Data sheet

Thermostatic mixing valve

TVM-H

Description

Ordering

TVM-H limits and maintains constant Ievel of

mixing temperature in heating applications.

The thermostatic mixing valve ensures a

constant temperature of the mixed water at the

outlet.

Advantages

• Constant temperature of the water at the

outlet

• Variable setting of the nominal temperature

range: 30 … 70 °C

• Special design with anti-scalding coating

• System components: accessories and spare

parts

Standard design

A thermostatic cartridge and a return spring

ensure the constant blend temperature at the

outlet.

Thanks to the design of the mixing valve, the

thermostatic cartridge can be easily replaced in

the installed valve if the performance decreases,

which occurs due to normal wear and tear.

DN G

TVM- H 20 1" 30 … 70 39 1.9 1.65 00 3Z1120

TVM- H 25 1¼" 30 … 70 61 3.0 2.6 0 03 Z1127

1)

E = extrac ted (outlet) quantity at Δp = 1.5 bar

2)

kVS1 = without check val ve

3)

kVS2 = with check valve

Temperature range

(°C)

1)

E

(l/min)

kVS1

2)

kVS2

3)

Code No.

Accessories and spare parts

Typ ew

Non-return

valve DN 20

Non-return

valve DN 25

Thermostatic element

Fitting set DN 20 00 3Z3134

Fitting set DN 25 00 3Z3135

Max.

pressure

(bar)

10 95 00 3Z3130

10 95 00 3Z3131

Max.

temperature

(°C)

Code No.

00 3Z3132

© Danfoss | 2016.11

VD.D1.F6.02 | 1

Data sheet Thermostatic mixing valve TVM-H

Technical data

Application

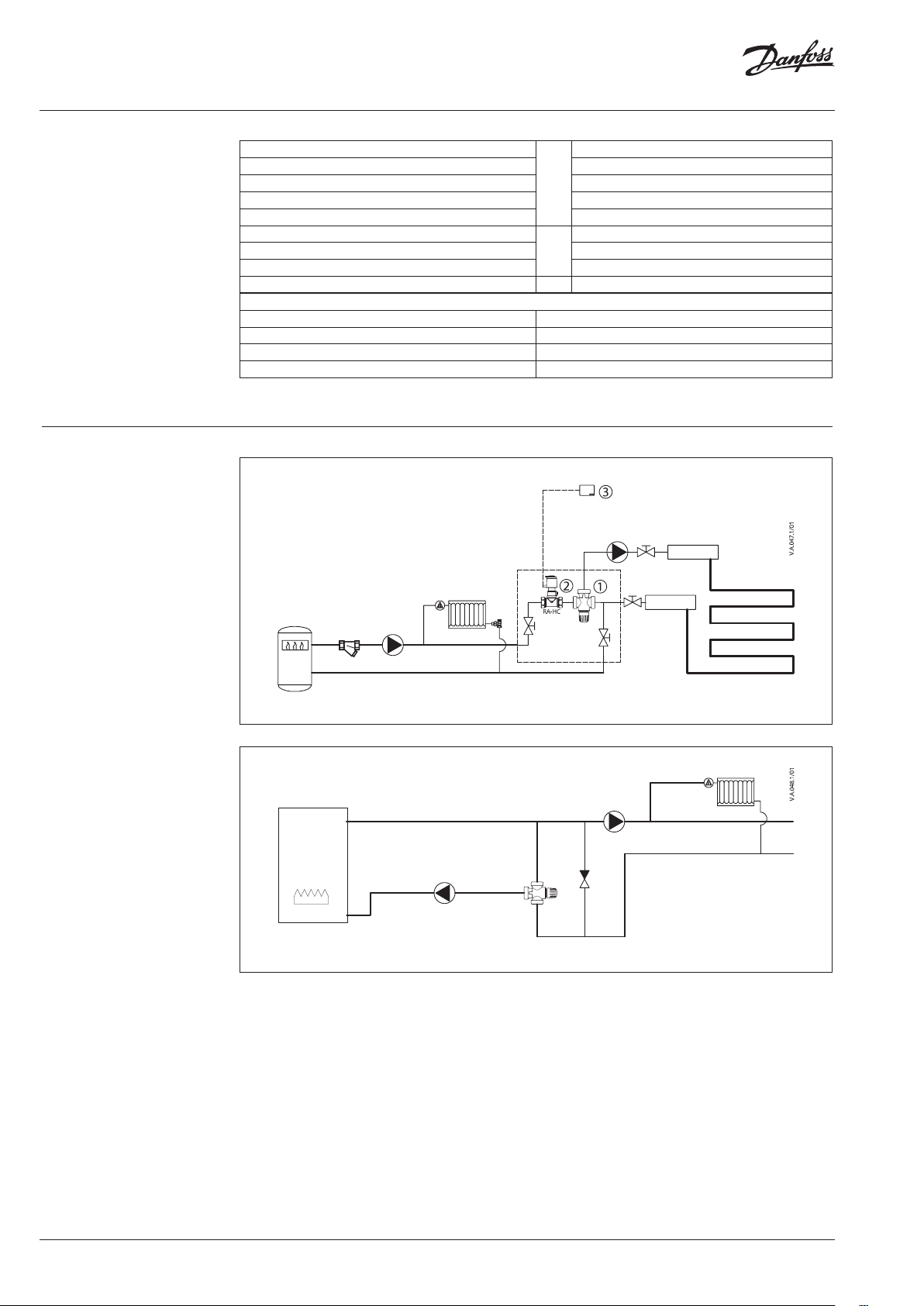

Note for fig. 1:

Danfoss PACK solution consists of

thermostatic mixing valve T VM-H,

motorised valve and programable

thermostat.

This solution gives excellent

temperature control for the under

floor heating system up 200 m2

(TVM- H DN 25) .

Factory temperature presseting

Cold water supply temperature 10

Hot water supply temperature 70

Temperature stability (depend on pressure and temperature) ± 3

Max. hot water operating temperature 100

Supply pressure, static (max.)

Supply pressure, dynamic (max.) 5

Constant inlet pressure diferential

Max. pressure loss ratio 10:1

Materials

Body DZR + antilimescale treatment

Plastic cap Polystyrene

Spring SS steel 1.4301 (inoxydable)

Sealing EPDM

1)

Between co ld and worm inlets

1)

°C

bar

① Danfoss T VM-H

② Danfoss zon e valve with TWA actua tor

③ Programable thermostat

70

10

2

Fig. 1 - Floor heating application

Fig. 2 - Mixing return temperature back to the boiler to avoid condense or to secure good incineration.

2 | VD.D1.F6.02

© Danfoss | 2016.11

Data sheet Thermostatic mixing valve TVM-H

Pressure diagram

Locking the presetting

② ③①

④

© Danfoss | 2016.11

⑤

⑥

VD.D1.F6.02 | 3

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Thermostatic mixing valve TVM-H

Locking the presetting

(continuous)

⑦ ⑨⑧

Spare parts

1. Non-return valve

2. Fitting set

3. Thermostatic element

Dimensions

Fitting set

DN G

20 1 ⁄ 32

25 1⁄ 1 42

115

G

G

74

G

45

Typ e DN G

TVM-H

20 1”

25 1⁄”

Lenght

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

4 | VD.D1.F6.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2016.11

Loading...

Loading...