Page 1

MT8924

PCM Conference Circuit (PCC)

Preliminary Information

Features

• Supports up to 10 indepen dent confere nces for

up to 32 PCM Voice Channels

• ST-BUS compatibl e 2.048 M b/s PCM Se rial

Interface (al so su pports 1.536 M b/s an d 1.5 44

Mb/s data rates)

• Per channel digita l gain contro l (0/-3/ -6 dB)

• Parallel microprocessor port for device control

• Programmab le noi se su ppres sion

• External Tone Input

• Pin select able A/µ -Law format

• Low power CM OS t echnol ogy

• Available in 24 P in PD IP an d SO IC pa ckage s

Applications

• Digital PBX / KTS

• Conference b rid ges

• Digit al C .O . s witc h es

ISSUE 1 April 1994

Ordering Information

MT8924AE 24 Pin Plastic DIP

MT8924A S 24 Pin SOIC

°

C to +70°C

0

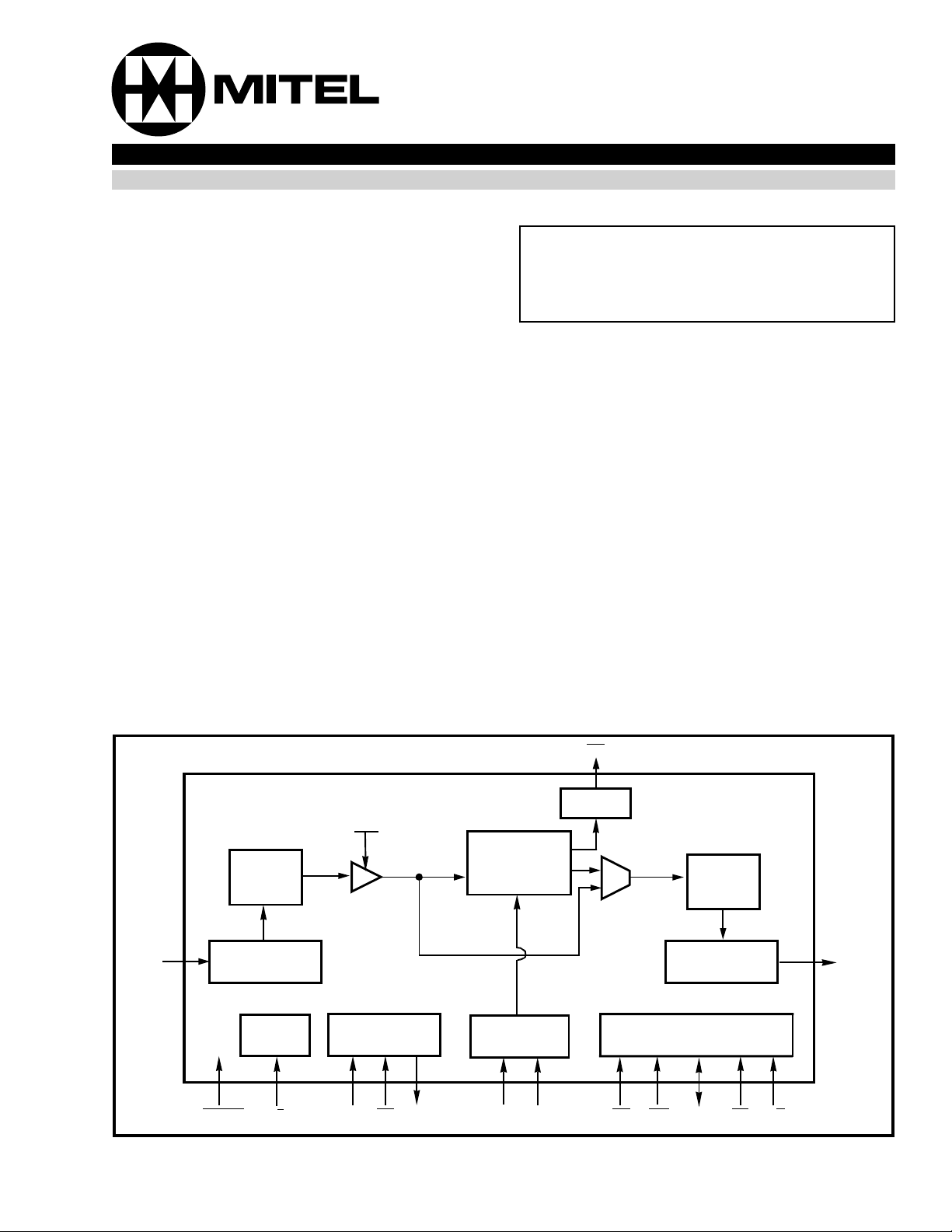

Description

The MT8924 is designed to provide conference call

capability in digital switching systems. It allows up to

10 independent conferences to be set for up to 32

PCM voice channels.

A/µ-Law companded data from the PCM input port is

converted to linear format, processed by a dedicated

arithmetic unit, re-converted to companded format

and then sent to the PCM output port.The PCM

output signal contains all the information of each

channel connected in conference except its own.

Programmable attenuation and noise suppression

are provided for channels connected in conference

or transparent mode. Additionally, an input for an

external tone is featured that can be used as a signal

to indicate to connected parties that they are on a

conference call.

