Page 1

Service Manual - Revision G

®

Danfoss Turbocor® Twin-Turbine

Centrifugal Series Compressors

TTS, TGS, TTH, TGH Series Compressors

http://turbocor.danfoss.com

Page 2

This manual covers Major Revision "F" and later compressors. If you have a Major Revision "E" or earlier compressor, we suggest

downloading Service Manual Revision E from our website since there are some steps that are unique.

Page 3

Table of Contents

Chapter 1.0 Introduction ........................................................................................................................................................................ 15

1.1 Application ................................................................................................................................................................................................................................................................... 15

1.2 Purpose .........................................................................................................................................................................................................................................................................16

1.3 Organization ................................................................................................................................................................................................................................................................17

1.4 Commitment to Quality and the Environment ...............................................................................................................................................................................................18

1.5 Safety Summary ......................................................................................................................................................................................................................................................... 18

1.6 Precautions ..................................................................................................................................................................................................................................................................18

1.7 Refrigerant Type .........................................................................................................................................................................................................................................................18

1.8 Electrical Isolation......................................................................................................................................................................................................................................................19

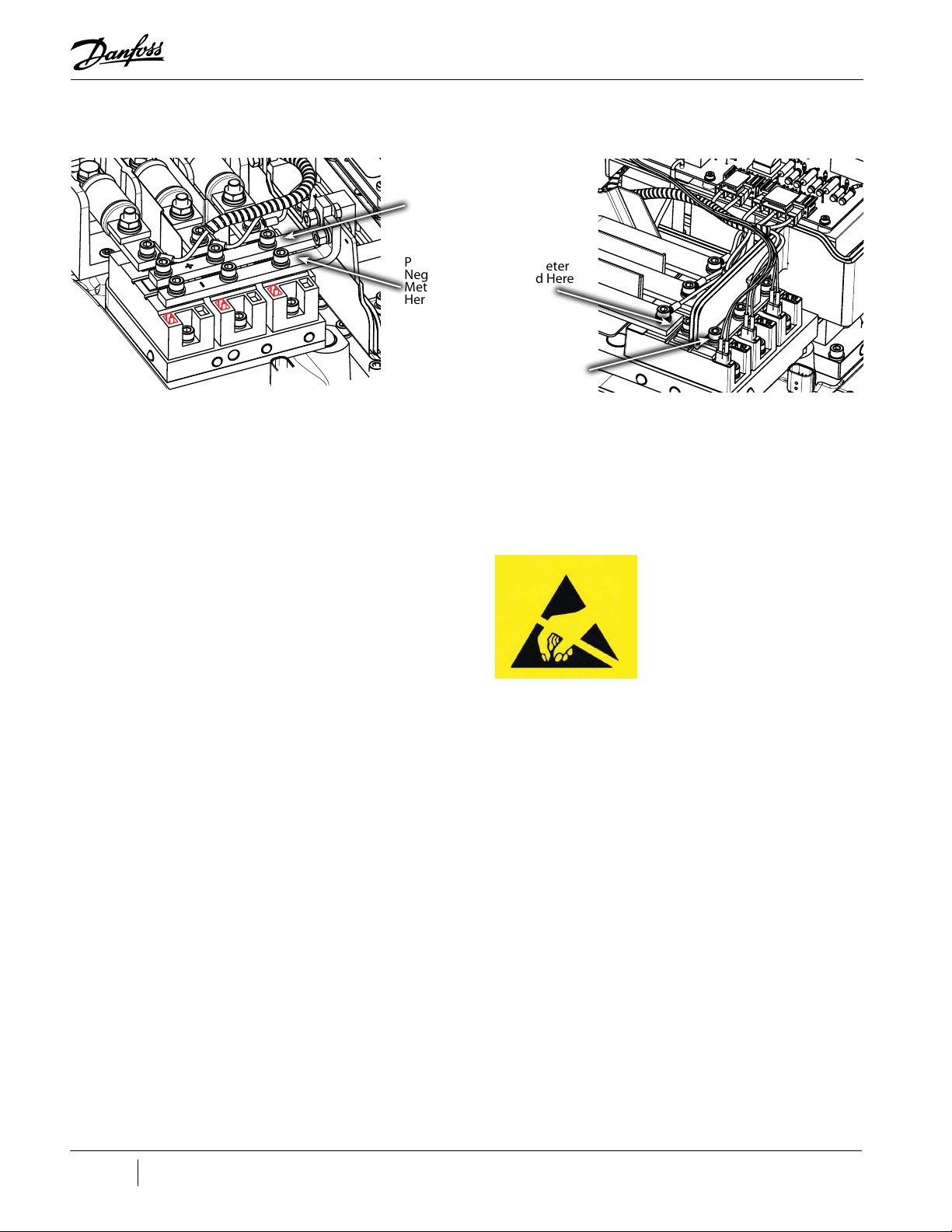

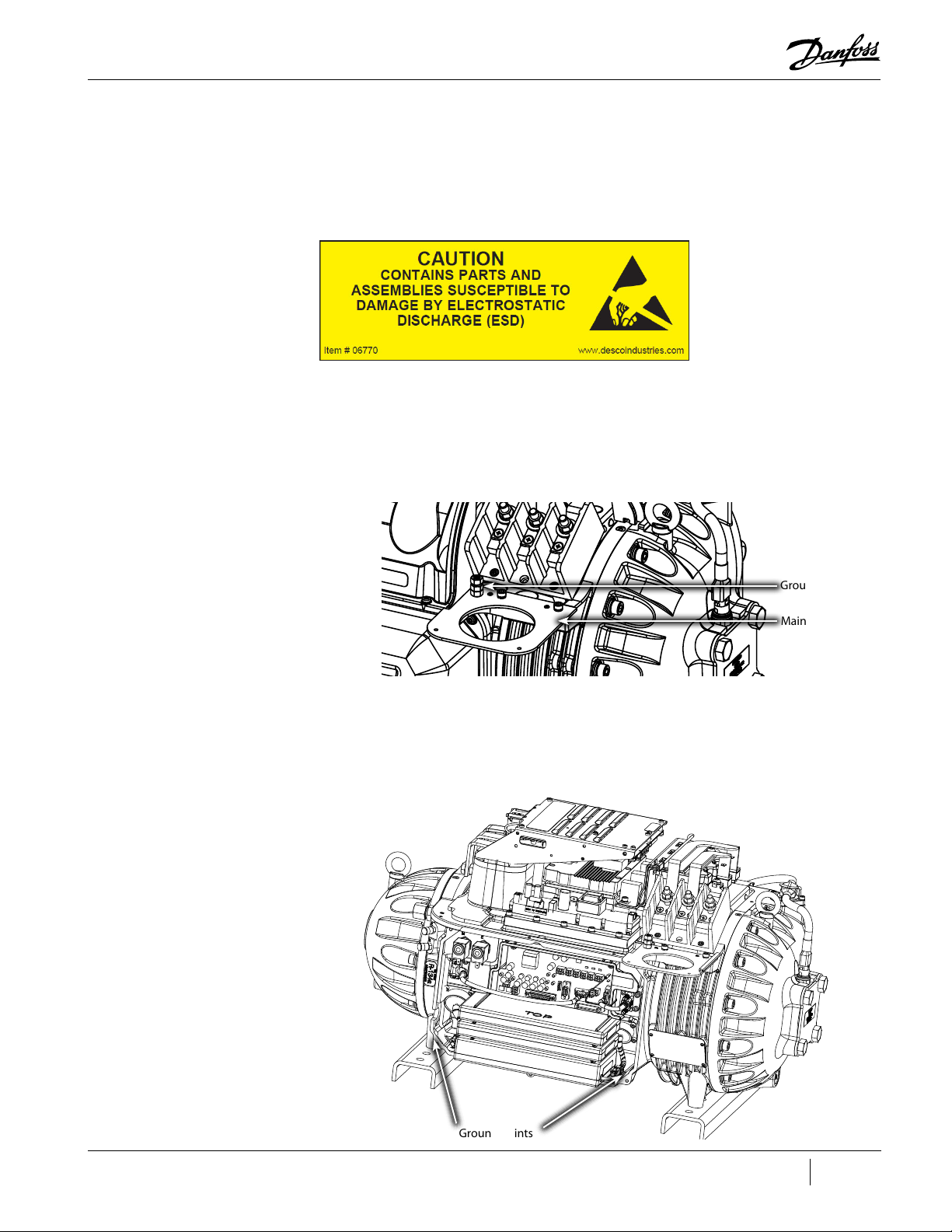

1.9 Handling Static Sensitive Devices ........................................................................................................................................................................................................................ 20

