Page 1

MAKING MODERN LIVING POSSIBLE

Installation Guide

Danfoss Turbocor

www.danfoss.com/drives

Page 2

Page 3

Contents Installation Guide

Contents

1 Introduction

1.1 Product Overview

1.2 Purpose of the Manual

1.3 Product Overview

1.4 Internal Controller Functions

2 Safety

2.1 Safety Symbols

3 Installation

3.1 Planning the Installation Site

3.2 Pre-Installation Check List

3.3 Mechanical Installation

3.3.1 Cooling 6

3.3.1.1 Refrigerant Cooling 6

3.3.2 Lifting 7

3.3.3 Wall Mounting - IP21 (NEMA 1) Units 7

3.4 Electrical Installation

3

3

4

4

4

5

5

6

6

6

6

7

3.4.1 General Requirements 7

3.4.2 Grounding Requirements 10

3.4.2.1 Leakage Current (>3.5 mA) 10

3.4.2.2 Grounding IP21 Enclosures 11

3.4.3 Motor Connection 11

3.4.3.1 Terminal Locations 12

3.4.4 Motor Cable 13

3.4.5 Motor Rotation Check 13

3.4.6 AC Mains Connection 13

3.4.7 DC-Link Connection 13

3.5 Control Wiring Connection

3.5.1 Access 14

3.5.2 Using Screened Control Cables 14

3.5.3 Grounding of Screened Control Cables 14

3.5.4 Control Terminal Types 15

3.5.5 Wiring to Control Terminals 16

3.6 Serial Communication

14

16

4 Start Up and Commissioning

4.1 Pre-start

4.2 Applying Power

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 1

17

17

18

Page 4

Contents Danfoss Turbocor

5 Specifications

5.1 Power-dependent Specifications

5.2 General Technical Data

5.3 Fuse Tables

5.3.1 Protection 22

5.3.2 Fuse Selection 22

5.3.3 Short Circuit Current Rating (SCCR) 23

5.3.4 Connection Tightening Torques 23

Index

19

19

20

22

24

2 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 5

1

15

14

8

9

12

13 (IP 20/Chassis)

13

(IP 21/54

NEMA 1/12)

