No other internal operation

of the device is affected. When the inhibit is released the PWM

outputs continue immediately. Note that as the inhibit is asserted

after the pulse deletion and pulse delay circuits, pulses shorter

than the normal minimum pulse width may be produced initially.

Overmodulation selection

The overmodulation bit OM is, in effect, the ninth bit (MSB)

of the amplitude word. When active (i.e., high) the output

waveform will be controlled in the 100% to 200% range by the

amplitude word.

The percentage amplitude control is now given by:

Overmodulated Amplitude =

A

POWER

+ 100%

where

A

POWER

= the power amplitude

Page 8

SA828

8

SA828 PROGRAMMING EXAMPLE

The following example assumes that a master clock of

12·288 MHz is used (12·288 MHz crystals are readily available).

This clock frequency will allow a maximum carrier frequency of

24 kHz and a maximum power frequency of 4 kHz.

Initialisation Register Programming Example

A power waveform range of up to 250Hz is required with a

carrier frequency of 6kHz, a pulse deletion time of 10µs and an

underlap of 5µs.

1. Setting the carrier frequency

The carrier frequency should be set first as the power

frequency, pulse deletion time and pulse delay time are all

defined relative to the carrier frequency.

We must calculate the value of

n

that will give the required

carrier frequency:

From Table 4, n = 4 corresponds to a 3-bit CFS word of

010 in temporary register R1.

2. Setting the power frequency range

We must calculate the value of m that will give the required

power frequency:

From Table 5,

m

= 16 corresponds to a 3-bit FRS word of

100 in temporary register R1.

3. Setting the pulse delay time

As the pulse delay time affects the actual minimum pulse width

seen at the PWM outputs, it is sensible to set the pulse delay time

before the pulse deletion time, so that the effect of the pulse delay

time can be allowed for when setting the pulse deletion time.

12·288 x 10

6

512 x 6 x 10

3

⇒

n = = = 4

AMP7AMP6AMP5AMP4AMP3AMP2AMP1AMP

0

AMPLITUDE

SELECT WORD

AMP7 = MSB

AMP

0

= LSB

Fig.14 Temporary register R2

Amplitude selection

The power waveform amplitude is determined by scaling

the amplitude of the waveform samples stored in the ROM by

the value of the 8-bit amplitude select word (AMP).

The percentage amplitude control is given by:

where

A

= decimal value of AMP.

POWER-UP C0NDITIONS

All bits in both the Initialisation and Control registers powerup in an unidentified state. Holding

RST low or using the SET

TRIP input will ensure that the PWM outputs remain inactive

(i.e., low) until the device is initialised.

Power Amplitude,

A

POWER

=

x

100%

f

CARR

=

k

512 x

f

CARR

f

RANGE

= x

m

⇒

m = = = 16

f

CARR

384

f

RANGE

x 384

f

CARR

250 x 384

6 x 10

3

A

255

k

512 x

n

However, the value of

pdy

must be an integer. As the

purpose of the pulse delay is to prevent ‘shoot-through’ (where

both top and bottom arms of the inverter are on simultaneously),

it is sensible to round the pulse delay time up to a higher, rather

than a lower figure.

Thus, if we assign the value 16 to

pdy

this gives a delay time

of 5·2µs. From Table 6,

pdy

= 16 corresponds to a 6-bit PDY

word of 110000 in temporary register R2.

4. Setting the pulse deletion time

In setting the pulse deletion time (i.e., the minimum pulse

width) account must be taken of the pulse delay time, as the

actual minimum pulse width seen at the PWM outputs is equal

to

t

pd

–

t

pdy

.

Therefore, the value of the pulse deletion time must, in this

instance, be set 5·2µs longer than the minimum pulse length

required

Minimum pulse length required = 10µs

∴ t

PD

to be set to 10µs + 5·2µs = 15·2µs

Now,

⇒

pdt =

f

pd

x

f

CARR

x 512

= 15·2 x 10

–6

x 6 x 103 x 512 = 46·7

t

pd

=

Again,

pdt

must be an integer and so must be either rounded

up or down – the choice of which will depend on the application.

Assuming we choose in this case the value 46 for

pdt

, this gives

a value of

t

pd

, of 15 µs and an actual minimum pulse width of 15

– 5·2µs = 9·8µs.

From Table 7,

pdt

= 46 corresponds to a value of PDT, the

7-bit word in temporary register R0 of 1010010.

The data which must be programmed into the three temporary

registers R0, R1 and R2 (for transfer into the initialisation

register) in order to achieve the parameters in the example

given, is shown in Fig. 15.

