Datasheet ATF1500ABV-12JC, ATF1500ABV-12AC, ATF1500ABVL-25JC, ATF1500ABVL-25AC, ATF1500ABV-15JI Datasheet (ATMEL)

...Page 1

Features

Operates Between 2.7V to 5.5V

•

High Density, High-Performance Electrically Erasable Complex

•

Programmable Logic Device

– 44-Pin, 32 I/O CPLD

– 12 ns Maximum Pin-to-Pin Delay

– Registered Operation Up To 90.9 MHz

– Fully Connected Input and Feedback Logic Array

Flexible Logic Macrocell

•

– D/T/Latch Configurable Flip Flops

– Global and Individual Register Control Signals

– Global and Individual Output Enable

– Programmable Output Slew Rate

Advanced Power Management Features

•

– Automatic 3 mA Stand-By (ATF1500ABVL)

– Pin-Controlled 5

– Programmable Pin-Keeper Inputs and I/Os

Available in Commercial and Industrial Temperature Ranges

•

Available in 44-Pin PLCC and TQFP Pack ages

•

Advanced Flash Technology

•

– 100% Tested

– Completely Reprogrammable

– 100 Program/Erase Cyc le s

– 20 Year Data Retention

– 2000V ESD Protection

– 200 mA Latch-Up Immunity

Supported By Popular 3rd Party Tools

•

Security Fuse Feature

•

µµµµ

A Stand-By Mode (Typical)

HighPerformance

EE PLD

ATF1500ABV

ATF1500ABVL

ATF1500ABV/L

Description

The ATF1500ABV is a hi gh performance , high density Co mplex PLD. Built on an

advanced Flash technology, it has maximum pin to pin delays of 12 ns and supports

sequential logic ope ration at speeds up to 90.9 MHz. With 32 logic macr oce lls a nd u p

to 36 inputs, it easily integrates logic from several TTL, SS I, MSI and classic PLDs.

The ATF1500ABV’s global input a nd feedb ack arc hitectur e simpli fies logic pla cemen t

and eliminates pinout changes due to design changes.

(continued)

