Page 1

SMT User Manual - Revision G

®

Danfoss Turbocor® Twin-Turbine

Centrifugal Series Compressors

TTS, TGS, TTH, T TG Series Compressors

http://turbocor.danfoss.com

Page 2

THIS PAGE INTENTIONALLY LEFT BLANK

2 of 88

M-SM-001-EN Rev. G

Page 3

Table of Contents

Chapter 1.0 Service Monitoring Tools Overview ..............................................................................9

1.1 Service Monitoring Tools Suite ...................................................................................................................................................... 9

1.2 Compatibility Requirements ........................................................................................................................................................ 10

1.3 General Usage ................................................................................................................................................................................... 12

Chapter 2.0 Recordings .....................................................................................................................15

2.1 Running a Recording ...................................................................................................................................................................... 15

Chapter 3.0 Compressor Connection Manager ...............................................................................23

3.1 Accessing the Compressor Connection Manager ................................................................................................................ 23

3.2 Compressor ........................................................................................................................................................................................24

3.3 Closing an Established Connection ........................................................................................................................................... 25

3.4 Detecting Compressor Settings ..................................................................................................................................................25

3.5 Changing Compressor Access Levels ........................................................................................................................................ 26

3.6 Synchronizing the Compressor Real-Time Clock with a PC Clock ..................................................................................26

3.7 Viewing a List of Recent Compressor Connection Settings .............................................................................................. 26

3.8 Selecting the Unit System ............................................................................................................................................................. 26

3.9 Connection Status Indications .................................................................................................................................................... 27

3.10 RAM Only and RAM & EEPROM Check boxes (TT/TG Only) ............................................................................................27

Chapter 4.0 ModComm Tool .............................................................................................................24

4.1 Accessing the ModComm Tool ....................................................................................................................................................24

4.2 Changing the Current Register Watch Range ........................................................................................................................24

4.3 Making a Single Write Request ................................................................................................................................................... 30

4.4 Making a Multiple Writes Request ............................................................................................................................................. 31

4.5 Changing the Current Data Interpretation View ..................................................................................................................32

Chapter 5.0 Active Alarm/Fault Viewer ............................................................................................35

5.1 Accessing the Active Alarm/Fault Viewer Tool ....................................................................................................................... 35

5.2 Viewing and Conguring Alarm/Fault Limits and Lockout Settings .............................................................................37

Chapter 6.0 Compressor Monitor .....................................................................................................39

6.1 Accessing the Compressor Monitor .......................................................................................................................................... 39

6.2 View Options ...................................................................................................................................................................................... 39

6.3 Changing the Demand .................................................................................................................................................................. 40

6.4 Changing the IGV Opening ( TT/TG Only) ................................................................................................................................40

6.5 Changing the Desired Motor Speed ......................................................................................................................................... 40

6.6 Levitating or De-levitating the Shaft ........................................................................................................................................40

Chapter 7.0 Logged Event and Fault Viewer ...................................................................................41

7.1 Accessing the Logged Event and Fault Viewer ...................................................................................................................... 41

Chapter 8.0 Compressor Data Recording and Playback Tool .........................................................47

8.1 Launching the Compressor Data Recording and Playback Tool .................................................................................... 47

8.2 Recording ............................................................................................................................................................................................47

8.3 Playback ...............................................................................................................................................................................................51

Chapter 9.0 Bearing Calibration Tool ...............................................................................................57

9.1 Accessing the Bearing Calibration Tool ....................................................................................................................................57

9.2 Performing a Calibration ............................................................................................................................................................... 58

9.3 Performing a Validation .................................................................................................................................................................59

9.4 Saving the Latest Bearing Calibration for Persistent Use ................................................................................................... 59

9.5 Viewing Bearing Calibration or Operation Settings ............................................................................................................59

9.6 Creating a Calibration Report ...................................................................................................................................................... 59

Chapter 10.0 Chiller and Analog Configuration Tool......................................................................61

10.1 Accessing the Chiller and Analog Conguration Tool ...................................................................................................... 61

10.2 Viewing or Modifying Chiller Controller Settings .............................................................................................................. 62

10.3 Viewing or Modifying Analog Output Controller Settings ............................................................................................. 62

Chapter 11.0 EXV Configuration Tool ..............................................................................................63

11.1 Accessing the EXV Conguration Tool ...................................................................................................................................63

11.2 Viewing and Modifying EXV Controller Settings ................................................................................................................ 65

Page 4

Chapter 12.0 Compressor Configuration Tool .................................................................................67

12.1 Accessing the Compressor Conguration Tool ................................................................................................................... 69

12.2 Viewing or Modifying Compressor Operation Settings ................................................................................................... 69

12.3 Viewing or Modifying Compressor Startup Settings ........................................................................................................ 69

12.4 Viewing of Modifying Shutdown Conguration Settings (TT/TG Only) .................................................................... 70

12.5 Viewing or Modifying IGV Conguration Settings (TT/TG Only) .................................................................................. 70

12.6 Viewing or Modifying Surge/Choke Conguration Settings (TT/TG Only) ............................................................... 70

12.7 Viewing or Modifying Capacity Control Conguration Settings (VTT Only) ............................................................70

12.8 Viewing or Modifying Communication Conguration ....................................................................................................71

12.9 Viewing Advanced Conguration ............................................................................................................................................71

Chapter 13.0 Compressor Commissioning Tool ..............................................................................73

13.1 Accessing the Compressor Commissioning Tool (TT/TG Only) ..................................................................................... 73

13.2 Importing a Commissioning Conguration from a File ...................................................................................................73

13.3 Adjusting Commissioning Parameters Requirement Step ............................................................................................. 74

13.4 Exporting a Commissioning Values Conguration to a File ...........................................................................................74

13.5 Exporting Commissioning Parameters to a Connected Compressor ......................................................................... 75

13.6 Creating a Commissioning Report .......................................................................................................................................... 75

Chapter 14.0 Compressor Data Trending Tool ................................................................................77

14.1 Accessing the Compressor Data Trending Tool (TT/TG Only) ........................................................................................ 77

14.2 Adding Parameters for Graphical Monitoring ..................................................................................................................... 77

14.3 Removing Parameters from Graphical Monitoring ........................................................................................................... 79

14.4 Selecting the Plot Color a Specic Parameter .....................................................................................................................79

14.5 Starting Graphical Monitoring ..................................................................................................................................................80

14.6 Stopping Graphical Monitoring ............................................................................................................................................... 80

14.7 Resetting Plot Data ....................................................................................................................................................................... 81

14.8 Saving Plot Data to a CSV File ................................................................................................................................................... 82

14.9 Loading a Saved or Pre-congured Watch Group .............................................................................................................82

14.10 Deleting a Saved or Pre-congured Watch Group ..........................................................................................................82

14.11 Saving the Active Watch Conguration for Later Recall................................................................................................83

14.12 Trending Tool ................................................................................................................................................................................83

14.13 Valve Control Setup (VTT Only) ..............................................................................................................................................84

14.14 Valve Control Tool........................................................................................................................................................................ 85

4 of 88

List of Tables

Table 1-1 SMT Software Requirements ........................................................................................................................................... 10

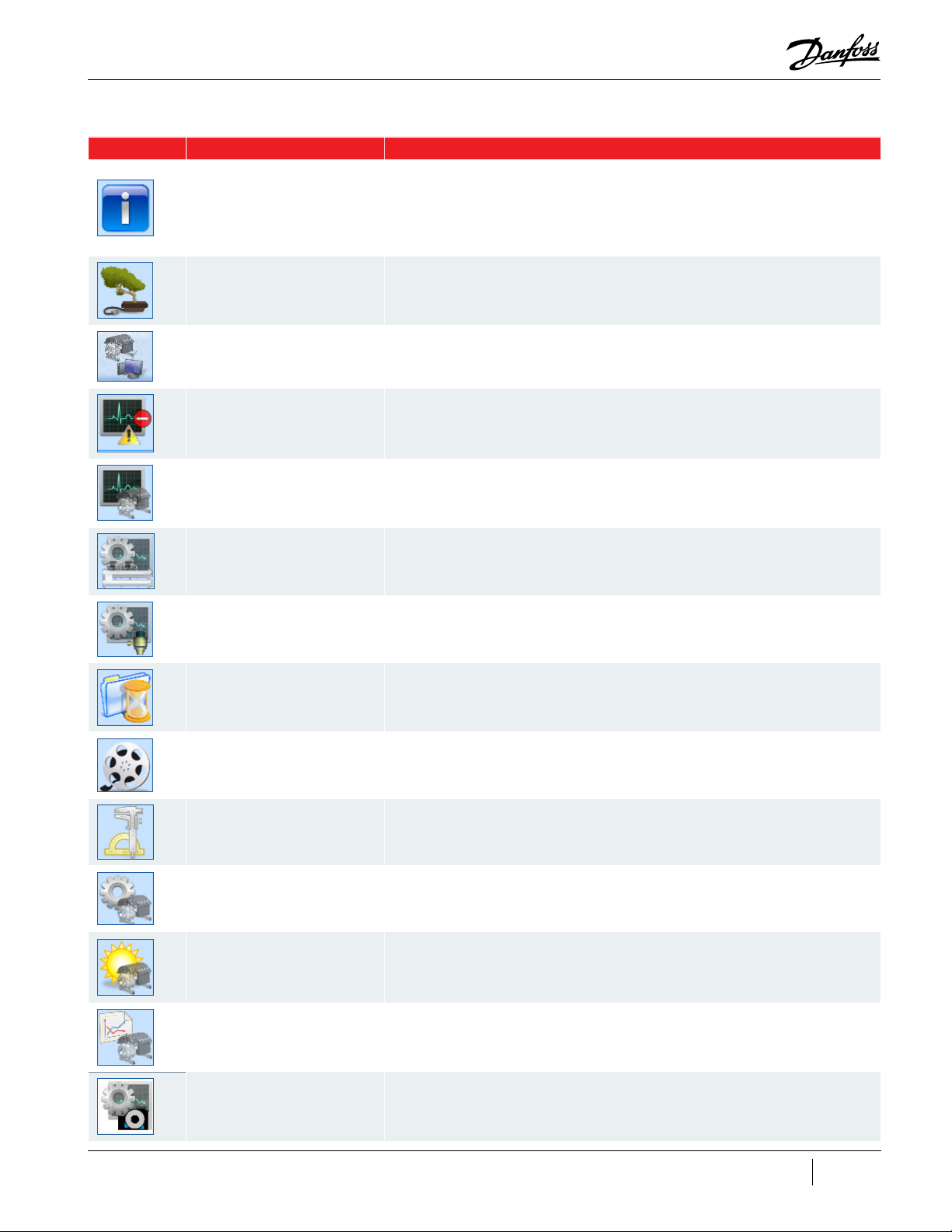

Table 1-2 SMT Software Icons ............................................................................................................................................................. 11

