Page 1

INTEGRATED CIRCUITS

AU5783

J1850/VPW transceiver with

supply control function

Preliminary specification

Supersedes data of 2000 Nov 29

2001 Feb 15

Page 2

Philips Semiconductors Preliminary specification

TYPE NUMBER

AU5783J1850/VPW transceiver with supply control function

FEATURES

•Supports SAE/J1850 VPW standard for in-vehicle class B

multiplexing

•Bus speed 10.4 kbit/s nominal

•4X transmission mode (41.6 kbit/s)

•Drive capability 32 bus nodes

•Low RFI due to output waveshape function

•Direct battery operation with protection against +40 V load dump

and 8 kV ESD

•Bus terminals proof against automotive transients up to

+100 V/–150 V and 8 kV ESD

•Power supply enable function

DESCRIPTION

The AU5783 is a line transceiver being primarily intended for

in-vehicle multiplex applications. It provides interfacing between a

J1850 link controller and the physical bus wire. The device supports

the SAE/J1850 VPWM standard with a nominal bus speed of

10.4 kbit/s. For data upload and download purposes the 4X

transmission mode is supported with a nominal bus speed of

41.6 kbit/s. The AU5783 provides protection against loss of ground

conditions, thus ensuring the network will be operational in case of

an electronic control unit loosing connection to ground potential. Low

power operation is supported through provision of a sleep mode with

very low power consumption. In addition an external voltage

regulator can be turned off via the AU5783 transceiver to further

reduce the overall power consumption. The voltage regulator will be

activated again upon detection of bus activity or upon a local

wake-up event.

•Very low sleep mode power consumption

•Diagnostic loop-back mode

•Thermal overload protection

•14-pin SOIC

ORDERING INFORMATION

PACKAGE

NAME DESCRIPTION VERSION

AU5783D SO14 plastic small outline package; 14 leads; body width 3.9 mm SOT108-1 –40 to +125°C

