Page 1

TWIN-TURBINE CENTRIFUGAL

COMPRESSOR

MODEL TT-300

SERVICE MONITOR USER MANUAL

Danfoss Turbocor Compressors Inc. ECD-00007M Rev. 1

Page 2

Contents

Introduction 1

System Requirements 2

Getting Started 3

Cable Connection 3

RS232 Connection 3

RS485 Connection 3

Monitor Program Installation 5

Starting the Monitor Program 5

User Interface 5

Monitor Program Toolbar 5

Entering User Input 6

Serial Port Connection 6

Compressor Configuration 7

Using the Setup Wizard 7

Start-up Settings 8

Electronics Valve Control 9

Analog Output Setup 11

Modbus Communications 12

Downloading and Saving Configuration Data 12

Using a Saved Configuration File 13

Controlling User Access 14

Starting and Stopping the Compressor 15

Analog Input 15

How to Start the Compressor 15

How to Stop the Compressor 15

Modbus Network 15

How to Start the Compressor 15

How to Stop the Compressor 16

Chiller Control 16

How to Start the Compressor 16

How to Stop the Compressor 16

Monitor Program Data and Controls 18

Main System 18

Bearing Calibration 20

Bearing Calibration Procedure 22

Calibration Data Interpretation 23

“Gain” Interpretation 23

“Offset” Interpretation 23

Compressor Control 23

Compressor Control Modes 26

Calibration 26

Manual Control 26

Analog Input 27

Modbus Network 27

Chiller Control 27

Compressor Faults/Alarms 27

Danfoss Turbocor Compressors Inc. i

ECD-00007M Rev. 1

Page 3

Contents

Motor Monitoring 28

Motor Monitoring Overview 28

Motor Faults / Alarms 30

Magnetic Bearing Monitoring 31

Bearing Monitoring Overview 31

Bearing Faults 33

Electronic Valve Data / Tuning 33

Chiller Control 36

System Information 38

Compressor Info 39

EEPROM Log Resets 39

EEPROM Settings 39

Compressor Controller Settings 40

Compressor Controller Alarms 41

Compressor Controller Fault Limits 43

Compressor Stepper Motor Settings 44

Stepper Motor Valve Controls 45

Analog Output Controls 47

Compressor Controller Impeller Specific Settings 49

Compressor Controller (CC) Critical Fault Lock Outs 50

Refrigerant 51

Compressor Event Log 51

History Data 52

Trending 53

Graphs 53

Trending & Data Acquisition 56

Compressor Map 57

Fault Captures 59

Data Capture 60

Appendix A: Determination of Actual Power Setting A-1

ii Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 4

1 Introduction

The Turbocor Service Monitor program is a rich, userfriendly, graphical user interface designed to control the

Turbocor compressor and to provide status information

about the compressor. Furthermore, it can be used as a tool

for troubleshooting purposes.

This manual describes the functions provided by the

Turbocor Service Monitor program.

Service Monitor User Manual

Danfoss Turbocor Compressors Inc. 1

ECD-00007M Rev. 1

Page 5

System Requirements

2 System Requirements

The monitor program must be installed on a PC that meets

the minimum requirements specified in Table 1. For

optimum performance, a 533 MHz Pentium or higher CPU

with 128 MB RAM running Windows 2000 (SP4) or XP is

recommended.

The monitor program was developed for the .NET

Framework and requires the .NET Framework to be

installed on the PC where the program runs. Microsoft

provides a re-distributable installer, Dotnetfx.exe, that

contains the common language runtime and .NET

Framework components that are necessary to run the

monitor program. Before installing the monitor program,

the .NET framework 1.1 re-distributable must be installed.

This can be downloaded from the Microsoft website.

The latest Windows service packs and security updates

should also be installed on the PC.

Table 1: Minimum Requirements

Processor 533-MHz Intel Pentium-class processor

Operating System

The .NET Framework 1.1 Re-distributable is supported on the following

platforms:

• Microsoft Windows® Server 2003 (.NET Framework 1.1 is installed as part

of the operating system)

• Windows XP Professional

• Windows XP Home Edition

• Windows 2000

• Windows Millennium Edition (Windows Me)

• Windows 98

Memory

Hard Disk

Display

Input Device

Other

• Microsoft Windows NT® 4.0 Service Pack 6a

The .NET Framework 1.1 Re-distributable cannot be installed on 64-bit

computers; Windows NT 4.0 Terminal Server is not supported

128 MB of RAM, 256 MB recommended

110 MB of hard disk space required, 40 MB additional hard disk space

required for installation (150 MB total)

800 x 600 or higher-resolution display with 256 colors

Microsoft mouse or compatible pointing device

Install the latest Windows service packs and critical updates from the

Windows Update site.

Installation of the .NET Framework 1.1 is split into two parts: the core

and language packs. The core cont ains everything yo u need to run .NET

Framework applications; all dialog boxes and error messages will be in

English. If you want dialog boxes and error messages in another

language, you must also install the corresponding language pack. For

more information, see the .NET Frame wo rk Dow nlo a ds page.

2 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 6

3 Getting Started

3.1 Cable Connection

The monitoring program communicates with the

compressor via the Modbus* protocol using either the

RS232 or RS485 connection at the Chiller Interface

module. RS485 communication requires an RS485/RS232

adapter (user-supplied). RS232 communication is

recommended for cable lengths not exceeding 15 meters

(50 feet) between the PC and compressor. For cables that

run up to 100 meters (328 feet), use the RS485

communication line. Always use shielded, twisted-pair

cable for data communications

*The Modbus protocol was originally developed to exchange information

between products on the factory floor. This protocol has become a de f acto

standard for exchanging data and control between PLC systems. Modbus is

a registered trademark of Modicon Corp.

Service Monitor User Manual

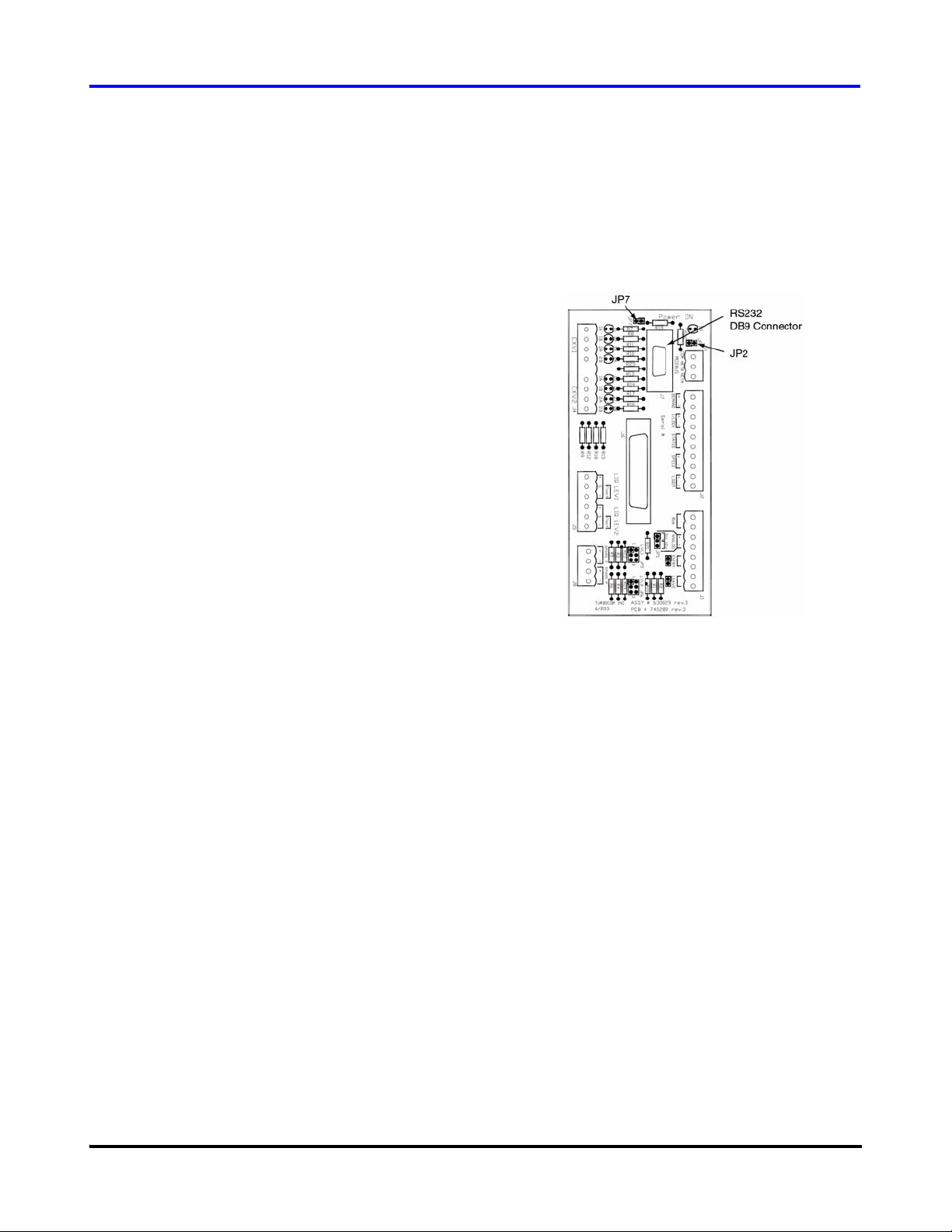

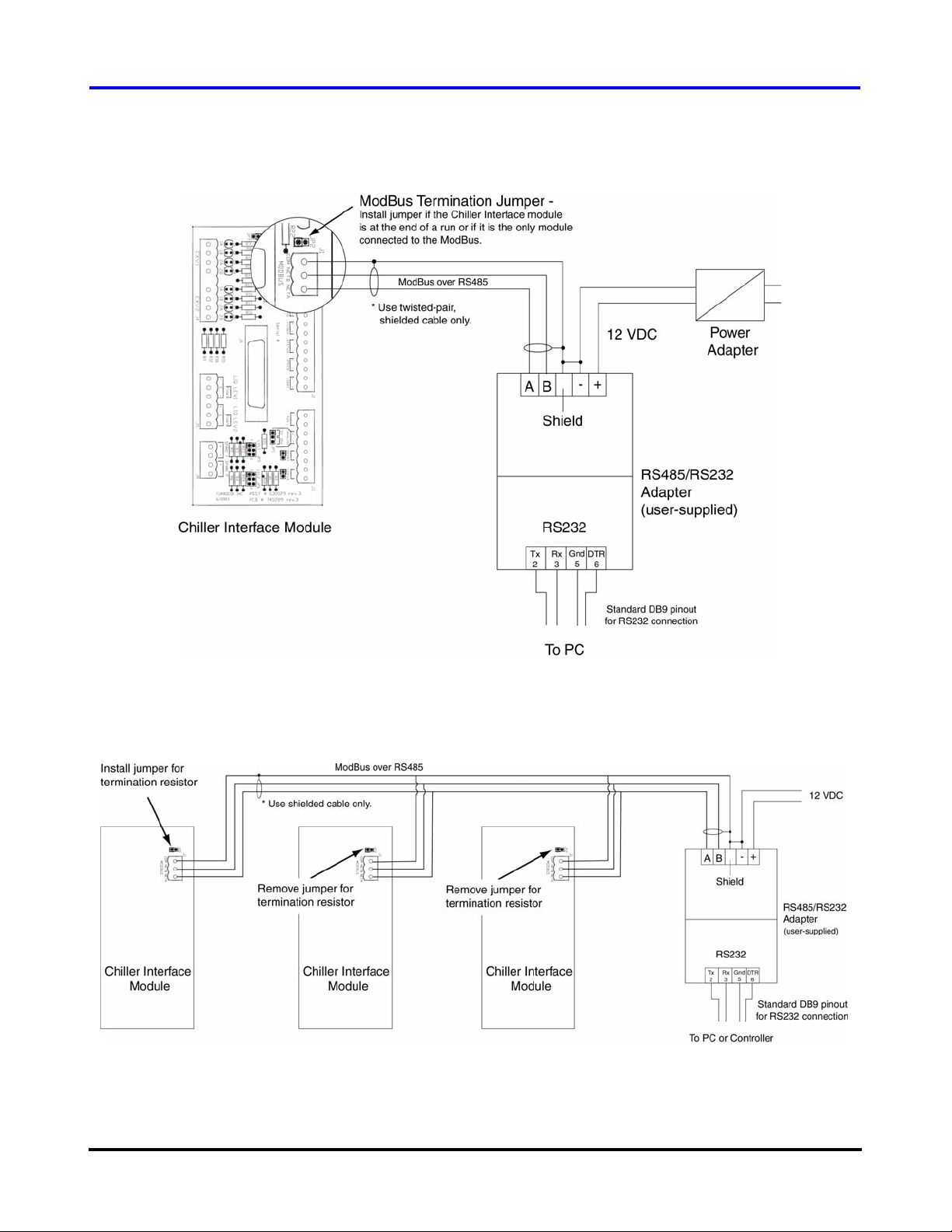

3.1.1 RS232 Connection

1. Connect one end of the RS232 cable (user-supplied) to

the DB9 connector on the Chiller Interface module; see

Figure 1.