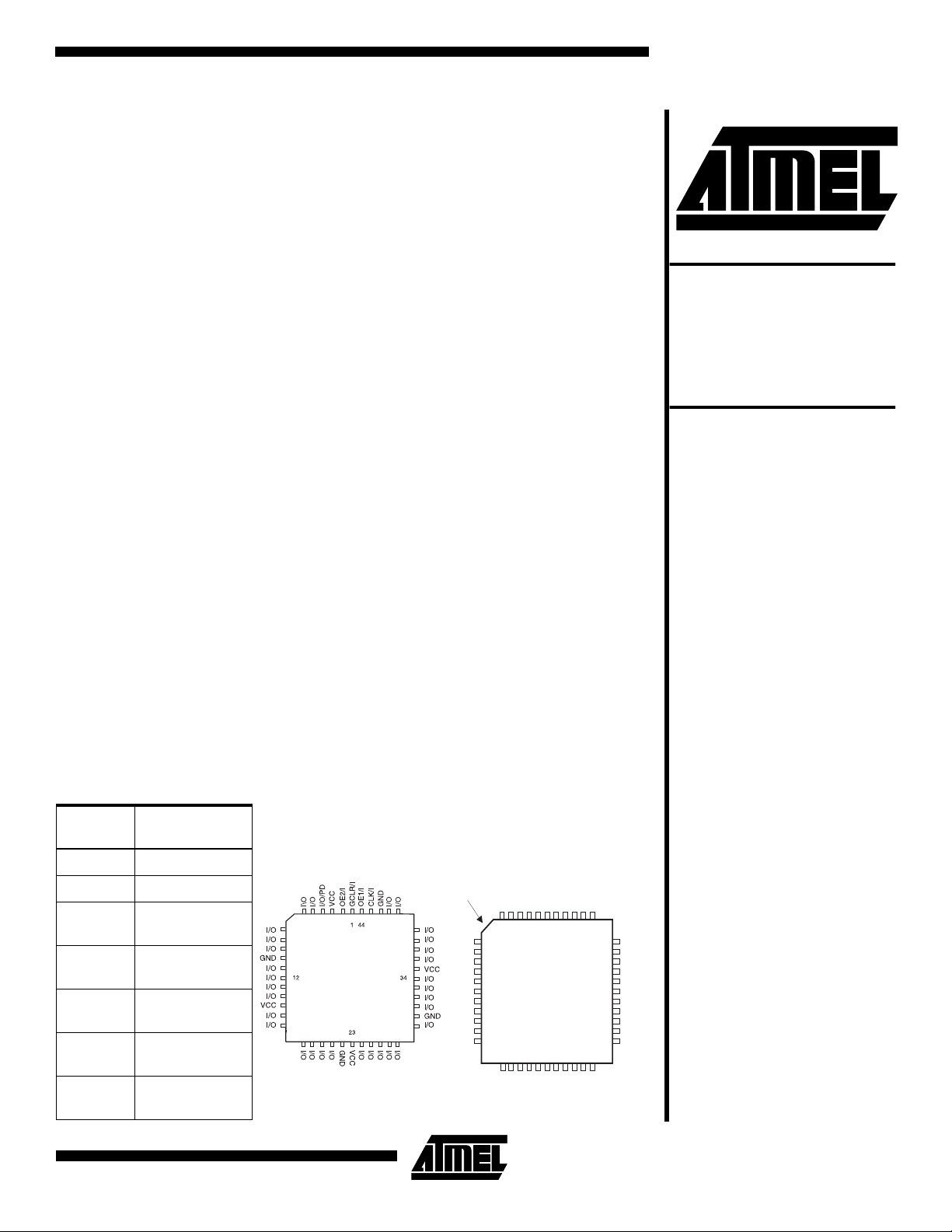

Pin Configurations

44

1

2

3

4

5

6

7

8

9

10

11

12

TQFP

Top View

VCC

I/O

I/O

I/O/PD

424340

41

15

13

14

I/O

I/O

I/O

I/O

16

GCLR/I

OE2/I

39

17

VCC

GND

OE1/I

38

18

I/O

CLK/I

GND

36

37

192021

I/O

I/O

I/O

I/O

34

35

I/O

33

I/O

32

I/O

31

I/O

30

29

VCC

I/O

28

I/O

27

I/O

26

I/O

25

GND

24

I/O

23

22

I/O

I/O

Pin

Name Function

CLK Clock

I Logic Inputs

I/O

GCLR

OE1,

OE2

V

CC

PD

Bidirectional

Buffers

Register Reset

(active low)

Output Enable

(active low)

(+3V to 5.25V)

Supply

Power Down

(active high)

