Page 1

TM

Product Reference Guide

Cobalto

On-Counter Omnidirectional Presentation Bar Code Scanner

CO5300 Scanner Family

Page 2

Datalogic ADC, Inc.

959 Terry Street

Eugene, OR 97402

USA

Telephone: (541) 683-5700

Fax: (541) 345-7140

©2014 Datalogic ADC, Inc.

An Unpublished Work - All rights reserved. No part of the contents of this documentation

or the procedures described therein may be reproduced or transmitted in any form or by

any means without prior written permission of Datalogic ADC, Inc. or its subsidiaries or

affiliates ("Datalogic" or “Datalogic ADC”). Owners of Datalogic products are hereby granted

a non-exclusive, revocable license to reproduce and transmit this documentation for the

purchaser's own internal business purposes. Purchaser shall not remove or alter any pro

prietary notices, including copyright notices, contained in this documentation and shall

ensure that all notices appear on any reproductions of the documentation.

Should future revisions of this manual be published, you can acquire printed versions by

contacting your Datalogic representative. Electronic versions may either be downloadable

from the Datalogic website (www.datalogic.com) or provided on appropriate media. If you

visit our website and would like to make comments or suggestions about this or other

Datalogic publications, please let us know via the "Contact Datalogic" page.

Disclaimer

Datalogic has taken reasonable measures to provide information in this manual that is

complete and accurate, however, Datalogic reserves the right to change any specification

at any time without prior notice.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many

countries, including the U.S.A. and the E.U. All other brand and product names may be

trademarks of their respective owners.

Cobalto is a trademark of Datalogic ADC S.r.l.

Patents

See www.patents.datalogic.com for patent list.

Page 3

Table of Contents

Introduction ........................................................................................................................................................... 1

About the Scanner ........................................................................................................................1

Capacitive Touch Button .................................................................................................................... 2

Bottom Button ....................................................................................................................................2

About this Manual ........................................................................................................................3

Overview ..............................................................................................................................................3

Conventions .........................................................................................................................................3

Technical Support .........................................................................................................................4

Datalogic Website Support ................................................................................................................4

Reseller Technical Support .................................................................................................................4

Telephone Technical Support .............................................................................................................4

Setup ...................................................................................................................................................................... 5

Unpacking ......................................................................................................................................5

Setting Up the Scanner ................................................................................................................5

Connect Host Interface ....................................................................................................................... 6

Interface Selection ........................................................................................................................ 8

Configuring the Interface ...................................................................................................................8

Customizing Configuration Settings ......................................................................................... 11

Using the Programming Bar Codes ................................................................................................11

Interface Settings ..............................................................................................................................12

Configuring Other Features .............................................................................................................12

Software Version Transmission ......................................................................................................12

Configuration Using Bar Codes ......................................................................................................................... 15

Configuration Parameters .........................................................................................................15

Global Interface Features ...........................................................................................................17

Host Commands — Obey/Ignore ...................................................................................................17

USB Suspend Mode ..........................................................................................................................18

RS-232 ONLY Interface ......................................................................................................................................19

RS-232 Standard Factory Settings ...........................................................................................19

Baud Rate ....................................................................................................................................19

Stop Bits .......................................................................................................................................20

Parity ............................................................................................................................................21

Handshaking Control ..................................................................................................................22

Product Reference Guide

i

Page 4

Contents

RS-232/USB-COM Interfaces ............................................................................................................................23

Standard Factory Settings .........................................................................................................23

Intercharacter Delay ...................................................................................................................23

Beep On ASCII BEL ......................................................................................................................24

Beep On Not on File ....................................................................................................................24

ACK NAK Options ........................................................................................................................25

ACK Character ....................................................................................................................................26

NAK Character ...................................................................................................................................26

ACK NAK Timeout Value ...................................................................................................................27

ACK NAK Retry Count .......................................................................................................................28

ACK NAK Error Handling ...................................................................................................................29

Indicate Transmission Failure ...................................................................................................30

Disable Character ........................................................................................................................30

Enable Character .........................................................................................................................31

Keyboard Interface .............................................................................................................................................33

Country Mode ..............................................................................................................................33

Caps Lock State ...........................................................................................................................36

Numlock .......................................................................................................................................36

Keyboard Numeric Keypad ........................................................................................................37

Keyboard Send Control Characters ...........................................................................................38

Wedge Quiet Interval ..................................................................................................................39

Intercharacter Delay ...................................................................................................................40

Intercode Delay ...........................................................................................................................41

USB Keyboard Speed ..................................................................................................................42

USB-OEM Interface .............................................................................................................................................43

Introduction .................................................................................................................................43

Standard Factory Settings .........................................................................................................43

USB-OEM Device Usage .............................................................................................................44

USB-OEM Interface Options ......................................................................................................44

Data Format ........................................................................................................................................................45

Global Prefix/Suffix ....................................................................................................................46

Global AIM ID ...............................................................................................................................47

GS1-128 AIM ID ...........................................................................................................................47

Label ID ........................................................................................................................................48

Label ID: Pre-loaded Sets .................................................................................................................48

Label ID: Set Individually Per Symbology ........................................................................................49

Label ID Control .................................................................................................................................49

Label ID Symbology Selection ..........................................................................................................50

Case Conversion ..........................................................................................................................56

Character Conversion .................................................................................................................56

ii

Cobalto™ CO5300 Scanner

Page 5

Contents

Reading Parameters ...........................................................................................................................................57

Double Read Timeout .................................................................................................................58

Label Gone Timeout ....................................................................................................................60

Timeout: Enter Low Power State ..............................................................................................61

Timeout: Enter Standby State ...................................................................................................63

Timeout: Laser Off After Single Line Scan ................................................................................65

Touch Button Option ..................................................................................................................66

LED and Speaker Indicators ....................................................................................................... 66

Power On Alert ..................................................................................................................................66

Audio Jingle Enable ..................................................................................................................... 67

Select Audio Jingle for Power-up Event ...................................................................................68

Select Audio Jingle for Good Read Event ..................................................................................70

Good Read: When to Indicate ...........................................................................................................73

Good Read Beep Type .......................................................................................................................74

Good Read Beep Frequency .............................................................................................................74

Good Read Speaker Volume .............................................................................................................75

Good Read Beep Length ...................................................................................................................76

Good Read LED Duration ..................................................................................................................77

Scanning Features ......................................................................................................................78

Scan Modes .......................................................................................................................................78

Symbologies ........................................................................................................................................................79

Introduction .................................................................................................................................79

Standard Factory Settings for Symbologies ............................................................................79

Disable All Symbologies .............................................................................................................80

Coupon Control ............................................................................................................................80

UPC-A ...........................................................................................................................................81

UPC-A Enable/Disable .....................................................................................................................81

UPC-A Check Character Transmission ............................................................................................81

Expand UPC-A to EAN-13 ................................................................................................................82

UPC-A Number System Character Transmission ..........................................................................82

In-Store Minimum Reads .................................................................................................................83

UPC-E ...........................................................................................................................................84

UPC-E Enable/Disable .....................................................................................................................84

UPC-E Check Character Transmission ............................................................................................84

Expand UPC-E to EAN-13 ................................................................................................................85

Expand UPC-E to UPC-A ..................................................................................................................85

UPC-E Number System Character Transmission ..........................................................................86

UPC-E Minimum Read ......................................................................................................................86

EAN 13 ..........................................................................................................................................87

EAN 13 Enable/Disable ....................................................................................................................87

EAN 13 Check Character Transmission ..........................................................................................87

EAN-13 Flag 1 Character ..................................................................................................................88

Product Reference Guide

iii

Page 6

Contents

EAN-13 ISBN Conversion .................................................................................................................88

ISSN Enable/Disable .........................................................................................................................89

EAN 13 Minimum Reads ..................................................................................................................89

EAN 8 ............................................................................................................................................ 90

EAN 8 Enable/Disable ......................................................................................................................90

EAN 8 Check Character Transmission ............................................................................................90

Expand EAN 8 to EAN 13 ..................................................................................................................91