TEMPERATURE

RANGE

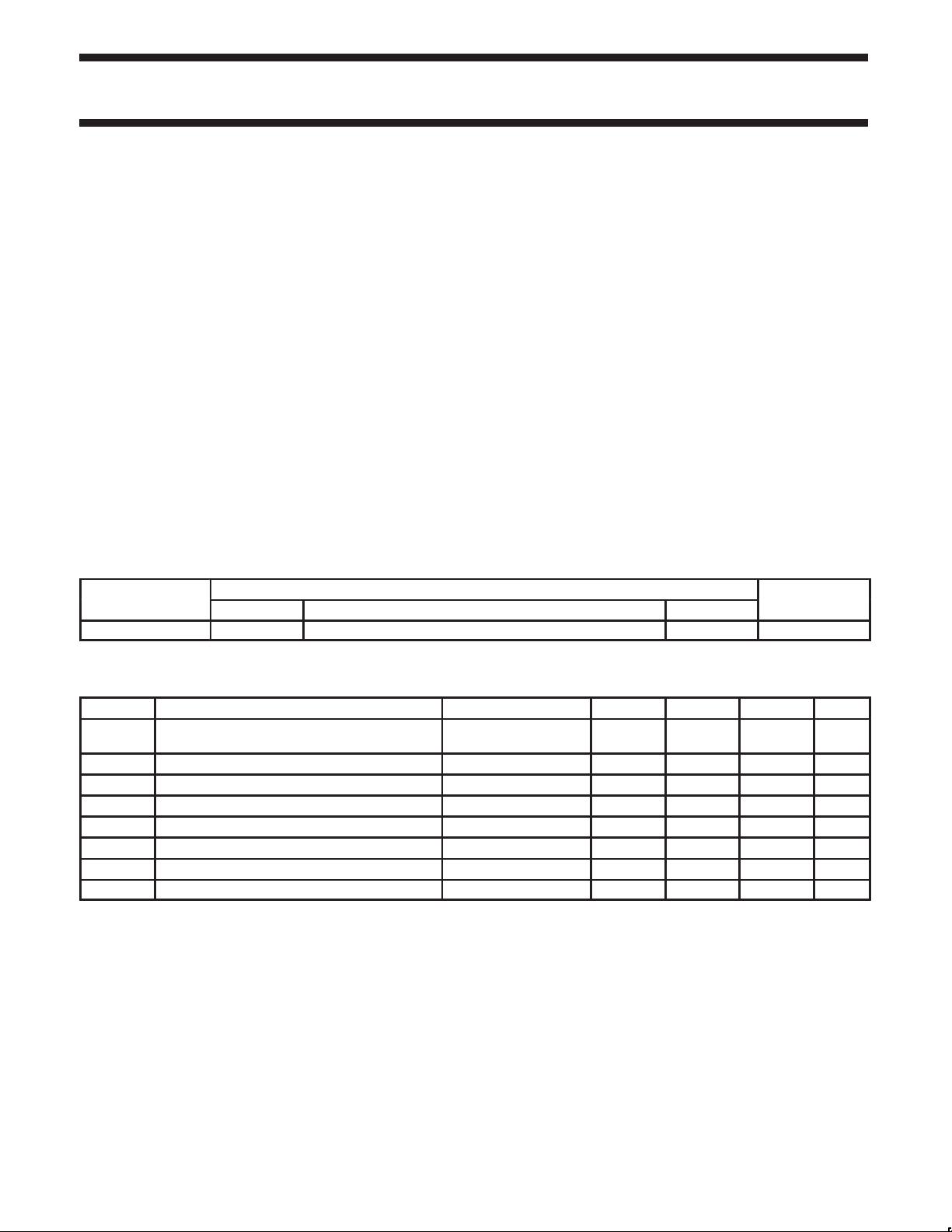

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

BAT.op

T

amb

V

BAT.ld

V

BOH

V

BI

I

BAT.lp

t

P

t

r

Operating supply voltage, including low battery

operation

Operating ambient temperature range –40 +125 °C

Battery voltage load dump, 1s +40 V

Bus output voltage 250 Ω < RL < 1.6 kΩ 6.7 8.0 V

Bus input threshold 3.4 4.2 V

Sleep mode supply current 90 µA

Propagation delay Tx to Rx 25 µs

Bus output rise time 14 µs

5.5 12 16 V

2001 Feb 15

2

Page 3

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

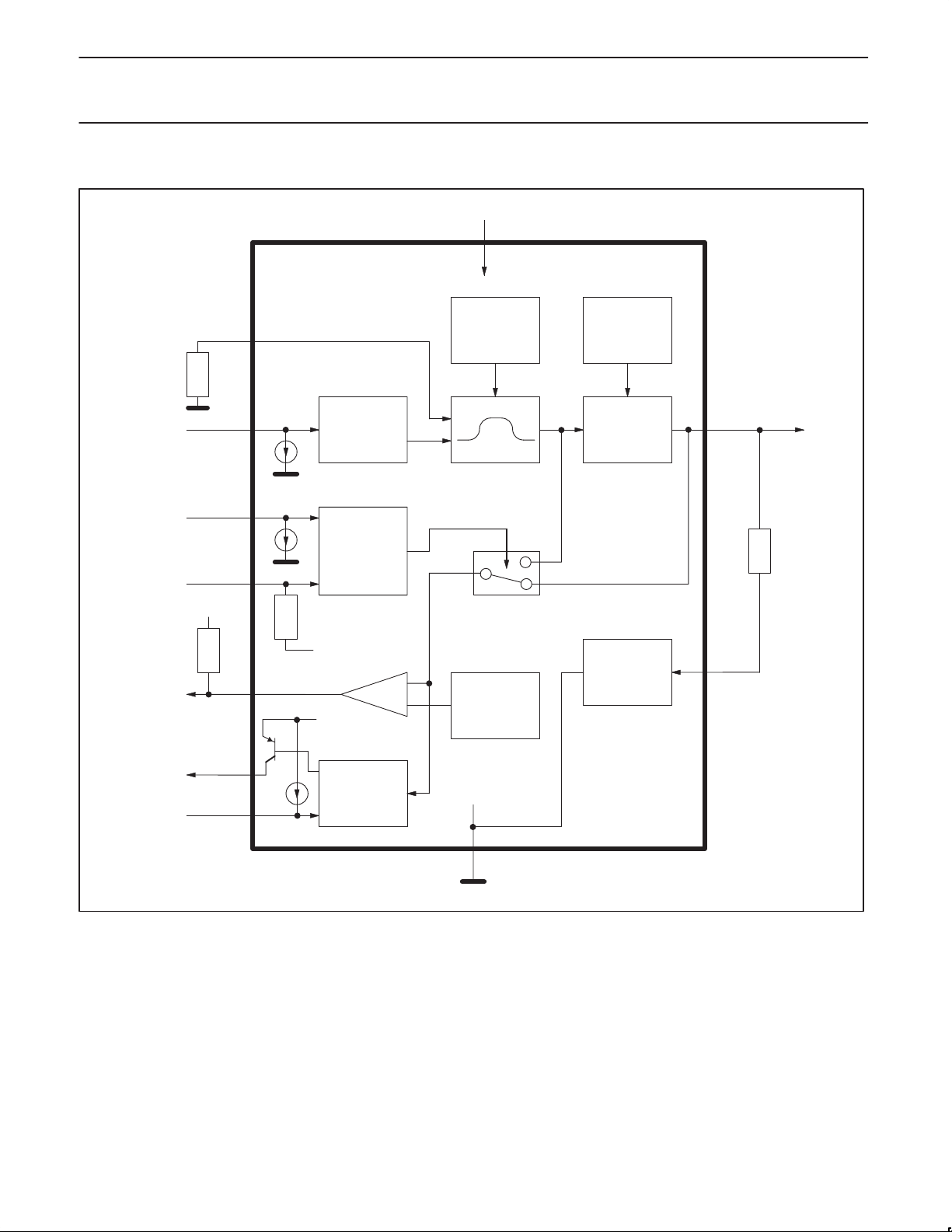

BLOCK DIAGRAM

BATTERY (+12V)

BAT

Rs

4X/LOOP

Vcc (+5V)

LWAKE

R/F

NSTB

Rd

RX

INH

VOLTAGE

REFERENCE

1.6V

Vbat

TX–

BUFFER

MODE

CONTROL

VOLTAGE

REFERENCE

WAKE-UP

CONTROL

TX

TEMP.