DSTi

OS

Overflow

Attenuation/Noise Suppression

Channel RAM

µ/A-Law

to

Linear

Serial-to -Parallel

Conversion

PCM Mode

Control

RESET WRRD CS C/ D

A/µ

Timebase

Cki F0i

Cko D0-D7TDTF

and

Adder

PCM Tone

Generator

Linear

MUX

to

µ/A-Law

Parallel-to-Serial

Conversion

Control

Figure 1 - Functional Block Diagram

DSTo

8-3

Page 2

MT8924 Preliminary Information

TD

TF

RESET

OS

DSTo

D7

D6

D5

D4

D3

D2

D1

10

11

12

1

2

3

4

5

6

7

8

9

24

23

22

21

20

19

18

17

16

15

14

13

VSS

A/µ

DSTi

Cko

Cki

F0i

WR

RD

CS

C/D

VDD

D0

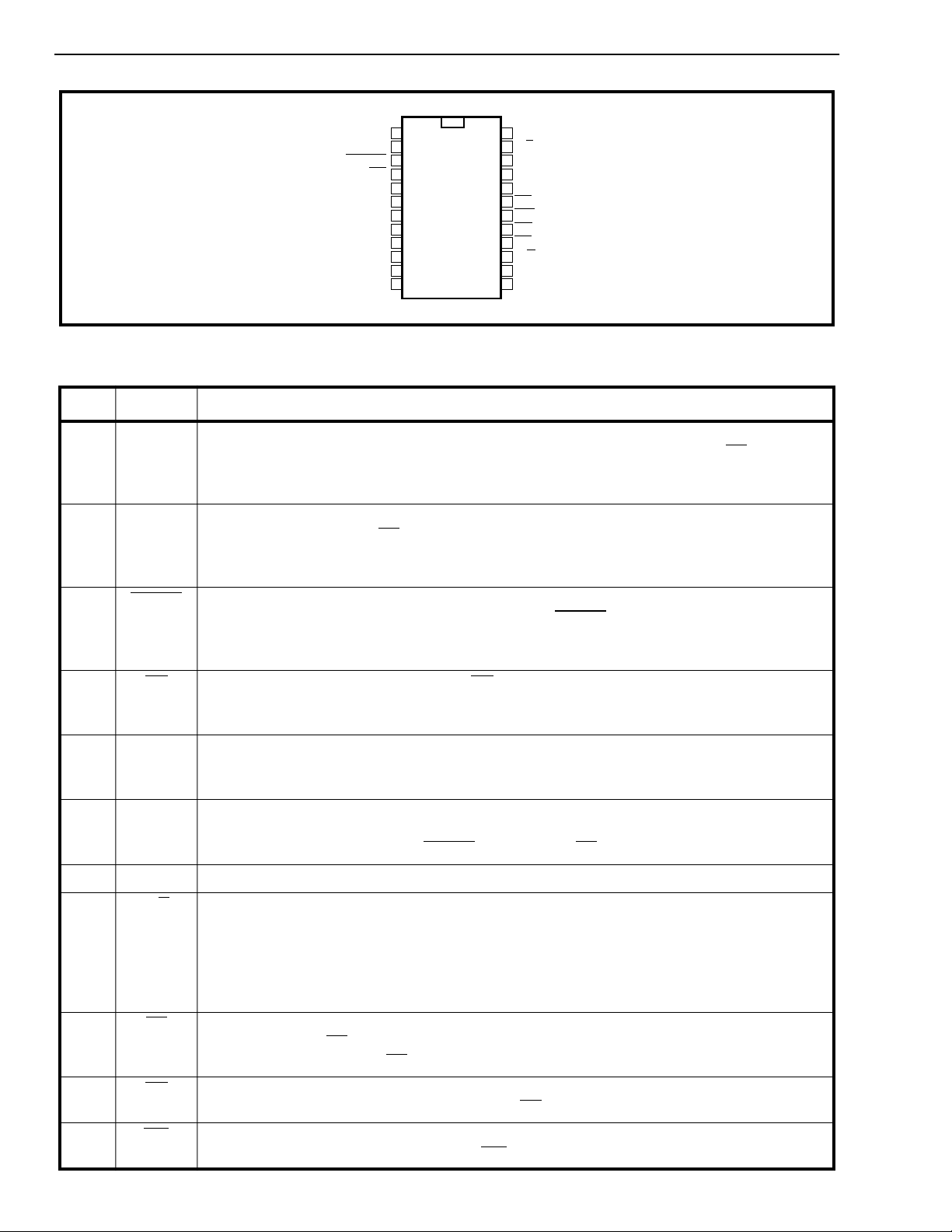

Figure 2 - Pin Connections

Pin Description

Pin # Name Description

1TDTone Duration (Input). When TD is High, a PCM-coded tone is sent out to all channels of

the enabled conferences instead of PCM dat a. TD is latched by frame pulse F0i

channels have the same tone during the same frame numb er. When TD is Low, normal

operation is enabled.

2TFTone Frequency (In put). This input is connected to an external squarewave generator. TF

is strobed by frame pulse F0i

so that all channels have the same tone frequency during the

same number of frames. Th e PCM-coded ton e level corresponds to 1/10th of the full scale

value, and is activated when TD is High.

so that all

3 RESET

Master RESET (Input). This input is used for system initializat ion after power up, or when

the companding law format has been changed. The RESET

pin is strobed by the rising edge

of clock Cki. Complete circuit initialization takes two frame periods. Initialization disables the

output drivers of the microprocessor interfa ce and DSTo.

4OS

Overflow Signalling (Output). When OS is Low, a conference is in the overflow condition.