2. Connect the other end of the cable to an available COM

port on the PC.

3. Confirm that jumpers JP2 and JP7 are in proper

positions before starting.

JP2 is the Modbus termination jumper. Install the

jumper if the Modbus connection is at the end of a

cable run.

Remove JP7 to enable RS-232 communication with the

PC.

Figure 1 RS232 Connector - Chiller Interface

Module

3.1.2 RS485 Connection

1. Connect the RS485/RS232 adapter directly onto the PC

COM port.

Connect the other side of the adapter to the Modbus. Figure

2 shows the PC and adapter connections to the Modbus for

a single compressor application. Ensure that the termination

jumper (JP2) on the Chiller Interface module is installed.

Figure 3 shows the PC and adapter connections to the

Modbus for a multiple compressor application. In this case,

set the termination jumper only on the Chiller Interface

module that is connected at the end of the Modbus cable

run.

Danfoss Turbocor Compressors Inc. 3

ECD-00007M Rev. 1

Page 7

Getting Started

Figure 2 PC to Modbus Connection (single compressor with > 10 m cable length)

Figure 3 PC to Modbus Connection (multiple compressors with > 10 m cable length)

4 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 8

3.2 Monitor Program Installation

Service Monitor User Manual

The monitor program is installed on the PC and

communicates with the compressor using the ModBus

protocol over a RS-232 or RS-485 serial link. Administrator

privileges may be required to install and remove software

on the PC.

NOTE:

If a previous version of the monitor program is already

installed on the PC, it must be uninstalled before proceeding

with the current installation. To uninstall the monitor

program: from the “Start” menu, select “Settings” →

“Control Panel”. Double-click “Add/Remove Programs”.

From the list, select “Danfoss Turbocor Service Monitoring

Tool” and then click the “Remove” button.

3.3 Starting the Monitor Program

To start the monitor program: from the “Start” menu, select

“Programs” → “Danfoss Turbocor Monitoring Tool”.

3.4 User Interface

Installation Procedure:

1. Insert the monitor program CD into th e drive.

2. In Windows Explorer, navigate to the

Turbocor_Service_Tool_Setup.msi file. Double-click

the file to launch the setup wizard.

3. Follow the instructions provided by the wizard to

complete the installation.

4. Click the Close button to exit the setup wizard.

3.4.1 Monitor Program Toolbar

NOTE:

The toolbar (located under the menu bar) provides the user

with easy access to the monitoring windows. Table 2

provides details for each icon on the toolbar.

Table 2 Monitor Program Toolbar Icons

Icon Name Description

Serial Port Connection Clicking on the “Serial Port Connection” icon opens the “Serial Port

Connection” window. Refer to section 3.5 "Serial Port Connection"

on page 6.

Compressor Controller

Parameters

Motor Monitor Clicking on the “Motor Monitor” icon opens the “Variable Speed

Magnetic Bearings Clicking on the “Magnetic Bearings” icon opens the “Magnetic

Clicking on the “Compressor Controller Parameters” icon opens

the “Compressor Controller” window. Refer to section 6.3

"Compressor Control" on page 23.

Permanent Magnet Motor Monitoring” window. Refer to section

6.4 "Motor Monitoring" on page 28.

Bearing Monitoring” window. Refer to section 6.5 "Magnetic

Bearing Monitoring" on page 31.

Up to three windows can be displayed at one time. If three

windows are already open, one must be closed before

another window can be opened.

Danfoss Turbocor Compressors Inc. 5

ECD-00007M Rev. 1

Page 9

Getting Started

Table 2 Monitor Program Toolbar Icons (Continued)

Icon Name Description

Expansion Valves Clicking on the “Expansion Valves” icon opens the “Electronic

Valve / Data Tuning” window. Refer to section 6.6 "Electronic

Valve Data / Tuning" on page 33.

Event Log Clicking on the “Event Log” icon opens the “Compressor Event

Log” window. Refer to section 6.10 "Compressor Event Log" on

page 51.

EEPROM Settings Clicking on the “EEPROM Settings” icon opens the “EEPROM

Settings” window. Refer to section 6.9 "EEPROM Settings" on

page 39.

Load Profile Graphs Clicking on the “Load Profile Graphs” icon opens the “Compressor

History Data” window. Refer to section 6.1 1 "History Data" on p age

52.

Fault Captures Clicking on the “Fault Captures” icon opens the “Fault Captures”

window. Refer to section 6.14 "Fault Captures" on page 59.

Trending Clicking on down arrow next to the “Trending” icon, and selecting

“Charts 1” opens the trending “Graphs” window; selecting on

“Charts 2” opens the “Trending and Data Acquisition” window.

Refer to section 6.12 "Trending" on page 53.

Chiller Control Clicking on the “Chiller Control” icon opens the “Chiller Control”

window. Refer to section 6.7 "Chiller Control" on page 36.

Compressor Envelope Clicking on the “Compressor Envelope” icon opens the

“Compressor Map” window. Refer to section 6.13 "Compressor

Map" on page 57.

3.4.2 Entering User Input

When user input is required for the monitor program fields,

perform the following sequence:

1. Double-click the variable field. (This activates the field

for user input.)

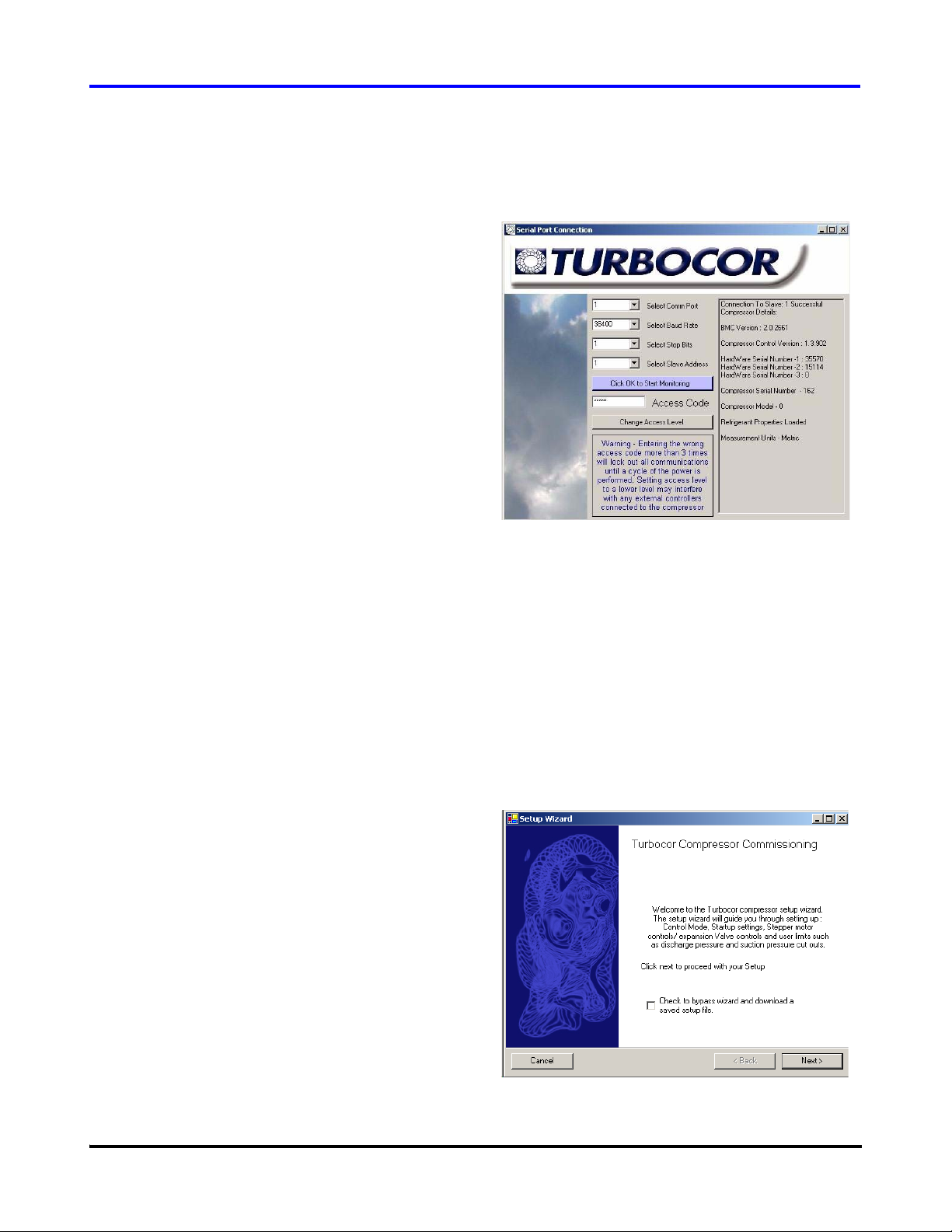

3.5 Serial Port Connection

The Serial Port Connection window contains fields that

must be filled in order to enable communication between

the monitor program and the compressor; refer to Figure 4.

The comm settings of the compressor must be known in

order for the monitor program to communicate with the

compressor.

To access the “Serial Port Connection” window, select

“Window”→ “Connection” from the menu bar, or click on

the “Serial Port Connection” icon located below the menu

bar.

2. Scroll or type in the new setting.

3. Press Enter. It is important to press Enter as this causes

the user input to be validated.

The following paragraphs describe the dialog box fields.

Comm Port - Serial communication port that the computer

will use to connect to the compressor. Enter the COM port

number such as COM1 or COM2, etc.

Baud Rate -19,200 or 38,400 baud (38,400: default)

Stop Bits - 1 or 2. (1: default)

Slave Address - 1-63. (1: default)

6 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 10

Service Monitor User Manual

Access Code - The access code controls access to all

adjustable parameters. The default user access level on

power up is read only. Enter the code that corresponds to

the access level you require. Contact Turbocor Product

Support to obtain the required access code.

1. Once the serial port connection data has been set, click

the Connect button. At this point, connection status,

compressor details, and user access level appear in the

right-hand pane of the dialog box.

2. If necessary, change the access level. Enter the access

code in the “Access Code” parameter box, then click

“Change Access Level”. Confirm that the correct

access level has been set on the right-hand pane of the

dialog box.

NOTE:

The access level connection cannot be changed prior to a

establishing connection.

Entering the wrong access code more than 3 times will lock

out all communications until a cycle of the power is

performed.

3. Click the “OK to start monitoring” button.

Figure 4 Serial Port Connection Dialog Box

4 Compressor Configuration

4.1 Using the Setup Wizard

The monitor program features a commissioning setup

wizard to guide the user through the complete compressor

configuration process.

1. To launch the commissioning setup wizard, select

“System Commissioning” from the “Advanced” menu

item. The introduction screen for the commissioning

setup wizard appears; refer to Figure 5. Click Next.

(To bypass the setup wizard and use a saved

configuration file to setup the compressor, check the

checkbox and click Next. Continue with 4.2 "Using a

Saved Configuration File" on page 13.)

2. Select the appropriate units of measurement (metric or

imperial). Refer to Figure 6.

3. Select the appropriate compressor control method.

There are three modes available:

external controller. The variable demand signal

corresponds to the range of 0-100% maximum

power available.