1.10 DC Bus Test Harness Installation and Removal .............................................................................................................................................................................................22

1.11 Compressor Fasteners ........................................................................................................................................................................................................................................... 27

1.12 General O-ring Handling ...................................................................................................................................................................................................................................... 27

Chapter 2.0 Compressor Fundamentals ................................................................................................................................................ 31

2.1 Main Fluid Path ........................................................................................................................................................................................................................................................... 31

2.2 Motor and Power Electronics Cooling ................................................................................................................................................................................................................31

2.3 Capacity Control......................................................................................................................................................................................................................................................... 34

2.4 Compressor Energy and Signal Flow .................................................................................................................................................................................................................. 34

Chapter 3.0 Compressor Removal and Installation .............................................................................................................................. 41

3.1 Refrigerant Containment ........................................................................................................................................................................................................................................41

3.2 Compressor Removal ............................................................................................................................................................................................................................................... 41

3.3 Compressor Installation .......................................................................................................................................................................................................................................... 42

3.4 Compressor Replacement Considerations for Motor Cooling Adapter .................................................................................................................................................43

3.5 Exterior Connection Torque Specifications ...................................................................................................................................................................................................... 45

Chapter 4.0 Compressor Components ................................................................................................................................................... 51

4.1 Component Identification ...................................................................................................................................................................................................................................... 51

4.2 Compressor Covers ................................................................................................................................................................................................................................................... 56

4.3 Cooling Adapter ......................................................................................................................................................................................................................................................... 61

4.4 Compressor Interface Module .............................................................................................................................................................................................................................. 63

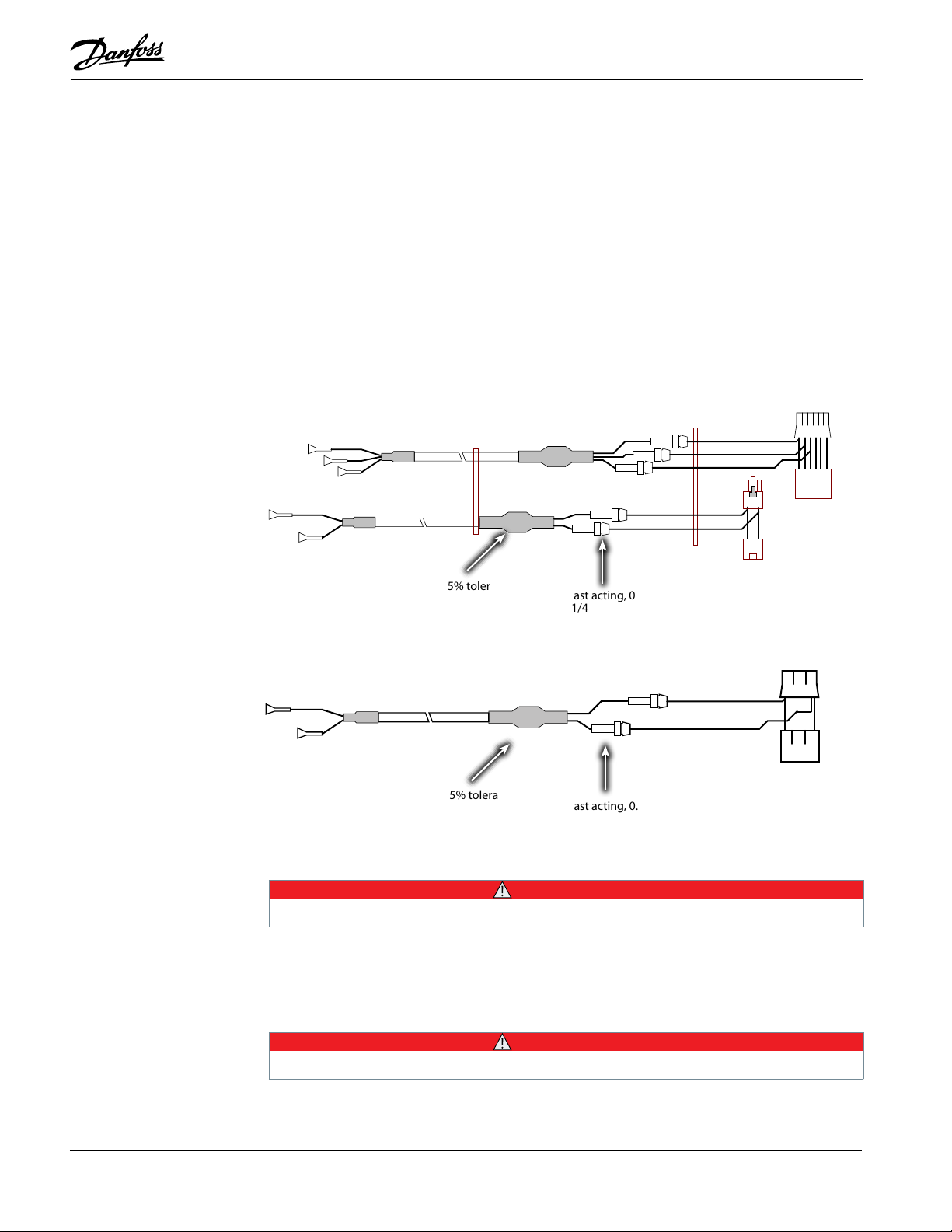

4.5 Compressor Interface Cable ..................................................................................................................................................................................................................................66

4.6 Compressor Controller Cable Harness ............................................................................................................................................................................................................... 67

4.7 Solenoids and Coils ................................................................................................................................................................................................................................................... 72

4.8 Interstage Pipe - TTH/TGH ......................................................................................................................................................................................................................................77

4.9 Compressor Housing End Cap .............................................................................................................................................................................................................................. 78

4.10 IGV ................................................................................................................................................................................................................................................................................80

4.11 Mains Plate Bracket ................................................................................................................................................................................................................................................ 93

4.12 3-Phase Main Voltage Input Terminal Block .................................................................................................................................................................................................. 95

4.13 Input Mains Bus Bars (Except TTS300/TGS230) ..........................................................................................................................................................................................103

4.14 Terminal Block Fuse Replacement ...................................................................................................................................................................................................................105

4.15 Soft Start ...................................................................................................................................................................................................................................................................107

4.16 SCR DC Bus Bar - TTS300/TGS230 ....................................................................................................................................................................................................................119

4.17 Soft Start SCR Gate Cable ...................................................................................................................................................................................................................................121

4.18 Soft Start AC/DC Harness ...................................................................................................................................................................................................................................124

4.19 Silicone-Controlled Rectifier ............................................................................................................................................................................................................................133

4.20 SCR Cooling Manifold ..........................................................................................................................................................................................................................................150

4.21 Snubber Capacitors ..............................................................................................................................................................................................................................................156

4.22 DC Capacitor Bus Bar Assembly .......................................................................................................................................................................................................................156

