Page 1

Data sheet

Injection valve

Type TXI 2

The TXI2 is an injection valve for desuperheating

in 2-stage refrigeration systems operating on

R22/R407C and other similar refrigerants where

the hot gas temperature and the intermediate

pressure are the controlling variables.

Application

In principle there are two dierent ways in which

to setup 2-stage refrigeration systems as far as

temperature signal to the liquid injection valve is

concerned.

© Danfoss | DCS (sw) | 2015.12

DKRCC.PD.AV0.A3.02 | 520H10558 | 1

Page 2

Data sheet | Injection valve type TXI 2

Application examples

Application examples

(continued)

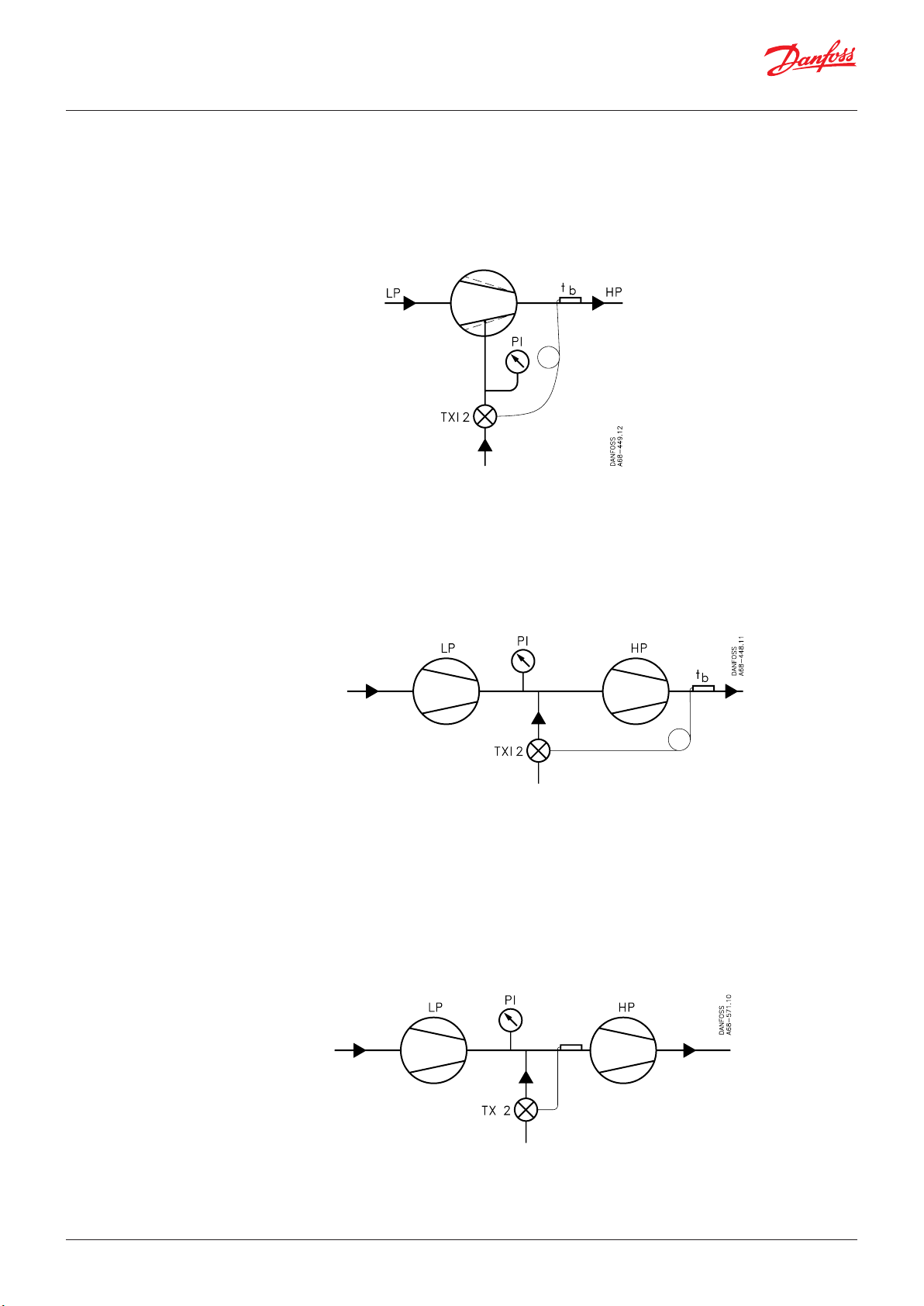

Example 1

2-stage refrigeration system built up with a

combined LP/HP compressor.

In this case the discharge gas temperature on

the HP side is used as temperature signal and the

Fig. 1

Example 2

2-stage refrigeration system with 2 separate

refrigerating compressors in series. In this set up

a solution with injection valve type TXI 2 can be

used, because the discharge gas temperature on

intermediate pressure as pressure signal to the

injection valve.

In this example a TXI 2 injection valve is used, see

g. 1.

LP: Low pressure

HP: High pressure

PI: intermediate pressure

the HP side can be used as temperature signal

and the inter mediate pressure as pressure signal

to the injection valve, see g. 2.

Fig. 2

Example 3

Same setup as in example 2 with 2 separate

refrigerating compressors in series. As in this

setup there is an accessible control signal where

there is correspondence between pressure

and temperature, regulation of the strongly

Fig. 3

LP: Low pressure compressor

HP: High pressure compressor

PI: Intermediate pressure

superheated condition of the refrigerant can

be undertaken by a traditional thermostatic

expansion valve e.g. Danfoss type TX 2 for

R22/R407C refrigeration systems, see g. 3.