• Analog Input: compressor loading controlled using

an analog demand signal of 0-10 VDC from an

Danfoss Turbocor Compressors Inc. 7

ECD-00007M Rev. 1

Figure 5 Commissioning Set-up Wizard

Page 11

Compressor Configuration

• Modbus Network: the compressor receives a

demand from an external computer, PLC, or

building management system using the Modbus

protocol on a RS-232 or RS-485 communication

link.

• Chiller Control: fully automatic; controls the chilled

water temperature using a temperature sensor

connected directly to the Chiller Interface module.

This mode can also be used to control evaporating

temperature which is derived from the suction

pressure measurement

6. Set the Chiller Control Set Point to the desired value.

7. Set the Proportional and Integral Gain values to obtain

stable control (the Proportional and Integral Gain

values will vary depending on the application).

NOTE:

The Integral part of the internal chiller controller is

switched off until the compressor reaches a speed of 18,500

RPM. Stopping the compressor and restarting also resets the

Integral part to 0.

8. Click in the Chiller Enable checkbox if you would like

to have the compressor start automatically. It is

advised, however, to open the interlock contact (located

on the Chiller Interface module) to prevent the

compressor from starting before the commissioning

sequence is complete.

Figure 6 General Compressor Settings

NOTE:

If the compressor is linked to an external controller, changes

made to the compressor demand via the monitor program

can conflict with controller-issued commands. This

situation can lead to unexpected results. Before testing the

demand input, isolate the compressor from the controller.

4. Click the Next button.

Steps 5 through 8 apply to the Chil ler Control mode

only.

5. Select the type of sensor that will control the chiller. If

selecting Entering or Leaving Chiller Air/Water

Temperature, connect an NTC temperature sensor (as

specified in the compressor Application manual) to

either the Entering- or Leaving Chilled Water

temperature input on the Chiller Interface module.

8 Danfoss Turbocor Compressors Inc.

Figure 7 Chiller Control Commissioning

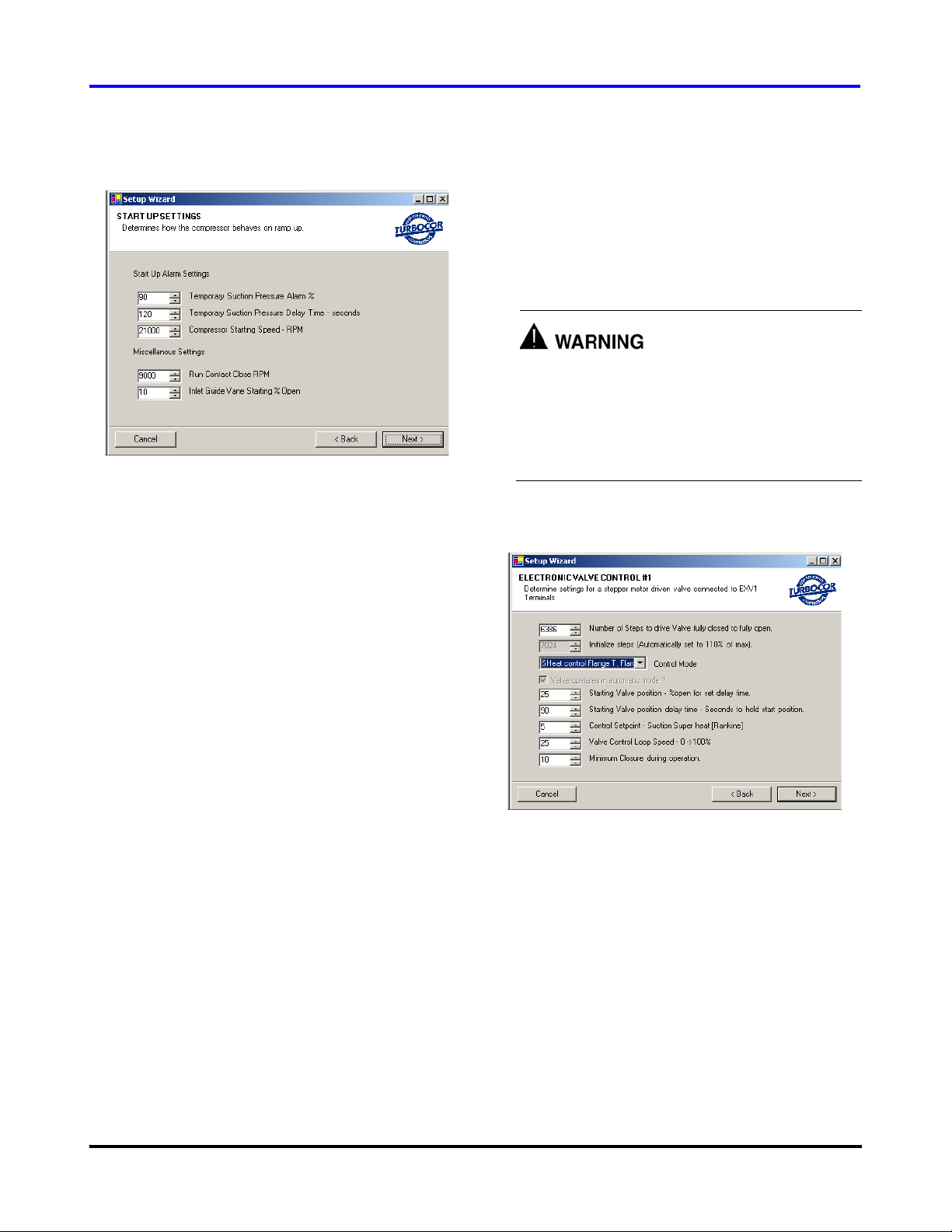

4.1.1 Start-up Settings

(Refer to Figure 8)

1. Enter the Temporary Suction Pressure Alarm %. The

limit is set up as a % of the current suction pressure

limit, e.g., if a suction pressure trip of 270 kPa was set

and the temporary suction pressure alarm was set to

50%, the temporary suction pressure trip limit would

be 135 kPa. This temporary alarm is only active while

the Suction Pressure Delay timer is counting down.

ECD-00007M Rev. 1

Page 12

Figure 8 Start-up Settings

Service Monitor User Manual

This section explains how to set up the expansion valves for

various applications. Both valves can be operated

independently or in parallel.

For Expansion Valve #1:

1. Enter the number of steps to drive the valve from fully

closed to fully open. Expansion valves with different

numbers of steps can be used.

If the incorrect number of steps is selected, the valves

may not have enough travel to allow the required

amount of mass flow or the valve may not be able to

throttle down to the required amount of mass flow.

This situation could cause liquid flood back and

damage to the compressor.

2. Enter the Temporary Suction Pressure Delay Time.

This parameter represents time in seconds that the

temporary suction pressure alarm / fault limit should be

enabled. The timer starts to count down once the shaft

starts to rotate.

3. Enter the Compressor Starting Speed. If the estimated

surge speed is greater than the starting speed setting,

the compressor will ramp up to the surge speed. If the

starting speed setting is greater than the estimated surge

speed, the compressor will ramp up to the starting

speed. In both cases, the compressor speed will

increase at the full ramp rate.

4. Enter the Run Contact Close RPM. The compressor

contains a NO relay contact that closes while the

compressor is running. The speed at which the contact

closes is determined by the Run Contact Close RPM.

5. Enter the Inlet Guide Vane Starting % Open. Typically,

the vanes will be set to the closed or almost closed

position at start-up.This is to minimize the possibility

of liquid flood back and to reduce the compressor’s

start-up current draw.

6. Click Next to continue.

4.1.2 Electronics Valve Control

(Refer to Figure 9)

Figure 9 Electronics Valve Control Setup

2. Select the control mode for the expansion valve.

Available options are: superheat, liquid level, or load

balance. See Table 3 for a description of the modes.

3. Enter the Starting Valve Position. If desired, at

compressor start-up, the valves can be set to open to a

pre-start value for a given time. This value represents

the percentage of maximum steps sent to the motor

upon start-up of the compressor. The stepper motor will

hold at this position until the stepper start delay timer

has expired.

4. Enter the Valve Starting Position Delay Time. The

delay is the amount of time (from compressor start-up)

Danfoss Turbocor Compressors Inc. 9

ECD-00007M Rev. 1

Page 13

Compressor Configuration

to hold the number of steps sent to the motor as

determined by the Starting Valve Position %. Value is

in seconds and starts to count down when the drive is

enabled.

5. Enter the Control Setpoint, i.e., suction superheat or

liquid level. (Not applicable to load balance control

mode.)

6. Enter the Valve Control Loop Speed. This value

represents the reaction time of the control loop to a

7. Enter the Minimum Closure During Operation. This is

8. Click Next to continue. Repeat steps 1 through 7 for

Table 3 Control Modes

Control Mode Description

Superheat

The calculation of superheat can be based on the temperature and pressure

measurements from one of the following sources:

• Superheat control using the compressor flange temperature and pressure (this

mode is not recommended as the temperature at the compressor flange is

influenced by external factors).

• Superheat control using the compressor flange pressure and a 10K thermistor

that is connected to the terminals labeled “ENTRY” on the Chiller Interface

module.

• Superheat control using the compressor flange pressure and a 10K thermistor

that is connected to the terminals labeled “LIQT” on the Chiller Interface

module.

process error and replaces the PID controller gains

(proportional, integral, and derivative).

the minimum close position for the valve while the

compressor is spinning.

electronic expansion valve # 2.

Liquid Level

Load Balance

• Superheat control using an external temperature and pressure sensor

connected to the terminals on the IO pcb labeled “SPARE T” & “SPARE P”.

Liquid level can be measured from one of the following sources:

• Liquid Level 1 contro l usin g a lev el sen so r co nn ec te d to the te rm ina ls on the

Chiller Interface module labeled “LIQ LEV1”.

• Liquid Level 2 contro l usin g a lev el sen so r co nn ec te d to the te rm ina ls on the

Chiller Interface module labeled “LIQ LEV2”.

For liquid level sensing, two types of level sensors can be used: a level sensor

with a supply of 15VDC and an output of 0-5VDC or a resistive-type level sensor,

0-90 Ohm. Refer to vendor documentation for wiri ng these types of se nsors to the

Chiller Interface module.

The Load Balance control mode uses the compressor’s own internal control

algorithm to determine the best mix of speed control, inlet guide vane opening and

load balance valve opening. Use this mode only if a load balancing valve is

installed in the system. Since the load balancing valve is connected to the

compressor’s capacity control algorithm, selecting this mode without a valve

installed will add a delay to the loading/unloading process, i.e., the compressor will

try to open and close the valve for 2 minutes r ather th an clo se the va ne or change

the speed.