PLCC

Top View

INDEX

CORNER

I/O

I/O

I/O

GND

I/O

I/O

I/O

I/O

VCC

I/O

I/O

Rev. 0723D–6/98

1

Page 2

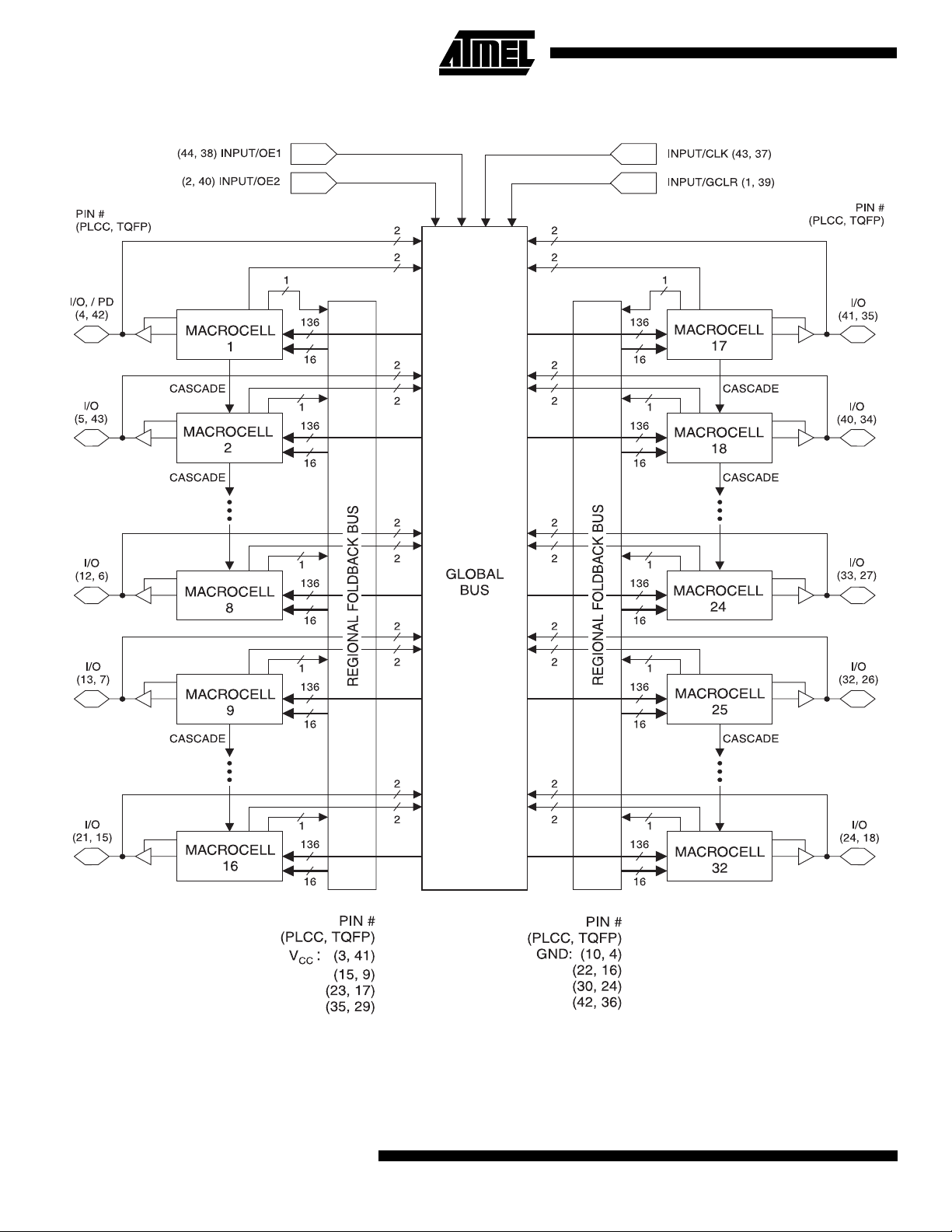

Functional Logic Diagram

(1)

Note: 1. Arrows connecting macrocells indicate direction and groupings of CASIN/CASOUT data flow.

2

ATF1500ABV/L

Page 3

ATF1500ABV/L

The ATF1500ABV has 32 bi-directional I/O pins and 4 dedicated input pins. Each dedicated input pin can also serve

as a global control signal: register clock, register reset or

output enable. Each of these control signals can be

selected for use individually within each macrocell.

Each of the 32 logic macrocells generates a buried feedback, which goes to th e global bus. Each in put and I/O pin

also feeds into the global bus. Because of this global bussing, each of these signals is always available to all 32

macrocells in the device.

Each macrocell also generates a foldback logic term, which

goes to a regional b us . Al l s i gnal s with in a r egional bus are

connected to all 16 macrocells within the region.

Cascade logic between macrocells in the ATF1500ABV

allows fast, efficient generation of complex logic functions.

The ATF1500AB V contains 4 such log ic chains, each

capable of creatin g sum te rm lo gic wi th a fan in of up to 40

product terms.

