Page 1

E2C0017-27-Y2

¡ Semiconductor MSC1201-xx

¡ Semiconductor

This version: Nov. 1997

Previous version: Jul. 1996

MSC1201-xx

60-Bit VFD Tube Driver with Digital Dimming and PWM Conversion Function

GENERAL DESCRIPTION

The MSC1201-xx is a 1/2 duty vacuum fluorescent display tube driver implemented in Bi-CMOS

technology. This LSI consists of 64-bit shift registers, 64 latches, PWM conversion circuit, a digital

dimming circuit, 30-segment driver and 2-grid driver. As the MSC1201-xx has both a digital

dimming circuit and a PWM conversion circuit which converts PWM signal for lamp dimming

control to PWM signal for VFD tube dimming control, the dimming control can be realized

without any external circuit.

The interface with a MCU can be done only with 3 wires (CS, DATA and CLOCK signals). Also,

DATA and CLOCK signal lines can be shared with other peripherals because of chip select

function by CS signal.

For the general purpose code, the code number is -01. (Product name: MSC1201-01GS-2K)

For a custom code, the code number will be ordered at any time.

FEATURES

• Single supply voltage : VDD = 8 V to 18 V (built-in 5 V logic regurator)

• Operating temperature range : Ta = –40°C to +85°C

• 30-segment driver outputs (IOH = –6 mA at VOH = V

• 2-grid pre-driver outputs (IOH = –30 mA at VOH = V

• Built-in digital dimming circuit (11-bit resolution)

• Built-in oscillation circuit (external R and C, f

• Built-in Power-On-Reset circuit.

• Lamp PWM signal Æ Buil-in PWM conversion circuit for vacuum fluorescent display tube.

• Built-in RC Oscillation (external R and C)

• Correspondence between shift register and output segment is settable optionally using built

in mask programmable 30 ¥ 30 PLA.

• Package :

44-pin plastic QFP (QFP44–P–910-0.80–2K)(Product name: MSC1201-xxGS-2K)

= 2.0 MHz)

OSC

xx indicates the code number

DD

DD

– 0.8 V)

– 0.8 V)