4.23 Inverter ......................................................................................................................................................................................................................................................................165

4.24 Motor Components ..............................................................................................................................................................................................................................................191

4.25 High Voltage DC-DC Converter ........................................................................................................................................................................................................................201

4.26 Backplane .................................................................................................................................................................................................................................................................207

4.27 Serial Driver .............................................................................................................................................................................................................................................................212

4.28 BMCC .........................................................................................................................................................................................................................................................................214

4.29 Bearing Pulse Width Modulator Amplifier....................................................................................................................................................................................................218

4.30 Magnetic Bearings ................................................................................................................................................................................................................................................223

4.31 Bearing Sensors .....................................................................................................................................................................................................................................................228

4.32 Cavity Temperature Sensor ................................................................................................................................................................................................................................231

4.33 Pressure/Temperature Sensor ..........................................................................................................................................................................................................................234

Chapter 5.0 Troubleshooting ...............................................................................................................................................................241

5.1 Alarm and Fault Indications .................................................................................................................................................................................................................................241

5.2 Troubleshooting with the Service Monitoring Tools Software ...............................................................................................................................................................243

5.3 Bearing Calibration .................................................................................................................................................................................................................................................250

5.4 Compressor Connection Status Indications...................................................................................................................................................................................................255

5.5 System and Compressor Level Troubleshooting ..........................................................................................................................................................................................255

M-SV-001-EN Rev. G

3 of 282

Page 4

Table of Contents

Chapter 6.0 Maintenance ......................................................................................................................................................................263

6.1 Preventative Maintenance Tasks ......................................................................................................................................................................................................................263

6.2 Moisture Prevention Measures .........................................................................................................................................................................................................................264

Appendix A – Acronyms/Terms ........................................................................................................................................................... 269

Appendix B – Compressor Troubleshooting Flowcharts ................................................................................................................... 271

Appendix C – Compressor Test Sheet ................................................................................................................................................. 277

4 of 282 M-SV-001-EN Rev. G

Page 5

List of Tables

Table 2-1 Compressor Fluid Paths ...............................................................................................................................................................................................................................31

Table 3-1 Exterior Connection Torque Specifications ...................................................................................................................................................................................... 45

Table 4-1 Compressor Components (Covers On) ..................................................................................................................................................................................................51

Table 4-2 Compressor Components Service Side (Excludes TTH/TGH Compressors) .............................................................................................................................52

Table 4-3 Compressor Components Service Side (TTH/TGH Only) ................................................................................................................................................................53

Table 4-4 Compressor Components Capacitor Side (Excludes TTH/TGH) .................................................................................................................................................... 54

Table 4-5 Compressor Components Capacitor Side (TTH/TGH Only) ............................................................................................................................................................55

Table 4-6 Compressor Cover Torque Specifications ............................................................................................................................................................................................. 60

Table 4-7 Cooling Adapter Torque Specifications ................................................................................................................................................................................................. 62

Table 4-8 CIM Ports and Jumpers ................................................................................................................................................................................................................................63

Table 4-9 Compressor Controller Cable Harness Torque Specifications ....................................................................................................................................................... 72

Table 4-10 Solenoid Coil Resistance Ranges ........................................................................................................................................................................................................... 73

Table 4-11 Solenoid Torque Specifications .............................................................................................................................................................................................................. 76

Table 4-12 Interstage Pipe Torque Specifications ................................................................................................................................................................................................. 78

Table 4-13 Compressor Housing End Cap Torque Specifications .................................................................................................................................................................... 79

Table 4-14 IGV Components ......................................................................................................................................................................................................................................... 80

Table 4-15 IGV Feedthrough Wiring Order .............................................................................................................................................................................................................. 84

Table 4-16 IGV Feedthrough Pin to Wire Reference .............................................................................................................................................................................................90

Table 4-17 IGV Torque Specifications.........................................................................................................................................................................................................................92

Table 4-18 Mains Plate Torque Specifications......................................................................................................................................................................................................... 95

Table 4-19 Expected AC Voltage Range ....................................................................................................................................................................................................................98

Table 4-20 Terminal Block Torque Specifications ................................................................................................................................................................................................103

Table 4-21 AC Bus Bar Torque Specifications ........................................................................................................................................................................................................105

Table 4-22 Terminal Block Fuse Torque Specifications ......................................................................................................................................................................................107

Table 4-23 Closed-Top Soft Start Connection Identification ...........................................................................................................................................................................108

Table 4-24 Open-Top Soft Start Connection Identification .............................................................................................................................................................................109

Table 4-25 Soft Start Fuse Details .............................................................................................................................................................................................................................112

Table 4-26 Soft Start Torque Specifications ...........................................................................................................................................................................................................119

Table 4-27 SCR DC Bus Bar Torque Specifications ...............................................................................................................................................................................................121

Table 4-28 Soft Start AC/DC Harness Torque Specifications ...........................................................................................................................................................................133

Table 4-29 SCR Diode Values ......................................................................................................................................................................................................................................137

Table 4-30 SCR Gate Resistance Ranges .................................................................................................................................................................................................................137

Table 4-31 SCR Temperature Sensor Torque Specifications ............................................................................................................................................................................141

Table 4-32 SCR Torque Specifications ......................................................................................................................................................................................................................149

Table 4-33 SCR Cooling Manifold Torque Specifications. .................................................................................................................................................................................155

Table 4-34 DC Capacitor Bus Bar Assembly Torque Specifications ...............................................................................................................................................................164

Table 4-35 Inverter Cable Harness Torque Specifications ................................................................................................................................................................................168

Table 4-36 Spring Identification Table .....................................................................................................................................................................................................................189

Table 4-37 Inverter Torque Specifications ..............................................................................................................................................................................................................190

Table 4-38 Motor Assembly Torque Specifications .............................................................................................................................................................................................200

Table 4-39 DC-DC Torque Specifications ................................................................................................................................................................................................................206

Table 4-40 Backplane Connections ..........................................................................................................................................................................................................................208

Table 4-41 Backplane Test Points ..............................................................................................................................................................................................................................209

Table 4-42 Backplane LED Locations .......................................................................................................................................................................................................................210

Table 4-43 Backplane Test Point Values ..................................................................................................................................................................................................................211

Table 4-44 Backplane Torque Specifications .........................................................................................................................................................................................................212

Table 4-45 PWM Torque Specifications ...................................................................................................................................................................................................................222

Table 4-46 Magnetic Bearing Coil Resistance Values .........................................................................................................................................................................................224

Table 4-47 Bearing Amperage Nominal Ranges ..................................................................................................................................................................................................225

Table 4-48 Magnetic Bearing Torque Specifications ..........................................................................................................................................................................................228

Table 4-49 Bearing Sensor Coil Resistance ............................................................................................................................................................................................................229

Table 4-50 Bearing Sensor Torque Specifications ...............................................................................................................................................................................................231

Table 4-51 Cavity Sensor Torque Specifications ..................................................................................................................................................................................................233

Table 4-52 Pressure/Temperature Sensor Torque Specifications...................................................................................................................................................................237

Table 5-1 Alarm Types ...................................................................................................................................................................................................................................................241

Table 5-2 Compressor Fault Types ............................................................................................................................................................................................................................241

Table 5-3 Compressor Status 2 Faults ......................................................................................................................................................................................................................242

Table 5-4 Motor Fault Types ........................................................................................................................................................................................................................................243

Table 5-5 Bearing Fault Types .....................................................................................................................................................................................................................................243

Table 5-6 Compressor Status ......................................................................................................................................................................................................................................245

Table 5-7 Compressor Status 2 Faults ......................................................................................................................................................................................................................247

Table 5-8 Motor Status ..................................................................................................................................................................................................................................................248