M-SM-001-EN Rev. G

Page 5

List of Figures

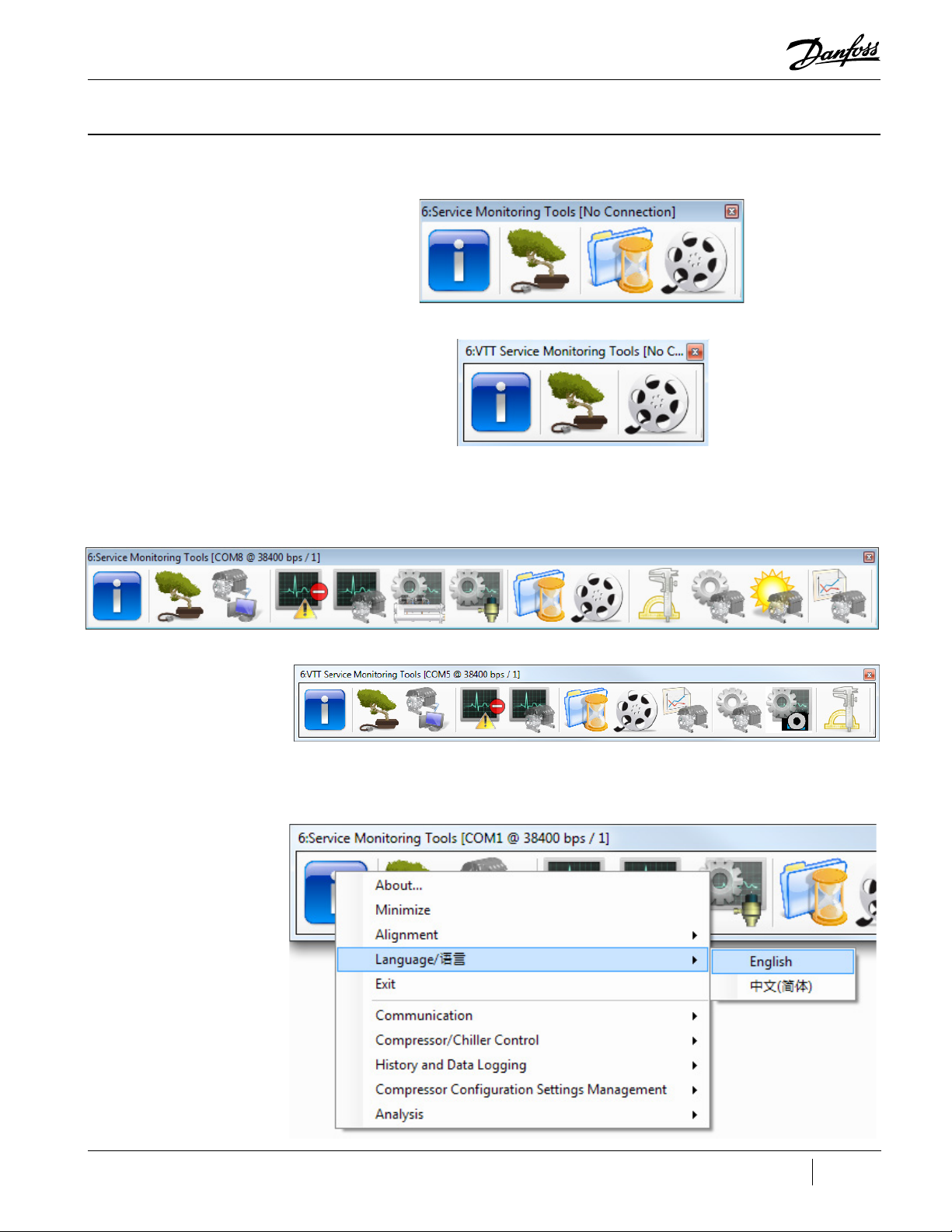

Figure 1-1 TT/TG SMT Suite Launcher Strip - Not Connected ................................................................................................... 9

Figure 1-2 VTT SMT Suite Launcher Strip - Not Connected ....................................................................................................... 9

Figure 1-3 TT/TG SMT Suite Launcher Strip - Connected............................................................................................................ 9

Figure 1-4 VTT SMT Suite Launcher Strip - Connected ................................................................................................................ 9

Figure 1-5 Select Language ................................................................................................................................................................... 9

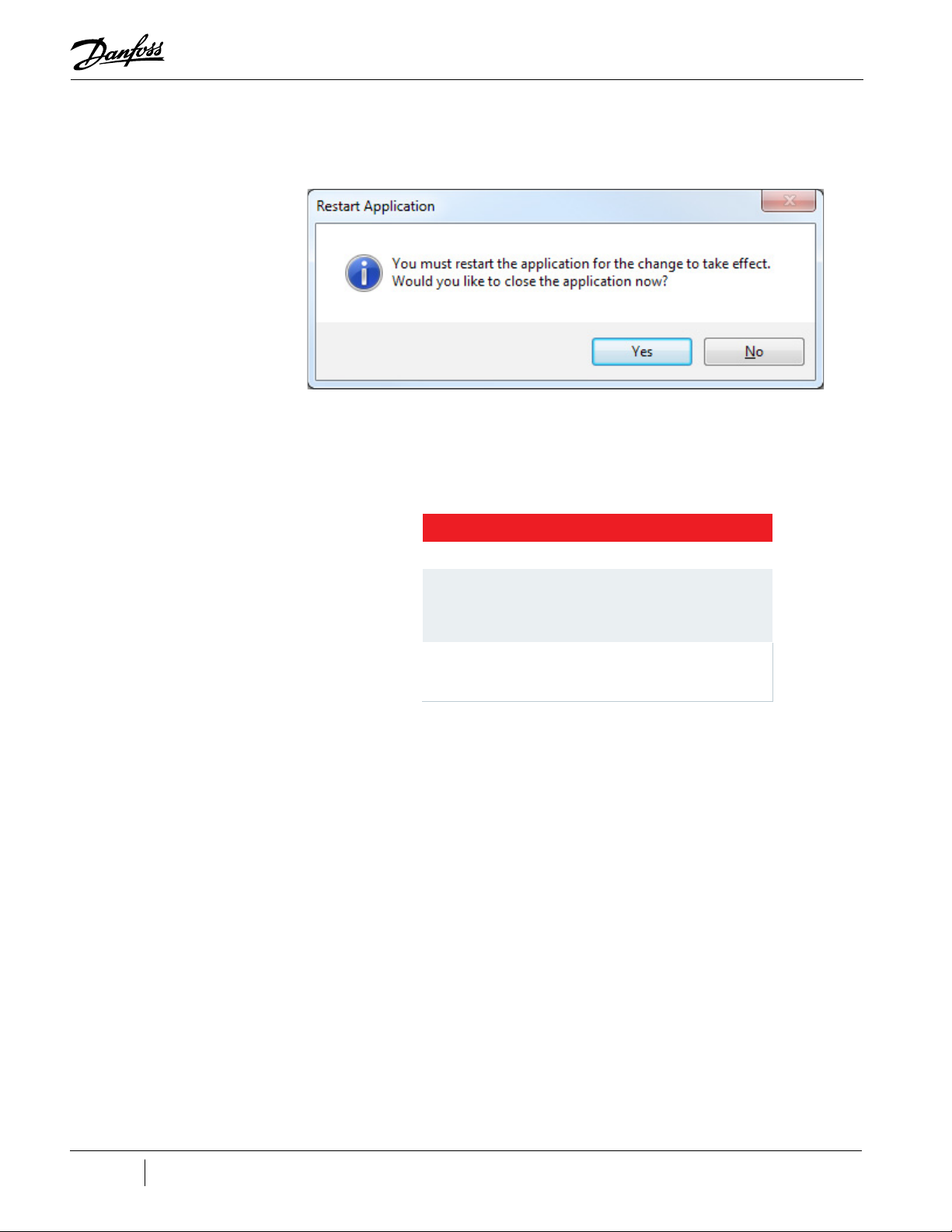

Figure 1-6 Restart Application ............................................................................................................................................................ 10

Figure 1-7 Collapsible Group Boxes Example (TT/TG SMT Shown) ....................................................................................... 13

Figure 2-1 SMT Suite Launcher Strip - Not Connected (TT SMT Shown) ............................................................................15

Figure 2-2 Compressor Data Recording & Playback Tool Icon ................................................................................................ 15

Figure 2-3 Compressor Data Recording and Playback Tool ..................................................................................................... 16

Figure 2-4 Open Recording Icon ........................................................................................................................................................ 16

Figure 2-5 Choose a Recording File to Open Window ...............................................................................................................17

Figure 2-6 Compressor Data Recording & Playback Tool .......................................................................................................... 18

Figure 2-7 Compressor Data Recording and Playback Tool showing Launch Playback Server .................................. 19

Figure 2-8 Launch Playback Server Icon ......................................................................................................................................... 19

Figure 2-9 Compressor Connection Manager Icon ..................................................................................................................... 20

Figure 2-10 Compressor Connection Manager ............................................................................................................................ 20

Figure 2-11 TT/TG SMT Suite Launcher Strip - Connected .......................................................................................................21

Figure 2-12 VTT SMT Suite Launcher Strip - Connected ........................................................................................................... 21

Figure 3-1 Compressor Connection Manager Icon ..................................................................................................................... 23

Figure 3-2 TT/TG Compressor Connection Manager .................................................................................................................. 23

Figure 3-3 V TT Compressor Connection Manager .....................................................................................................................24

Figure 3-4 Parameter Saving Frame .................................................................................................................................................27

Figure 4-1 ModComm Tool Icon ........................................................................................................................................................29

Figure 4-2 VTT ModComm Window (VTT Displayed) ................................................................................................................29

Figure 4-3 ModComm Window Displaying Menu .......................................................................................................................30

Figure 4-4 ModComm Tool Window Showing Menu ................................................................................................................. 30

Figure 4-5 Write Single Register .........................................................................................................................................................30

Figure 4-6 Write Single Register Result Window ..........................................................................................................................31

Figure 4-7 ModComm Tool Window Showing Menu ................................................................................................................. 31

Figure 4-8 Write Multiple Registers Result Window ....................................................................................................................32

Figure 4-9 TT/TG ModComm Tool Window Showing Menu .................................................................................................... 32

Figure 4-10 VTT ModComm Tool Window Showing Menu ......................................................................................................33

Figure 4-11 VTT ModComm Tool Window Showing Display Format Options ..................................................................33

Figure 4-12 ModComm Tool Window Showing Chosen New Display Format (VTT Displayed) .................................33

Figure 5-1 Active Alarm/Fault Viewer Tool Icon............................................................................................................................35

Figure 5-2 TT/TG Active Alarm/Fault Viewer Window ................................................................................................................35

Figure 5-3 VTT Active Alarm/Fault Viewer Window ....................................................................................................................36

Figure 5-4 Clearing Faults (TT/TG)..................................................................................................................................................... 36

Figure 5-5 TT/TG Compressor Status Tab ........................................................................................................................................ 37

Figure 5-6 VTT Compressor Status Tab ............................................................................................................................................37

Figure 5-7 Alarm and Fault Conguration (1) (TT/TG Shown) ................................................................................................ 38

Figure 5-8 Alarm and Fault Conguration (2) Page 2 (TT/TG Only) ...................................................................................... 38

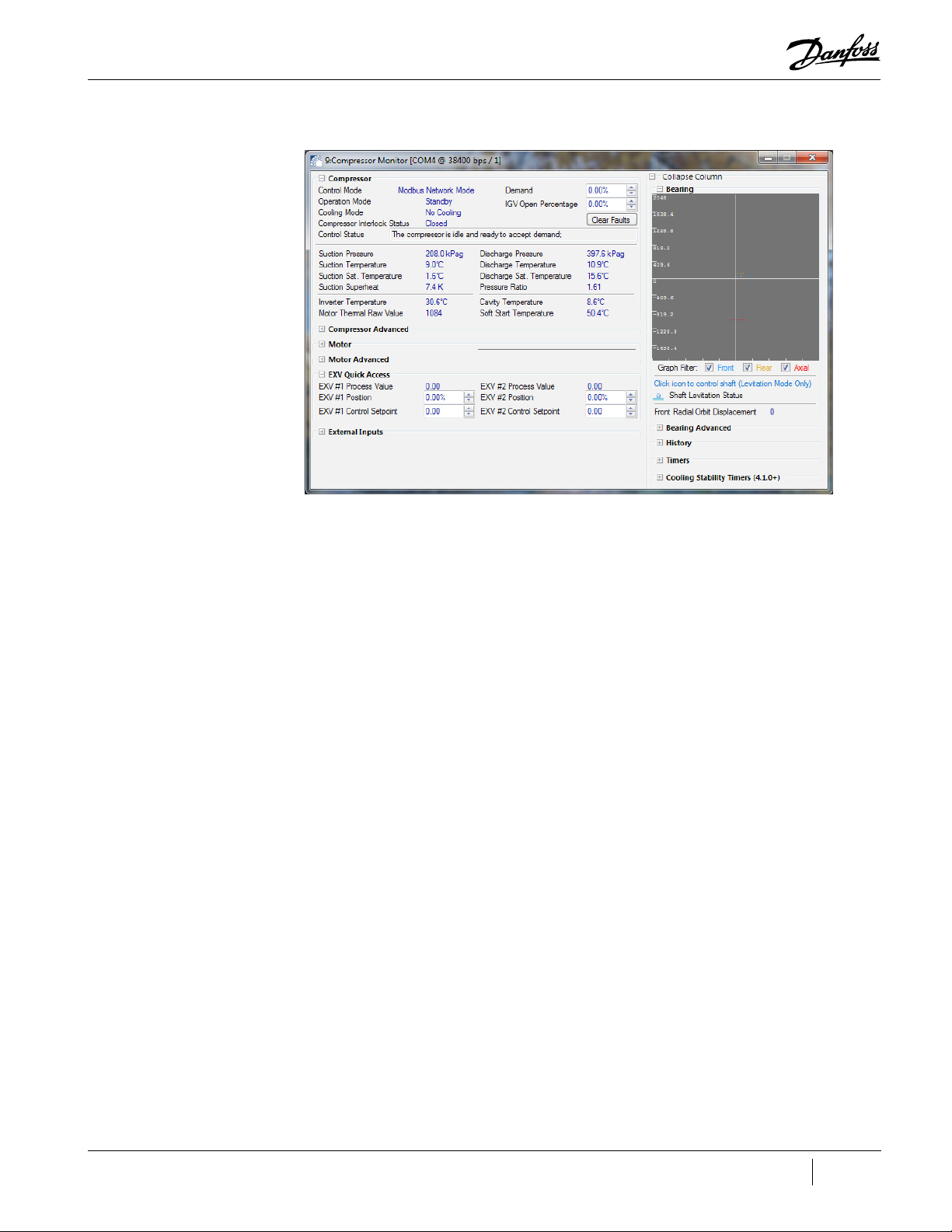

Figure 6-1 Compressor Monitor Tool Icon ......................................................................................................................................39