1/20

Page 2

¡ Semiconductor MSC1201-xx

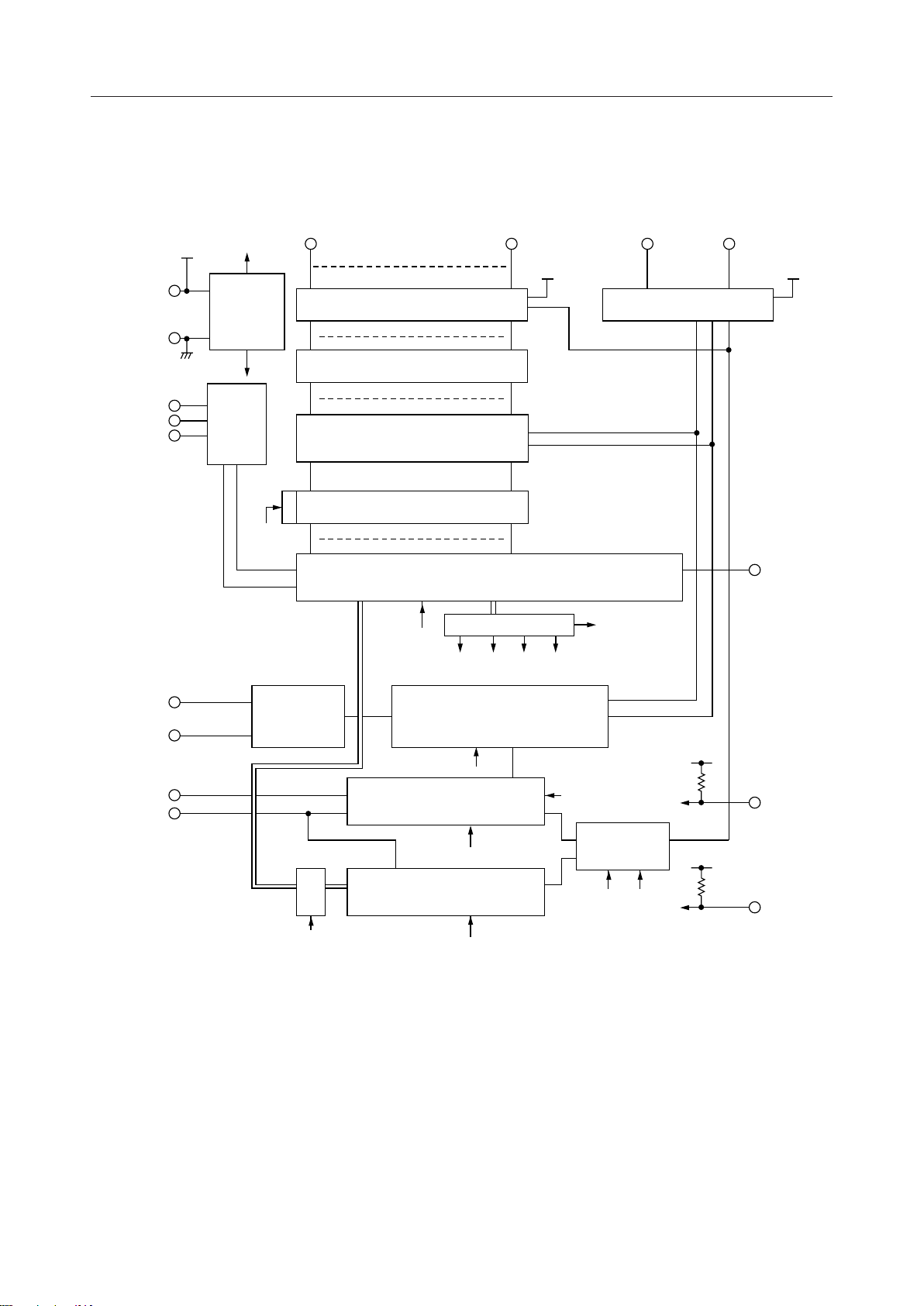

BLOCK DIAGRAM

V

DD

GND

CS

DATA

CLOCK

5 V

5 V Reg

&

POR Circuit

POR

Control

Circuit

S1

SEG1

D

CK

30-Segment Driver

30 ¥ 30 PLA Matrix

Multiplexer

Latch

64-Bit Shift Register

D48-59

R

POR

SEG30 GRID1 GRID2

2-Grid Driver

M3 M2 M1 M0

Mode Selector

S1 S2 S3 S4

Test Mode

DATA OUT

OSC0

OSC1

PWMIN

VK

RC

OSC

S2

Timing Generator

R

POR

PWM Conversion Circuit

R

POR

Digital Dimming Circuit

R

POR

S2

Selector

S3 S4

INH

TEST1

2/20

Page 3

¡ Semiconductor MSC1201-xx

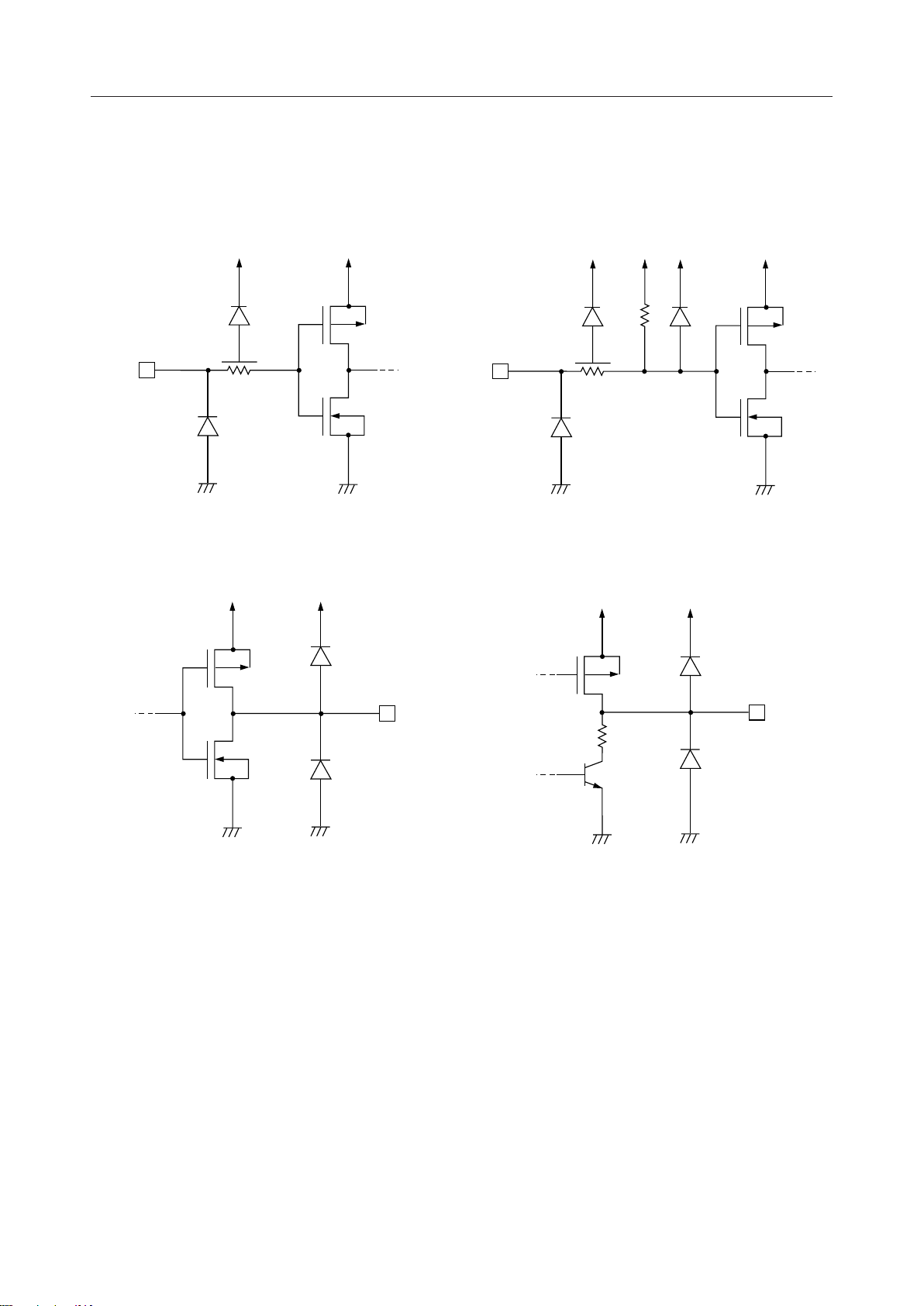

INPUT AND OUTPUT CONFIGURATION

• Schematic Diagrams of Logic Portion Input

Circuit 1

INPUT

V

DD

GND

(5V Reg.)

GND

• Schematic Diagrams of Logic Portion Output

Circuit

(5V Reg.)

(5V Reg.)