Table 5-9 Bearing Status ...............................................................................................................................................................................................................................................250

Table 6-1 Preventative Maintenance Tasks ............................................................................................................................................................................................................263

Table 6-2 SCR Fastener Torque Specifications ......................................................................................................................................................................................................267

Table A-1 Acronyms/Terms .........................................................................................................................................................................................................................................269

M-SV-001-EN Rev. G

5 of 282

Page 6

List of Figures

Figure 2-1 Compressor Fluid Paths .............................................................................................................................................................................................................................31

Figure 2-2 Cooling Inlet Adapter .................................................................................................................................................................................................................................32

Figure 2-3 Split Cooling Path - TTH375/TGH285 ...................................................................................................................................................................................................33

Figure 2-4 Split Cooling Path - (TTS/TGS (Except TTS300/TGS230 Serial Cooling) ....................................................................................................................................33

Figure 2-5 Serial Cooling Path - TTS300/TGS230 ...................................................................................................................................................................................................34

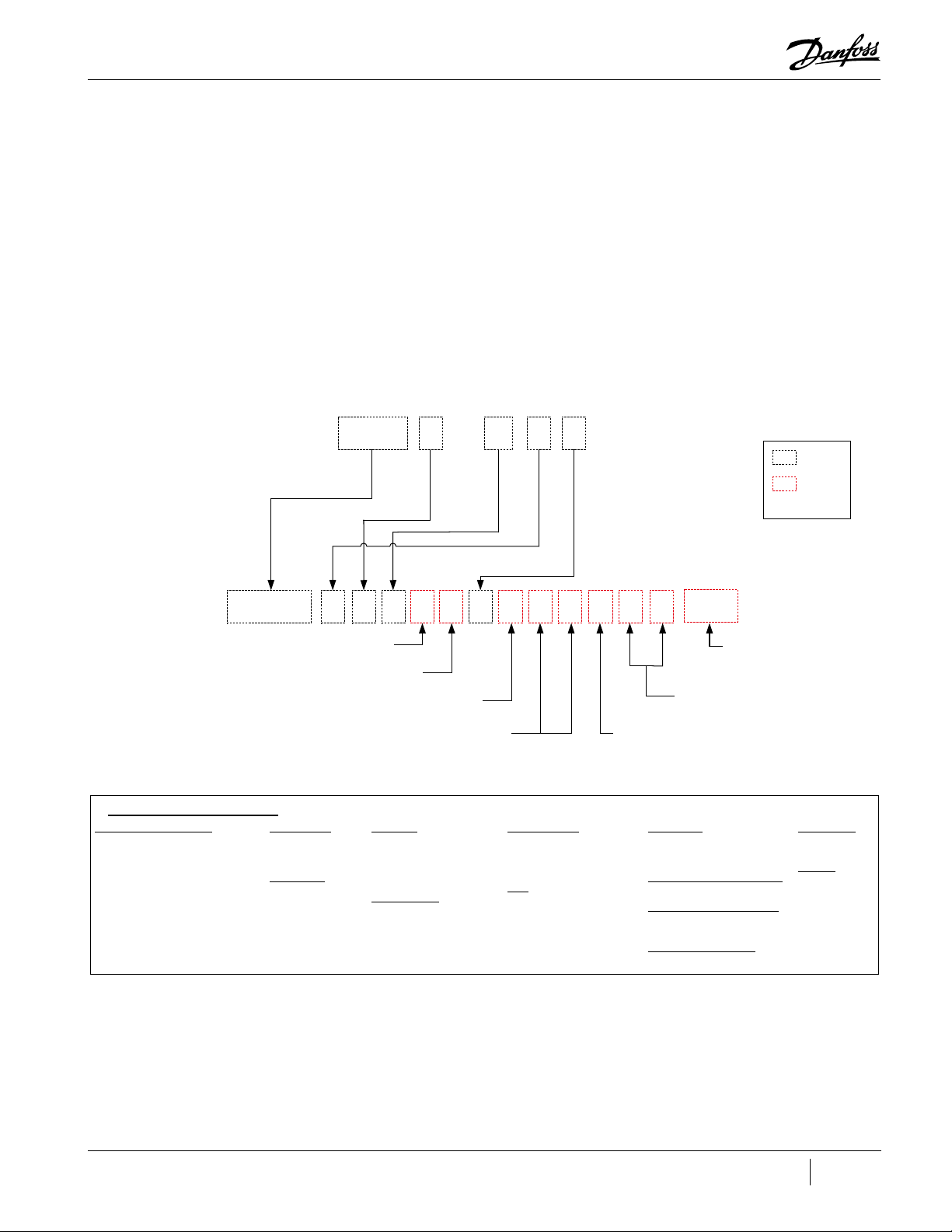

Figure 2-6 Compressor Energy and Signal Flow Connections .........................................................................................................................................................................36

Figure 2-7 Compressor Energy and Control Flow Block Diagram - TTS/TGS Compressors .................................................................................................................... 37

Figure 3-1 Compressor Power Cable Removal .......................................................................................................................................................................................................41

Figure 3-2 Compressor Mounting Fasteners...........................................................................................................................................................................................................42

Figure 3-3 Motor Cooling Fitting.................................................................................................................................................................................................................................43