EAN 8 Minimum Reads ....................................................................................................................91

UPC/EAN Global Settings ..........................................................................................................92

UPC/EAN Decoding Level .................................................................................................................92

UPC/EAN Price Weight Check .........................................................................................................93

UPC-A Minimum Reads ...................................................................................................................94

Add-Ons .......................................................................................................................................95

Optional Add-ons ..............................................................................................................................95

Optional Add-On Timer ....................................................................................................................96

P2 Add-Ons Minimum Reads ..........................................................................................................97

P5 Add-Ons Minimum Reads ..........................................................................................................98

GS1 DataBarTM Omnidirectional ................................................................................................99

GS1 DataBar Omnidirectional Enable/Disable ..............................................................................99

GS1 DataBar Omnidirectional GS1-128 Emulation .......................................................................99

GS1 DataBar Omnidirectional Minimum Reads ..........................................................................100

GS1 DataBarTM Expanded ........................................................................................................101

GS1 DataBar Expanded Enable/Disable .......................................................................................101

GS1 DataBar Expanded GS1-128 Emulation ................................................................................101

GS1 DataBar Expanded Minimum Reads .....................................................................................102

GS1 DataBar Expanded Length Control ........................................................................................103

GS1 DataBar Expanded Set Length 1 ...........................................................................................103

GS1 DataBar Expanded Set Length 2 ...........................................................................................104

GS1 DataBarTM Limited ............................................................................................................105

GS1 DataBar Limited Enable/Disable ...........................................................................................105

GS1 DataBar Limited GS1-128 Emulation ....................................................................................105

GS1 DataBar Limited Minimum Reads .........................................................................................106

Code 39 .......................................................................................................................................107

Code 39 Enable/Disable .................................................................................................................107

Code 39 Check Character Calculation ............................................................................................108

Code 39 Check Character Transmission .......................................................................................109

Code 39 Start/Stop Character Transmission ...............................................................................109

Code 39 Full ASCII ............................................................................................................................110

Code 39 Quiet Zones .......................................................................................................................111

Code 39 Minimum Reads ...............................................................................................................112

Code 39 Decoding Level ..................................................................................................................113

Code 39 Length Control ..................................................................................................................114

Code 39 Set Length 1 ......................................................................................................................115

iv

Cobalto™ CO5300 Scanner

Page 7

Contents

Code 39 Set Length 2 ......................................................................................................................116

Code 39 Interdigit Ratio ..................................................................................................................117

Code 39 Stitching ............................................................................................................................119

Code 32 (Italian Pharmaceutical) .............................................................................................119

Code 32 Enable/Disable .................................................................................................................119

Code 32 Feature Setting Exceptions .............................................................................................120

Code 32 Check Character Transmission .......................................................................................120

Code 32 Start/Stop Character Transmission ...............................................................................120

Code 39 CIP (French Pharmaceutical) .....................................................................................121

Code 39 CIP Enable/Disable ..........................................................................................................121

Code 128 ....................................................................................................................................121

Code 128 Enable/Disable ...............................................................................................................121

Expand Code 128 to Code 39 .........................................................................................................122

Code 128 Check Character Transmission .....................................................................................122

Code 128 Function Character Transmission ................................................................................123

Code 128 Sub-Code Change Transmission ..................................................................................123

Code 128 Quiet Zones .....................................................................................................................124

Code 128 Minimum Reads .............................................................................................................125

Code 128 Decoding Level ...............................................................................................................126

Code 128 Length Control ................................................................................................................127

Code 128 Set Length 1 ....................................................................................................................128

Code 128 Set Length 2 ....................................................................................................................129

Code 128 Stitching ..........................................................................................................................129

GS1-128 .....................................................................................................................................130

GS1-128 Enable ...............................................................................................................................130

Interleaved 2 of 5 (I 2 of 5) ........................................................................................................131

I 2 of 5 Enable/Disable ...................................................................................................................131

I 2 of 5 Check Character Calculation ..............................................................................................132

I 2 of 5 Check Character Transmission .........................................................................................133

I 2 of 5 Minimum Reads .................................................................................................................134

I 2 of 5 Decoding Level ....................................................................................................................135

I 2 of 5 Length Control ....................................................................................................................136

I 2 of 5 Set Length 1 ........................................................................................................................137

I 2 of 5 Set Length 2 ........................................................................................................................138

I 2 of 5 Zero Pattern ........................................................................................................................138

Interleaved 2 of 5 CIP HR .........................................................................................................139

Interleaved 2 of 5 CIP HR Enable/Disable ....................................................................................139

Datalogic 2 of 5 ..........................................................................................................................140

Datalogic 2 of 5 Enable/Disable ....................................................................................................140

Datalogic 2 of 5 Check Character Calculation ...............................................................................140

Datalogic 2 of 5 Check Character Transmission ..........................................................................141

Datalogic 2 of 5 Minimum Reads ..................................................................................................141

Datalogic 2 of 5 Decoding Level .....................................................................................................142

Product Reference Guide

v

Page 8

Contents

Datalogic 2 of 5 Length Control .....................................................................................................142

Datalogic 2 of 5 Set Length 1 .........................................................................................................143

Datalogic 2 of 5 Set Length 2 .........................................................................................................144

Datalogic 2 of 5 Interdigit Ratio .....................................................................................................145

Codabar ......................................................................................................................................147

Codabar Enable/Disable ................................................................................................................147

Codabar Check Character Calculation ...........................................................................................147

Codabar Check Character Transmission .......................................................................................148

Codabar Start/Stop Character Transmission ..............................................................................148

Codabar Start/Stop Character Set ................................................................................................149

Codabar Start/Stop Character Match ...........................................................................................149

Codabar Quiet Zones ......................................................................................................................150

Codabar Minimum Reads ...............................................................................................................151

Codabar Decoding Level .................................................................................................................152

Codabar Length Control .................................................................................................................153

Codabar Set Length 1 .....................................................................................................................154

Codabar Set Length 2 .....................................................................................................................155

Codabar Interdigit Ratio .................................................................................................................156

ABC Codabar ..............................................................................................................................158

ABC Codabar Enable/Disable ........................................................................................................158

ABC Codabar Concatenation Mode ...............................................................................................158

ABC Codabar Dynamic Concatenation Timeout ...........................................................................159

ABC Codabar Force Concatenation ...............................................................................................159

Code 11 .......................................................................................................................................160

Code 11 Enable/Disable .................................................................................................................160

Code 11 Check Character Calculation ............................................................................................161

Code 11 Check Character Transmission .......................................................................................161

Code 11 Minimum Reads ...............................................................................................................162

Code 11 Length Control ..................................................................................................................163

Code 11 Set Length 1 ......................................................................................................................163

Code 11 Set Length 2 ......................................................................................................................164

Code 11 Interdigit Ratio ..................................................................................................................165

Code 11 Decoding Level ..................................................................................................................167

Standard 2 of 5 ..........................................................................................................................168

Standard 2 of 5 Enable/Disable ....................................................................................................168

Standard 2 of 5 Check Character Calculation ...............................................................................168

Standard 2 of 5 Check Character Transmission ..........................................................................169

Standard 2 of 5 Minimum Reads ..................................................................................................169

Standard 2 of 5 Decoding Level .....................................................................................................170

Standard 2 of 5 Length Control .....................................................................................................170

Standard 2 of 5 Set Length 1 .........................................................................................................171

Standard 2 of 5 Set Length 2 .........................................................................................................172

Industrial 2 of 5 .........................................................................................................................173

vi

Cobalto™ CO5300 Scanner

Page 9

Contents

Industrial 2 of 5 Enable/Disable ...................................................................................................173

Industrial 2 of 5 Check Character Calculation ..............................................................................173

Industrial 2 of 5 Check Character Transmission ..........................................................................174

Industrial 2 of 5 Length Control ....................................................................................................174

Industrial 2 of 5 Set Length 1 ........................................................................................................175

Industrial 2 of 5 Set Length 2 ........................................................................................................176

Industrial 2 of 5 Minimum Reads ..................................................................................................177