Fig. 15

1 1 0 1 0 0 1 0

CR PDT6PDT5PDT4PDT3PDT2PDT1PDT

0

Temporary Register R0

1

0 0 X X 0 1 0

Temporary Register R1

FRS

2

FRS1FRS0X X CFS2CFS2CFS

2

X X 1 1 0 0 0 0

Temporary Register R2

X X PDY

5

PDY4PDY3PDY2PDY1PDY

0

We must calculate the value of

pdy

that will give the required

pulse delay time:

⇒

pdy =

t

pdy

x

f

CARR

x 512

= 5 x 10

–6

x 6 x 103 x 512 = 15·4

pdy

f

CARR

x 512

t

pdy

=

pdt

f

CARR

x 512

Page 9

9

SA828

Fig. 17 Typical SA828 programming routine

WRITE R1

WRITE R2

WRITE R4

POWER ON

WRITE R0

RST ↓ 0

RST ↑ 1

CHANGE

CONTROL

DATA ?

CHANGE

INITIALISATION

DATA ?

YES

NO

YES

NO

WRITE R1

WRITE R2

WRITE R3

WRITE R0

WRITE R1

WRITE R2

WRITE R3

WRITE R0

WRITE

INITIALISATION

DATA

WRITE TO CONTROL

REGISTER INHIBITING

PWM OUTPUTS

BEFORE COMPLETING

RESET CYCLE

ENABLE

PWM OUTPUTS

WRITE

CONTROL

DATA

Control Register Programming Example

The control register would normally be updated many times

while the motor is running, but just one example is given here.

It is assumed that the initialisation register has already heen

programmed with the parameters given in the previous example.

A power waveform of 100Hz is required with a PWM

waveform amplitude of 80% of that stored in the ROM. The

phase sequence should be set to give forward motor rotation.The

outputs should be enabled and no overmodulation is required.

1. Setting the power frequency

The power frequency,

f

POWER

, can be selected to 12-bit

accuracy (i.e 4096 equal steps) from 0Hz to

f

RANGE

as defined

in the initialisation register. In this case, with

f

RANGE

= 250Hz,

the power frequency can be adjusted in increments of 0·06Hz.

We can only have

pfs

as an integer, so if we assign

pfs

=

1638 this gives

f

POWER

= 99.97 Hz.The 12-bit binary equivalent

of this value gives a PFS word of 011001100110 in temporary

registers R0 and R1.

2. Setting overmodulation, forward/reverse, output inhibit

Overmodulation is not required therefore OM = 0.

Forward motor control is required (i.e., the phase sequence

of the PWM outputs should be red-yellow-blue) therefore forward/

reverse bit F/R = 0.

Output inhibit should be inactive (i e., the outputs should be

active), therefore INH= 1.

These bits are all set in temporary register R1.

3. Setting the power waveform amplitude

A

POWER

x 255

100

A

POWER

=x 100%

0 1 1 0 0 0 1 1

Temporary Register R0

0

0 1 X 0 1 1 0

Temporary Register R1

1 1 0 0

Temporary Register R2

1100

PFS

7

PFS6PFS5PFS4PFS3PFS2PFS1PFS

0

F/R OM INH X PFS11PFS10PFS9PFS

8

AMP7AMP6AMP5AMP4AMP3AMP2AMP1AMP

0

Fig. 16

The 8-bit binary equivalent of this value gives an AMP word

of 11001100 in temporary register R2. The data which must be

programmed into the three temporary registers R0, R1 and R2

(for transfer into the control register) in order to achieve the

parameters in the example given, is shown in Fig. 16.

80 x 255

100

⇒

A = = = 204

f

POWER

x 4096

f

RANGE

f

RANGE

4096

⇒

pfs = = = 1638·4

100 x 4096

250

A

225

f

POWER

=

x

pfs

Page 10

SA828

10

PRODUCT DESIGNATION

Two standard options exist, defining waveform shape. These

are designated SA828-1 and SA828-2 as follows:

SA828-1

Sine + third harmonic at one-sixth the amplitude of the

fundamental:

x(t)

= A [

sin

(

ω

t

) +

sin 3(ωt)

]

SA828-2

Pure sinewave:

x(t)

= A [

sin

(

ω

t

)]

Additional wave shapes can be implemented to order, provided

they are symmetrical about the 90°, 180° and 270° axes.

Contact your local Mitel Semiconductor Customer Service

Centre for further details.