LP: Low pressure compressor

HP: High pressure compressor

PI: Intermediate pressure

© Danfoss | DCS (sw | 2015.12

DKRCC.PD.AV0.A3.02 | 520H10558 | 2

Page 3

Data sheet | Injection valve type TXI 2

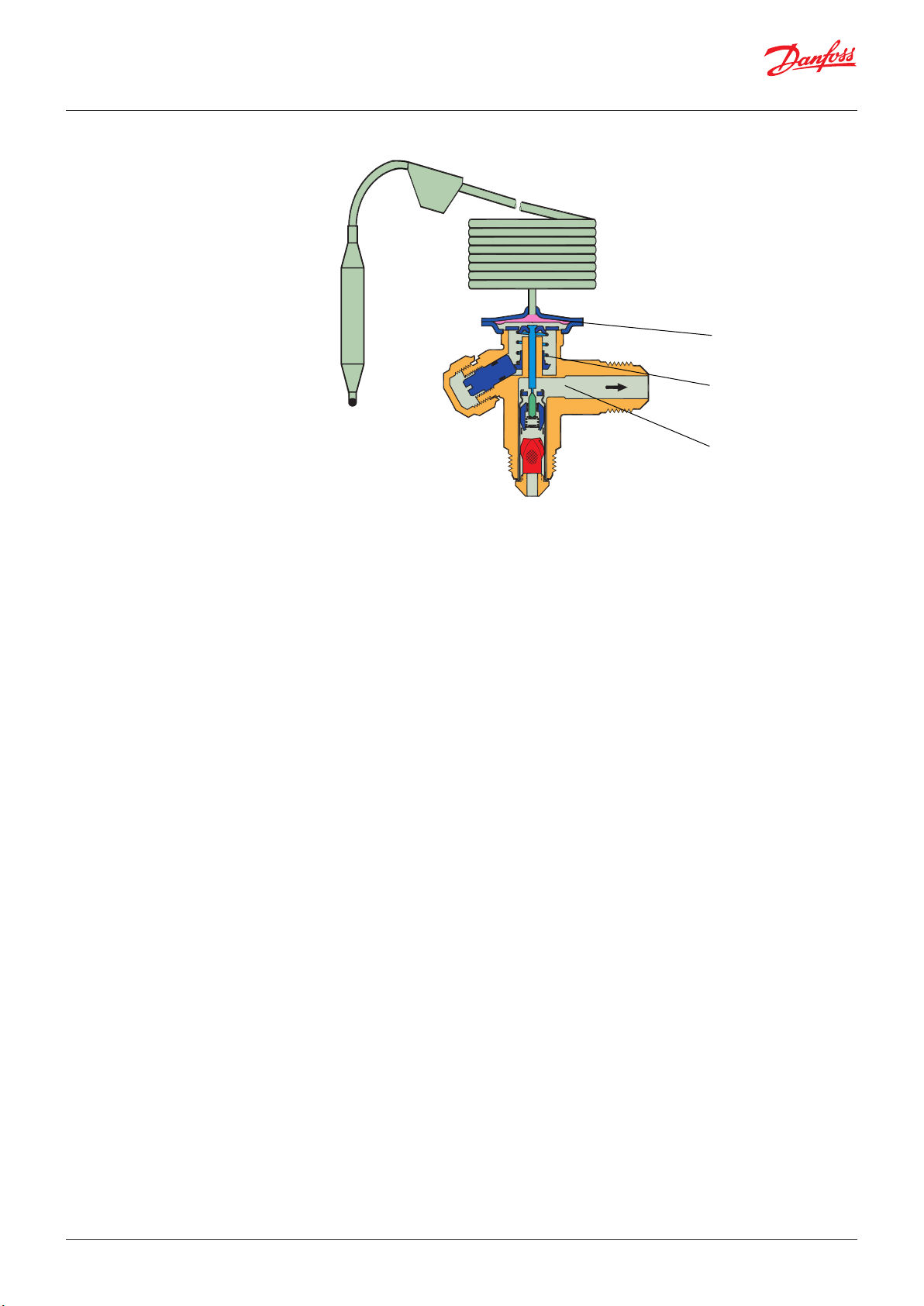

Operation

Fig. 4

Danfoss

68-651.10

P

P

PI

bulb

spring

The valve function is controlled by the

intermediate pressure (PI) acting under the

diaphragm and the bulb pressure derived

from the discharge gas temperature across the

diaphragm (g. 4).

© Danfoss | DCS (sw | 2015.12

DKRCC.PD.AV0.A3.02 | 520H10558 | 3

Page 4

Data sheet | Injection valve type TXI 2

Operation

(continued)