IATA ............................................................................................................................................178

IATA Enable/Disable .......................................................................................................................178

IATA Check Character Transmission .............................................................................................178

ISBT 128 .....................................................................................................................................179

ISBT 128 Concatenation .................................................................................................................179

ISBT 128 Concatenation Mode .......................................................................................................179

ISBT 128 Dynamic Concatenation Timeout ..................................................................................180

ISBT 128 Force Concatenation .......................................................................................................181

ISBT 128 Advanced Concatenation Options .................................................................................181

MSI ..............................................................................................................................................182

MSI Enable/Disable ........................................................................................................................182

MSI Check Character Calculation ...................................................................................................182

MSI Check Character Transmission ..............................................................................................183

MSI Length Control .........................................................................................................................183

MSI Set Length 1 .............................................................................................................................184

MSI Set Length 2 .............................................................................................................................185

MSI Minimum Reads ......................................................................................................................186

MSI Decoding Level .........................................................................................................................187

Code 93 .......................................................................................................................................188

Code 93 Enable/Disable .................................................................................................................188

Code 93 Check Character Calculation ............................................................................................188

Code 93 Check Character Transmission .......................................................................................189

Code 93 Length Control ..................................................................................................................189

Code 93 Set Length 1 ......................................................................................................................190

Code 93 Set Length 2 ......................................................................................................................191

Code 93 Minimum Reads ...............................................................................................................192

Code 93 Decoding Level ..................................................................................................................193

Code 93 Quiet Zones .......................................................................................................................194

Codablock F ................................................................................................................................195

Codablock F Enable/Disable ..........................................................................................................195

Codablock F EAN Enable/Disable .................................................................................................195

Codablock F AIM Check ...................................................................................................................196

Codablock F Length Control ...........................................................................................................196

Codablock F Set Length 1 ...............................................................................................................197

Codablock F Set Length 2 ...............................................................................................................198

Code 4 .........................................................................................................................................199

Product Reference Guide

vii

Page 10

Contents

Code 4 Enable/Disable ...................................................................................................................199

Code 4 Check Character Transmission .........................................................................................199

Code 4 Hex to Decimal Conversion ...............................................................................................200

Code 5 .........................................................................................................................................200

Code 5 Enable/Disable ...................................................................................................................200

Code 5 Check Character Transmission .........................................................................................201

Code 5 Hex to Decimal Conversion ...............................................................................................201

Code 4 and Code 5 Common Configuration Items .................................................................202

Code 4 and 5 Decoding Level .........................................................................................................202

Code 4 and Code 5 Minimum Reads .............................................................................................203

Follett 2 of 5 ..............................................................................................................................204

Follett 2 of 5 Enable/Disable .........................................................................................................204

BC412 .........................................................................................................................................204

BC412 Enable/Disable ....................................................................................................................204

BC412 Check Character Calculation ..............................................................................................205

BC412 Minimum Reads ..................................................................................................................205

BC412 Decoding Level ....................................................................................................................206

BC412 Length Control .....................................................................................................................207

BC412 Set Length 1 ........................................................................................................................207

BC412 Set Length 2 ........................................................................................................................208

Plessey .......................................................................................................................................209

Plessey Enable/Disable .................................................................................................................209

Plessey Check Character Calculation ............................................................................................210

Plessey Check Character Transmission ........................................................................................211

Plessey Length Control ..................................................................................................................211

Plessey Set Length 1 ......................................................................................................................212

Plessey Set Length 2 ......................................................................................................................213

Plessey Minimum Reads ...............................................................................................................214

Plessey Decoding Level ..................................................................................................................215

References .........................................................................................................................................................217

RS-232 Parameters ..................................................................................................................218

RS-232 Only .....................................................................................................................................218

RS-232/USB COM Parameters ......................................................................................................218

Keyboard Interface ...................................................................................................................226

Wedge Quiet Interval ......................................................................................................................226

Intercharacter Delay .......................................................................................................................227

Intercode Delay ...............................................................................................................................228

Data Format ..............................................................................................................................229

Data Editing .....................................................................................................................................229

Global Prefix/Suffix .........................................................................................................................229

Global AIM ID ...................................................................................................................................231

Label ID ............................................................................................................................................232

viii

Cobalto™ CO5300 Scanner

Page 11

Contents

Character Conversion .....................................................................................................................236

Reading Parameters .................................................................................................................237

Label Gone Timeout ........................................................................................................................237

Good Read LED Duration ................................................................................................................238

Symbologies ..............................................................................................................................239

Decoding Levels ..............................................................................................................................239

Set Length ........................................................................................................................................239

Technical Specifications ................................................................................................................................... 243

Standard Cable Pinouts ............................................................................................................245

LED and Speaker Indications ...................................................................................................246

Error Codes ................................................................................................................................247

Standard Defaults .............................................................................................................................................249

Default Exceptions ....................................................................................................................259

Sample Bar Codes .............................................................................................................................................263

1D Bar Codes .............................................................................................................................263

GS1 DataBar (RSS) ....................................................................................................................265

GS1 DataBar-14 ..............................................................................................................................265

Keypad ...............................................................................................................................................................267

Scancode Tables ................................................................................................................................................271

Control Character Emulation ...................................................................................................271

Interface Type PC AT PS/2 or USB-Keyboard ........................................................................272

Interface type PC AT PS/2 Alt Mode or USB-Keyboard Alt Mode ........................................274

Microsoft Windows Codepage 1252 .......................................................................................276

Index .................................................................................................................................................277

ASCII Chart .................................................................................................................................279

Product Reference Guide

ix

Page 12

Contents

NOTES

x

Cobalto™ CO5300 Scanner

Page 13

About the Scanner

The Cobalto™ scanner (reader) delivers high performance in a small, fixed scanner that can also

be used as a targeted handheld scanner. Its innovative design maximizes productivity and

minimizes operator stress, strain and fatigue.

The scanner guarantees an excellent value for customers looking for outstanding performance

in a stylish and full-featured product. An elegant blue “Ring of Light’ encircles the reading

window, which turns a bright green to visually confirm a good read.

Additionally, a high quality polyphonic speaker can be configured to provide the preferred

sound or ‘jingle’ for audio confirmation of a good read.