• Schematic Diagrams of Logic Portion Input

Circuit 1

TEST1

INH

V

DD

GND

(5V Reg.)

GND

• Schematic Diagrams of Driver Output Circuit

V

DD

V

DD

GND

GND

OUTPUT

GND

OUTPUT

GND

3/20

Page 4

¡ Semiconductor MSC1201-xx

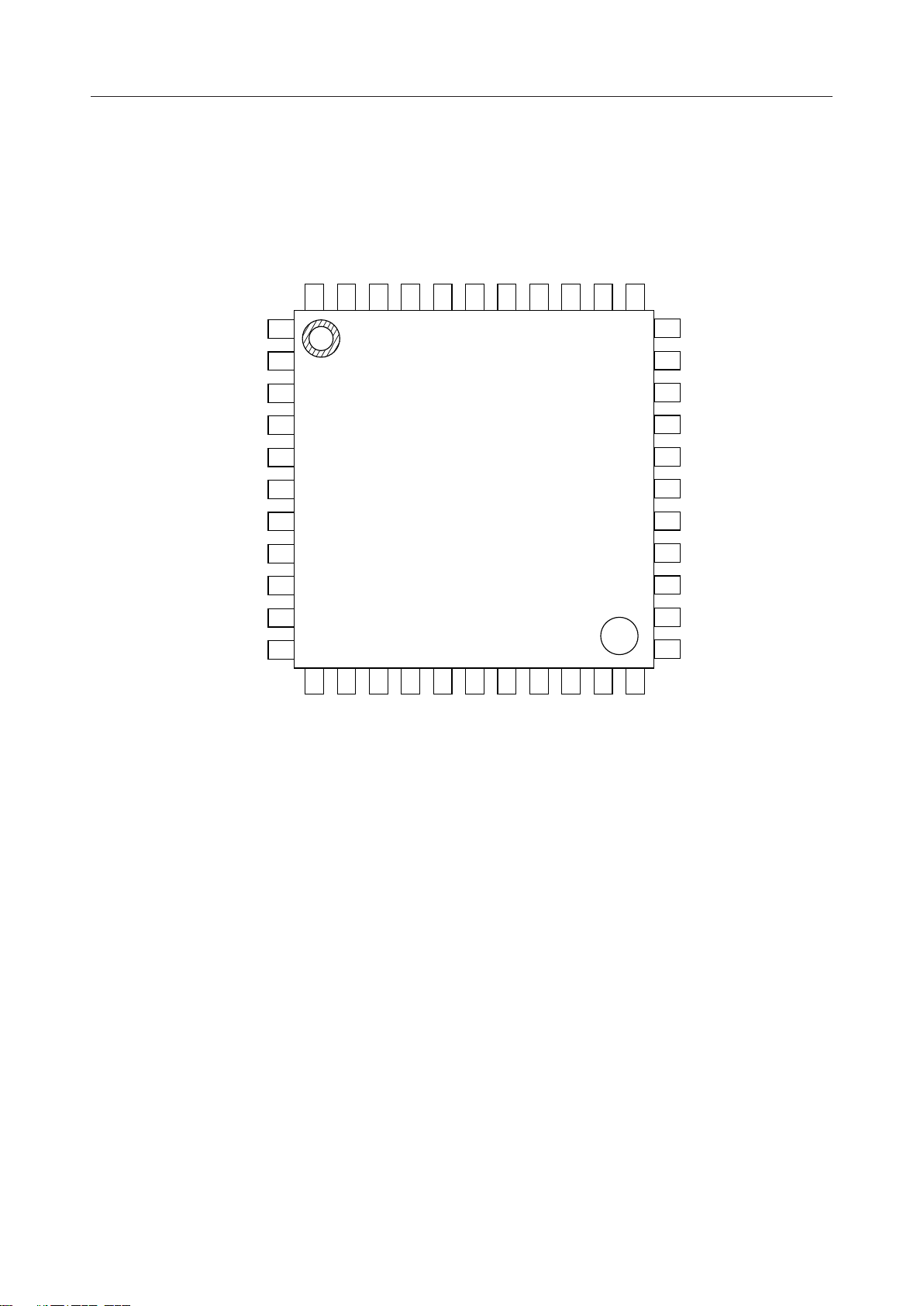

PIN CONFIGURATION (TOP VIEW)

