Page 1

PowerScan™ M8500

Industrial Handheld Area Imager Bar Code Reader

with Datalogic’s STAR Cordless System

™

Product Reference Guide

Page 2

Datalogic Scanning, Inc.

959 Terry Street

Eugene, Oregon 97402

USA

Telephone: (541) 683-5700

Fax: (541) 345-7140

ts of this documentation or the procedures described

An Unpublished Work - All rights reserved. No part of the conte

n

therein may be reproduced or transmitted in any form or by any means without prior written permission of Datalogic

Scanning, Inc. or its subsidiaries or affiliates ("Datalogic" or “Datalogic Scanning”). Owners of Datalogic products are hereby

granted a non-exclusive, revocable license to reproduce and transmit this documentation for the purchaser's own internal

business purposes. Purchaser shall not remove or alter any proprietary notices, including copyright notices, contained in

this documentation and shall ensure that all notices appear on any reproductions of the documentation.

u can acquire printed versions by contacting your Datalogic repre-

Should future revisions of this manual be published, y

o

sentative. Electronic versions may either be downloadable from the Datalogic website (www.scanning.datalogic.com) or

provided on

appropriate media. If you visit our website and would like to make comments or suggestions about this or

other Datalogic publications, please let us know via the "Contact Datalogic" page.

Disclaimer

o

Datalogic has taken reasonable measures t

provide information in this manual that is complete and accurate, however,

Datalogic reserves the right to change any specification at any time without prior notice.

Datalogic and the Datalogic logo are registered

trademarks of Datalogic S.p.A. in many countries, including the U.S.A and

the E.U. All other brand and product names referred to herein may be trademarks of their respective owners.

Microsoft Windows®, Windows® 2000, Windows®CE, Windows® NT, Windows® XP and the Windows logo are registered

ks of M

trademar

icrosoft Corporation.

Patents

This product is covered by one or more of the following patents:

Design Pat. AU 310201; AU 310202; CN 693980; CN 735959; HK 0602013.5M001; HK 0602013.5M002; JP 1305693;

KR 30-0460940; US D570,843 S.

US Pat. 6,478,226 B2; 6,512,218 B1; 6,808,114 B1; 6,877,664 B1; 6,997,385 B2; 7,053,954 B1; 7,102,116 B2;

7,282,688 B2; 7,387,246.

European Pat. 996,284 B1; 999,514 B1; 1,128,315 B1; 1,396,811 B1.

Additional patents pending.

Page 3

Table of Contents

Preface ........................................................................................................................................................... 7

About this Guide ....................................................................................................................................................................................................................7

Manual Overview ...................................................................................................................................................................................................................7

Manual Conventions ............................................................................................................................................................................................................8

References ................................................................................................................................................................................................................................ 8

Service and Support .............................................................................................................................................................................................................8

PRODUCTS ......................................................................................................................................................................................................8

SERVICE & SUPPORT .................................................................................................................................................................................... 8

CONTACT US .................................................................................................................................................................................................. 8

Compliance .............................................................................................................................................................................................................................. 9

Aiming System.............................................................................................................................................................................................................. 9

Power Supply ...............................................................................................................................................................................................12

WEEE Compliance ......................................................................................................................................................................................13

Introduction................................................................................................................................................. 15

Overview .................................................................................................................................................................................................................................15

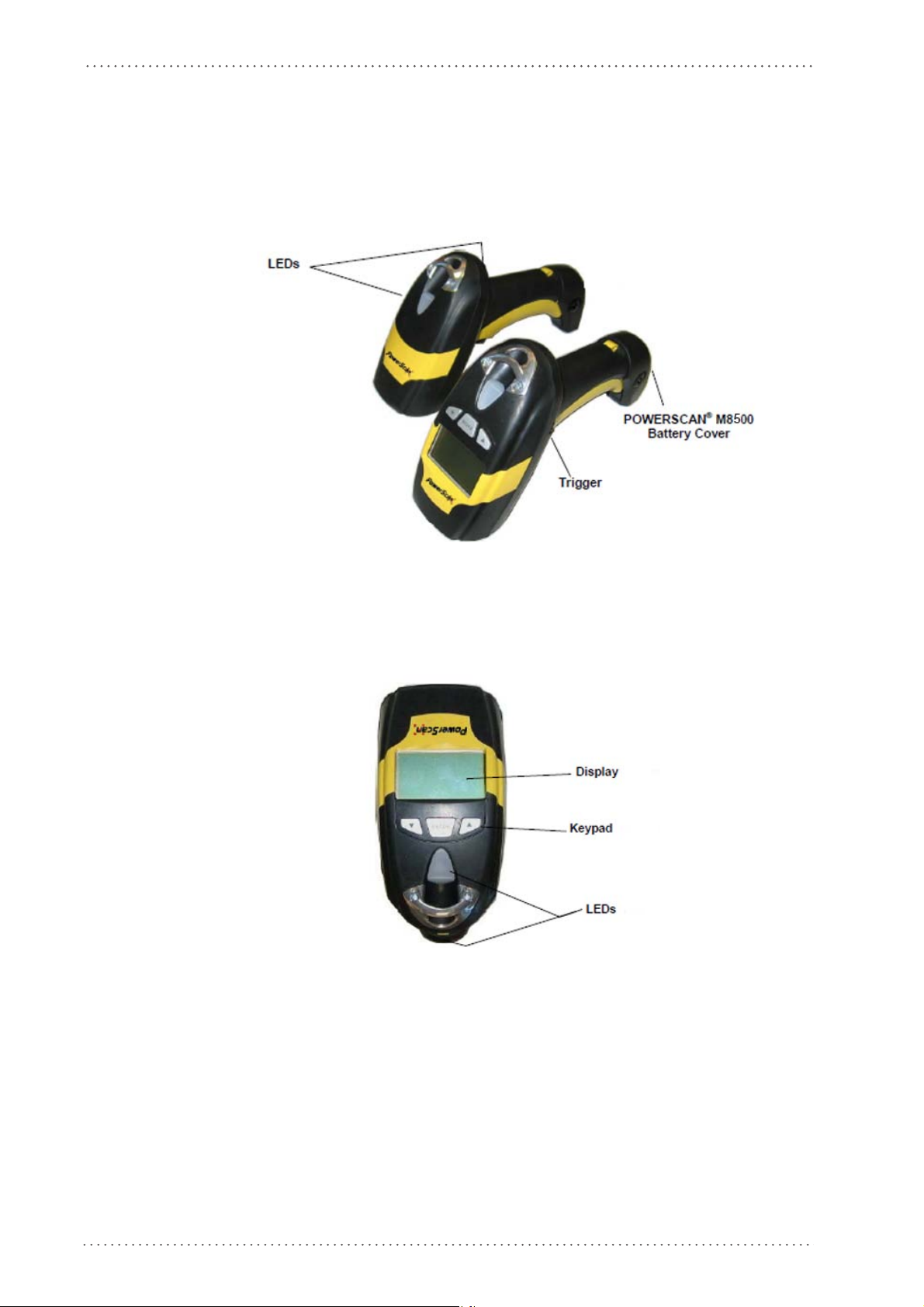

General View .........................................................................................................................................................................................................................16

Powerscan® M8500 Readers .................................................................................................................................................................................. 16