Chapter 1

Introduction

Product Reference Guide

1

Page 14

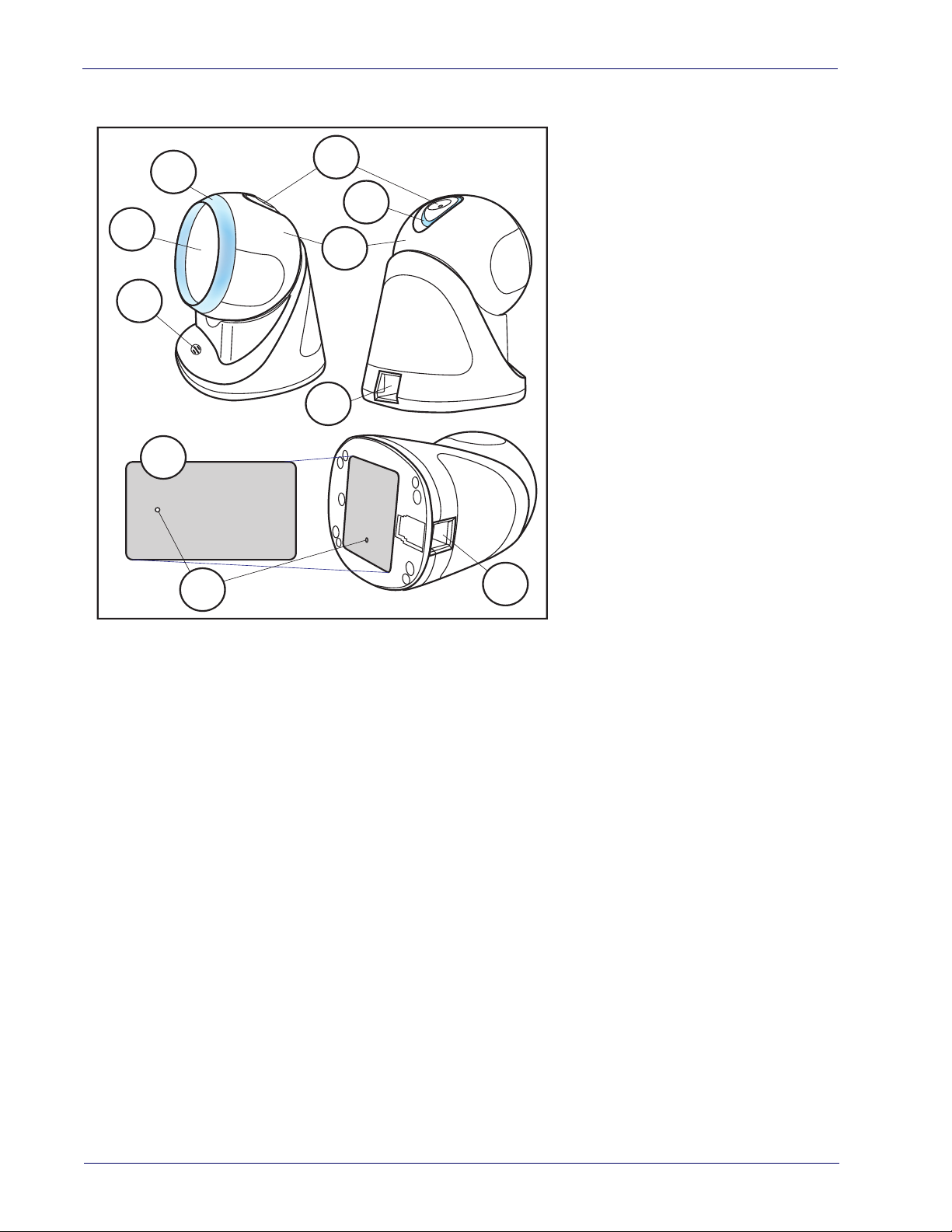

Introduction

5

7

6

8

8

9

3

4

2

1

1

Serial Number/Regulatory Label

2

Speaker

3

Scan Window

4

Ring of Light

5

Touch Button

6

Visual Indicator

7

Head

8

Interface / Power Port

9

Bottom Button

Figure 1. Nomenclature and Labeling

Capacitive Touch Button

The Touch Button (also referred to as the trigger) located on the top of the scanner is actuated

by the electrical impulses present in a human fingertip, and is thus a capacitive Touch Button.

Normally, the scanner operates in omnidirectional mode, simultaneously projecting 20 lines

which form a scan pattern; highly useful for capturing bar codes presented from multiple

directions and angles.

When the Touch Button is actuated, the scanner enters single scan line operation, allowing the

scanner to more easily target and read truncated bar codes, or aim at a single label from

amongst multiple bar codes as an ordinary handheld scanner would do. For example, it is

recommended to use single line operation to read the programming bar codes presented in

this manual.

This button can also be used to wake up the scanner when it has gone to sleep.

Bottom Button

The scanner is also equipped with a mechanical button located at the bottom side of its base.

This Bottom Button s protected by a rubber seal and can perform two functions:

1. While using the Aladdin

made, the Bottom Button is used to activate this function.

2. This button is also used to activate the boot loader for firmware upgrade when this

request is made using the Aladdin utility. This is the button used when the Aladdin utility

asks to reset the product by powering up the product while keeping the button pressed.

TM

configuration utility, when a “force device connect” request is

2

Cobalto™ CO5300 Scanner

Page 15

About this Manual

This Product Reference Guide (PRG) is provided for users seeking advanced technical

information, including connection, programming, maintenance and specifications. The Quick

Reference Guide (QRG) and other publications associated with this product are downloadable

free of charge from the website listed on the back cover of this manual.

Typically, units are factory-programmed for the most common terminal and communications

ttings. If you need to modify any programmable settings, custom configuration can be

se

accomplished by scanning the programming bar codes within this guide.

Programming can alternatively be performed using the Datalogic Aladdin™

application which is available from the Datalogic website listed on the back cover of this

manual. This multi-platform utility program allows device configuration using a PC. It

communicates to the device using a serial or USB cable and can also create configuration bar

codes to print.

Overview

Chapter 1, Introduction provides a product overview, unpacking instructions, and cable

connection information.

Chapter 2, Setup presents information about unpacking and setting up the scanner, and

interface configuration bar code

Chapter 3, Configuration Using Bar Codes provides instructions and bar code labels for

customizing your scanner. There are different sect

data formatting, symbology-specific and model-specific features.

Chapter 4, References provides details concerning programmable features.

Appendix A, Appendix A, Technical Specifications lists physical and performance

characteristics, as well as environmental and r

standard cable pin-outs and descriptions of the functions and behaviors of the scanner’s LED

and Speaker indicators.

Appendix B, Appendix B, Standard Defaults references common factory default settings

for scanner features and options.

Appendix C, Appendix C, Sample Bar Codes offers sample bar codes of several common

symbologies.

Appendix D, Appendix D, Keypad includes numeric bar codes to be scanned for certain

parameter settings.

Appendix E, Appendix E, Scancode Tables lists control character emulation information for

Wedge and USB Keyboard interfaces.

About this Manual

Configuration

s and details.

ions for interface types, general features,

egulatory specifications. It also provides

Conventions

The symbols listed below are used in this manual to notify the scanner of key issues or

procedures that must be observed when using the scanner:

Notes contain information necessary for properly diagnosing, repairing and operating the scanner.

NOTE

Product Reference Guide

3

Page 16

Introduction

The CAUTION symbol advises you of actions that could damage equipment or

property.

CAUTION

Technical Support

Datalogic Website Support

The Datalogic website (www.datalogic.com) is the complete source for technical support and

information for Datalogic products. The site offers product suppor

product manuals, product tech notes, software updates, demos, and instructions for returning

products for repair.

Reseller Technical Support

An excellent source for technical assistance and information is an authorized Datalogic

reseller. A reseller is acquainted with specific types of businesses, application software, and

computer systems and can provide individualized assistance.

t, warranty information,

Telephone Technical Support

If you do not have internet or email access, you may contact Datalogic technical support at

(541) 349-8283 or check the back cover of your manual for more contact information.

Current versions of the Product Reference Guide (PRG), Quick Reference Guide (QRG), the

alogic Aladdin™ Configuration application, software/firmware and any additional manuals,

Dat

instruction sheets and utilities for this product can be downloaded from the website listed on

the back cover of this manual. Alternatively, printed copies or product support CDs can be

purchased through your Datalogic reseller.

4

Cobalto™ CO5300 Scanner

Page 17

Unpacking

1

Cable Connector

2

Interface / Power Port

3

Paper clip

Check carefully to ensure the scanner and any cables or accessories ordered are present and

undamaged. If any damage occurred during shipment, contact

KEEP THE PACKAGING. Should the unit ever require service, it should be returned in its original

shipping container.

Setting Up the Scanner

Follow the steps provided in this section to connect and get your scanner up and

communicating with its host:

1. Connect the Interface Cable at the scanner as shown in Figure 1. To disconnect the cable,

insert a paper clip or similar object into the opening shown (item #3).

2. Connect the other end to the Host (see the next section, Connect Host Interface and Figure 2).

Chapter 2

Setup

Technical Support on page 4.

3. Modify Customizing Configuration Settings on page 11 (only if modifications are needed

from factory settings).