10 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 14

Service Monitor User Manual

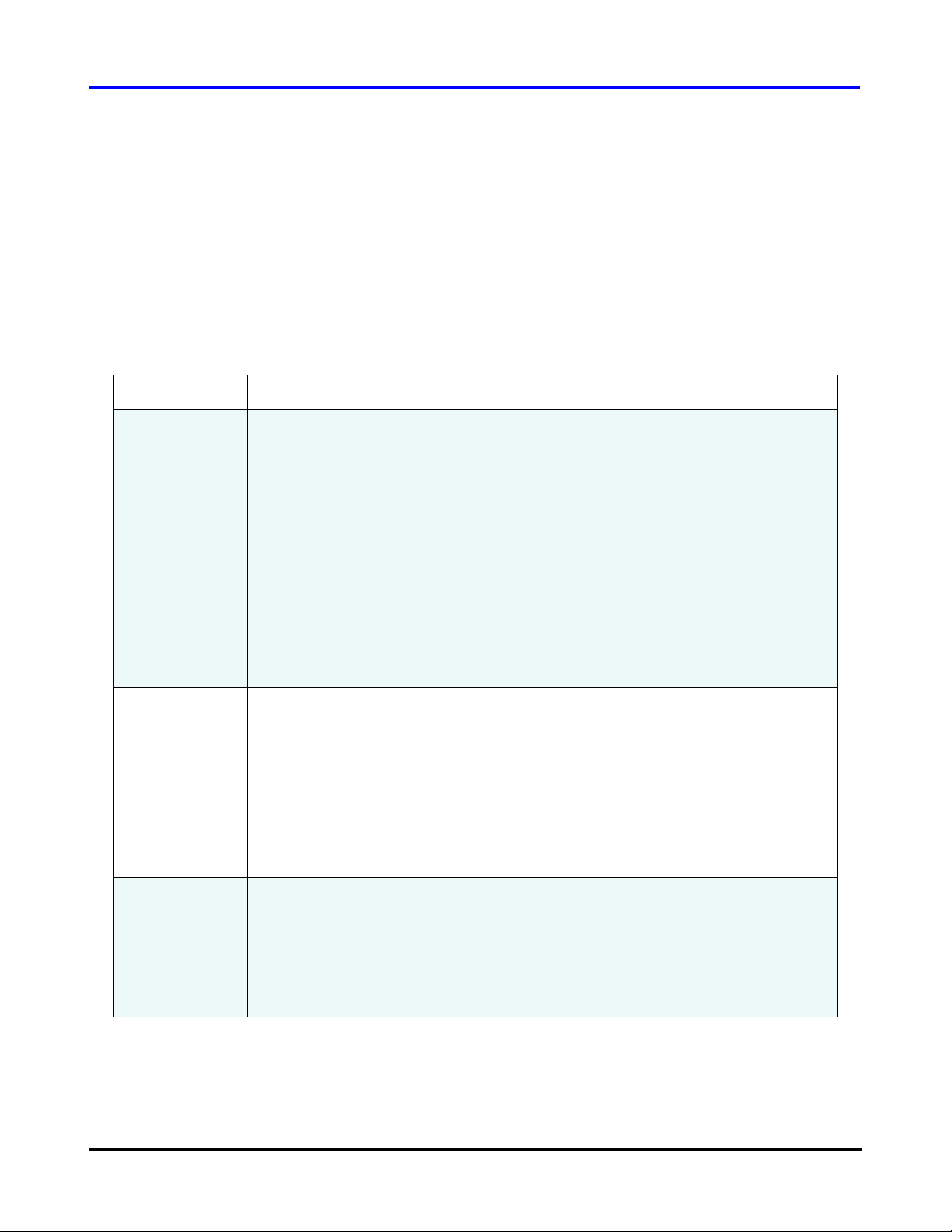

4.1.3 Analog Output Setup

The compressor features a universal analog output for load

balancing valve, IGV position, discharge pressure, etc. The

operating range can be set to 0-5V or 0-10V via jumpers on

the Chiller Interface module.

Figure 10 shows a typical application for the analog output.

In this example, the analog output from the Chiller Interface

module is connected to a 3-way valve that channels chilled

water to a cooling coil. A temperature sensor at the cooling

coil is connected to the Leave terminals of the Chiller

Interface module. The analog output controls the amount of

chilled water entering the cooling coil based on the air

temperature setpoint.

Figure 10 Analog Output Application Example

Configure the analog output as follows (Refer to Figure 11):

1. Select the control mode for the analog output. The

selection determines which control variable will be the

source for the 0-10vdc output (at the ANALOG output

terminals on the Chiller Interface module). The options

are:

• Load Balance

•HP

•IGV

Danfoss Turbocor Compressors Inc. 11

ECD-00007M Rev. 1

•Auto

• Superheat - Flange TP

• Superheat - FlangeP, EWT

• Superheat - FlangeP, LIQT

• Suction Pressure.

• Leaving Temp

•Entering Temp

•Liquid Temp

Page 15

Compressor Configuration

Figure 11 Analog Output Setup

2. Enter the Starting Output. This value equals the

percentage of maximum voltage sent to the terminals of

the Chiller Interface module on compressor start-up.

The analog output will hold at this position until the

start delay timer has expired.

3. Enter Starting Output Delay Time. This value is the

amount of time from compressor start-up to hold the

voltage at the start-up %. Value is in seconds and starts

to count down when the drive is enabled.

4. Check the Control Action checkbox for reverse acting.

Leaving the checkbox unchecked will enable direct

acting.

5. Enter the Proportional, Integral, and Derivative gains to

provide stable control.

6. Enter the minimum analog output (in DC volts) during

operation, if required. This parameter can be used, for

example, to maintain a minimum valve open position

during operation.

4.1.4 Modbus Communications

(Refer to Figure 12)

Figure 12 Modbus Communications Setup

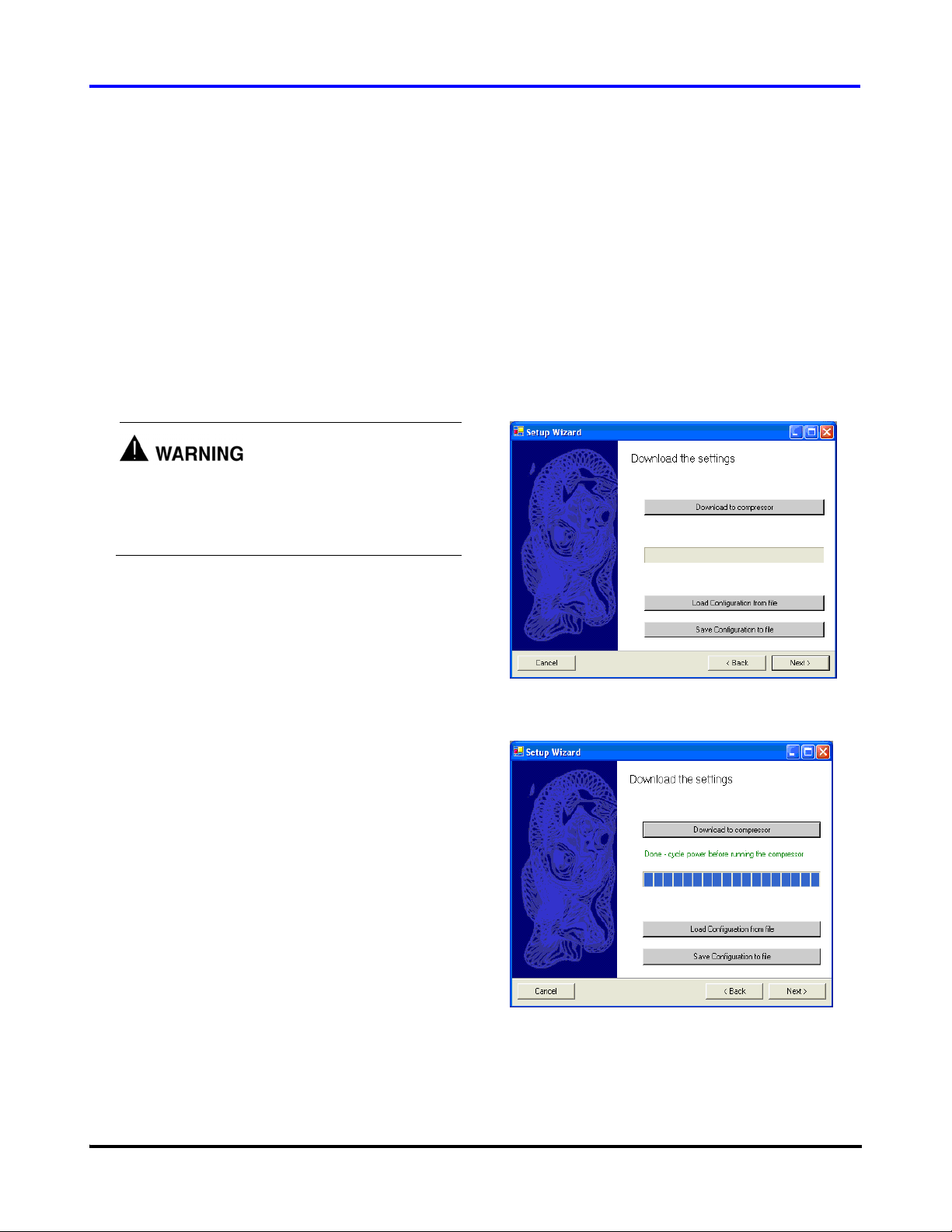

4.1.5 Downloading and Saving

Configuration Data

At the end of the commissioning sequence, you have the

choice of either downloading the configuration data to the

compressor or saving it to a file for later use.

To save the data to a configuration file, click the Save to

Configuration File button. In the Save As dialog box, name

the file and save it in a designated location.

NOTE:

If modifications are made to the configuration data after the

commissioning is complete, the new values must be

recorded in a new commissioning session if the data is to be

saved to a file.

Never attempt a download while the compressor is

running as it can lead to a loss of compressor control.

Open interlock contacts on the Chiller Interface

module before downloading configuration data.

Set up the RS-485 and RS-232 ports, as required, on the

Chiller Interface module to enable communication with an

external PLC, computer or building management system.

12 Danfoss Turbocor Compressors Inc.

For immediate downloading of the configuration data to the

compressor, click the Download to Compressor button. To

enable the new configuration data, perform the following

steps:

ECD-00007M Rev. 1

Page 16

1. Turn OFF power to the compressor. Wait at least 5

minutes, then check that the LEDs on the Backplane

are OFF.

2. Turn ON power to the compressor.

4.2 Using a Saved Configuration File

Service Monitor User Manual

IMPORTANT:

Record the comm settings before you close the monitor

program since they will be necessary to communicate with

the compressor when you restart the monitor program.

3. Close and then restart the Monitor program.

Follow the steps outlined here if you have bypassed the

commissioning wizard in order to download a configuration

file to the compressor.

Never attempt a download while the compressor is

running as it can lead to a loss of compressor control.

Open interlock contacts on the Chiller Interface

module before downloading configuration data.

1. Click the “Load configuration from file” button; refer

to Figure 13.

2. In the Open File dialog box, browse to the location of

the .ttc file.

3. Click Open.

4. On the Download Settings form, click “Download to

compressor” button.

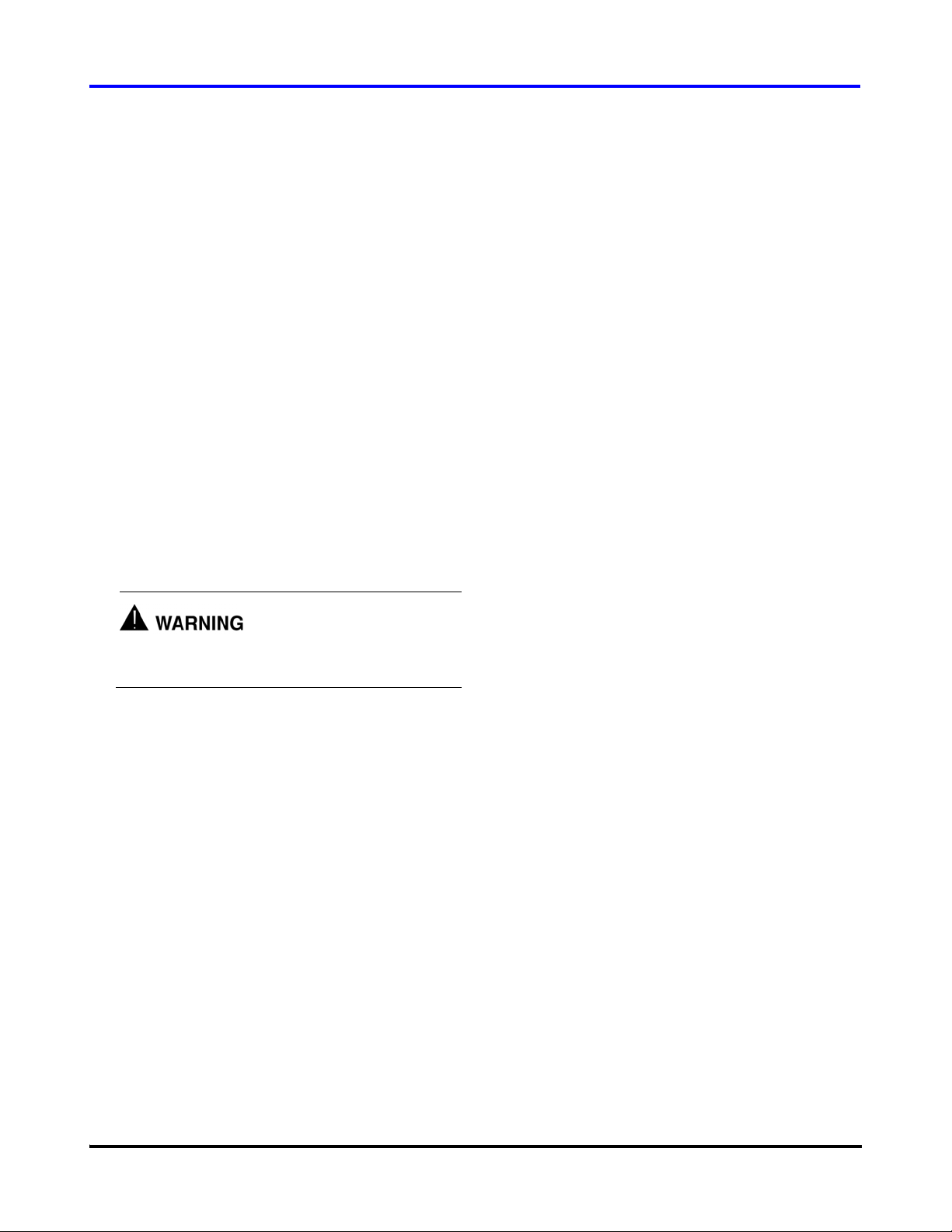

5. When the message “Done. Cycle power before running

the compressor” appears, turn OFF power to the

compressor; refer to Figure 14. Wait at least 5 minutes,

then check that the LEDs on the Backplane are OFF.

configuration file has been successfully downloaded to

the compressor.