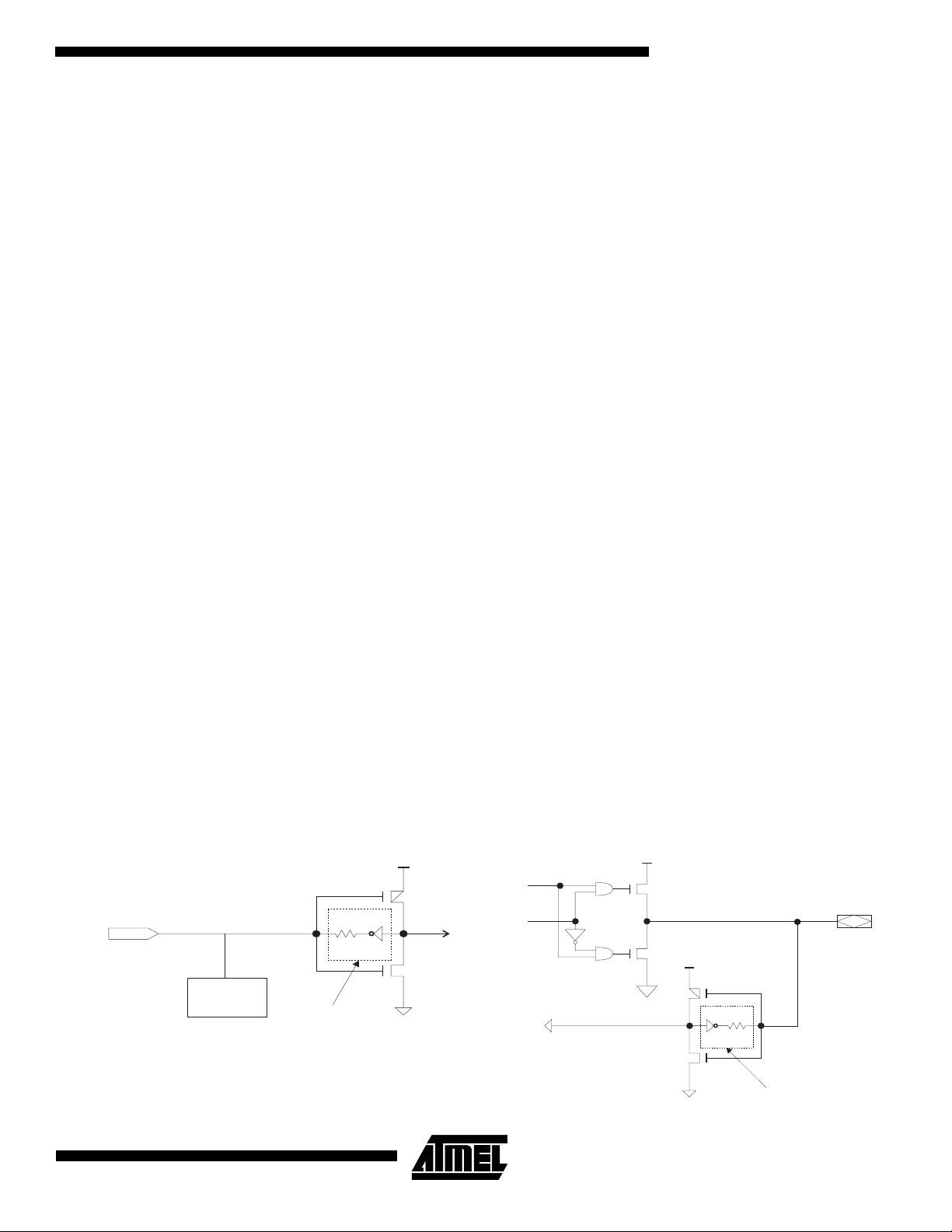

Bus Friendly Pin-Keeper Input and

I/O’S

All Input and I/O pins on the ATF1500ABV have programmable “data keeper” circui ts. If activated, when any pi n is

driven high or low and t hen su bsequently left floating, it will

stay at that previous high or low level.

This circuitry prevents un used Input and I/O lines from

floating to inter mediat e volt age leve ls, whic h caus e unnecessary power consumption and system noise. The keeper

circuits eliminate the need for external pull-up resistors and

eliminate their DC power consumption.

Pin-keeper circuits c an be di sabled. Pr ogramming is co ntrolled in the logic design file. Once the pin-keeper circuits

are disabled, normal termination procedures are required

for unused inputs and I/Os.

Speed/Power Management

The ATF1500ABV has several built-in s peed and power

management features. The ATF1500ABV contains circuitry

that automatically puts the device into a low power standby mode when no logic trans itions are oc curring. This not

only reduces power consumption during inactive periods,

but also prov ides a p roportion al power savings for most

applications running at system speeds below 10 MHz.

All ATF1500AB Vs also have an op tional pin-contr olled

power down mode. In this mod e, c urre nt d rops to b elo w 10

µA. When the power down op tion i s sel ec ted , the P D pi n i s

used to power down the part. The power down option is

selected in the design source file. When enab led, the

device goes into power down wh en the PD pin i s high. In

the power down mode, all internal logic signal s are latched

and held, as are any enabled outputs. All pin transitions are

ignored until the PD is brou ght low. W hen the po wer down

feature is ena bled, the PD c annot be used as a logi c inp ut

or output. However, the PD pin's macrocell may still be

used to generate buried foldb ack and cascade log ic signals.

Each output also has individual slew rate control. This may

be used to reduce system noise by slowing down outputs

that do not need to operate at maximum speed. Outputs

default to slow switching, and may be specified as fast

switching in the design file.

Design Software Support

ATF1500ABV designs are support ed by several 3rd party

tools. Automated fitters allow logic synthesis using a variety

of high level description languages and formats.