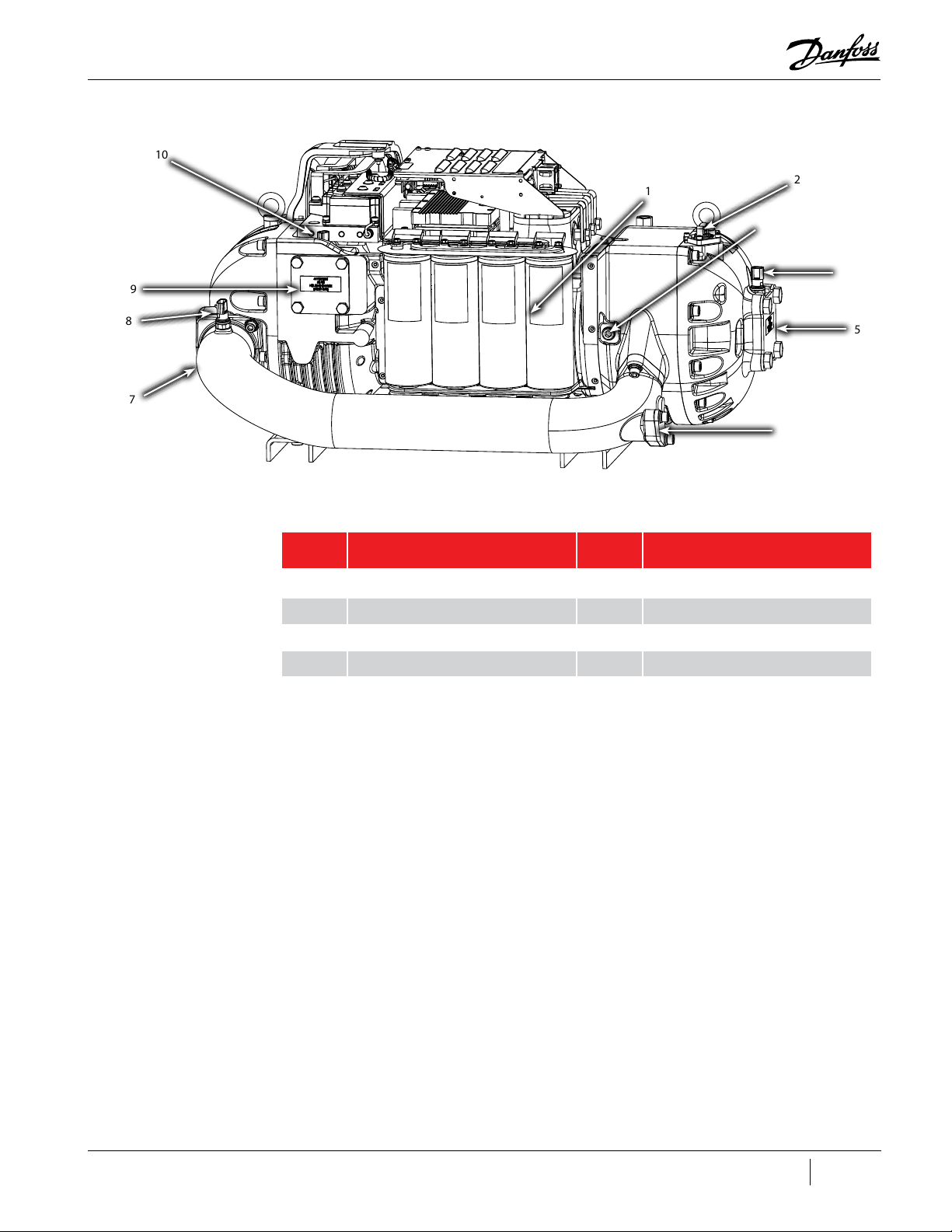

Figure 4-1 Compressor Components Identification (Covers On) ....................................................................................................................................................................51

Figure 4-2 Compressor Component Identification - Service Side (Excludes TTH/TGH Compressors) ...............................................................................................52

Figure 4-3 Compressor Component Identification - Service Side (TTH/TGH Only) .................................................................................................................................. 53

Figure 4-4 Compressor Component Identification - Capacitor Side (Excludes TTH/TGH) ......................................................................................................................54

Figure 4-5 Compressor Component Identification - Capacitor Side (TTH/TGH Only) ............................................................................................................................. 55

Figure 4-6 Top Covers Removal ...................................................................................................................................................................................................................................56

Figure 4-7 Mains Input Cover Torque Sequence ................................................................................................................................................................................................... 57

Figure 4-8 Top Cover ........................................................................................................................................................................................................................................................ 57

Figure 4-9 Service Side Cover ....................................................................................................................................................................................................................................... 58

Figure 4-10 Service Side Cover .................................................................................................................................................................................................................................... 58

Figure 4-11 Capacitor Cover ......................................................................................................................................................................................................................................... 59

Figure 4-12 Capacitor Nylon Nuts ...............................................................................................................................................................................................................................59

Figure 4-13 Relief Membrane Position ...................................................................................................................................................................................................................... 60

Figure 4-14 Recessed Holes .......................................................................................................................................................................................................................................... 60

Figure 4-15 Capacitor Cover Torque Sequence...................................................................................................................................................................................................... 60

Figure 4-16 Cooling Adapter - Excludes TTH375/TGH285 .................................................................................................................................................................................61

Figure 4-17 Cooling Adapter - TTH375/TGH285) ..................................................................................................................................................................................................61

Figure 4-18 Compressor Interface Module Ports & Jumpers ............................................................................................................................................................................ 63

Figure 4-19 Removing the Compressor Interface Module from the DIN Rail ............................................................................................................................................. 66

Figure 4-20 Compressor Interface Cable ..................................................................................................................................................................................................................67

Figure 4-21 Compressor Controller Cable Harness Variants..............................................................................................................................................................................68

Figure 4-22 Backplane Connections .......................................................................................................................................................................................................................... 69

Figure 4-23 Pressure/Temperature and SCR Temperature Sensor Locations - TTS300/TGS230 ...........................................................................................................69

Figure 4-24 Pressure/Temp and SCR Temp Sensor Locations - TTS/TGS .......................................................................................................................................................70

Figure 4-25 Pressure/Temperature Sensors - TTH375/TGH285 ........................................................................................................................................................................ 70

Figure 4-26 IGV Connector Clamp .............................................................................................................................................................................................................................. 70

Figure 4-27 Cable Passage ............................................................................................................................................................................................................................................. 71

Figure 4-28 Cooling Valve Bodies ...............................................................................................................................................................................................................................72

Figure 4-29 Compressor Cooling Solenoid Coils ................................................................................................................................................................................................... 72

Figure 4-30 Solenoid Coil Harness ..............................................................................................................................................................................................................................73

Figure 4-31 Backplane - J16 Connector .................................................................................................................................................................................................................... 73

Figure 4-32 Compressor Cooling Solenoid Coil Cable Connector .................................................................................................................................................................. 74

Figure 4-33 Backplane - Cool LEDs and +24V Test Points .................................................................................................................................................................................. 74

Figure 4-34 Solenoid Cooling Path - TTS300/TGS230 ..........................................................................................................................................................................................74

Figure 4-35 Solenoid Component Removal ............................................................................................................................................................................................................ 75

Figure 4-36 Solenoid Actuator Coil Position ........................................................................................................................................................................................................... 76

Figure 4-37 Interstage Pipe ........................................................................................................................................................................................................................................... 77

Figure 4-38 Interstage Pipe Removal .........................................................................................................................................................................................................................77

Figure 4-39 Compressor Housing End Cap - TTS/TGS .........................................................................................................................................................................................78

Figure 4-40 Compressor Housing End Cap - TTH/TGH ........................................................................................................................................................................................78

Figure 4-41 IGV Assembly .............................................................................................................................................................................................................................................. 80

Figure 4-42 IGV Connections ........................................................................................................................................................................................................................................ 80

Figure 4-43 IGV Motor Feedthrough ..........................................................................................................................................................................................................................81

Figure 4-44 SMT Icon ....................................................................................................................................................................................................................................................... 81

Figure 4-45 Compressor Configuration Tool ........................................................................................................................................................................................................... 81

Figure 4-46 Control Mode..............................................................................................................................................................................................................................................82

Figure 4-47 Compressor Monitor Tool.......................................................................................................................................................................................................................82

Figure 4-48 IGV Open Percentage - 100% ................................................................................................................................................................................................................ 82

Figure 4-49 IGV Open Percentage - 0%.....................................................................................................................................................................................................................82

Figure 4-50 Backplane Cool LEDs ............................................................................................................................................................................................................................... 83

Figure 4-51 Backplane +15V Test Point .....................................................................................................................................................................................................................83

Figure 4-52 IGV Harness Removal ...............................................................................................................................................................................................................................83

Figure 4-53 IGV Housing Removal .............................................................................................................................................................................................................................. 84

Figure 4-54 IGV Feedthrough Removal.....................................................................................................................................................................................................................84

Figure 4-55 Set Screw Removal ................................................................................................................................................................................................................................... 85

Figure 4-56 IGV Motor Assembly Removal .............................................................................................................................................................................................................. 85

Figure 4-57 Locking Collar Tool ...................................................................................................................................................................................................................................85

6 of 282 M-SV-001-EN Rev. G

Page 7

List of Figures

Figure 4-58 Locking Collar Removal .......................................................................................................................................................................................................................... 86

Figure 4-59 Worm Gear Removal ................................................................................................................................................................................................................................86

Figure 4-60 Large Worm Gear Bearing Removal ...................................................................................................................................................................................................86

Figure 4-61 IGV Throat Removal ..................................................................................................................................................................................................................................87

Figure 4-62 Small Worm Gear Bearing Removal ....................................................................................................................................................................................................87

Figure 4-63 Small Worm Gear Bearing Installation ............................................................................................................................................................................................... 87

Figure 4-64 IGV Position Indicator Magnet ............................................................................................................................................................................................................. 88

Figure 4-65 Large Worm Gear Bearing Installation...............................................................................................................................................................................................88

Figure 4-66 Locking Collar Installation ..................................................................................................................................................................................................................... 89

Figure 4-67 IGV Worm Gear Alignment ....................................................................................................................................................................................................................89