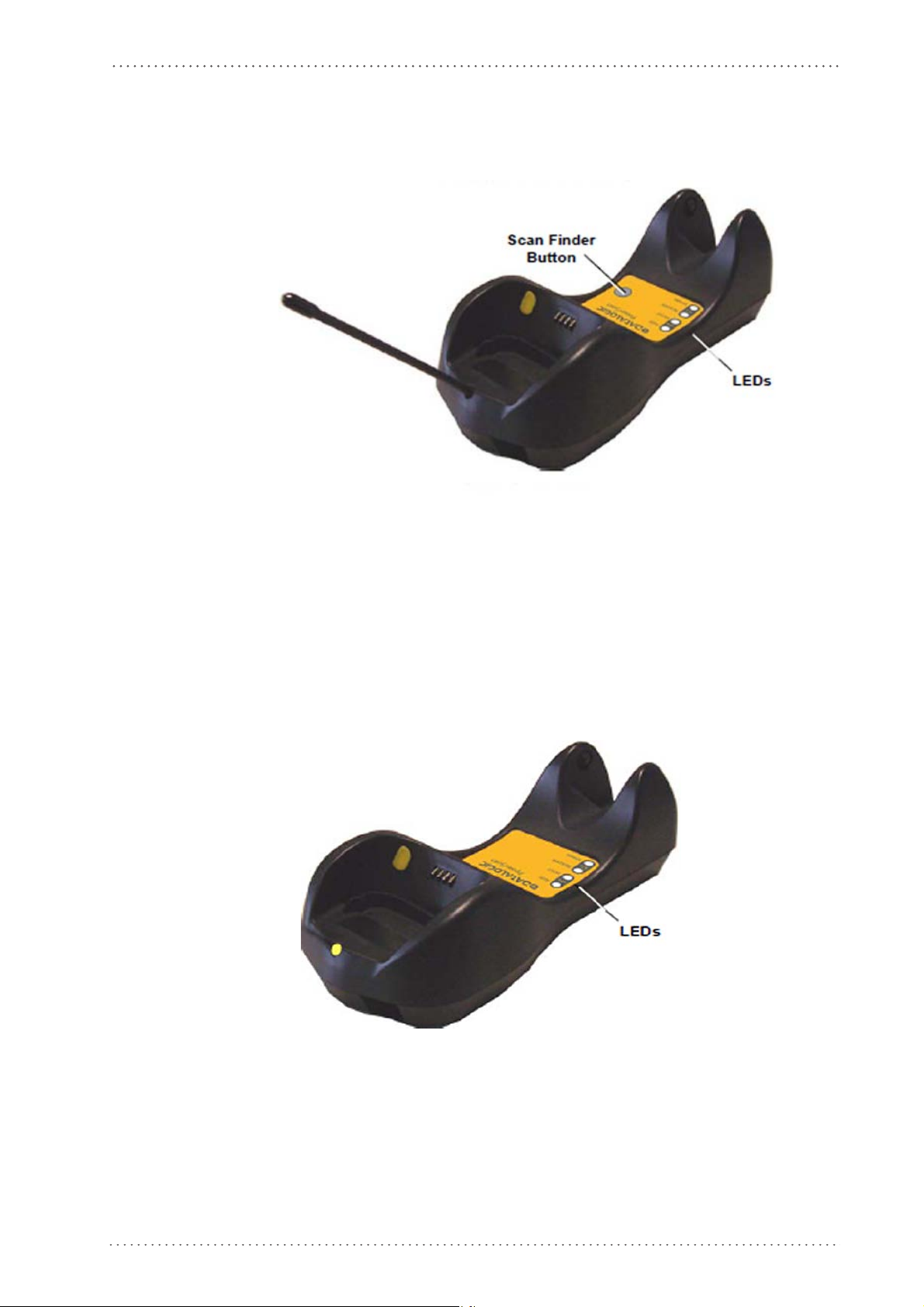

BC-80X0 / C-8000 CRADLES ................................................................................................................................................................................... 17

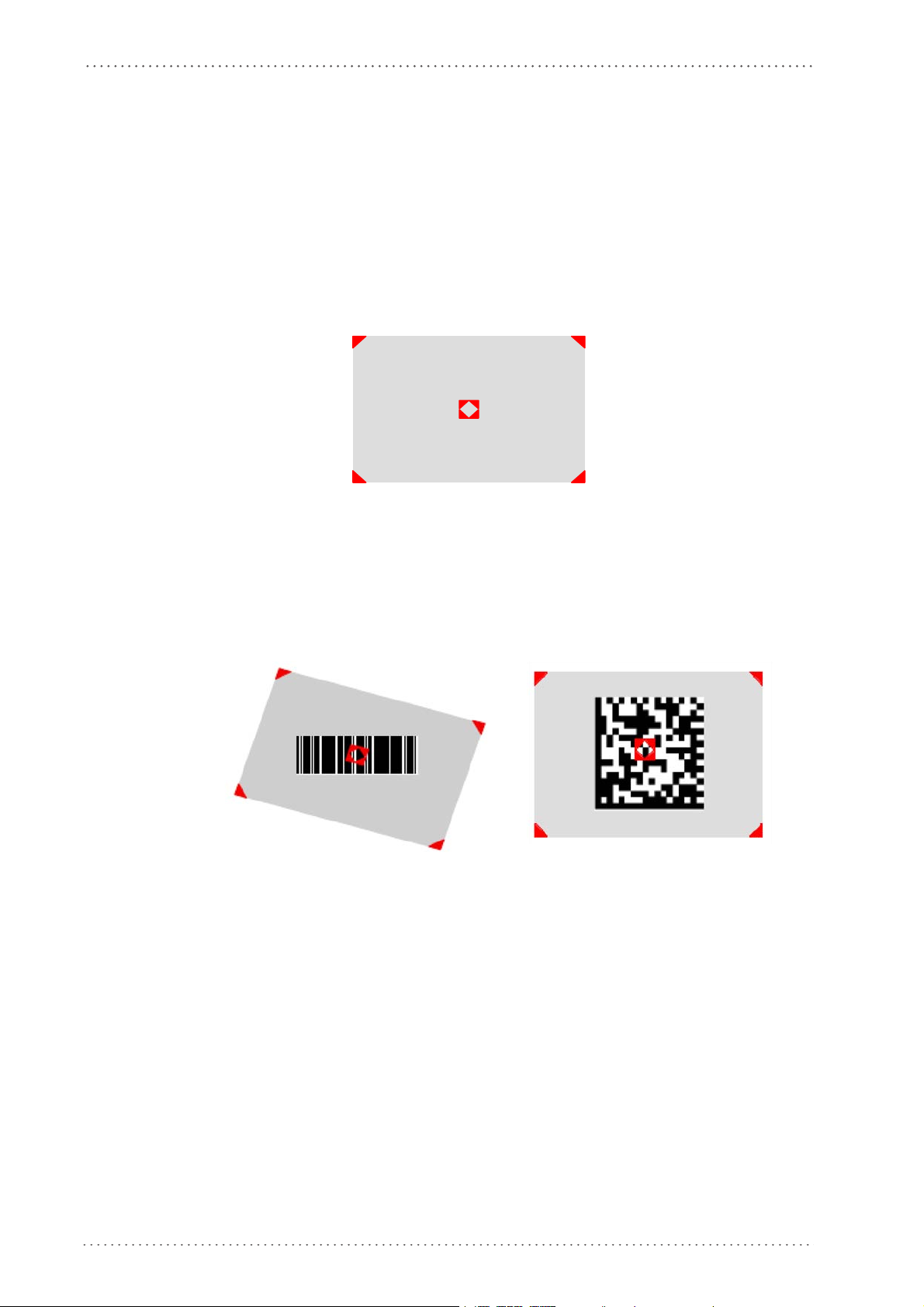

Using the Reader .................................................................................................................................................................................................................18

Aiming System............................................................................................................................................................................................................ 18

Normal Operation...................................................................................................................................................................................................... 19

Configuration Methods .....................................................................................................................................................................................................19

Reading Configuration Codes ...............................................................................................................................................................19

Using Datalogic Aladdin™ ......................................................................................................................................................................19