11

10

16

130BC252.11

130BC301.11

1

2

3

4

5

6

7

8

9

10

11

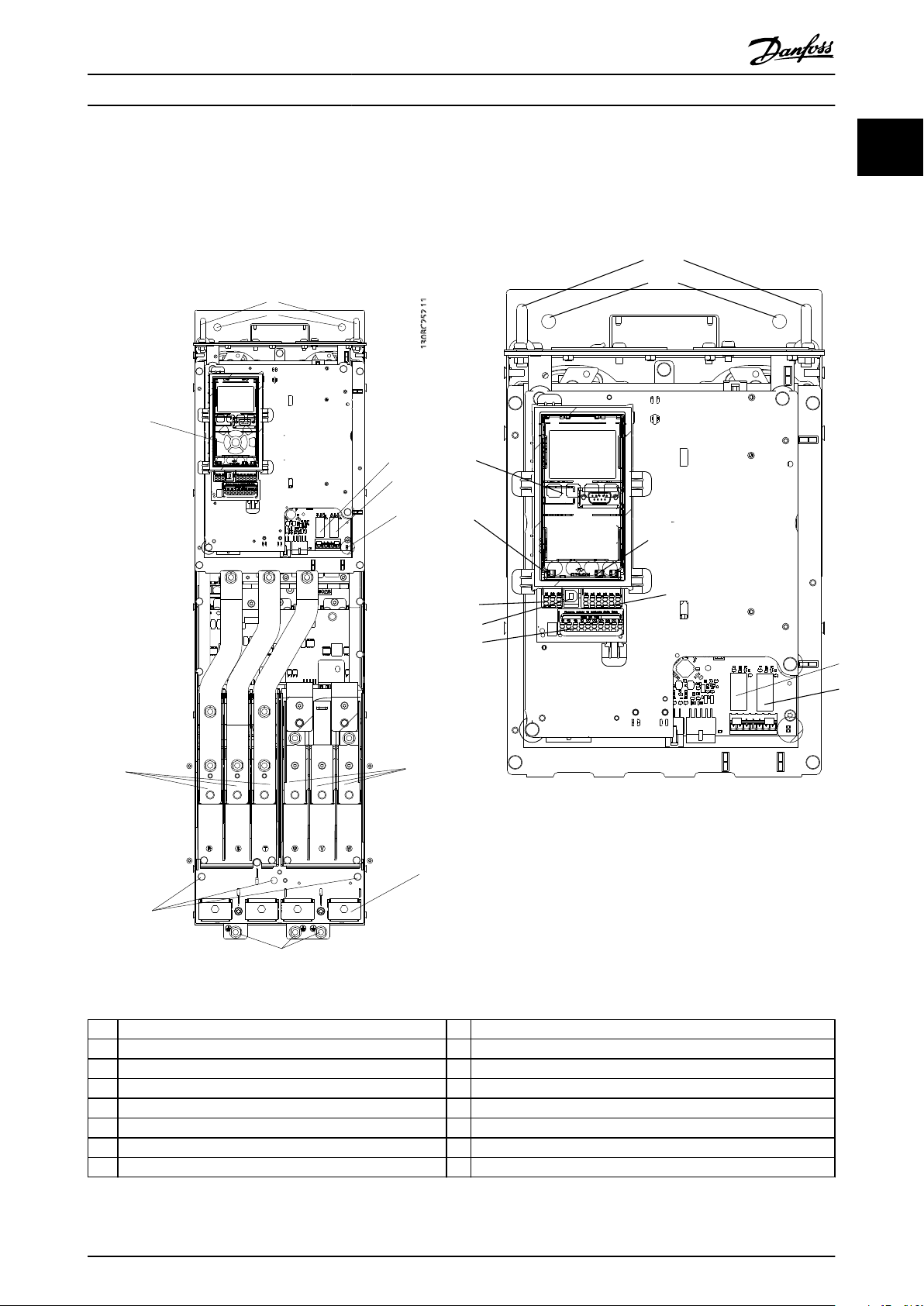

Introduction

1 Introduction

1.1 Product Overview

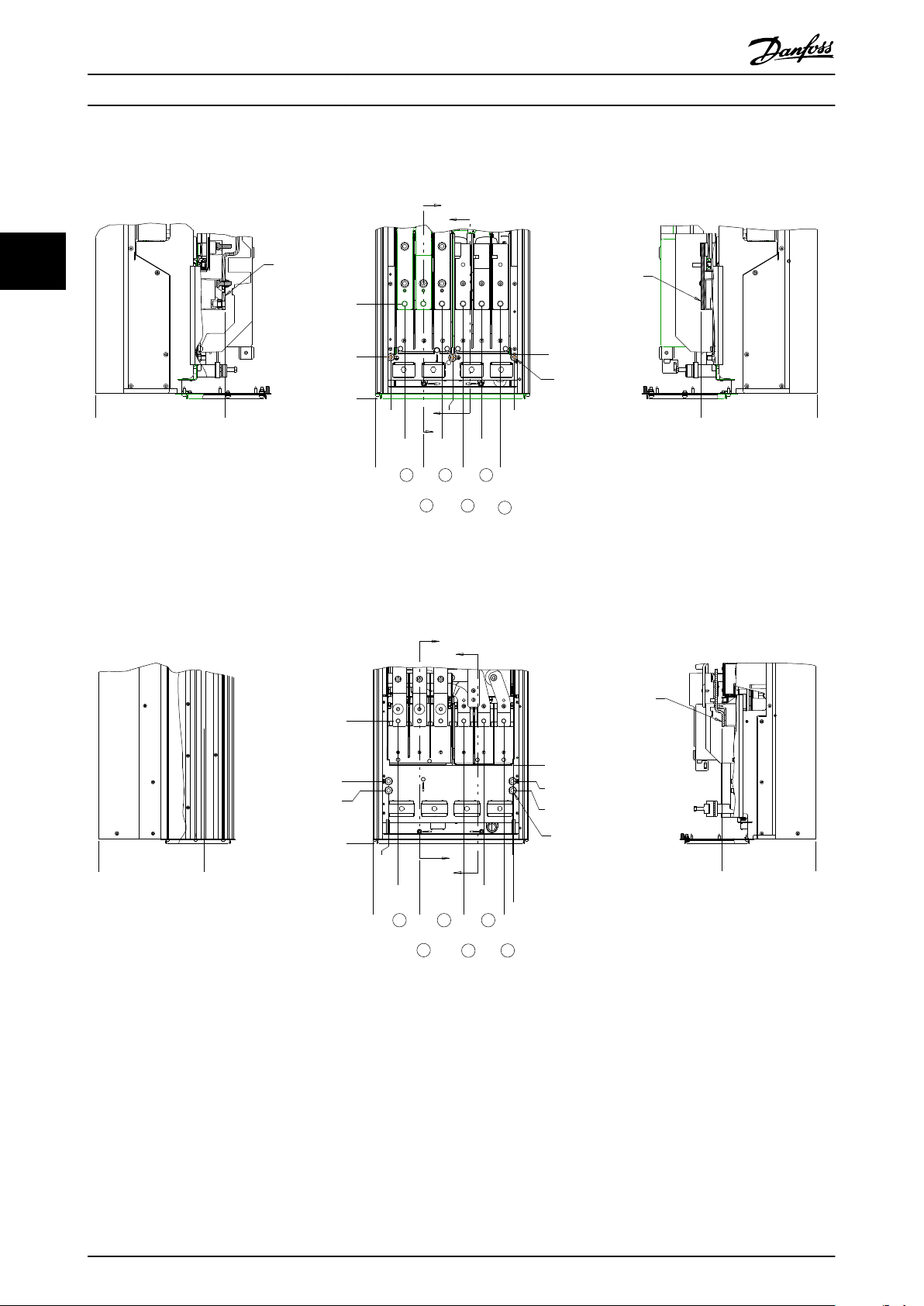

1.1.1 Interior Views

Installation Guide

1

1

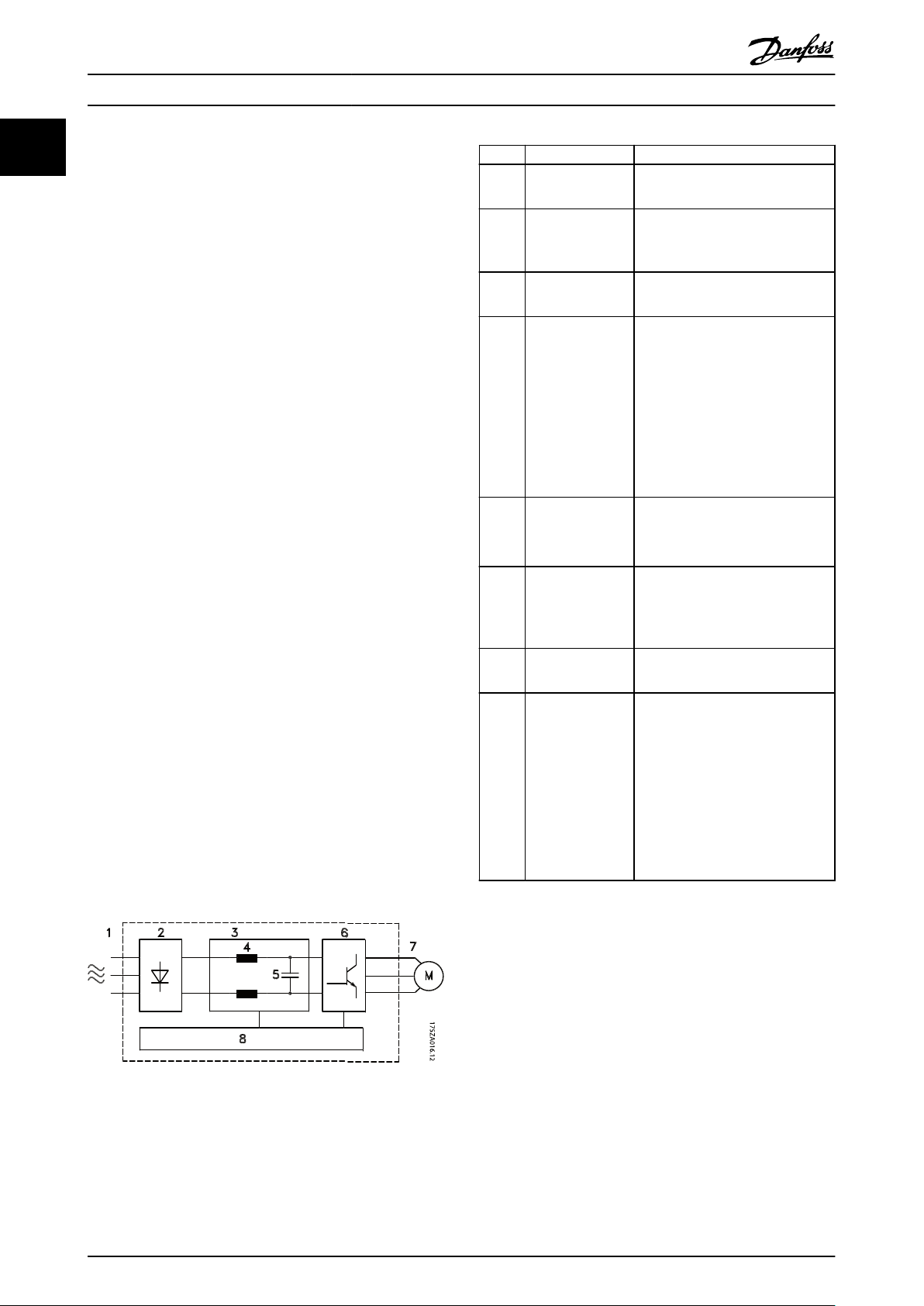

Illustration 1.1 D1 Interior Components

LCP (Local Control Panel) 9 Relay 2 (04, 05, 06)

1

2 RS-485 serial bus connector 10 Lifting ring

3 Digital I/O and 24 V power supply 11 Mounting slot

4 Analog I/O connector 12 Cable clamp (PE)

5 USB connector 13 Earth (ground)

6 Serial bus terminal switch 14 Motor output terminals 96 (U), 97 (V), 98 (W)

7 Analog switches (A53), (A54) 15 Mains input terminals 91 (L1), 92 (L2), 93 (L3)

8 Relay 1 (01, 02, 03) 16 TB5 (IP21 only). Terminal block for anti-condensation heater

Table 1.1 Legend to Illustration 1.1 and Illustration 1.2

Illustration 1.2 Close-up View: LCP and Control Functions

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 3

Page 6

Introduction Danfoss Turbocor

1

1.2 Purpose of the Manual

This manual provides detailed information for the installation and start up of the frequency converter.

Chapter 3 Installation provides requirements for mechanical

and electrical installation, including:

Input

•

Motor

•

Control wiring

•

Serial communications wiring

•

Control terminal functions

•

VLT® is a registered trademark.

1.3 Product Overview

A frequency converter is an electronic motor controller

that converts DC into a variable AC waveform output. The

frequency and voltage of the output are regulated to

control the motor speed or torque. The frequency

converter can vary the speed of the motor in response to

remote commands from external controllers.

The frequency converter offers many control, monitoring

and efficiency functions such as

monitoring the system and motor status

•

Issuing warnings or alarms for fault conditions

•

starting and stopping the motor

•

optimising energy efficiency

•

Operation and monitoring functions are available as status

indications to an outside control system or serial communication network.

