IXBD4410 / IXBD4411

ISOSMARTTM Half Bridge Driver Chipset

Type Description Package Temperature Range

IXBD4410PI Full-Feature Low-Side Driver 16-Pin P-DIP -40 to +85°C

IXBD4411PI Full-Feature High-Side Driver 16-Pin P-DIP -40 to +85°C

IXBD4410SI Full-Feature Low-Side Driver 16-Pin SO -40 to +85°C

IXBD4411SI Full-Feature High-Side Driver 16-Pin SO -40 to +85°C

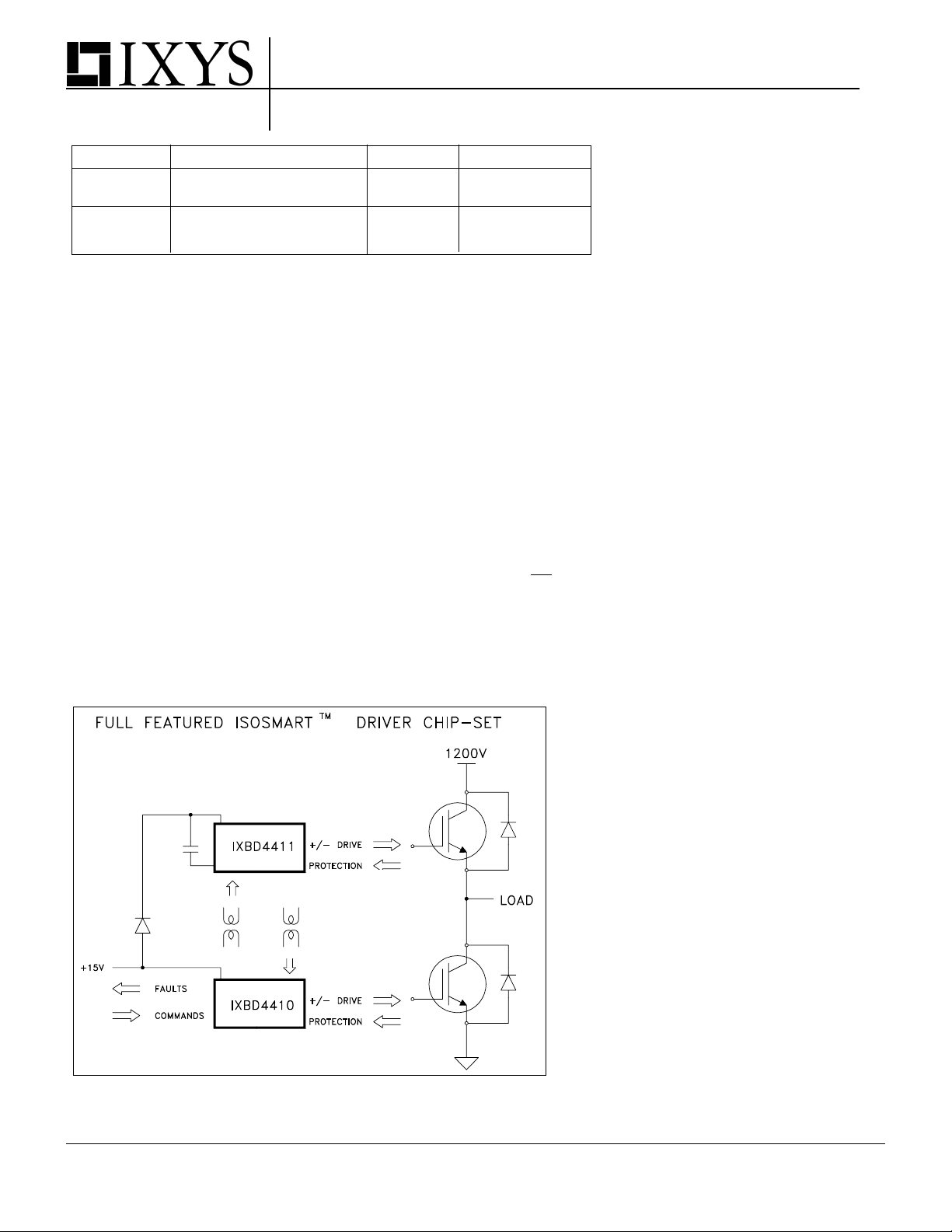

The IXBD4410/IXBD4411

ISOSMART chipset is designed to

control the gates of two Power

MOSFETs or Power IGBTs that are

connected in a half-bridge (phaseleg) configuration for driving

multiple-phase motors, or used in

applications that require half-bridge

power circuits. The IXBD4410/

IXBD4411 is a full-feature chipset

consisting of two 16-Pin DIP or SO

devices interfaced and isolated by

two small-signal ferrite pulse

transformers. The small-signal

transformers provide greater than

1200 V isolation.

Even with commutating noise

ambients greater

than ±50 V/ns and

up to 1200 V potentials, this chipset

establishes error-free two-way

communications between the

system ground-referenced

IXBD4410 and the inverter output-

referenced IXBD4411. They incorporate undervoltage V

and overcurrent or desaturation

or VEE lockout

DD

shutdown to protect the IGBT or

Power MOSFET devices from

damage.

The chipset provides the necessary

gate drive signals to fully control the

grounded-source low-side power

device as well as the floatingsource high-side power device.

Additionally, the IXBD4410/4411

chipset provides a negative-going,

off-state gate drive signal for

improved turn-off of IGBTs or Power

MOSFETs and a system logiccompatible status fault output FLT to

indicate overcurrent or desaturation,

and undervoltage V

a status fault, both devices drive

or VEE. During

DD

their respective gate outputs at VEE,

and keep their driven MOSFETs or

IGBTs off.

Features

● 1200 V or greater low-to-high side

isolation.

● Drives Power Systems Operating on

up to 575 V AC mains

● dv/dt immunity of greater than

±50V/ns

● Proprietary low-to-high side level

translation and communication

● On-chip negative gate-drive supply

to ensure Power MOSFET or IGBT

turn-off and to prevent gate noise

interference

● 5 V logic compatible HCMOS inputs

with hysteresis

● Available in either the 16-Pin DIP or

the 16-Pin wide-body, small-outline

plastic package

● 20 ns switching time with 1000 pF

load; 100 ns switching time with

10,000 pF load

● 100 ns propagation delay time

● 2 A peak output drive capability

● Self shut-down of output in response

to over-current or short-circuit

● Under-voltage and over-voltage V

lockout protection

● Protection from cross conduction of

DD

the half bridge

● Logic compatible fault indication

from both low and high-side driver

540 V-

IXYS reserves the right to change limits, test conditions and dimensions.