Input Diagram

INPUT

ESD

PROTECTION

CIRCUIT

100K

PROGRAMMABLE

OPTION

I/O Diagram

V

V

CC

OE

DATA

CC

I/O

V

CC

100K

PROGRAMMABLE

OPTION

3

Page 4

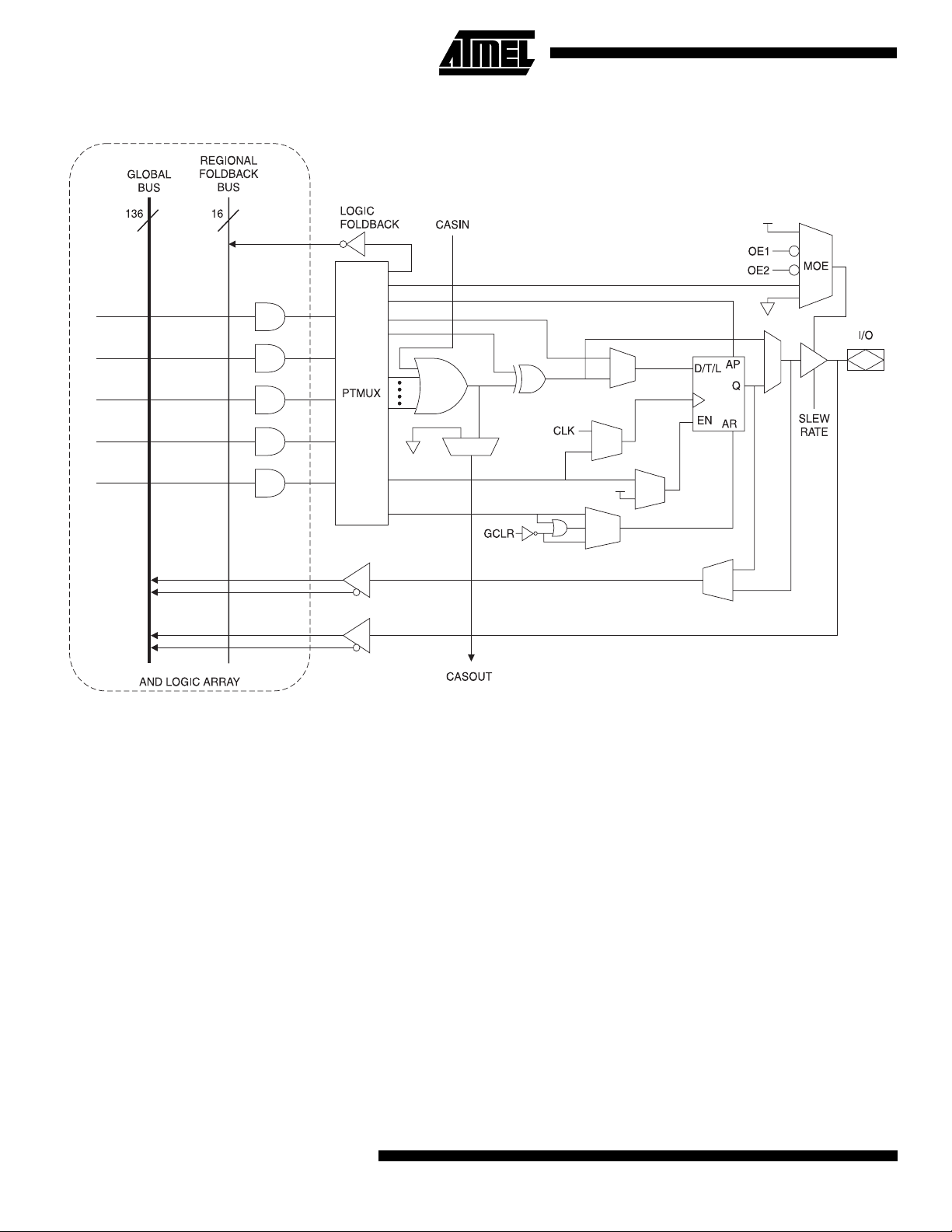

ATF1500ABV Macrocell

ATF1500ABV Macrocell

The ATF1500ABV macrocell is flexib le enough to su pport

highly complex logi c functions operating at high speed. The

macrocell consists of five sections: product terms and product term select multiplex er; OR/XOR/CASCADE logic; a flip

flop; output select and enable; and logic array inputs.

Product Terms and Select Mux

Each ATF1500ABV macrocell has five product terms. Each

product term recei v es as its i nputs all signals from both the

global bus and regional bus.

The product term selec t multi plex er (PTMU X) allo cates the

five product terms as needed to the macrocel l logic g ates

and control signals. The PTMUX programming is determined by the design compiler, wh ich sel ects the opti mum

macrocell configuration.

OR/XOR/CASCADE Logic

The ATF1500ABV macrocell's OR/XOR/CASCADE l ogic

structure is designed to efficiently support all types of logic.

Within a single mac rocell, all the product terms can be

routed to the OR gate, creating a five input AND/OR sum

4

ATF1500ABV/L

term. With the addition of the CASIN from neighboring

macrocells, this can be expanded to as many as 40 product

terms with a very small additional delay.

The macrocell's XOR gate allows efficient implementation

of compare and arithmeti c function s. One inpu t to the XOR

comes from the OR sum term. The other XOR input can be

a product term or a fixed high or low level. For combinatorial outputs, the fixed level input allows output polarity

selection. For regi stered functions, the fixed levels allow De

Morgan minimization of the product terms. The XOR gate is

also used to emulate JK type flip flops.

Flip Flop

The ATF1500ABV’s flip fl op has very flexible data and control functions. The data input can come from either the XOR

gate or from a separate product term. Selecting the separate product term allows creation of a buried registered

feedback within a combinatorial output macrocell.

In addition to D, T, JK and SR operation, the flip flop can

also be configured as a flow-through latch. In this mode,

Page 5

ATF1500ABV/L

data passes through when the clock is high and is latched

when the clock is low.

The clock itself ca n be eit her the gl obal CL K pin or an indi vidual prod uct term. The flip flop chan ges stat e on the

clock's rising edge. When the CLK pin is used as the clock,

one of the macrocell product terms can be selected as a

clock enable. W hen the clock enab le fu nctio n is act ive and

the enable sign al (prod uct ter m) is lo w, all cloc k edge s are

ignored.

The flip flop's asynchronous reset signal (AR) can be either

the pin global clear (GCLR), a product term, or always off.

AR can also be a logic O R of GCLR with a p roduct te rm.

The asynchronous preset (AP) can be a product term or

always off.

Output Select and Enable

The ATF1500ABV macrocell output can be selected as

registered or combinatorial. When the output is registered,

the same registered si gnal is fed bac k interna lly to the global bus. When the output i s combi nator ial, th e buried feedback can be either the same combinatorial signal or it can

be the register output if the separate pro duct term is chosen as the flip flop input.