Figure 6-2 Compressor Monitor Tool Window (TT/TG Shown) ...............................................................................................39

Figure 6-3 Shaft Levitation Status Graphic .................................................................................................................................... 40

Figure 7-1 Logged Event and Fault Viewer Icon ...........................................................................................................................41

Figure 7-2 Logged Event and Fault Viewer Window (TT/TG) ...................................................................................................41

Figure 7-3 Logged Events Fault Viewer ...........................................................................................................................................43

Figure 7-4 Logged Event and Fault Viewer Window (VTT).......................................................................................................44

Figure 7-5 VTT System Snapshot Log Window .............................................................................................................................45

Figure 8-1 Compressor Data Recording and Playback Tool Icon ........................................................................................... 47

Figure 8-2 Compressor Data Recording and Playback ..............................................................................................................48

Figure 8-3 Choose Destination Filename (TT/TG Shown) ........................................................................................................48

Figure 8-4 Site Information .................................................................................................................................................................. 49

Figure 8-5 Start Recording Icon ......................................................................................................................................................... 49

Figure 8-6 Stop Recording Icon..........................................................................................................................................................50

Figure 8-7 Cancel Recording Icon ..................................................................................................................................................... 50

Figure 8-8 Pause Recording Icon .......................................................................................................................................................50

Figure 8-9 Start Recording Icon ......................................................................................................................................................... 51

Figure 8-10 Open Recording Icon ..................................................................................................................................................... 51

Figure 8-11 Choose a Recording to Open Window .....................................................................................................................51

Figure 8-12 Play Icon .............................................................................................................................................................................. 52

Figure 8-13 Compressor Connection ............................................................................................................................................... 52

Figure 8-14 Compressor Data Recording and Playback Window ..........................................................................................53

Figure 8-15 Close Recording Icon ..................................................................................................................................................... 53

5 of 88M-SM-001-EN Rev. G

Page 6

Figure 8-16 Stop Playback Server ...................................................................................................................................................... 54

Figure 8-17 Play Button .........................................................................................................................................................................54

Figure 8-18 Pause Button ..................................................................................................................................................................... 54

Figure 8-19 Rewind Button .................................................................................................................................................................. 54

Figure 8-20 Slow Forward Button .....................................................................................................................................................54

Figure 8-21 Slow Reverse Button.......................................................................................................................................................54

Figure 8-22 Save as CSV File Button .............................................................................................................................................55

Figure 8-23 Save to CSV ..................................................................................................................................................................... 55

Figure 8-24 Tools Button .......................................................................................................................................................................56

Figure 8-25 Manage Parameters Window ...................................................................................................................................56

Figure 8-26 Speed Registers Selected ............................................................................................................................................. 56

Figure 9-1 Bearing Calibration Tool Icon ......................................................................................................................................... 57

Figure 9-2 Bearing Calibration Window ..........................................................................................................................................57

Figure 9-3 Bearing Calibration Tool Showing Graphs ................................................................................................................58

Figure 10-1 Chiller and Analog Conguration Tool Icon ...........................................................................................................61

Figure 10-2 Chiller and Analog Conguration Window ............................................................................................................61

Figure 11-1 EXV Conguration Tool Icon ........................................................................................................................................ 63

Figure 11-2 EXV Conguration Tool (Applies to rmware prior to 4.X) ...............................................................................63

Figure 11-3 EXV Conguration Tool (Applies to 4.x rmware) ................................................................................................64

Figure 12-1 Compressor Conguration Tool Icon ........................................................................................................................ 67

Figure 12-2 Compressor Conguration Window .........................................................................................................................67

Figure 12-3 Compressor Conguration Window (Basic Conguration) ..............................................................................68

Figure 12-4 Compressor Conguration Window (Advanced Conguration) ....................................................................68

Figure 13-1 Compressor Commissioning Tool Icon .................................................................................................................... 73

Figure 13-2 Compressor Commissioning Window......................................................................................................................73

Figure 13-3 Compressor Commissioning Finish Window .........................................................................................................74

Figure 13-4 Choose Commissioning File Location ......................................................................................................................74

Figure 13-5 Commissioning Complete............................................................................................................................................75

Figure 13-6 Report Prompt .................................................................................................................................................................. 75

Figure 13-7 Report Save As Window ................................................................................................................................................76

Figure 14-1 Compressor Data Trending Tool Icon .......................................................................................................................77

Figure 14-2 Compressor Data Trending Window ......................................................................................................................... 77

Figure 14-3 Compressor Trending Window - Parameter Pane ................................................................................................78

Figure 14-4 Parameter Color Selection............................................................................................................................................79

Figure 14-5 Watched Parameters After Color Change ............................................................................................................... 80

Figure 14-6 Watched Parameters Being Plotted .......................................................................................................................... 80

Figure 14-7 Save Data Prompt ............................................................................................................................................................81

Figure 14-8 Save Data to a CSV File ..................................................................................................................................................81

Figure 14-9 Managed Watch Congurations Button .................................................................................................................82

Figure 14-10 Watch Management Window ...................................................................................................................................82

Figure 14-11 Compressor Data Trending ........................................................................................................................................83

Figure 14-12 Compressor Data Trending ........................................................................................................................................84

Figure 14-13 Motor Cooling Valve Tool Icon ..................................................................................................................................84

Figure 14-14 Valve Control Setup - Motor Cooling .....................................................................................................................85

Figure 14-15 Valve Control Setup - VFD Cooling .........................................................................................................................85

Figure 14-16 Valve Control Setup - IFV ............................................................................................................................................85

Figure 14-17 Valve Control Setup - Staging ...................................................................................................................................86

6 of 88

M-SM-001-EN Rev. G

Page 7

Proprietary Notice

Copyright, Limitations of Liability and Revision Rights.

This publication contains proprietary information to Danfoss Turbocor Compressors, Inc. (DTC). This

publication is protected under the Copyright laws of the United States of America (USA) and most

other countries. This work is owned by DTC, and was published as of the most recent revision of

this publication, as indicated on the Title page of this document. This document is for the use DTC

customers and prospective customers only. Any use beyond that is prohibited.

Tests have demonstrated that equipment produced according to the guidelines provided in this

manual will function properly, however DTC cannot guarantee the equipment to work in every

physical, hardware or software environment.

The guidelines provided in this manual are provided “AS-IS” without any warranty of any kind, either

express or implied, including, without limitation, any implied warranties of condition, uninterrupted

use, merchantability, fitness for a particular purpose.

In no event shall DTC be liable for direct, indirect, special, incidental or consequential damages

arising out of the manufacture, use, or the inability to manufacture or use information contained in

this manual, even if advised of the possibility of such damages. In particular, DTC is not responsible

for any costs, including but not limited to those incurred as a result of lost profits or revenue, loss of

damage or equipment, loss of computer programs, loss of data, the costs to substitute these, or any

claims by third parties. In any event, DTC’s total aggregate liability for all damages of any kind and type

(regardless of whether based in contract or tort) shall not exceed the purchase price of this product.

DTC reserves the right to revise the publication at any time and to make changes to its contents

without prior notice or any obligation to notify former or present users of such revisions or changes.

Danfoss Turbocor Compressors Inc.

1769 East Paul Dirac Drive Tallahassee,

Florida 32310

USA

Phone 1-850-504-4800

Fax 1-850-575-2126

http://turbocor.danfoss.com

Encounter an error or see opportunity for improvements while reading

this manual? Email us at turbocor.contact@danfoss.com with a brief

description.

* Subject to change without notice.

* Danfoss Turbocor’s commitment to excellence ensures continuous product improvements.

7 of 88M-SM-001-EN Rev. G

Page 8

THIS PAGE INTENTIONALLY LEFT BLANK

8 of 88

M-SM-001-EN Rev. G

Page 9

Chapter 1.0 Service Monitoring Tools Overview

1.1 Service Monitoring Tools Suite

Figure 1-1 TT/TG SMT Suite Launcher Strip - Not Connected

Figure 1-2 VTT SMT Suite Launcher Strip - Not Connected

Once connected, more tool icons may appear in the SMT Suite Launcher Strip depending on the

compressor’s established access level.

Figure 1-3 TT/TG SMT Suite Launcher Strip - Connected

Figure 1-4 VTT SMT Suite Launcher Strip - Connected

To change the language in the SMT, Right-Click the main toolbar and select Language then English

or Chinese.

Figure 1-5 Select Language

9 of 88M-SM-001-EN Rev. G

Page 10

To save language preference, restart the application. The chosen language will be stored in settings.

The default language found in local machine settings will be used during installation.

Figure 1-6 Restart Application

1.2 Compatibility Requirements

"Table 1-1 SMT Software Requirements" provides the system requirements for the SMT.

Table 1-1 SMT Software Requirements

TT/TG/VTT

Framework: .NET Framework Version 4.0 or later.

Operating System: Microsoft Windows XP

(32-bit or 64-bit) SP2 or later, Microsoft Windows Vista (32-bit or

64-bit) Basic or better, Microsoft Windows 7 (32-bit or 64-bit)

Home Basic, or Windows 10 (32-bit or 64-bit).

Hardware: 1.0 GHz or higher CPU, minimum OS-required RAM,

1024x768 high-color display (or better), and 20 MB or more

available hard-disk space.

Depending on compressor access level, the following tools may be available from the SMT Suite

Launcher Strip:

10 of 88

M-SM-001-EN Rev. G

Page 11

Table 1-2 SMT Software Icons

Icon Tool Description

The About tool displays a form showing OS and framework version information, SMT software

system release product version info, and a listing of software assemblies loaded for the SMT

About

Compressor Connection Manager Discover and establish a means of communication with the compressor. ( TT/TG and VTT)

software product.

• To view a detailed description of any given assembly, select an item in the loaded assemblies

listing and a text description and graphic icon (if exists) displays in the area below

• To copy all of the version information to the clipboard, click the Copy Info button. (TT/TG

and VTT )

ModComm Tool

Active Alarm/Fault Viewer

Compressor Monitor

Chiller and Analog Conguration

EXV Conguration Tool

Logged Event and Fault Viewer

Compressor Data

Recording and Playback

Assists in troubleshooting a Bearing, Motor and Compressor Controller (BMCC) or monitoring

registers by providing access to ModBus registers on a raw level. (TT/TG and VTT )

Instantaneously monitor the alarm and fault status of a connected compressor device and

congure the alarm and fault limits. (TT/TG and VTT )

Monitor the most commonly desired parameters of the BMCC related to motor, bearing, and

compressor operation. (TT/TG and VTT )

Allows you to view or modify the chiller control and analog output control conguration

parameters and settings. (TT/TG 3.1.X or older Firmware Only)

This allows you to view and congure the electronic expansion valve conguration

parameters and settings. (TT/TG Only)

Retrieve logged fault and event data regarding the operation of a connected compressor for

the purpose of troubleshooting and diagnostics. (TT/TG 3.1.X or older Firmware Only)

Start and stop recording of any variables on the BMCC, as well as launch a server partially

simulating an actual compressor using previously recorded data. The intended usage of

this tool is not only for training, but for testing, evaluation and compressor troubleshooting

purposes. (TT/TG and VTT)

Bearing Calibration Execute a bearing calibration procedure and analyze the outcome. (TT/TG and VTT)

Compressor Conguration

Compressor

Commissioning

Compressor Data Trending

Valve Control

View and congure the compressor operation, IGV startup, surge/choke, and other

operational conguration parameters. (TT/TG and VTT)

View, modify and commit site-specic compressor parameter values of a connected

compressor, as well as import and export congurations between portable les. Minor

guidance is provided to the user by presenting any number of conguration pages which

are necessary for consideration during the deployment of a compressor system and the

displaying of basic coverage/ow indication. (TT/TG Only)

Graphically monitor selected compressor parameter values and load or save usercongurable watch congurations. (TT/TG and VTT)

View and congure the valve operation: Motor Cooling, VFD Cooling, IFV, and Staging valves.

