Page 1

Applications and Installation Manual - Revision N

®

Danfoss Turbocor® Twin-Turbine

Centrifugal Compressors

TT & TG Series Compressors

http://turbocor.danfoss.com

Page 2

THIS PAGE INTENTIONALLY LEFT BLANK

Page 2 of 108

M-AP-001-EN Rev. N

Page 3

Content

1 Introduction ........................................................................................................................................9

1.1 Scope ........................................................................................................................................................................................................9

1.2 Organization of this Manual ..............................................................................................................................................................9

1.3 Document Symbols ........................................................................................................................................................................... 10

1.4 Denitions ............................................................................................................................................................................................. 11

2 Overview of the TT/TG Compressor ................................................................................................15

2.1 TT/TG Compressor Nomenclature ................................................................................................................................................ 15

2.2 Refrigerant Type .................................................................................................................................................................................. 15

2.2.1 TG Series ..................................................................................................................................................................................... 15

2.3 Environment ........................................................................................................................................................................................ 16

2.4 Congurations of the TT/TG Compressor Models .................................................................................................................. 16

2.5 Compressor Module .......................................................................................................................................................................... 17

3 Functional Description ....................................................................................................................19

3.1 Main Fluid Path ...................................................................................................................................................................................19

3.2 Motor Cooling ..................................................................................................................................................................................... 20

3.3 Inlet Guide Vanes ............................................................................................................................................................................... 22

3.4 Compressor Control Overview ..................................................................................................................................................... 22

3.4.1 Motor Drive System ................................................................................................................................................................ 23

3.4.2 Soft-Start Board ....................................................................................................................................................................... 23

3.4.3 Bearing Motor Compressor Controller ............................................................................................................................ 23

3.4.4 Compressor Control ................................................................................................................................................................ 23

3.4.5 Capacity Control ....................................................................................................................................................................... 23

3.4.6 Expansion Valve Control ........................................................................................................................................................ 24

3.4.7 Motor/Bearing Control ........................................................................................................................................................... 24

3.4.8 Monitoring Functions ............................................................................................................................................................. 24

3.4.9 Abnormal Conditions ............................................................................................................................................................ 24

3.4.10 Bearing PWM Amplier ...................................................................................................................................................... 25

3.4.11 Serial Driver ............................................................................................................................................................................. 25

3.4.12 Backplane ................................................................................................................................................................................ 25

3.4.13 High-Voltage DC-DC Converter ....................................................................................................................................... 26

3.5 Magnetic Bearing System ............................................................................................................................................................... 26

3.5.1 Overview .................................................................................................................................................................................... 26

3.5.2 Bearing Control System ........................................................................................................................................................ 26

4 Control Interface Wiring ...................................................................................................................28

4.1 Control Wiring Connection Guidelines ...................................................................................................................................... 29

4.2 Interface Cable ................................................................................................................................................................................... 30

4.3 Compressor I/O Board Mounting Details .................................................................................................................................. 31

4.3.1 Compressor I/O Board - Mounting Instructions ........................................................................................................... 31

5 General Specications ......................................................................................................................33

5.1 Construction ........................................................................................................................................................................................ 33

5.2 Maximum Pressure ............................................................................................................................................................................ 33

5.3 Maximum Discharge Temperature ............................................................................................................................................... 34

5.4 Suction Pressure Limits ................................................................................................................................................................... 35

5.5 Codes and Standards Compliance .............................................................................................................................................. 35

6 Electrical Specications ...................................................................................................................37

6.1 Supply Voltage and Frequency..................................................................................................................................................... 37

6.2 Compressor Current Limit and Operating Range Settings.................................................................................................37

6.3 Disconnects ......................................................................................................................................................................................... 38

6.4 Motor Insulation Class ..................................................................................................................................................................... 39

6.5 AC Input Line/Power Electronic Component Protection .................................................................................................... 39

6.6 Power Line Contactor.......................................................................................................................................................................39

6.7 CE Compliance and EMI/EMC Filtering ...................................................................................................................................... 39

6.8 Surge Protection ................................................................................................................................................................................ 40

6.9 Harmonic Filtering (IEEE 519) ........................................................................................................................................................ 40

6.10 Grounding (Earth) Connection Guidelines ............................................................................................................................ 40

6.11 Equipment Panel ............................................................................................................................................................................. 41

6.12 Mains Input Cable Specication ................................................................................................................................................ 42

6.13 Idle Power Consumption .............................................................................................................................................................. 42

7 Compressor Performance ................................................................................................................43

7.1 Performance Ratings ......................................................................................................................................................................... 43

7.2 Tolerance of Performance Ratings ................................................................................................................................................ 43

M-AP-001-EN Rev. N

Page 3 of 108

Page 4

Content

8 Operating Envelopes ........................................................................................................................45

9 Minimum Unloading Capacity .........................................................................................................51

10 Control Logic Guidelines for Multiple Compressors ....................................................................53

11 Product Certication ......................................................................................................................55

12 Guide Specications .......................................................................................................................57

12.1 General................................................................................................................................................................................................ 57

12.2 Refrigerant ......................................................................................................................................................................................... 57

12.3 Compressor Bearings ..................................................................................................................................................................... 57

12.4 Capacity Control .............................................................................................................................................................................. 57

12.5 Compressor Motor .......................................................................................................................................................................... 57

12.6 Compressor Electronics ................................................................................................................................................................ 57

12.6.1 Ancillary Devices ................................................................................................................................................................... 57