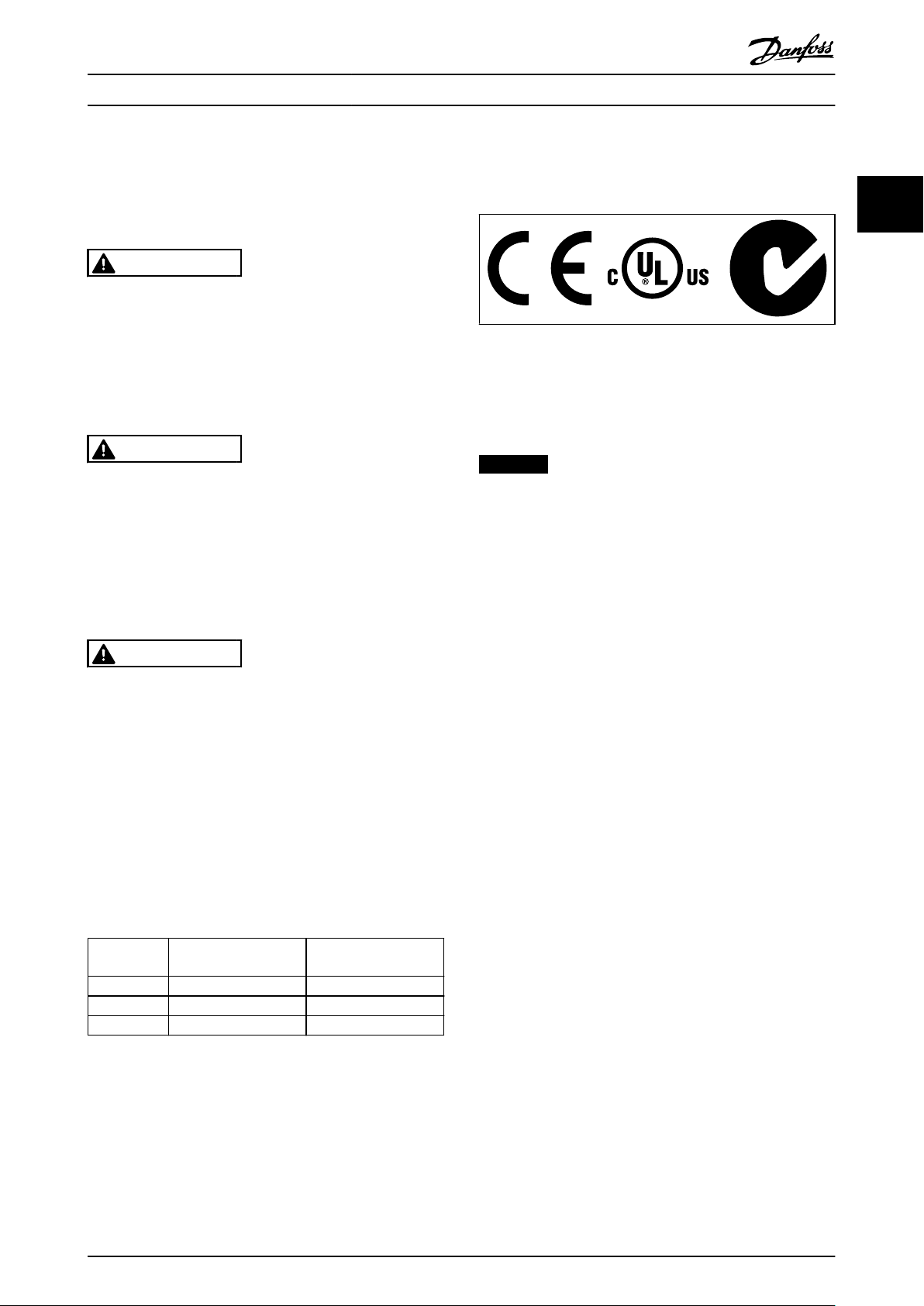

1.4

Internal Controller Functions

Illustration 1.3 is a block diagram of the frequency

converter's internal components.

Area Title Functions

3-phase AC mains supply to the

1 Mains input

2 Rectifier

3 DC-bus

4 DC reactors

5 Capacitor bank

6 Inverter

7 Output to motor

8 Control circuitry

Table 1.2 Legend to Illustration 1.3

•

frequency converter

The rectifier bridge converts the

•

AC input to DC current to

supply inverter power.

Intermediate DC-bus circuit

•

handles the DC current.

Filter the intermediate DC circuit

•

voltage.

Prove line transient protection.

•

Reduce RMS current.

•

Raise the power factor reflected

•

back to the line.

Reduce harmonics on the AC

•

input.

Stores the DC power.

•

Provides ride-through protection

•

for short power losses.

Converts the DC into a

•

controlled PWM AC waveform

for a controlled variable output

to the motor.

Regulated 3-phase output

•

power to the motor

Input power, internal processing,

•

output, and motor current are

monitored to provide efficient

operation and control.

User interface and external

•

commands are monitored and

performed.

Status output and control can

•

be provided.

Illustration 1.3 Frequency Converter Block Diagram

4 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 7

Safety

Installation Guide

2 Safety

2.1 Safety Symbols

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input power. Qualified personnel

only should perform installation, start up, and

maintenance. Failure to perform installation, start up,

and maintenance by qualified personnel could result in

death or serious injury.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

the motor may start at any time. The frequency

converter, motor, and any driven equipment must be in

operational readiness. Failure to be in operational

readiness when the frequency converter is connected to

AC mains could result in death, serious injury,

equipment, or property damage.

2 2

Table 2.2 Approvals

The frequency converter complies with UL508C thermal

memory retention requirements. For more information,

refer to the section Motor Thermal Protection in the

product specific design guide.

NOTICE

Imposed limitations on the output frequency

(due to export control regulations):

From software version 6.72 onwards, the output

frequency of the frequency converter is limited to 590

Hz. Software versions 6x.xx also limit the maximum

output frequency to 590 Hz, but these versions cannot

be flashed, that is, neither downgraded nor upgraded.

WARNING

DISCHARGE TIME

Frequency converters contain DC-link capacitors that can

remain charged even when the frequency converter is

not powered. To avoid electrical hazards, disconnect AC

mains, any permanent magnet type motors, and any

remote DC-link power supplies, including battery backups, UPS, and DC-link connections to other frequency

converters. Wait for the capacitors to fully discharge

before performing any service or repair work. The

amount of wait time is listed in the Discharge Time table.

Failure to wait the specified time after power has been

removed before doing service or repair could result in

death or serious injury.

Voltage [V] Power range [kW] Minimum waiting time

(minutes)

3x400 110-315 20

3x460 110-315 20

3x575 110-315 20

Table 2.1 Discharge Time

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 5

Page 8

Installation

Danfoss Turbocor

3 Installation

3.1 Planning the Installation Site

Ensure that frequency converter output current

33

NOTICE

Before performing the installation it is important to plan

the installation of the frequency converter. Neglecting

this may result in extra work during and after installation.

Select the best possible operation site by considering

the following (see details on the following pages and

the respective Design Guides):

Ambient operating temperature

•

Installation method

•

How to cool the unit

•

Position of the frequency converter

•

Cable routing

•

Ensure the power source supplies the correct

•

voltage and necessary current

Ensure that the motor current rating is within the

•

maximum current from the frequency converter

If the frequency converter is without built-in

•

fuses, ensure that the external fuses are rated

correctly

Voltage [V] Altitude restrictions

380-500 At altitudes above 3,000 m, contact Danfoss

regarding PELV

525-690 At altitudes above 2,000 m, contact Danfoss

regarding PELV

Table 3.1 Installation in High Altitudes

3.2

Pre-Installation Check List

Before unpacking the frequency converter, ensure

•

the packaging is intact. If any damage has

occurred, immediately contact the shipping

company to claim the damage.

Before unpacking the frequency converter, locate

•

it as close as possible to the final installation site

Compare the model number on the nameplate to

•

what was ordered to verify the proper equipment

Ensure each of the following are rated for the

•

same voltage:

Mains (power)

•

Frequency converter

•

Motor

•

•

rating is equal to or greater than motor full load

current for peak motor performance

Motor size and frequency converter

•

power must match for proper overload

protection

3.3 Mechanical Installation

3.3.1 Cooling

Top and bottom clearance for air cooling must be

•

provided. Generally, 225 mm (9 in) is required.

Improper mounting can result in over heating

•

and reduced performance

NOTICE

A door fan(s) is required on the enclosure to remove the

heat not contained in the backchannel of the frequency

converters and any additional losses generated by other

components inside the enclosure. The total required air

flow must be calculated so that the appropriate fans can

be selected.

Airflow

The necessary airflow over the heat sink must be secured.

The flow rate is shown in Table 3.2.

Frame Door fan/top fan Heat sink fan

D1h

D2h

Table 3.2 Airflow

3.3.1.1

The Danfoss Turbocor frequency converters are equipped

with refrigerant cooling.

The refrigerant inlet is on the top of the frequency

converter to the left.

The refrigerant outlet is on the top of the frequency

converters to the right.