(VT T only)

11 of 88M-SM-001-EN Rev. G

Page 12

1.2.1 Right-Click Context Menu

From the SMT Launcher Strip, you can right-click with your mouse to view a context menu providing

easy access to tasks, including:

1.3 General Usage

There are several helpful features common across all tools in the SMT software system geared toward

simplifying day-to-day as well as extensive usage. These features include: internal logging system,

informative tooltips, highlight-on-click, collapsible group boxes, interactive graphs, persistent user

settings, normalized tool framework, and product update checking.

1.3.1 Internal Logging System

To enhance maintenance and troubleshooting the SMT software system, all tools utilize a common

logging system functionality for outputting to file internal trace information, as well as any error

occurrences which may occur.

The log file is located at: [My Documents]\Danfoss Turbocor\SMT\smt.log

• Launching a tool - select the desired tool by name.

• Display the About form - click About.

• Minimize the tool suite - click Minimize and the tool will be minimized to your task bar under

one window button.

• Change the SMT Launcher Strip orientation - click Alignment -> Horizontal to display the SMT

Launcher Strip in a landscape format or Alignment -> Vertical for a portrait layout.

1.3.2 Informative Tooltips

To aid in general use and interpretation of compressor data, all compressor parameter edit/display

fields will display a tooltip which pops up if the mouse cursor hovers over the field and will describe

the modbus register associated with that parameter.

1.3.3 Highlight-on-click

To assist you in viewing data ‘at a glance’, certain readout fields can be highlighted to make them stand

out from the rest. The highlighting of fields with this functionality enabled can be toggled by leftclicking on the desired field.

1.3.4 Expand/Collapse-on-click

Any group boxes which display a box bearing a +/- box in the upper left-hand corner may be collapsed

in order to reduce the size of a form when some information is not desired to be viewed. To collapse or

expand these regions, left-click on the +/- graphic.

12 of 88

M-SM-001-EN Rev. G

Page 13

Figure 1-7 Collapsible Group Boxes Example (TT/TG SMT Shown)

1.3.5 Interactive Graphs

Graphs display data and provide a different perspective. The graphing feature provides the ability to

pan, zoom, etc.

• To pan: if panning is enabled, click and drag in either the X or Y direction.

• To fast pan: hold the control key while clicking and dragging within a graph to pan across larger

areas.

• To zoom: if zooming is enabled, use the scroll wheel on the mouse to zoom in and out - holding

shift while scrolling will only stretch the Y axis; holding ctrl while scrolling will only stretch the X axis.

• To reset to initial view: double-click anywhere on the graph.

1.3.6 Persistent User Settings

Many of the interface settings are saved in a local settings file in order to persist common settings on a

user-by-user basis.

Typical persistent settings include: tool form screen location, tool form normal/maximized state,

collapsible form collapse/expand states, user-entered application fields (e.g., hostnames, DTC ports,

technician name fields, etc.).

The settings file is located at:

[My Documents]\Danfoss Turbocor\SMT\Settings.xml

1.3.7 Normalized Tool Framework

All components considered to be tools contain a commonly-structured data identifying a tool and its

interface components.

Data included in the tool metadata (assembly information) include: Tool Id #, Tool Name Id, Tool

Description Id, Tool Classification, Minimum (execution) Access Level, Enumeration Count, Persistence,

Connection Requirement, Dedication Requirement, and an Application Graphic.

In addition to the framework metadata, there are several components geared toward the utilization of

these tool components, including standalone execution support, common interfacing components, etc.

13 of 88M-SM-001-EN Rev. G

Page 14

1.3.8 Tool Identification

Each tool’s title frame contains information identifying it. This information includes:

• Tool/Form ID - The first number, indicating the ID number of the current tool.

• Tool Title - The localized text title of the current tool.

• Device Connection Info - This includes the serial port and baud rate or IP address and port

number and the slave address of the device with which the current tool is connected.

NOTE

To dierentiate between instances of the SMT, look at the device communication information displayed in the tool’s frame.

14 of 88

M-SM-001-EN Rev. G

Page 15

Chapter 2.0 Recordings

2.1 Running a Recording

While the SMT Suite Tools are intended to be used with live Danfoss Turbocor (DTC) compressors, it is

possible to partially simulate communication with a compressor using recorded data. The playback

simulation can be used for displaying values, but cannot accept write requests (parameter updates)

and certain features may not be available (such as fault or event log retrieval).

When you first open the Service Monitoring Tools software, a limited version of the Service Monitoring

Tools (SMT) Suite Launcher Strip is displayed.

Figure 2-1 SMT Suite Launcher Strip - Not Connected (TT SMT Shown)

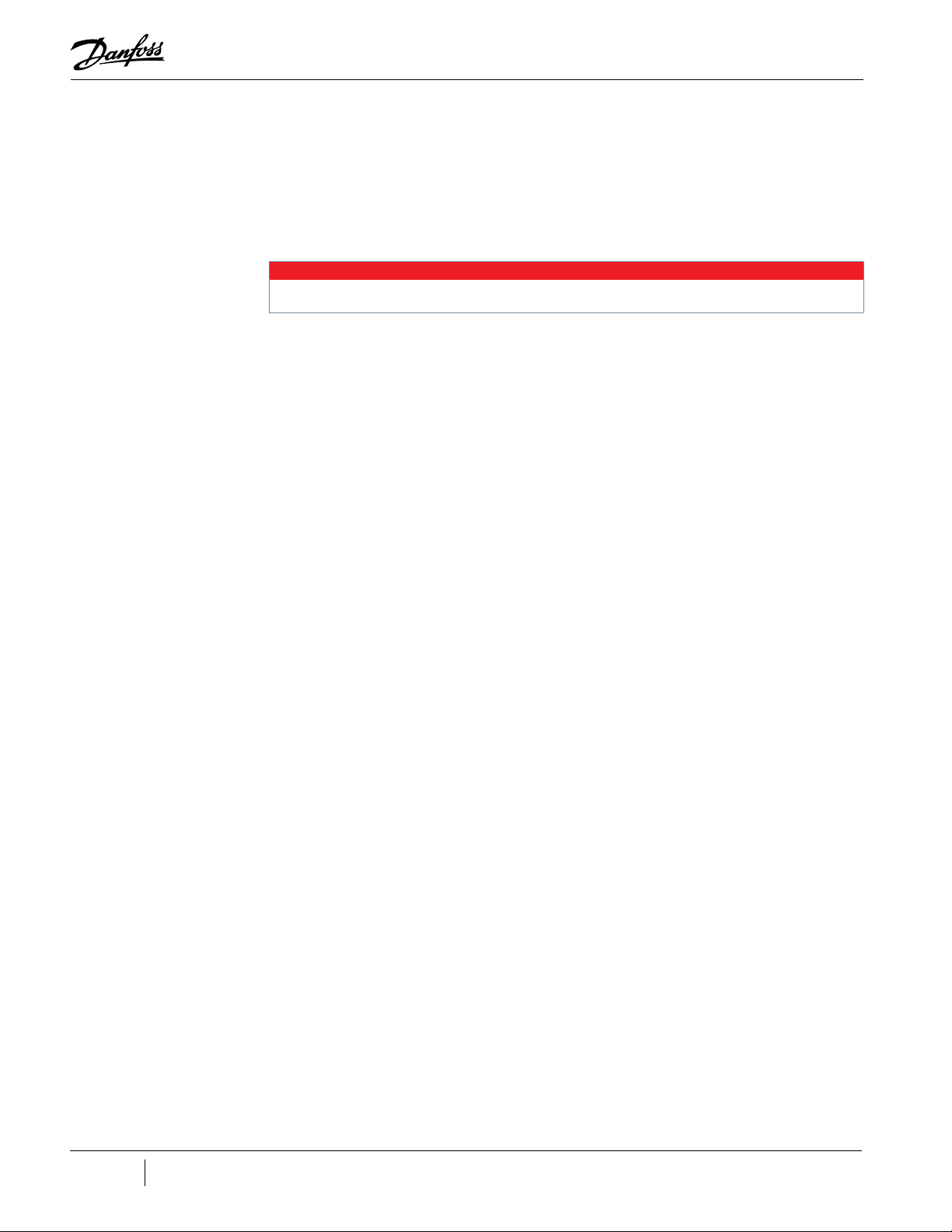

1. Click the Compressor Data Recording & Playback Tool icon.

Figure 2-2 Compressor Data Recording & Playback Tool Icon

2. The Compressor Data Recording & Playback Tool window displays.

15 of 88M-SM-001-EN Rev. G

Page 16

Figure 2-3 Compressor Data Recording and Playback Tool

Figure 2-4 Open Recording Icon

16 of 88

M-SM-001-EN Rev. G

3. Click the Open Recording icon.

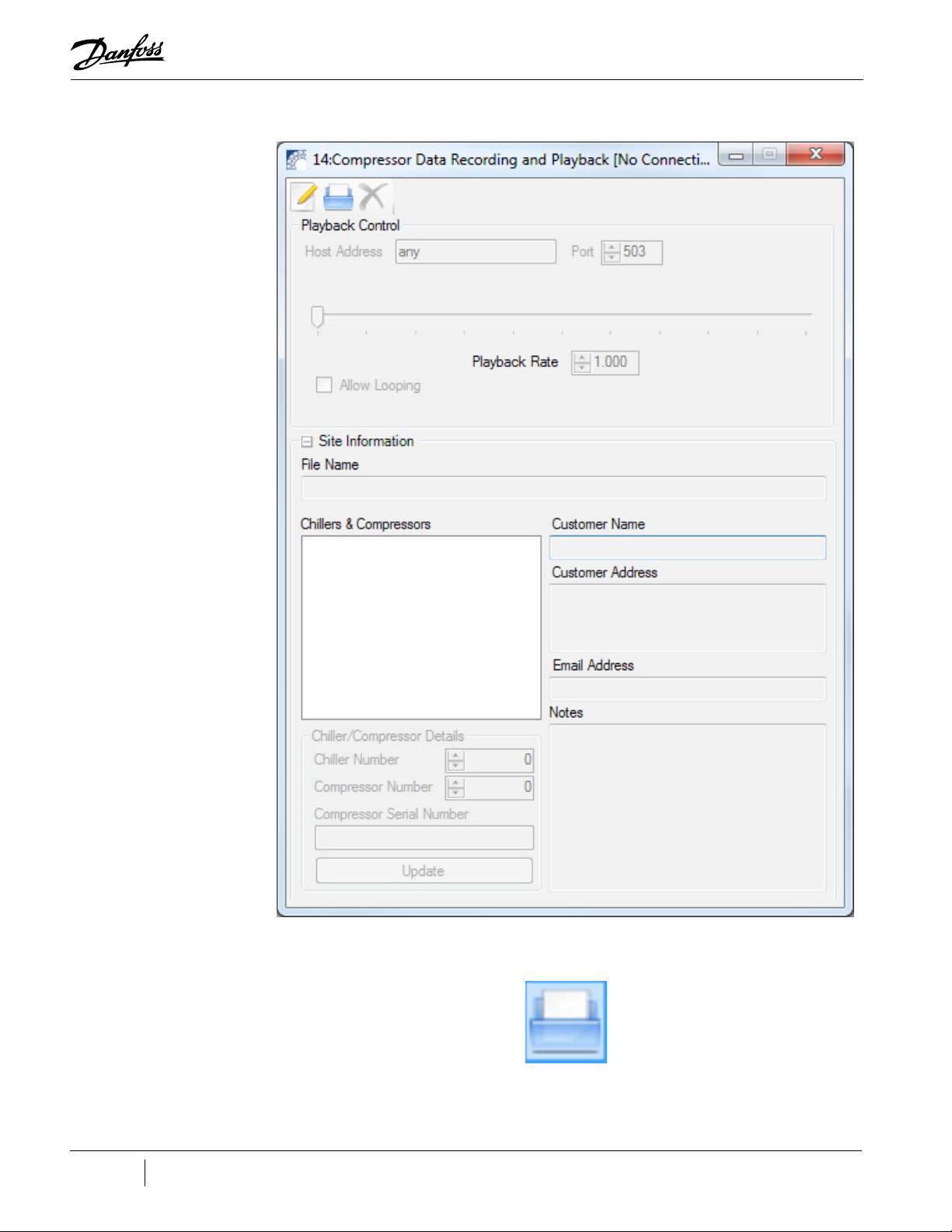

The Choose a recording file to open window displays:

Page 17

Figure 2-5 Choose a Recording File to Open Window

4. Select a recording file, and then click Open.

The playback host will automatically start when you connect to it.