Sending Configuration Strings from Host ........................................................................................................................................19

Autoscanning ........................................................................................................................................................................................................................20

Normal Mode............................................................................................................................................................................................................... 20

Pattern Mode............................................................................................................................................................................................................... 20

Camera Control ....................................................................................................................................................................................................................20

Defining Data Formatting ................................................................................................................................................................................................21

Concatenation ............................................................................................................................................................................................................ 22

PowerScan M8500 Setup............................................................................................................................ 23

Package Contents...................................................................................................................................................................................................... 23

Installation .............................................................................................................................................................................................................................23

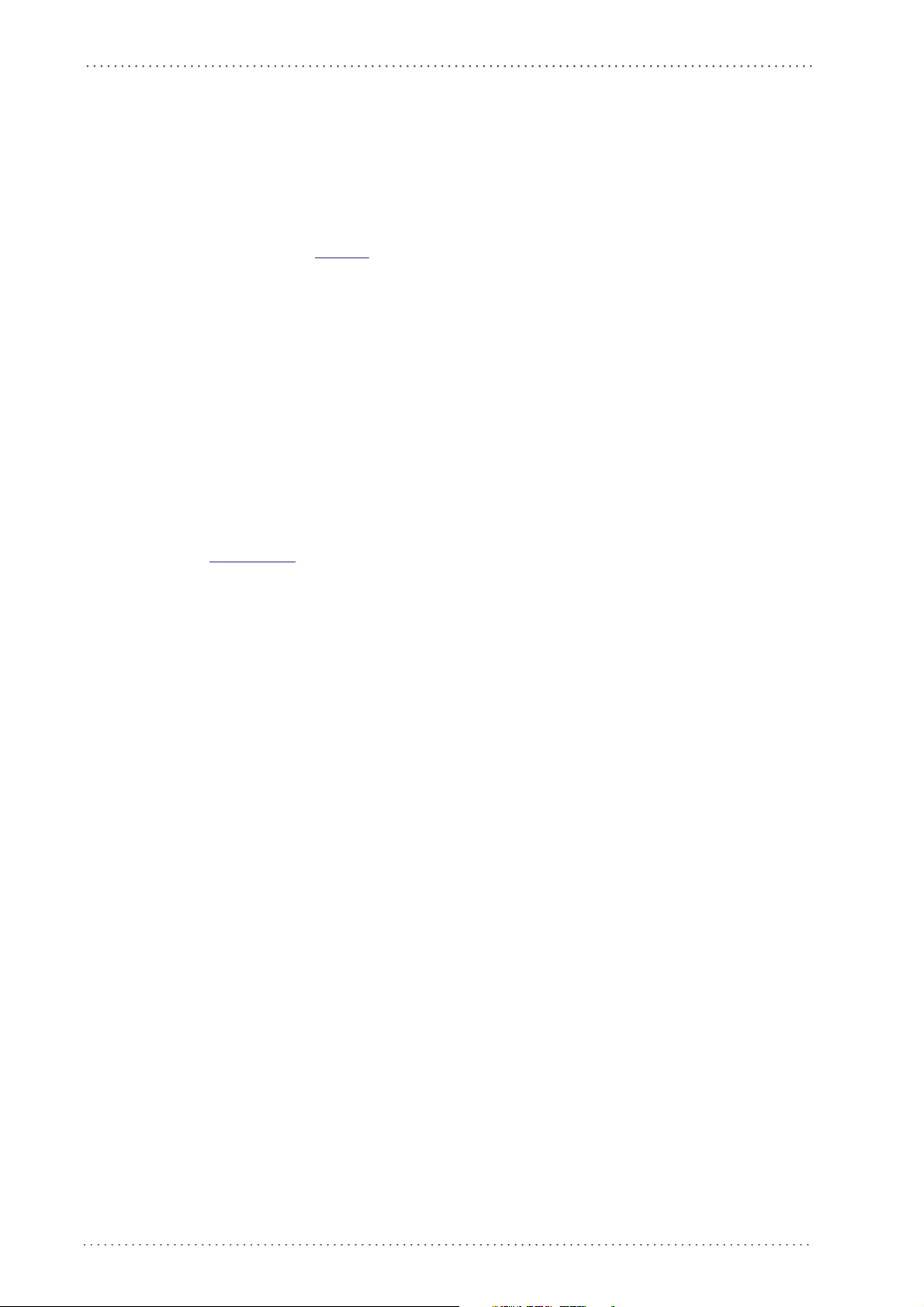

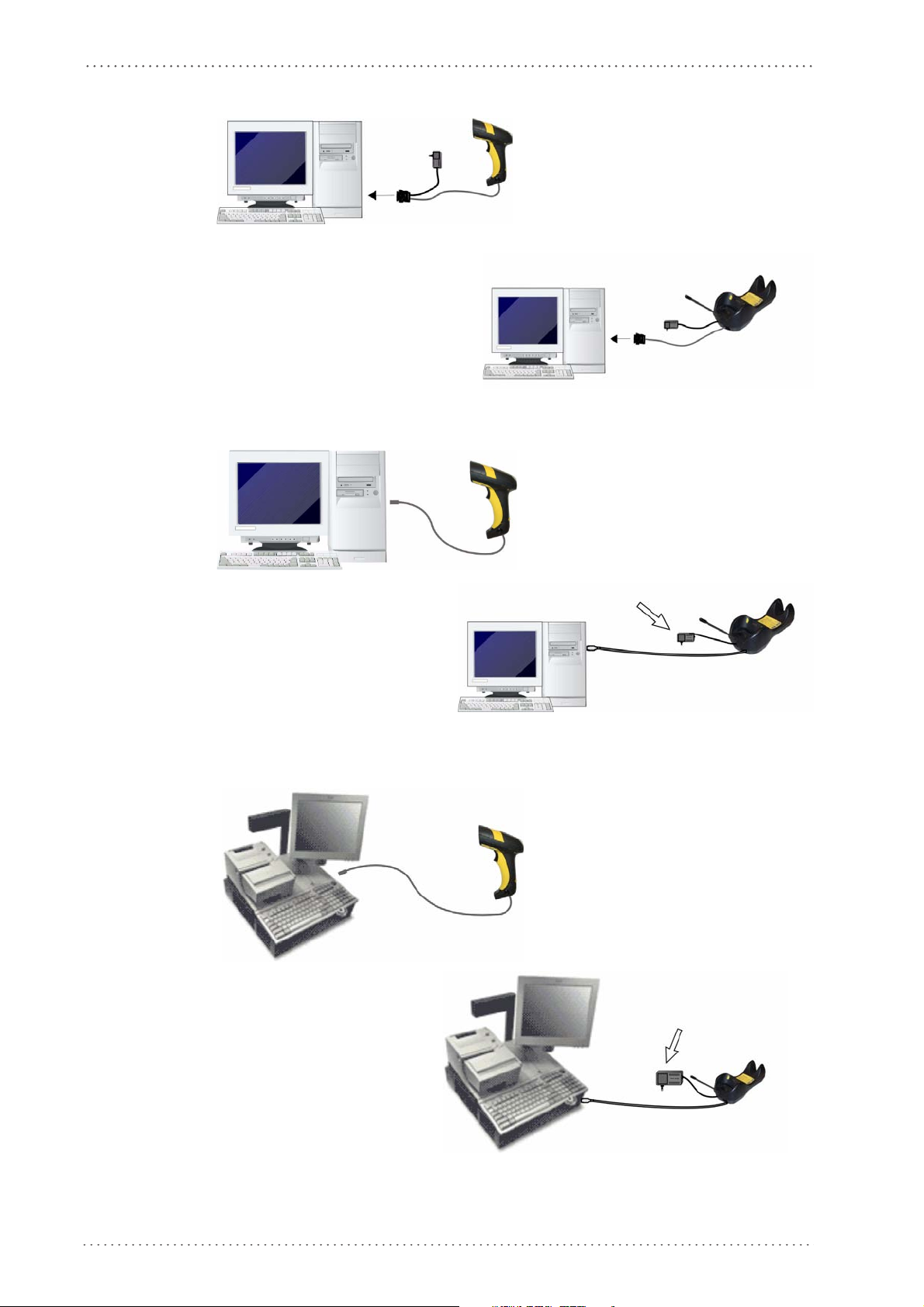

BC-80X0 Interface Cable Connections ............................................................................................................................................................... 23