Dimensions

Material COPPER ALLOY 122, ASTM B-75, annealed

Nominal operating

pressure

Maximum working

pressure

Table 3.3 Tubing Specifications

102 m3/hr (60 CFM) 420 m3/hr (250 CFM)

204 m3/hr (120 CFM) 840 m3/hr (500 CFM)

Refrigerant Cooling

3/8 inch OD X 0.049 inch wall thk

10 bar/145 psi

12 bar/174 psi

6 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 9

Installation

Installation Guide

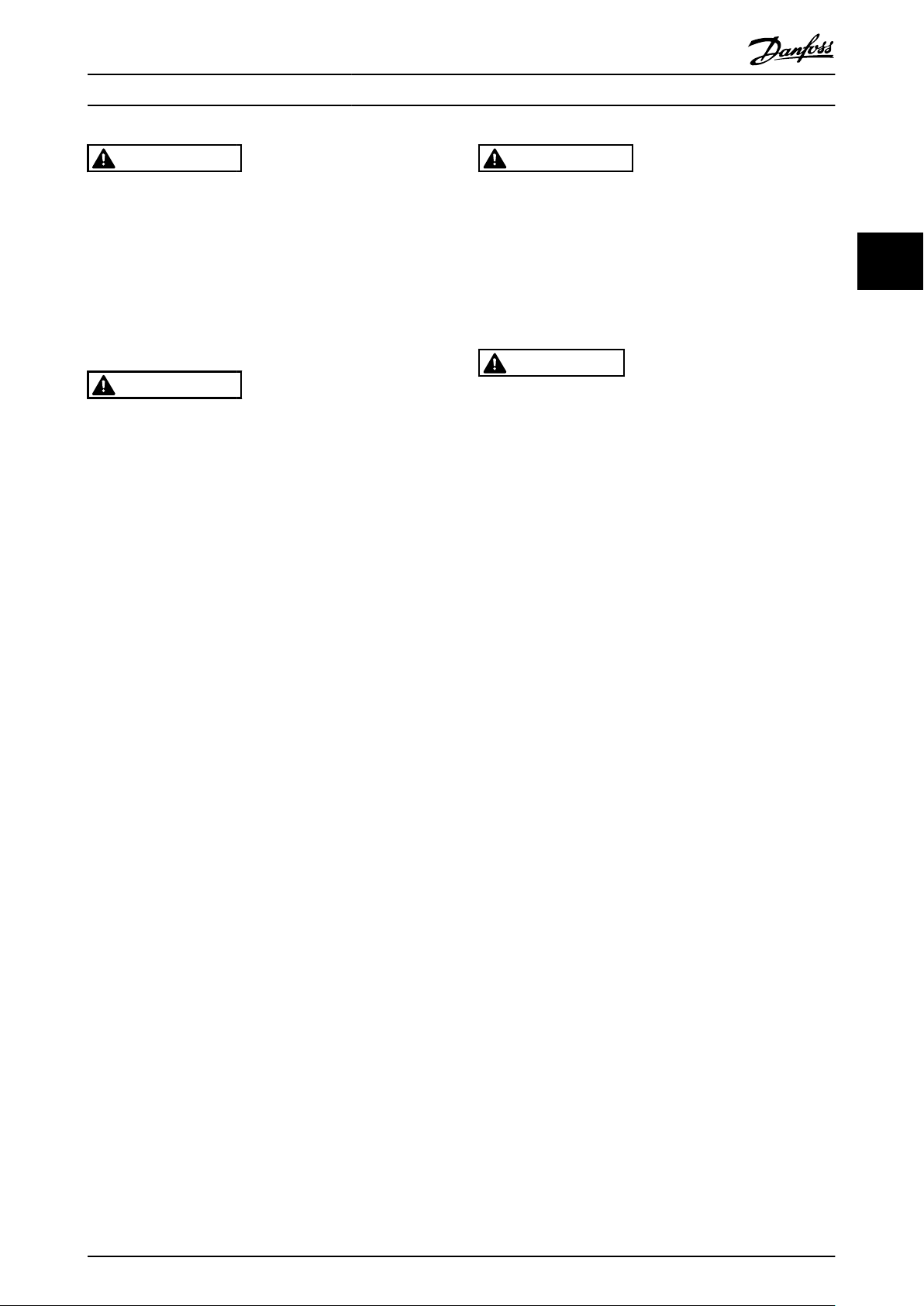

WARNING

CONDENSATION

Condensation must not be allowed to form on the inside

of the frequency converter. The flow of refrigerant must

be controlled in a way that ensures that the temperature

of the internal heatsink stays above the dew point.

Failure to control condensation will result in damage to

the frequency converter.

3.3.2 Lifting

WARNING

RISK OF INJURY OR DEATH

The lifting bar must be able to handle the weight of the

frequency converter to ensure that it will not break

during lifting.

See chapter 5.1 Power-dependent Specifications

•

for the weight of the different enclosure types.

Maximum diameter for bar is 2.5 cm (1 inch).

•

The angle from the top of the frequency

•

converter to the lifting cable should be 60° or

greater.

Failure to follow recommendations could result in death

or serious injury.

WARNING

EQUIPMENT HAZARD!

Rotating shafts and electrical equipment can be

hazardous. All electrical work must conform to national

and local electrical codes. It is strongly recommended

that installation, start up, and maintenance be

performed only by trained and qualified personnel.

Failure to follow these guidelines could result in death or

serious injury.

CAUTION

WIRING ISOLATION!

Run input power, motor wiring and control wiring in

three separate metallic conduits or use separated

shielded cable for high frequency noise isolation. Failure

to isolate power, motor and control wiring could result

in less than optimum frequency converter and associated

equipment performance.

3 3

Wall Mounting - IP21 (NEMA 1) Units

3.3.3

Consider the following before selecting the final installation site:

Free space for cooling

•

Access to open the door

•

Cable entry from the bottom

•

3.4

Electrical Installation

3.4.1 General Requirements

This section contains detailed instructions for wiring the

frequency converter. The following tasks are described:

Wiring the motor to the frequency converter

•

output terminals

Wiring the AC mains to the frequency converter

•

input terminals

Connecting control and serial communication

•

wiring

After power has been applied, checking input

•

and motor power

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 7

Page 10

230 VAC

50/60 Hz

230 VAC

50/60 Hz

TB6 Contactor

TB5

R1

1

2

Brake Temp

(NC)

Anti-condensation heater (optional)

(optional)

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24 V OUT)

13 (+24 V OUT)

18 (D IN)

20 (COM D IN)

15 mA

200 mA

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

0/4-20 mA

03

+10 VDC

0 VDC - 10 VDC

0/4-20 mA

24 VDC

02

01

05

04

06

240 VAC, 2A

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

19 (D IN)

24 V (NPN)

0 V (PNP)

27

24 V

0 V

(D IN/OUT)

0 V (PNP)

24 V (NPN)

(D IN/OUT)

0 V

24 V

29

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

A53 U-I (S201)

ON

21

A54 U-I (S202)

ON=0-20 mA

OFF=0-10 V

95

400 VAC, 2A

P 5-00

(R+) 82

(R-) 81

+ - + -

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

0 V

5 V

S801

RS-485

RS-485

21

ON

S801/Bus Term.

OFF-ON

3 Phase

power

input

Load Share

Switch Mode

Power Supply

Motor

Analog Output

Interface

Relay1

Relay2

ON=Terminated

OFF=Open

Brake

resistor

(NPN) = Sink

(PNP) = Source

= ==

240 VAC, 2A

400 VAC, 2A

0 VDC - 10 VDC

10 VDC

37 (D IN) - option

130BC548.12

Installation Danfoss Turbocor

33

8 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Illustration 3.1 Interconnect Diagram

Page 11

Motor

Line Power

Stop

Start

Speed

Control

130BX370.10

Installation Installation Guide

For safety, comply with the following requirements

Electronic controls equipment is connected to

•

hazardous mains voltage. Extreme care should be

taken to protect against electrical hazards when

applying power to the unit.

Run motor cables from multiple frequency

•

converters separately. Induced voltage from

output motor cables run together can charge

equipment capacitors even with the equipment

turned off and locked out.

Field wiring terminals are not intended to receive

•

a conductor one size larger.

Overload and equipment protection

An electronically activated function within the

•

frequency converter provides overload protection

for the motor. The overload calculates the level of

increase to activate timing for the trip (controller

output stop) function. The higher the current

draw, the quicker the trip response. The overload

provides Class 20 motor protection.

Because the motor wiring carries high frequency

•

current, it is important that wiring for mains,

motor power, and control are run separately. Use

metallic conduit or separated shielded wire. See

Illustration 3.2. Failure to isolate power, motor,

and control wiring could result in less than

optimum equipment performance.