The output enable multiplexer (MOE) controls the output

enable signals. Any buf fer can be pe rmanen tly enabled for

simple output operation. Buffers c an also be permanently

disabled to allow use of the pin as an input. In thi s con figuration all the macroc ell reso urces are still avai lable, in cluding the buried feedback, expander and CASCADE logic.

The output enable for eac h mac rocell can also be s elect ed

as either of the two OE pins or as an individual product

term.

Global/Regional Busses

The global bus contains all Input and I/O pin signals as well

as the buried feed back signal from al l 32 macrocells.

Together with the complemen t of eac h s ign al, t his pr ov id es

a 68-bit bus as input to every product term. Having the

entire global bus available to each macrocell eliminates any

potential rout ing prob lems. With this arch itecture d esigns

can be modified without requiring pinout changes.

Each macrocell also generat es a foldback product term.

This signal goes to the regi onal bus , and is a vailabl e to 16

macrocells. The foldback is an inverse polarity of one of the

macrocell's product terms. T he 16 foldb ack terms in ea ch

region allow generation of high fan-in sum terms (up to 21

product terms) with a small additional delay.

5

Page 6

Absolute Maximum Ratings*

Temperature Under Bias................................ -55°C to +125°C

Storage Temperature..................................... -65°C to +150°C

Voltage on Any Pin with

Respect to Ground .......................................-2.0V to +5.25V

(1)

Voltage on Input Pins

with Respect to Ground

During Programming.....................................-2.0V to +14.0V

Programming Voltage with

Respect to Ground .......................................-2.0V to +14.0V

(1)

(1)

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the dev ice . This is a s tress rating only an d

functional oper ation of the device at these o r any

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions f or e xtended periods ma y af fect de vice

reliability.

Note: 1. Minimum voltage is -0.6V dc, which may under-

shoot to -2.0V for pulses of less than 20 ns. Maximum out put pin voltage is V

which may overshoot to 5.25V for pulses of less

than 20 ns.

DC and AC Operating Conditions

Commercial Industrial

Operating Temperature (Case) 0°C - 70°C -40°C - 85°C

V

Power Supply 2.7V - 5.5V 2.7V - 5.5V

CC

+ 0.75V dc,

CC

DC Characteristics

Symbol Parameter Condition Min Typ Max Units

I

IL

I

IH

(1)

I

CC1

I

CC2

I

OS

V

IL

V

IH

V

OL

V

OH

Note: 1. All ICC parameters measured with outputs open, and a 16 bit loadable, up/down counter programmed into each region.

Input or I/O

Low Leakage Current

Input or I/O

High Leakage Current

0 ≤ VIN ≤ VIL(max) -10 µA

,min < VIN ≤ V

V

IH

CC

10 µA

Com. 35 mA

ATF1500ABV

Power Supply Current,

Standby

VCC = MAX,

= 0, V

V

IN

CC

Ind. 40 mA

Com. 3 mA

ATF1500ABVL

Ind. 5 mA

Power Supply Current,

Power Down Mode

Output Short Circuit

Current

Input Low Voltage

= MAX,

V

CC

= 0, V

V

IN

V

OUT

VCC, min < VCC

< V

CC

= 0.5V -130 mA

CC

, max

-0.5 0.8 V

2mA

Input High Voltage 2.0 VCC + 1 V

Output Low Voltage VCC = MIN IOL = 4 mA 0.45 V

Output High Voltage VCC = MIN IOH = -0.1 mA VCC - .2 V

6

ATF1500ABV/L

Page 7

AC Waveforms

ATF1500ABV/L

Register AC Characteristics, Input Pin Clock

(1)

Symbol Parameter 2.7-volt Adder

(2)

t

COS

t

CFS

t

SIS

t

SFS

t

HS

t

PS

t

WS

F

MAXS

t

RPRS

t

RTRS

Clock to Output .5 2728 ns

Clock to Feedback 033ns

I, I/O Setup Time 11011ns

Feedback Setup Time 11011ns

Input, I/O, Feedback Hold Time 00 0 ns

Clock Period 113 14 ns

Clock Width .5 6.5 7 ns

External Feedback 1/(t

Internal Feedback 1/(t

No Feedback 1/(t

PS

+ t

SIS

SFS

) -5 58.8 52.6 MHz

COS

+ t

) -5.5 76.9 71.4 MHz

CFS

) -5.5 76.9 71.4 MHz

Reset Pin Recovery Time 13 4 ns

Reset Term Recovery Time 110 12 ns

Notes: 1. AC Characteristics are for VCC = 3.0 volts. For 2.7 volts, add the "2.7-volt adder."

2. For slow slew outputs, add t

SSO

.