RS-232 Connection ....................................................................................................................................................................................24

USB ...................................................................................................................................................................................................................24

IBM USB POS ................................................................................................................................................................................................24

WEDGE Connection ...................................................................................................................................................................................25

PEN Emulation Connection ....................................................................................................................................................................25

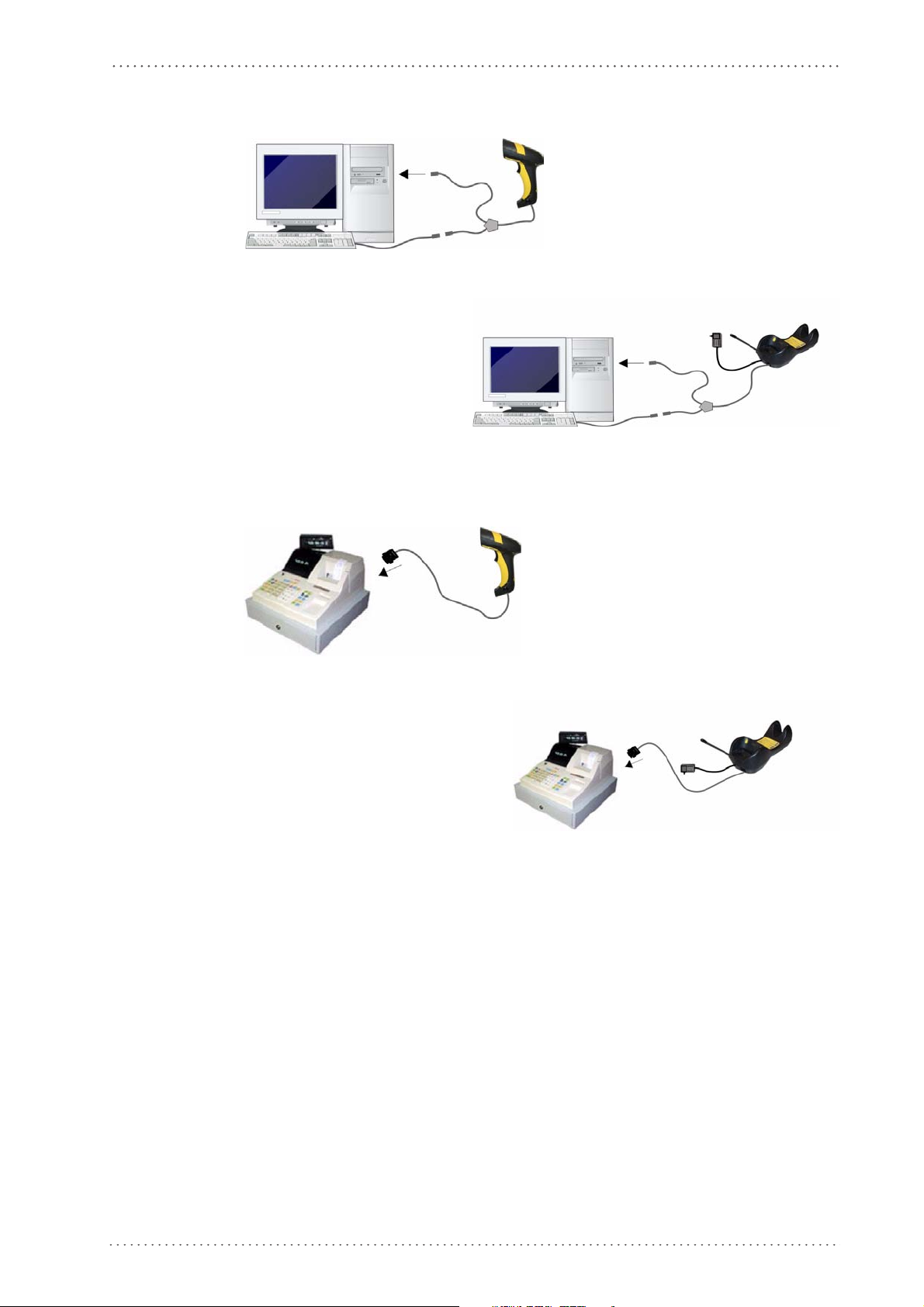

Network Connections ........................................................................................................................................................................................................26

BC-8060 Network Connectors............................................................................................................................................................................... 26