3 3

Illustration 3.2 Example of Proper Electrical Installation Using

Conduit

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 9

Page 12

L1

L1L2L2L3L3

2

91 92 93

1

130BB460.11

Installation Danfoss Turbocor

A dedicated ground wire is required for input

•

power, motor power and control wiring

Use the clamps provided with the equipment for

•

proper ground connections

Do not ground one frequency converter to

•

33

3.4.2.1

1 Fuses

2 Ground

Illustration 3.3 Frequency Converter Fuses

Wire Type and Ratings

All wiring must comply with local and national

•

regulations regarding cross-section and ambient

temperature requirements.

Danfoss recommends that all power connections

•

be made with a minimum 75 °C rated copper

wire.

Grounding Requirements

3.4.2

WARNING

GROUNDING HAZARD!

For operator safety, it is important to ground the

frequency converter properly in accordance with national

and local electrical codes as well as instructions

contained within this document. Do not use conduit

connected to the frequency converter as a replacement

for proper grounding. Ground currents are higher than

3.5 mA. Failure to ground the frequency converter

properly could result in death or serious injury.

Follow national and local codes regarding protective

earthing of equipment with a leakage current >3.5 mA.

Frequency converter technology implies high frequency

switching at high power. This will generate a leakage

current in the earth connection. A fault current in the

frequency converter at the output power terminals might

contain a DC component, which can charge the filter

capacitors and cause a transient earth current. The earth

leakage current depends on various system configurations

including RFI filtering, screened motor cables, and

frequency converter power.

EN/IEC61800-5-1 (Power Drive System Product Standard)

requires special care if the leakage current exceeds 3.5 mA.

Earthing (grounding) must be reinforced in one of the

following ways:

See EN 60364-5-54 § 543.7 for further information.

another in a “daisy chain” fashion

Keep the ground wire connections as short as

•

possible

Using high-strand wire to reduce electrical noise

•

is recommended

Follow motor manufacturer wiring requirements

•

Leakage Current (>3.5 mA)

Earth (ground) wire of at least 10 mm

•

Two separate earth (ground) wires both

•

complying with the dimensioning rules

2

NOTICE

It is the responsibility of the user or certified electrical

installer to ensure correct grounding of the equipment in

accordance with national and local electrical codes and

standards.

Follow all local and national electrical codes to

•

ground electrical equipment properly

Proper protective earthing for equipment with

•

ground currents higher than 3.5 mA must be

established, see chapter 3.4.2.1 Leakage Current

(>3.5 mA)

10 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 13

130BC304.10

Installation Installation Guide

3.4.2.2 Grounding IP21 Enclosures

The frequency converter can be grounded using conduit or

shielded cable. For grounding of the power connections,

use the dedicated grounding points as shown in

Illustration 3.4.

Illustration 3.4 Grounding for IP21 Enclosures.

Motor Connection

3.4.3

WARNING

INDUCED VOLTAGE!

Run output motor cables from multiple frequency

converters separately. Induced voltage from output

motor cables run together can charge equipment

capacitors even with the equipment turned off and

locked out. Failure to run output motor cables separately

could result in death or serious injury.

For maximum cable sizes, see chapter 5.1 Power-

•

dependent Specifications

Comply with local and national electrical codes

•

for cable sizes

Gland plates are provided at the base of IP21

•

units

Do not install power factor correction capacitors

•

between the frequency converter and the motor

Do not wire a starting or pole-changing device

•

between the frequency converter and the motor

Connect the 3-phase motor wiring to terminals

•

96 (U), 97 (V), and 98 (W)

Earth (ground) the cable in accordance with the

•

instructions provided

Torque terminals in accordance with the

•

information provided in chapter 5.3.4 Connection

Tightening Torques

Follow motor manufacturer wiring requirements

•

3 3

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 11

Page 14

A

A

B

B

33

1.3[ ]

0

0.0[ ]

62

2.4[ ]

101

4.0[ ]

140

5.5[ ]

163

6.4[ ]

185

7.3[ ]

224

8.8[ ]

263

10.4[ ]

293

11.5[ ]

GROUND 88

3.5[ ]

0

0.0[ ]

200

7.9[ ]

94

3.7[ ]

244

9.6[ ]

0

0.0[ ]

272

10.7[ ]

0

0.0[ ]

S

U

W

R T V

3X M8x20 STUD

WITH NUT

SECTION A-A

MAINS TERMINALS

MAINS TERMINAL

SECTION B-B

MOTOR TERMINALS

MOTOR

TERMINAL

130BC305.10

B

B

A

A

254.7

10[ ]

0.0

0[ ]

GROUND 143.4

6[ ]

0.0

0[ ]

GROUND 168.4

7[ ]

331.2

13[ ]

211.1

8[ ]

GROUND168.4

7[ ]

GROUND143.4

6[ ]

42.4

2[ ]

0.0

0[ ]

68.1

3[ ]

125.8

5[ ]

183.5

7[ ]

245.8

10[ ]

299.8

12[ ]

353.8

14[ ]

377.6

15[ ]

284.2

11[ ]

0.0

0[ ]

R

S

T

U

V

W

4X M10x20 STUD

WITH NUT

SECTION B-B

MOTOR TERMINALS AND

BRAKE TERMINALS

MOTOR TERMINAL

SECTION A-A

MAINS TERMINALS

MAINS TERMINAL

130BC332.10

Installation Danfoss Turbocor

3.4.3.1 Terminal Locations

33

Illustration 3.5 Terminal Locations D1h

Illustration 3.6 Terminal Locations D2h

12 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 15

175HA036.11

U1V

1

W

1

96 97 98

FC

Motor

U

2V2

W

2

U1V

1

W

1

96 97 98

FC

Motor

U

2V2

W

2

130BC254.10

2

1

Installation

Installation Guide

3.4.4 Motor Cable

The motor must be connected to terminals U/T1/96, V/

T2/97, W/T3/98. Earth (ground) to terminal 99. The factory

setting is for clockwise rotation with the frequency

converter output connected as follows:

Terminal number Function

96, 97, 98,

99

Table 3.4 Terminals for Motor Cable Connection

Motor Rotation Check

3.4.5

The direction of rotation can be changed by switching 2

phases in the motor cable.

Terminal U/T1/96 connected

•

to U-phase

Terminal V/T2/97 connected

•

to V-phase

Terminal W/T3/98

•

connected to W-phase

Mains U/T1, V/T2, W/T3

Earth (ground)

1. Ground the cable in accordance with the

instructions provided.

2. Connect 3-phase AC input power wiring to

terminals L1, L2, and L3 (see Illustration 3.7).

3 3

Table 3.5 Wiring for Changing Motor Direction

AC Mains Connection

3.4.6

All frequency converters may be used with an

•

isolated input source as well as with ground

reference power lines. When supplied from an

isolated mains source (IT mains or floating delta)

or TT/TN-S mains with a grounded leg (grounded

delta), set 14-50 RFI Filter to [0] Off. When off, the

internal RFI filter capacitors between the chassis

and the intermediate circuit are isolated. Isolating

the capacitors prevents damage to the

intermediate circuit and reduces ground capacity

currents in accordance with IEC 61800-3.

Size wiring is based upon the input current of the

•

•

frequency converter.

Comply with local and national electrical codes

for cable sizes.

1 Mains connection

2 Motor connection

Illustration 3.7 Connecting to AC Mains

DC-Link Connection

3.4.7

Two field terminals are provided for connecting to the DCLink. The terminals are marked “+REGEN82” and “REGEN83”.

WARNING

REGEN TERMINALS

Frequency converters contain high voltage The REGEN

terminals must be connected to the correct polarity and

properly insulated from ground. Qualified personnel only

should perform installation, start up, and maintenance.

Failure to perform installation, start up, and maintenance

by qualified personnel could result in death or serious

injury.

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 13

Page 16

175ZA166.13

0,01 0,1 1 10 100 MHz

10

10

10

1

10

10

10

10

10

a

b

c

d

e

f

g

The lower the Z the better the cable screening performance

Transfer impedance, Z

t

mOhm/m

Installation

Danfoss Turbocor

WARNING

HIGH VOLTAGE

The DC-link of a frequency converter contains high

voltage when connected to AC mains input power.

Qualified personnel only should perform installation,

33

start-up, and maintenance. Failure to perform installation, start-up, and maintenance by qualified personnel

could result in death or serious injury.