-12 -15

UnitsMinMaxMinMax

= Preliminary Information

7

Page 8

Register AC Characteristics, Product Term Clock

(1)

-12 -15

Symbol Parameter 2.7-volt Adder

(2)

t

COA

t

CFA

t

SIA

t

SFA

t

HA

t

PA

Clock to Output 21215ns

Clock to Feedback 1 8 10 ns

I, I/O Setup Time 04 4 ns

Feedback Setup Time 04 4 ns

Input, I/O, Feedback Hold Time 04 4 ns

Clock Period 112 14 ns

UnitsMin Max Min Max

tWAClock Width .5 6 7 ns

F

MAXA

t

RPRA

t

RTRA

External Feedback 1/(t

Internal Feedback 1/(t

No Feedback 1/(t

PA

Reset Pin Recovery Time 00 0 ns

Reset/Preset Term Recovery Time 06 6 ns

+ t

SIA

SFA

) -7 62.5 52.6 MHz

COA

+ t

) -6.4 83.3 71.4 MHz

CFA

) -6.4 83.3 71.4 MHz

Notes: 1. AC Characteristics are for VCC = 3.0 volts. For 2.7 volts, add the “2.7-volt Adder.”

2. For slow slew outputs, add t

SSO .

AC Characteristic

-12 -15

Symbol Parameter 2.7-volt Adder

(2)

t

PD

t

PD2

(2)

t

PD3

t

PD4

(2)

t

EA

I, I/O or FB to Non-Registered Output 2312315ns

I, I/O to Feedback 189ns

Feedback to Non-Registered Output 2312315ns

Feedback to Feedback 189ns

OE Term to Output Enable 1312315ns

tEROE Term to Output Disable 1212215ns

(2)

t

PZX

t

PXZ

t

PF

(2)

t

PO

t

RPF

(2)

t

RPO

t

RTF

(2)

t

RTO

t

CAS

t

SSO

t

FLD

OE Pin to Output Enable 12829ns

OE Pin to Output Disable 1 1.581.59 ns

Preset To Feedback 1912ns

Preset to Registered Output 21420ns

Reset Pin to Feedback 135ns

Reset Pin to Registered Output 1811ns

Reset Term to Feedback 1912ns

Reset Term to Registered Output 21420ns

Cascade Logic Delay 011ns

Slow Slew Output Adder 034ns

Foldback Term Delay 178ns

Notes: 1. AC Characteristics are for VCC = 3.0 volts. For 2.7 volts, add the “2.7-volt Adder.”

2. For slow slew outputs, add t

8

ATF1500ABV/L

SSO

.

= Preliminary Information

UnitsMin Max Min Max

Page 9

ATF1500ABV/L

P ower Down AC Characteristics

(1)

Symbol Parameter 2.7-volt Adder

t

IVDH

t

GVDH

t

CVDH

t

DHIX

t

DHGX

tDHCX Clock Don't Care After PD High

t

DLIV

t

DLGV

t

DLCV

(1)

t

DLOV

Valid I, I/O Before PD High 112 15 ns

Valid OE

Valid Clock

(3)

Before PD High 112 15 ns

(3)

Before PD High 112 15 ns

Input Don't Care After PD High 122 25 ns

OE Don't Care After PD High 122 25 ns

122 25 ns

PD Low to Valid I, I/O 011µs

PD Low to Valid OE

PD Low to Valid Clock

(3)

(3)

011µs

011µs

PD Low to Valid Output 011µs

Notes: 1. AC Characteristics are for VCC = 3.0 volts. For 2.7 volts, add the “2.7-volt Adder.”

2. For slow slew outputs, add t

SSO

.

3. Pin or Product Term.

Input Test Waveforms and

Output Test Load

Measurement Levels

-12 -15

UnitsMinMaxMinMax

= Preliminary Information

Pin Capacitance

(f = 1 MHz, T = 25°C)

C

IN

C

OUT

Note: 1. Typical values for nominal supply voltage. This parameter is only sampled and is not 100% tested.

(1)

Typ Max Units Conditions

4.5 5.5 pF VIN = 0V

3.5 4.5 pF V

OUT

= 0V

9

Page 10

Power Up Reset

The ATF1500ABV’s registers are designed to reset during

power up. At a point delayed slightly from V

, all registers will be reset to the low sta te. As a res ult,

V

RST

crossing

CC

the registered output state will always be low on power-up.

This feature is critical for state machine initialization. How-

ever, due to the asynchronous nature of reset and the

uncertainty of how V

actually rises in the sy stem, the fol -

CC

lowing conditions are required:

1. The V

rise must be monotonic, from below .7

CC

volts.

2. Signals from which clocks are derived must remain

stable during T

3. After T

occurs, all input and feedbac k setup times

PR

PR

.

must be met before driving the cloc k signal high.

Power Down Mode

The ATF1500ABV includes an optional pin controlled

power down feature. When this mode is enabled, the PD

pin acts as the power down pin. When the PD pin is high,

the device supply cur rent is reduced to less than 1 0 µA.