This signal is delayed by half of a timeslot relative to the beginning of the output channe l of

the conference in overflow (se e Figure 9).

5DST

ST-BUS Seria l O u t p u t. This pin is the output for the PCM signal. It is enabled upon

o

channel selection, otherwise it is placed in a high impedance state. Maximu m bit rate is

2.048 Mb/s.

6-13 D7 to D0 Data Bus I/O Port. These are bidirectional data pins over which data and instructions are

transferred to and from the microprocessor (where D0 is the least significant bit). The bus is

14 V

DD

15 C/D

in a high impedance state when RESET

Positive Supply Voltage. Nominally 5 volts.

Control/Data Select (Input). The signal on this input defines whether the information on the

is Low and/or CS is High.

data bus should be interpreted as opcode or data. During a write operation a Low signal

defines the bus content as data, while a High signal def ines it as opcode. During a read

operatio n this input differen tiat es overflo w statu s between the first eig ht channels for C/D

being LOW, and the last two channels for C/D being HIGH (see Instruction 4). This input also

allows status monitoring (see Inst ructio n 6) during a read operation.

16 CS

Chip Select (Input). This active low input selects the device for microprocessor read/write

operations. When CS

microprocessor, and when CS

is Low, data and instructions can be transferred to or from the

is High, the data bus is in a high impedance state.

17 RD

18 WR

8-4

Read (Input). This active low input is for the read signal on the microprocessor interface.

The data bus is updated on the falling edge of RD

.

Write Input. This active low input is for the write signal on the microprocessor interface. The

data bus is strobed on the rising edge of WR

.

Page 3

Preliminary Information MT8924

Pin Description (continued)

Pin # Name Description

19 F0i Frame Pulse (Input). This is an 8 kHz active low input used for frame synchronization of the

PCM bit stream. The first falling edge of Cki followin g the falling edge of frame pulse F0i

determines the start of a new frame and mu st correspond to the first bit of the first channel.

When PCM frames o f 1544 kbit/s are used, the rising edge of F0i

must correspond to the

Extra (193rd) bit.

20 Cki Clock (Input). This signal is the timing reference used for all int ernal operat ion s. The PCM

bit cell boundaries lie on the alternate fall ing edges of this clock. The maxim um all owable

clock frequency is 4096 kHz.

21 Cko Clock (Output). This pin provides the master clock for a digital crosspo int switch (e.g. ,

MT898x series, or the MT9080, MT9085 co mbi nat ion). Normall y the signal on this pin is

identical to Cki. Wh en Extra bit operating m ode is selected (see Inst ructio n 5), the first two

cycles of the master clock are suppressed (see Figure 10). This feature allows the MT8924

to operate in 1544 kbit/s systems.

22 DST

ST-BUS Serial Input. This pin accepts the serial PCM input stream at a maximum allowable

i

bit rate of 2048 kbit/s. In normal operation the first bit of the first channel is defi ned by the

rising edge of Cki following the falling edge of fram e pulse F0i

mode is selected, the first bit of the first channel defines the extra bit.

23 A/µ

A/µ - Law Select Input. When A/µ is High, A-Law is selected, and when A/µ is Low, µ -Law is

selected. The companding law selection m ust be done before init iali zing the device using

pin.

24 V

the RESE T

Negative Power Supply Voltage. Nominally 0 Volts.

SS

Functional Description

The MT8924 is a device designed to provide

conferencing in a digital switching system in any

combination for up to all 32 channels of a 2048 kbit/s

ST-BUS stream (see Figure 3).

The information of channel N, frame M is first

converted to Linear PCM and then added to the

signal from other conferencees during the first half of

Microcontroller

STi0

.

.

.

.

STix-1

STix

MT8980/81/82

Digital Switch

MT8924

PCM Conference

Circuit (PCC)

STo0

.

.

.

.

STox-1

STox

. When Extra bit opera tin g

channel N+1, frame M and subtracted during the

second half of channel N-1, frame M+1. After Linearto-PCM conversion the subtraction result goes to the

parallel-to-serial converter, and appears at the

output on the N+1 channel, M+1 frame with respect

to the corresponding sending party information (see

Figure 4).

To a microprocessor the MT8924 appears as a

memory mapped peripheral device that can be

controlled by a set of six instructions. These

commands can be used to establish or cancel

conferences between the PCM channels and also to

transmit control messages on specific operating

modes. The microprocessor can initiate and receive

status messages or check conference connections

that are currently in operation.

