Data sheet

Thermostatic Mixing Valve

TVM-W

Description

The TVM-W is a self-acting mixing valve, which

provides mixed water at a constant temperature.

It is used for instant supply of water at a required

temperature in domestic hot water applications.

- The quick reaction of the thermostatic

elements ensures accurate temperature

control.

- It is suitable for single outlets (e.g. baths,

basins, showers and bidets) or small numbers

of grouped outlets.

- Its robust and non-complex construction

provides superior reliability, improved

safety, energy efficiency and user comfort.

If the cold supply fails, a total and fast flow

shut-off results in greater safety for the enduser. Simplified design and construction,

with fewer components, ensures superior

reliability, longevity and safety.

- The TVM-W ensures a high level of protection

from scalding, which is important especially in

hospitals, schools or multi family houses (e.g.

in case of legionella disinfections).

- TVM-W “Low lead brass” valves meet the

new regulations enforced by the European

Drinking Water Directive that comes into

effect in December 2013.

Main data:

• Setting temperature in the range 35 … 70 °C

• Preset and locked at 50 °C

• Locking function locks the set temperature

• DN 20 and DN 25

• Shuts off flow if the hot or cold supply fails

• Maintains the temperature by varying supply

conditions

• integrated non-return valves

Ordering

Typ e DN Connection

TVM-W

E = extrac ted (outlet) quantity at ∆p = 1.0 bar

1)

with check valve

20 G 1 35 … 70 35 2.1 00 3Z3145

25 G 1⁄ 35 … 70 55 3.3 0 03Z314 6

Temp. range

(°C)

E

(l/min)

kVS

1)

Code No.

Accessories and spare parts

Typ e

Non-return valve DN 20 10 90 00 3Z3137

Non-return valve DN 25 10 90 003Z 3138

Max. pressure

(bar)

Thermostatic element 003Z3139

Fitting set DN 20 00 3Z3134

Fitting set DN 25 00 3Z3135

Max. temperature

(°C)

Code No.

© Danfoss | 2022.03 AI120786478310en-011001 | 1

Data sheet Thermostatic Mixing Valve TVM-W

Technical data

Applications

Factory temperature presseting

50

Cold water supply temperature 10

Hot water supply temperature 70

Temperature stability (depend on pressure and temperature)

Max. hot water temperature 90

Max. operating pressure

Min. operating pressure 0.5

Max. inlet pressure diferential

2)

°C

3)

± 3

1)

10

bar

2

Supply pressure, (dynamic) 5

Materials

Body CW626N (Low Lead brass) + antilimescale treatment

Plastic cap Polystyrene

Spring SS steel 1.4301 (inoxydable)

Sealing EPDM

1)

100 °C without Non -return valve

2)

Betwee n cold and worm inlets

3)