Figure 1. Cable Connection/Disconnection at the Scanner

r

1

Product Reference Guide

2

3

5

Page 18

Setup

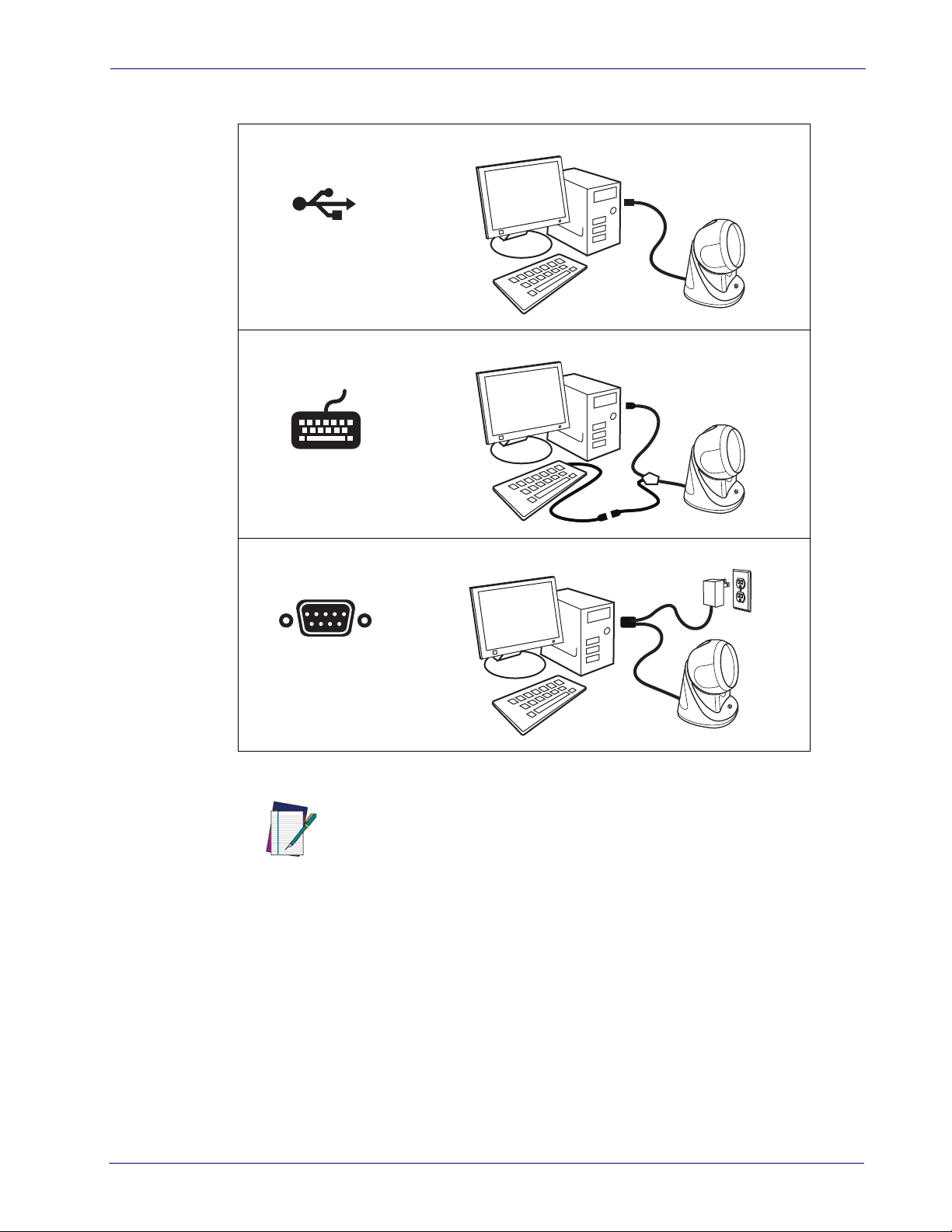

Connect Host Interface

The scanner kit you ordered to match your interface should provide a compatible cable for your

installation. If this is not so, contact

Depending on the model, the scanner can communicate using the following interfaces:

RS-232 Serial Connection

Turn off power to the terminal/PC and connect the scanner to the terminal/PC serial port via

the RS-232 cable as shown in

Terminal) to supply scanner power, use the approved power supply (AC Adapter). Plug the AC

Adapter barrel connector into the socket on the RS-232 cable connector and the AC Adapter

plug into a standard power outlet.

Technical Support.

Figure 2. If the terminal will not support POT (Power Off the

RS-232 —

host.

RS-232 OPOS —

The scanner can communicate with a standard or Wincor-Nixdorf (W-N) RS-232

This interface is used for OPOS/UPOS/JavaPOS systems.

Keyboard Wedge Connection

The Keyboard Wedge cable has a ‘Y’ connection from the scanner. Connect the female to the

male end from the keyboard and the remaining end at the keyboard port at the terminal/PC.

Keyboard Wedge (KBW) —

data as keystrokes and supports several international keyboards (for the Windows

environment). See

Country Mode on page 35 for a full listing.

When connected using this interface, the host interprets scanned

®

USB Connection

Connect the scanner to a USB port on the terminal/PC using the correct USB cable for the

interface type you ordered.

USB —

types by scanning the appropriate interface type bar codes available in this manual. The

default interface is USB-KBD, or RS-232-STD.

Select to communicate either by USB OEM, USB COM STD, or USB Keyboard interface

6

Cobalto™ CO5300 Scanner

Page 19

Figure 2. Connection to the Host

USB

Keyboard Wedge

Setting Up the Scanner

RS-232

NOTE

Specific cables are required for connection to different hosts. The connections illustrated in Figure 2 are examples only. Actual connecto

trated, but the steps to connect the scan

ner remain the same.

rs may vary from those illus-

Product Reference Guide

7

Page 20

Setup

Interface Selection

Upon completing the physical connection between the scanner and its host, proceed directly to

Configuring the Interface on page 8 for information and programming for the interface type

the scanner is connected to (for example: RS-232

appropriate bar code in tha section to select your system’s correct interface type.

The scanner, depending upon the model, will support one of the following sets of host

in

terfaces:

USB Models (3.0 full speed)

•USB-KBD

• USB-COM STD

•USB-OEM

•USB-KBD-ALT

• USB-KBD + USB COM

RS-232 / Keyboard Wedge Models

• RS-232 (Standard, Wincor-Nixdorf, OPOS)

• Keyboard Wedge

, Keyboard Wedge, USB, etc.) and scan the

Configuring the Interface

Scan the programming bar code from the following section which selects the appropriate

interface type to match the system the scanner will be connected to. Next, proceed to the

corresponding chapter in this manual (also listed in the table) to configure any desired settings

and features associated with that interface.

Unlike some other programming features and options, interface selections

require that you scan only one programming bar code label. DO NOT scan an

ENTER/EXIT bar code prior to scanning an interface selection bar code.

Some interfaces require the scanner to start in

NOTE

up. If additional scanner configuration is desired while in this state, pull the trigger and hold it for five seconds. The scanner will change to a

programming with bar codes.