I - 1

Applications

● 1- or 3-Phase Motor Controls

● Switch Mode Power Supplies

(SMPS)

● Uninterruptible Power Supplies

(UPS)

● Induction Heating and Welding

Systems

● Switching Amplifiers

● General Power Conversion Circuits

© 2001 IXYS All rights reserved

IXBD4410 / IXBD4411

Symbol Definition Maximum Ratings

VDD/V

EE

V

in

I

in

Io (rev) Peak Reverse Output Current (OUT) 2 A

P

D

Supply Voltage -0.5 to 24 V

Input Voltage (INH, INL) -0.5 to VDD+0.5 V

Input Current (INL, INH, IM) ±10 mA

Maximum Power Dissipation (TA ≤ 25°C)

16 Pin PDIP (PI) 1.6 W

16 Pin SOIC (SI) 1.2 W

θθ

θ

θθ

JA

Thermal Impedance (Junction To Ambient)

16 Pin PDIP (PI) 75 °C/W

16 Pin SOIC (SI) 100 °C/W

T

A

T

JM

T

stg

T

L

Operating Ambient Temperature -40 to +85 °C

Maximum Junction Temperature +150 °C

Storage Temperature Range -55 to +150 °C

Lead Soldering Temperature for 10 s 300 °C

Recommended Operating Conditions

V

DD/VEE

VDD/LG 10 to 16.5 V

LGh/L

Gl

Supply Voltage 10 to 20 V

Maximum Common Mode dv/dt ±50 V/ns

Symbol Definition/Condition Characteristic Values

= 25°C, VDD = 15 V, unless otherwise specified)

(T

A

min. typ. max.

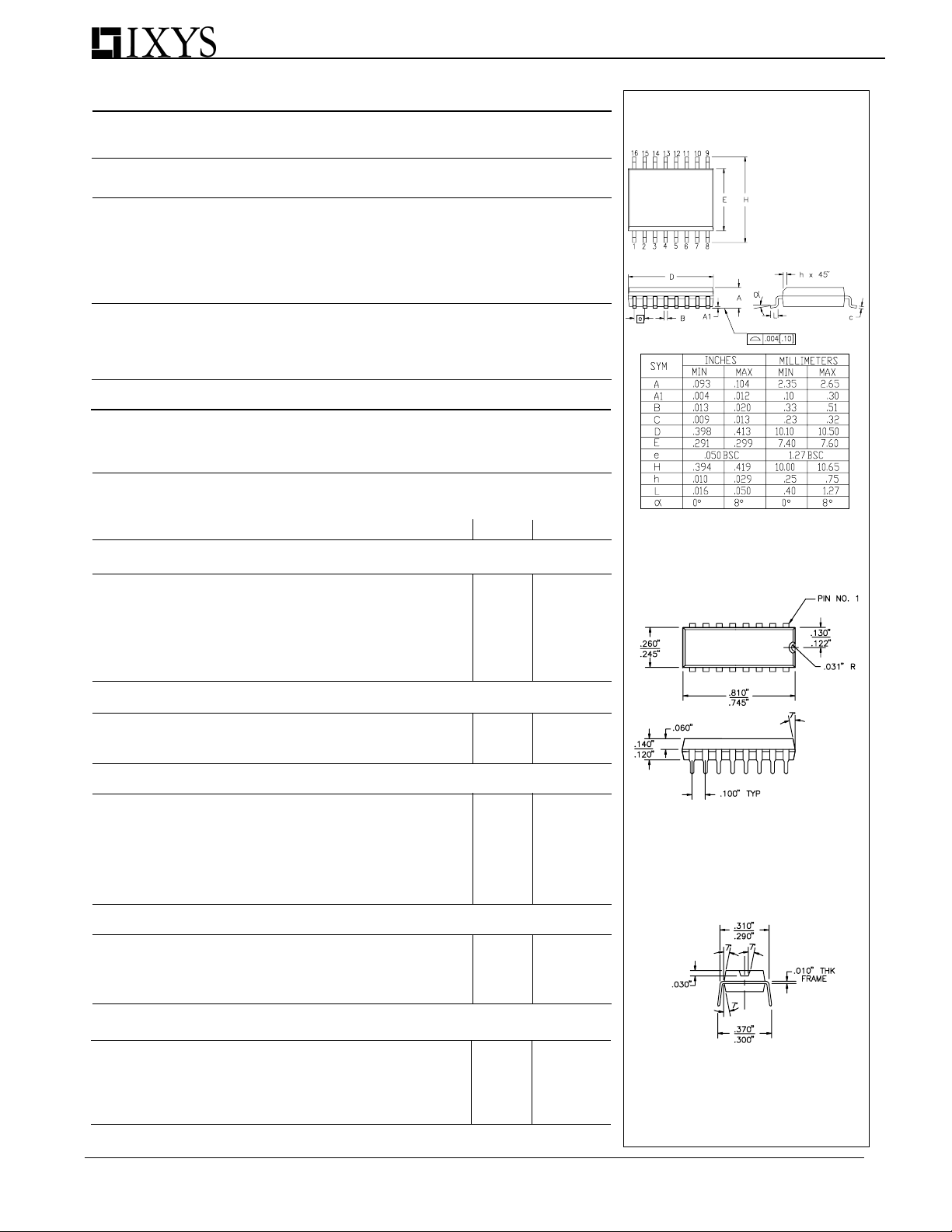

Dimensions in inch (1" = 25.4 mm)

16-Pin SO

INL, INH Inputs (referred to LG)

V

t+

V

t-

V

ih

I

in

C

in

Positive-Going Threshold 3.65 V

Negative-Going Threshold 1.5 V

Input Hysteresis .6 V

Input Leakage Current/Vin=VDD or LG -1 1 µA

Input Capacitance 10 p F

Open Drain Fault Output (referred to LG)

V

oh

V

ol

HI Output/Rpu = 10 kΩ to V

DD

LO Output/Io = 4 mA 0.4 0.7 V

OUT Output (referred to LG)

V

oh

V

ol

R

o

R

o

I

pk

HI Output/Io = -5 mA VDD-0.05 V

LO Output/Io = 5 mA VEE+0.05 V

Output HI Res./Io = -0.1 A 3 5 Ω

Output LO Res./Io = 0.1 A 3 4 Ω

Peak Output Current/CL = 10 nF 1.5 2 A

IM Input (referred to KG)

V

t+

C

in

R

s

Positive-Going Threshold 0.24 0.3 0.36 V

Input Capacitance 10 p F

Shorting Device Output Resistance 80 12 0 150 Ω

16-Pin Plastic DIP

VDD-0.05 V

Cross view

VEE Supply (referred to LG)