Cold inlet water te mperature should not be a bove 15°C

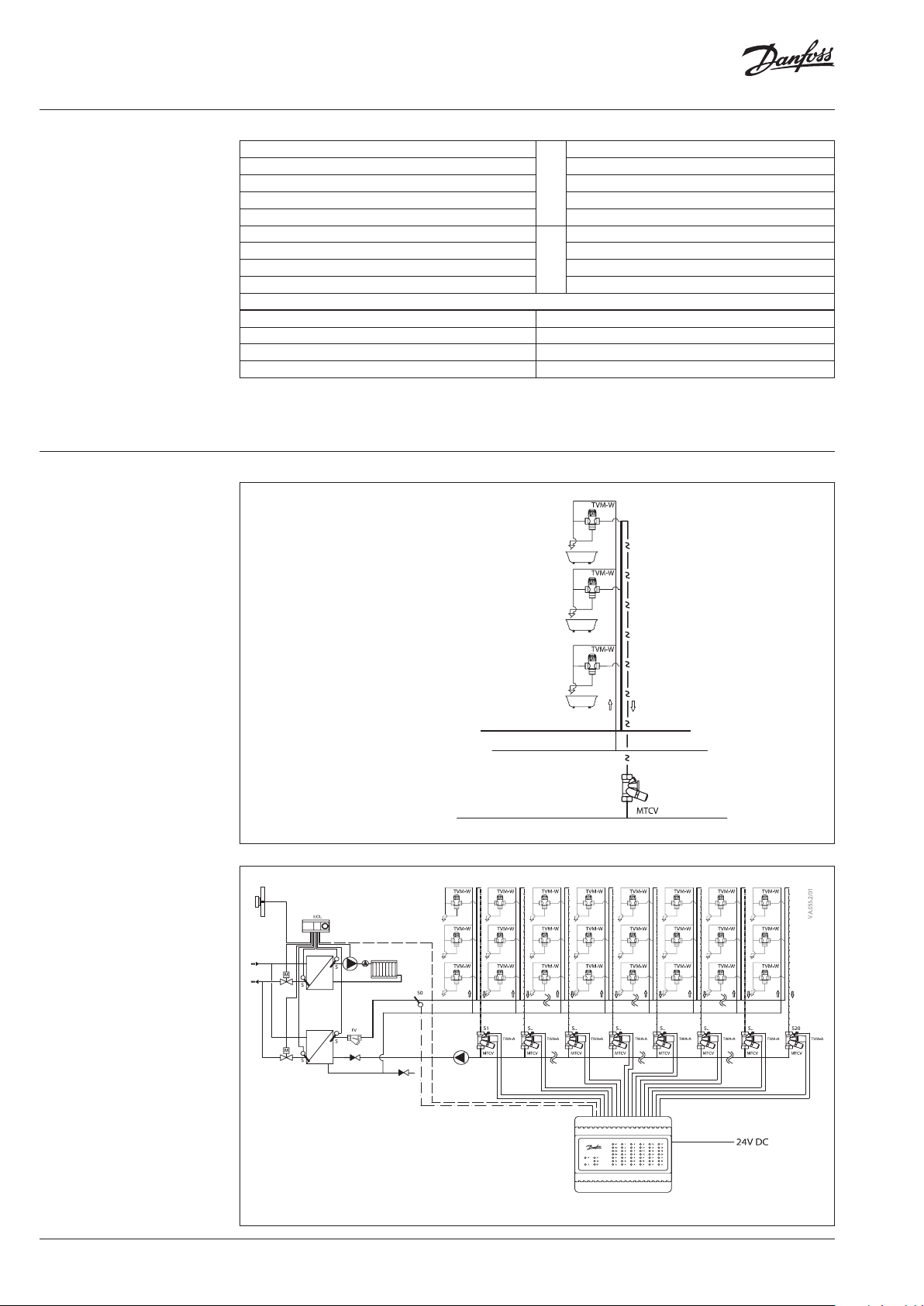

Recommended scheme of hot

water installation with TVM-W

Recommended installation of hot water and circulation system.