1

6

HARDWARE INPUT/OUTPUT FUNCTIONS

Set Output Trip (SET TRIP input)

The SET TRIP input is provided separately from the

microprocessor interface in order to allow an external source

to override the microprocessor and provide a rapid shutdown

facility. For example, logic signals from overcurrent sensing

circuitry or the microprocessor ‘watchdog’ might be used to

activate this input.

When the SET TRIP input is taken to a logic high, the output

trip latch is activated. This results in the

TRIP output and the

six PWM outputs being latched low immediately. This condition

can only be cleared by applying a reset cycle to the

RST input.

It is essential that when not in use SET TRIP is tied low and

isolated from potential sources of noise; on no account should

it be left floating.

SET TRIP is latched internally at the master clock rate in

order to reduce noise sensitivity.

Output Trip Status (TRIP output)

The TRIP output indicates the status of the output trip latch

and is active low.

Reset (RST input)

The RST input performs the following functions when active

(low):

1. All PWM outputs are forced low (if not already low) thereby

turning off the drive switches.

2. All internal counters are reset to zero (this corresponds to 0°

for the red phase output).

3. The rising edge of

RST reactivates the PWM outputs

resetting the output trip and setting the

TRIP output high –

assuming that the SET TRIP input is inactive (i.e. Iow).

A sixth register, R5, located at A2:O = 101 is used to place

the device into a factory test mode. This is achieved by writing

dummy data to R5 immediately after

RST goes high. Care

must be exercised to ensure that the microprocessor/controller

cannot write to this register.

Zero Phase Pulses (ZPPR, ZPPY and ZPPB outputs)

The zero phase pulse outputs provide pulses at the same

frequency as the power frequency with a 1 : 2 mark-space

ratio. When in the forward mode of operation the falling edge

of ZPPR corresponds to 0° for the red phase, the falling edge

of ZPPY to 0° for the yellow phase and the ZPPB falling edge

to 0° for the blue phase. In the reverse mode, the rising edge

of a zero phase pulse corresponds to 0° for the relevant phase

PWM output.

Waveform Sampling Synchronisation (WSS output)

This output provides a square wave signal of 50% duty

cycle at a frequency 1536 times higher than the fundamental

of the power waveform. Each successive pulse of WSS

corresponds to the SA828 reading the next location of the

waveform ROM. It may be used in conjunction with the ZPP

signals to monitor the position of the machine rotor and may

form part of a closed loop control system such as slip

compensation.

Clock (CLK input)

The CLK input provides a timing reference used by the

SA828 for all timings related to the PWM outputs. The

microprocessor interface, however, derives all its timings from

the microprocessor and therefore the microprocessor and the

SA828 may be run either from the same or from different

clocks.

WAVEFORM DEFINITION

The waveform amplitude data used to construct the PWM

output sequences is read from the internal 384X8 ROM. This

contains the 90° span of the waveform as shown in Fig. 18.

Each successive 8-bit sample linearly represents the

instantaneous amplitude of the waveform. It is assumed that

the waveform is symmetrical about the 90°, 180° and 270° axes.

The SA828 reconstructs the full 360° waveform by reading the

0°-90° section held in ROM and assigning negative values for

the second half of the cycle.

These samples are used to calculate the instantaneous

amplitudes for all three phases, which will be 120° transposed

in the normal R-Y-B orientation for forward rotation or B-Y-R for

reverse rotation. The 384 8-bit samples are regularly spaced

over the 0° to 90° span, giving an angular resolution of

approximately 0·23°.

Waveform segment

0°- 30°

30·23°- 60°

60·23°- 89·77°

Sample number

0 - 127

128 - 255

256 - 383

Table 8 90° of the 360° cycle is divided into 384 8-bit

samples

Fig. 18 90° sample of typical power waveform

VALUE

OF

8-BIT

SAMPLE

0° 45° 90°

255

0

PHASE (384-BIT RESOLUTION)

POWER

WAVEFORM

Page 11

11

SA828

Fig. 19 A typical SA828 application

3-PHASE

VARIABLE VOLTAGE,

VARIABLE FREQUENCY

WAVEFORM

3-PHASE AC

INDUCTION

MOTOR

INVERTER

ISOLATOR

TTL LEVEL

PWM

WAVEFORMS

6

6

FAST

SHUTDOWN

SA828

DC LINK

–

+

SINGLE OR

3-PHASE

POWER

SUPPLY

R

Y

B

RECTIFIER

AND

SMOOTHING

DATA/ADDRESS BUS

(AD

0

-AD7)

8

MICROPROCESSOR

OR

MICROCONTROLLER

WITH ON-CHIP

ROM AND RAM

OPTIONAL

EXTERNAL

ROM

OPTIONAL

EXTERNAL

RAM

Page 12

SA828

12

Page 13

13

SA828

PACKAGE DETAILS

Dimensions are shown thus: mm (in). For further package information, please contact your local Customer Service Centre.