Figure 4-68 Shaft Position ..............................................................................................................................................................................................................................................89

Figure 4-69 IGV Motor Alignment ...............................................................................................................................................................................................................................90

Figure 4-70 Motor Wire Position ..................................................................................................................................................................................................................................90

Figure 4-71 IGV Motor Wires Connected ..................................................................................................................................................................................................................91

Figure 4-72 Feedthrough Orientation ....................................................................................................................................................................................................................... 91

Figure 4-73 IGV Housing Installation ......................................................................................................................................................................................................................... 91

Figure 4-74 IGV Position Indicator .............................................................................................................................................................................................................................. 92

Figure 4-75 Mains Plate Bracket .................................................................................................................................................................................................................................. 93

Figure 4-76 Ground Post Nuts ...................................................................................................................................................................................................................................... 94

Figure 4-77 Mains Input Nut Installation - TTS300/TGS230 Compressors ................................................................................................................................................... 94

Figure 4-78 Mains Input Nut Installation - TTS/TGS/TTH/TGH Rev. H and Earlier (Except TTS300/TGS230) ...................................................................................94

Figure 4-79 Input Terminal Block - TTS300/TGS230 ............................................................................................................................................................................................. 95

Figure 4-80 Input Terminal Block - TTS/TGS/TTH/TGH Rev. H (Except TTS300/TGS230) .........................................................................................................................96

Figure 4-81 Input Terminal Block - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230) ....................................................................................................96

Figure 4-82 Measuring the 3-Phase AC Input Voltage on the AC Input Terminals - TTS300/TGS230 .................................................................................................97

Figure 4-83 Measuring 3-Phase AC Input Voltage on AC Input Terminals (TTS/TGS/TTH/TGH (Except TTS300/TGS230) ..........................................................97

Figure 4-84 Terminal Block Removal - TTS300/TGS230 ....................................................................................................................................................................................... 98

Figure 4-85 Input Terminal Block Removal - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230) ................................................................................99

Figure 4-86 Input Terminal Block Removal - TTS/TGS/TTH/TGH Rev. H (Except TTS300/TGS230) ....................................................................................................100

Figure 4-87 Input Terminal Block Installation - TTS300/TGS230 ....................................................................................................................................................................100

Figure 4-88 Terminal Block - Input Pressure Screws - TTS300/TGS230 ........................................................................................................................................................101

Figure 4-89 Input Terminal Block Installation - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230) ..........................................................................101

Figure 4-90 Input Terminal Block Installation - TTS/TGS/TTH/TGH Rev. H (Except TTS300/TGS230) ..............................................................................................102

Figure 4-91 Input Mains Bus Bar Examples ...........................................................................................................................................................................................................103

Figure 4-92 AC/DC Bus Bus Bar Connectors - TTS/TGS/TTH/TGS Rev. F and earlier (Except TTS300/TGH230) .............................................................................104

Figure 4-93 AC/DC Bus Bus Bar Connectors - TTS/TGS/TTH/TGS Rev. H (Except TTS300/TGH230) ...................................................................................................104

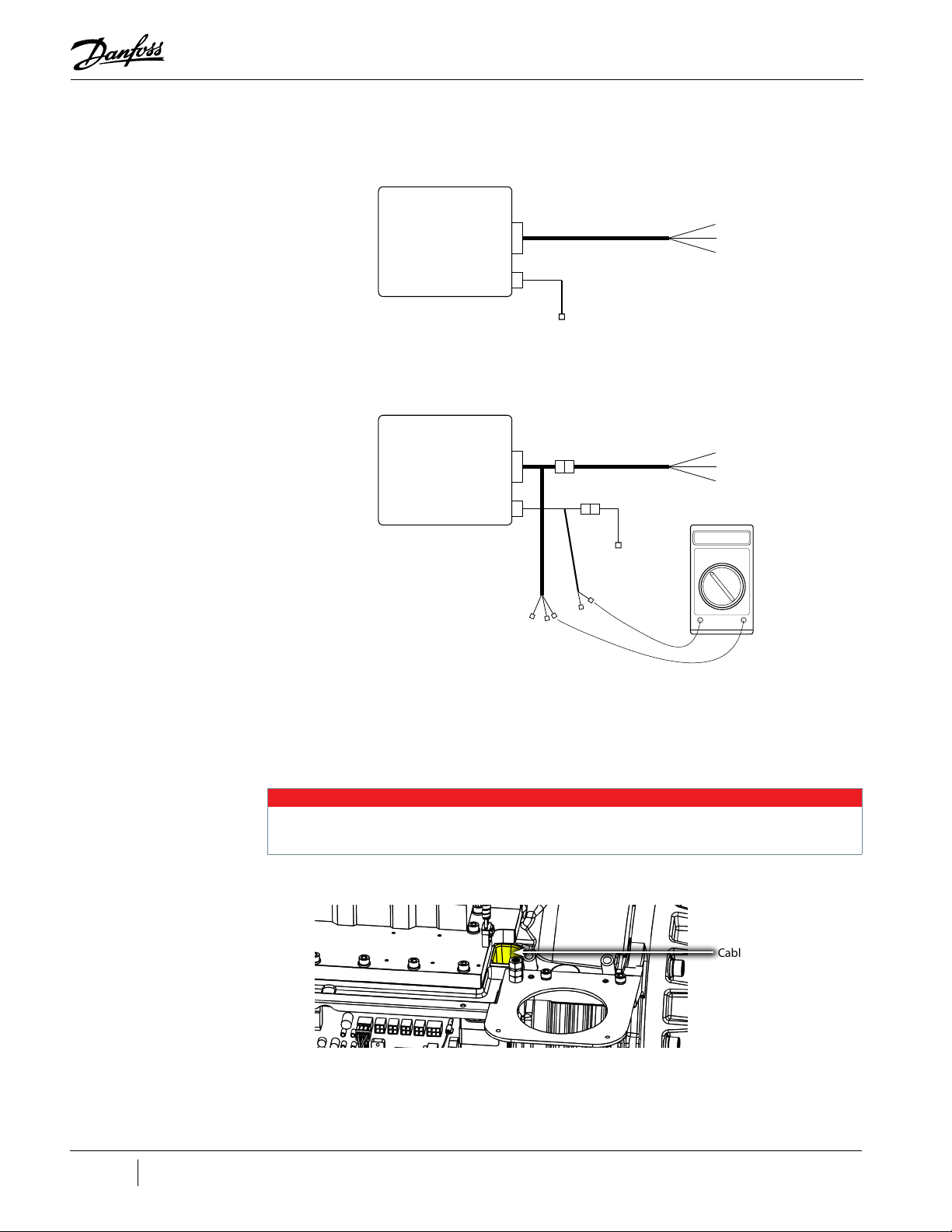

Figure 4-94 Terminal Block Fuse ................................................................................................................................................................................................................................105

Figure 4-95 Terminal Block Fuse Test .......................................................................................................................................................................................................................106

Figure 4-96 Terminal Block Fuse Removal..............................................................................................................................................................................................................106

Figure 4-97 Soft Start Variants....................................................................................................................................................................................................................................107

Figure 4-98 Closed-Top Soft Start Connections ...................................................................................................................................................................................................108

Figure 4-99 Open-Top Soft Start Connections .....................................................................................................................................................................................................109

Figure 4-100 Soft Start Label Location ....................................................................................................................................................................................................................110

Figure 4-101 Soft Start Fuse Locations ...................................................................................................................................................................................................................111

Figure 4-102 Closed-Top Soft Start J9 Connector ...............................................................................................................................................................................................112

Figure 4-103 Ground Location ...................................................................................................................................................................................................................................113

Figure 4-104 Closed-Top Soft Start ...........................................................................................................................................................................................................................113