Output

Information

B+C A+C A+B

DSTo

N+2 N+3N+1

Output Channels

Frame M+1

DSTi

Input

Information

B

A

Input Channels

Frame M

C

N+2N+1N

MT8924

Figure 3 -Typical Conference Connec tion

Figure 4 - Input/ Outp ut Chan nel Relati on shi p

8-5

Page 4

MT8924 Preliminary Information

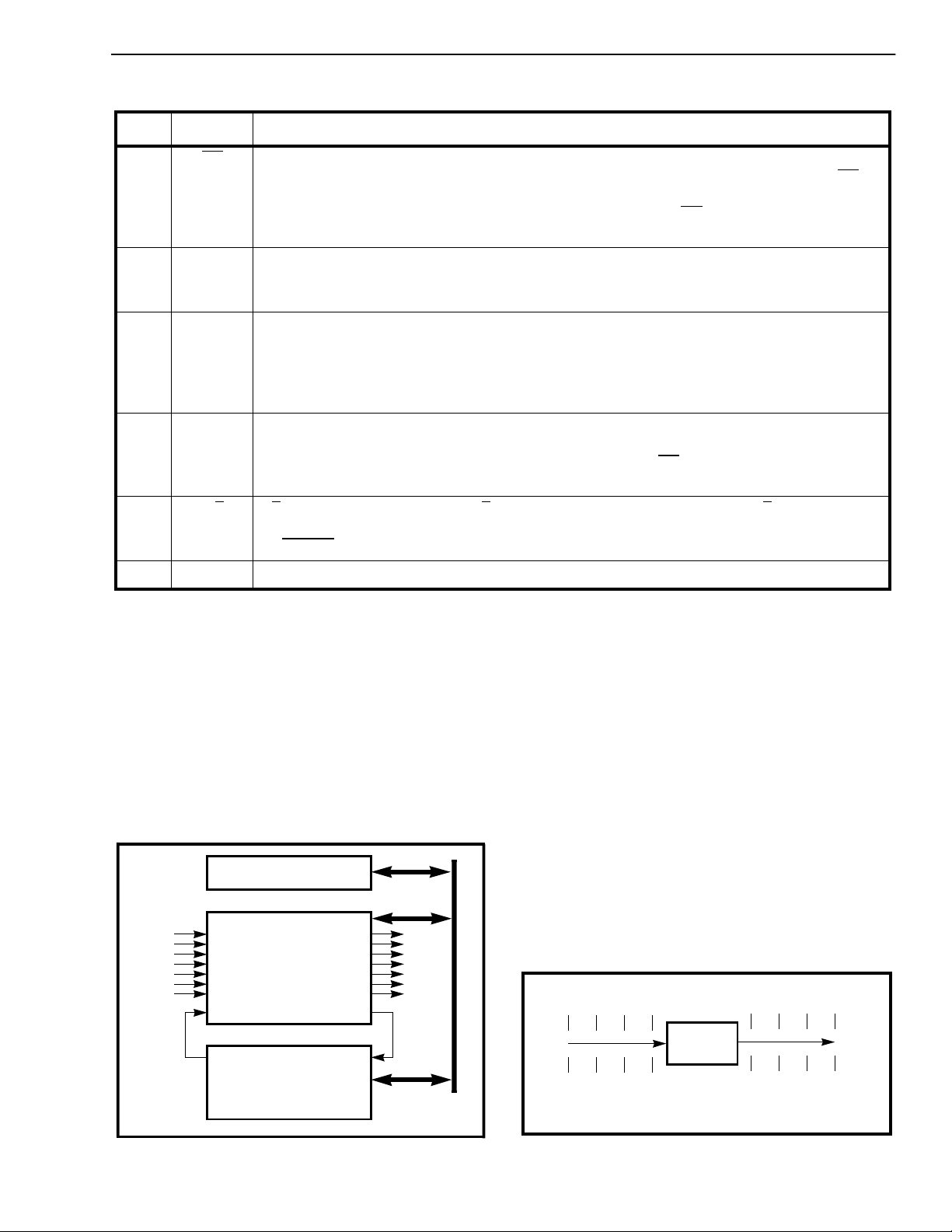

Noise

Threshold

A-Law 1/4096 1000 0000 0000 0000

9/4096 1000 0100 0000 0100

16/4096 1000 1000 0 000 1000

32/4096 1000 1111 0000 1111

µ-Law 1 /8159 1111 1111 011 1 11 11

9/8159 1111 1011 0111 1011

16/8159 1111 0111 0111 0111

32/8159 1111 0000 0111 0000

Table 1 - PCM Noise Suppression Threshold Levels

Overflow Detection / Input Channel Attenuation

If the sum of the channels involved in one

conference exceeds the full scale value of the

accumulator, an overflow condition is generated

which can be monitored specifically by reading the

status of the overflow register. If an overflow

condition occurs, then each channel in a conference

can be independently attenuated if desired.

PCM Byt e

+ve input -ve input

B7 - B0 B7 - B0

Alternatively, a conference in the overflow condition

can be detected using the OS

with frame pulse F0i

second half of a general output channel slot time N,

if channel N belongs to a conference in overflow (see

Figure 11). This information can be used to control

input channel attenuation through software control.

. OS will be low during the

signal in conjunction

F1 F0 B7 B6 B5 B4 B3 B2 B1 B0 Comments

00+ Full Scale11111111No Inversion

+ 0 Level 10000000

- 0 Level 00000000

- Full Scale01111111

01+ Full Scale10101010Even Bit Inversion

+ 0 Level 11010101

- 0 Level 01010101

- Full Scale00101010

10+ Full Scale11010101Odd Bit Inversion

+ 0 Level 10101010

- 0 Level 00101010

- Full Scale01010101

11+ Full Scale10000000Bit Inversion

+ 0 Level 11111111

- 0 Level 01111111

- Full Scale00000000

B7 (sign bit) is the MSB and B0 is the LSB

F1-F0 corresponds to the D5-D4 bits of the control byte of Operating Mode Instruction 5

Table 2 - PCM Byte Format

8-6

Page 5

Preliminary Information MT8924

Noise Suppression

When noise suppression is enabled for a specific

input channel then the PCM bytes for this channel,

when below the selected threshold level, are

converted to PCM bytes corresponding to the

minimum PCM code level before being added to the

conference sum.