During power down, all output data and internal logic states

are latched and held. Therefore, all registered and combinatorial output data remain valid. Any outputs which were

in a HI-Z state at the onset of power down will remain at HIZ. During power do wn, all inpu t signals ex cept the powe r

down pin are blocked. Input and I/O hold latches remain

active to insure that pins do not float to indeterminate levels, further reducing system power. The power down pin

feature is enabled in the logic design file. Designs using the

power down pin may not use the PD pin l ogic array input.

However, all other PD pin macrocell resources may still be

used, including the buried feedb ack and foldback produc t

term array inputs.

Register Preload

The ATF1500ABV’s registers are provided with circuitry to

allow loading of each register with either a high or a low.

This feature will simplify testing since any state c an be

forced into the register s to control test s equencing. A

JEDEC file with pr eload is gen erated when a sou rce file

with preload vectors is c ompiled. Once downl oaded, the

JEDEC file preload seque nce will be don e automatically

when vectors are run by any approved programmers. The

preload mode is ena bled by raising an input pin to a high

voltage level. Contact Atmel PLD Applications for PRELOAD pin assignments, timing and voltage requirements.

Parameter Description Typ Max Units

T

PR

V

RST

Power-Up

Reset Time

Po w er-Up

Reset

Voltage

210

2.2 2.7 V

s

µ

Output Slew Rate Control

Each ATF1500ABV macrocel l contains a c onfiguration bit

for each I/O to control its output slew rate. This allows

selected data paths to operate at maximum throughput

while reducing system noise from outputs that are not

speed-critical. Outputs default to slow edges, and m ay be

individually set to fas t in the des ign file . Output tra nsition

times for outputs confi gured as “slow” ha ve a t

SSO

delay

adder.

Security Fuse Usage

A single fuse is provided to preven t unauthorized copy ing

of the ATF1500ABV fuse patterns. Once programmed, fuse

verify and preload are prohibited. However, the 160-bit

User Signature remains accessible.

The security fuse should be programmed last, as its effect

is immediate.

10

ATF1500ABV/L

Page 11

Ordering Information

ATF1500ABV/L

t

PD

(ns)

12 6 62.5 ATF1500ABV-12AC

15 8 52.6 ATF1500ABV-15AC

25 TBD TBD ATF1500ABVL-25AC

t

COS

(ns)

F

MAXS

(MHz) Ordering Code Package Operation Range

ATF1500ABV-12JC

ATF1500ABV-15JC

ATF1500ABV-15AI

ATF1500ABV-15JI

ATF1500ABVL-25JC

44A

44J

44A

44J

44A

44J

44A

44J

Commercial

(0°C to 70°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Package Type

44A 44 Lead, Thin Plastic Gull Wing Quad Flatpack (TQFP)

44J 44 Lead, Plastic J-Leaded Chip Carrier (PLCC)

11

Page 12

Packaging Information

.045(1.14) X 45°

PIN NO.1

IDENTIFY

.045(1.14) X 30° - 45°

.012(.305)

.008(.203)

.021(.533)

.013(.330)

.630(16.0)

.590(15.0)

.043(1.09)

.020(.508)

.120(3.05)

.090(2.29)

.180(4.57)

.165(4.19)

.500(12.7) REF SQ

.032(.813)

.026(.660)

.050(1.27) TYP

.022(.559) X 45° MAX (3X)

.656(16.7)

.650(16.5)

.695(17.7)

.685(17.4)

SQ

SQ

44A

, 44-Lead, Thin (1.0 mm)

Plastic Gull Wing Quad Flat Package (TQFP)

Dimensions in Millimeters and (Inches)*

*Controlling dimension: millimeters

44J

, 44-Lead, Plastic J-Leaded Chip Carrier (PLCC)

Dimensions in Inches and (Millimeters)

© Atmel Corporation 1998.

Atmel Corporation makes no warranty for the use of its products, other than those expressly contained in the

Company’s standard warranty which is detailed in Atmel’s Terms and Conditions located on the Company’s

website. The Company assumes no responsibility for any errors which may appear in this document, reserves

the right to change devices or specifications detailed herein at any time without notice, and does not make any

commitment to update the information contained herein. No licenses to patents or other intellectual property of

Atmel are granted by the Company in connection with the sale of Atmel products, expressly or by implication. Atmel’s products are not

authorized for use as critical components in life support devices or systems.

Atmel Headquarters, 2325 Orchard Pa rkway, San Jose, CA 95131, TEL (408) 441-0311, FAX (408) 487-2600

Atmel Colorado Springs, 1150 E. Cheyenne Mtn. Blvd., Colorado Springs, CO 80906, TEL (719) 576-3300, FAX (719) 540-1759

Atmel Rousset, Zone Industrielle, 13106 Rousset Cedex, France, TEL (33) 4 42 53 60 00, FAX (33) 4 42 53 60 01

Terms and product names in this document may be trademarks of others.

12

ATF1500ABV/L

Printed on recycled paper.

0723D–6/98/XM

Loading...

Loading...