V

EE

I

out

f

inv

V

EEF

Output Voltage/Io = 1 mA, Co = 1 µF -5 -5.5 -6.5 V

Output Current/V

Inverting Frequency 35 0 kHz

Undervoltage Fault Indication -4 -4.8 V

I - 2

= 0.70 • V

out

EE

-20 -25 mA

© 2001 IXYS All rights reserved

Symbol Definition/Condition Characteristic Values

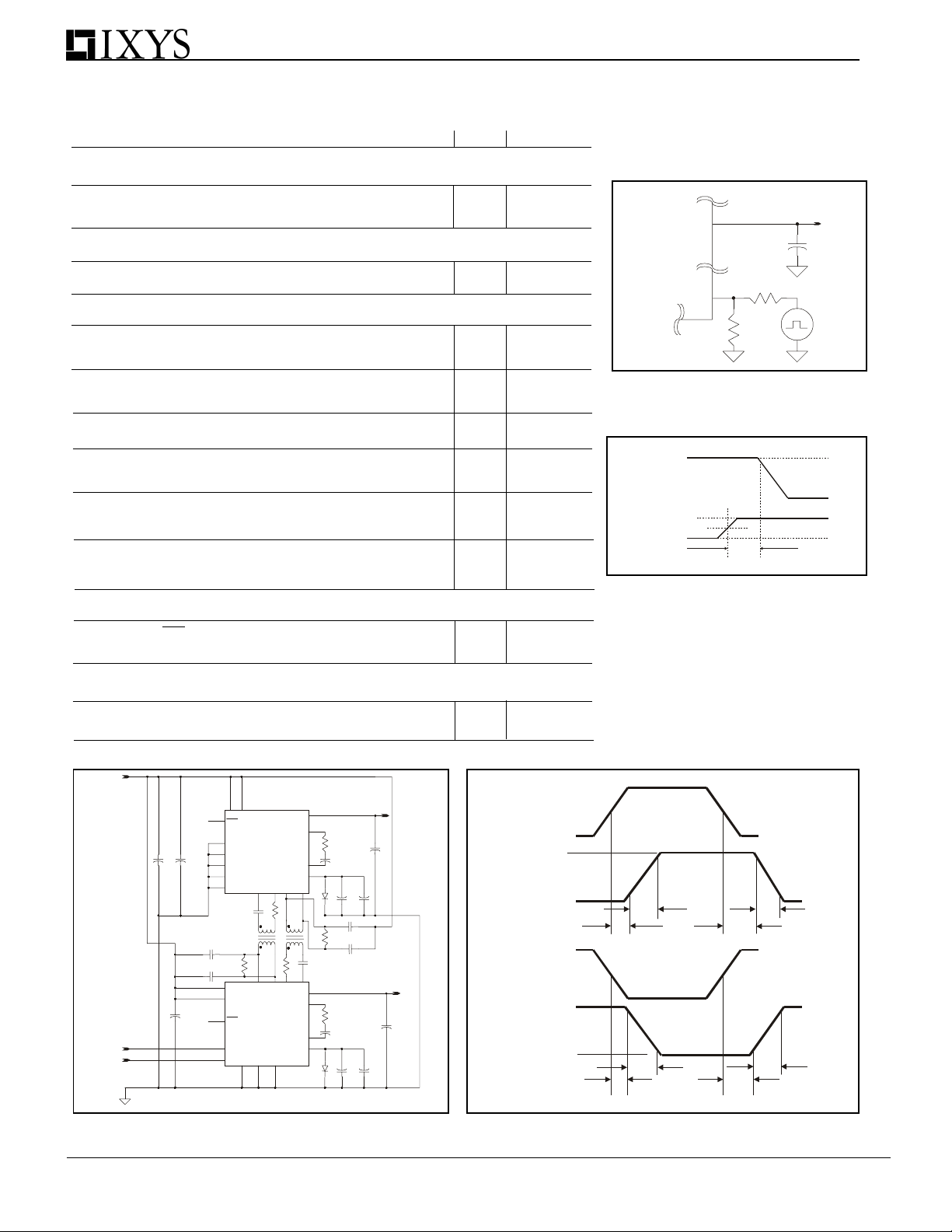

(Fig. 1A, T

= 25°C, VDD = 15 V, unless otherwise specified)

A

min. typ. max.

VDD Undervoltage Lockout

V

uv

V

uh

Drop Out 9.5 10.5 11.5 V

Hysteresis 0.1 0.3 0.5 V

Quiescent Power Supply Current

V

I

DD

Current/Vin=VDD or LG, Io = 0 3 8 mA

DD

INL and INH Inputs (Fig. 2a, 2b))

t

d(on)

t

r

t

d(off)

t

f

t

dlh(off)

t

dlh(on)

Turn-on delay time; CL =1nF 250 275 ns

4410

Rise time; CL =10 nF 70 100 ns

4410 or 4411 C

=1 nF 15 20 ns

L

Turn-off delay time CL =1nF 150 175 ns

4410

Fall time CL =10nF 70 150 ns

CL =1nF 15 20 ns

4410 to 4411

Turn-off delay time CL =1nF 250 275 ns

4410 to 4411

Turn-on delay time CL =1nF 270 300 ns

Fault Output Delay for any Fault Conditions (4410/4411)

t

FLT

FLT Delay/R

= 2 kΩ CL = 20 pF 2 3 us

pu

IXBD4410 / IXBD4411

15

OUT

IXBD4410

or

IXBD4411

R2

9

Im

Fig. 1a Overcurrent Detection

VOUT

IXBD4410

or

IXBD4411

5V

VIN

Fig. 1b Overcurrent Delay

R1

to c

4.7K

4.7K

50%

90%

CL

V IN

15V

-5V

+5V

0V

Overcurrent Protection Delay

t

oc

+15V

Driver-Off delay time CL = 10 nF 200 300 ns

(Fig. 1a, 1b)

16

1

Vdd

8

FLT

U2

3

INH

IXBD4411

2

22nF

22nF

INL

(HIGH SIDE)

9

Im

10

KG

11

LG

T+

5

22nF

22

4.7

Ω

7

16

R+

Vdd

1

U1

IXBD4410

8

FLT

(LOW SID E)

3

INH

2

INL

KG Im

LG

11

10 9

+

F

u

uF

7

.