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

SEG21

34

35

36

37

38

39

40

41

42

43

44

SEG10

SEG22

SEG23

1

2

33

32

SEG9

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

GRID1

GRID2

10

11

3

4

5

6

7

8

9

21

20

19

18

17

16

15

14

13

12

V

DD

VK

OSC0

TEST1

OSC1

44-Pin Plastic Package

GND

CS

DATA

CLOCK

INH

31

30

29

28

27

26

25

24

23

22

PWM IN

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

DATAOUT

4/20

Page 5

¡ Semiconductor MSC1201-xx

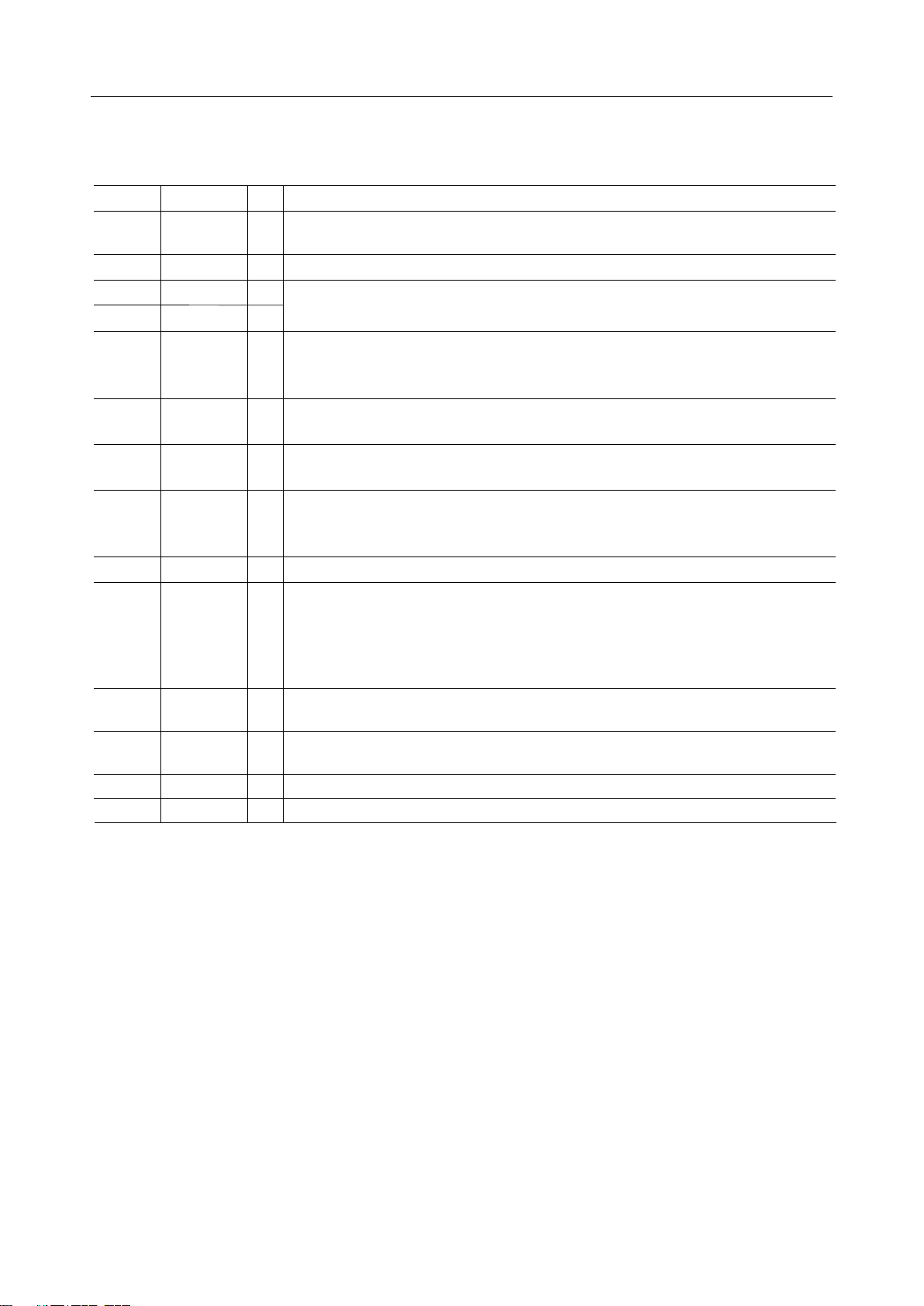

PIN DESCRIPTIONS

Pin Symbol

1-9

24-44

10, 11

16

15

18

20

19

23

22

14

SEG1-30

OSC0

OSC1

CS

DATA

CLOCK

DATA

OUT

PWMIN

VK

I/O

Segment output pin for VFD

O

OGRID1, 2 Grid 1 and Grid 2 output pins for VFD

I

RC oscillation pins. Connect a resistor between OSC1 and OSC0 pin and a capacitor

between OSC0 and GND pin.

O

Chip select input. Only when the high level is input to this pin, interfacing with a MCU

I

is available through "CLOCK" and "DATA" pins.

Therefore, 2-signal lines of "CLOCK" and "DATA" can be shared with other peripherals.

Input which receives display data and digital dimming data from a MCU. Data is

I

shifted in at the rising edge of the shift clock.

Serial clock input. Data that is input through "DATA" pin is input and output by

I

synchronization with the rising edge of the serial clock.

O

Serial data output. Data is shifted out at the rising edge of the serial clock with the

delay of 64-bit time. This pin is used for cascading this LSI with other drivers such

as a LED driver.

PWM signal input.

I

I

Dimming select input. When the high level is input, daylight-mode output duty cycle

is about 100% for each grid time for PWM conversion and digital dimming mode.

When the low level is input, the dark-mode output duty cycle is determined by the

duty cycle of the PWM signal input to PWM IN and the digital dimming output duty

cycle is determined by digital dimming data.

Description

21

13

12

17

INH

TEST1

V

DD

GND

I

Blank Display input with a built-in pull-up resistor. When set to "L", all the drivers

output "L". When display duly is not controlled by this signal, leave this pin open.

I

Test signal input pin. As this pin is used for shipping test of the LSI, leave open in the

normal operation mode.

—

Power Supply

— Ground

5/20

Page 6

¡ Semiconductor MSC1201-xx

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Condition Rating Unit

Supply Voltage V

Power Dissipation P

DD

IN

STG

D

—

All inputsInput Voltage V

—Storage Temperature Range T

Ta = 85°C

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Condition Max. Unit

Supply Voltage V

High Level Input Voltage (1) V

High Level Input Voltage (2) V

High Level Input Voltage (3) V

Low Level Input Voltage (1) V

Low Level Input Voltage (2) V

Clock Frequency f

DD

IH1

IH2

IH3

IL1

IL2

C

OSC

FR

op

All inputs except OSC0, VK

All inputs except OSC0

R = 4.7kW, C=22pFOSC Frequency f

f

OSC

—

VK

OSC0

OSC0

—

= 2 MHzFrame Frequency F

—Operating Temperature Range T

–0.3 to +20 V

–0.3 to +6 V

–65 to +150 °C

0.4 W

Min.