PROTECTION

OUTPUT

BUFFER

LOAD

SWITCH

AU5783

BUS

Rld

LOAD

2001 Feb 15

GND

SL01224

Figure 1. Block diagram

3

Page 4

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

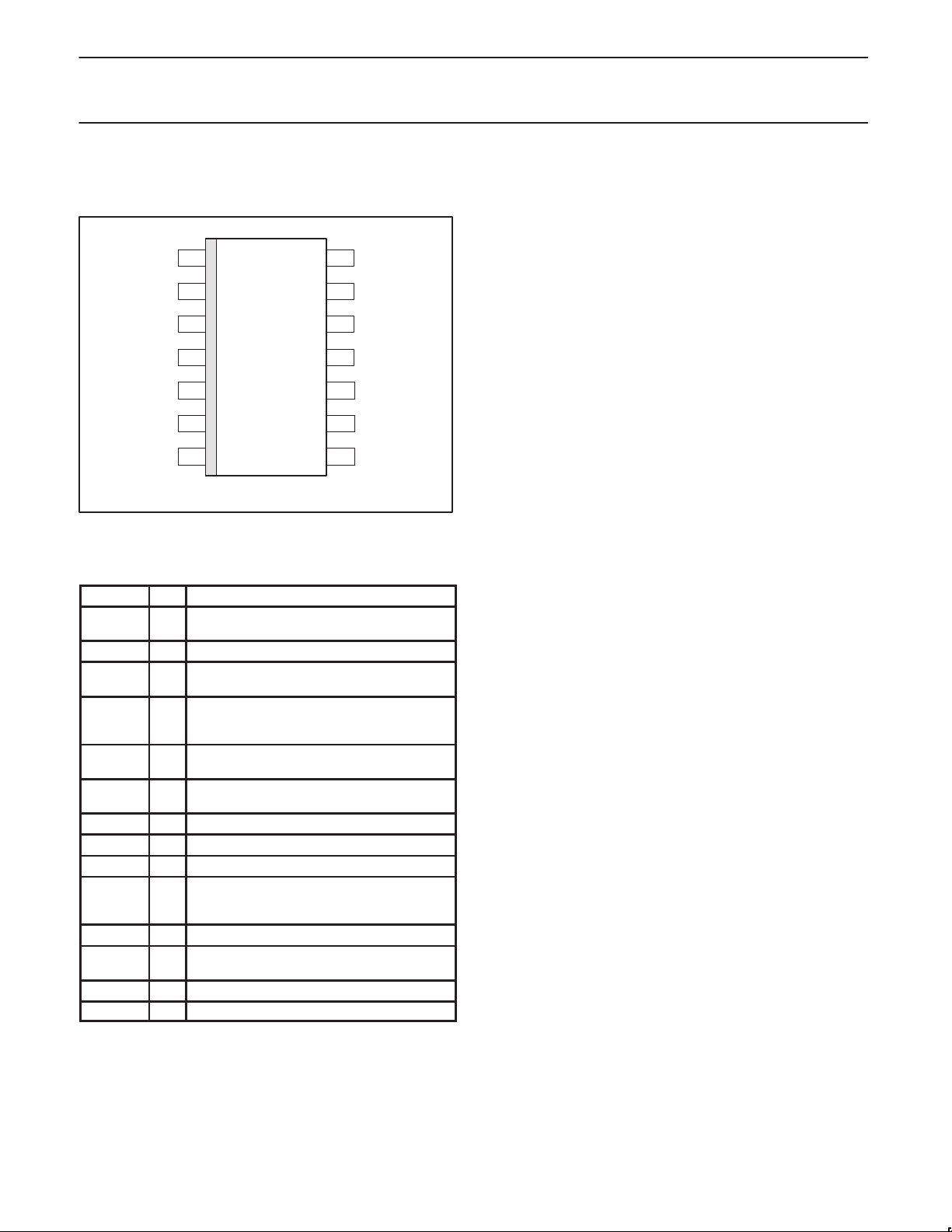

PINNING

Pin configuration

R/F

GND

4X/LOOP

NSTB

RX

N.C.

1

2

3

4

5

TX

6

7

AU5783

Figure 2. Pin configuration

SO14

14

13

12

10

9

8

11

GND

N.C.

BUS

LOAD

INH

LWAKE

BAT

SL01225

Pin description

SYMBOL PIN DESCRIPTION

R/F 1 Rise/fall time control input; connect to ground

GND 2 Ground

4X/LOOP 3 Tx mode control input; low: normal mode;

NSTB 4 Network STandBy power control input; low:

TX 5 Transmit data input; low: transmitter passive;

RX 6 Receive data output; low: active bus condition

N.C. 7 Not connected

BAT 8 Battery supply input, 12V nominal

LWAKE 9 Local wake-up input, edge sensitive

INH 10 Activity indication flag (inhibit) output high side

LOAD 11 Bus load in/output

BUS 12 Bus line transmit/receive input/output, active

N.C. 13 Not connected

GND 14 Ground

potential via a resistor

high: 4X mode; float: loopback

transmit function disabled (low power modes);

high: transmit function enabled

high: transmitter active

detected; high: otherwise

driver; e.g., to control a voltage regulator.

Active high enables the regulator

high side driver

FUNCTIONAL DESCRIPTION

The AU5783 is an integrated line transceiver IC that interfaces an

SAE/J1850 protocol controller IC to the vehicle’s multiplex bus line.

It is primarily intended for automotive “Class B” multiplexing

applications in passenger cars using VPW (Variable Pulse Width)

modulated signals with a nominal transmission speed of 10.4 kbit/s.

The device provides transmit and receive capability as well as

protection to a J1850 electronic module.

A J1850 link controller feeds the transmit data stream to the

transceiver’s TX input. The AU5783 transceiver waveshapes the TX

data input signal so as to minimize electromagnetic emission. The

bus output signal features controlled rise & fall characteristic

including rounded shape. A resistance being connected to the R/F

control input sets the bus output slew rate.

The LOAD output is connected to the physical bus line via an

external load resistor R

ground potential being the default state, e.g., when no transmitter

outputs an active state. This output ensures the J1850 network will

not be affected by a potential loss of ground condition at an

individual electronic control unit.

The AU5783 includes a bus receiver with filter function to minimize

susceptibility against interference. The logic state of the J1850 bus

signal is indicated at the RX output being connected to the J1850

link controller.

The AU5783 also provides advanced low-power modes to help

minimize ignition-off power consumption of an electronic control unit.

The bus receiver function is kept alive in the low-power modes. If an

active state is being detected on the bus line this will be indicated

via the RX output. By default the AU5783 enters the low-power

standby mode when the mode control inputs NSTB and 4X/LOOP

are not driven. A 100 kΩ pull down resistor is required on NSTB.

Ignition-off current draw can be reduced further by turning off the

voltage regulator being typically provided in an electronic control

unit. This is supported by the activity indication function of the

AU5783. In this application the activity indication flag INH will control

external devices such as a voltage regulator. To turn-off the INH flag

and thus the voltage regulator, the go to sleep command needs to

be applied to the Network Standby power control input,

e.g., NSTB = 0. The INH output is turned off after the sleep time-out

period thereby , reducing the power consumption of an electronic

control unit to an extremely low level.