.1

4

.1uF

Ω

T-

46

6

R-

R- R+

22

4

T- T+

OUT

CA

CB

Vee

7

Ω

5

OUT

CA

CB

Vee

1N5817

15

13

12

14

22nF

15

13

12

14

68

.1uF

7

1

8

5

N

1

4.7

68

Ω

.1uF

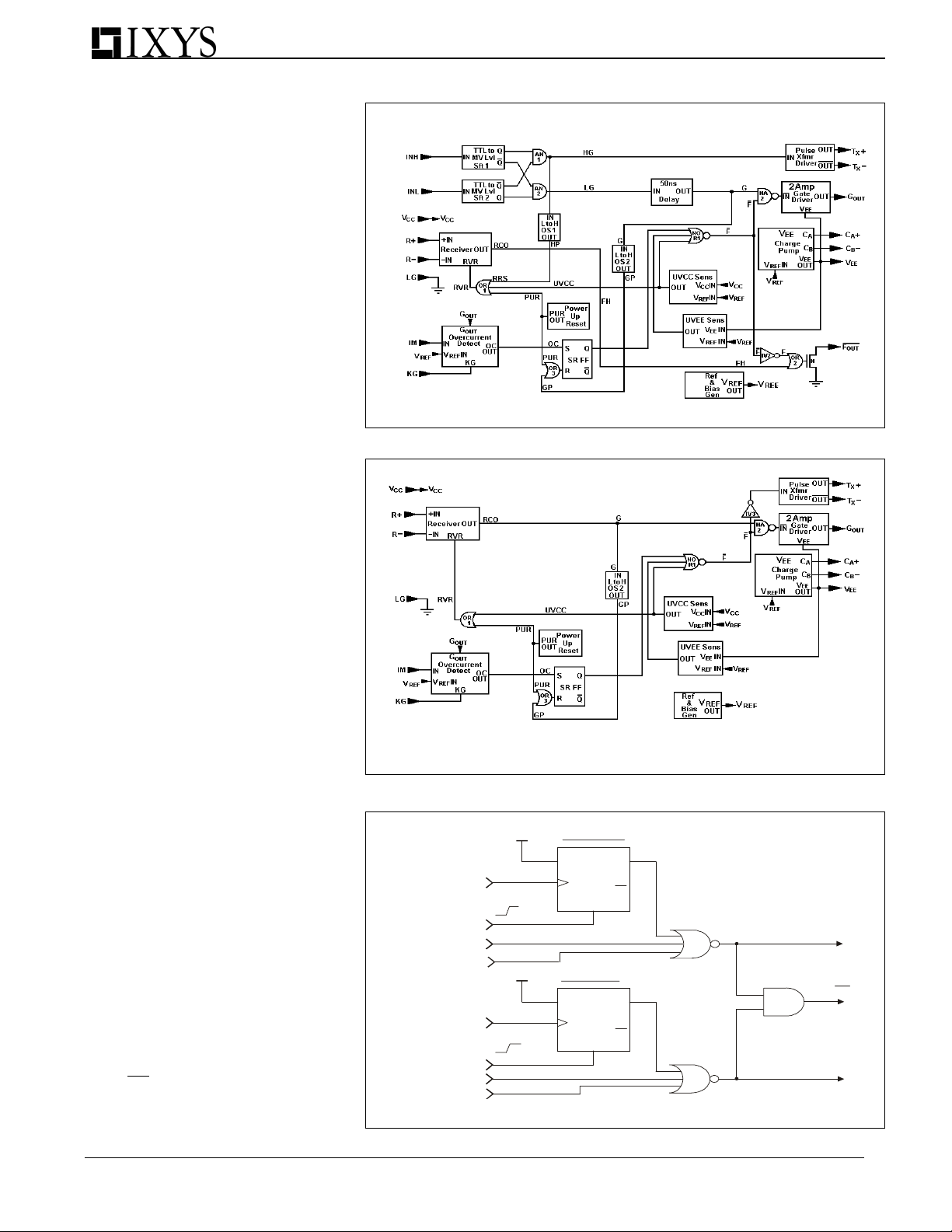

Fig. 2a: IXBD4410/4411 Switching time test circuit

Ω

F

u

1

.

+

22nF

Ω

22nF

.1uF 4.7uF

+

(IX B D 44 1 0 )

IN L

CL

F

u

7

.

4

+15V

OUT

LOW SID E

-5 V

tr

-5 0%

-9 0%

tf

-1 0%

td (of f)td (on )

(IX BD 4 4 1 0 )

IN H

+15V

CL

OUT

HIGH SIDE

-5 V

(IX B D 44 1 1 )

tf

td lh (o ff)

-5 0%

-

90%

-1 0%

tr

td lh (o n)

Fig. 2b: Output signal waveform

© 2001 IXYS All rights reserved

I - 3

Chipset Overview

This ISOSMARTTM chipset is a pair of

integrated circuits providing isolated

high- and low-side drivers for phase-leg

motor controls, or any other application

which utilizes a half bridge, 2- or 3phase drive configuration. They consist

of two drive control inputs (INL and

INH) for two Power-MOSFET/IGBT

gate-drive outputs. Both inputs operate

from a common ground and are

activated by HCMOS compatible logic

levels. The low-side output operates

near input ground, while the high-side

output operates from a floating ground

that is nominally the source connection

of the high-side phase-leg power

device. Both outputs typically provide

2A of transient current drive for fast

switching of the phase-leg power

device.

IXBD4410 / IXBD4411

Fig. 3: IXBD4410, low-side driver block diagram

IXBD4410/IXBD4411

The full featured ISOSMART

TM

driver

chipset incorporates an IXBD4410 as

the low-side driver (Fig. 3) and an

IXBD4411 as the high-side driver (Fig.

4). When input "INL" is set to a positive

logic level, the low-side gate output

goes high (turns on); when "INH" is set

to a positive logic level, the high-side

gate drive output goes high. The highside IC is isolated from the low-side IC

by a magnetic barrier, across which the

turn on/off signal is transmitted to the

high-side gate drive. The IXBD4411

fault signal is also transmitted back to

the IXBD4410 driver via these

transformers. This isolation only

depends on the low cost communications transformer, which is designed to

withstand 1200 V or more.

There are two magnetic transmission

channels between the low- and highside IC's for bi-directional communication. One sends a signal from the

low-side IXBD4410 IC up to the highside IXBD4411 IC and the other sends

a signal back from the high-side to the

low-side IC. The signal that is sent up

controls the IXBD4411 gate-drive

output. The signal sent from the

IXBD4411 back to the IXBD4410

indicates a high-side fault has occurred

(overcurrent, or under-voltage of the

high-side + power supplies). This is

detected at the IXBD4410 driver and

sets "FLT" pin low, to indicate the highside fault.

Fig. 4: IXBD4411, high-side driver block diagram

VCC

OVER CURRENT

INH

VDD UNDE R VOLTAGE

VEE UN DE R VO LTAGE

VC C

OVER CURRENT

INL

VDD UNDE R VOLTAGE

VEE UN DE R VO LTAGE

HIGH SIDE

D

R

LO W S ID E

D

R

Q

Q

Q

Q

HIGH-SIDE

OUTPUT ENABLE

FLT

LO W-SIDE

OUTPUT ENABLE

The fault signal that is returned from

I - 4

Fig. 5: Logic Representation of IXBD4410 FLT Signal

© 2001 IXYS All rights reserved

IXBD4410 / IXBD4411

the IXBD4411 is strictly for status only.

Any gate-drive shutdown because of a

high-side fault is done locally within the

high-side IXBD4411. The IXBD4411 gatedrive will turn-off the power device

whenever an overcurrent or under voltage

condition arises. The overcurrent sensing

is active only while the gate driver output

is "high" (on). The overcurrent fault

condition is latched and is reset on the

next INH gate input positive transition. The

FLT (pin 8) of the IXBD4411 is not used

and should be grounded.