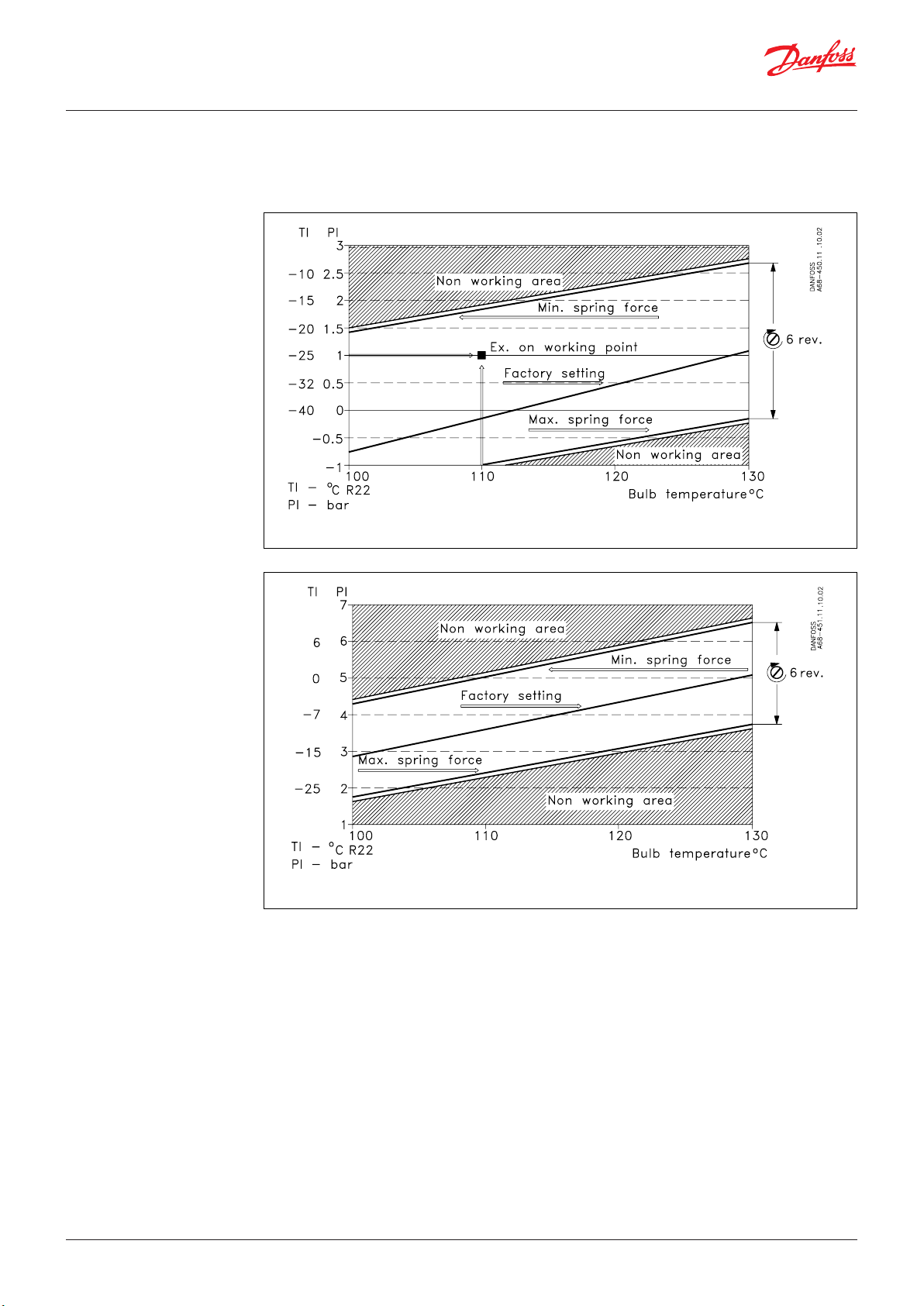

The intermediate pressure (PI), setting spring and

bulb temperature form a working range which,

expressed in a co-ordinate system, makes up a

working area, see g. 5.

Fig. 5 Valid for code no. 068-3249 only

© Danfoss | DCS (sw | 2015.12

Fig. 5 Valid for code no. 068-3258 only

Within the limits of this area, the working point

required is found (PI/t

bulb

).

The location of the working point depends

on the spring force set and in addition to that

dependent on the proportional band (the

superheat) and the valve capacity (size of orice).

Therefore, the sizing is decisive for a satisfactory

result.