8

3.8

Typ.

—

18 V

5.5 V—

V

DD

5.5 V—4.5

0.8 V—0

0.5 V—0

250 kHz——

— MHz2—

—Hz224—

85 ˚C—–40

V—3.8

6/20

Page 7

¡ Semiconductor MSC1201-xx

ELECTRICAL CHARACTERISTICS

DC Characteristics

Parameter

Hight Level Input Voltage (1)

Hight Level Input Voltage (2)

Hight Level Input Voltage (3)

Low Level Input Voltage (1)

Low Level Input Voltage (2)

Hight Level Input Current (1)

Hight Level Input Current (2)

Hight Level Input Current (3)

Low Level Input Current (1)

Low Level Input Current (2)

Low Level Input Current (3)

High Level Output Voltage (1)

High Level Output Voltage (2) V

Symbol Min. Unit

*1

*9

*2

*10

*2

*3

*4

*5

*3

*4

*5

*6

*7

V

High Level Output Voltage (3)

*8

V

V

*6

Low Level Output Voltage (1)

V

*7

V

Low Level Output Voltage (2)

*8

Power Supply Current

V

IH1

V

IH2

V

IH3

V

IL1

V

IL2

I

IH1

I

IH2

I

IH3

I

IL1

I

IL2

I

IL3

V

OH1

OH2

OH3-1

OH3-2

OL1-1

OL1-2

OL1-3

V

OL2

DD

Condition

V

V

V

V

V

V

V

I

OH1

VDD = 9.5 V

I

OH2

V

I

OH3-1

VDD = 9.5 V

Output Open

V

I

OL1-1

VDD = 9.5 V

I

OL1-2

V

I

OL1-3

VDD = 9.5 V

I

OL2

= 2 MHz, No loadI

f

OSC

—

—

—

—

—

= 5.0 V

IH1

= 5.0 V

IH2

= 5.0 V

IH3

= 0.0 V

IL1

= 0.0 V

IL2

= 0.0 V

IL3

= 9.5 V

DD

= –6 mA

= –30 mA

= 9.5 V

DD

= –200 mA

= 9.5 V

DD

= 500 mA

= 200 mA

= 9.5 V

DD

= 2 mA

= 200 mA

(Ta = –40 to +85˚C, V

3.8

3.8

4.5

0

0

–5

–80

–60

–5

–0.6

–320

-0.8

V

DD

-0.8 V—

V

DD

4

4.5

—

—

—

—

= 8 to 18 V)

DD

Max.

5.5

V

DD

5.5

0.8

0.5

5

80

60

5

–0.1

–30

—

6

6

2

1

0.3

0.8

20

V

V

V

V

V

mA

mA

mA

mA

mA

mA

V

V

V

V

V

V

V—

mA

Notes: *1 Applicable to all input pins (except VK, OSC0 pin)

*2 Applicable to OSC0 pin

*3 Applicable to CLOCK, DATA, CS, VK, and PWMIN pin

*4 Applicable to TEST1

*5 Applicable to INH pin

*6 Applicable to pins SEG1 to SEG30

*7 Applicable to GRID1 and GRID2

*8 Applicable to DATA OUT pin

*9 Applicable to VK pin

*10 Applicable to all input pins (except OSC0 pin)