The four threshold levels available correspond to the

first, fifth, ninth and sixteenth step of the first

segment. These are 1/4096, 9/4096, 16/4096, and

32/4096 with respect to full scale A-Law, and 1/8159,

9/8159, 16/8159, and 32/8159 with respect to full

scale µ-Law (see Table 1).

PCM Form a t S e le ct ion

PCM digital code assignment is register

programmable and achieved through the use of

Instruction 5 (see Table 2). The available formats are

CCITT G.711 A-Law or µ-Law, with true-sign

Alternate Digit Inversion or true-sign/Inverted

Magnitude coding.

Output clock Cko provides a reference time base for

a digital time/space crosspoint switch. Normally this

signal is identical to the master clock input Cki.

When operating with the extra bit selection, through

Instruction 5, Cko is low for two clock periods, which

allows operation of the MT8924 with the 1.544 MHz

PCM frame format (see Figure 10).

Testing and Diagnostic Feature

For testing and diagnostic purposes, a status

instruction has been provided that indicates

conference location and attenuation level for each

channel requested. This data appears on the

databus upon status request.

Programmable Control

Instruction 1 : Conference Mode Connection

This function connects a PCM channel to a

conference. The control information from the

microproc esso r cons ists of two da ta by tes and one

control byt e. T he first byte cont ains the conf erence

number (bits D0-D3) and th e St a r t bi t S (D4). When

S is High, the accumul ator regi sters conn ecte d to a

conference are initialized. S set to High is only

required in Instruction 1 of the first channel

connecte d to a n ew con ference, otherwi se S i s set

LOW to bring other channels into the conference.

The second byte contains the number of the

channel to be connected (D0-D4), and the Insert

Tone Enable bit IT (D5). When IT and TD ar e both

High all the channels belonging to that conference

are enabled using the insert tone function. The

third byte c ontains a four bit opco de (D0-D3) plus

information about the attenuation level and noise

suppress ion to be app lied to the spe cific chan nel.

Transparent Mode

The MT8924 can operate in transparent mode. In

this case the PCM input (DSTi) is passed unmodified

through the MT8924 to the output (DSTo) with a

delay of one frame and one channel. This feature

allows attenuation of specific channels that are not

connected to a conference.

Tone Insertion

The MT8924 provides for tone insertion into PCM

output channels by using the two input pins TD and

TF. An externally generated square wave tone

applied to the TF input will generate a level

corresponding to 1/10 of the full scale accumulator

value when TD is High. Only channels connected in

a conference with the insertion tone bit (IT) active

will have the PCM coded tone at their output (see

Instruction 1).

Instructio n 2 : Transparent M ode Conn ection

This function sets up a PCM channel for

transparent mode operation. The control

information from the microprocessor consists of

one data by te and on e co ntrol byte.

The first byte contains the channel number, and

the second byte contains a four bit opcode (D0-D3)

and information about attenuation and noise

suppression levels to be applied to the specific

channel. P CM data o n this c hannel is not a dded to

any conference, but is transferred to the PCM

output after a full frame pulse plus one channel

delay. It is not affecte d by the tone contro l pins (TF,

TD).

Instructio n 3 : Disco nn ectio n

This function disconnects a PCM channel from a

conference. The control information from the

microproc essor consists of one data byt e and one

8-7

Page 6

MT8924 Preliminary Information

control byte. The data byte contains the number of

the channel to be disconnected. The second byte

contains the opcode (D0-D3). One frame pulse

must pass between disconnection and

reconnection of the same channel.

Instruction 4 : Overflow Status Monitoring

This function extracts overflow status information

on all existing conferences and transfers it to the

microprocessor data bus. This instruction consists

of two co ntrol by tes whic h are d ifferentiated by the

control signal. C/D set Low reads the status of

C/D

the first eight conferences, while C/D

reads the status of the remaining two conferences.

A conference is in overflow when the

correspond ing st atus bi t is high .

Instruction 5 : PCM Mode Select

This function is used to set the PCM format. The

control byte from the microprocessor consists of

one data byt e. It contains the Extra Bi t E (D6), the

Format Bits F1-F0 (D5, D4), and the opcode (D0D3). The E bit must be high when the PCM f rame

contains an extra bit (i.e. 1.544 Mb/s). Normally E

is Low. Bits F1-F0 are used to select the PCM byte

format, according to Table 2. After RESET

default valu es correspond to F1 at Low and F0 at

High if A-Law is s elected , and F1 a t High and F0 at

High if µ-Law is selected. All channels must be

disconnected when the PCM mode select

instruction is sent. They must rema in disconnected

for at lea st tw o frame pu lses a fte r the ins tructi on i s

sent. It is recommended that this instruction be

used immediately following a system reset (see

RESET

pin descrip tion).

set High

the

Instruction 6 : Status Monitoring

This function is a read operation which consists of

a data byte, a control byte, and a status byte. It

extracts information for test and diagnostic

purposes and transfers it to the microprocessor

bus. The first byte contains the channel number,

while the second byte contains the opcode (D0D3). The third byte contains the status information

about the operating mod e of the cha nnel (D4-D7);

the attenuation level (D2-D3); and the noise

suppressi on leve l (D0-D1 ).