The low-side IXBD4410 driver provides

an output pin 8 (FLT) to indicate a highside

(IXBD4411) or a low-side (IXBD4410)

fault. This output pin is an "open-drain"

output. The IXBD4410 low-side driver fault

indications are similar to the IXBD4411

high-side driver indications as outlined

above. A "graphic" logic diagram of the

chipset's FLT function is presented in Fig.5.

Note that this diagram presents the logic of

this function at the "low-side" IXBD4410

driver and is not the actual circuit. It

describes the combined logic of the "fault

logic" and "hi-side fault sense" blocks in

both the IXBD4410 and IXBD4411 as

shown in Fig. 3 and 4.

The most efficient method of providing

power for the high-side driver is by

bootstrapping. This method is illustrated in

the Fig. 7 application example by diode D1

and capacitor C1. Using this method, the

power is drawn through a high-voltage

diode onto a reservoir capacitor whenever

the floating high-side ground returns to near

the real ground of the low-side driver. When

the high-side gate is turned on and the

floating ground moves towards a higher

potential, the bootstrapping diode backbiases, and the high-side driver draws its

power solely from the reservoir capacitor.

Power may also be provided via any

isolated power supply (usually an extra

secondary on the system housekeeping

supply switching transformer).

Both the IXBD4410 and IXBD4411

contain on-board negative charge pumps

to provide negative gate drive, which

ensures turn-off of the high- or low-side

power device in the presence of currents

induced by power device Miller capacitance or from inductive ground transients.

These charge pumps provide -5 V relative

to the local driver ground when V

+15 V, and at rated average currents of 25

DD

is at

mA. The charge pump requires two external

capacitors, C7 and C11 in Fig. 7. The

charge pump frequency is nominally 350

The charge pump clock is turned off

kHz.

whenever the difference between the V

and VEE supplies exceed 20 V, to prevent

DD

exceeding the breakdown rating of the IC.

Both the IXBD4410 and IXBD4411 drivers

possess two local grounds each, a

common logic ground, and "Kelvin"

ground. The Kelvin ground and logic

grounds are first connected directly to

each other, and then to the Kelvin-source

of the power device for accurate overcurrent measurement in the presence of

inductive transients on the power device

source terminal.

Power MOSFET or IGBT overcurrent

sensing utilizes an on-chip comparator

with a typical 300 mV threshold. In a

typical application, the current mirror pin

of the Power MOSFET or IGBT is connected to a grounded, low-value resistor,

and to the overcurrent comparator input

on the high- or low-side driver. The

comparator will respond typically within 200

ns to an overcurrent condition to shutdown

the driver output. The power switches

could be protected also by desaturation

detection (see Fig. 7 and 8).

To assure maximum protection for the

phase-leg power devices, the chipset

incorporates the following Power

MOSFET and IGBT protection circuits:

● Power device overcurrent or desa-

turation protection. The IXBD4410/4411

will turn off the driven device within

200ns of sensing an output overcurrent

or desaturation condition.

● Gate-drive lockout circuitry to prevent

cross conduction (simultaneous

conduction of the low- and high-side

phase-leg power devices), either under

normal operating conditions or when a

fault occurs.

● During power-up, the chipset's gate-

drive outputs will be low (off), until the

voltage reaches the under-voltage trip

point.

● Under-voltage gate-drive lockout on

the low- and/or high- side driver whenever the respective positive power

supply falls below 9.5 V typically.

● Under-voltage gate-drive lockout on

the low- and high- side driver

whenever the respective negative

power supply rises above -3 V

typically.

© 2001 IXYS All rights reserved

I - 5

IXBD4410 / IXBD4411

Pin Description

IXBD4410 (Low-Side Driver)

Sym. Pin Description of IXBD 4410/4411

VDD 1 Positive power supply.

16

INL 2 Logic input signal referenced to

NC LG (logic ground). In the

IXBD4410. A "high" to this pin

turns on its gate drive output

and resets its fault logic. A "low"

to this pin turns off the gate drive

output. In the IXBD4411 this pin

is not used and should be

connected to its ground (LG).

No Connection (IXBD 4411)

INH 3 Logic input signal referenced to

NC LG (logic ground). In the

IXBD4410, this signal is

transmitted to the IXBD4411

"high-side" driver through pins 4

and 5 (T- and T+). A "high" to

this pin turns on the IXBD4411

gate drive output and resets its

fault logic. A "low" to this pin

turns off the IXBD4411 gate

drive output. In the IXBD4411

this pin is not used and should

be connected to its ground (LG).

No Connection (IXBD 4411)

T- 4 Transmitter output complemen-

T+ 5 tary drive signals. Direct drive of

the low signal transformer, which

is connected to the receiver of

the chipset's companion device.

In the IXBD4410, this signal

transmits the on/off command to

its companion IXBD4411. In the

IXBD4411, this signal transmits

the fault indication to its

companion IXBD4410 driver.

R- 6 Receiver input complementary

R+ 7 signal. Directly connected to the

low signal transformer, which is

driven by the chipset's companion device. In the IXBD4410,

this input receives the fault

indication from its companion

IXBD4411 driver. In the

IXBD4411, this input receives

the on/off command from its

companion IXBD4410 driver.

Pin Description

IXBD4411 (High-Side Driver)

VDD VDD

NC OUT

NC VEE

T- C A

T+ CB

R- LG

R+ KG

NC IM

Sym. Pin Description of IXBD 4410/4411

FLT 8 Low/high side fault output. In the

NC IXBD4410, this output indicates

IM 9 Current sense or desaturation

KG 10 Kelvin ground. This ground is

LG 11 Logic and power ground.

CB 12 Capacitor terminals for negative

CA 13 terminal is CB (pin 12).

VEE 14 Negative supply terminal.

OUT 15 Gate drive output. In the

a fault condition of either device

of the chipset. A "high" indicates

no fault, A "low" indicates that

either overcurrent,V

under-voltage occurred. In case

DD

or V

EE

of overcurrent, this output will

remain active "low" until the next

input cycle of the respective

driver. In case of under-voltage,

this output will remain "low" until

the proper voltage is restored.

The IXBD4411 does not have a

FLT output,and its pin 8 should

be tied to LG

No Connection (IXBD 4411)

detection input. This input is

active only while the OUT pin is

"high" (on). When the OUT pin is

"low" (off) this input is pulled to

ground through a 70 Ω resistor.

Any voltage at this pin above the

threshold of .3 V typical, will turn

the output (pin 15) off. This pin is

used for power device

overcurrent protection.

used as Kelvin connection for

overcurrent or desaturation

sensing.

charge pump (VEE); "+"

IXBD4410 this output responds

to the INL signal. A "high" at INL

will turn it on ("high"), a "low" will

turn it off ("low"). In the

IXBD4411, this output responds

to the transmitted signal from the

companion IXBD4410. A "high"

at INH of the IXBD4410 drives

will turn it on ("high"). A "low"

will turn it off ("low"). This output

will turn off ("low") also in

response to any fault condition.