NOTE

17 of 88M-SM-001-EN Rev. G

Page 18

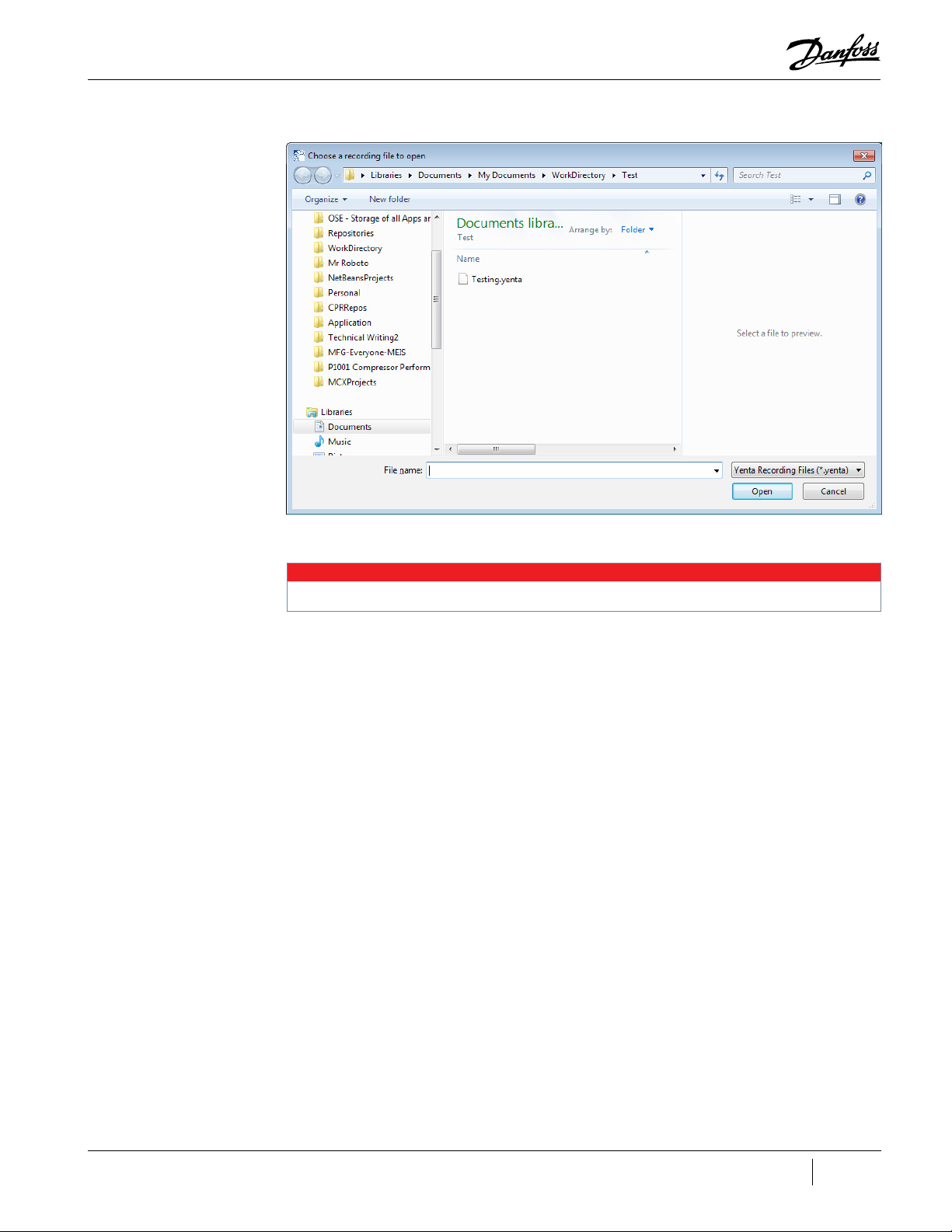

Figure 2-6 Compressor Data Recording & Playback Tool

18 of 88

5. If the playback control icons do not appear at the top of the Compressor Data Recording &

Playback Tool, a window similar to "Figure 2-7 Compressor Data Recording and Playback Tool

showing Launch Playback Server" on page 19 will display. Complete steps a and b; otherwise

jump to step 6.

M-SM-001-EN Rev. G

Page 19

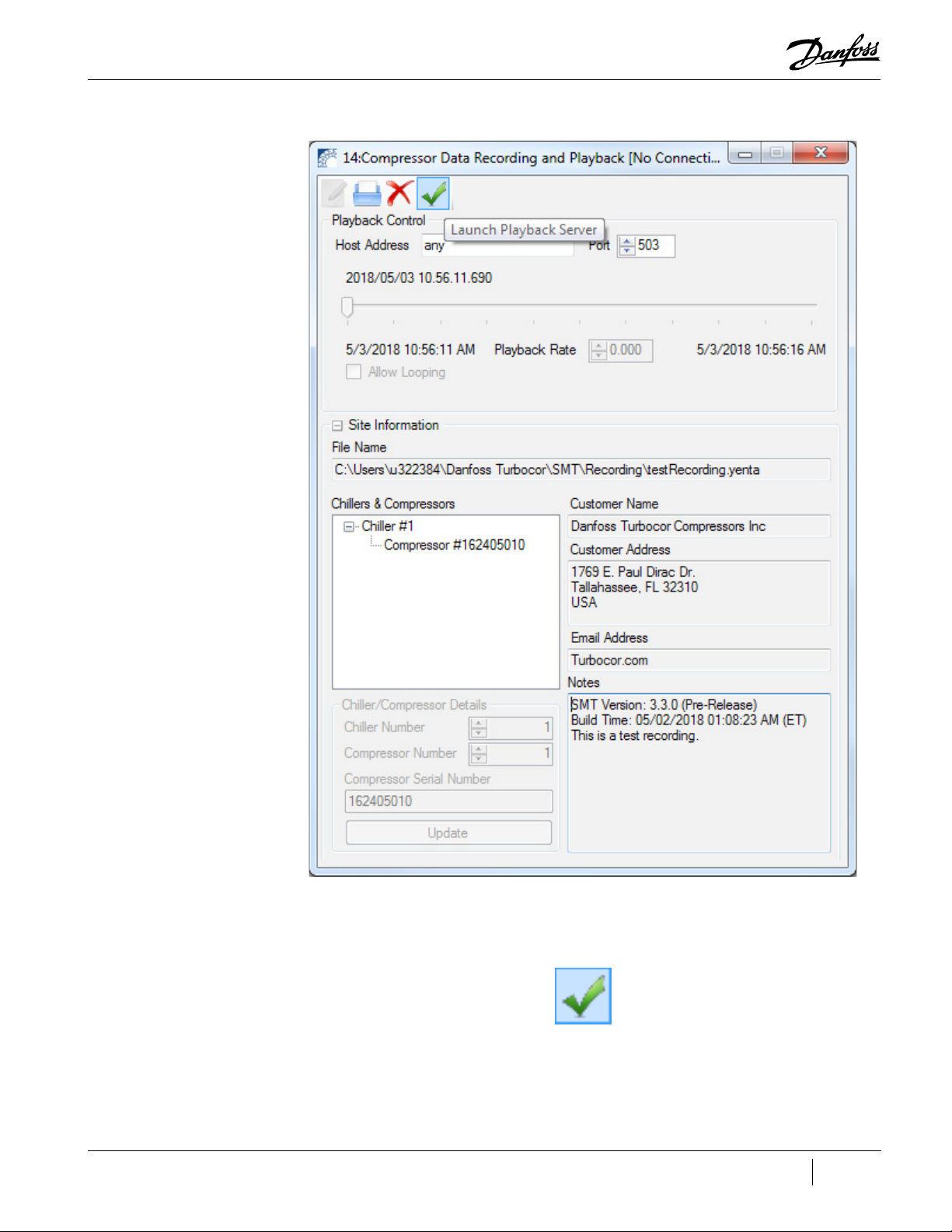

Figure 2-7 Compressor Data Recording and Playback Tool showing Launch Playback Server

Figure 2-8 Launch Playback Server Icon

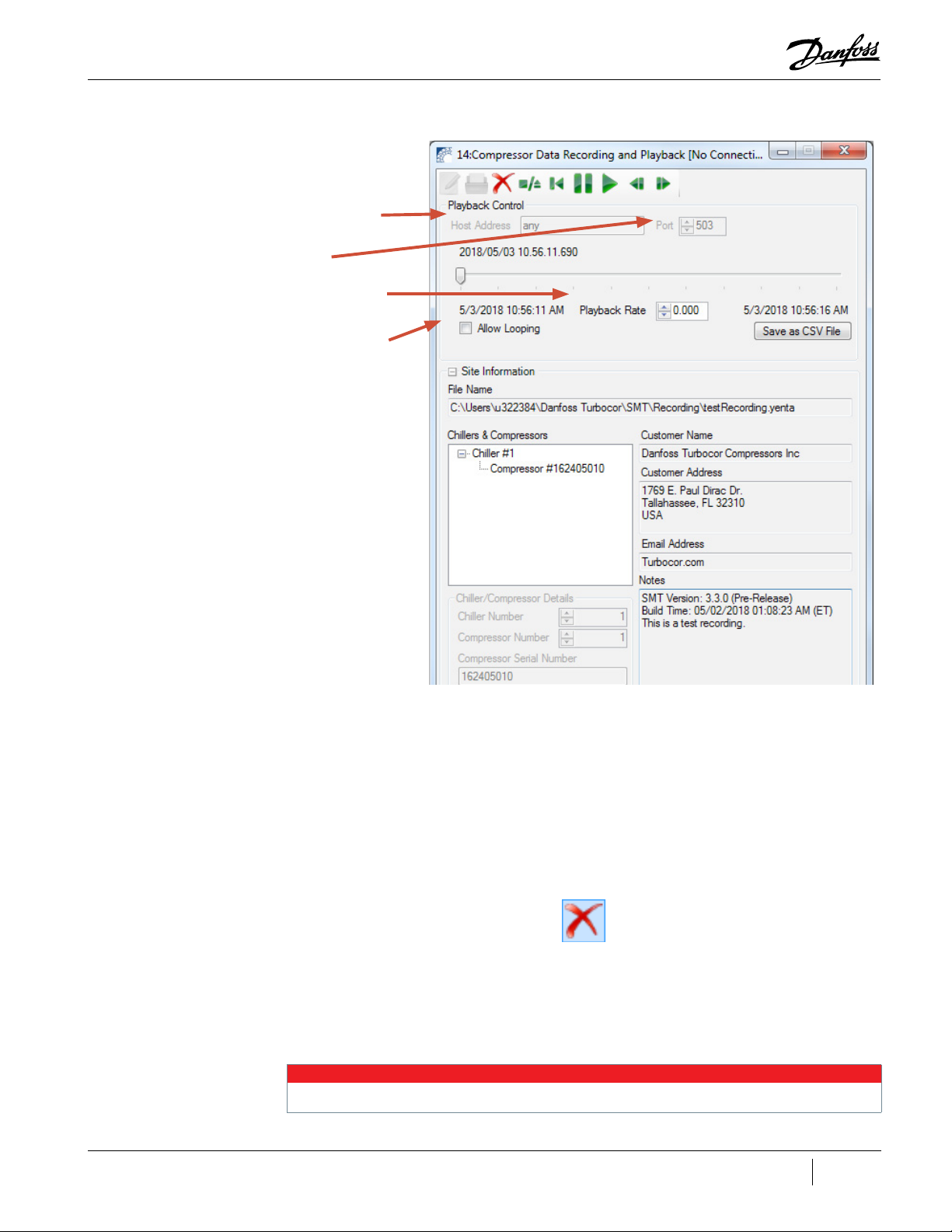

6. Click the Compressor Connection Manager icon.

a. Check the settings of the Host Address and Port fields (default values are ‘any’ and ‘503’).

b. Click the Launch Playback Server icon. For more information, refer to Section "8.1