8-8

Page 7

Preliminary Information MT8924

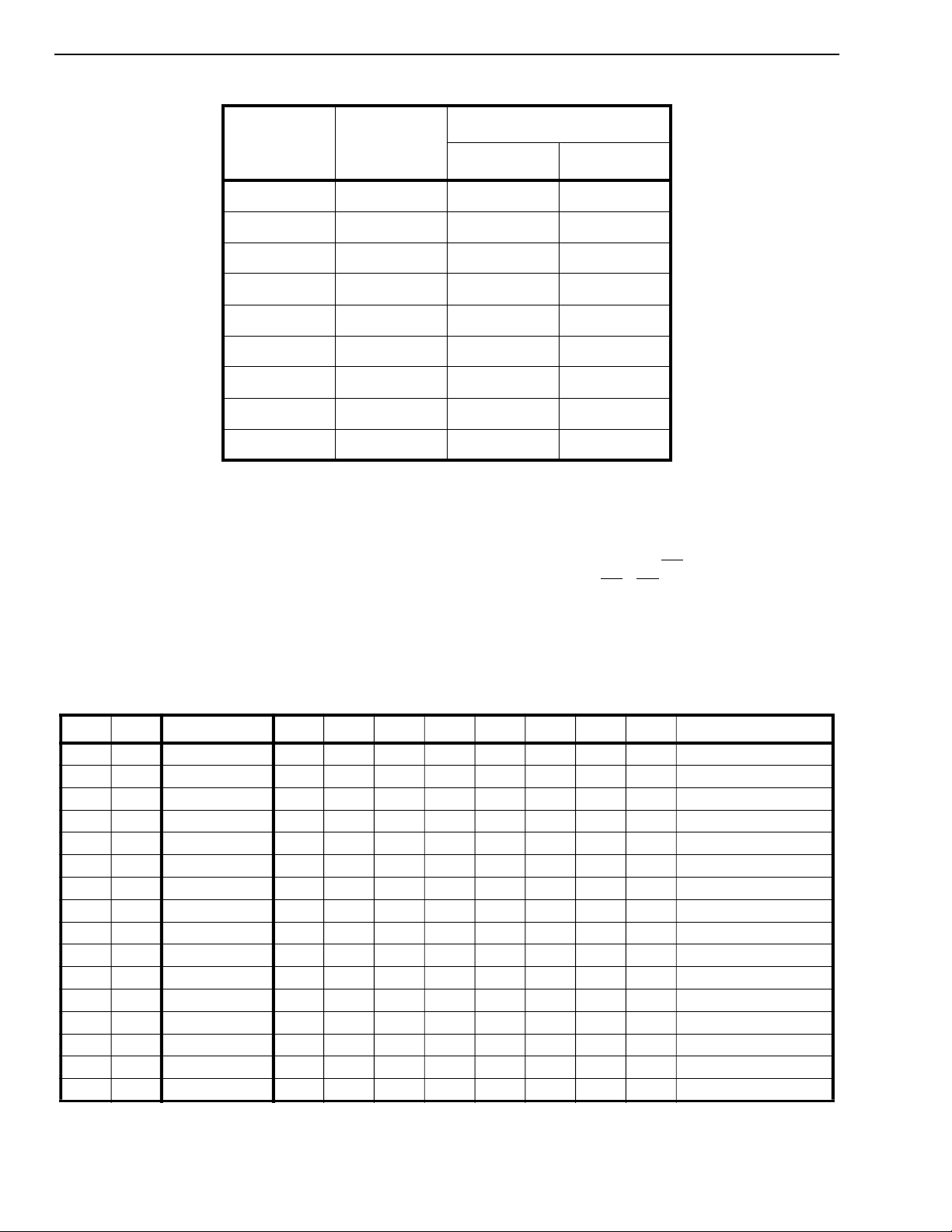

Instruction 1 : Channel Connection in Conference Mode

Control Signals Data Bus Comments

CS

RD C/D WR D7 D6 D5 D4 D3 D2 D1 D0

0100XXXSP3P2P1P0Conference Number

0100XXITC4C3C2C1C0PCM Channel Number and

Insertion Tone control

0110A1A0T1T00111Opcod e, Attenuation , and

Noise Suppression control

S: Conference Start Bit T1-T0: Channel Noise Suppression

P3-P0: Conference Number (1-10) T1/T0

IT: Insertion Tone Function Enable (IT=1) 00 no noise suppression

C4-C0: Channel Number (0-31) 01 9/4096 9/8159

A1-A0: Channel Attenuation 10 16/4096 16/8159

00 = -0dB 11 32/4096 32/8159

01 = -3dB

10 = -6dB

Instruction 2 : Channel Connection in Transparent Mode

A-Law µ-Law

Control Signals Data Bus Comments

CS

RD C/D WR D7 D6 D5 D4 D3 D2 D1 D0

0100XXXC4C3C2C1C0PCM Chann el Number

0110A1A0T1T00011Opcode and Attenuation

T1-T0: see noise suppression description given for Instruction 1

Instruction 3 : Channel Disconnection

Control Signals Data Bus Comments

RD C/D WR D7 D6 D5 D4 D3 D2 D1 D0

CS

0100XXXC4C3C2C1C0PCM Chann el Number

0110XXXX1111Opcode

Instruction 4: Overflow Status Monitoring

Control Signals Data Bus Comments

RD C/D WR D7 D6 D5 D4 D3 D2 D1 D0

CS

0001CF

8CF7

CF6CF5CF4CF3CF2CF1Conferences 1 to 8

0011XXXXXXCF10CF9Conferences 9 to 10

CF10 - CF1 : Conference is in overflow when bit is HIGH

Note : as long as RD

remains LOW, the overflow status of the conference selected by C/D can be monitored in real time