The activity indication flag INH will be turned on again upon

detection of a remote wake-up condition (i.e. bus activity) or upon

detection of a local wake-up condition or a respective command

from the microcontroller. A local wake-up condition is detected

when an edge occurs at the wake-up input LWAKE. The INH flag

will also be turned on upon detection of a high input level at the

mode control input NSTB. Activation of the INH output enables

external devices, e.g., a voltage regulator. This condition will power-up

logic devices, e.g., a microcontroller in order to perform appropriate

action, e.g., activation of the AU5783 and the J1850 network.

The AU5783 contain a power on reset (POR) circuit, which is active

at low voltages. This circuit insures that if the control input NSTB is

at 0 V or floating during power up, the device will be forced into the

standby mode by the time the battery voltage rises to 4.4 V. This will

also insure that the INH pin is in the high state to turn on the local

voltage regulator. If there is a dip going below 4.4 V in battery

voltage while in the sleep mode, the device may return to the

. The load resistor pulls the bus line to

ld

2001 Feb 15

4

Page 5

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

standby mode if the POR is tripped. Even if the device is not in

sleep mode the INH output will turn off at some battery voltages

below 4.4 V when the internal POR circuit is active. At still lower

voltages where the POR circuit does not operate, the INH may

again pull up toward the battery level, typically with battery voltages

below approximately 3.6 V. The operation of the POR circuit can be

verified by placing the device in the sleep mode while the battery

voltage is above 4.4 V. The INH output, which is a high side driver,

should turn off when the sleep mode is entered. Next ramp the

battery voltage down to 2.0V and finally return the battery voltage to

4.4 V . When the battery supply is returned to 4.4V, the INH output

will pull high since the device enters standby mode. The actual

voltages at which the POR engages and releases will vary from part

to part. The lowest voltage at which the POR will be active is 2.6 V

and it will always release below 4.4 V .

The AU5783 provides a high-speed data transmission mode where

the bus output waveshape function is disabled. In this mode transmit

signals are output as fast as possible thus allowing higher data

rates, e.g., the so-called 4X mode with 41.6 kbit/s nominal speed.

The AU5783 also provides a loop-back mode for diagnostic

purpose, e.g., self-test of an electronic control unit. In loop-back

mode the bus transmit and receive functions are disabled thus

8

essentially disconnecting an electronic control unit from the J1850

bus line. The TX signal is internally looped back to the RX output.

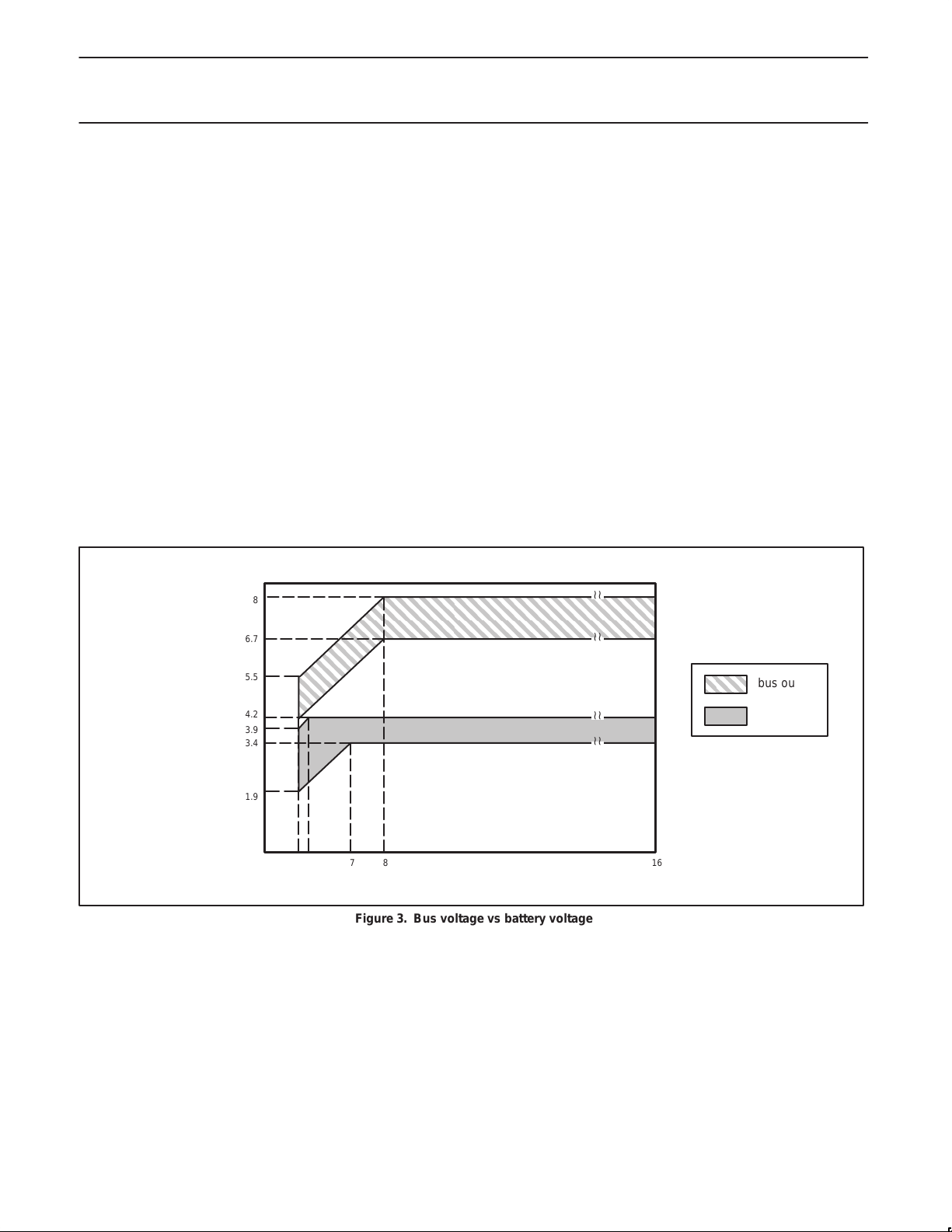

The AU5783 only requires one power supply V

BAT

. Bus

transmissions can continue with battery voltage down to 5.5 V . The

bus output voltage will track 1.3V bellow the battery voltage. The

bus input voltage threshold will also follow the battery voltage going

down as shown in Figure 3. This ratio metric behavior of the input

threshold partially compensates for the reduced dominant level

transmitted during low battery operation.