Launching the Compressor Data Recording and Playback Tool" on page 47

19 of 88M-SM-001-EN Rev. G

Page 20

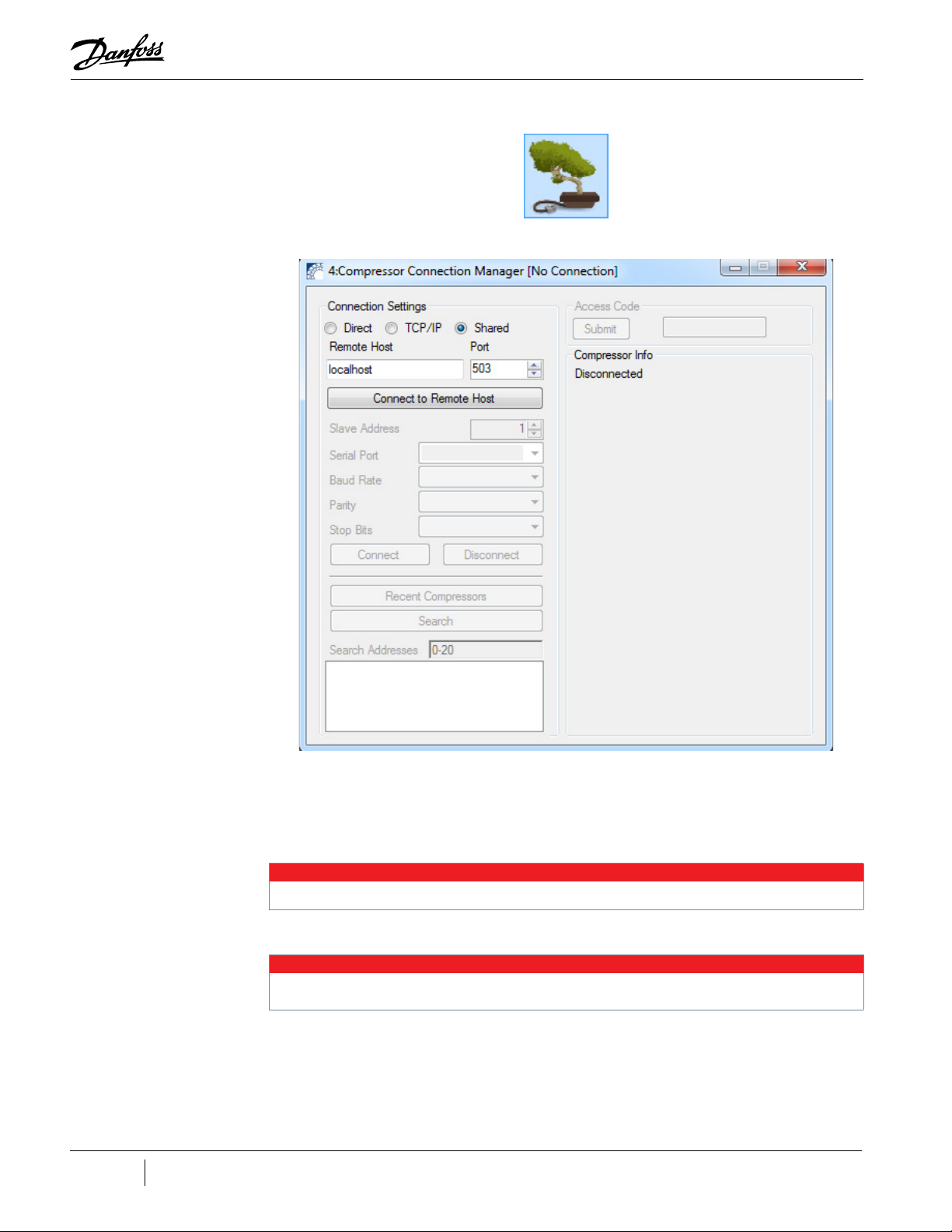

Figure 2-9 Compressor Connection Manager Icon

Figure 2-10 Compressor Connection Manager

7. In the Compressor Connection Manager, ensure that Shared is selected under the Connection

Settings.

8. Ensure that the field labeled Port matches the Port filed displayed on the Compressor Data

Recording & Playback Tool and that the field labeled ‘Remote Host’ says ‘localhost’.

9. In the Compressor Connection Manager, click Connect to Remote Host.

NOTE

No other information (e.g., Serial Port, Baud Rate) will need to be selected/entered prior to clicking the Connect button.

10. Click Connect. You are now connected.

NOTE

Access level is determined by the recording and cannot be changed. For example, if the recording was made at an OEM level, the

recording playback will display OEM level access.

20 of 88

M-SM-001-EN Rev. G

Page 21

Figure 2-11 TT/TG SMT Suite Launcher Strip - Connected

Figure 2-12 VTT SMT Suite Launcher Strip - Connected

21 of 88M-SM-001-EN Rev. G

Page 22

THIS PAGE INTENTIONALLY LEFT BLANK

22 of 88

M-SM-001-EN Rev. G

Page 23

Chapter 3.0 Compressor Connection Manager

The Compressor Connection Manager is used to discover and establish a means of communication

with a compressor. This tool can be used to establish a connection with a compressor, close an

established connection, detect compressor settings, change compressor access level, synchronize

the compressor real-time clock (RTC) with a personal computer (PC) clock, and view a list of recent

compressor connection settings.

When a connection with a compressor is established, information detailing the compressor’s current

access level, Bearing and Motor Control (BMC) version, Compressor Controller (CC) version, part

number, configuration number, refrigerant type, unit system, and current real-time clock readout are

displayed as well as the current connection status.

3.1 Accessing the Compressor Connection Manager

Please see Section 1.5 “Running a Simulation” if you wish to evaluate the software without connecting to a compressor.

1. Click the Compressor Connection Manager icon.

Figure 3-1 Compressor Connection Manager Icon

NOTE

The Compressor Connection Manager window displays:

Figure 3-2 TT/TG Compressor Connection Manager

23 of 88M-SM-001-EN Rev. G

Page 24

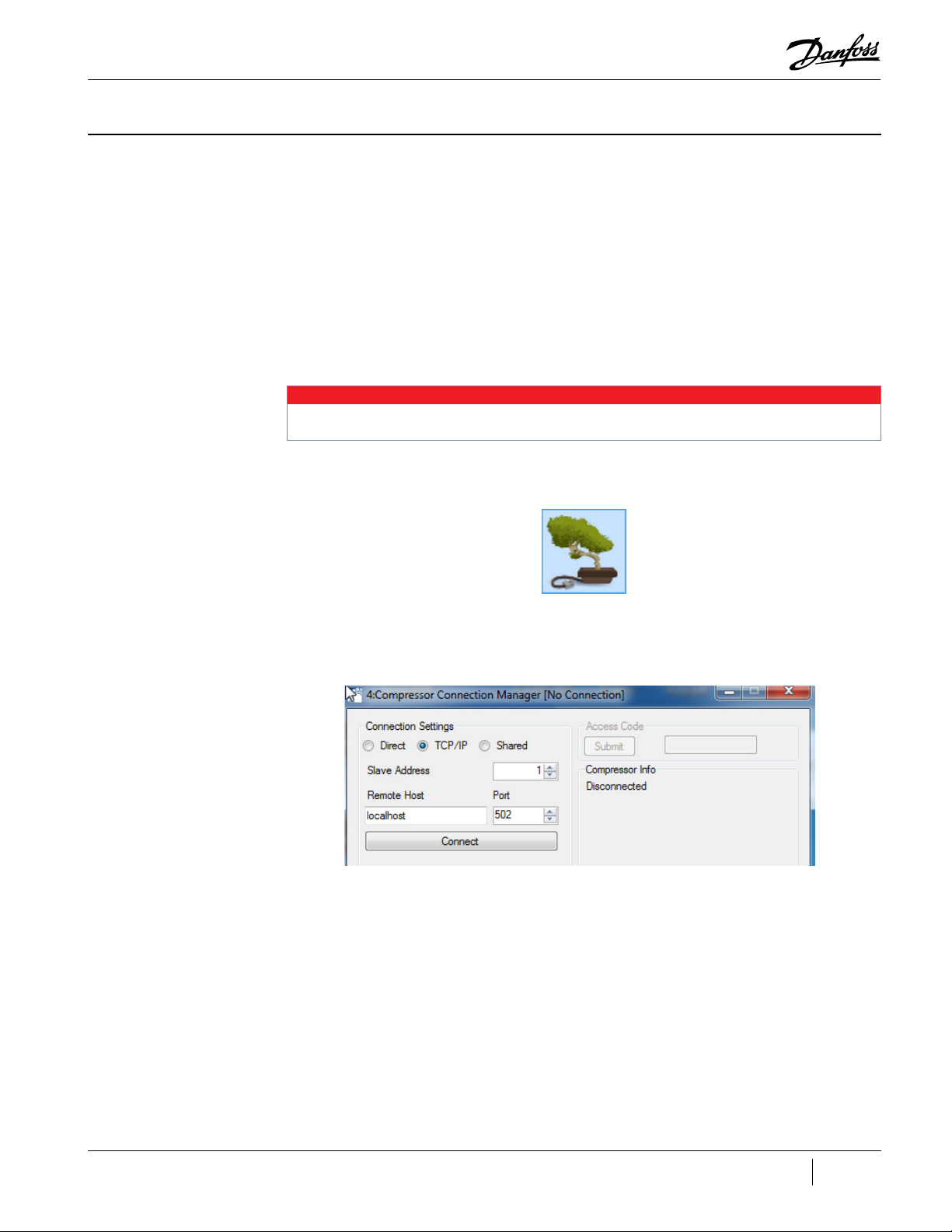

Figure 3-3 V TT Compressor Connection Manager

3.2 Compressor

To establish a connection with a compressor:

1. From the Connection Settings group, select a connection type:

• Direct for direct use of the serial port. This is the default recommended setting.

• Shared for indirect use of a serial port, allowing multiple applications access to the same

compressor via the same serial port.

• Transmission Control Protocol/Internet Protocol (TCP/IP) for communication with a Modbus TCP

compressor interface.

2. If using Shared or TCP/IP, enter your shared host name and TCP port number - usually the

default values (localhost and 502) will work.

a. For a Direct Connection, refer to Section "3.2.1 Direct Connection" on page 24.

b. For a Shared Connection, refer to Section "3.2.2 Shared Connection" on page 25.

c. For TCP/IP, refer to Section "3.2.3 TCP/IP Connection" on page 25.

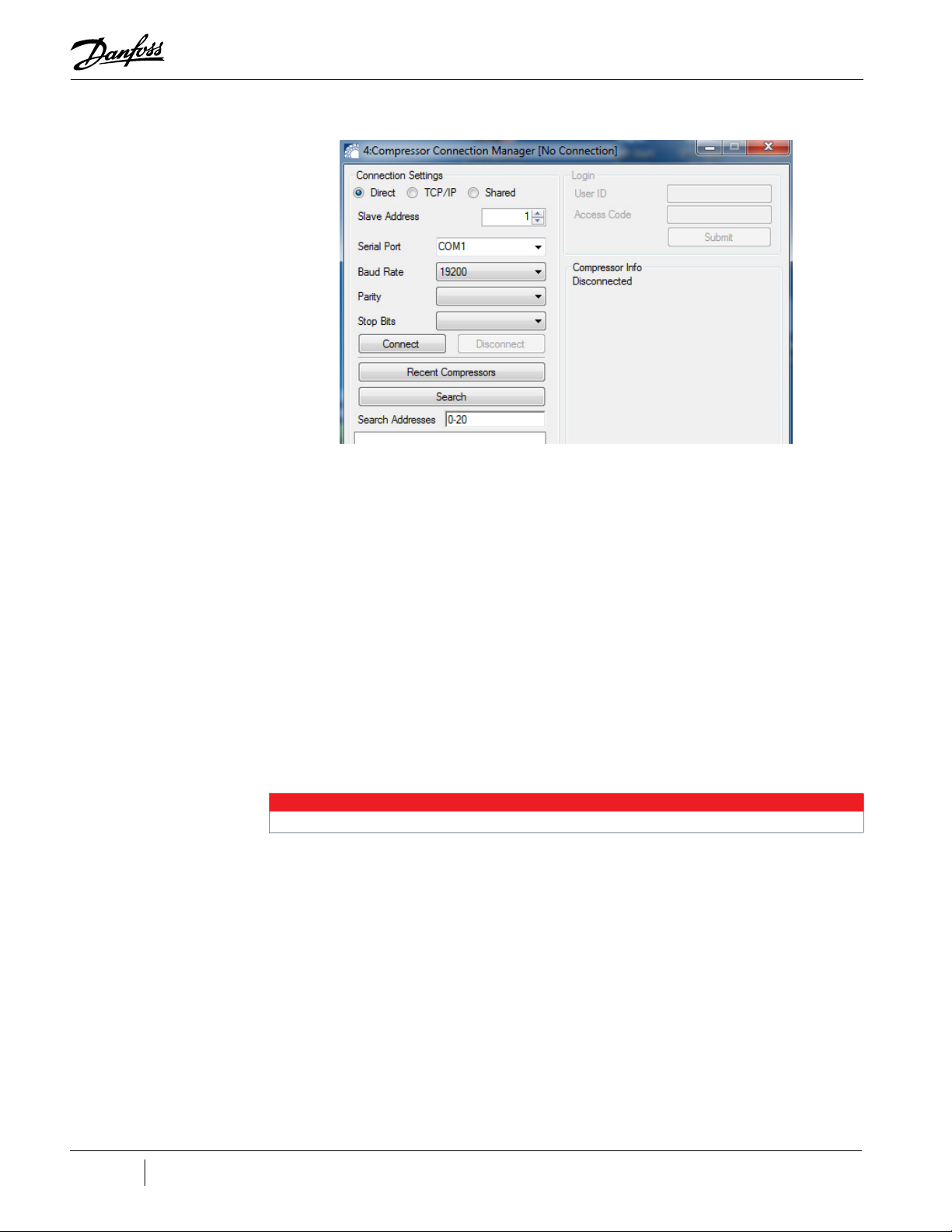

3.2.1 Direct Connection

24 of 88

M-SM-001-EN Rev. G

1. From the Connection Settings group, select Direct as your connection type.

2. Select the serial port to which the compressor is connected from the Serial Port drop-down list.

NOTE

The Serial Port listing only shows serial port names which currently exist on the local/host machine.