I - 6

© 2001 IXYS All rights reserved

IXBD4410 / IXBD4411

Application

The IXBD4410/4411 chipset devices

are specifically designed as MOSgated transistor drivers in half-bridge

power converters, 1- and 3-phase

motor controls, and UPS applications.

The phase-leg PWM command is

normally generated by previous (user

provided) circuitry. It must be

decomposed into two separate logic

signals, one for the high-side and one

for the low-side power transistors, with

appropriate deadtime for each state

transition. The deadtime insures nonoverlapping conduction even if the turnon and turn-off delay times of the

power devices are unequal. The

minimum deadtime should be greater

than t

device like the IXYS deadtime

generator IXDP630, (fig. 7), can be used

to perform this function. The

ISOSMART™ chipset family of devices

do not generate deadtime, although

there is an internal lockout that

prohibits one device form being

commanded "on" before the other is

commanded "off". This simplifies startup and shutdown protection circuitry,

preventing logic error during power-up

from turning on both high-and low-side

transistors simultaneously.

Negative V

Design

The on-chip V

the IXBD4410/4411 generates a negative power supply, regulated at 20 V

below the positive VDD rail. If VDD is +10

V, VEE will be -10 V. If VDD is +15 V, V

will be -5 V. This negative drive potential in the off-state is either desirable or

required in many instances. When

switching a clamped inductive load

(Fig. 6), the turn-on of Q2 will commutate

the freewheeling diode around Q1.

Whether this diode is intrinsic (as in a

MOSFET) or extrinsic (IGBT or

bipolar), its reverse recovery is critical

to proper circuit operation.

At high turn-on di/dt in Q2 and near its

rated voltage, the recovery of D1 can

get quite "snappy" (the di/dt in the

second half of the recovery process,

after the diode has begun to recover its

blocking capability, can get very large),

creating a very high dv/dt across Q1.

This dv/dt is impressed across the

Miller capacitance of Q1, forcing a

large current to flow out the gate

A separate circuit, or an IC

dlh.

Charge Pump Circuit

EE

generator provided in

EE

EE

failure, this problem is even more likely

to occur. In an industrial module package

(e.g.: a 150 A/1200 V IGBT phase-leg

module), the series inductance contributed by the long gate leads and

connectors further complicate the design.

In a heavily snubbered converter, or in

a power supply design with low

transformer leakage inductance, the

design problem is relatively simple and

negative drive is seldom required.

However, in a modern snubberless or

lightly snubbered converter design, it is

important to keep the gate drive

impedance high enough during

transistor turnoff to limit the reapplied

dv/dt (the transistor is its own 'active'

snubber). This is always important for

EMI control, and in the case of IGBT

may be required to achieve the

necessary RBSOA. At the same time, it

is mandatory to keep the off-state gate

Fig. 6: Switching a clamped inductive

load

drive impedance very low to assure the

transistor remain off during induced

dv/dt (including diode recovery dv/dt).

terminal of the device. If this current pulse

causes a high enough voltage drop

across the output impedance of the gate

drive circuit, R

, Q1 will be turned on.

out

The Q1 conduction in every instance

Q2 is turned on (and vice versa), aside

from degrading efficiency, can lead to

catastrophic failure of both power

transistors. At high temperature, where

In some instances, it is simply not

possible to satisfy both criteria with 0 V

applied in the off-state. In these cases

the IXBD4410/4411 with V

bias generator must be used.

The internal V

pump circuit. Referring to Fig. 7, an

generator is a charge

EE

negative

EE

external charge pump capacitor is

required between the CA and CB

the -6 to -7 mV/°C temperature

coefficient of IGBT/MOSFET threshold

reduces the voltage required to create a

Fig. 7: IXBD4410/4411 Detailed one phase circuit with dead time generator IXDP 630

© 2001 IXYS All rights reserved

I - 7

IXBD4410 / IXBD4411

terminals (C7, C11), and an output

reservoir capacitor between V

GND (C10, C14). A 0.1 µF charge

EE

and

pump capacitor (C7, C11) is recommended. The voltage regulation

method used in the IXBD4410/4411

allows a 1 to 2 V ripple frequency and

depends on the size of the V

reservoir capacitor (C10, C14) and the

output

EE

average load current. The minimum

recommended output reservoir (C10,

C14) is 4.7 µF tantalum, or 10 µF if

aluminium electrolytic construction is

chosen. Note that this reservoir

capacitor is in addition to a good

quality high frequency bypass capacitor (0.1 µF) that should be placed from

VEE to GND (C9, C13).

A small resistor in series with the

charge pump capacitor, (R7, R8)

reduces the peak charging currents of

the charge pump. A value or 68 Ω or

greater is recommended, as illustrated

in the applications example in Fig. 7.

Current Sense / Desaturation

Detection Circuit

All members of the ISOSMART™

driver family provide a very flexible

overcurrent/short circuit protection

capability that will work with both

standard three-terminal power transistors,

and with 4- and 5-terminal current sensing

power devices. Overcurrent detection is

accomplished as illustrated in Fig. 8a (for

a current mirror power device) and Fig.

8b (for a standard three terminal power

transistor). Desaturation detection is

accomplished with the same internal

circuits by measuring the voltage across

the power transistor in the on-state with

an external resistor divider (Fig. 8c).

The IM input trip point V

300 mV, is referenced to the Kelvin

, typically

TIM

ground pin KG.

Current Mirror

MOSFET and IGBT allow

good control of peak let-through

currents and excellent short circuit

protection when combined with the

ISOSMART™ driver family of devices.

The sense resistor is chosen to

develop 300 mV at the desired peak

transistor current, assuming a mirror

ration of 1400:1, and a trip point of 30

A is desired:

= 300 mV • 1400/30 A = 14 Ω

R

s

(use 15 Ω CC).

It is important to realize that C

unit area of the mirror cells is much larger

oss

per

a b c

IM

KG

GND

With Current Mirror

R

s

IM

KG

GND

With Standard

MOSFET/IGBT

Fig. 8: Alternative overcurrent protection circuits

that C

chip due to periphery effects. This

per unit area of the bulk of the

oss

causes a large transient current pulse at

the mirror output whenever the transistor

switches (C • dv/dt currents), which can

cause false overcurrent trigger. The RC

filter indicated in Fig. 8a will eliminate this

problem.

Standard three-terminal MOSFET and

IGBT devices (in discrete as well as

modern industrial single transistor and

phase-leg modules) can also be

protected from short circuit with the

ISOSMART™ driver family devices. In

discrete device designs, where the

source/emitter terminal is available,

overcurrent protection with an external

power resistor can be implemented.