The AU5783 features special robustness at its BAT and BUS pins

hence the device is well protected for applications in the automotive

environment. Specifically the BA T input is protected against 40 V

load dump and jump start condition. The BUS output is protected

against wiring fault conditions, e.g., short circuit to ground and

battery voltage as well as typical automotive transients and

electrostatic discharge. In addition, an over-temperature shutdown

function with hysteresis is incorporated which protects the device

under network fault conditions. In case of the die temperature

reaching the trip point, the AU5783 will latch-off the transceiver

function. The device is reset on the first rising edge on the TX input

after a decrease in the junction temperature.

~

~

Bus Voltage (V)

6.7

5.5

4.2

3.9

3.4

1.9

5.5 5.8 7 8 16

Battery Voltage (V)

Figure 3. Bus voltage vs battery voltage

~

~

bus output

~

~

~

~

bus input

SL01254

2001 Feb 15

5

Page 6

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

Table 1. Control input summary

Z = Input connected to high impedance permitting it to float. Typically accomplished by turning off the output of a microcontroller.

X = Don’t care; The input may be at either logic level.

NSTB

1 0 1 normal operation active high low high

1 0 0 normal operation passive float bus state,

1 1 1 4X transmit active high low high

1 1 0 4X transmit passive float bus state,

1 Z 1 loop-back passive float low high

1 Z 0 loop-back passive float high high

0 or Z X X standby (default state after power on),

1 –> 0 X 0 go to sleep command, Note 4, Note 6 off float bus state,

0 or Z X X sleep, Note 4, Note 6 off float bus state,

NOTES:

1. After power-on, the AU5783 enters standby mode since the input pins NSTB and 4X/LOOP are assumed to be floating. In standby mode the

voltage regulator is enabled via the INH output, and therefore power is supplied to the microcontroller. When the microcontroller begins

operation it will normally set the control inputs NSTB high and 4X/LOOP to low state in order to start normal operation of the AU5783.

2. RX outputs the bus state. If the bus level is below the receiver threshold (i.e., all transmitters passive), then RX will be high. Otherwise, if the

bus level is above the receiver threshold (i.e., at least one transmitter is active), then RX will be low.

3. INH is turned off after a time-out period.

4. For entering the sleep mode (e.g., to deactivate INH), the “Go To Sleep” command needs to be applied. The “Go T o Sleep” comma nd is a

high-to-low transition on the NSTB input. When the “Go To Sleep” command is present, the INH flag is deactivated. This signal can be used

to turn-off the voltage regulator of an electronic module. After the voltage regulator is turned off the microcontroller is no longer supplied and

the NSTB input will be floating. The INH output will be set again upon detection of bus activity or occurrence of a local wake-up event.

5. In standby and sleep mode, the detection of a wake-up condition (e.g., high level on BUS) will be signalled on the output RX.

6. The NSTB pin contains a weak pull down which is active in the normal, loop-back and high-speed modes but is disabled in the sleep mode.

To insure a logic 0 input if the microcontroller’s outputs are tri-stated or the microcontroller is not powered, a 100 kΩ resistor between NSTB

and ground is suggested.

4X/LOOP TX Mode Bus

transmitter

off float bus state,

Note 1, Note 6

BUS RX (out) INH

high

Note 2

high

Note 2

high

Note 5

float, Note 3

Note 5

float

Note 5

2001 Feb 15

6

Page 7

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

ABSOLUTE MAXIMUM RATINGS

According to the IEC 134 Absolute Maximum System.

Unless otherwise specified, operation is not guaranteed under these conditions: all voltages are referenced to pin GND; positive currents flow

into the IC.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

BAT

V

BAT.ld

V

BAT.tr

V

B0

V

B1

V

B.tr

V

WKE

V

WKR

V

INH

V

I

V

I,RF

ESD

ESD

P

tot

Θ

JA

T

amb

T

vj

T

stg

HBM1

HBM2

Voltage on pin BAT –0.3 +34 V

Short-term supply voltage load dump, t < 1s +40 V

Transient voltage on pin BAT and pin

LWAKE

Bus voltage V

Bus voltage V

Transient bus voltage SAE J1113, test pulses 3A and 3B,

SAE J1113 test pulses 3A and 3B,

–150 +100 V

Rwake > 9 kΩ

< 2 V, Rld > 1.4 kΩ –16 +18 V

BAT

> 2 V, Rld > 1.4 kΩ –10 +18 V

BAT

–150 +100 V

coupled via C = 1 nF; Rld > 1.4 kΩ

Voltage on pin LWAKE –0.3 ≤ V

BAT

V

Voltage on pin LWAKE via series resistor of Rwake > 9 kΩ –16 +34 V

DC voltage on pin INH –0.3 ≤ V

DC voltage on pins TX, RX, NSTB and

–0.3 7.0 V

BAT

V

4X/LOOP

DC voltage on pin R/F –0.3 5.0 V

ESD capability of pins BAT, BUS, LOAD

and LWAKE

ESD capability of all pins Human body model, direct contact

Human body model, direct contact

discharge, R = 1.5 kΩ, C = 100 pF,

R

> 1.4 kΩ; Rwake > 9 kΩ

ld

–8 +8 kV

–2 +2 kV

discharge, R = 1.5 kΩ, C = 100 pF

Maximum power dissipation @ T

= +125°C 205 mW

amb

Thermal impedance with standard test PCB 120 °C/W

Operating ambient temperature –40 +125 °C

Operating junction temperature –40 +150 °C

Storage temperature –40 +150 °C

2001 Feb 15

7

Page 8

Philips Semiconductors Preliminary specification

Mode)