2 | AI120786478310en-011001 © Danfoss | 2022.03

Data sheet Thermostatic Mixing Valve TVM-W

CENTRAL INSTALLATION

COLD

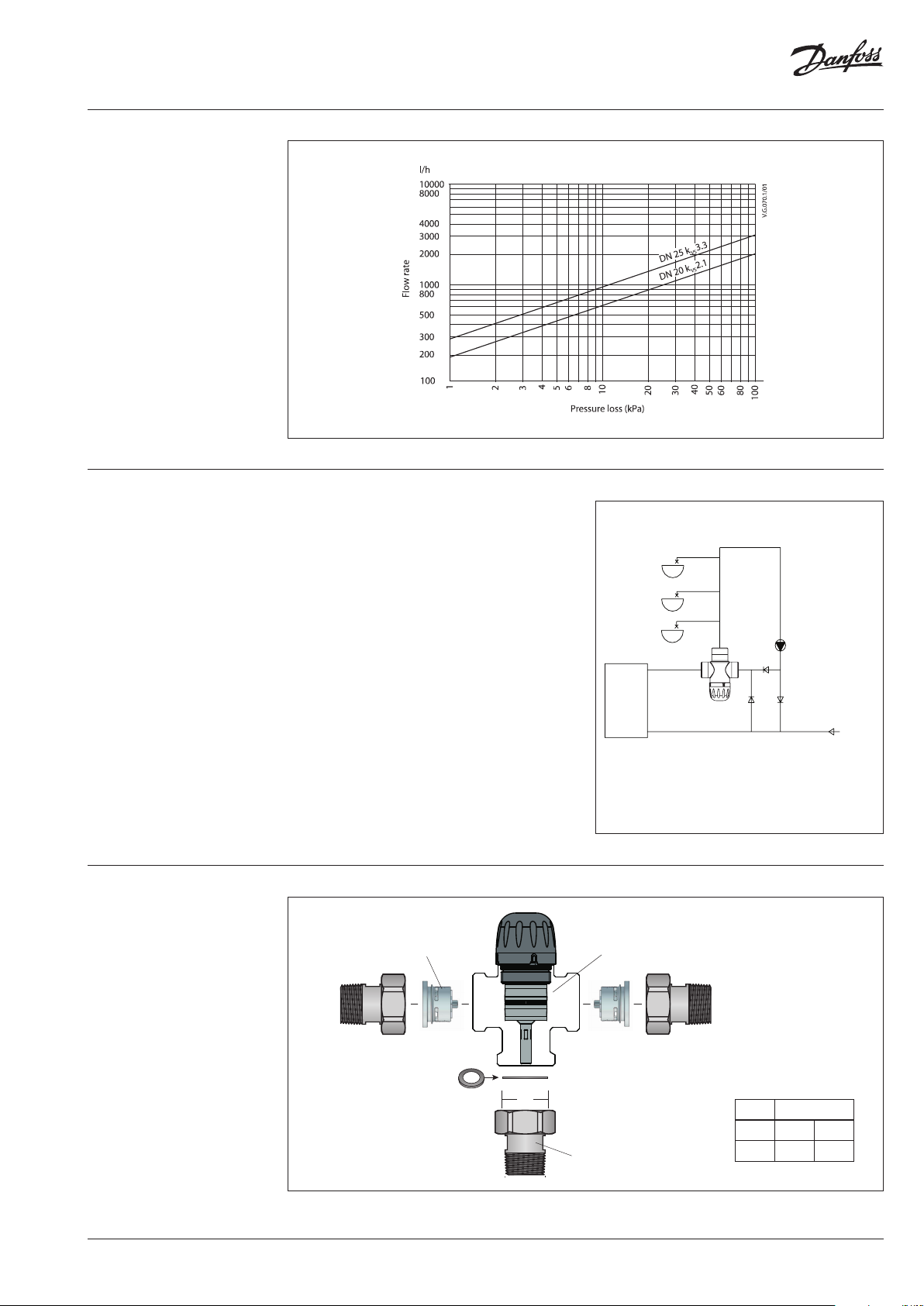

Pressure diagram

Installation

Spare parts

1. Non-return valve

2. Fitting set

3. Thermostatic element

By mixing hot and cold water to achieve the

desired temperature, the valve effectively

provides a greater volume of hot water from the

given tank size.

High temperature water storage prevents the

growth of legionella bacteria.

The valve can be installed in any position into the

riser:

• In situations where the hot pressure may

exceed the cold pressure and on pumped

systems, non-return valves must be fitted to

both hot and cold inlets.

• A TVM-W will provide optimum performance

when installed with hot and cold supplies of

equal dynamic pressure, i.e. pressure under

flow conditions.

• In order to ensure the correct function of

the failsafe and optimum performance it is

recommended that the hot supply temperature is at least 10 °C higher than the set

temperature.

1

CENTRAL INSTALLATION

COLD

Typical installation of the TVM-W - with boiler

application.