The resistor is placed in series with the

device emitter, with the full device

current flowing through it (Fig. 8b). The

sense resistor is again selected to

develop 300 mV at the desired peak

transistor current, assuming a trip point

of 30 A is desired:

= 300 mV / 30 A = 10 mΩ

R

s

(use 10 mΩ, noninductive

current sense resistor).

It is important to recognize that

"noninductive" is a relative term,

especially when applied to current

sense resistor construction and

characterization. There is always

significant series inductance inserted

with the sense resistor, and L • di/dt

voltage transients can cause false

overcurrent trigger.

The RC filter indicated in Figure 8b will

eliminate this problem. Choosing the

RC pole at the current sense resistor

RL zero should exactly compensate for

series inductance. Because the exact

value is not normally known (and can

vary depending on PC layout and

component lead dress) this is not

normally a good idea. Usually, the RC

R

IM

s

KG

GND

Desaturation Detection

with Standard

MOSFET/IGBT

R

s

time constant should be two to ten

times longer than the suspected RL

time constant.

Desaturation detection as in Figure 8c is

probably the most common method of

short circuit protection in use today.

While not strictly an "overcurrent"

detector, if the power transistor gain,

and consequently short circuit letthrough current, is well controlled (as

with modern MOSFET and IGBT) this

methodology offers very effective

protection.

The IXBD4410/4411 half-bridge circuits

in Fig. 7 uses desaturation detection. In

Fig. 7, the voltage across the two power

MOSFET devices (or IGBTs) are

monitored by two sets of voltagedivider networks, R10 and R11 for the

high-side gate driver, and R13 and R14

for the low-side gate driver. The

dividers are set to trip the IM input

comparators when either Power

MOSFET device V

reasonable value, perhaps 50 V

exceeds a

DS

(usually a value of 10 % of the nominal

DC bus voltage works well). R10 or

R13 are chosen to tolerate the applied

steady state DC bus voltage at an

acceptable power dissipation. Dielectric

withstand capability, power handling,

temperature rise, and PC board creep

and strike spacings, must all be

carefully considered in the design of

the voltage-divider networks.

In the off-state, the voltage across the

Power MOSFET device may go as high

as the DC bus potential. To keep this

normal condition from setting the

internal fault flip-flop of the IXBD4410

or the IXBD4411, an internal CMOS

switch is turned on and placed across

lM and KG pins shorting them together.

This effectively discharges C8 or C12

in Fig. 7 and maintains zero potential with

respect to KG at IM.

I - 8

© 2001 IXYS All rights reserved

IXBD4410 / IXBD4411

When the command arrives to switch

on the Power MOSFET device, the

CMOS switch shorting IM to KG is

turned off. The driven Power MOSFET

device is switched on approximately

100 ns to 1 µs later, and with typical

load conditions, its drain-to-source

potential, V

10 µs of delay to collapse to the normal

, may take an additional

DS

on-state voltage level. To prevent false

triggering due to this, C8 or C12 in

parallel combination with R10 and R11,

or R13 and R14, delays the IM input

signal. During this turn-on interval, the

voltage across C8 or C12 will rise until

the Power MOSFET device finally

comes on and pulls the voltage across

C8 or C12 back down. If the MOSFET

device load circuit is shorted, its V

voltage cannot collapse at turn-on. In

DS

this case, the voltage across C8 or C12

rises rapidly until it reaches 300 mV,

tripping the fault flip-flop and shutting

down the driver output. At the same

time, C8 or C12 must be kept small

enough that the added delay does not

slow down the detection of a short

circuit event so much that the Power

MOSFET device fails before the driver

realizes that it is in trouble. The

desaturation detection circuit in Fig. 7

functions as just described. Current limit

or desaturation detection is latched, and

reset on a cycle-by-cycle basis with the

rising edge of the respective input

command.

100 A in a typical application). Fig. 7 is

a detailed schematic of one phase of

three 3-phase motor control, showing

the interconnection of the IXBD4410/

4411 and its associated circuitry.

PCB Layout Considerations

The IXBD4410/4411 is intended to be

used in high voltage, high speed, high

dv/dt applications.

To ensure proper operation, great care

must be taken in laying out the printed

circuit board. The layout critical areas

include the communication links, current

sense, gate drive, and supply bypassing.

The communication path should be as

short as possible. Added inductance

disturbs the frequency response of the

signal path, and these distortions may

cause false triggering in the receiver.

The transformer should be placed

between the two ICs with the orienta-

tion of one IC reversed (Fig. 10).

Capacitance between the high-side

and low-side should be minimized. No

signal trace should run underneath the

communication path, and high- and lowside traces should be separated on the

PCB. The dv/dt of the high-side during

power stage switching may cause false

logic transitions in low-side circuits due

to capacitive coupling.

The low signal pulse transformer

provides the isolation between high-

Three Phase Motor Controls

Fig. 9 is a block diagram of a typical 3phase PWM voltage-source inverter

motor control. The power circuit consists

of six power switching transistors with

freewheeling diodes around each of

them. The control function may be

performed digitally by a microprocessor,

microcontroller, DSP chip, or user custom

IC; or it may be performed by a PC

board full of random logic and analog

circuits. In any of these cases, the PWM

command for all six power transistors is

generated in one circuit, and this circuit is

usually referred to system ground

potential - the bottom terminal of the

power bridge.

The ISOSMART™ family of drivers is

the interface between the world of control

logic and the world of power, 5 V input

logic commands precisely control actions

at high voltage and current (1200 V and

Fig. 9: Typical 3-phase motor control system block diagram

© 2001 IXYS All rights reserved

I - 9

IXBD4410 / IXBD4411

low-side circuits. For 460 V~ line

operation, a spacing of 4 mm is recommended between low- and high-side

circuits, and a transformer HIPOT

specification of at least 1500 V~ is

required. This creep spacing is usually

adequate to control leakage currents on

the PCB with up to 1200 V~ applied

after 10 to 15 years of accumulated dust

and particulates in a standard industrial

environment. In other environments, or

at other line voltages, this spacing

should be appropriately modified.

Fig. 10: Suggested IC Orientation

Power Circuit Noise Considerations

In a typical transistor inverter, the output

MOSFET may switch on or off with di/dt

>500 A/µs. Referring to Fig.11 and

assuming that the MOSFET source

terminal has a one inch path on the

PCB to system ground, a voltage as

high as V = 27 nH • 500 A/µs = 13.5 V

can be developed. If the MOSFET

switched 25 A, the transient will last as

long as (25/500) µs or 50 ns, which is

more than the typical 6 or 7 ns propagations or of a 74HC series gate.

while positioning the transistors next

to their heat sink and meeting UL/VDE

voltage spacings is just too difficult.