Figure 4-105 Soft Start Lift...........................................................................................................................................................................................................................................113

Figure 4-106 Closed-Top Soft Start Connector Removal ..................................................................................................................................................................................114

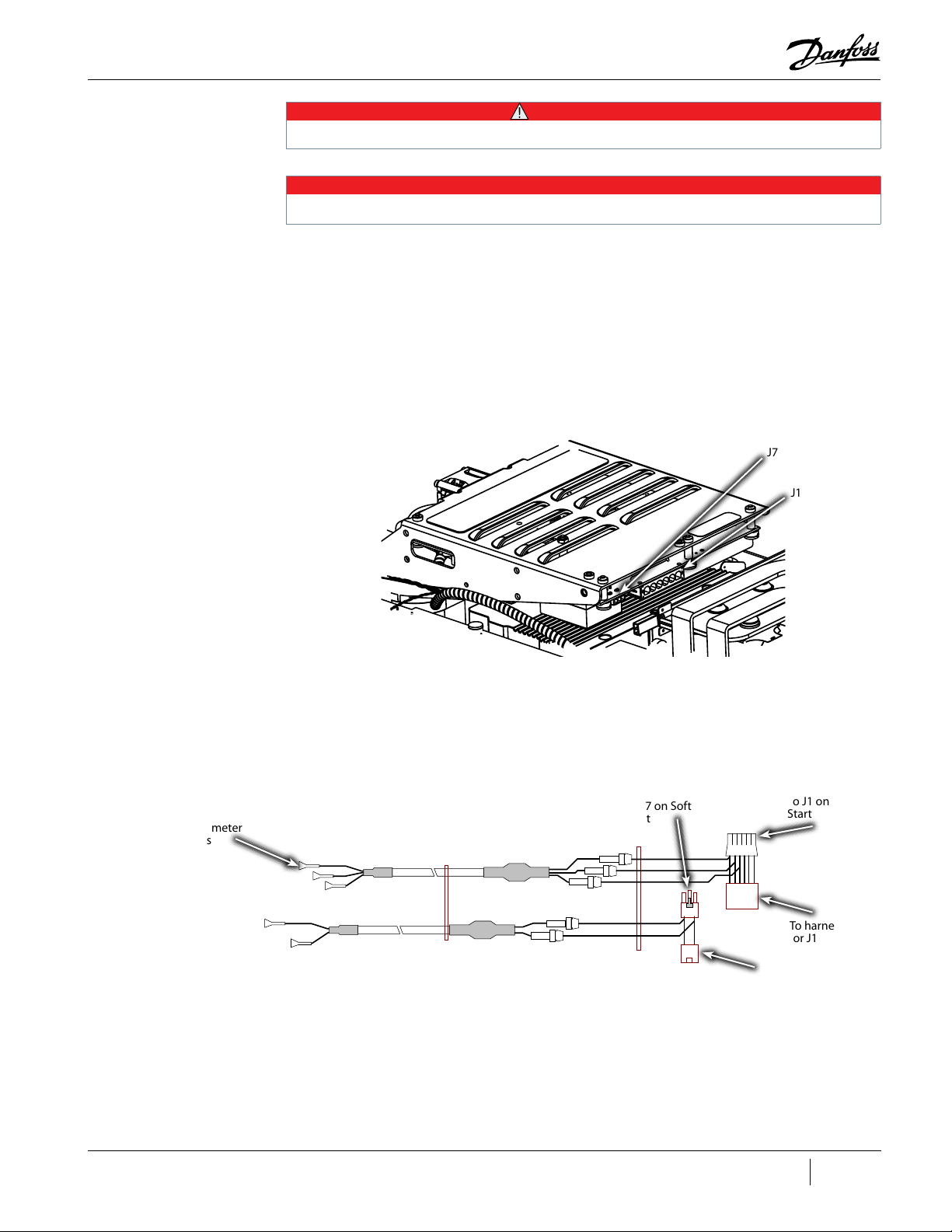

Figure 4-107 Open-Top Soft Start J7 Connector ..................................................................................................................................................................................................114

Figure 4-108 Ground Location ...................................................................................................................................................................................................................................114

Figure 4-109 Open-Top Soft Start Connector Removal ....................................................................................................................................................................................115

Figure 4-110 Open-Top Soft Start Removal ...........................................................................................................................................................................................................115

Figure 4-111 Closed-Top-Soft Start Installation ...................................................................................................................................................................................................116

Figure 4-112 Ground Stud Location .........................................................................................................................................................................................................................116

Figure 4-113 Open-Top-Soft Start Installation .....................................................................................................................................................................................................117

Figure 4-114 Soft Start without Adapter ................................................................................................................................................................................................................118

Figure 4-115 Soft Start Fan Orientation ..................................................................................................................................................................................................................118

Figure 4-116 Soft Start Fan Installation ..................................................................................................................................................................................................................118

Figure 4-117 Soft Start Fan Connector ....................................................................................................................................................................................................................119

Figure 4-118 SCR DC Bus Bars ....................................................................................................................................................................................................................................119

Figure 4-119 SCR DC Bus Bar Removal - TTS300/TGS230 .................................................................................................................................................................................120

Figure 4-120 SCR DC Bus Bar to SCR Alignment ..................................................................................................................................................................................................120

Figure 4-121 Soft Start SCR Gate Cable (Closed-Top Soft Starts)...................................................................................................................................................................121

Figure 4-122 Soft Start SCR Gate Cable (Open-Top Soft Starts) .....................................................................................................................................................................121

Figure 4-123 Soft Start SCR Gate Cable Removal - TTS300/TGS230 .............................................................................................................................................................122

Figure 4-124 Soft Start SCR Gate Cable Removal at SCR - TTS/TGS/TTH/TGH Models Rev. F and Earlier (Except TTS300/TGS230) ......................................122

M-SV-001-EN Rev. G

7 of 282

Page 8

List of Figures

Figure 4-125 Soft Start SCR Gate Cable Removal at SCR - TTS/TGS/TTH/TGH Models Rev. H (Except TTS300/TGS230) ...........................................................122