AU5783J1850/VPW transceiver with supply control function

DC ELECTRICAL CHARACTERISTICS

7V < V

–2V < V

LWAKE connected to BAT via 10 kΩ resistor; all voltages are referenced to pin 14 (GND); positive currents flow into the IC;

typical values reflect the approximate average value at V

Pin BAT & thermal shutdown

Pins TX, NSTB

Pin 4X/LOOP

Pin LWAKE

Pin INH

Pin RX

< 16 V; –40 °C < T

BAT

< +9 V; NSTB = 5 V; 4X/LOOP = 5 V; Rs = 56 kΩ ± 1%; RX connected to +5 V via Rd = 3.9 kΩ; INH loaded with 100 kΩ to GND;

bus

SYMBOL

I

BAT.sl

I

BAT.sb

I

BAT.p.nl

I

BAT.p.h

I

BAT.wl

I

BAT.fl

T

sd

T

hys

V

ih

V

il

I

ihtx

I

ih.nstb,nlh

I

il

V

ih

Sleep mode supply current Note 1 90 µA

Standby mode supply current Note 1 500 µA

Supply current; passive state, in normal or

loopback modes

Supply current; passive state, in high

speed mode

Supply current; weak load TX = 5 V, RL = 1.38 kΩ, Note 2 25 mA

Supply current; full load TX = 5 V, RL = 250 Ω 45 mA

Thermal shutdown temperature Note 2 155 190 °C

Thermal shutdown hysteresis Note 2 5 15 °C

High level input voltage 2.7 V

Low level input voltage 0.9 V

TX high level input current VTX = 5 V 50 200 µA

NSTB high level input current in normal,

loop back and high speed modes

Low level input current Vi = 0 V –2 +2 µA

High level input voltage (High Speed

< +125 °C; 250 Ω < RL < 1.6 kΩ; 1.4 kΩ < Rld < 12 kΩ;

amb

= 13 V and T

BAT

= 25 °C; unless otherwise specified.

amb

PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

TX = 5 V; LWAKE = 0 V,

4X/LOOP = 0 or Z

TX = 5 V; LWAKE = 0 V,

4X/LOOP = 5 V

V

= 5 V 10 50 µA

NSTB

NSTB = 5 V 2.7 V

NSTB = 5 V, Bare Die 2.9 V

I

ih-5

I

ih-3

V

ilb

I

ilb

V

il

–I

il

–I

ils

V

i_wh

V

i_Wl

–I

I_w

–I

oh_inh

–I

ol_inh

V

bat_POR

V

ol_rx

I

ol_rx

I

oh_rx

High level input current with 5 V logic 4X/LOOP = 5 V, NSTB = 5 V 50 300 µA

High level input current with 3 V logic 4X/LOOP = 3 V, NSTB = 3 V 30 250 µA

Mid level input voltage (Loop back

NSTB = 5 V 1.25 1.65 V

operation)

Loopback mode input current NSTB = 5 V; Note 4 –2 2 µA

Low level input voltage (Normal Mode) NSTB = 5 V +0.7 V

Low level input current V4X = 0 V, NSTB = 5 V 50 200 µA

Low level input current in standby and

V4X = 0 V, NSTB = 0 V –5 +5 µA

sleep mode

Local wake-up high NSTB = 0 V 3.9 V

Local wake-up low NSTB = 0 V 2.5 V

Low level input current V

INH high level output current V

INH off-state output leakage V

Power-on reset release voltage; Battery

voltage threshold for setting INH output

high

Low level output voltage IRX = 1.6 mA, BUS = 7 V,

= 0 V 2 25 µA

LWAKE

= V

INH

4.9 V < V

INH

– 1 V;

BAT

< 16 V

BAT

= 0 V; NSTB = 0 V –5 +5 µA

120 500 µA

NSTB = 0 V, BUS = 0 V,

V

= 4.4 V, verify INH = 1

BAT

0 0.45 V

all modes

Low level output current VRX = 5 V, BUS = 7 V 2 20 mA

High level output leakage VRX = 5 V, BUS = 0 V, all modes –10 +10 µA

3 mA

10 mA

4.4 V

2001 Feb 15

8

Page 9

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

SYMBOL UNITMAX.TYP.MIN.CONDITIONSPARAMETER

Pin BUS

V

BOh_n

V

BOh_h

V

BOhl

–I

BO.LIM

–I

BO.LK1

–I

BO.LK0

–I

BO.LK5

–I

BO.LKLB0

–I

BO.LKLB5

–I

LOG

V

Bih

V

Bil

V

Bhy

V

Bih_l

V

BiL_L

V

Bih_s

V

Bil_s

V

Bih_sl

V

Bil_sl

Pin LOAD

V

ld

V

ldoff

NOTES:

1. TX = 0 V; NSTB = 0 V; 7 V < V

2. This parameter is characterized but not subject to production test.

3. For V

For 16 V < V

to be less than 2 minutes.

4. For 3-State devices driving the 4X/LOOP Pin, the leakage in the 3-State output must be below the specified input current to ensure the pin is

biased in the center state to provide the loop back function. For 3-State devices driving the 4X/LOOP pin, the leakage in the 3-State output

must be below the specified input current to insure the pin is biased in the center state to provide the loop back function. If the leakage

current of the microcontroller is too high, then an alternate approach is to connect a resistor voltage divider between the V

the microcontroller’s supply to provide approximately 1.45 V bias on the 4X/LOOP pin.