7/20

Page 8

¡ Semiconductor MSC1201-xx

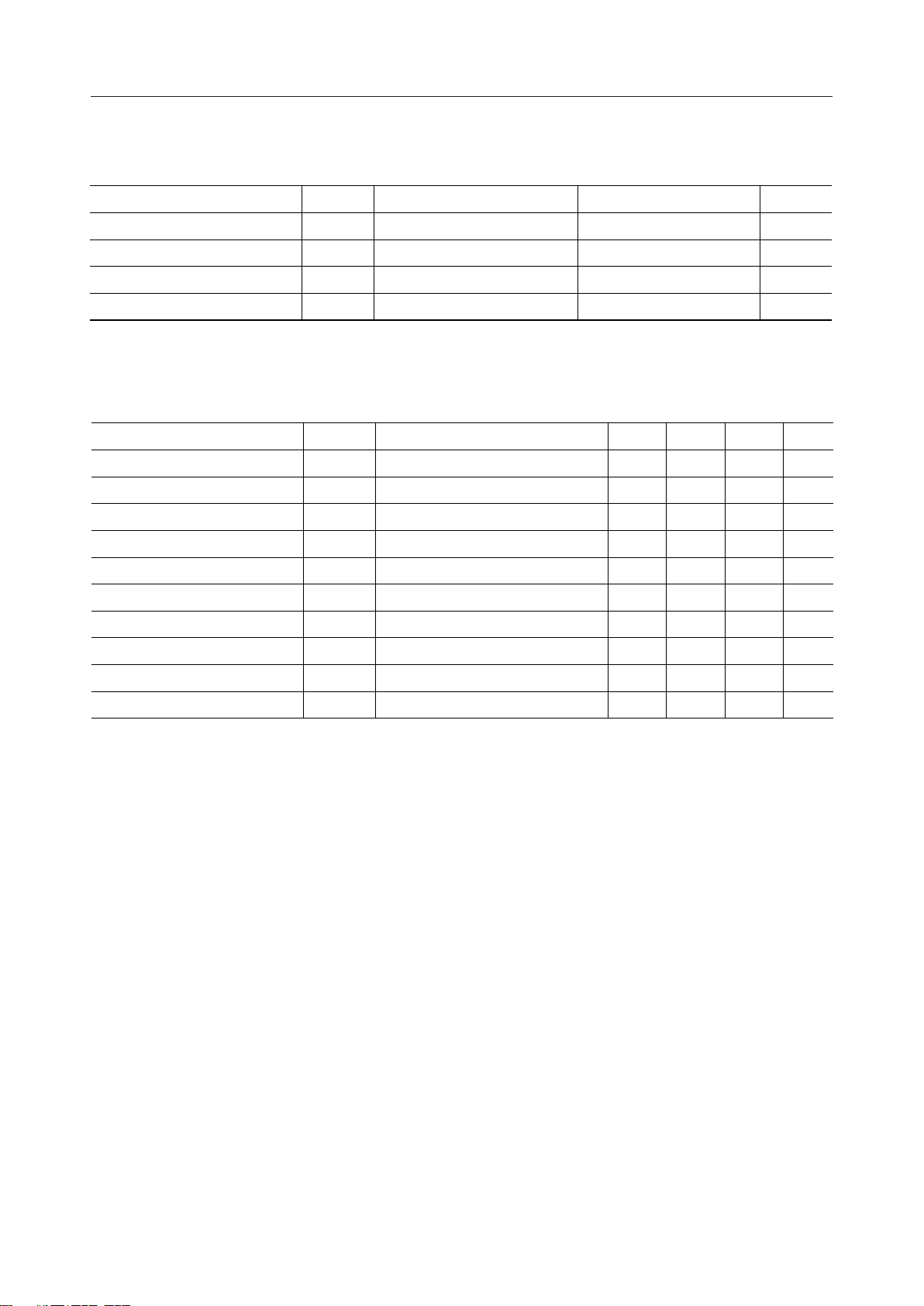

AC Characteristics

Parameter Symbol Condition Max. Unit

Oscillation Frequency f

OSC0 Input Frequency f

Clock Frequency f

Clock Pulse Width t

Data Set-up Time t

Data Hold Time t

CS Pulse Width t

CS Off Time t

CS Set-up Time

CS-Clock Time

CS Hold Time

Clock-CS Time

Data Output Delay

Clock-Data out Time

SEG & GRID Output Delay

from CS

OSC

OSCI

CW

DS

DH

CSW

CSL

t

CSS

t

CSH

t

PD

t

ODS

(Ta = –40 to +85°C, V

= 8 to 18 V)

DD

Min.

R = 4.7kW, C = 22pF

1.2

External input only

C

—

—

—

—

—

—

—

—

—

C

= 100pF

L

2.8 MHz

2.5 MHz1.5

250 kHz—

— ms1.3

— ms1

—ns200

— ms68

— ms30

— ms2

— ms2

1 ms—

8 ms—

PCS

t

POF

PRZ

t

R

FR

Slew Rate (All Drivers)

Power-off Hold Time

PWM Conversion Characteristics

Parameter

PWM Input Frequency

Input Threshold Voltage

PWM Input Duty Cycle d

Symbol Condition Unit

f

PWM

v

R

U

= 100pF, t = 20% to 80% or

C

L

80% to 20%

—Power-on CS Time t

When the Unit mounted

V

= 0 V

DD

When the Unit mountedPower-on Rise Time t

—Frame Frequency F

—

—

—

(Ta = –40 to +85°C, V

Min.

176

0.8

20

Typ.

256

2.5

—

5 ms—

— ms300

—ms5

100 ms—

342 Hz146

= 8 to 18 V)

DD

Max.

336

3.8

100

Hz

V

%

8/20

Page 9

¡ Semiconductor MSC1201-xx

TIMING DIAGRAM

t

CSW

CS

CLOCK

DATA

3.8V

0.8V

3.8V

0.8V

3.8V

0.8V

DH

f

C

t

CSS

t

CW

t

DS

t

VALID VALID

Fig. 1 Data Input Timing

t

CW

t

CSL

t

CSH

t

DS

t

DH

CLOCK

DATA

3.8V

0.8V

3.8V

0.8V

t

CW

t

PD

t

CW

Fig. 2 Data Output Timing

t

PD

9/20

Page 10

¡ Semiconductor MSC1201-xx

TIMING DIAGRAM (Continued)

V

CS

CS

DD

8V

3.8V

0.8V

3.8V

0.8V

t

PCS

Fig. 3 Power-On Timing

t

ODS

t

R

t

POF

t

CSW

t

PRZ

t

ODS

t

R

SEG1-30

GRID1, 2

PWMIN

80%

20%

Input

Threshold

Voltage

Fig. 4 SEG & GRID Driver Output Timing

PWM Frequency (f

A

) Duty Cycle dU = A/(A+B)

PWM

B

Fig. 5 PWM Input Waveform

10/20

Page 11

¡ Semiconductor MSC1201-xx

FUNCTIONAL DESCRIPTION

Power-On-Reset

The status of the internal circuit after power-on reset is as follows;

1) Shift registers and latches are reset.

2) PWM conversion mode is selected.