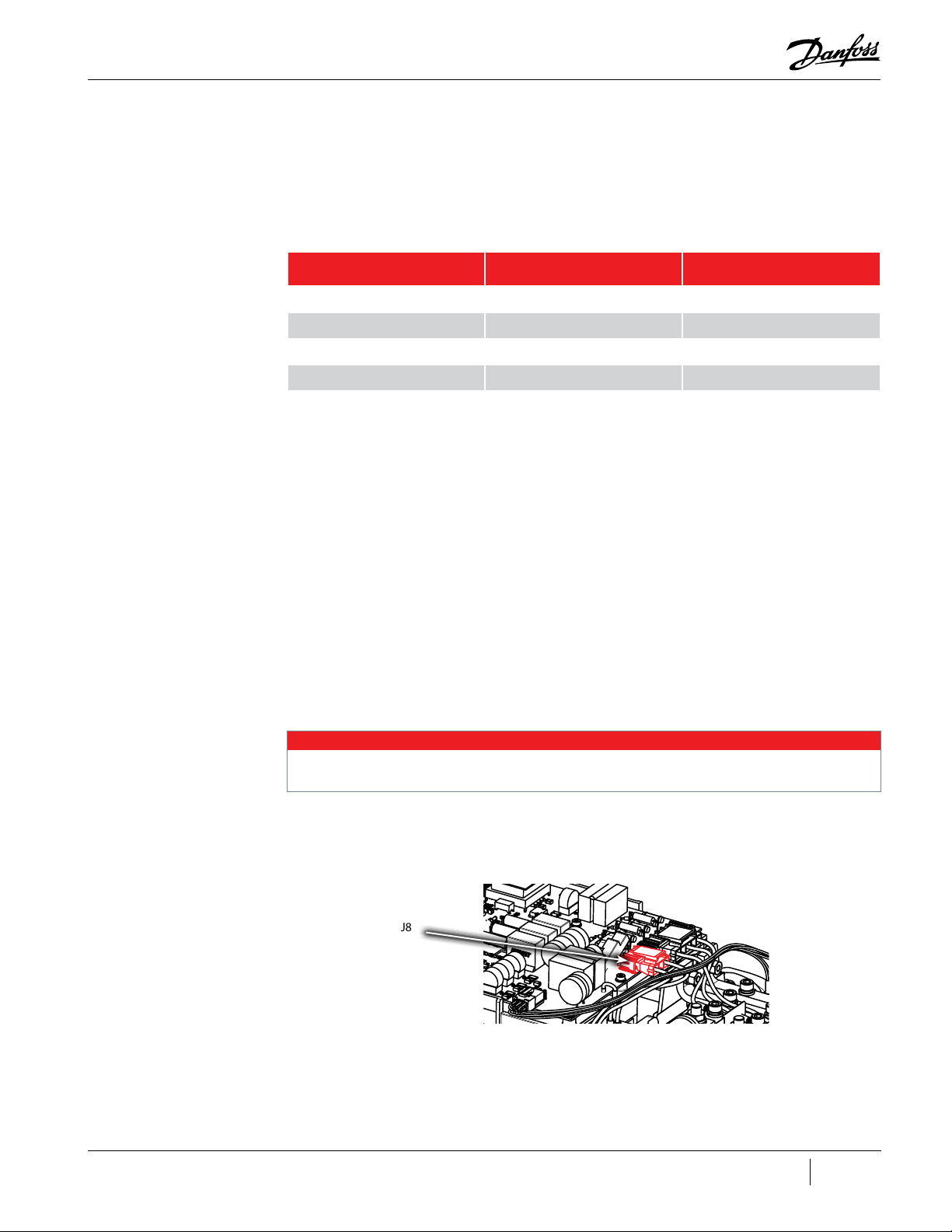

Figure 4-126 Closed-Top Soft Start J8 Connector Top .......................................................................................................................................................................................123

Figure 4-127 Open-Top Soft Start J2 Connector ..................................................................................................................................................................................................123

Figure 4-128 SCR Gate Connector Alignment ......................................................................................................................................................................................................124

Figure 4-129 Soft Start AC/DC Harness Connections - TTS300/TGS230 .....................................................................................................................................................125

Figure 4-130 Soft Start AC/DC Harness Connections - TTS/TGS/TTH/TGH (Except TTS300/TGS230) .............................................................................................126

Figure 4-131 AC Input Ring Terminal Removal - TTS300/TGS230 .................................................................................................................................................................127

Figure 4-132 DC Ring Terminal Removal - TTS300/TGS230 .............................................................................................................................................................................127

Figure 4-133 DC-DC Connectors (Open Frame) ...................................................................................................................................................................................................127

Figure 4-134 DC-DC Connectors (Potted) ..............................................................................................................................................................................................................128

Figure 4-135 Closed-Top Soft Start J1 and J7 Removal .....................................................................................................................................................................................128

Figure 4-136 Open-Top Soft Start J1 and J8 Removal .......................................................................................................................................................................................129

Figure 4-137 AC Input Spade and DC Spade Connector Removal - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230) ...................................129

Figure 4-138 AC Input Ring and DC Spade Connector Removal - TTS/TGS/TTH/TGH Rev. H (Except TTS300/TGS230) ............................................................130

Figure 4-139 Soft Start AC/DC Harness Position - TTS300/TGS230 ..............................................................................................................................................................131

Figure 4-140 AC Input and Spade Connector Installation - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230) ..................................................132

Figure 4-141 AC Input and Spade Connector Installation - TTS/TGS/TTH/TGH Rev. H (Except TTS300/TGS230) ........................................................................133

Figure 4-142 SCR Styles ................................................................................................................................................................................................................................................134

Figure 4-143 SCR Connections - TTS300/TGS230 ................................................................................................................................................................................................134

Figure 4-144 SCR Connections - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230) .....................................................................................................135

Figure 4-145 SCR Connections - TTS/TGS/TTH/TGH Rev. H (Except TTS300/TGS230) ...........................................................................................................................135

Figure 4-146 SCR Terminals - Two Hole Mount ....................................................................................................................................................................................................136

Figure 4-147 SCR Terminals - Four Hole Mount ...................................................................................................................................................................................................136

Figure 4-148 SCR Temperature Sensor Assembly ...............................................................................................................................................................................................137

Figure 4-149 J17 Connector ........................................................................................................................................................................................................................................137

Figure 4-150 Discharge Pressure/Temperature Sensor Connector Removal - TTS300/TGS230 .........................................................................................................138

Figure 4-151 SCR Temperature Sensor Connector - TTS300/TGS230 .........................................................................................................................................................138

Figure 4-152 SCR Temperature Sensor Removal -TTS300/TGS230 ..............................................................................................................................................................139

Figure 4-153 SCR Temperature Sensor Connector - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230) .................................................................139

Figure 4-154 Discharge Pressure/Temperature Sensor Connector Removal - TTS/TGS/TTH/TGH (Except TTS300/TGS230) ..................................................139

Figure 4-155 SCR Temperature Sensor Removal - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230).....................................................................140

Figure 4-156 Fuse Block Assemblies - Two Hole Mount - TTS300/TGS230 .................................................................................................................................................142

Figure 4-157 DC Bus Bar Removal - TTS300/TGS230..........................................................................................................................................................................................142

Figure 4-158 SCR Removal - TTS300/TGS230........................................................................................................................................................................................................143

Figure 4-159 SCR Gate Cable and AC/DC Harness Connections - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230) .......................................143

Figure 4-160 SCR Gate Cable and AC/DC Harness Connections - TTS/TGS/TTH/TGH Rev. H (Except TTS300/TGS230) ..........................................................144

Figure 4-161 SCR Bus Fastener Removal - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230)....................................................................................144

Figure 4-162 SCR Bus Fastener Removal - TTS/TGS/TTH/TGH Rev. H (Except TTS300/TGS230) ........................................................................................................145

Figure 4-163 SCR Removal - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230) .............................................................................................................145

Figure 4-164 SCR Removal - TTS/TGS/TTH/TGH Rev. H (Except TTS300/TGS230) ..................................................................................................................................145

Figure 4-165 SCR Heat Sink Paste Application - TTS300/TGS230 ..................................................................................................................................................................146

Figure 4-166 SCR Orientation - TTS300/TGS230 ..................................................................................................................................................................................................146

Figure 4-167 Bus Bar Installation - TTS300/TGS230 ............................................................................................................................................................................................147

Figure 4-168 Bus Bar Locations - TTS300/TGS230 ...............................................................................................................................................................................................147

Figure 4-169 SCR Thermal Paste Application - TTS/TGS/TTH/TGH (Except TTS300/TGS230) .............................................................................................................148

Figure 4-170 SCR Torque Sequence - TTS/TGS/TTH/TGH Rev. F and Earlier (Except TTS300/TGS230)............................................................................................148

Figure 4-171 SCR Cooling Manifold .........................................................................................................................................................................................................................150

Figure 4-172 Inverter Assembly Removal - TTS300/TGS230 ...........................................................................................................................................................................150

Figure 4-173 SCR Cooling Manifold Removal - TTS300/TGS230 ....................................................................................................................................................................151

Figure 4-174 SCR Cooling Manifold Removal .......................................................................................................................................................................................................152

Figure 4-175 SCR Cooling Plate O-ring Installation - TTS300/TGS230 .........................................................................................................................................................152