BUS output high voltage in normal mode TX = 5 V, 4X/LOOP = 0 V;

BUS output high voltage in high speed

mode

8 V < V

250 Ω < R

TX = 5 V, 4X/LOOP = 5 V;

8 V < V

250 Ω < R

< 16 V

BAT

< 1.6 kΩ; Note 3

L

< 16 V

BAT

< 1.6 kΩ; Note 3

L

BUS voltage; low battery TX = 5 V; Note 3

5.5 V<V

250 Ω < R

BUS short circuit current TX = 5 V; V

< 8 V;

BAT

< 1.6 kΩ

L

BUS

BUS leakage current; passive state TX = 0 V; 0 V < V

–2 V < V

,

BUS current with loss of battery V

,

BUS leakage current; loop back mode TX = 0 V or 5 V; 0 V<V

BAT

–2 V < V

BUS leakage current at loss of ground 0 V < V

BUS input high voltage 5.8 V < V

4X/LOOP = 5 V and

< +9 V

BUS

< 2 V; –2 V < V

< +9 V

BUS

< 16 V; see test circuit –20 +100 µA

BAT

< 16 V,

BAT

= –2 V 30 100 mA

< 16 V;

BAT

< +9 V –100 +100 µA

BUS

<16 V;

BAT

6.7 8.0 V

6.7 9.0 V

V

–1.3 V

BAT

–100 +100 µA

–100 +100 µA

4.2 V

4X/LOOP = 0 V

BUS input low voltage 4X/LOOP = 5 V or

4X/LOOP = 0 V

BUS input hysteresis 4X/LOOP = 5 V and

0.1 0.5 V

4X/LOOP = 0 V

BUS input high voltage at low battery 5.5 V < V

4X/LOOP = 5 V and

BAT

< 5.8 V,

V

BAT

1.6 V

–

4X/LOOP = 0 V

BUS input low voltage at low battery 5.5 V < V

4X/LOOP = 5 V and

BAT

< 7 V,

4X/LOOP = 0 V

BUS input high voltage in standby and

sleep mode

NSTB = 0 V,

4X/LOOP = 5 V and

4.2 V

4X/LOOP = 0 V,

BUS input low voltage in standby

and sleep mode

6 V < V

NSTB = 0 V,

4X/LOOP = 5 V and

BAT

< 16 V

4X/LOOP = 0 V,

BUS input high voltage in standby and

sleep mode at low battery

6 V < V

NSTB = 0 V,

4X/LOOP = 5 V and

BAT

< 16 V

1

/2 (V

2.4)

BAT

+

4X/LOOP = 0 V ,

BUS input low voltage in standby and

sleep mode at low battery

4.5 V < V

NSTB = 0 V,

4X/LOOP = 5 V and

BAT

< 6 V

4X/LOOP = 0 V ,

4.5 V < V

BAT

< 6 V

Load output voltage Ild = 2 mA 0.2 V

Load output voltage unpowered Ild = 6 mA, V

< 13 V; T

BAT

< 8.3 V the bus output voltage is limited by the supply voltage.

BAT

< 27 V the load is limited by the package power dissipation ratings. The duration of the latter condition is recommended

BAT

< 125°C; –1 V < V

j

BUS

= 0 V 1 V

BAT

< 1 V; LWAKE connected to BAT via 10 kΩ; INH not connected.

BAT

3.4 V

V

–

BAT

3.6 V

2.2 V

1

/

(V

–

2

BAT

1.6)

and ground of

CC

V

V

V

V

V

2001 Feb 15

9

Page 10

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

DYNAMIC CHARACTERISTICS

7 V < V

BUS: 250 Ω < R

Bus load A: R

R/F pin: R

RX pin: R

Typical values reflect the approximate average value at V

NSTB and 4X/LOOP rise and fall times < 10 ns.

SYMBOL

INH output function

BUS output function

BUS input function

NOTES:

1. This parameter is characterized but not subject to production test.

< 16 V; –40°C < T

BAT

< 1.6 kΩ; 3 nF < CL < 17 nF; 1.7 µs < (RL * CL) < 5.2 µs

L

= 1.38 kΩ, CL = 3.3 nF; Bus load B: RL = 300 Ω, CL = 16.5 nF

L

= 56 kΩ ± 1%; INH loaded with 100 kΩ and 30 pF to GND

s

= 3.9 kΩ to 5 V; CL = 30 pF to GND; NSTB = 5 V; 4X/LOOP = 0 V

d

< +125°C; –2 V < V

amb

< +9 V; 1.4 kΩ < Rld < 12 kΩ

bus

= 13 V and T

BAT

= 25°C, unless otherwise specified.

amb

PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

CTX TX input capacitance Note 1 15 pF

t

inhoff

t

inhonl

t

inhonr

t

BOon

t

BOoff

t

BrA

t

BrB

t

BfA

t

BfB

t

ir

t

if

t

wBh

INH turn-off delay BUS = 0 V, LWAKE = V

measured from NSTB = 0.9 V to INH = 3.5 V

or 0 V, go to sleep command,

BAT

LWAKE to INH turn-on delay NSTB = 0 V, BUS = 0 V, measured from LWAKE = 3 V to

INH = 3.5 V

BUS to INH turn-on delay sleep mode, LWAKE = V

INH = 3.5 V

;

Delay TX to BUS rising and

from TX = 2.5 V to BUS = 3.875 V; bus load A and bus load B 13 22 µs

, measured from BUS = 3.875 V to

BAT

falling edge

BUS voltage rise time bus load A, 9 V < V

BUS voltage rise time bus load B, 9 V < V

BUS output voltage fall time bus load A, 9 V < V

BUS output voltage fall time bus load B, 9 V < V

< 16 V, measured at 1.5 V and 6.25 V 11 18 µs

BAT

< 16 V, measured at 1.5 V and 6.25 V 11 18 µs

BAT

< 16 V, measured at 1.5 V and 6.25 V 11 18 µs

BAT

< 16 V, measured at 1.5 V and 6.25 V 11 18 µs

BAT

BUS output current rise time bus load B connected to –2 V,

9 V < V

capacitor current

< 16 V, measured at 20% and 80% of load

BAT

BUS output current fall time bus load B connected to –2 V ,

9 V < V

capacitor current

< 16 V, measured at 20% and 80% of load

BAT

BUS high pulse width TX = high for 64 µs, bus load condition A, 9 V < V

minimum width measured at BUS = 6.25 V , maximum width

BAT

< 16 V;