8-9

Page 8

MT8924 Preliminary Information

Instruction 5 : PCM Operating Mode Selection

Control Signals Data Bus Comments

CS

RD C/D WR D7 D6 D5 D4 D3 D2 D1 D0

0110XEF1F00101see Table 1

E: Extra bit insertion (active when E=1)

F1 - F0: PCM byte format selection (see Table 1)

Instruction 6 : Status Monitoring

CS

0100XXXC4C3C2C1C0

0110XXXX0110

00 = no bit inverted

01 = even bit (B0, B2, B4, B6) inverted

10 = odd bit (B1, B3, B5) inverted

11 = all bits (B0, B1, B2, B3, B4, B5, B6) inverted

Control Signals Data Bus Comments

RD C/D WR D7 D6 D5 D4 D3 D2 D1 D0

0011P3P2P1P0A1A0T1T0

P3 - P0: channel mode operation information A1 - A0: see channel attenuation description

Note: Instruction 6 enables the data bus to read the status until reset by C/D

0000 = no connection for Instruction 1

1111 = t ransparent m ode T 1 - T0: see noise suppression description

1010 - 0001 = conference mode for Instruction 1

P3 - P0 provides conference number

=0, WR=1, and CS=0

8-10

Page 9

Preliminary Information MT8924

Absolute Maximum Ratings*

Parameter Symbol Min Max Units

1 Supply Voltage V

DD

2 Voltage on any I/O pin V

3 Current on any I/O pin I

4 Storage Temperature T

5 Power Dissipation (plastic package) P

- V

I/O

I/O

ST

D

SS

- 0.3 7 V

VSS - 0.3 VDD + 0.3 V

± 10 mA

- 65 + 150 °C

500 m W

* Exceeding these figures may cause permanent damage. Functional operation under these conditions is not guaranteed.

Recommended Operating Conditions

Characteristics Sym Min Typ* Max Units Test Conditions

1 Supply Voltage V

2 Ambient Operating Temp. Range T

3 Input Voltage High V

4 Input Voltage Low V

DD

OP

IH

IL

* Typical figures are at 25°C and are for design aid only; not guaranteed and not subject to production testing.

DC Characteristics: Clocked operation (T

4.75 5 5.25 V

0+70°C

2.4 V

V

SS

=0 to 70 ° C; VDD=5V±5%)

OP

DD

0.8 V

V for 400mv noise

margin

Characteristics Sym M in Typ Max Units Test Conditions

1 Input Low Level

2 Input High Level

3 Output Low Level V

4 Output High Level V

5 Output Low Level V

6 Input Leakage Current I

7 Data Bus Leakage Current I

8 Supply Current I

All DC characterisitics are valid 250µs after V

V

IL

V

OH

OL

IL

OL

DD

and C4i have been applied.

DD

2.0 V Pins 1-3, 6-13, 15-20, 22-23

IH

OL

2.4 V Pins 4, 6-13; IOL=4 mA

AC Electrical Characteristics - Capacitances

Characteristics Sym Mi n Typ Max Units Test Conditions

1 Input Capacit a nce C

2 I/O Capacitance (Bidirectional) C

3 Outp ut Capacitance C

I

I/O

O

0.8 V Pins 1-3, 6-13, 15-20, 22-23

0.4 V Pins 4, 6-13; IOL=4 mA

0.4 V Pins 5, 21; IOL=8 mA

10 µA Pins 1-3, 6-13, 15-20, 22-23;

V

=0 to V

IN

DD

±10 µA Pins 6-13; VIN=0 to VDD;

CS

=V

DD

10 mA Pin 14; Cki=4.096 MHz

5 pF frequency=1MHz; TOP=0

15 pF

10 pF

to 70°C;

unused pins tied to V

V

=5V±5%

DD

SS

;

8-11

Page 10

MT8924 Preliminary Information

AC Electrical Characteristics - Clocked Timing* (T

Characteristics Sym Min Typ Max Units Test Conditions

1 Clock period t

2 Clock low level width t

3 Clock high level width t

4 Clock rise time t

5 Clock fall time t

6 Sync. low setup time t

7 Sync. low level hold time t

8 Sync. high setup time t

9 Sync. high width t

10 OS

propagation delay from rising

CK

WLCK

WHCK

RCK

FCK

SLSY

HLSY

SHSY

WHSY

t

PDOS

edge of Clock

11 Cko propagation delay to Clock

t

PDEC

edges

12 TD setup time t

13 TD hold time t

14 TD setup time t

15 TD hold time

* All AC characteristics are valid 250µs after V

resistor. With Extra Bit Insert operating mode these times are 80ns longer.

** With Extra Bit Insert operating mode this time becomes 3t

DD

STD

HTD

STF

t

HTD

and the clock have been applied. CL is the max. capacitive load and RL is the test pull up

230 ns

100 ns

100 ns

50 ns **

40 ns

80 ns

t

CK

80 ns

40 ns

80 ns

40 ns

.

CK

=0 to 70°C; VDD=5V±5%)

OP

25 ns

25 ns

ns

100 ns CL=50pF

80 ns CL=50pF

Cki

F0i

TD

TF

Cko

OS

t

WHCK

t

CK

t

WLCK

t

SLSY

t

t

HLSY

t

t

STD

t

STFtHTF

t

PDEC

RCK

HTD

t

SHSY

t

PDEC

t

PDOS

t

FCK

t

WHSY

8-12

Figur e 5 - C loc k Tim i ng

Page 11

Preliminary Information MT8924

AA

AA

AA

AA

AA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAA

AAA

AAA

AAA

AAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AA

AA

AA

AA

AA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

A

A

A

A

A

AC Electrical Characteristics - PCM Timing* (T

Characteristics Sym Min Typ Max Units Test Conditions

1 Input PCM setup time t

2 Input PCM hold time

3 O utput PCM propagation delay t

*All AC characteristics are valid 250µs after V

DD

SPCM

t

HPCM

PD

and the clock have been applied. CL is the max. capacitive load and R

resistor.