Figure 13 Download Settings Screen

6. Close the Monitor program.

7. Turn ON power to the compressor.

8. Restart the Monitor program.

9. Once reconnected, the text in the right-hand pane of the

Serial Port Connection dialog box appears in red.

When the text turns black, it indicates that the new

Figure 14 Download Settings Screen (After

Download)

Danfoss Turbocor Compressors Inc. 13

ECD-00007M Rev. 1

Page 17

Compressor Configuration

4.3 Controlling User Access

The access code system allows OEM customers to set their

own unique pass codes thereby restricting access to

company authorized personnel.

These access codes control access to all adjustable

parameters via the Modbus communications layer. The

access levels are:

• Read only ~ User may only view values across the

Modbus layer.

• Low Level ~ User may only alter basic settings such as

leaving chilled water temp, display units, chiller enable/

disable, etc.

• Mid Level ~ User may alter all settings that are required

for commissioning a compressor in the field. Values

alterable, for example, are control mode, valve control

settings, run status contact energize RPM, reset load

profile data, and retrieve and save fault data.

• High level ~ User may alter all settings. This level of

access is reserved for users that configure motor/

compressor and bearing control only.

Upon power-up of the compressor, the access codes are

calculated and stored in RAM memory. The default user

access level on power up is read only.

The Access Code Change form appears. To change the

access code for a specific user level:

1. Select the appropriate radio button.

2. Enter the current access code followed by the new

access code for the selected user level (if you enter the

incorrect access code nothing will be changed).

3. Re-enter the new access code in the Confirm Access

Code field.

4. Click the Change Access Code button.

NOTE:

The new access code does not take effect until the

compressor has been restarted.

To change the access code, select “Access Codes” from the

“Advanced” menu item; refer to Figure 15.

Figure 15 Navigating to the Access Code

Change Form

Figure 16 Access Code Change Form

14 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 18

Service Monitor User Manual

5 Starting and Stopping the Compressor

The following sections describes how to start and stop the

compressor. Refer to the section corresponding to the

5.1 Analog Input

The Analog Input mode controls the compressor loading

using an analog demand signal of 0-10 VDC from an

external controller. The variable demand signal corresponds

to the range of 0-100% maximum power available.

NOTE:

The Chiller Interface interlock switch must be closed and

no errors present for the compressor to start up and run.

5.1.1 How to Start the Compressor

1. Make sure the contact to the ‘Interlock’ input on the

Chiller Interface is closed.

Ensure that power to the compressor is OFF before

connecting wiring to the Chiller Interface module.

control method selected during configuration of the

compressor.

2. Connect a 0-10VDC demand signal to the Chiller

Interface module.

3. Apply a signal between 2 and 10VDC to the ‘Demand’

input. (2VDC = min kW/min speed, 10VDC = max kW

according to model capacity.)

5.1.2 How to Stop the Compressor

Decrease the demand signal to 0VDC or open the contact

connected to the ‘Interlock’ input on the Chiller Interface

module. The compressor will ramp down to 0 RPM and delevitate.

5.2 Modbus Network

In Modbus Network mode, the compressor receives a

demand from an external computer, PLC, or building

management system using the Modbus protocol on a RS232

or RS485 communication link.

NOTE:

The Chiller Interface interlock switch must be closed and

no errors present for the compressor to start up and run.

Danfoss Turbocor Compressors Inc. 15

ECD-00007M Rev. 1

5.2.1 How to Start the Compressor

Open the “Compressor Controller” window. Click on the

“Compressor Controller Parameters” icon located below the

menu bar.

On the Compressor Control Data form, click in the Loading

Demand field and enter a value representing a percentage of

maximum power available. (The maximum power available

is dependent on the compressor model.) The compressor

will levitate and spin up. Refer to Figure 17

Page 19

Starting and Stopping the Compressor

5.2.2 How to Stop the Compressor

To stop the compressor, enter ‘0’ in the Loading Demand

field.

Figure 17 Compressor Control Form

5.3 Chiller Control

The Chiller Control mode is fully automatic and controls

the chilled water temperature using a temperature sensor

connected directly to the Chiller Interface module. This

mode can also be used to control evaporating temperature

which is derived from the suction pressure measurement

NOTE:

The Chiller Interface interlock switch must be closed and

no errors present for the compressor to start up and run.

5.3.1 How to Start the Compressor

Open the “Chiller Control” window. Select “Window”→

“Chiller Control” from the menu bar, or click on the

“Chiller Control” icon located below the menu bar.

On the Chiller Control form, check the Chiller Enable

Status box. The compressor will ramp up and adjust its

speed to reach and maintain the setpoint. Refer to Figure 18.

5.3.2 How to Stop the Compressor

On the Chiller Control form, uncheck the Chiller Enable

Status box. The compressor will ramp down to 0 RPM and

de-levitate.

16 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 20

Service Monitor User Manual

Figure 18 Chiller Control Form

Danfoss Turbocor Compressors Inc. 17

ECD-00007M Rev. 1

Page 21

Monitor Program Data and Controls

6 Monitor Program Data and Controls

This section provides a detailed description of the forms

and related data and controls that are accessible via the

monitor program’s user interface. The forms are organized

as follows:

• main system

• bearing calibration

• compressor control

• motor monitoring

• magnetic bearing monitor

• electronic valve tuning

6.1 Main System

The “General Data Page” allows the user to quickly view

the following major compressor parameters:

• AC input power

• compressor demand

• shaft speed

• suction temperature/pressure

• discharge temperature/pressure

• IGV % open

To view the “General Data Page”, select “Window” →

“Main System” from the menu bar. Table 4 provides a

description of the “General Data Page” parameters.

The “General Data Page” also plots the following

parameters with respect to time:

• chiller control

• system information

• EEPROM settings

• compressor event log

• history data

• trending

• compressor map

• fault captures

• data captures

• evaporating temperature

• condensing temperature

• power input

• shaft speed

•IGV % Open

• demand

The units used to display the temperature readings depend

on the measurement unit set (Metric: ºC; Imperial: ºF). To

verify or change the measurement unit, refer to section 6.3

"Compressor Control" on page 23. The time displayed

corresponds to the PC system time, and is displayed in

HH:MM format. To clear the graphs, click on the “Reset

Graphs” button.

18 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 22

Service Monitor User Manual

Figure 19 General Data Page

Table 4 General Data Page Parameters

Parameter Description

Ts [sat] Saturated suction temperature

Tc [sat] Saturated discharge temperature

3 Phase Power In 3-phase AC input power (mains input)

Shaft Speed Actual shaft speed in RPM

Compressor Demand Requested motor power demand as a percentage of maximum motor

power [kW].

Discharge Pressure The actual discharge gauge pressure at the compressor flange as

measured by the suction pressure transducer.

Discharge Temperature The actual discharge temperature at the compressor flange as

measured by the suction temperature/pressure transducer.

Suction Temperature The actual suction temperatur e at the compresso r flange as measured

by the suction temperature/pressure transducer.

Suction Pressure The actual suction pressure at the compressor flange as measured by

the suction pressure transducer.

IGV % Open % of Inlet guide vane opening, 0.0% means the vanes are at 90º to the

pipe line (Fully closed). 110% means 10º over turned from fully open.

Fault Text Box Displays the compressor’s most recent active critical fault. Refer to

6.3.2 "Compressor Faults/Alarms" for fault details.

Alarm Text Box Displays the compressor’s most recent active alarm. Refer to 6.3.2

"Compressor Faults/Alarms" for alarm details.

Interlock Statu s Displays the status of the interlock: either open or closed.

Danfoss Turbocor Compressors Inc. 19

ECD-00007M Rev. 1

Page 23

Monitor Program Data and Controls

6.2 Bearing Calibration

The “Calibration Data” window allows the user to view and

compare the data of the latest calibration performed with

the latest stored calibration data, thus allowing the user to

verify that the bearing calibration was performed

successfully. It also allows the user to perform a manual

bearing calibration.

To view the “Calibration Data” window: from the menu

bar, select “Advanced”→ “Bearing Calibration” .

NOTE:

Bearing calibration is always automatically performed

during compressor startup.

Figure 20 Bearing Calibration Window

The “Description” column lists the calibration data

parameters. A more detailed description of the calibration

data parameters is provided in Table 5.

The “Latest Check” column shows the calibration data of

the latest calibration performed.

The “Stored Calibration” column shows the calibration data

of the latest saved calibration data.

The “Diff” column shows the difference between the

“Latest Check” value and the “Stored Calibration” value.

Clicking on the “Save Calibration” button stores the data

from the “Latest Check” as the “Stored Calibration” data.

Clicking on the “Save Data To File” button saves the

calibration data displayed on the “Calibration Data” screen

to a .csv file, which may be viewed using a spreadsheet

editor such as Microsoft® Excel.

Clicking on the “Perform Calibration” button, performs a

manual bearing calibration.

Table 5 Calibration Data Details

Data Parameter Description

FRX Min Minimum DC voltage indicating minimum front radial x displacement.

FRX Max Maximum DC voltage indicating maximum front radial x displacement.

FRY Min Minimum DC voltage indicating minimum front radial y displacement.

20 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 24

Service Monitor User Manual

Table 5 Calibration Data Details

Data Parameter Description

FRY Max Maximum DC voltage indicating maximum front radial y displacement.

BRX Min Minimum DC voltage indicating minimum rear radial x displacement.

BRX Max Maximum DC voltage indicating maximum rear radial x displacement.

BRY Min Minimum DC voltage indicating minimum rear radial y displacement.

BRY Max Maximum DC voltage indicating maximum rear radial y displacement.

Ax Min Minimum DC voltage indicating minimum axial displacement.

Ax Max Maximum DC voltage indicating maximum axial displacement.

FRX Gain Gain Formula: Fixed Voltage / (FRX Min Voltage - FRX Max Voltage)

FRX Offset Difference between the x-component of the front radial sensor center and the

x-component of the front touchdown bearing center. Refer to Figure 22.

FRX HW Offset Hardware offset.

FRY Gain Gain Formula: Fixed Voltage / (FRY Min Voltage - FRY Max Voltage)

FRY Offset Difference between the y-component of the front radial sensor center and the

y-component of the front touchdown bearing center. Refer to Figure 22.

FRY HW Offset Hardware offset.

BRX Gain Gain Formula: Fixed Voltage / (BRX Min Voltage - BRX Max Voltage)

BRX Offset Difference b etween the x-com ponent of the re ar r adia l sen sor ce nter a nd th e x-

component of the rear touchdown bearing center. Refer to Figure 22.

BRX HW Offset Hardware offset.

BRY Gain Gain Formula: Fixed Voltage / (BRY Min Voltage - BRY Max Voltage)

BRY Offset Dif fe re nce between the y-compon ent of the re ar r adia l sen sor ce nter and th e y-

component of the rear touchdown bearing center. Refer to Figure 22.

BRY HW Offset Hardware offset.

Ax Gain Gain Formula: Fixed V oltage / (Ax Min Voltage - Ax Max Voltage)

Ax Offset Difference between the axial sensor zero and the touchdown axial center.