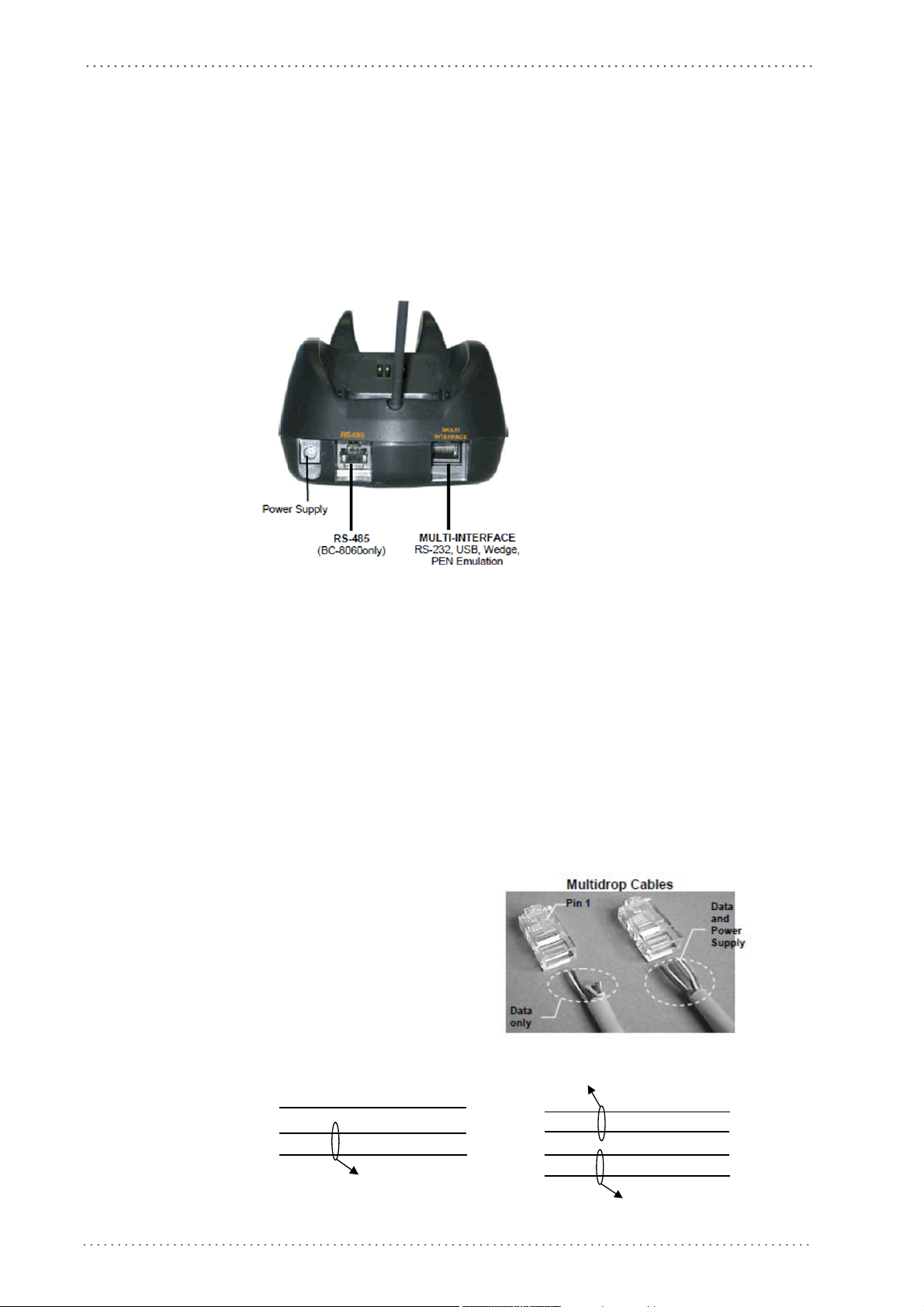

Network Cabling ........................................................................................................................................................................................................ 26

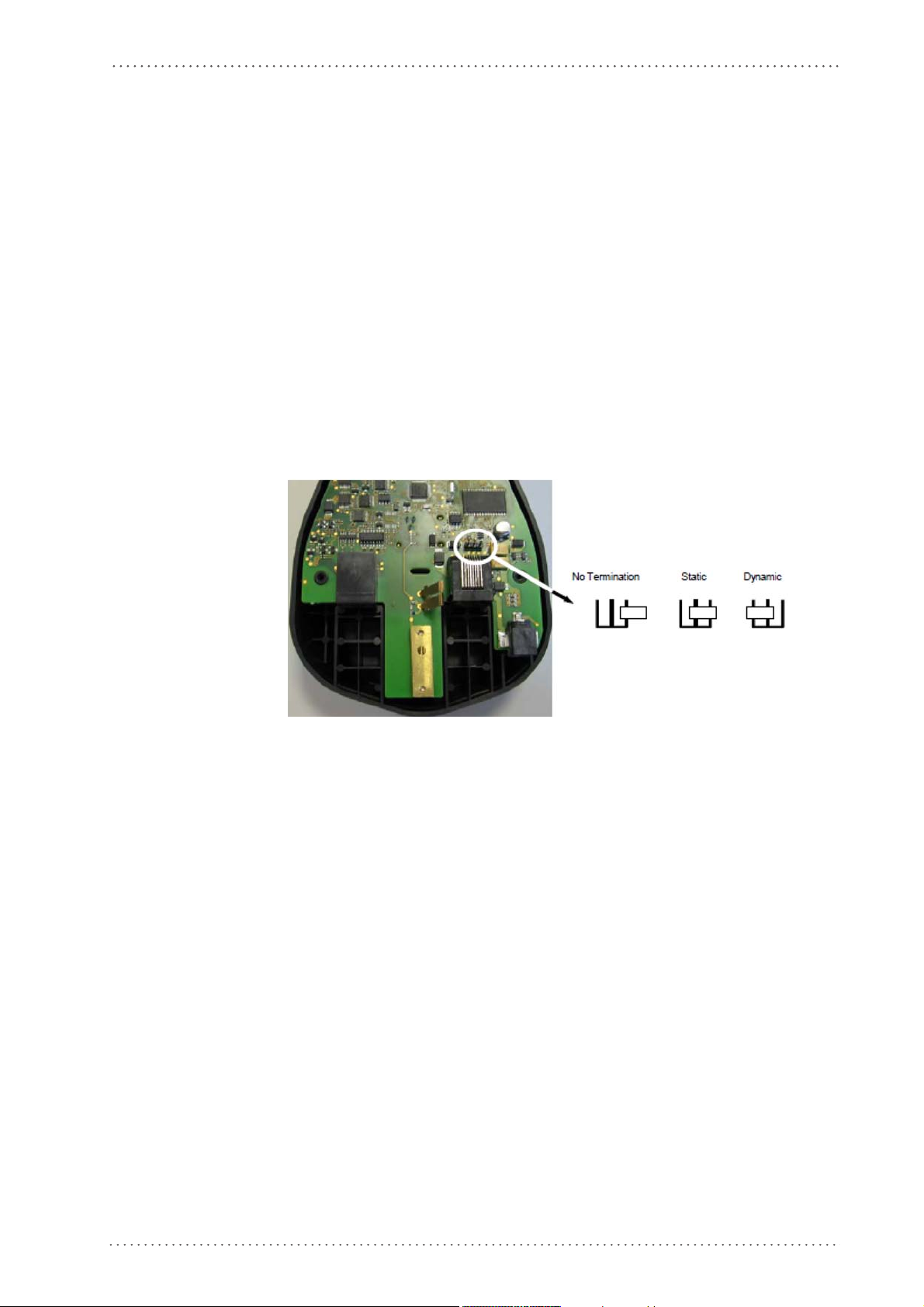

Network Termination ............................................................................................................................................................................................... 27

PowerScan® M8500 Battery Maintenance ..................................................................................................................................................................28

Battery Charging........................................................................................................................................................................................................ 28

Replacing PowerScan® M8500 Batteries ........................................................................................................................................................... 28

Mounting The BC-80X0 / C-8000 Cradle............................................................................................................................................................ 30

Desktop Mounting .................................................................................................................................................................................................... 31

Portable Desktop Use ...............................................................................................................................................................................31

Fixed Desktop Use .....................................................................................................................................................................................32

Wall Mounting .............................................................................................................................................................................................33

System and Network Layouts .........................................................................................................................................................................................35

Stand-Alone Layouts ................................................................................................................................................................................................ 35

Product Reference Guide

1

Page 4

Contents

Multiple Stand-Alone Layouts............................................................................................................................................................................... 36

Multidrop STAR-System™ Network Layouts..................................................................................................................................................... 37

Host Master Layout ...................................................................................................................................................................................37

BC-8060 Master Layout ............................................................................................................................................................................38

Master BC-8060 Network Troubleshooting .....................................................................................................................................38

Setup Procedures ................................................................................................................................................................................................................39

PowerScan® M8500/BC-80X0 Point-to-Point Setup...................................................................................................................................... 39

PowerScan® M8500/BC-80X0 Stand-Alone Setup ......................................................................................................................................... 40

Using Multiple M-Series Readers with Same Cradle .....................................................................................................................42

PowerScan® M8500/STAR-Modem™ in Stand-Alone Mode .....................................................................................................42

PowerScan® M8500/STAR-System™ Setup....................................................................................................................................................... 43

BC-8060 STAR-System™ Network Setup............................................................................................................................................................ 45

Interface Selection ..............................................................................................................................................................................................................47

RS-232.......................................................................................................................................................................................................................................47

POS Terminals ............................................................................................................................................................................................................. 47

PEN.............................................................................................................................................................................................................................................47

WEDGE......................................................................................................................................................................................................................................48

IBM Terminals 31xx, 32xx, 34xx, 37xx: ................................................................................................................................................................ 48

KEY TRANSMISSION MODE..................................................................................................................................................................................... 48

ALT MODE..................................................................................................................................................................................................................... 49

WYSE TERMINALS .................................................................................................................................................................................................................49

KEYBOARD TYPE......................................................................................................................................................................................................... 49

DIGITAL TERMINALS ...........................................................................................................................................................................................................50

USB Configuration..................................................................................................................................................................................................... 50

USB Start-up .................................................................................................................................................................................................50

Configuration Using Code Symbols........................................................................................................... 53

Configuration Parameters ...................................................................................................................................................................................... 53