DATA Input

Data input is available only when the high level is applied to the "CS" pin. Input data is shifted

into shift registers through "Data" pin at the rising edge of the shift clock. The data is

automatically loaded to latches at the falling edge of "CS" signal. When M0 = "0", input data

should include display data (total of 64 bits data should be input.) and when M0 = "1", input data

should exclude display data (Total of 16-bit data should be input.)

[Data Format]

1) Display Data Input Mode

Input Data : 64 bits

VF Display Data : 60 bits

Mode Select Data : 4 bits

First In

Bit

64

D5963D5862D57

Display

Data

53

D4852M351M250M149M048D47

Mode

Data

3D22D11

D0

Display

Data

2) Segment outputs/Shift Registers Bit Correspondence Table

The content of the table depends on a PLA code.

This table is modeled on the general purpose code of -01.

Segment output positions can be changed dependent on the PLA code, but the segment-bit

correspondence cannot be changed.

302928272625242322212019181716151413121110987654321

302928272625242322212019181716151413121110987654321

Bit

60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31

SEGn

GRID1

GRID2

11/20

Page 12

¡ Semiconductor MSC1201-xx

3) Digital Dimming Data Input Mode

Input Data : 16 bits

Digital Dimming Data : 11 bits

Mode Select Data : 4 bits

64 63 621061960859758657556455354253152

xx 11

MSB

Dimming Data

(MSB) INPUT DATA (LSB)

0000000000

X

0000000000

X

1111111000

X

1111111111

X

4) Function Mode

0

1

0

1

LSB

51

M

M

3

2

Mode Data

DUTY CYCLE

0/2048

1/2048

2032/2048

2032/2048

50

M

49

First inBit

M

1

0

Mode

S1

S2 0 0 0 1 Digital Dimming Data Input

S3 0 0 1 0 PWM Conversion Select & Display Data Input

S4 0 0 1 1 PWM Conversion Select

S5 0 1 0 0 Digital Dimming Select & Display Data Input

S6 0 1 0 1 Digital Dimming Select

M3

0 0 0 0 Display Data Input

M2 M1 M0 Function

12/20

Page 13

¡ Semiconductor MSC1201-xx

PWM Conversion

In the PWM conversion mode, "lamp PWM", which is used for dimming control of back-light for

instrument clusters or other displays, is used to generate the PWM signal for VFD tube dimming

control. The lamp PWM input to "PWM IN" pin is converted to PWM signal for VFD tube with

a built-in PWM conversion look-up table (User-Programmable Mask ROM).

The duty cycle of the lamp PWM is defined as follows:

PWMIN

A

PWM Input Frequency = 256 ± 80Hz

Duty Cycle = A / (A+B)

B5V

Note: The duty cycle of the lamp PWM signal is measured with a reference point of 2.5 V typ.

As the reference point of 2.5 V is the threshold voltage of "PWM IN" pin, it deviates to

some value between 0.8 V and 3.8 V due to process parameter deviation. Therefore, the

PWM conversion error increases as the rise/fall time of the lamp PWM increases.

GRID/SEG Driver Operation and Digital/Analog Dimming Operation

Figure 6 shows an output timing of the GRID and SEG Driver when the VK is "H" level.

Output timings of the GRID and SEG drivers are shown in figure 7 for the digital dimming mode

operation in figure 8 for the PWM conversion mode operation.

(1) GRID and SEG drivers output timings when VK = "H"

1 Frame (4096-bit times)

f

FR

GRID1

GRID2

SEG1-30

Fig. 6 GRID and SEG Output Timing (VK = "H")

Note: One bit time = 2/f

6-bit times

= 1 ms typ.

OSC

2032-bit times

2038-bit times

16-bit times

10-bit times

13/20

Page 14

¡ Semiconductor MSC1201-xx

(2) GRID and SEG driver output timing when VK = "L" and in Digital Dimming Mode.

1 Frame (4096-bit times)

f

FR

GRID1

GRID2

SEG1-30

Max.

2032-bit times

6-bit times

Max.

2038-bit times

10-bit times

16-bit times

Fig. 7 GRID and SEG Output Timing (digital dimming mode)

Notes: • The above indicates the timing for the digital dimming mode with the duty cycle of

2032/2048 at V

PARK

= "L" level.

• The On-times for GRID and SEG are specified with the 11 bits of the digital dimming

data.

• One bit time = 2/f

= 1 ms typ.

OSC

(3) GRID and SEG driver output timings when VK = "L" and in PWM Conversion Mode

1 Frame (2048-bit times)

f

FR

GRID1

GRID2

Max.

256-bit times

3-bit times

SEG1-30

Max.

259-bit times

8-bit times

Fig. 8 GRID and SEG Driver Output Timing (PWM conversion mode)

Notes: • The above indicates the GRID and SEG Drivers Timing when the PWM conversion

mode at VK = "L" level is selected.

• One bit time = 4/f

= 2 ms typ.

OSC

14/20

Page 15

¡ Semiconductor MSC1201-xx

PWM Conversion Table

MSC1201-01

STEP No.

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

LAMP PWM

DUTY CYCLE

98.75%

97.50%

96.25%

95.00%

93.75%

92.50%

91.25%

90.00%

88.75%

87.50%

86.25%

85.00%

83.75%

82.50%

81.25%

80.00%

78.75%

77.50%

76.25%

75.00%

73.75%

72.50%

71.25%

70.00%

68.75%

67.50%

66.25%

65.00%

63.75%

62.50%

61.25%

60.00%

VF PWM

DUTY CYCLE

12.50%100.00%

12.30%

12.11%

11.91%

11.72%

11.52%

11.33%

11.13%

10.94%

10.74%

10.55%

10.35%

10.16%

9.96%

9.77%

9.57%

9.38%

9.18%

8.98%

8.79%

8.59%

8.40%

8.20%

8.01%

7.81%

7.62%

7.42%

7.23%

7.03%

6.84%

6.64%

6.45%

6.25%

STEP No.