Refer to Figure 23.

Ax HW Offset Hardware offset.

Time Stamp Date and time of calibration.

Danfoss Turbocor Compressors Inc. 21

ECD-00007M Rev. 1

Page 25

Monitor Program Data and Controls

Figure 21 Magnetic Bearing Configuration

6.2.1 Bearing Calibration Procedure

For the bearing calibration to be performed:

• The shaft must be de-levitated

• The interlock connection on the Chiller Interface

module must be open

1. Turn OFF the AC input power to the compressor and

wait 3-5 minutes for the capacitors to discharge.

2. Turn ON the AC input power to the compressor.

3. Launch the monitor program. If the monitor program is

already running, close it and open it again.

4. Change the compressor control mode to “Calibration

Mode”. Refer to 6.3 "Compressor Control" on page 23.

NOTE:

In Calibration mode, the compressor prepares itself for

calibration. Any external demand will be blocked from the

system, i.e., any external computer, PLC, building

management system, or automatic control will not be able

to write to the compressor.

Figure 22 Front and Rear Bearing Offset

Figure 23 Axial Bearing Offset

5. From the menu bar, select “Advanced”→ “Bearing

Calibration”. The “Startup Check Calibration Data”

window appears, as shown in Figure 20.

6. Click on “Perform Calibration”. The message “Bearing

Calibration in Progress” appears. Observe if the

compressor makes a distinctive knocking noise; this

confirms the calibration is in progress. Do not click on

“Save Calibration”.

7. Open the “Compressor Event Log” window. From the

menu bar, select “W indow”→ “Event Log”, or click on

the “Event Log” icon located below the menu bar.

Verify that the following message is displayed:

- “Bearing Calibration Performed”

Verify that the following error is not displayed:

- “Bearing Error: Calibration Failed”

If the bearing calibration is reported to have failed, try

to perform the bearing calibration one more time. If the

bearing calibration is still not successful, contact

Turbocor technical support.

8. For the following parameters in the “Startup Check

Calibration Data” window , compare the values between

22 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 26

Service Monitor User Manual

the “Latest Check” and the “Stored Calibration”; see

6.2.2 "Calibration Data Interpretation":

- FRX Gain

- FRY Gain

- BRX Gain

- BRY Gain

- AX Gain

6.2.2 Calibration Data Interpretation

“Gain” Interpretation

• One or more of the gains are zero

Interpretation: There is an electrical fault.

Refer to the Troubleshooting Manual for the appropriate

troubleshooting procedure.

6.3 Compressor Control

• The difference between the “Latest Check” and

“Stored Calibration” is less than 20% of the “Stored

Calibration” value

Interpretation: Bearing calibration was successful.

• The difference between the “Latest Check” and

“Stored Calibration” is greater than 20% of the

“Stored Calibration” value

Interpretation: Excess carbon obstructing the shaft.

Refer to the Troubleshooting Manual for the appropriate

troubleshooting procedure.

“Offset” Interpretation

Only the difference between the “Latest Check” offset and

the “Stored Calibration” offset is important. The “Latest

Check” offset value or the “Stored Calibration” offset value

by itself has no significance. The change between the offset

values signifies a change in the area of shaft orbit.

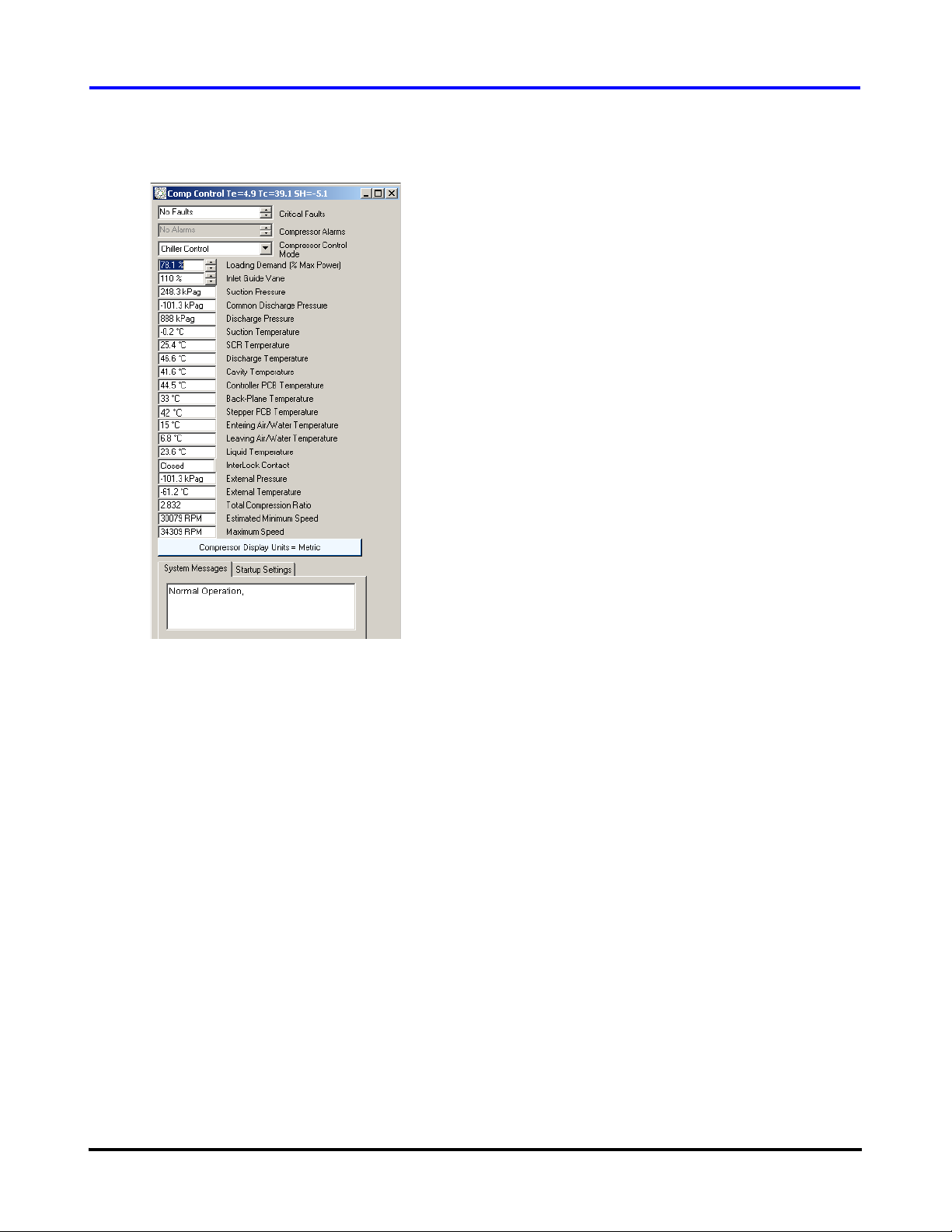

The “Compressor Controller” window allows the user to:

• Control the suction pressure at compressor start-up

• Set the compressor control mode

• Set the compressor loading demand

• Set the inlet guide vane opening

• View the current temperature and pressure sensor

readings

• View the compressor control faults and alarms

• View the sys tem messages

To view the “Compressor Controller” window, click on the

“Compressor Controller Parameters” icon located below the

menu bar. Table 6 provides a description of the compressor

controller parameters.

IMPORTANT:

To change a parameter setting, double-click the variable

field, scroll or type in the new setting, and press Enter. It is

important to press Enter as this causes the user input to be

validated.

Danfoss Turbocor Compressors Inc. 23

ECD-00007M Rev. 1

Page 27

Monitor Program Data and Controls

Figure 24 Compressor Controller Form

24 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 28

Service Monitor User Manual

Table 6 Compressor Controller Parameters

Parameter Description

Te (on title bar) Evaporation Temperature

Tc (on title bar) Condensation Temperature

SH (on title bar) Superheat Calculation [Metric: ºK; Imperial: ºR]

If the absolute superheat value is < 5, then the gas is wet and will

cause the motor to overwork (as wet gas is heavier than dry gas).

Critical Faults Displays the compressor’s most recent active critical fault.

Refer to 6.3.2 "Compressor Faults/Alarms" for furt he r de tails.

Compressor Alarms Displays the compressor’s most recent active critical alarm.

Refer to 6.3.2 "Compressor Faults/Alarms" for furt he r de tails.

Compressor Control Mode Selects the source of demand for the compressor: Calibration, Manual

Control, Analog Input, Modbus Network, or Chiller Control. Refer to

6.3.1 "Compressor Control Modes" for further details.

Loading Demand (% max power) Compressor Demand: requested motor power demand as a

percentage of the maximum motor power [kW].

Inlet Guide Vane % of Inlet guide vane opening, 0.0% means the vanes are at 90º to the

pipe line (Fully closed). 110% means 10º over turned from fully open.

Suction Pressure The actual suction gauge pressure at the compressor flange as

measured by the suction pressure transducer.

Common Discharge Pressure Used when an extra discharge pressure transducer is mounted to a

common discharge line in the case of multiple compressors.

Discharge Pressure The actual discharge gauge pressure at the compressor flange as

measured by the discharge pressure transducer.

Suction Temperature The actual suction temperature at the compressor flange as measured

by the suction temperature/pressure transducer.

SCR Temperature Temperature of the SCR heat sink plate.

Discharge Temperature The actual discharge temperature at the compressor flange as

measured by the discharge temperature/pressure transducer.

Cavity Temperature Temperature of the superheated gas moving past the shaft.

Controller PCB Temperature Temperature of the BMCC circuit board.

Backplane Temperature Temperature of the backplane.

Stepper PCB Temperature Temperature of the serial driver circuit board.

Entering Air/water Temperature Temperature as measured by the 10K thermistor connected to the

terminals marked “ENTRY” on the Chiller Interface module.

Leaving Air/water Temperature Temperature as measured by the 10K thermistor connected to the

terminals marked “LEAVE” on the Chiller Interface module.

Interlock Contact Status of the digital input marked “I/LOCK” on the Chiller Interface

module. Possible values are “OPEN” and “CLOSED”. If condition is

open the compressor will not run.

External Pressure Gauge pressure as measured from a pressure transducer connected

to the terminals marked “SPARE P” on the Chiller Interface module.

External Temperature Temperature as measured from a thermistor connected to the

terminals marked “SPARE T” on the Chiller Interface module.

Danfoss Turbocor Compressors Inc. 25

ECD-00007M Rev. 1

Page 29

Monitor Program Data and Controls

Table 6 Compressor Controller Parameters (Continued)

Parameter Description

Total Compression Ratio Ratio of the absolute discharge pressure and the absolute suction

pressure.

Estimated Minimum Speed Estimated minimum RPM the compressor can run at with a fully open

inlet guide vane.

Maximum Speed Maximum RPM the compressor can run at for a given set of inlet and

outlet conditions.

Compressor Display Units Button Changes the measurement unit used when button is pressed.

The options are:

• Metric Units - kPa, ºC, ºK

• Imperial Units - Psi, ºF, ºR

System Messages Describes the state of the system.

Start-up Settings

- Suction Press Start Limit (% Trip)

Start-up Settings

- Suction Start Press Fault delay

Start-up Settings

- Suction Pressure Delay

(Count down)

Temporary alarm and trip limit for the suction pressure. The limit is set

up as a % of the current suction pressure limit, e.g. if a suction

pressure trip of 270 kPa was set and the suction pressure start limit

was set to 50%, the temporary suction pressure trip limit would be 135

kPa. This temporary limit is only active while the Suction press start

fault delay is timing down.

Time in seconds that the temporary suction pressure alarm / fault limit

should be enabled.

Current count down in seconds. The timer starts to count down once

the shaft starts to rotate.

6.3.1 Compressor Control Modes

Calibration

In Calibration mode, the compressor prepares itself for

calibration. Any external demand will be blocked from the

system, i.e., any external computer, PLC, building

management system, or automatic control will not be able

to control the compressor.

In Calibration mode, the user may only calibrate the

bearings. Refer to section 6.2 "Bearing Calibration" on page

20.

NOTE:

The compressor must be de-levitated, and the Chiller

Interface interlock circuit must be open for the compressor

to be calibrated.