3

0304 7M

G

2

Fitting set

DN G

20 1 ⁄

25 1⁄ 1

AI120786478310en-011001 | 3© Danfoss | 2022.03

Data sheet Thermostatic Mixing Valve TVM-W

G

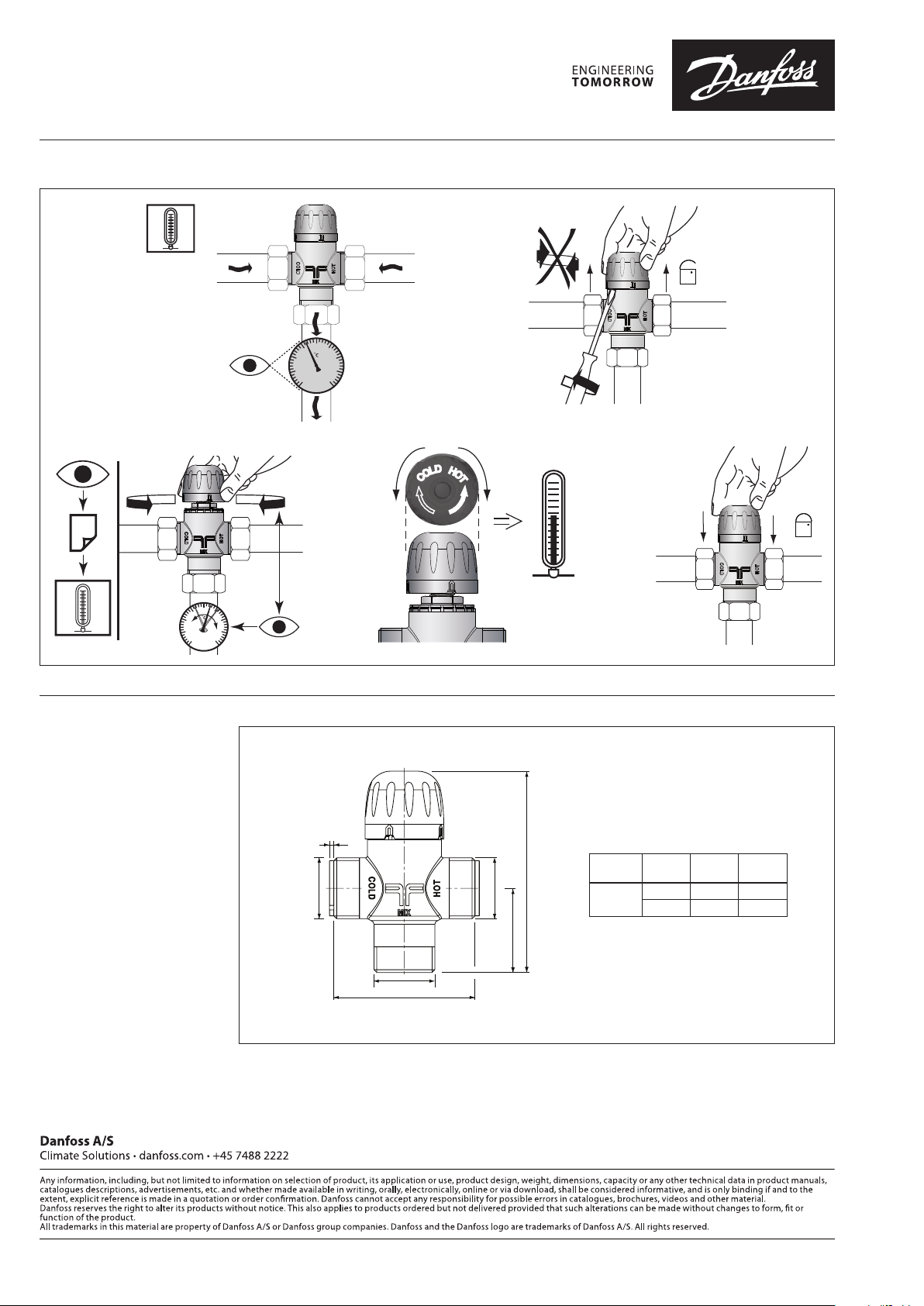

Locking the presetting

60

°C

50

40

30

20

①

MIX °C

40

60

20

80

0

②

60

°C

50

40

30

20

Dimensions

③

④

+

-

⑤

°C MIX

40

60

20

80

0

2,5

G

max. 122

46

Typ e DN

TVM-W

A

mm

20 77 1

25 77 1⁄

G

“

G

A

© Danfoss | DCS-SGDPT/SI | 2022.034 | AI120786478310en-011001

Loading...

Loading...