Reading Configuration Barcodes ......................................................................................................................................................................... 54

RS-232 PARAMETERS ..........................................................................................................................................................................................................55

Baud Rate...................................................................................................................................................................................................................... 56

Parity............................................................................................................................................................................................................................... 56

Data Bits ........................................................................................................................................................................................................................ 57

Stop Bits ........................................................................................................................................................................................................................ 57

Handshaking................................................................................................................................................................................................................ 57

ACK/NACK Protocol................................................................................................................................................................................................... 58

FIFO................................................................................................................................................................................................................................. 58

Inter-character Delay................................................................................................................................................................................................ 58

RX Timeout................................................................................................................................................................................................................... 59

Serial Trigger Lock ..................................................................................................................................................................................................... 59

USB PARAMETERS ................................................................................................................................................................................................................60

USB-COM ............................................................................................................................................................................................................................61

Handshaking................................................................................................................................................................................................................ 61

ACK/NACK Protocol................................................................................................................................................................................................... 61

FIFO................................................................................................................................................................................................................................. 61

Inter-character Delay................................................................................................................................................................................................ 62

RX Timeout................................................................................................................................................................................................................... 62

Serial Trigger Lock ..................................................................................................................................................................................................... 63

USB-KBD ..............................................................................................................................................................................................................................64

Keyboard Nationality................................................................................................................................................................................................ 64

FIFO................................................................................................................................................................................................................................. 65

Inter-character Delay................................................................................................................................................................................................ 66

Inter-code Delay......................................................................................................................................................................................................... 66

USB Keyboard Speed................................................................................................................................................................................................ 66

WEDGE PARAMETERS ........................................................................................................................................................................................................67

Keyboard Nationality................................................................................................................................................................................................ 68

Caps Lock...................................................................................................................................................................................................................... 69

Caps Lock Auto-Recognition (IBM AT compatible only).............................................................................................................................. 70

Num Lock...................................................................................................................................................................................................................... 70

Inter-character Delay................................................................................................................................................................................................ 70

Inter-code Delay......................................................................................................................................................................................................... 71

Keyboard Setting ....................................................................................................................................................................................................... 71

2

PowerScan® M8500

Page 5

Contents

Control Character Emulation................................................................................................................................................................................. 73

PEN EMULATION ..................................................................................................................................................................................................................74

Operating Mode......................................................................................................................................................................................................... 75

Minimum Output Pulse ........................................................................................................................................................................................... 76

Conversion to Code 39 ............................................................................................................................................................................................ 76

Conversion to Code 128.......................................................................................................................................................................................... 77

Overflow........................................................................................................................................................................................................................ 77

Output Level................................................................................................................................................................................................................ 77

Idle Level ....................................................................................................................................................................................................................... 78

Inter-Block Delay........................................................................................................................................................................................................ 78

NETWORK PARAMETERS ...................................................................................................................................................................................................79

RS-485 Network.......................................................................................................................................................................................................... 80

Network Baud Rate.................................................................................................................................................................................................... 80

Slave Address Range................................................................................................................................................................................................. 81

Network Warning Message .................................................................................................................................................................................... 81

Reception Warning Message................................................................................................................................................................................. 81

Master Cradle Header............................................................................................................................................................................................... 82

Master Cradle Terminator....................................................................................................................................................................................... 83

DATA FORMAT ......................................................................................................................................................................................................................84

Code Identifier ............................................................................................................................................................................................................ 85

Custom Code Identifier............................................................................................................................................................................................ 86

Header............................................................................................................................................................................................................................ 89

Terminator.................................................................................................................................................................................................................... 90

Code Length Tx .......................................................................................................................................................................................................... 91

Address Stamping ..................................................................................................................................................................................................... 91

Address Delimiter ..................................................................................................................................................................................................... 92

Time Stamping .......................................................................................................................................................................................................... 92

Time Stamping Delimiter........................................................................................................................................................................................ 93

Symbology Dependent Parameters .........................................................................................................................................................................94

Symbology Specific Format ................................................................................................................................................................................... 95

Symbology Headers.................................................................................................................................................................................................. 95

Headers.......................................................................................................................................................................................................................... 96

Symbology Terminators.......................................................................................................................................................................................... 96

Terminators.................................................................................................................................................................................................................. 96

Symbology Character Substitution..................................................................................................................................................................... 97

Character Substitution............................................................................................................................................................................................. 97

Symbology Character Deletion ............................................................................................................................................................................ 97

Character Deletion .................................................................................................................................................................................................... 98

Symbology Specific Format Default ................................................................................................................................................................... 98

Concatenation ..................................................................................................................................................................................................................99

Define Concatenation .............................................................................................................................................................................................. 99

Concatenation Enable/Disable ............................................................................................................................................................................. 99

Concatenation Length ...................................................................................................................................................................................................99

First Concatenated Code Length ......................................................................................................................................................................... 99

Second Concatenated Code Length................................................................................................................................................................... 99

Third Concatenated Code Length .................................................................................................................................................................... 100

Fourth Concatenated Code Length ................................................................................................................................................................. 100

Concatenation with Intercode Delay............................................................................................................................................................... 100

Concatenation Failure Transmission ............................................................................................................................................................... 100

Concatenation Timeout ..........................................................................................................

smission After T

Tran

Concatenation Result Code ID........................................................................................................................................................................... 101

CAMERA CONTROL ..........................................................................................................................................................................................................102

Exposure Mode........................................................................................................................................................................................................ 102

AIMING SYSTEM ................................................................................................................................................................................................................103

Good Read Spot ...................................................................................................................................................................................................... 103

CODE SELECTION .............................................................................................................................................................................................................104

Issue Identical Codes ............................................................................................................................................................................................. 104

Linear Symbologies .....................................................................................................................................................................................................105

UPC/EAN/JAN Family............................................................................................................................................................................................. 105

Code 39 Family ........................................................................................................................................................................................................ 106

imeout................................................................................................................................................................................ 101

............................................................................. 100

Product Reference Guide

3

Page 6

Contents

Code 32 Family ........................................................................................................................................................................................................ 107

Interleaved 2 of 5 Family...................................................................................................................................................................................... 107

Codabar Family........................................................................................................................................................................................................ 108

Code 128 Family...................................................................................................................................................................................................... 109

Code 93 Family ........................................................................................................................................................................................................ 110

GS1 Databar™ Family............................................................................................................................................................................................. 111

2D Symbologies ............................................................................................................................................................................................................ 112

PDF417........................................................................................................................................................................................................................ 112

Micro PDF417 ........................................................................................................................................................................................................... 113

DataMatrix Family................................................................................................................................................................................................... 113

QR Family................................................................................................................................................................................................................... 113

Micro QR..................................................................................................................................................................................................................... 114

Postal Codes Family ............................................................................................................................................................................................... 114

Australian Table Selection ................................................................................................................................................................................... 115

Intelligent Mail Barcode ....................................................................................................................................................................................... 115

Maxicode Family ..................................................................................................................................................................................................... 115

Aztec............................................................................................................................................................................................................................ 116

Composite Codes.................................................................................................................................................................................................... 116

READING PARAMETERS .................................................................................................................................................................................................. 117

Trigger Mode............................................................................................................................................................................................................ 118

Trigger Type.............................................................................................................................................................................................................. 118

Flash Mode................................................................................................................................................................................................................ 118

Beeper Tone.............................................................................................................................................................................................................. 118

Beeper Volume ........................................................................................................................................................................................................ 119

Beeper Duration ...................................................................................................................................................................................................... 119

Reads per Cycle........................................................................................................................................................................................................ 119

Scan Timeout............................................................................................................................................................................................................ 119

User Defined Beeper ................................................................................................................................................................................................... 120