200 µs

100 µs

60 µs

4 µs

4 µs

35 93 µs

measured at BUS = 1.5 V

B

HRM

t

BO4Xon

t

BO4Xoff

t

pon

t

poff

t

plbon

t

plboff

t

DRXon

t

DRXoff

t

tRX

t

tRXsl

BUS output voltage harmonic

content; normal mode

;

TX to BUS delay in 4X mode 4X/LOOP = 1 V, bus load B,

;

Delay TX to RX rising and

f = 530 kHz to 1670 kHz, bus load B connected to –2 V,

TX = 7.81 kHz, 50% duty cycle, 9 V < V

9 V < V

< 16 V, from TX = 1.8 V to BUS = 3.875 V

BAT

measured from 1.8 V on TX to 2.5 V on RX 13 25 µs

falling edge in normal mode

;

Delay TX to RX rising and

falling edge in loop-back mode

;

BUS input delay time, rising

NSTB = 5 V, 4X = floating, measured from 1.8 V on TX to

2.5 V on RX

measured from V

and falling edge

RX output transition time, rising

NSTB = 5 V, measured at 10% and 90% of waveform 1 µs

and falling edge

RX output transition time in

NSTB = 0 V, measured at 10% and 90% of waveform 5 µs

standby and sleep mode, rising

< 16 V, Note 1

BAT

0.5 5 µs

13 25 µs

= 3.875 V to VRX = 2.5 V 0.2 2 µs

BUS

70 dBµV

and falling edge

t

DRXsl

BUS to RX delay in sleep and

standby modes

NSTB = 0 V, LWAKE = V

to RX = 2.5 V

, measured from BUS = 3.875 V

BAT

8 60 µs

2001 Feb 15

10

Page 11

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

TEST CIRCUITS

5.1V

TX

S1

NSTB

4X/LOOP

S2

RX

3.9k

AU5783

NOTE:

1. Check I_LOG with the following switch positions:

1. S1 = open = S2

2. S1 = open, S2 = closed

3. S1 = closed, S2 = open

4. S1 = closed = S2

Figure 4. Test circuit for loss of ground condition

INH

R/F

GND

BUS

LOAD

BAT

LWAKE

10k

100k

56k

10.7k

I_LOG V_bat

1.5k

1uF

S3

+

SL01226

2001 Feb 15

11

Page 12

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

APPLICATION INFORMATION

µC with J1850 Link Controller

+5V

VPWO

VPWI

port port

3.9 k

V

CC

100 KΩ

Ra

10 k

100 nF

Rb

1 k

4X/LOOP

TX RX

LWAKE

LOAD

NSTB

AU5783

Transceiver

BUS

10.7 k

Rld

47 uH

R/F

INH

BAT

GND

56 k

470 pF

1%1%

Rs

5V

Reg.

SAE/J1850/VPW BUS LINE

NOTES:

1. Value of R

2. For connection of the NSTB and 4X/LOOP pins there are different options, e.g., connect to a port pin or to V

depends, e.g., on type of bus node. Example: secondary node Rld =10.7 k, primary node Rld =1.5 k.

ld

Figure 5. Application of the AU5783 transceiver

+12V

SL01227

or to active low reset.

CC

2001 Feb 15

12

Page 13

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

SO14: plastic small outline package; 14 leads; body width 3.9 mm SOT108-1

2001 Feb 15

13

Page 14

Philips Semiconductors Preliminary specification

AU5783J1850/VPW transceiver with supply control function

Data sheet status

Data sheet

status

Objective

specification

Preliminary

specification

Product

specification

[1] Please consult the most recently issued datasheet before initiating or completing a design.

Product

status

Development

Qualification

Production

Definition

This data sheet contains the design target or goal specifications for product development.

Specification may change in any manner without notice.

This data sheet contains preliminary data, and supplementary data will be published at a later date.

Philips Semiconductors reserves the right to make changes at any time without notice in order to

improve design and supply the best possible product.

This data sheet contains final specifications. Philips Semiconductors reserves the right to make

changes at any time without notice in order to improve design and supply the best possible product.

Definitions

Short-form specification — The data in a short-form specification is extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one

or more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or

at any other conditions above those given in the Characteristics sections of the specification is not implied. Exposure to limiting values for extended

periods may affect device reliability.

Application information — Applications that are described herein for any of these products are for illustrative purposes only. Philips

Semiconductors make no representation or warranty that such applications will be suitable for the specified use without further testing or

modification.

[1]

Disclaimers

Life support — These products are not designed for use in life support appliances, devices or systems where malfunction of these products can

reasonably be expected to result in personal injury . Philips Semiconductors customers using or selling these products for use in such applications

do so at their own risk and agree to fully indemnify Philips Semiconductors for any damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to make changes, without notice, in the products, including circuits, standard

cells, and/or software, described or contained herein in order to improve design and/or performance. Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no license or title under any patent, copyright, or mask work right to these

products, and makes no representations or warranties that these products are free from patent, copyright, or mask work right infringement, unless

otherwise specified.

Bare Die — All die are tested and guaranteed to comply with all data sheet limits up to the point of wafer sawing for a period of ninety (90) days

from the date of Philips’ delivery. If there are data sheet limits that are not guaranteed, these will be separately indicated in the data sheet. There

are no post packing tests performed on individual die or wafers. Philips Semiconductors has no control over third party procedures in the sawing,

handling, packing, or assembly of the die. Accordingly , Philips Semiconductors assumes no liability for device functionality or performance of the

die or system after third party sawing, handling, packaging, or assembly of the die. It is the responsibility of the customer to test and qualify their

application in which the die is used.

Philips Semiconductors

811 East Arques Avenue

P.O. Box 3409

Sunnyvale, California 94088–3409

Telephone 800-234-7381

Copyright Philips Electronics North America Corporation 2001

All rights reserved. Printed in U.S.A.

Date of release: 02-01

Document order number: 9397 750 08083

2001 Feb 15

14

Loading...

Loading...