the disabled state when powered

state that allows

8

Cobalto™ CO5300 Scanner

Page 21

Interface Selection

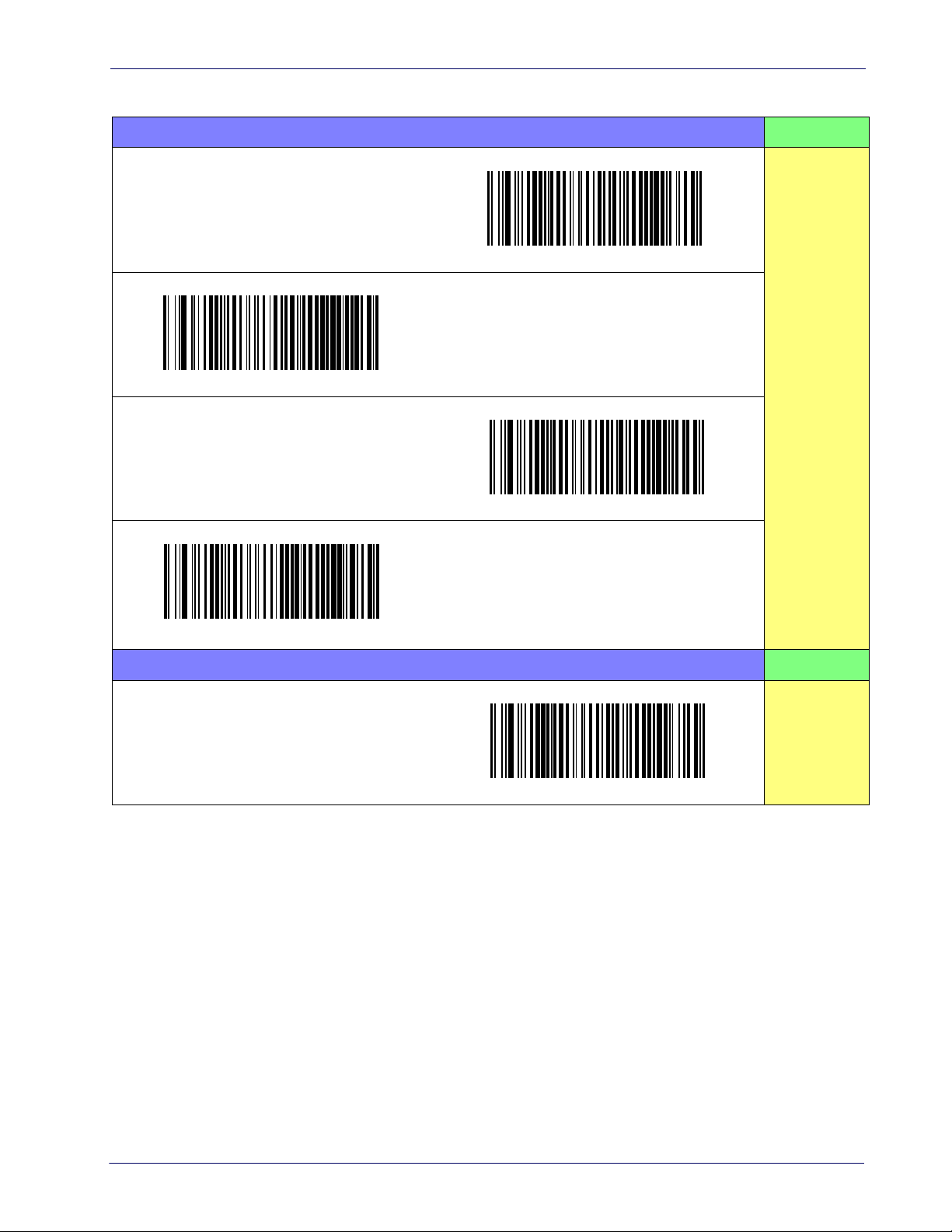

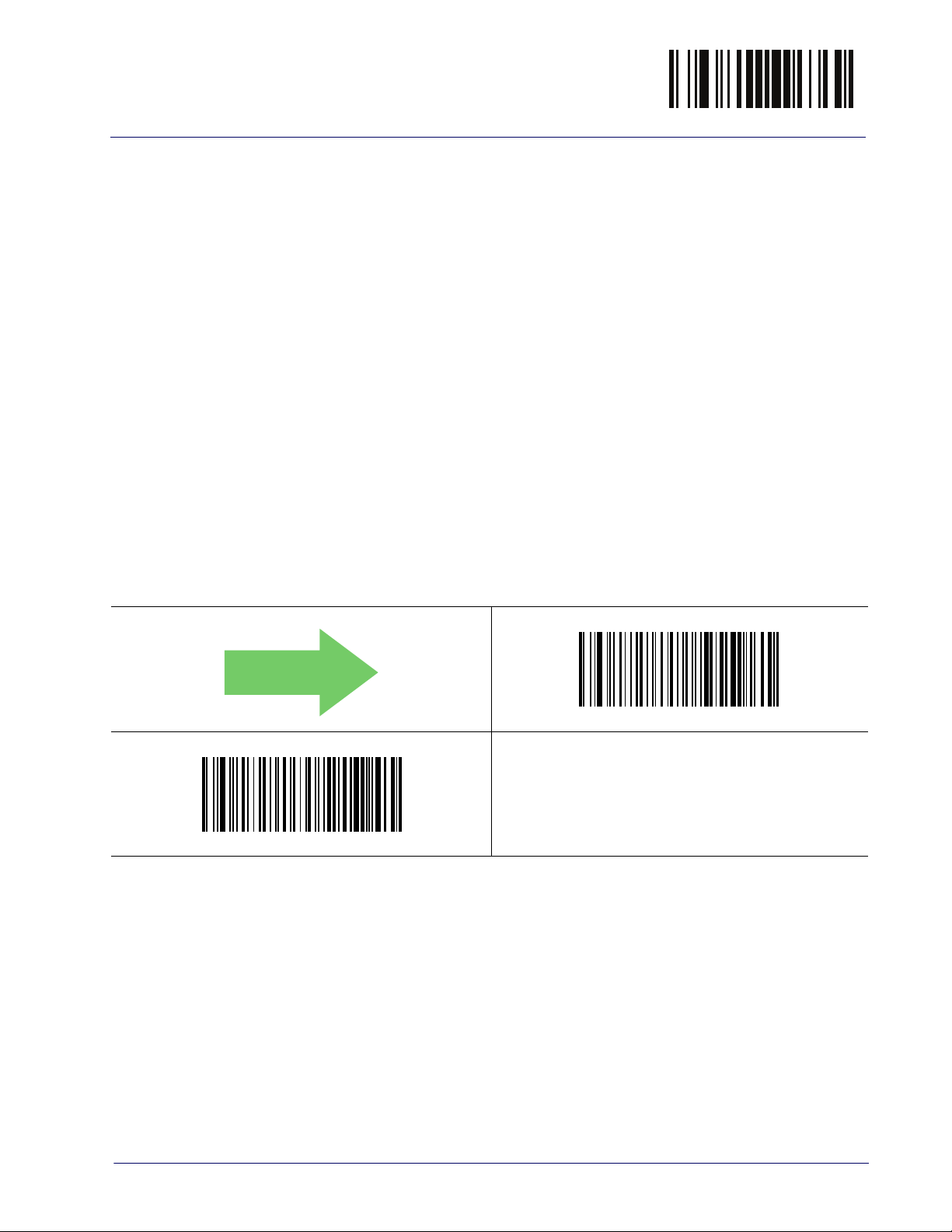

Table 3. Available Interfaces

RS-232 FEATURES

RS-232 standard interface

$P,HA12,P

Select RS232-WN

RS-232 for use with OPOS/UPOS/JavaPOS

$P,HA13,P

$P,HA05,P

Select RS232-STD

RS-232 Wincor-Nixdorf

$P,HA13,P

Select RS-232 OPOS

USB Com to simulate RS-232 standard inter-

face

Set RS-232

Interface

Features

starting on

page 19

Select USB-COM-STD

USB-OEM FEATURES

USB-OEM

e used for OPOS/UPOS/JavaPOS)