Transfer impedance (Z

the following factors:

The conductibility of the screen material.

•

The contact resistance between the individual

•

screen conductors.

The screen coverage, i.e. the physical area of the

•

cable covered by the screen - often stated as a

percentage value.

Screen type, i.e. braided or twisted pattern.

•

) can be assessed on the basis of

T

WARNING

DISCHARGE TIME

Frequency converters contain DC-link capacitors that can

remain charged even when the frequency converter is

not powered. To avoid electrical hazards, disconnect AC

mains, any permanent magnet type motors, and any

remote DC-link power supplies, including battery backups, UPS, and DC-link connections to other frequency

converters. Wait for the capacitors to fully discharge

before performing any service or repair work. The

amount of wait time is listed in Table 2.1. Failure to wait

the specified time after power has been removed before

doing service or repair could result in death or serious

injury.

3.5 Control Wiring Connection

3.5.1

All terminals to the control cables are located on the inside

of the frequency converter. To access, open the door

(IP21).

3.5.2

Danfoss recommends braided screened/armoured cables to

optimise EMC immunity of the control cables and the EMC

emission from the motor cables.

The ability of a cable to reduce the incoming and

outgoing radiation of electric noise depends on the

transfer impedance (ZT). The screen of a cable is normally

designed to reduce the transfer of electric noise; however,

a screen with a lower transfer impedance (ZT) value is

more effective than a screen with a higher transfer

impedance (ZT).

Transfer impedance (ZT) is rarely stated by cable manufacturers, but it is often possible to estimate transfer

impedance (ZT) by assessing the physical design of the

cable.

Isolate control wiring from high power

•

components in the frequency converter

Access

Using Screened Control Cables

a Aluminium-clad with copper wire

b Twisted copper wire or armoured steel wire cable

c Single-layer braided copper wire with varying percentage

screen coverage (this is the typical Danfoss reference

cable).

d Double-layer braided copper wire

e Twin layer of braided copper wire with a magnetic,

screened/armoured intermediate layer

f Cable that runs in copper tube or steel tube

g Lead cable with 1.1 mm wall thickness

Illustration 3.8 Cable Screening Performance

Grounding of Screened Control

3.5.3

Cables

Correct screening

The preferred method in most cases is to secure control

and serial communication cables with screening clamps

provided at both ends to ensure best possible high

frequency cable contact. If the ground potential between

the frequency converter and the PLC is different, electric

noise may occur that disturbs the entire system. Solve this

14 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 17

1

2

PE

FC

PE

PLC

130BB922.12

PE PE

<10 mm

100nF

FC

PE

PE

PLC

<10 mm

130BB609.12

PE

FC

PE

FC

130BB923.12

PE PE

69

68

61

69

68

61

1

2

<10 mm

PE

FC

PE

FC

130BB924.12

PE PE

69

69

68

68

1

2

<10 mm

1

4

2

3

130BA012.12

61

68

69

39

42

50

53

54

55

12

13

18

19

27

29

32

33

20

37

Installation

Installation Guide

problem by fitting an equalizing cable next to the control

cable. Minimum cable cross section: 16 mm2.

1

Min. 16 mm

2 Equalizing cable

Illustration 3.9 Correct Screening

2

50/60 Hz ground loops

With very long control cables, ground loops may occur. To

eliminate ground loops, connect one end of the screen-toground with a 100 nF capacitor (keeping leads short).

Illustration 3.10 Avoiding Ground Loops

1

Min. 16 mm

2

2 Equalizing cable

Illustration 3.12 Screening without Using Terminal 61

3.5.4 Control Terminal Types

3 3

Avoid EMC noise on serial communication

This terminal is connected to ground via an internal RC

link. Use twisted-pair cables to reduce interference

between conductors. The recommended method is shown

below:

Illustration 3.13 Control Terminal Locations

Connector 1 provides four programmable digital

•

input terminals, two additional digital terminals

programmable as either input or output, a 24 V

1

Min. 16 mm

2

2 Equalizing cable

Illustration 3.11 Avoiding EMC Noise

DC terminal supply voltage, and a common for

optional customer supplied 24 V DC voltage

Connector 2 terminals (+)68 and (-)69 are for an

•

RS485 serial communications connection

Connector 3 provides 2 analog inputs, one

•

analog output, 10 V DC supply voltage, and

Alternatively, the connection to terminal 61 can be

omitted:

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 15

commons for the inputs and output

Connector 4 is a USB port available for use with

•

the MCT 10 Set-up Software

Also provided are 2 Form C relay outputs that are

•

located on the power card

Page 18

130BT306.10

130BT310.11

Installation Danfoss Turbocor

3.5.5 Wiring to Control Terminals

Terminal plugs can be removed for easy access.

33

Illustration 3.14 Removal of Control Terminals

3.6

Serial Communication

RS485 is a two-wire bus interface compatible with multidrop network topology.

Terminate each segment at both ends, using the

termination switch (S801) of the frequency converter.

Always use screened twisted pair (STP) cable for bus

cabling, and always follow good common installation

practice.

Low-impedance earth (ground) connection of the screen at

every node is important, including at high frequencies.

Thus, connect a large surface of the screen to earth

(ground), for example with a cable clamp or a conductive

cable gland. It may be necessary to apply potentialequalizing cables to maintain the same earth (ground)

potential throughout the network. Particularly in installations with long cables.

Cable Screened twisted pair (STP)

Impedance

Max. cable length

Table 3.6

120 Ω

1200 m (including drop lines)

500 m station-to-station

Illustration 3.15 Location of Bus Termination Switch

To run STO, additional wiring for the frequency converter

is required. Refer to VLT® Frequency Converters Safe Torque

Off Operating Instructions for further information.

16 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 19

Start Up and Commissioning

Installation Guide

4 Start Up and Commissioning

4.1 Pre-start

CAUTION

Before applying power to the unit, inspect the entire installation as detailed in Table 4.1. Check mark those items when

completed.

Inspect for Description

Auxiliary equipment

Cable routing

Control wiring

Cooling clearance

EMC considerations

Environmental considerations

Fusing and circuit

breakers

Grounding

Input and output power

wiring

Panel interior

Switches

Vibration

Look for auxiliary equipment, switches, disconnects, or input fuses/circuit breakers on the input

•

power side of the frequency converter or output side to the motor. Ensure that they are ready for

full speed operation.

Check function and installation of any sensors used for feedback to the frequency converter.

•

Remove power factor correction caps on motors, if present.

•

Use separate metallic conduits for each of the following:

•

-

-

-

Check for broken or damaged wires and loose connections.

•

Check that control wiring is isolated from power and motor wiring for noise immunity.

•

Check the voltage source of the signals, if necessary.

•

Use shielded or twisted pair cable. Ensure that the shield is terminated correctly.

•

Measure that top and bottom clearance is adequate to ensure proper air flow for cooling.

•

Check for proper installation regarding electromagnetic compatibility.

•

See equipment label for the maximum ambient operating temperature limits.

•

Humidity levels must be 5–95%, non-condensing.

•

Check for proper fusing or circuit breakers.

•

Check that all fuses are inserted firmly and in operational condition and that all circuit breakers are

•

in the open position.

The unit requires a ground wire from its chassis to the building ground.

•

Check for good ground connections that are tight and free of oxidation.

•

Grounding to conduit or mounting the back panel to a metal surface is not sufficient.

•

Check for loose connections.

•

Check that motor and mains are in separate conduit or separated screened cables.

•

Inspect that the unit interior is free of debris and corrosion.

•

Ensure that all switch and disconnect settings are in the proper positions.

•

Check that the unit is mounted solidly or that shock mounts are used, as necessary.

•

Check for an unusual amount of vibration.

•

Input power

Motor wiring

Control wiring

☑

4 4

Table 4.1 Start-up Checklist

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 17

Page 20

Start Up and Commissioning Danfoss Turbocor

4.2 Applying Power

WARNING

HIGH VOLTAGE!

Frequency converters contain high voltage when

connected to the energised DC bus. Only qualified

personnel should install, start up and maintain the

freqeuncy converters. Failure to let qualified personnel

44

install, start up and maintain the frequency converters

could result in death or serious injury.

WARNING

UNINTENDED START!

When the frequency converter is connected to the

energised DC bus, the motor may start at any time. The

frequency converter, motor, and any driven equipment

must be in operational readiness. Failure to be in

operational readiness when the frequency converter is

connected to the energised DC bus could result in death,

serious injury, equipment, or property damage.