3. Do one of the following:

a. If the slave address and baud rate are known: enter the known slave address in the Slave

Address field and select the known baud rate from the Baud Rate drop-down and click

Connect - a connection should now be established.

b. If the slave address or baud rate are unknown, enter a slave address search range or list

of values to test for detection in the Search Addresses field and click Search (default is

0-20).

After a short period of time (the fewer addresses to check, the quicker the search will be), the search

results containing a list of communication setting combinations display in the Search Addresses field.

Double-click any of the communication setting combinations to automatically connect using those

settings. A connection should now be established.

If no compressors are detected, No compressors found! will display in the listing.

4. Type in your Access Code and click Submit.

Page 25

3.2.2 Shared Connection

3.2.3 TCP/IP Connection

To enter a Shared connection:

1. From the to Connection Settings group, select Shared as your connection type.

2. Enter your shared host name and TCP port number - usually the default values will work.

3. Click the Connect to Remote Host button.

4. Select the serial port to which the compressor is connected from the Serial Port drop-down

box.’

5. Do one of the following:

a. If the slave address and baud rate are known: enter the known slave address in the Slave

Address field and select the known baud rate from the Baud Rate drop-down and click

Connect - a connection should now be established.

b. If the slave address or baud rate are unknown, enter a slave address search range or list

of values to test for detection in the Search Addresses field and click Search (default is

0-20).

After a short period of time (the less addresses to check, the quicker the search will be), the search

results containing a list of communication setting combinations display in the Search Results listing.

Double-click any of the communication setting combinations to automatically connect using those

settings. A connection should now be established If no compressors are detected, No compressors

found! will display in the listing.

6. Type in your Access Code and click Submit.

1. From the Connection Settings group, select TCP/IP as your connection type:

2. Enter the slave address in the Slave Address field.

3. Click Connect.

A connection should now be established.

4. Type in your Access Code and click Submit.

3.3 Closing an Established Connection

To close an established connection:

1. Click the Disconnect button.

2. To also disconnect from a remote host (such as the Compressor Data Recording & Playback

tool’s playback host), click the Disconnect from Remote Host button. The tool will close any

connections established and data polling will stop.

3.4 Detecting Compressor Settings

To detect compressor settings:

• Enter a slave address search range or list of values to test for detection in the Search Results

listing and click the Search.

After a short period of time (the less addresses to check, the quicker the search will be), the search

results display in the Search Addresses field. If no compressors are detected, No compressors found! will

display in the listing; otherwise, communication setting combinations will display.

25 of 88M-SM-001-EN Rev. G

Page 26

3.5 Changing Compressor Access Levels

On connection, the SMT requires a valid access code in order to allow access to the various tools available at the given

access level.

A user must not change the access level of the BMCC to a value lower than 2 if the compressor is being controlled by Modbus.

If the access level is lower than access level 2, the compressor can not accept a demand write.

For rmware versions of 3.X.X or lower, for example, if the lowest level that a compressor can accept a demand write is at

Access Level 2 (Low Level), then on submission of a “0” in the Access Code eld, the SMT will revert to a read-only state and the

compressor will not accept writes to demand from the Modbus controller. In this case, the compressor access level should be left

at Access Level 2 (Low Level) or higher.

To change the compressor access level:

TT/TG SMT

1. Enter the desired Access Code, then click Submit.

VTT/TG SMT

1. Enter the desired User ID and Access Code, then click Submit.

The tool will send the access code to the compressor and indicate the access level on the connected

compressor.

If the access code is incorrect: the compressor will revert the access to the lowest level. After five failed

access code change attempts, the compressor will no longer accept access codes and will require a

power cycle before allowing an access level change.

NOTE

Since the access level on the compressor will remain after disconnecting from the compressor, be sure to either downgrade the

access level or power cycle the compressor after completing service.

3.6 Synchronizing the Compressor Real-Time Clock with a PC Clock

To synchronize a compressor real-time clock (RTC) with a PC clock:

• Click the Sync Compressor/Computer Time button.

The tool will attempt to update the compressor’s RTC to match the local computer’s date and time to

within ±500 ms.

3.7 Viewing a List of Recent Compressor Connection Settings

To view a list of recent compressor connection settings:

• Click the Recent Compressors button.

A list of recent compressor communication settings will display. If there is no connection history,

No compressors found! displays in the listing; otherwise, communication setting combinations are

displayed. Double-clicking any of the settings combination entries will automatically attempt to

connect using the those settings.

3.8 Selecting the Unit System

To select the appropriate unit system for the compressor:

• Click the Units Drop-Down Box and select the desired unit system.

NOTE

26 of 88

M-SM-001-EN Rev. G

Page 27

3.9 Connection Status Indications

The Connection Status is indicated in the Compressor Info section of the Compressor Connection

Manager Window.

• Disconnected: no connection exists with a compressor or remote compressor host.

• Ready to Connect: a connection with a remote host (if applicable) has been established, but no

compressor connection has yet been established.

• Compressor is starting up: The currently connected compressor is in startup mode.

• Connected: There has been established a connection with a remote host (if applicable) and a

connection with a compressor has been established and verified.

• No compressor found: Any serial ports or connections have been established, but a valid

compressor was not able to be detected.

• Error opening port: There was an error opening the specified serial port (either the port is

already in use, the port name doesn’t exist, or there was some other error attempting to open

the serial port).

• Server not found: Could not connect to remote host.

• There was a time out during communication’ (Error Time out): There was a timeout during

communication.

• Invalid response: The response received was invalid.

• Received an error response: The host responded with an error.

• Error: CRC mismatch: The received message has a CRC mismatch.

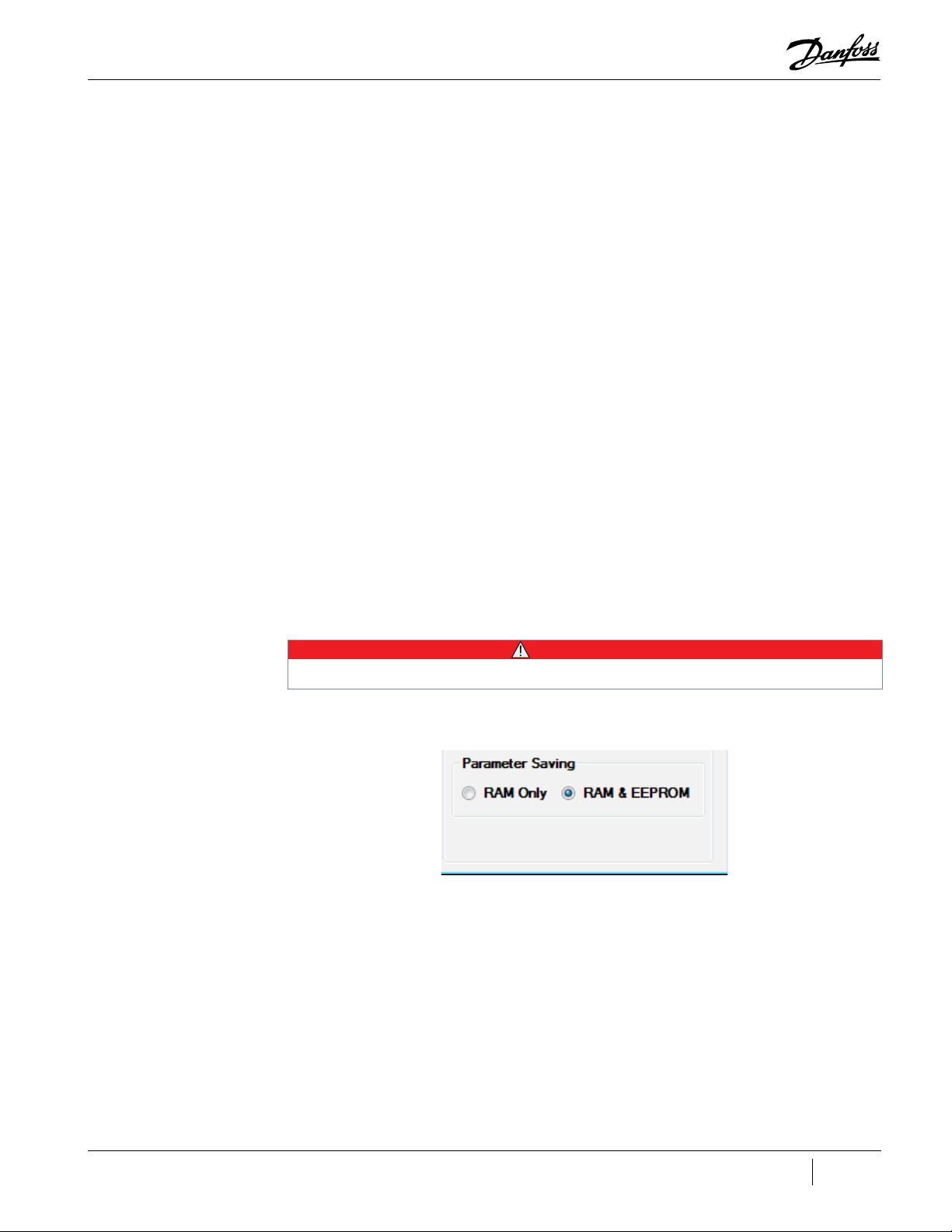

3.10 RAM Only and RAM & EEPROM Check boxes (TT/TG Only)

By default, changes made in the SMT are set to RAM & EEPROM.

If the RAM & EEPROM check box is clicked, all parameter changes are saved to persistent memory, if

said register is capable of doing so.

Saving to RAM & EEPROM will commit all the current values to permanent memory and all previous values will be lost.

Figure 3-4 Parameter Saving Frame

The Parameter Saving frame is located in the lower right corner of the Compressor Connection Tool.

See "Figure 3-4 Parameter Saving Frame".

• • • CAUTION • • •

27 of 88M-SM-001-EN Rev. G

Page 28

THIS PAGE INTENTIONALLY LEFT BLANK

28 of 88

M-SM-001-EN Rev. G

Page 29

Chapter 4.0 ModComm Tool

The ModComm Tool assists users in troubleshooting a Bearing, Motor and Compressor Controller

(BMCC) or monitoring extra registers by providing access to Modbus registers on a raw level. This tool

can be used to change the current register watch range, toggle between watching the specified watch

range and all currently polled register watches, make a single write request, and change the current

data interpretation view.

4.1 Accessing the ModComm Tool

• Once connected, select the ModComm tool icon from the SMT Suite Launcher Strip.

Figure 4-1 ModComm Tool Icon

The ModComm window displays.

Figure 4-2 VTT ModComm Window (VTT Displayed)

4.2 Changing the Current Register Watch Range

To change the current register watch range:

1. Double-click the Display register number in the header and change the register number to

update the range.

2. If desired, the Count can be changed to display a desired number of registers.

29 of 88M-SM-001-EN Rev. G

Page 30

Figure 4-3 ModComm Window Displaying Menu

4.3 Making a Single Write Request

To make a single write request:

1. Click on Modbus Function and select Single Register Write from the context menu.

Figure 4-4 ModComm Tool Window Showing Menu

Figure 4-5 Write Single Register

30 of 88

M-SM-001-EN Rev. G

2. Enter a valid register address (if necessary) and the appropriate value.

3. Click Send to perform the write. A window displays indicating the result of the operation.

Page 31

Figure 4-6 Write Single Register Result Window

4. Look for the Write ok! message.

4.4 Making a Multiple Writes Request

1. Click on Modbus Function and select Multi-Register Write from the context menu.

Figure 4-7 ModComm Tool Window Showing Menu

2. Enter the base register number and select the Number of Registers to be updated.

3. Update the desired registers then click Write Values.

4. Look for the Write ok! message.

31 of 88M-SM-001-EN Rev. G

Page 32

Figure 4-8 Write Multiple Registers Result Window

4.5 Changing the Current Data Interpretation View

To change the current data interpretation view:

1. Right-click anywhere on the main form and the context menu will display.

Figure 4-9 TT/TG ModComm Tool Window Showing Menu

32 of 88

M-SM-001-EN Rev. G

Page 33

Figure 4-10 VTT ModComm Tool Window Showing Menu

2. Highlight Display Format.

Figure 4-11 VTT ModComm Tool Window Showing Display Format Options

3. Select the desired value display format. The values displayed in the main form will be

formatted as specified.