Manual Control

In Manual Control mode, the user:

• Must set the “Loading Demand (% max power)”

parameter from the “Compressor Control” window.

Refer to 6.3 "Compressor Control".

• Must set the “Inlet Guide Vane” (% opening) from

the “Compressor Control” window. Refer to 6.3

"Compressor Control".

• Must set the “Desired Shaft Speed (RPM)”

parameter from the “Magnet Motor Monitoring”

window. Refer to section 6.4 "Motor Monitoring" on

page 28.

• May calibrate the bearings. Refer to section 6.2

"Bearing Calibration" on page 20.

Use Manual Control mode when servicing or

troubleshooting the compressor.

26 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 30

NOTE:

In Manual Control mode, the Chiller Interface interlock

switch has no effect on the compressor state.

Analog Input

The Analog Input mode controls the compressor loading

using an analog demand signal of 0-10 VDC from an

external controller. The variable demand signal corresponds

to the range of 0-100% maximum power available.

NOTE:

The Chiller Interface interlock switch must be closed and

no errors present for the compressor to start up and run.

Modbus Network

In Modbus Network mode, the compressor receives a

demand from an external computer, PLC, or building

management system using the Modbus protocol on a RS232 or RS4-85 communication link.

In Modbus Network mode, the user may only set the

“Loading Demand (% max power)” parameter from the

“Compressor Controller” window. Refer to 6.3

"Compressor Control". All other parameters in the monitor

program may only be viewed.

NOTE:

The Chiller Interface interlock switch must be closed and

no errors present for the compressor to start up and run.

Chiller Control

The Chiller Control mode is fully automatic and controls

the chilled water or air temperature using a temperature

sensor connected directly to the Chiller Interface module.

This mode can also be used to control evaporating

Service Monitor User Manual

temperature which is derived from the suction pressure

measurement.

NOTE:

The Chiller Interface interlock switch must be closed and

no errors present for the compressor to start up and run.

6.3.2 Compressor Faults/Alarms

This section describes the possible “Critical Faults” and

“Compressor Alarms” displayed in the “Compressor

Controller” window. Table 7 provides a description of the

possible cause of the fault/alarm.

If a compressor controller fault/alarm occurs, it is an

indication that the EEPROM fault/alarm limit setting has

been exceeded. Check that the EEPROM fault/alarm limit

settings are adequate for the current compressor load. From

the menu bar, select “Window”→ “Eeprom Settings”, or

click on the “Eeprom Settings” icon located below the

menu bar. Then select the “CC Trip Limits” tab to view the

“Compressor General Fault Limits”, or select the “CC

Alarm Limits” tab to view the “Compressor General Alarm

Limits”. Refer to section 6.9 "EEPROM Settings" on page

39. If the current user access level does not permit viewing

of the EEPROM settings, contact a service technician with a

higher access level

If a fault or alarm occurs, refer to the Troubleshooting

Manual for the appropriate procedure(s) to follow.

NOTE:

A “Compressor Alarm” will slow down the motor, whereas

a “Critical Fault” will trip the motor. A “Compressor

Alarm” occurs when a compressor parameter (e.g.

temperature/pressure) has exceeded its alarm limit setting.

A “Critical Fault” occurs when a compressor parameter has

exceeded its fault limit setting.

Table 7 Compressor Faults and Alarms

Fault / Alarm Possible Cause

Inverter Temperature Fault / Alarm Insufficient motor cooling

Discharge Temperature Fault / Alarm Insufficient charge (not enough gas)

Suction Pressure Fault / Alarm Insufficient charge or insufficient system load

Discharge Pressure Fault / Alarm Faulty condenser

Note: A “Discharge Pressure” fault will lock out the compressor.

The compressor will have to be powered down and restarted.

Danfoss Turbocor Compressors Inc. 27

ECD-00007M Rev. 1

Page 31

Monitor Program Data and Controls

Table 7 Compressor Faults and Alarms (Continued)

Fault / Alarm Possible Cause

3-Phase Over-Current Fault / Alarm Excessive system load (usually due to compressor pumping liquid).

Note: A “3 Phase Over Current” fault will lock out the compressor.

The compressor will have to be powered down and restarted.

Cavity Temperature Fault / Alarm Insufficient motor cooling

Leaving Water Temp Fault / Alarm Insufficient water flow.

Compression Ratio Fault / Alarm Faulty condenser or insufficient load on the evaporator.

BMC Fault Faulty BMCC

Sensor Fault Faulty sensor or faulty BMCC

SCR Temperature Fault / Alarm Insufficient cooling to the SCR plate

Lock Out Fault If any (or a combination of) the alarms listed below occurs more

than 3 times within 30 minutes, a “Lock Out Fault” occurs:

• Inverter temperature alarm

• Cavity temperature alarm

• SCR temperature alarm

Winding Temperature Fault Motor winding temperature has exceeded 155ºC

6.4 Motor Monitoring

6.4.1 Motor Monitoring Overview

The “Variable Speed Permanent Magnet Motor

Monitoring” window allows the user to:

• View the actua l shaft speed, and set the de sired shaft

speed

• View motor parameters such as current, voltage, and

power

• View motor faults and alarms

• View the number of energized motor cooling

solenoids

• View the Soft-Start Controller data

To view the “Variable Speed Permanent Magnet Motor

Monitoring” window, select “Window”→ “Motor” from the

menu bar, or click on the “Motor Monitor” icon located

below the menu bar. Table 8 provides a description of the

motor monitoring parameters.

NOTE:

The measurement unit (metric/imperial) displayed depends

on the measurement unit previously set. To verify or change

the measurement unit, refer to section 6.3 "Compressor

Control" on page 23.

IMPORTANT:

To change a parameter setting, double-click the variable

field, scroll or type in the new setting, and press Enter. It is

important to press Enter as this causes the user input to be

validated.

28 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 32

Service Monitor User Manual

Figure 25 Motor Monitoring Form

Table 8 Motor Monitoring Parameters

Parameter Description

General Motor Data:

Actual Shaft Speed (RPM) Actual shaft speed in RPM.

Desired Shaft Speed (RPM) Commanding shaft speed in RPM (always higher than the actual shaft

speed).

Inverter Side Motor Amps = Id Current output from the IGBT Inverter to the motor.

Torque-generating current component.

Inverter Side Motor Amps = Iq Current output from the IGBT Inverter to the motor.

Flux-generating current component.

Earth Leakage Current Motor current that leaks to ground due to an insulation fault.

Calculated Total Power Calculated 3-phase input power in kW.

Requested Motor Power Requested motor power in kW. Value is a function of the compressor

model designation and demand percentage. The demand percentage

is set through the “Loading Demand (% max power)” in the

“Compressor Controller” window. Refer to section 6.3 "Compressor

Control" on page 23.

Inverter Temperature Inverter temperature as measured by thermistor mounted under the

IGBT Inverter.

Back EMF Value Internal motor voltage

Fault Code Hexadecimal motor fault code from the bearing motor control.

Alarm Code Hexadecimal motor alarm code from the bearing motor control.

Danfoss Turbocor Compressors Inc. 29

ECD-00007M Rev. 1

Page 33

Monitor Program Data and Controls

Table 8 Motor Monitoring Parameters (Continued)

Parameter Description

Fault Text Box Displays the motor’s most recent active fault.

Refer to 6.4.2 "Motor Faults / Alarms" for alarm details.

Alarm Text Box Displays the motor’s most recent active alarm.

Refer to 6.4.2 "Motor Faults / Alarms" for fault details.

Motor Cooling:

Number of solenoids energized Indicates the number of motor-cooling solen oids that are open.

Soft Start Data:

Three-Phase Mains Voltage Calculated three phase mains voltage.

Three-Phase Current Calculated three phase mains current.

DC Bus Regulation Percentage of maximum DC Bus output voltage.

DC Bus Volt age DC Bus Voltage as measured at the inverter

Graph: Amps Id & Iq Graphical representation of the torque-generating current (Id) and the

flux-generating current (Iq) versus time.

Under normal conditions, when the motor is driving, Iq should

decrease to at least -1 during compressor start-up, an d the “Amps - Id

& Iq” graph should look like:

The turquoise line represents Id, and the red line represents Iq.

Notice that the red line (Iq) dips to negative values. If Iq does not

decrease to negative values during compressor start-up, then there is

no motor drive.

Id should stabilize towards the torque value;

Iq should stabilize towards zero at medium motor speeds, and

increase with positive values at high motor speeds.

6.4.2 Motor Faults / Alarms

This section describes the possible faults displayed in the

“Variable Speed Permanent Magnet Motor Monitoring”

30 Danfoss Turbocor Compressors Inc.

window. Table 9 provides a description of the possible

cause of the fault/alarm. If a fault or alarm occurs, refer to

the Troubleshooting Manual for the appropriate

procedure(s) to follow.

ECD-00007M Rev. 1

Page 34

NOTE:

A motor alarm will slow down the motor, whereas a motor

fault will trip the motor.

Table 9 Motor Faults and Alarms

Fault / Alarm Possible Cause

Service Monitor User Manual

Motor Single Phase Over-Current

Detected

DC Bus Over-Voltage Detected DC bus voltage exceeds acceptable voltage range.

Motor High Current Warning The AC input voltage is too low, or the compressor is overloaded

Motor High Current Fault The AC input voltage is too low, or the compressor is overloaded

Inverter Error Signal Faulty IGBT Inverter

Over-Current During S tartup - Rotor

May Be Locked

Bearing Warning Active The shaft is out of orbit, the compressor communication is affected

Bearing Error Active Shaft is blocked or the bearings are faulty.

Output voltage on the motor Faulty IGBT Inverter.

Soft Start Error Detected Faulty Soft Start Controller.

24Vdc Fault Faulty 24VDC supply.

Motor back EMF is low. Motor magnet strength is weak, possibly caused by insufficient

EEPROM checksum error. Faulty BMCC.

Generator mode active Compressor is coasting down due to loss of power supply.

SCR phase loss Excessive imbalance may exist between the phases.

Excess liquid at the suction valve, thus causing the motor to

overwork and generate too much current.

(due to wet gas or exceeded compressor capacity).

(due to wet gas or exceeded compressor capacity).

Too m uch cur rent output to the shaft (rotor) during compressor

start-up.

by noise, or there is excessive compressor load.

motor cooling.

6.5 Magnetic Bearing Monitoring

6.5.1 Bearing Monitoring Overview

The “Magnetic Bearing Monitoring” window allows the

user to:

• Change the shaft levitation state

• View the shaft unbalance percentage

• View the current required to counteract the shaft

unbalance

• View bearing faults and alarms

Danfoss Turbocor Compressors Inc. 31

ECD-00007M Rev. 1

T o view the “Magnetic Bearing Monitoring” window , select

“Window”→ “Bearing” from the menu bar, or click on the

“Magnetic Bearings” icon located below the menu bar.

Table 10 provides a description of the bearing monitorin g

parameters.

IMPORTANT:

To change a parameter setting, double-click the variable

field, scroll or type in the new setting, and press Enter. It is

important to press Enter as this causes the user input to be

validated.

Page 35

Monitor Program Data and Controls

Figure 26 Magnetic Bearing Monitoring Form

Table 10 Bearing Monitoring Parameters

Parameter Description

Shaft Levitation State Shaft state control.

When in the “Shaft Levitated” st ate, click the up ar row to change to the

“Shaft De-Levitated” state

When in the “Shaft De-Levitated” st ate, click the down ar row to change

to the “Shaft Levitated” state

Note: Shaft state may only be changed while in Manual Control Mode.

Refer to section 6.3 "Compressor Control" on page 23.

Axial Unbalance % Percentage unbalance of total allowable axial displacement.

Front Radial Unbalance % Percentage unbalance of total allowable front radial displaceme n t.

Rear Radial Unbalance % Percentage unbalance of total allowable rear radial displacement.

Axial Bearing Force (Amps) Current required to counteract axial unbalance force.

Front X Bearing Force (Amps) Current required to counteract front x unbalance force.

Front Y Bearing Force (Amps) Cur rent required to counteract front y unbalance force.

Rear X Bearing Force (Amps) Current required to counteract rear x unbalance force.

Rear Y Bearing Force (Amps) Current required to counteract rear y unbalance force.