1. Confirm input voltage is balanced within 3%. If

not, correct input voltage imbalance before

proceeding. Repeat procedure after voltage

correction.

2. Ensure optional equipment wiring, if present,

matches installation application.

3. Ensure that all operator devices are in the OFF

position. Panel doors closed, or a cover mounted.

4. Apply power to the unit. DO NOT start the

frequency converter now. For units with a

disconnect switch, turn to the ON position to

apply power to the frequency converter.

18 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 21

Specifications

Installation Guide

5 Specifications

5.1 Power-dependent Specifications

DTC 302 N165 N232 N262

Typical shaft output at 400 V [kW] 165 232 262

Typical shaft output at 460 V [hp] 221 311 352

Enclosure IP21 D1h D2h D2h

Output current

Continuous (at 400 V) [A] 318 424 480

Continuous (at 460 V) [A] 263 350 443

Continuous kVA (at 400 V) [kVA] 179 252 285

Continuous kVA (at 460 V) [kVA] 179 252 285

Max. input current

Continuous (at 400 V) [A] 271 380 430

Continuous (at 460 V) [A] 235 330 374

Max. cable size: mains, motor, mm (AWG) 2x95 (2x3/0 mcm) 2x185 (2x350 mcm) 2x185 (2x350 mcm)

Max. external mains fuses [A] 400 550 630

Estimated power loss at 400 V [W] 4271 5232 6203

Estimated power loss at 460 V [W] 3561 4390 5830

Efficiency 0.98

Output frequency [Hz] 0–590

Heat sink overtemperature trip [°F] ([°C])

Control card ambient trip [°F] ([°C])

158 (70) 149 (65) 149 (65)

230 (110)

5 5

Table 5.1 Mains Supply 3x380-500 V AC

DTC 302 N165 N232

Typical shaft output at 575 V [kW] 165 232

Typical shaft output at 575 V [hp] 221 311

Enclosure IP21 D1h D2h

Output current

Continuous (at 575 V) [A] 205 286

Continuous kVA (at 575 V) [kVA] 179 252

Max. input current

Continuous (at 575 V) [A] 188 264

Max. cable size: mains, motor, mm (AWG) 2x95 (2x3/0) 2x185 (2x350)

Max. external mains fuses [A] 315 550

Estimated power loss at 575 V [W] 3873 5288

Weight, enclosure IP21 kg (lbs.) 62 (135) 125 (275)

Efficiency 0.98

Output frequency [Hz] 0–590

Heat sink overtemperature trip [°F] ([°C])

Control card ambient trip [°F] ([°C])

Table 5.2 Mains Supply 3x575 V AC

The typical power loss is at nominal load conditions and expected to be within ±15% (tolerance relates to variety

•

167 (75) 176 (80)

230 (110)

in voltage and cable conditions).

The losses are based on the default switching frequency. The losses increase significantly at higher switching

•

frequencies.

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 19

Page 22

Specifications

Danfoss Turbocor

5.2 General Technical Data

Mains supply (L1, L2, L3)

Supply voltage 380-500 V ±10%, 575 V ±10%

Mains voltage low/mains voltage drop-out:

During low mains voltage or a mains drop-out, the frequency converters continues until the intermediate circuit voltage drops

below the minimum stop level, which corresponds typically to 15% below the frequency converter's lowest rated supply voltage.

Power-up and full torque cannot be expected at mains voltage lower than 10% below the frequency converter's lowest rated

supply voltage.

Supply frequency 50/60 Hz ±5%

Max. imbalance temporary between mains phases 3.0% of rated supply voltage

55

True Power Factor (λ) ≥0.9 nominal at rated load

Displacement Power Factor (cos Φ) near unity (>0.98)

Switching on input supply L1, L2, L3 (power ups) maximum one time/2 minutes

Environment according to EN60664-1 overvoltage category III/pollution degree 2

The unit is suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical Amperes, 480/600 V

Motor Output (U, V, W)

Output voltage 0-100% of supply voltage

Output frequency 0-590 Hz*

Switching on output Unlimited

Ramp times 0.01-3600 s

* Dependent on voltage and power

Cable lengths and cross sections

Max. motor cable length, screened/armoured 150 m

Max. motor cable length, unscreened/unarmoured 300 m

Max. cross section to motor, mains*

Maximum cross section to control terminals, rigid wire 1.5 mm2/16 AWG (2x0.75 mm2)

Maximum cross section to control terminals, flexible cable 1 mm2/18 AWG

Maximum cross section to control terminals, cable with enclosed core 0.5 mm2/20 AWG

Minimum cross section to control terminals 0.25 mm

Digital inputs

Programmable digital inputs 4 (6)

Terminal number 18, 19, 271), 291), 32, 33

Logic PNP or NPN

Voltage level 0-24 V DC

Voltage level, logic '0' PNP <5 V DC

Voltage level, logic '1' PNP >10 V DC

Voltage level, logic '0' NPN >19 V DC

Voltage level, logic '1' NPN <14 V DC

Maximum voltage on input 28 V DC

Input resistance, R

All digital inputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

1) Terminals 27 and 29 can also be programmed as output.

Control card, RS485 serial communication

Terminal number 68 (P,TX+, RX+), 69 (N,TX-, RX-)

Terminal number 61 Common for terminals 68 and 69

The RS485 serial communication circuit is functionally seated from other central circuits and galvanically isolated from the

supply voltage (PELV).

i

approx. 4 kΩ

2

20 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 23

Specifications Installation Guide

Control card, 24 V DC output

Terminal number 12, 13

Max. load 200 mA

The 24 V DC supply is galvanically isolated from the supply voltage (PELV ), but has the same potential as the analog and digital

inputs and outputs.

Control characteristics

Resolution of output frequency at 0-1000 Hz ±0.003 Hz

System response time (terminals 18, 19, 27, 29, 32, 33) ≤2 ms

Speed control range (open loop) 1:100 of synchronous speed

Speed accuracy (open loop) 30-4000 rpm: Maximum error of ±8 rpm

All control characteristics are based on a 4-pole asynchronous motor

Surroundings

Enclosure type D1h/D2h IP21/Type 1

Vibration test all enclosure types 0.7 g

Relative humidity 5%-95% (IEC 721-3-3; Class 3K3 (non-condensing) during operation

Aggressive environment (IEC 60068-2-43) H2S test

Test method according to IEC 60068-2-43 H2S (10 days)

Ambient temperature (at 60AVM switching mode)

- at full continuous FC output current max. 104 °F [40 °C]

class Kd

5 5

Minimum ambient temperature during full-scale operation 0 °C

Minimum ambient temperature at reduced performance - 10 °C

Temperature during storage/transport -25 to +65/70 °C

Maximum altitude above sea level without derating 1,000 m

Maximum altitude above sea level with derating 3,000 m

1) For more information on derating see the Design Guide, section on Special Conditions.

EMC standards, Emission EN 61800-3, EN 61000-6-3/4, EN 55011, IEC 61800-3

EN 61800-3, EN 61000-6-1/2,

EMC standards, Immunity

See the Design Guide, section on Special Conditions.

Control card performance

Scan interval 5 ms

Protection and Features

Electronic thermal motor protection against overload.

•

Temperature monitoring of the heat sink ensures that the frequency converter trips if the temperature reaches

•

95 °C ±5 °C. An overload temperature cannot be reset until the temperature of the heat sink is below 70 °C ±5 °C

(Guideline - these temperatures may vary for different power sizes, enclosures etc.).

The frequency converter is protected against short-circuits on motor terminals U, V, W.

•

If a mains phase is missing, the frequency converter trips or issues a warning (depending on the load).

•

Monitoring of the intermediate circuit voltage ensures that the frequency converter trips if the intermediate circuit

•

voltage is too low or too high.

The frequency converter is protected against earth (ground) faults on motor terminals U, V, W.

•

EN 61000-4-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-5, EN 61000-4-6

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 21

Page 24

Specifications Danfoss Turbocor

5.3 Fuse Tables

5.3.1 Protection

Branch circuit protection

In order to protect the installation against electrical and fire hazard, all branch circuits in an installation, switch gear,

machines etc., must be short-circuited and over-current protected according to national/international regulations.