DKRCC.PD.AV0.A3.02 | 520H10558 | 4

Page 5

Data sheet | Injection valve type TXI 2

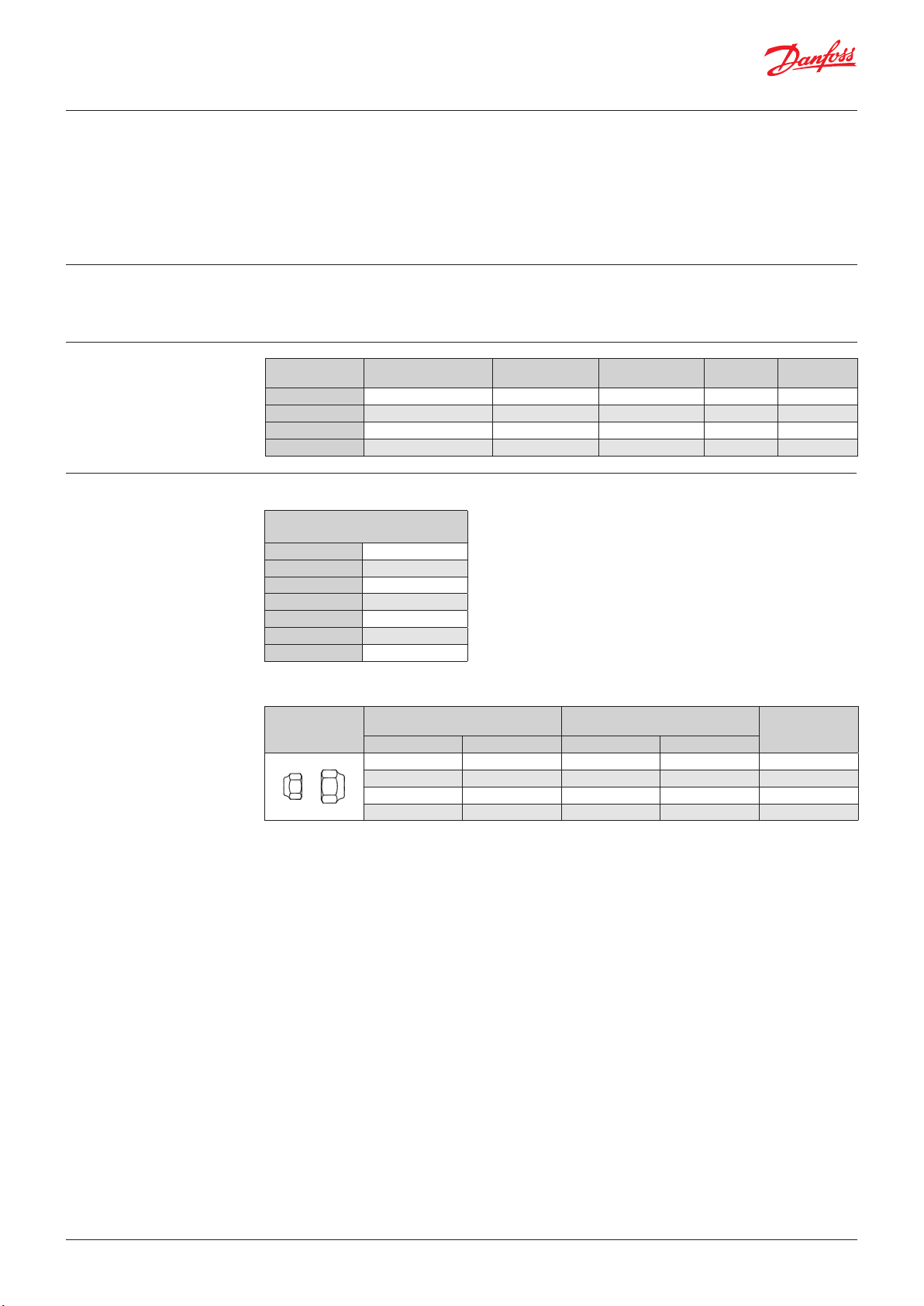

Sizing

To size TXI 2 the refrigerating capacity required to

remove the superheat at the intermediate stage

must be known as well as the required discharge

evaporating temperature t0 (PI) of the

intermediate stage and the pressure drop across

TXI 2, the correct orice size can be determined.

gas temperature on the discharge side.

Besides this the pressure drop ∆p across the

injection valve must be determined as the

dierence between the condensing pressure and

the pressure at the intermediate stage.