**With Extra Bit Insert operating mode these times are 80ns longer.

Cki

0

12

F0i

t

SPCMtHPCM

DSTi

t

PD

MSB

80 ns

35 ns

25 125 ns CL=150pF, RL=1KΩ

=0 to 70°C; VDD=5V±5%)

OP

in 2.048MHz mode **

is the test pull up

L

DSTo

MSB

Figur e 6 - PCM Tim in g

AC Electrical Characteristics - RESET Timing* (T

=0 to 70°C; VDD=5V±5%)

OP

Characteristics Sym Min Typ Max Units Test Conditions

1 RESET

2 RESET

3 RESET

4 RESET

low setup time t

low hold time t

high setup time t

high level width t

SLRES

HLRES

SHRES

WHRES

* All AC characteristics are valid 250µs after VDD and the clock have been applied. CL is the max. capacitive load and RL is the test pull up

resistor.

Cki

t

SLRES

t

RESET

100 ns

50 ns

90 ns

t

CK

HLRES

t

SHRES

t

WHRES

ns

Figur e 7 - Rese t Tim i ng

8-13

Page 12

MT8924 Preliminary Information

AC Electrical Characteristics - Write Timing (T

Characteristics Sym Min Typ M ax Units Test Conditions

1 Write Pulse low width t

2 Write Pul se high widt h t

3 Repetition Interval between active Write

Pulses

4 Read high setup time to active Write

Pulse

5 Read high hold time from active Write

Pulse

6 Write Pulse rise time t

7 Write Pulse fall time t

8CS

9CS

10 CS

11 CS

12 C/D

13 C/D

low setup time to WR falling edge t

low hold time from WR falling ed ge t

high setup time to WR rising edge t

high hold time from WR rising edge t

setup time to Write Pulse end t

hold time from Write Pulse end t

14 Input setup time to Write Pulse end t

15 Input hold time from Bus Write Pulse

end

WL WR

WHWR

t

REPWR

t

SHRD

t

HHRD

RWR

FWR

SLCSWR

HLCSWR

SHCSWR

HHCSWR

SC/DWR

HCDWR

SDWR

t

HDWR

=0 to 70°C; VDD=5V±5%)

OP

150 ns

200 ns

500 ns

0ns

20 ns

60 ns

60 ns

0 ns Active case

0 ns Active case

0ns

0ns

130 ns

25 ns

130 ns

25 ns

WR

RD

CS

C/D

DIN

t

SHRD

t

SLCSWR

t

HHRD

t

HCDWR

t

HDWR

t

WHWR

t

SHCSWR

t

HLCSWR

t

REPWR

t

FWR

t

WLWR

t

SCDWR

t

SDWR

Figure 8 - Write Timing Characteristics

t

RWR

t

HHCSWR

8-14

Page 13

Preliminary Information MT8924

AC Electrical Characteristics - Read Timing (T

Characteristics Sym Min Typ Max Un its Test Conditions

1 Read Pulse low width t

2 Read Pulse high widt h t

3 Repetition Interval between active Read

Pulses

4 Write high setup tim e to active Read

Pulse

5 Write high hold time from active Read

Pulse

6 Read Pulse rise tim e t

7 Read Pulse fall time t

8 Low setup time to RD

9 Low hold time from RD

10 High setup time to RD

11 High hold time from RD

12 C/D

setup time to RD Pulse start t

falling edge t

falling edge t

falling edge t

rising edge t

13 Hold time from Read Pulse end t

14 Propagat ion del ay from fallin g edge of

Read Pulse

15 Propagat ion delay from rising edge of

Read Pulse to high impedance state

WLRD

WHRD

t

REPRD

t

SHWR

t

HHWR

RRD

FRD

SLCSRD

HLCSRD

SHCSRD

HHCSRD

SCDRD

HCDRD

t

PDD

t

HZ

=0 to 70°C; VDD=5V±5%)

OP

180 ns

200 ns

500 ns

0ns

20 ns

60 ns

60 ns

0 n s Active case

0 n s Active case

0 n s Active case

0 n s Active case

20 ns

25 ns

120 ns Read; CL=200pF

80 ns Write; CL=200pF

RD

WR

CS

C/D

DOUT

t

SLCSRD

t

SHWR

t

SCDRD

t

HHWR

t

HCDRD

t

HZ

t

WHRD

t

SHCSRD

t

HLCSRD

t

REPRD

t

FRD

t

PDD

t

WLRD

Figure 9 - Read Timing Characteristics

t

RRD

t

HHCSRD

8-15

Page 14

MT8924 Preliminary Information

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AA

AA

AA

AA

AA

Cki

Cko

F0i

Cki

OS

Figur e 11 - OS

t

PDEC

Extra Bit

Bit 0 Channel 0

Bit 1 Channel 0

Figure 10 - CKo Timing with Extra Bit Insertion Mode

Channel N Channel N+1 Channel N-1

Timing with Output PCM Channel belonging to a Conference in Overflow

8-16

Loading...

Loading...