Fault Code Hexadecimal bearing fault code from the bearing motor control.

32 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 36

Service Monitor User Manual

Table 10 Bearing Monitoring Parameters (Continued)

Parameter Description

Alarm Code Hexadecimal bearing alarm code from the bearing motor control.

Fault Text Box Displays the most recent active bearing fault.

Refer to 6.5.2 "Bearing Faults" for fault details.

Graph Graphical representation of the front radial orbit of the shaft.

Percentile shown at the bottom right-hand corner in dicates the average

front orbit displacement.

Note: The domain of the graph shows half of the allowable area of

shaft displacement. However, if the shaft orbit is shown to exceed 500

units in any direction, then there is excessive shaft vibration, possibly

caused by a surge of gas flow.

6.5.2 Bearing Faults

This section describes the possible faults displayed in the

“Magnetic Bearing Monitoring” window. Table 11 provides

a description of the possible cause of the fault. If a fault

occurs, refer to the Troubleshooting Manual for the

appropriate procedure(s) to follow.

Table 11 Bearing Faults

Fault Possible Cause

Calibration Failed Manual calibration performed on compressor failed.

Startup Check Failed Automatic calibration during compressor startup failed.

Axial Displacement Fault Current force exerted on the axial bearing exceeds 60% of the

calibration value.

Front Radial Displacement Fault Current force exerted on the front radial bearing exceeds 60% of

the calibration value.

Rear Radial Displacement Fault Current force exerted on the rear radial bearing exceeds 60% of the

calibration value.

Axial Static Load Current force exerted on the axial bearing exceeds 2.5 amps.

Front Radial Static Load Current force exerted on the front radial bearing exceeds 2.5 amps.

Back Radial Static Load Current force exerted on the back ra dial bearing exceed s 2.5 amp s.

6.6 Electronic Valve Data / Tuning

The “Electronic Valve Data / Tuning” window allows the

user to:

• Control the electronic expansion valve stepper

motors

• Control the analog output

To view the “Electronic Valve Data / Tuning” window,

select “Window”→ “Expansion V alves” from the menu bar ,

or click on the “Expansion Valves” icon located below the

menu bar.

To access the stepper motor control settings, select the

“Stepper Motor” tab. The “EXV#1 Control Settings”

controls the stepper motor connected to “EXV1” on the

Danfoss Turbocor Compressors Inc. 33

ECD-00007M Rev. 1

Page 37

Monitor Program Data and Controls

Chiller Interface module. Similarly, the “EXV#2 Control

Settings” controls the stepper motor connected to “EXV2”

on the Chiller Interface module. Table 12 describes the

stepper motor control parameters.

To access the analog output controls, select the “Analogue

Output” tab. The “Analog Output Controls” controls the

output labeled “Analog” on the Chiller Interface module.

Table 13 describes the analog output control parameters.

NOTE:

The measurement unit (metric/imperial) displayed depends

on the measurement unit previously set. To verify or change

the measurement unit, refer to section 6.3 "Compressor

Control" on page 23.

IMPORTANT:

To change a parameter setting, double-click the variable

field, scroll or type in the new setting, and press Enter. It is

important to press Enter as this causes the user input to be

validated.

Figure 27 Electronic Valve Data / Tuning Form

34 Danfoss Turbocor Compressors Inc.

ECD-00007M Rev. 1

Page 38

Service Monitor User Manual

Table 12 Electronic Valve Data / Tuning Parameters (Stepper Motors)

Parameter Description

Control Mode Selects which control variable will be maintained by the stepper motor

output. The options are:

1. Superheat control using the compressor flange temperature and

pressure (this mode is not recommended as the temperatur e at the

compressor flange is influenced by external factors).

2. Superheat control using the compressor flange pressure and a

10K thermistor that is connected to the terminals labeled “ENTR Y”

on the Chiller Interface module.

3. Superheat control using the compressor flange pressure and a

10K thermistor that is connected to the terminals labeled “LIQT” on

the Chiller Interface module.

4. Superheat control using an external temperature and pressure

sensor connected to the terminals labeled “SPARE T” & “SPARE

P” on the Chiller Interface module.

5. Liquid Level 1 control usin g a lev el sen so r co nn ec te d to the

terminals on the Chiller Interface module labeled “LIQ LEV1”.

6. Liquid Level 2 control usin g a lev el sen so r co nn ec te d to the

terminals on the Chiller Interface module labeled “LIQ LEV2”.

7. Load Balance control uses the compressor’s own internal control

algorithm to determine the best mix of speed control, inlet guide

vane opening and load balance valve opening.

Auto/Manual In automatic mode the compressor has complete control over the

stepper motor output. In Manual mode the user is able to enter the

valve position.

Process Value Value of the controlled variable selected from the Control Mode.

Valve % Open Ratio of the actual number of steps sent to the stepper motor over the

maximum number of steps the motor is allowed to drive.

Stepper Startup % Percentage of maximum steps sent to the motor on start of the

compressor. The stepper motor will hold at this position until the

stepper start delay timer has expired.

Stepper Start Position Delay Amount of time from compressor start to hold the number of step s sent

to the motor at the stepper startup %. Value is in seconds and starts to

count down when the drive enables.

Stepper Control Setpoint Desired value of the controlled variable.

Stepper Control Loop Speed Reaction time of the control loop to a process error.

Stepper Minimum Close % The minimum close position for the valve while the compressor is

spinning.

Maximum Step Count Number of steps from fully closed to fully open for the installed stepper

motor driven device.

Graph Displays the “Process Value” parameter with respect to time. The time

corresponds to the PC system time, and is displayed in HH:MM format.

Danfoss Turbocor Compressors Inc. 35

ECD-00007M Rev. 1

Page 39

Monitor Program Data and Controls

Table 13 Electronic Valve Data / Tuning Parameters (Analog Output)

Parameter Description

Control Mode Selects which control variable will be maintained by the 0 -10 VDC

output labeled “ANALOG” on the Chiller Interface module.

The options are:

• Load Balance Valve

• Discharge Pressure

• Inlet Guide Vane %

• Superheat – Flange TP

• Superheat – FlangeP, EWT

• Superheat – FlangeP, LIQT

• Suction Pressure

•Leaving Temp

• Entering Temp

•Liquid Temp

Auto/Manual Selects the compressor control mode. In automatic mode the

compressor has complete control over the stepper motor output. In

Manual mode the user is able to enter the valve position.

Analog Output % Actual percentage of the maximum voltage sent to the output.

Analog Output Starting % Percentage of maximum voltage sent to the terminals on start of the

compressor. The analog output will hold at this position until st art delay

timer has expired.

Analog Output Start Delay Amount of time from compressor start to hold the volta ge at the star tup

percentage. Value is in seconds and starts to count down when the

drive enables.

Analog Setpoint Desired value of the controlled variable.

Analog Proportional Gain Controller Proportional Gain

Analog Integral Gain Controller Integral Gain

Analog Derivative Gain Controller Derivative Gain

Direct Acting/ Reverse Acting Control action.

Direct Acting: output increases as process variable increases.

Reverse Acting: output decreases as process variable increases.

Minimum Analog Output The minimum voltage output while the compressor is spinning.

Process Variable Value of the controlled variable.

Process Error Difference between the analog setpoint and the process variable.

Process Graph Plots the process variable (selected from the Control Mode) versus

time. Time is the PC system time, and is displayed in HH:MM format.

Output Graph Plots the percentage of the maximum o utput voltage versu s time. T ime

is the PC system time, and is displayed in HH:MM format.

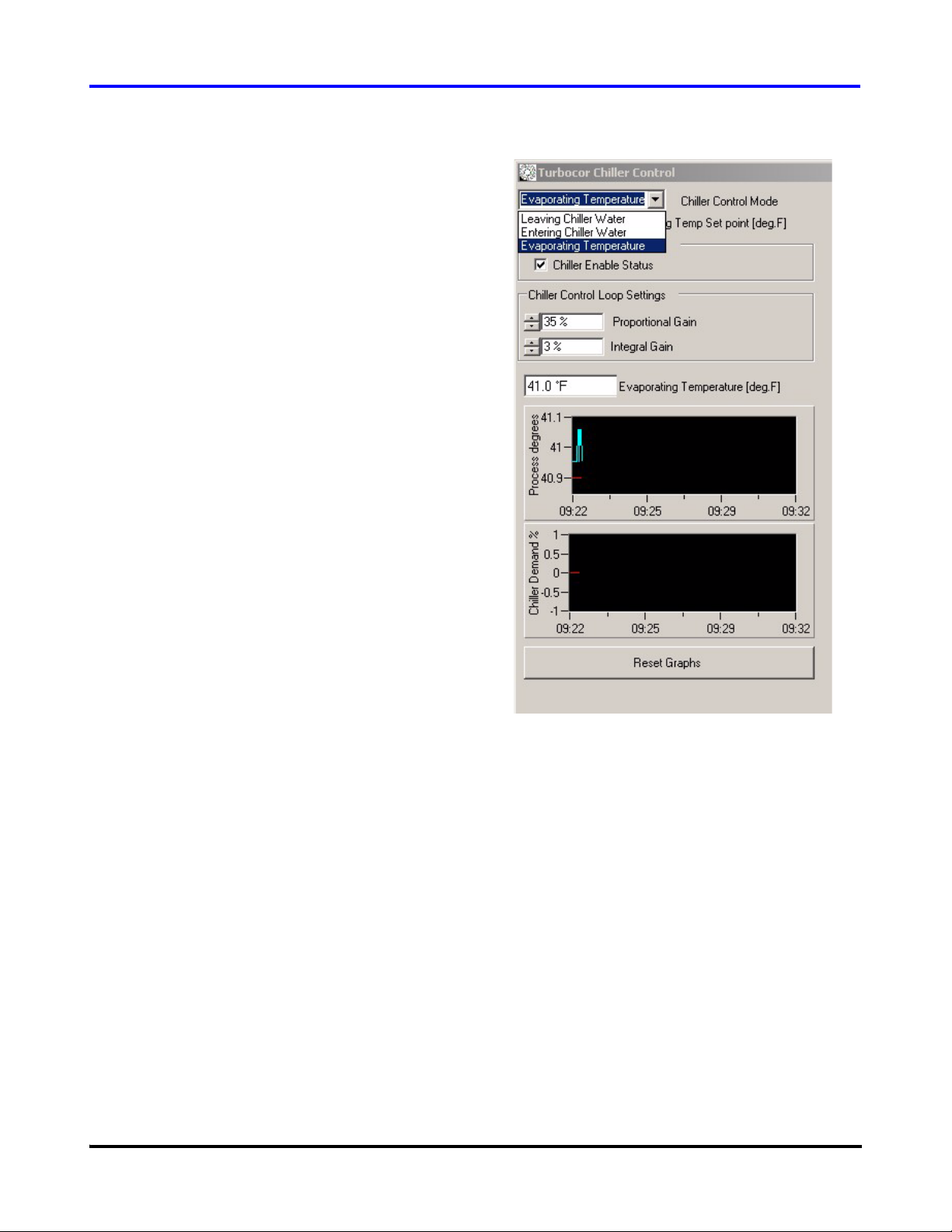

6.7 Chiller Control

The “Chiller Control” window allows the user to control

one of the following:

• Leaving chiller water or air temperature

36 Danfoss Turbocor Compressors Inc.

• Entering chiller water or air temperature

• Evaporating (saturated suction) temperature

ECD-00007M Rev. 1

Page 40

To view the “Chiller Control” window, select “Window”→

“Chiller Control” from the menu bar, or click on the

“Chiller Control” icon located below the menu bar. T able 14

provides details about the chiller controller parameters.

NOTE:

The measurement unit (metric/imperial) displayed depends

on the measurement unit previously set. To verify or change

the measurement unit, refer to section 6.3 "Compressor

Control" on page 23.

Service Monitor User Manual

IMPORTANT:

To change a parameter setting, double-click the variable

field, scroll or type in the new setting, and press Enter. It is

important to press Enter as this causes the user input to be

validated.

Figure 28 Chiller Control Form

Danfoss Turbocor Compressors Inc. 37

ECD-00007M Rev. 1

Page 41

Monitor Program Data and Controls

Table 14 Chiller Controller Parameters

Parameter Description