Grounding the gate driver as in option

(a) in Fig. 11 solves the MOSFET turn

on problem by eliminating LS1 from the

source feedback loop. Now, unfortunately, the gate driver will oscillate

every time it is turned on or off. As the

IXDP630 output goes "high", the gate

drive output follows (after its propagation delay) and the MOSFET starts to

conduct. The voltage transient induced

The current sense/desaturation detect

input is noise sensitive. The 300 mV trip

point is referred to the KG (Kelvin

ground) pin, and the applied signal must

be kept as clean as possible, A filter is

recommended, preferably a monolithic

ceramic capacitor placed as close to the

IC as possible directly between IM and

KG. To preserve maximum noise

immunity, the KG pin should first be

connected directly to the LG pin, and

the pair then sent directly to the power

transistor source/emitter terminal, or (if

a desaturation detection circuit is used)

to the bottom of the divider resistor

chain.

All supply pins must be bypassed with a

low impedance capacitor (preferably

monolithic ceramic construction) with

minimum lead length. The output driver

stage draws 2 A (typical) currents during

transitions at di/dt values in excess of

100 A/µs. Supply line inductance will

cause supply and ground bounce on the

chip that can cause problems (logic

oscillations and, in severe cases,

possible latch-up failure) without proper

bypassing. These bypass elements are

in addition to the reservoir capacitors

required for the negative Vee

the high-side bootstrapped supply if

supply and

these features are used.

Fig. 11: Potential layout problems that create functional problems

Fig. 11 illustrates an example layout

problem. The power circuit consists of

three power transistors (MOSFETs in

this example). With the ISOSMART™

gate driver chipset grounded as in

option (b) in Fig. 11, the communication

path from the IXDP630 will operate

without errors. The PC trace induced

voltages are not common with the digital

path, so the input of the gate driver will

not see or respond to them.

Unfortunately, the MOSFET will not

operate properly. The voltage induced

across LS1 when Q1 is turned on, acts

as source degeneration, modifying the

turn-on behavior of the MOSFET. If

LS1= 27 nH, and V

the gate plateau of the MOSFET is 6 V),

is 15 V (assuming

CC

the di/dt at turn-on will be regulated by

the driver/MOSFET/LS1 loop to about

200 A/µs; quite a surprise when your

circuit requires 500 A/µs to operate

correctly.

It is possible to make use of this

behavior to create a turn-on or turn-off

di/dt limiter (perhaps to snub the upper

across LS1 (V = LS1 • di/dt) raises the

local ground (point a) until it exceeds V

(630) - Vil and the driver (after its

propagation delay) turns the MOSFET

off. Now the MOSFET current falls,

V(LS1) drops, point (a) drops to system

ground (or slightly below), and the driver

detects a "1" at its input. After its

propagation delay, it again turns the

MOSFET on, continuing the oscillation

for one more cycle.

To eliminate this problem, a ground level

transformation circuit must be added,

that rejects this common mode

transient. The simplest is a de-coupling

circuit, also illustrated in Fig. 11. The

capacitor voltage on Cd remains

constant while the transient voltage is

dropped across Rd and the driver

detects no input transition, eliminating

the oscillation. This circuit does add

significantly to turn-on and turn-off delay

time, and cannot be used if the transient

lasts longer than the allowable delays.

Delay times must be considered in

selection of system dead time.

free wheeling diode reverse recovery).

While possible, this is normally not

desirable or practical where two or more

transistors are controlled. Equalizing the

parasitic impedances of three traces

The most complex (and most effective)

method of eliminating the effects of

transients between grounds is isolation.

Optocouplers and pulse transformers

oh

I - 10

© 2001 IXYS All rights reserved

IXBD4410 / IXBD4411

are the most commonly used isolation

techniques, and work very well in this

case. The IXDP630/631 has been

specifically designed to directly drive a

high speed optocoupler like the Hewlett

Packard HCPL22XX family or the

General Instrument 740L60XX optologic

family. These optos are especially well

suited to motor control and power

conversion equipment due to their very

high common mode dv/dt rejection

capabilities.

Transformer Considerations

The transformer is the communication

link and isolation barrier between the

high- and low-side ICs. The high-side

gate and fault signals are transmitted

through the transformer while maintaining the proper isolation. The

transmitter signal is in the form of a

square wave, but the receiver responds

only to the logic edges. This allows for

much smaller transformer designs,

since a 10 kHz switching frequency

does not require a 10 kHz pulse

transformer.

The recommended transformer for this

ISOSMART™ driver chipset is

fabricated using a very small ferrite

shield bead (see Fig. 12), onto which a

six-turn primary and a two-turn

secondary winding of 36 AWG magnet

wire are made. The two windings are

Fig. 12: Ferrite bead dimensions

segment wound to achieve primary-tosecondary isolation of up to 2500 V~.

The six-turn primaries are connected

to the respective IXBD4410/4411

transmitter outputs and the two-turn

secondaries are connected to their

respective receiver inputs.

The nominal electrical specifications of

the transformer are as follows:

● Open circuit inductance

(100 kHz; 20 mV): 3 µH

● Interwinding capacitance: 2 pF

● Primary leakage inductance: 0.1 µH

● Turns ratio: 6:2

● Primary-to-secondary isolation

(1min): 1500 V~

● Core permeability (µ

): 125

i

The recommended ferrite bead is Fair

Rite Products part number

2661000101, which is manufactured

by:

Fair-Rite Products Corp.

Wallkill, NY

Phone: (800) 836-0427

Web site: www.fair-rite.com

As seen in the application drawings

(Fig. 6, 9 and 13) a coupling capacitor

(22 nF) and a damping resistor (22 Ω)

are added in series with the primary

side of the transformer. The capacitor

will control the small amount of energy

needed to transfer the signal to the

companion driver. The resistor will

control the damping of the signal and

limit

the peak transmitter output current.

The receiver is designed to operate

over a wide common mode input range.

To reduce noise pickup, the receiver

has ±250 mV of input hysteresis.

If the signal is being distorted at the

transmitter, the transmitter is probably

running into current limit. A decrease in

the coupling capacitance or an

increase in the damping resistance

should solve this problem. The receiver

operates over a wide input range. The

minimum amplitude for one side of the

receiver is about 1 V and a maximum of

about 3 V. It is critical that there be no

overshoot on the transformer

secondary wave-form. Each signal

should be slightly overdamped. If

significant overshoot exists, the

received signal may be logically

inverted. An increase of the damping

will solve this problem.

resistor

IXYS Corporation

3540 Bassett St; Santa Clara, CA 95054

Tel: 408-982-0700; Fax: 408-496-0670

e-mail: sales@ixys.net

www.ixys.com

© 2001 IXYS All rights reserved

Fig. 13: Transmitter/Receiver Waveforms

IXYS Semiconductor GmbH

Edisonstrasse15 ; D-68623; Lampertheim

Tel: +49-6206-503-0; Fax: +49-6206-503627

e-mail: marcom@ixys.de

Doc #9200-0237 Rev 2

I - 11

Loading...

Loading...