(can b

a. Download the correct USB Com driver from www.datalogic.com

a

$P,HA45,P

Select USB-OEM

Set USB-

OEM

Interface

Features

starting on

page 43

Product Reference Guide

9

Page 22

Setup

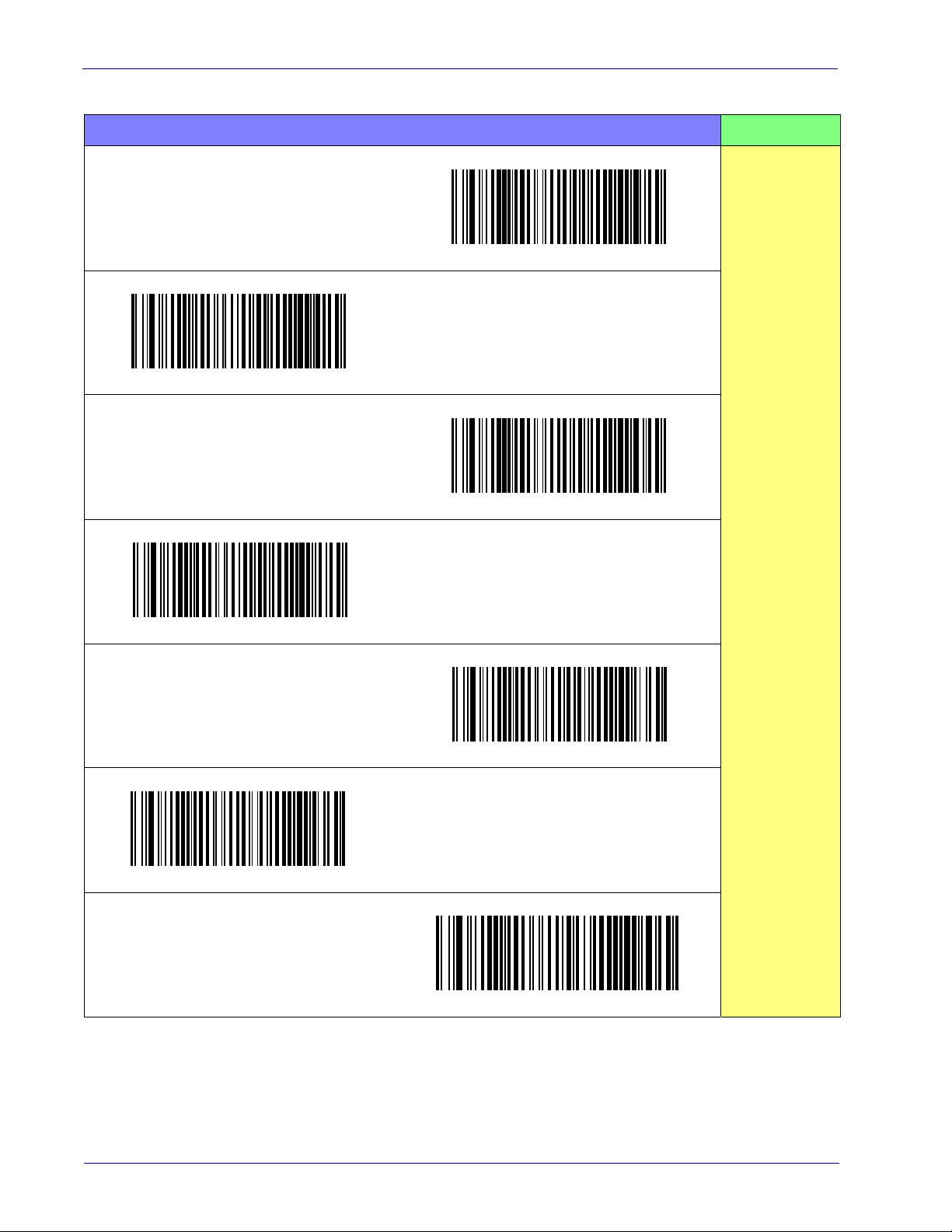

KEYBOARD FEATURES

$P,HA29,P

AT, PS/2 25-286, 30-286, 50, 50Z, 60, 70, 80,

& 95 w/Standard Key Encoding

90

Select KBD-AT

$P,HA11,P

Keyboard Wedge for IBM AT PS2 with standard key encoding but without external keyboard

Select KBD-AT-NK

$P,HA26,P

AT, PS/2 25-286, 30-286, 50, 50Z, 60, 70, 80,

& 95 w/Alternate Key

90

Select KBD-AT-ALT

$P,HA10,P

Select KBD-AT-ALT-NK

USB Keyboard with standard key encoding

$P,HA2B,P

Select USB Alternate Keyboard

USB Keyboard + USB COM

Keyboard Wedge for IBM AT PS2 with alter-

nate key encoding but without external key-

board

$P,HA35,P

Select USB Keyboard

USB Keyboard with alternate key encoding

$P,HA4D,P

Set KEYBOARD

WEDGE

Interface

Features

starting on

page 33

10

Select USB Keyboard + USB COM

Cobalto™ CO5300 Scanner

Page 23

Customizing Configuration Settings

Using the Programming Bar Codes

This manual contains feature descriptions and bar codes which allow you to reconfigure your

scanner. Some programming bar code labels, like Resetting the Product Configuration to

Defaults on page 13, require only the scan of that single label to enact the change. Most of the

programming labels in this manual, however, requir

Mode prior to scanning them. Scan an ENTER/EXIT bar code once to enter Programming

Mode. Once the scanner is in Programming Mode, you can scan a number of parameter

settings before scanning the ENTER/EXIT bar code a second time, which will then accept your

changes, exit Programming Mode and return the scanner to normal operation.

There are some exceptions to the typical programming sequence described

above. Please read the description and setting instructions carefully when

configuring each given programmable feature.

NOTE

Datalogic Aladdin™ Utility

Programming can alternatively be performed using the Datalogic Aladdin™ Configuration

application which is available for free download from the Datalogic website listed on the back

cover of this manual. This multi-platform utility program allows device configuration using a

PC. It communicates to the device using a serial or USB cable and can also create configuration

bar codes to print.

Datalogic Aladdin™ is a multi-platfor

configuration method via the RS-232/USB-COM interface. the Aladdin utility is available on

the CD-ROM provided with your product, and also from the Datalogic website. Aladdin allows

you to program the scanner by selecting configuration commands through a user-friendly

graphical interface running on a PC. These commands are sent to the scanner over the

selected communication interface, or they can be printed as bar codes to be scanned.

Aladdin also provides the ability to perform a soft

the Datalogic Aladdin™ Help On-Line for more details).

m utility program providing a quick and user-friendly

Customizing Configuration Settings

e the scanner to be placed in Programming

ware upgrade for the connected device (see

Product Reference Guide

11

Page 24

Setup

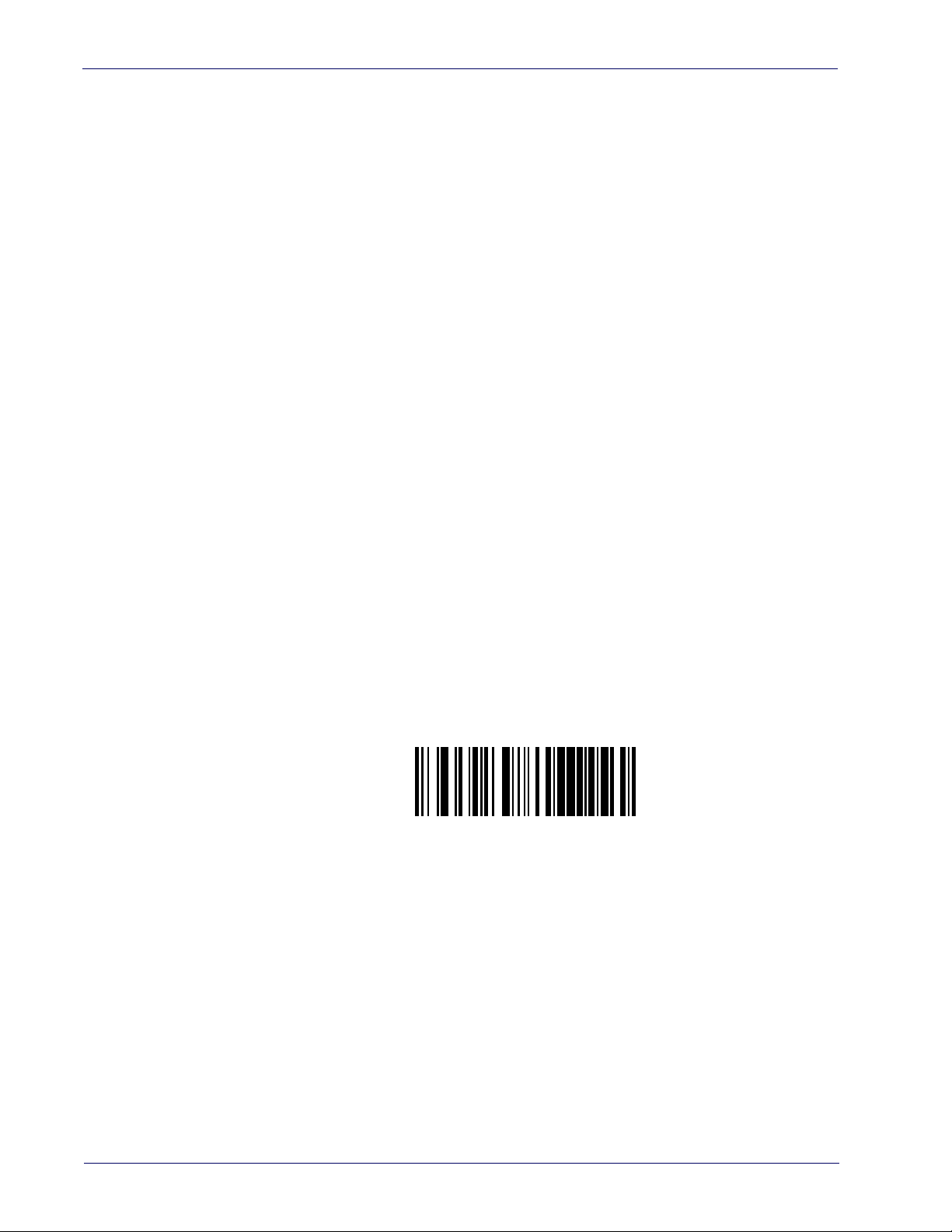

Transmit Software Version

RevA

Interface Settings

The scanner is typically factory-configured with a set of default features standard to the

interface type you ordered. See Interface Selection on page 8.