Figure 4-12 ModComm Tool Window Showing Chosen New Display Format (VTT Displayed)

33 of 88M-SM-001-EN Rev. G

Page 34

THIS PAGE INTENTIONALLY LEFT BLANK

34 of 88

M-SM-001-EN Rev. G

Page 35

Chapter 5.0 Active Alarm/Fault Viewer

The Active Alarm/Fault Viewer allows you to instantaneously monitor the alarm and fault status of a

connected compressor device and configure the alarm and fault limits. This tool can be used to view

compressor alarms and faults, view motor alarms and faults, view bearing alarms and faults, and view/

configure alarm and fault limits and lockout settings.

This tool may not function properly if the connected compressor’s access level is below Low.

For alarm/fault indicators, alarm and fault status are indicated by the colored LED graphic to the left of the alarm/fault name

(alarms are yellow, faults are red, and alarm + fault are orange)

5.1 Accessing the Active Alarm/Fault Viewer Tool

• Once connected, select the Active Alarm/Fault Viewer tool icon from the SMT Suite

Launcher Strip.

Figure 5-1 Active Alarm/Fault Viewer Tool Icon

The Active Alarm/Fault Viewer window displays.

Figure 5-2 TT/TG Active Alarm/Fault Viewer Window

NOTE

NOTE

35 of 88M-SM-001-EN Rev. G

Page 36

Figure 5-3 VTT Active Alarm/Fault Viewer Window

5.1.1 Clearing Faults

To attempt to clear or reset the fault status, click the Clear Faults button in the Compressor Monitor

Window refer to Section "Chapter 4.0 ModComm Tool" on page 29.

Figure 5-4 Clearing Faults (TT/TG)

NOTE

If the cause of the fault has not be resolved, then clicking the Clear Faults button will not clear or reset the faults, since the cause

of the fault still remains.

36 of 88

M-SM-001-EN Rev. G

Page 37

5.2 Viewing and Configuring Alarm/Fault Limits and Lockout Settings

To view/configure alarm and fault limits and lockout settings:

• Click the Configure Alarms/Faults menu option.

If the cause of the fault has not be resolved, then clicking the Clear Faults button will not clear or reset the faults, since the cause

of the fault still remains. The method to access the Congure Alarms/Faults window diers between the two dierent SMTs. Refer

to "Figure 5-5 TT/TG Compressor Status Tab" and "Figure 5-6 VTT Compressor Status Tab" illustrate the dierences.

Figure 5-5 TT/TG Compressor Status Tab

NOTE

Figure 5-6 VTT Compressor Status Tab

37 of 88M-SM-001-EN Rev. G

Page 38

Figure 5-7 Alarm and Fault Configuration (1) (TT/TG Shown)

Figure 5-8 Alarm and Fault Configuration (2) Page 2 (TT/TG Only)

38 of 88

M-SM-001-EN Rev. G

Page 39

Chapter 6.0 Compressor Monitor

The Compressor Monitor tool allows you to monitor the most commonly desired parameters of the

BMCC related to motor, bearing, and compressor operation. This tool can be used to view compressor,

bearing, and motor operational readouts, change the demand, change the IGV opening, change the

desired motor speed, and levitate/de-levitate the shaft.

6.1 Accessing the Compressor Monitor

• Once connected, select the Compressor Monitor Tool icon from the SMT Suite Launcher Strip.

Figure 6-1 Compressor Monitor Tool Icon

The Compressor Monitor window displays.

Figure 6-2 Compressor Monitor Tool Window (TT/TG Shown)

6.2 View Options

The following view options are available on the Compressor Monitor Tool window:

• To view bearing-related readouts, expand the Bearing section.

• For compressor-related readouts, expand the Compressor section.

NOTE

The Pressure Ratio value displayed CAN NOT be guaranteed to accurately reect the pressure ratio as calculated by the BMCC for

BMCC software versions earlier than 1210 - in such a case, it is at best an approximation of what the compressor is assumed to

be calculating.

• For motor-related readouts, expand the Motor section.

39 of 88M-SM-001-EN Rev. G

Page 40

6.3 Changing the Demand

To change the demand:

1. Expand the Compressor section.

2. In the Demand field, either use the up/down arrows or manually enter a value and press

Enter to submit a new value.

6.4 Changing the IGV Opening (TT/TG Only)

To change the IGV opening:

1. Make sure you are in Manual mode. (To change the Compressor Control Mode, refer to Section

"12.2.1 Modifying Control Mode" on page 69.

2. Expand the Compressor section.

3. In the IGV Open Percentage field, either use the up/down arrows or manually enter a value

and press Enter to submit a new value.

Only values between 25%-110% are valid.

6.5 Changing the Desired Motor Speed

To change the desired motor speed:

1. Make sure you are in Manual mode. (To change the Compressor Control Mode, refer to Section

"12.2.1 Modifying Control Mode" on page 69.

2. Expand the Motor section.

3. In the Desired Speed field, either use the up/down arrows (TT/TG Only) or manually enter a

value and press Enter to submit a new value.

6.6 Levitating or De-levitating the Shaft

NOTE

To levitate or de-levitate the shaft:

1. Make sure you are in Levitate Only mode. (To change the Compressor Control Mode, refer to

Section "12.2.1 Modifying Control Mode" on page 69.

2. Click the Shaft Levitation Status graphic located just above the Bearing graph.

Figure 6-3 Shaft Levitation Status Graphic

The graphic will appear as a floating yellow ball when the shaft is levitating and a blue ball on the

ground if the shaft is de-levitated.

40 of 88

M-SM-001-EN Rev. G

Page 41

Chapter 7.0 Logged Event and Fault Viewer

The Logged Event and Fault Viewer allows you to retrieve logged fault and event data regarding the

operation of a connected compressor for the purpose of troubleshooting and diagnostics.

This tool can be used to retrieve logged event/fault data, watch for new logged event/fault data, view

details pertaining to logged events/faults, export logged event/fault data to file, import logged event/

fault data from file, and view application help information.

This tool may not function properly if the connected compressor’s access level is below Low.

7.1 Accessing the Logged Event and Fault Viewer

Launch this tool after connecting to a compressor.

Any instance of this tool launched before connecting to a compressor will remain “oine”.

Launch another instance of this tool after connecting if you later want to view logs of a connected device.

7.1.1 TT/TG Logged Event and Fault Viewer

1. Click the Logged Event and Fault Viewer icon.

Figure 7-1 Logged Event and Fault Viewer Icon

NOTE

NOTE

The Logged Event and Fault Viewer window displays:

Figure 7-2 Logged Event and Fault Viewer Window (TT/TG)

41 of 88M-SM-001-EN Rev. G

Page 42

7.1.1.1 Applying Filters for Data Retrieval and Watching

To apply filters for data retrieval and watching:

• To retrieve logged event data from the connected compressor, check the Retrieve check box to

the side of the Events count indicator.

• To retrieve logged fault data from the connected compressor, check the Retrieve check box to

the side of the Faults count indicator.

• To apply a cut-off date/time for items retrieved, select the Don’t retrieve older than check box,

and then choose a date from the calendar drop-down. Items older than the selected date will

not be retrieved.

7.1.1.2 Retrieving Logged Event and Fault Data

Closing the Logged Event & Fault Viewer will terminate the retrieve functions.

To retrieve logged event and fault data:

1. Click the Data->Start Retrieving menu item.

The tool will automatically start retrieving events and faults as specified until either there are no more

entries to retrieve or there are no more entries within the specified date/time range filter. Entries will

appear in the event/fault listing panel.

2. To stop retrieving logged event and fault data before retrieval is completed, click Data->Stop

Retrieving Data.

NOTE

7.1.1.3 Watching for New Logged Event and Fault Data

Closing the Logged Event & Fault Viewer will terminate the retrieve functions.

To watch for new logged event/fault data:

1. Click Data->Watch for New… menu item.

The tool will continuously check for changes in the event and fault logs as specified. Entries will display

in the Event/Fault Listing pane.

2. To stop watching for new logged event and fault data, click the Data->Stop Watching menu

item.

7.1.1.4 Viewing Logged Events and Faults Details

To view details pertaining to logged events and faults:

• Click on any entry in the Event/Fault Listing panel.

The tool will display details and analysis information describing the selected event

or fault.

NOTE

42 of 88

M-SM-001-EN Rev. G

Page 43

Figure 7-3 Logged Events Fault Viewer

7.1.1.5 Exporting Logged Event and Fault Data to a File

To export logged event/fault data to file:

1. Do one of the following:

a. To export only selected entries, select the desired entries in the event/fault listing panel,

and then select File->Export Selected...

b. To export all entries, select File->Export all.

2. In the Save as window, select an output file name. The logged faults and events will be saved

as .CSV and .TLF files.

7.1.1.6 Importing Logged Event and Fault Data

You do not have to be connected to a compressor to import a saved TLF le for viewing.

To import logged event/fault data from a file:

• Click File>Import Data.

• In the Open file window, select a previously exported TLF logged event/fault data file.

If the file is valid, event and fault entries will display in the Event/Fault Listing panel.

7.1.1.7 Viewing Application Help Information

To view application help information:

• Click the Help menu option, and then select any help area item from the list which appears.

The tool will display relevant help information in the details view.

NOTE

43 of 88M-SM-001-EN Rev. G

Page 44

7.1.2 VTT Logged Event and Fault Viewer

Figure 7-4 Logged Event and Fault Viewer Window (VTT)

7.1.2.1 Event Log Tab

Event Log Tab

1. Click Refresh Status.

2. Choose a Date Range in the Event Retrieval Filter section.

3. Change Retrieval Count to “0” to get all events in the date range.

4. Click the Retrieve Event Logs button.

5. Once the event log is done with the retrieval process, click Save Results to File.

System Snapshot Log Tab

This first step will create the Collection Log.

1. Click Refresh Status.

2. Choose a Date Range in the Snapshot Retrieval Filter section.

3. Change Retrieval Count to “0” to get all events in the date range.

4. Click Retrieve Collection List.

5. Once the Collection List is done with the retrieval process, click Save Results to File.

This second step will create the Snapshot.

1. Click Refresh Status.

2. Choose a Date Range in the Snapshot Retrieval Filter section.

3. Change Retrieval Count to “0” to get all events in the date range.

4. Click Retrieve Collection List.

5. Click on a specific fault you want to view in the list displayed.

6. Click download snapshot from selection.

7. Once the Snapshot is downloaded from the compressor, click Save Results to File.

44 of 88

M-SM-001-EN Rev. G

Page 45

7.1.2.2 System Snapshot Log Tab

Figure 7-5 VTT System Snapshot Log Window

45 of 88M-SM-001-EN Rev. G

Page 46

THIS PAGE INTENTIONALLY LEFT BLANK

46 of 88

M-SM-001-EN Rev. G

Page 47

Chapter 8.0 Compressor Data Recording and Playback Tool

The Compressor Data Recording & Playback tool is used to start and stop recordings of variables in

the BMCC, as well as to launch a server partially simulating an actual compressor using previously

recorded data. The intended usage of this tool is for training, evaluation, and compressor

troubleshooting purposes. This tool can be used to either record data communicated between

the desktop SMT system and a compressor or to host (‘playback’) recorded data for use with the

SMT system.

When recording, the tool can be used to create a new recording, start recording, end recording, cancel

recording, and pause/resume recording. A recording can be created and started either before or after

establishing a connection with a compressor.

When playing back, the tool can be used to open a recording, close a recording, manually launch a

playback server, stop a playback server, manipulate the playback rate, seek playback time, and specify

the minimum access level.

8.1 Launching the Compressor Data Recording and Playback Tool

To launch the Compressor Data Recording and Playback Tool:

• Click the Compressor Data Recording and Playback Tool icon.

Figure 8-1 Compressor Data Recording and Playback Tool Icon

8.2 Recording

8.2.1 Creating a Recording

To create a new recording:

1. Click the New Recording icon.

47 of 88M-SM-001-EN Rev. G

Page 48

Figure 8-2 Compressor Data Recording and Playback

New Recording

icon

2. A Save as window displays. Select an output filename and click OK.

Figure 8-3 Choose Destination Filename (TT/TG Shown)

3. In the Site Information section, optionally enter the Customer Name, Customer Address,

Email Address, and any Notes regarding the recording. Any of this information can be