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

LAMP PWM

DUTY CYCLE

58.75%

57.50%

56.25%

55.00%

53.75%

52.50%

51.25%

50.00%

48.75%

47.50%

46.25%

45.00%

43.75%

42.50%

41.25%

40.00%

38.75%

37.50%

36.25%

35.00%

33.75%

32.50%

31.25%

30.00%

28.75%

27.50%

26.25%

25.00%

23.75%

22.50%

21.25%

20.00%

VF PWM

DUTY CYCLE

6.05%

5.86%

5.66%

5.47%

5.27%

5.08%

4.88%

4.69%

4.49%

4.30%

4.10%

3.91%

3.71%

3.52%

3.32%

3.13%

2.93%

2.73%

2.54%

2.34%

2.15%

1.95%

1.76%

1.56%

1.37%

1.17%

0.98%

0.78%

0.59%

0.39%

0.20%

0.10%

15/20

Page 16

¡ Semiconductor MSC1201-xx

PLA Code Table

MSC1201-01

SEG 1

SEG 2

SEG 3

SEG 4

SEG 5

SEG 6

SEG 7

SEG 8

SEG 9

SEG 10

SEG 11

SEG 12

SEG 13

SEG 14

SEG 15

SEG 16

SEG 17

SEG 18

SEG 19

SEG 20

SEG 21

SEG 22

SEG 23

SEG 24

SEG 25

SEG 26

SEG 27

SEG 28

SEG 29

SEG 30

PIN 24

PIN 25

PIN 26

PIN 27

PIN 28

PIN 29

PIN 30

PIN 31

PIN 32

PIN 33

PIN 34

PIN 35

PIN 36

PIN 37

PIN 38

PIN 39

PIN 40

PIN 41

PIN 42

PIN 43

PIN 44

PIN 1

PIN 2

PIN 3

PIN 4

PIN 5

PIN 6

PIN 7

PIN 8

PIN 9

BIT 1, 31

BIT 2, 32

BIT 3, 33

BIT 4, 34

BIT 5, 35

BIT 6, 36

BIT 7, 37

BIT 8, 38

BIT 9, 39

BIT10, 40

BIT11, 41

BIT12, 42

BIT13, 43

BIT14, 44

BIT15, 45

BIT16, 46

BIT17, 47

BIT18, 48

BIT19, 49

BIT20, 50

BIT21, 51

BIT22, 52

BIT23, 53

BIT24, 54

BIT25, 55

BIT26, 56

BIT27, 57

BIT28, 58

BIT29, 59

BIT30, 60

16/20

Page 17

¡ Semiconductor MSC1201-xx

Pin Name Output Pin Name Output

SEG1 BIT 1,31 SEG16 BIT 16,46

SEG2 BIT 2,32 SEG17 BIT 17,47

SEG3 BIT 3,33 SEG18 BIT 18,48

SEG4 BIT 4,34 SEG19 BIT 19,49

SEG5 BIT 5,35 SEG20 BIT 20,50

SEG6 BIT 6,36 SEG21 BIT 21,51

SEG7 BIT 7,37 SEG22 BIT 22,52

SEG8 BIT 8,38 SEG23 BIT 23,53

SEG9 BIT 9,39 SEG24 BIT 24,54

SEG10 BIT 10,40 SEG25 BIT 25,55

SEG11 BIT 11,41 SEG26 BIT 26,56

SEG12 BIT 12,42 SEG27 BIT 27,57

SEG13 BIT 13,43 SEG28 BIT 28,58

SEG14 BIT 14,44 SEG29 BIT 29,59

SEG15 BIT 15,45 SEG30 BIT 30,60

17/20

Page 18

¡ Semiconductor MSC1201-xx

APPLICATION CIRCUITS

(1) Digital Dimming Mode

1/2 Duty VF Tube

Micro-

controller

12 V

SEG1 SEG30 G1,G2

VDD

GND

CS

DATA

CLOCK

OSC1

OSC0

VK

PWM IN

MSC1201-xx

18/20

Page 19

¡ Semiconductor MSC1201-xx

(2) PWM Conversion Mode

1/2 Duty VF Display Tube

SEG1 SEG30 G1 G2

12 V

V

DD

GND

CS

Micro-

controller

DATA

CLOCK

MSC1201-xx

Daylight Mode "1"

Dark Mode "0"

Illumination Switch

Dashboard Lamp

Lamp PWM Signal

Illumination Lamp

5 V

OSC1

OSC0

VK

PWMIN

19/20

Page 20

¡ Semiconductor MSC1201-xx

PACKAGE DIMENSIONS

(Unit : mm)

QFP44-P-910-0.80-2K

Mirror finish

Package material

Lead frame material

Pin treatment

Solder plate thickness

Package weight (g)

Epoxy resin

42 alloy

Solder plating

5 mm or more

0.41 TYP.

Notes for Mounting the Surface Mount Type Package

The SOP, QFP, TSOP, SOJ, QFJ (PLCC), SHP and BGA are surface mount type packages, which

are very susceptible to heat in reflow mounting and humidity absorbed in storage.

Therefore, before you perform reflow mounting, contact Oki’s responsible sales person for the

product name, package name, pin number, package code and desired mounting conditions

(reflow method, temperature and times).

20/20

Loading...

Loading...