With the values for the required capacity, the

Example:

Required refrigerating capacity Q = 5 kW

Evaporating temperature

at intermediate state t0 = –25°C

Pressure drop across TXI 2 ∆p = 12 bar'

Discharge gas temperature (HP) = 110°C

Valve type

TXI 2 - 0.2 00 0.69 0.83 0.94 1.02 1.08 1.12 1.14 1.15

TXI 2 - 0.3 01 1.21 1.51 1.71 1.85 1.96 2.04 2.09 2.11

TXI 2 - 0.6 02 1.66 2.13 2.42 2.62 2.77 2.87 2.94 2.97

TXI 2 - 0.8 03 2.98 3.82 4.33 4.69 4.96 5.15 5.27 5.33

TXI 2 - 1.2 04 4.36 5.59 6.35 6.89 7.30 7.60 7.80 7.91

TXI 2 - 1.5 05 5.55 7.10 8.06 8.74 9.26 9.64 9.89 10.02

TXI 2 - 2.0 06 6.80 8.68 9.84 10.67 11.30 11.77 12.08 12.25

Orice

No.

2 4 6 8 10 12 14 16

Evaporating temperature –25°C

Pressure drop across valve ∆p bar

Capacity in kW

TXI 2 with orice 03 ts that example as the

values in the capacity tables are shown with a

proportional band of 6 K.

Valve type

TXI 2 - 0.2 00 0.79 0.96 1.1 1.2 1.2 1.3 1.3 1.3

TXI 2 - 0.3 01 1.6 2.0 2.3 2.5 2.6 2.7 2.8 2.8

TXI 2 - 0.6 02 2.2 2.9 3.3 3.6 3.8 4.0 4.1 4.1

TXI 2 - 0.8 03 3.9 5.1 5.9 6.4 6.8 7.1 7.3 7.3

TXI 2 - 1.2 04 5.8 7.6 8.7 9.5 10.1 10.5 10.8 10.9

TXI 2 - 1.5 05 7.4 9.6 11.0 12.0 12.8 13.3 13.6 13.8

TXI 2 - 2.0 06 9.1 11.8 13.5 14.7 15.6 16.2 16.6 16.8

Valve type

TXI 2 - 0.2 00 0.88 1.0 1.1 1.1 1.2 1.2 1.2

TXI 2 - 0.3 01 17 1.9 2.0 2.2 2.3 2.3 2.3

TXI 2 - 0.6 02 2.4 2.7 2.9 3.1 3.2 3.3 3.3

TXI 2 - 0.8 03 4.2 4.8 5.2 5.5 5.8 5.9 6.0

TXI 2 - 1.2 04 6.2 7.1 7.7 8.2 8.5 8.7 8.8

TXI 2 - 1.5 05 7.9 9.0 9.8 10.3 10.8 11.0 11.2

TXI 2 - 2.0 06 9.6 11.0 11.9 12.6 13.1 13.5 13.7

Orice

No.

Orice

No.