User Defined Beeper Tone................................................................................................................................................................................... 120

User Defined Beeper Volume ............................................................................................................................................................................. 120

User Defined Beeper Duration........................................................................................................................................................................... 120

Test User Defined Beeper .................................................................................................................................................................................... 120

Code Ordering and Selection ................................................................................................................................................................................... 121

Codes per Scan ........................................................................................................................................................................................................ 121

Central Code Transmission.................................................................................................................................................................................. 121

Order By Code Length........................................................................................................................................................................................... 121

Order By Code Symbology .................................................................................................................................................................................. 121

Autoscan .......................................................................................................................................................................................................................... 122

Autoscan Mode ....................................................................................................................................................................................................... 122

Autoscan Aiming System..................................................................................................................................................................................... 122

Autoscan Hardware Trigger................................................................................................................................................................................ 122

Autoscan Illumination System ........................................................................................................................................................................... 122

Safety Time................................................................................................................................................................................................................ 123

Safety Time Duration............................................................................................................................................................................................. 123

RADIO PARAMETERS .......................................................................................................................................................................................................124

Radio Protocol Timeout........................................................................................................................................................................................ 125

Radio RX Timeout ................................................................................................................................................................................................... 125

Power-Off Timeout..............................................................................................................

der Shut-Down .........

Rea

Transmission Mode ................................................................................................................................................................................................ 126

Beeper Control for Radio Response ................................................................................................................................................................. 127

Single Store............................................................................................................................................................................................................... 128

Batch Mode............................................................................................................................................................................................................... 129

Find Me....................................................................................................................................................................................................................... 129

DISPLAY and KEYPAD PARAMETERS .........................................................................................................................................................................130

DISPLAY PARAMETERS ............................................................................................................................................................................................... 131

Date and Time.......................................................................................................................................................................................................... 131

Contrast...................................................................................................................................................................................................................... 131

Font Size..................................................................................................................................................................................................................... 131

Backlight .................................................................................................................................................................................................................... 132

Display-Off Timeout............................................................................................................................................................................................... 132

........................................................................................................................................................................................ 126

................................................................................... 126

4

PowerScan® M8500

Page 7

Contents

Display Mode............................................................................................................................................................................................................ 132

KEYPAD PARAMETERS ................................................................................................................................................................................................133

Keypad........................................................................................................................................................................................................................ 133

Advanced Data Formatting...................................................................................................................... 135

Format Definition .............................................................................................................................................................................................................136

Method 1 - Extracting Information from Barcode ...................................................................................................................... 137

Method 2 - Manipulating the Barcode Data .................................................................................................................................142

Match Conditions .............................................................................................................................................................................................................151

Format Enable/Disable ................................................................................................................................................................................................... 152

Mismatch Result ................................................................................................................................................................................................................153

References ................................................................................................................................................. 155

RS-232 Parameters ...........................................................................................................................................................................................................155

Handshaking............................................................................................................................................................................................................. 155

ACK/NACK Protocol................................................................................................................................................................................................ 156

PowerScan® M8500 Readers ............................................................................................................................................................... 156

FIFO.............................................................................................................................................................................................................................. 156

PowerScan® M8500 Readers ............................................................................................................................................................... 156

RX Timeout................................................................................................................................................................................................................ 157

Pen Parameters .................................................................................................................................................................................................................157

Minimum Output Pulse ........................................................................................................................................................................................ 157

Conversion to Code 39 and Code 128............................................................................................................................................................. 157

PowerScan® M8500 Series Readers ..................................................................................................................................................157

Overflow..................................................................................................................................................................................................................... 157

Output and Idle Levels.......................................................................................................................................................................................... 158

Inter-Block Delay..................................................................................................................................................................................................... 158

Network Parameters ........................................................................................................................................................................................................ 158

Slave Address Range First/Last .......................................................................................................................................................................... 158

Network Warning Message ................................................................................................................................................................................. 159

Reception Warning Message.............................................................................................................................................................................. 159

Master Header/Terminator Selection .............................................................................................................................................................. 159

Data Format ........................................................................................................................................................................................................................ 160

Header/Terminator Selection............................................................................................................................................................................. 160

Define Special Key Sequence ............................................................................................................................................................................. 161

Address Stamping .................................................................................................................................................................................................. 168

Address Delimiter ................................................................................................................................................................................................... 168

Time Stamping Format......................................................................................................................................................................................... 168

Time Stamping Delimiter..................................................................................................................................................................................... 168

Reading Parameters ........................................................................................................................................................................................................168

Trigger Signal ........................................................................................................................................................................................................... 168

Reads per Cycle........................................................................................................................................................................................................ 168

Safety Time................................................................................................................................................................................................................ 169

Configuration Editing Commands.................................................................................................................................................................... 169

Radio Parameters ............................................................................................................................................................................................................. 170

Radio Protocol Timeout........................................................................................................................................................................................ 170

Radio RX Timeout ................................................................................................................................................................................................... 170

Power-Off Timeout................................................................................................................................................................................................. 170

Transmission Mode ................................................................................................................................................................................................ 171

Beeper Control for Radio Response ................................................................................................................................................................. 171

Single Store............................................................................................................................................................................................................... 171

Batch Mode............................................................................................................................................................................................................... 172

Find Me....................................................................................................................................................................................................................... 172

Display Parameters .........................................................................................................................................................................................................173

Display Mode............................................................................................................................................................................................................ 173

Default Parameters for POS Terminals ...................................................................................................................................................................... 174

Message Formatting................................................................................................................................. 175

Standard Message Formatting ....................................................................................................................................................................................175

Messages from Host to Reader .................................................................................................................................................................................... 175

Cursor Control.......................................................................................................................................................................................................... 176

Font Selection .......................................................................................................................................................................................................... 177

Clearing Display....................................................................................................................................................................................................... 177

Product Reference Guide

5

Page 8

Contents

LED and Beeper Control ....................................................................................................................................................................................... 177

Setting RTC................................................................................................................................................................................................................ 177

Messages from SCANNER Command Keys .............................................................................................................................................................. 178

PowerScan M8500 Keypad.................................................................................................................................................................................. 178

Technical Features .................................................................................................................................... 179

Technical Features ...........................................................................................................................................................................................................179

BC-80X0 / C-8000 .................................................................................................................................................................................................... 184

System and Radio Features................................................................................................................................................................................. 185

Indicators ............................................................................................................................................................................................................................. 186

PowerScan® M8500 LED Indicators.................................................................................................................................................................. 186

Beeper .........................................................................................................................................................................................................186

Good Read Spot .......................................................................................................................................................................................187

Default Settings ................................................................................................................................................................................................................. 189

Host Configuration Strings....................................................................................................................... 193

Serial Configuration Strings .......................................................................................................................................................................................... 194

Programming for Expert Users................................................................................................................ 209

Function Description ............................................................................................................................................................................. 209

FindStringByStarting&EndingChar (FSTR) .....................................................................................................................................210

FindStringByStartingChar&Len (FLSTR) ..........................................................................................................................................210

SelectString (SSTR) ..................................................................................................................................................................................210

FindPosition (FPOS) ................................................................................................................................................................................211

StringLength (LSTR) ............................................................................................................................................................................... 211

StringConcatenation ..............................................................................................................................................................................211

StringDiscard ............................................................................................................................................................................................ 211

InsertString (ISTR) ....................................................................................................................................................................................211

ReplaceString (RSTR) ..............................................................................................................................................................................211

Using Format Output in Format Definition ................................................................................................................................... 212

Code Identifier Table ................................................................................................................................ 213

Sample Barcodes....................................................................................................................................... 215

Test Code Symbols ................................................................................................................................................................................. 215

Hex & Numeric Table................................................................................................................................. 217

Hex Numeric Table ........................................................................................................................................................................................................... 219

Autoscan Pattern Code .................................................................................................................................................................................................. 222

6

PowerScan® M8500

Page 9

About this Guide

This Product Reference Guide (PRG) is provided for users seeking advanced technical

information, including connection, programming, maintenance and specifications. The

Quick Reference Guide (QRG) and other publications associated with this product are

downloadable free of charge from the website listed on the back cover of this manual.