Short-circuit protection

The frequency converter must be protected against short-circuit to avoid electrical or fire hazard. Danfoss recommends

using the fuses mentioned below to protect service personnel and equipment in case of an internal failure in the frequency

conveter. The frequency converter provides full short-circuit protection in case of a short-circuit on the motor output.

55

Over-current protection

Provide overload protection to avoid fire hazard due to overheating of the cables in the installation. The frequency

converter is equipped with an internal over-current protection that can be used for upstream overload protection (ULapplications excluded). Moreover, fuses or circuit breakers can be used to provide the over-current protection in the

installation. Over-current protection must always be carried out according to national regulations.

Fuse Selection

5.3.2

Danfoss recommends using the following fuses which ensures compliance with EN 50178. In case of malfunction, not

following the recommendation may result in unnecessary damage to the frequency converter.

The fuses below are suitable for use on a circuit capable of delivering 100,000 Arms (symmetrical).

N165, N232, N262

N165, N232 575 V type aR

Table 5.3 Recommended Fuses

VLT

Model

N165 T5 170M2621 LA50QS400-4 L50S-400 FWH-400A 20 610

N232 T5 170M4015 LA50QS500-4 L50S-500 FWH-500A 20 610

N262 T5 170M4016 LA50QS600-4 L50S-600 FWH-600A 20 610

Table 5.4 Fuse Options for 380–500 V Frequency Converters

Table 5.5 Fuse Options for 575 V Frequency Converters

BussmanPNLittelfuse PN LittelfusePNBussmannPNSiba PN Ferraz ShawmutPNFerraz Shawmut PN

VLT Model Bussmann PN Siba PN Ferraz Shawmut European PN Ferraz Shawmut North American PN

N165 T7 170M2619 20 610 31.315 6,9URD31D08A0315 A070URD31KI0315

N232 T7 170M4015 20 620 31.550 6,9URD32D08A0550 A070URD32KI0550

380–500 V type aR

31.400

31.550

31.630

Ferraz Shawmut PN

(Europe)

A50QS400-4 6,9URD31D08A0400 A070URD31KI0400

A50QS500-4 6,9URD31D08A0550 A070URD31KI0550

A50QS600-4 6,9URD31D08A0630 A070URD31KI0630

(North America)

For UL compliance, use the Bussmann 170M series.

22 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 25

Specifications Installation Guide

5.3.3 Short Circuit Current Rating (SCCR)

The Short Circuit Current Rating (SCCR) of the frequency

converters is 100,000 amps at all voltages (380–575 V).

5.3.4 Connection Tightening Torques

When tightening all electrical connections it is very

important to tighten with the correct torque. Too low or

too high torque results in a bad electrical connection. Use

a torque wrench to ensure correct torque. Always use a

torque wrench to tighten the bolts.

5 5

Frame

size

D1h Mains

D2h Mains

Table 5.6 Torque for Terminals

Terminal Torque [Nm (in-lbs)] Bolt

Motor

Load sharing

Regen

Earth (Ground)

Brake

Motor

Regen

Load sharing

Earth (ground)

Brake 8.5-20.5 (75-181) M8

size

19-40 (168-354) M10

8.5-20.5 (75-181) M8

19-40 (168-354) M10

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 23

Page 26

Index Danfoss Turbocor

Index

A

AC input............................................................................................... 4, 13

AC mains................................................................................................ 4, 5

AC mains connection.......................................................................... 13

AC waveform............................................................................................ 4

Airflow......................................................................................................... 6

Analog input.......................................................................................... 15

Analog output....................................................................................... 15

B

Block diagram........................................................................................... 4

C

Cable length........................................................................................... 20

Check list, pre-installation.................................................................... 6

Circuit breaker....................................................................................... 17

Conduit................................................................................................ 9, 17

Control cable.......................................................................................... 15

Control cable, screened..................................................................... 15

Control card performance................................................................. 21

Control card, 24 V DC output........................................................... 21

Control card, RS485 serial communication................................. 20

Control characteristic.......................................................................... 21

Control system......................................................................................... 4

Control terminal.................................................................................... 16

Control terminal type.......................................................................... 15

Control wiring........................................................................ 7, 9, 10, 17

Control wiring connection................................................................ 14

Cooling clearance................................................................................. 17

Cross section.......................................................................................... 20

Current rating........................................................................................... 6

D

DC current.................................................................................................. 4

Derating............................................................................................... 6, 21

Digital input..................................................................................... 15, 20

Discharge time......................................................................................... 5

Disconnect switch................................................................................ 18

E

Electrical installation.............................................................................. 7

Electrical noise....................................................................................... 10

EMC.............................................................................................. 15, 17, 21

Equalizing cable.................................................................................... 15

External command................................................................................. 4

External controller.................................................................................. 4

F

Feedback................................................................................................. 17

Floating delta......................................................................................... 13

Frequency converter block diagram................................................ 4

Full load current...................................................................................... 6

Functional testing................................................................................... 4

Fuse........................................................................................................... 17

Fusing................................................................................................... 9, 17

G

Ground connection....................................................................... 10, 17

Ground loop........................................................................................... 15

Ground wire..................................................................................... 10, 17

Grounded delta..................................................................................... 13

Grounding........................................................................................ 10, 17

Grounding hazard................................................................................ 10

Grounding, IP21/54 enclosure......................................................... 11

Grounding, screened control cable............................................... 15

H

Harmonic.................................................................................................... 4

I

IEC 61800-3............................................................................................. 21

Induced voltage....................................................................................... 9

Input current.......................................................................................... 13

Input power....................................................................... 4, 5, 7, 10, 17

Input voltage.......................................................................................... 18

Installation.............................................................................. 4, 9, 17, 18

Installation site......................................................................................... 6

Installation, electrical............................................................................. 7

Installation, mechanical........................................................................ 6

Isolated mains........................................................................................ 13

L

Leakage current (>3.5 mA)................................................................ 10

M

Mains........................................................................................................... 9

Mains supply (L1, L2, L3).................................................................... 20

Mechanical installation......................................................................... 6

Motor cable................................................................................. 9, 11, 13

Motor connection................................................................................. 11

24 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

Page 27

Index Installation Guide

Motor current........................................................................................... 4

Motor output (U, V, W)........................................................................ 20

Motor power............................................................................................. 9

Motor protection.............................................................................. 9, 21

Motor rotation check.......................................................................... 13

Motor status.............................................................................................. 4

Motor wiring.................................................................................. 7, 9, 17

Mounting................................................................................................. 17

Multiple frequency converters.................................................... 9, 11

N

Noise isolation................................................................................... 7, 17

O

Open loop............................................................................................... 21

Optional equipment............................................................................ 18

Overload protection.......................................................................... 6, 9

P

PELV.................................................................................................... 14, 21

Power........................................................................................................ 10

Power connection................................................................................ 10

Power factor................................................................................ 4, 11, 17

Pre-installation check list..................................................................... 6

Product overview.................................................................................... 3

Programming........................................................................................... 4

Protection................................................................................................ 22

Protection, feature............................................................................... 21

STO............................................................................................................. 16

Supply voltage................................................................................ 14, 15

Surroundings......................................................................................... 21

System feedback..................................................................................... 4

T

Temperature limit................................................................................. 17

Terminal location, D1h....................................................................... 12

Terminal location, D2h....................................................................... 12

Thermal protection................................................................................ 5

Thermistor............................................................................................... 14

Thermistor control wiring................................................................. 14

Torque, terminal................................................................................... 23

Transient protection.............................................................................. 4

Trip function............................................................................................. 9

Troubleshooting...................................................................................... 4

W

Wire type, rating................................................................................... 10

Wiring, control terminal..................................................................... 16

R

Relay output........................................................................................... 15

Remote command.................................................................................. 4

Reset.......................................................................................................... 21

RFI filter.................................................................................................... 13

RMS current............................................................................................... 4

RS485........................................................................................................ 16

S

Safe torque off....................................................................................... 16

Screened control cable....................................................................... 15

Screened control cable, using.......................................................... 14

Serial communication............................................................. 4, 15, 16

Shielded cable................................................................................... 7, 17

Shielded wire............................................................................................ 9

Specification............................................................................................. 4

Start-up....................................................................................................... 4

MG35Q202 Danfoss A/S © 01/2015 All rights reserved. 25

Page 28

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property

of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

www.danfoss.com/drives

130R0572 MG35Q202 01/2015

*MG35Q202*

Loading...

Loading...