Global Interface Features, starting on page 17 provides settings configurable by all interface

types. If your installation requir

options through use of the instructions and programming bar codes available in the

appropriate section for your interface.

• RS-232 ONLY Interface, starting on page 19

• RS-232/USB-COM Interfaces, starting on page 23

• Keyboard Interface, starting on page 33

• USB-OEM Interface, starting on page 43

Configuring Other Features

If your installation requires different programming than the standard factory default settings,

the following sections of this manual allow configuration of non-interface-specific settings

you might require:

es you to further customize your scanner, you can select other

Configuration Using Bar Codes —

speaker and LED indicators and other such universal settings.

Reading Parameters —

LED indicators and other universal settings.

Symbologies —

settings allow you to enable/disable symbologies, set label lengths, require check digit, etc.

Includes options concerning the bar code label types (symbologies). These

Reading Parameters include programming for scanning, speaker and

Software Version Transmission

The software version of the device can be transmitted over the RS-232, Keyboard and USB

interfaces by scanning the following label.

General Features includes programming for scanning,

12

Cobalto™ CO5300 Scanner

Page 25

Customizing Configuration Settings

Restore Custom Default Configuration

Restore USA Factory Configuration

Restore EU Factory Configuration

Resetting the Product Configuration to Defaults

If you aren't sure what programming options are in your scanner, or you've changed some

options and want to restore the Custom Default Configuration that may have been saved in

the scanner, scan the Restore Custom Default Configuration bar code below. This will restore

the custom configuration for the

Custom defaults are based on the interface type. Configure the scanner for the

correct interface before scanning this label.

NOTE

If you aren't sure what programming options are in your scanner, or you've changed some

options and want to restore the Factory Configuration, you have two options. You can scan the

Restore USA Factory Configuration bar code or the Restore EU Factory Configuration bar code

below. Both labels restore the scanner configuration to the factory settings including the

terface type. The USA label restores Label IDs to those historically used in the USA. The EU

in

label restores Label IDs to those historically used in Europe. The Label ID sets for USA and EU

are shown in the Label ID section of this manual.

currently active interface.

Scanning either of the “Restore Factory Configuration” commands below will

result in the loss of any custom configuration settings for your device.

CAUTION

The programming section on the following pages lists the factory default settings for each of

the menu commands (indicated by shaded blocks and bold text).

Product Reference Guide

13

Page 26

Setup

NOTES

14

Cobalto™ CO5300 Scanner

Page 27

Configuration Using Bar Codes

This and following sections provide programming bar codes to configure your scanner by

changing the default settings. For details about additional methods of programming, see

Customizing Configuration Settings" on page 11.

"

You must first enable your scanner to read bar codes in order to use this

section. If you have not done this, go to

NOTE

Configuration Parameters

Once the scanner is set up, you can change the default parameters to meet your application

needs. Refer to "

configuration in order to set the default values

The following configuration parameters are divided into logical groups, making it easy to find

the

desired function based on its reference group.

Interface Configuration:

• "RS-232 ONLY Interface" on page 19

• "RS-232/USB-COM Interfaces" on page 23

• "Keyboard Interface" on page 33

• "USB-OEM Interface" on page 43

Resetting the Product Configuration to Defaults" on page 13 for initial

complete the appropriate procedure.

Chapter 3

Setup, starting on page 5

and select the interface for your application.

and

Parameters common to all interface applications:

• "Global Prefix/Suffix" on page 46

Data Format" on page 45 offers advanced configuration options for customization of

• "

scanned data output.

Reading Parameters" on page 57 control various operating modes and indicators

• "

status functioning.

Symbology-specific parameters:

"Symbologies" on page 79 defines options for all symbologies and provides the

programming bar codes necessary for config

Product Reference Guide

uring these features.

15

Page 28

Enter/Exit Programming Mode Configuration Parameters

You must first enable your scanner to read bar codes in order to use this

section. If you have not done this, go to

complete the appropriate procedure.

Setup, starting on page 5

and

NOTE

To program features:

1. Scan the ENTER/EXIT PROGRAMMING bar code, available at the top of each programming page, when applicable.

2. Scan the bar code to set the desired prog

unused bar codes on the page, and possibly the facing page, to ensure that the scanner

reads only the bar code you intend to scan.

3. If additional input param

appropriate characters from the keypad.

Additional information about many features can be found in the “References”

chapter.

NOTE

4. Complete the programming sequence by scanning the ENTER/EXIT PROGRAMMING bar

code to exit Programming Mode.

For more detailed descriptions, programming information and examples for setting selected

figuration items, see

con

If you make a mistake before the last character, scan the CANCEL bar code to

abort an

eters are needed, go to Appendix D, Keypad, and scan the

d not save the entry string. You can then start again at the beginning.

References, starting on page 217.

ramming feature. You may need to cover

16

Cobalto™ CO5300 Scanner

Page 29

Global Interface Features Enter/Exit Programming Mode

DEFAULT

Global Interface Features

The following interface features are configurable by all interface types. To set features specific

to your interface, turn to that section of this manual:

"RS-232 ONLY Interface" on page 19

•

• "RS-232/USB-COM Interfaces" on page 23

• "Keyboard Interface" on page 33

• "USB-OEM Interface" on page 43

Host Commands — Obey/Ignore

This option specifies whether the scanner will obey or ignore host commands. When set to

ignore, the scanner will ignore all host commands except for those necessary for:

• service mode

• flash programming mode

• keeping the interface active

• transmission of labels.

$CIFIH01

Host Commands = Ignore

$CIFIH00

Host Commands = Obey

Product Reference Guide

17

Page 30

Enter/Exit Programming Mode Global Interface Features

USB Suspend Mode

This setting enables/disables the ability of the USB interface to enter suspend mode.

$CUSSE00

USB Suspend Mode = Disable

$CUSSE01

DEFAULT

USB Suspend Mode = Enable

18

Cobalto™ CO5300 Scanner

Page 31

RS-232 Standard Factory Settings Enter/Exit Programming Mode

RS-232 ONLY Interface

Use the programming bar codes in this chapter if modifications to the standard RS-232

interface settings are necessary to meet your system’s requirements. Additional settings

which apply to both the RS-232 and USB interfaces are available in

COM Interfaces

.

RS-232 Standard Factory Settings

Reference Appendix B, Standard Defaults for a listing of standard factory settings.

Baud Rate

Baud rate is the number of bits of data transmitted per second. Set the scanner's baud rate to

match the baud rate setting of the host device. With an improper baud rate setting, data may

not reach the host correctly.

$CR2BA00

Chapter 5, RS-232/USB-

$CR2BA01

Baud Rate = 2400

$CR2BA03

Baud Rate = 9600

Baud Rate = 1200

$CR2BA02

Baud Rate = 4800

Product Reference Guide

19

Page 32

Enter/Exit Programming Mode Stop Bits

DEFAULT