Typically, units are factory-programmed for the most common terminal and communications

settings. If

accomplished by scanning the programming barcodes within this guide.

Preface

you need to modify any programmable settings, custom configuration can be

Programming can alternatively be performed using the Data

application which is downloadable from the Datalogic website listed on the back cover of this

manual. This multi-platform utility program allows device configuration using a PC. It

communicates to the device using a serial or USB cable and can also create configuration

barcodes to print.

Manual Overview

Chapter 1, Introduction gives an general description of the product.

Chapter 2, PowerScan M8500 Setup provides information needed to get the device up and

running.

Chapter 3, Configuration Using Code Symbols defines options for all symbologies and

provides programming barcodes necessary for configuring these features.

Chapter 4, Advanced Data Formatting, provides information about advanced formatting

parameters.

Chapter 5, References gives additional, more detailed information for some complex

parameters.

Chapter 6, Message Formatting explains the communication format between the reader

and the host.

Appendix

environmental and regulatory specifications and functions and behaviors of the reader’

and Beeper indicators.

A, Technical Features lists physical and performance characteristics, as well as

logic Aladdin™ Configuration

s LED

Appendix

configuration using serial strings sent from the host.

Appendix

users who want to define a personalized code formatting.

Appendix

Appendix

functioning.

Appendix F, Hex & Numeric Table includes numeric barcodes to be scanned for certain

parameter settings.

B, Host Configuration Strings provides a description of how to modify the device

C, Programming for Expert Users describes programming language for expert

D, Code Identifier Table lists Code IDs for various symbologies.

E, Sample Barcodes provides test code symbols allowing you to check the reader’s

Product Reference Guide 7

Page 10

Preface

Manual Conventions

The following conventions are used in this document:

The symbols listed below are used in this manual to notify the reader of key issues or

procedures that must be

CAUTION

WAR NI NG

observed when using the reader:

Notes contain information necessary for properly diagnosing, repairing

and operating the reader.

The CAUTION symbol advises you of actions that could damage equipment or

A WARNING symbol calls attention to actions that could result in personal injury.

property.

References

Current versions of the Product Reference Guide (PRG), Quick Reference Guide (QRG),

Datalogic Aladdin™ Configuration application, and any other manuals, instruction sheets

and utilities for this product can be downloaded from the website listed on the back cover of

this manual. Alternatively, printed copies or product support CDs can be purchased

through your Datalogic reseller.

Service and Support

Datalogic provides several services as well as technical support through its website. Log on to

www.scanning.datalogic.com and click on the links indicated for further information

including:

PRODUCTS

Search through the links to arrive at your product page where you can download specific

Manuals and Software & Utilities including:

• Datalogic Aladdin™ a multi-platform utility program that allows device configuration using a PC. It pro

barcode printing

vides RS-232 interface configuration as well as configuration

.

SERVICE & SUPPORT

• Technical Support - Product documentation and programming guides and Technical

Support Department in the world

• Service Programs - Warranty Extensions and Maintenance Agreements

• Repair Services - Flat Rate Repairs and Return M

• Downloads – Manuals & Documentation, Data Sheets, Prod

aterial Au

thorization (RMA) Repairs.

uct Catalogues, etc.

CONTACT US

Information Request Form and Sales & Service Network

8 PowerScan® M8500

Page 11

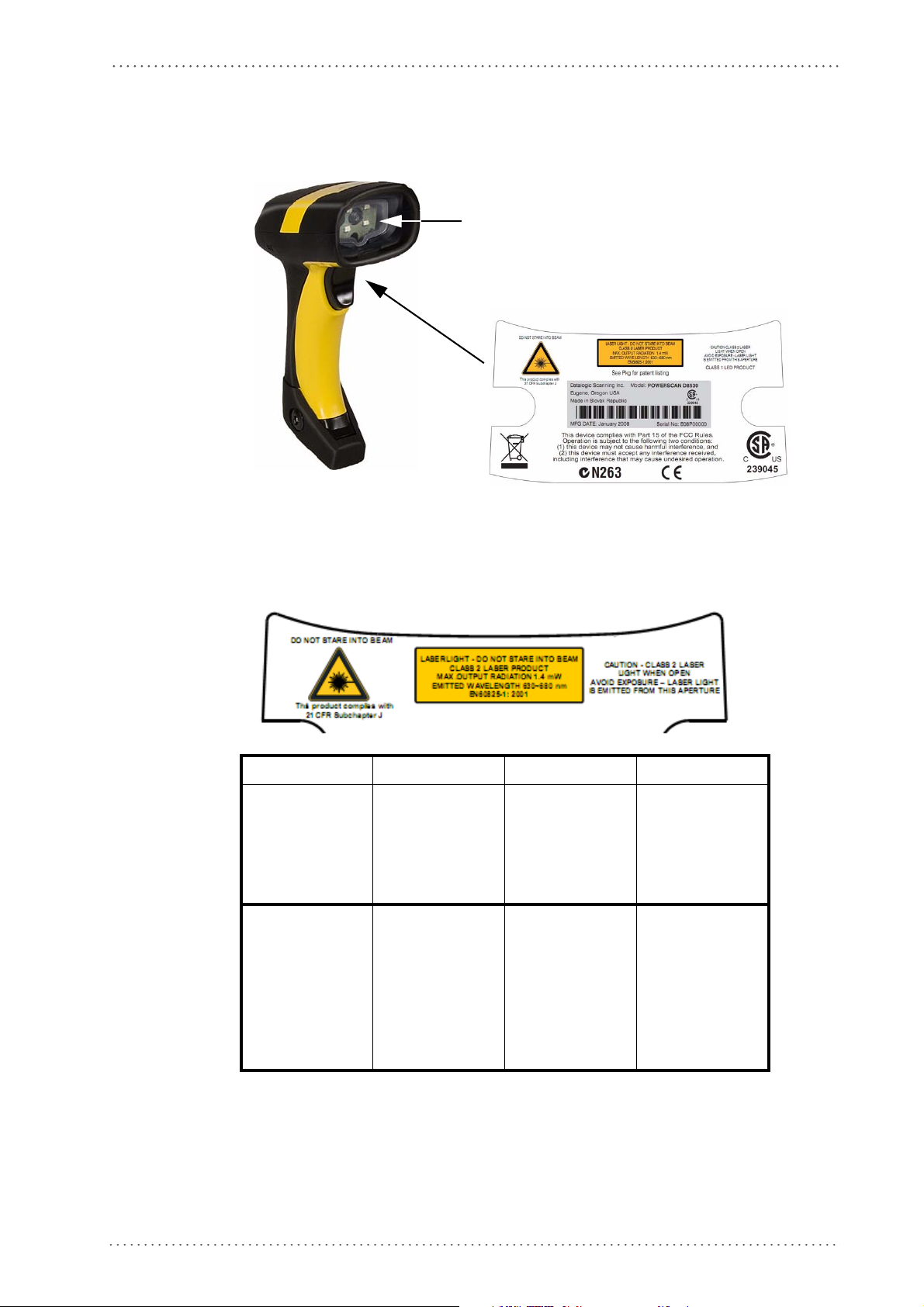

Compliance

Aiming System Imager Beam Output Window

Figure 1. POWERSCAN® PM8500 Reader Product Label

Compliance