2·36/2·64

(0·093/0·104)

28 LEADS AT

1·27 (0·050)

NOM. SPACING

17·70/18·10

(0·697/0·713)

0·10/0·30

(0·004/0·012)

0·41/1·27

(0·016/0·050)

0·25/0·71

(0·010/0·028)

0·23/0·33

(0·009/0·013)

28-LEAD MINIATURE PLASTIC DIL - MP28

0·74 (0·029)

MAX.

×45°

0·36/0·48

(0·014/0·019)

7·40/7·60

(0·291/0·299)

10·00/10·64

(0·394/0·419)

1

28

SPOT REF.

CHAMFER

REF.

0-8°

NOTES

1. Controlling dimensions are inches.

2. This package outline diagram is for guidance

only. Please contact your Mitel Semiconductor

Customer Service Centre for further information.

0·51 (0·02)

MIN

0·38/0·61

(0·015/0·024)

38·10 (1·5)

MAX

28-LEAD PLASTIC DIL – DP28

1

28

3·05 (0·120)

MIN

PIN 1 REF

NOTCH

14·73 (0·58)

MAX

5·08/(0·200)

MAX

0·23/0·41

(0·009/0·016)

15.24 (0·6)

NOM CTRS

28 LEADS AT 2·54 (0·10)

NOM. SPACING

1·14/1·65

(0·045/0·065)

NOTES

1. Controlling dimensions are inches.

2. This package outline diagram is for guidance only.

Please contact your Mitel Semiconductor Customer

Service Centre for further information.

SEATING PLANE

Page 14

SA828

14

Internet: http://www.gpsemi.com

CUSTOMER SERVICE CENTRES

●

FRANCE & BENELUX Les Ulis Cedex Tel: (1) 69 18 90 00 Fax : (1) 64 46 06 07

●

GERMANY Munich Tel: (089) 419508-20 Fax : (089) 419508-55

●

ITALY Milan Tel: (02) 6607151 Fax: (02) 66040993

●

JAPAN Tokyo Tel: (03) 5276-5501 Fax: (03) 5276-5510

●

KOREA Seoul Tel: (2) 5668141 Fax: (2) 5697933

●

NORTH AMERICA Scotts Valley, USA Tel: (408) 438 2900 Fax: (408) 438 5576/6231

●

SOUTH EAST ASIA Singapore Tel:(65) 3827708 Fax: (65) 3828872

●

SWEDEN Stockholm Tel: 46 8 702 97 70 Fax: 46 8 640 47 36

●

TAIWAN, ROC Taipei Tel: 886 2 25461260 Fax: 886 2 27190260

●

UK, EIRE, DENMARK, FINLAND & NORWAY

Swindon Tel: (01793) 726666 Fax : (01793) 518582

These are supported by Agents and Distributors in major countries world-wide.

© Mitel Corporation 1998 Publication No. DS4226 Issue No. 2.0 November 1996

TECHNICAL DOCUMENTATION – NOT FOR RESALE. PRINTED IN UNITED KINGDOM

HEADQUARTERS OPERATIONS

MITEL SEMICONDUCTOR

Cheney Manor, Swindon,

Wiltshire SN2 2QW, United Kingdom.

Tel: (01793) 518000

Fax: (01793) 518411

MITEL SEMICONDUCTOR

1500 Green Hills Road,

Scotts Valley, California 95066-4922

United States of America.

Tel (408) 438 2900

Fax: (408) 438 5576/6231

This publication is issued to provide information only which (unless agreed by the Company in writing) may not be used, applied or reproduced for any purpose nor form part of any order or contract nor to be regarded

as a representation relating to the products or services concerned. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or service. The Company

reserves the right to alter without prior notice the specification, design or price of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any

guarantee that such methods of use will be satisfactory in a specific piece of equipment. It is the user's responsibility to fully determine the performance and suitability of any equipment using such information and

to ensure that any publication or data used is up to date and has not been superseded. These products are not suitable for use in any medical products whose failure to perform may result in significant injury

or death to the user. All products and materials are sold and services provided subject to the Company's conditions of sale, which are available on request.

All brand names and product names used in this publication are trademarks, registered trademarks or trade names of their respective owners.

Loading...

Loading...