2 4 6 8 10 12 14 16

4 6 8 10 12 14 16

Evaporating temperature –10°C

Pressure drop across valve ∆p bar

Evaporating temperature –20°C

Pressure drop across valve ∆p bar

© Danfoss | DCS (sw | 2015.12

DKRCC.PD.AV0.A3.02 | 520H10558 | 5

Page 6

Data sheet | Injection valve type TXI 2

Capacity in kW

Valve type

TXI 2 - 0.2 00 0.69 0.83 0.94 1.02 1.08 1.12 1.14 1.15

TXI 2 - 0.3 01 1.21 1.51 1.71 1.85 1.96 2.04 2.09 2.11

TXI 2 - 0.6 02 1.66 2.13 2.42 2.62 2.77 2.87 2.94 2.97

TXI 2 - 0.8 03 2.98 3.82 4.33 4.69 4.96 5.15 5.27 5.33

TXI 2 - 1.2 04 4.36 5.59 6.35 6.89 7.30 7.60 7.80 7.91

TXI 2 - 1.5 05 5.55 7.10 8.06 8.74 9.26 9.64 9.89 10.02

TXI 2 - 2.0 06 6.80 8.68 9.84 10.67 11.30 11.77 12.08 12.25

Valve type

TXI 2 - 0.2 00 0.79 0.90 0.96 1.0 1.1 1.1 1.1

TXI 2 - 0.3 01 1.4 1.5 1.7 1.8 1.8 1.9 1.9

TXI 2 - 0.6 02 1.9 2.2 2.7 2.5 2.6 2.6 2.7

TXI 2 - 0.8 03 3.4 3.9 4.2 4.4 4.6 4.7 4.8

TXI 2 - 1.2 04 5.0 5.7 6.2 6.5 6.8 7.0 7.1

TXI 2 - 1.5 05 6.4 7.2 7.8 8.3 8.6 8.8 9.0

TXI 2 - 2.0 06 7.8 8.8 9.6 10.1 10.5 10.8 11.0

Valve type

TXI 2 - 0.2 00 0.60 0.71 0.80 0.86 0.92 0.95 0.98 0.99

TXI 2 - 0.3 01 0.90 1.11 1.25 1.35 1.43 1.49 1.53 1.55

TXI 2 - 0.6 02 1.23 1.55 1.74 1.88 1.97 2.05 2.09 2.12

TXI 2 - 0.8 03 2.20 2.78 3.12 3.36 3.54 3.68 3.77 3.81

TXI 2 - 1.2 04 3.20 4.04 4.56 4.93 5.21 5.43 5.58 5.67

TXI 2 - 1.5 05 4.07 5.14 5.79 6.26 6.62 6.90 7.09 7.20

TXI 2 - 2.0 06 4.98 6.28 7.07 7.65 8.09 8.44 8.68 8.82

Orice

No.

Orice

No.

Orice

No.

2 4 6 8 10 12 14 16

4 6 8 10 12 14 16

2 4 6 8 10 12 14 16

Evaporating temperature (PI) –25°C

Pressure drop across valve ∆p bar

Evaporating temperature (PI) –30°C

Pressure drop across valve ∆p bar

Evaporating temperature (PI) –40°C

Pressure drop across valve ∆p bar

© Danfoss | DCS (sw | 2015.12

DKRCC.PD.AV0.A3.02 | 520H10558 | 6

Page 7

Data sheet | Injection valve type TXI 2

Setting

Technical data

Ordering valve

Ordering accessories

TXI 2 cannot be set until the refrigerant system

is started up. Setting after start-up is carried

out when the discharge gas temperature has

been recorded and the intermediate pressure is

known or measured. By means of the diagram,

g. 5, the actual working point is found. From the

location of the working point in the diagram, g.

Perm. working pressure PS/MWP: 34 bar

Capillary tube: 1.5 m.

Type

TXI-2

TXI-2

TXI-2

TXI-2

Connections

[in.]

3

2

/8 × 1/

SAE are +100 → +130°C 0 - 2 bar 0.3 068-3249

3

2

/8 × 1/

SAE are +100 → +130°C 1 - 5 bar 0.3 068-3258

3

/8 SAE are × 1/2 solder +100 → +130°C 1 - 5 bar 0.3 068-3343

3

2

/8 × 1/

SAE are +80 → +110°C 1 - 5 bar 0.3 068-3360

Temp. range

Orice assembly

Orice no.

00 068-2003

01 068-2010

02 068-2015

03 068-2006

04 068-2007

05 068-2008

06 068-2009

Code no.

TE 2

5, it should be decided whether to increase or

decrease the spring force.

Alteration of the spring from slack to tight setting

corresponds to 6 revolutions of the TXI 2 setting

screw.

Pressure range

(pi)

Weight

kg

Code no.

Flare nuts

Symbol

Connection for copper tubing with

outside cam.

Reducer for copper tubing with

outside diam.

in. mm. in. mm.

1

4

/

3

8

/

1

2

/

3

8

/

6 011L1201

10 011L1235

12 011L1203

1

10

4

/

Code no.

6 011L1207

© Danfoss | DCS (sw | 2015.12

DKRCC.PD.AV0.A3.02 | 520H10558 | 7

Page 8

Dimensions and weight

97

9.8

Dimensions in mm

Weight: 0.354 Kg

Danfoss

68-652.10

© Danfoss | DCS (sw) | 2015.12

DKRCC.PD.AV0.A3.02 | 520H10558 | 8

Loading...

Loading...