13 System Design Guidelines .............................................................................................................59

13.1 General Requirements .................................................................................................................................................................. 59

13.2 Economizer Option ........................................................................................................................................................................ 60

13.3 Motor/Electronics Cooling Requirements ............................................................................................................................. 60

13.4 Electrical Requirements ................................................................................................................................................................ 61

13.5 Application-Specic Requirements .......................................................................................................................................... 61

13.5.1 Medium Evaporating Temperature Application (TT300) ....................................................................................... 61

13.5.2 Low Lift Application ............................................................................................................................................................. 61

13.5.3 Limited Capacity at Low pressure Ratios ..................................................................................................................... 62

14 Sample Refrigeration Circuits .......................................................................................................63

15 Sound and Power Specications ...................................................................................................71

15.1 TT300 and TT400 Sound Power Measurements ................................................................................................................... 71

15.1.1 Results ....................................................................................................................................................................................... 71

16 Physical Data ...................................................................................................................................75

16.1 Clearance ........................................................................................................................................................................................... 75

16.2 Center of Gravity ............................................................................................................................................................................. 77

16.3 Torque Specications..................................................................................................................................................................... 86

17 Piping Considerations ....................................................................................................................87

18 Environmental Considerations ......................................................................................................89

18.1 Humidity ............................................................................................................................................................................................ 89

18.2 Vibration ............................................................................................................................................................................................. 89

19 Shipping Considerations ...............................................................................................................91

19.1 Vibration ............................................................................................................................................................................................. 91

20 Installation ......................................................................................................................................93

20.1 Unpacking and Inspection .......................................................................................................................................................... 93

20.2 Rigging Requirements .................................................................................................................................................................. 93

20.3 Unit Placement ................................................................................................................................................................................ 93

20.4 Mounting Base ................................................................................................................................................................................. 94

20.5 Piping Connections ........................................................................................................................................................................ 95

20.6 Control Wiring ..................................................................................................................................................................................96

20.6.1 Control Wiring Connections ............................................................................................................................................. 96

20.6.2 Circuit Grounding ................................................................................................................................................................. 98

20.6.3 Voltage-Free Contacts ......................................................................................................................................................... 99

20.7 Power Wiring...................................................................................................................................................................................100

Appendix A: Power Line Accessories Installation .......................................................................... 103

A.1 Line Reactor Installation Instructions ....................................................................................................................................... 103

A.1.1 AC Line Cable Connection (From External Disconnect) ..........................................................................................103

A.1.2 AC Line Cable Connection (to Compressor Terminal) ..............................................................................................103

Appendix B: Power Line Accessories Installation .......................................................................... 105

B.1 EMI/EMC Filter Installation Instructions ...................................................................................................................................105

B.1.1 Line Side Connection ............................................................................................................................................................105

B.1.2 Load Side Connection ..........................................................................................................................................................105

B.1.3 Harmonic Filter........................................................................................................................................................................105

Page 4 of 108

M-AP-001-EN Rev. N

Page 5

List of Tables

Table 1-1 - Application Manual Applicability .....................................................................................................................................9

Table 1-2 - Denitions .............................................................................................................................................................................. 11

Table 2-1 - Refrigerant Used with Turbocor Compressors .......................................................................................................... 15

Table 3-1 - Backplane LEDs .................................................................................................................................................................... 25

Table 4-1 - Control Wiring Details ........................................................................................................................................................ 29

Table 5-1 - Discharge Pressure Alarm and Trip Settings ..............................................................................................................33

Table 5-2 - Discharge Temperature Trip Settings ........................................................................................................................... 34

Table 5-3 - Maximum Pressure Ratio Limits ..................................................................................................................................... 34

Table 5-4 - Maximum Allowable Pressure [PS] ................................................................................................................................ 34

Table 5-5 - Suction Pressure Alarm and Trip Settings ...................................................................................................................35

Table 6-1 - Acceptable AC Voltage Range .........................................................................................................................................37

Table 6-2 - Acceptable Frequency Range ......................................................................................................................................... 37

Table 6-3 - FLA and LRA Value Range ................................................................................................................................................. 38

Table 6-4 - Main Cable Connector Plate Hole Sizes ....................................................................................................................... 42

Table 13-1 - Recommended Minimum Copper Tube Size .......................................................................................................... 60

Table 13-2 - Low Lift Pump Sizing........................................................................................................................................................ 61

Table 15-1 - Sound Power Measurements for TT300 .................................................................................................................... 71

Table 15-2 - Sound Pressure Calculation for TT300 ....................................................................................................................... 71

Table 15-3 - Sound Power at Third Octave Band, TT300 Compressor ..................................................................................... 72

Table 15-4 - Sound Power Measurements ........................................................................................................................................ 72

Table 15-5 - Sound Pressure Calculation ........................................................................................................................................... 72

Table 15-6 - Sound Power at Third Octave Band of TT400 Compressor ................................................................................73

Table 16-1 - Physical Dimensions ......................................................................................................................................................... 75

Table 16-2 - Center of Gravity X-Y Coordinates ............................................................................................................................... 78

Table 16-3 - Screw Hole Specications ..............................................................................................................................................85

Table 16-4 - Torque Specications ....................................................................................................................................................... 86

M-AP-001-EN Rev. N

Page 5 of 108

Page 6

List of Figures

Figure 2-1 - Compressor Nomenclature ............................................................................................................................................15

Figure 2-2 - Major Components ........................................................................................................................................................... 16

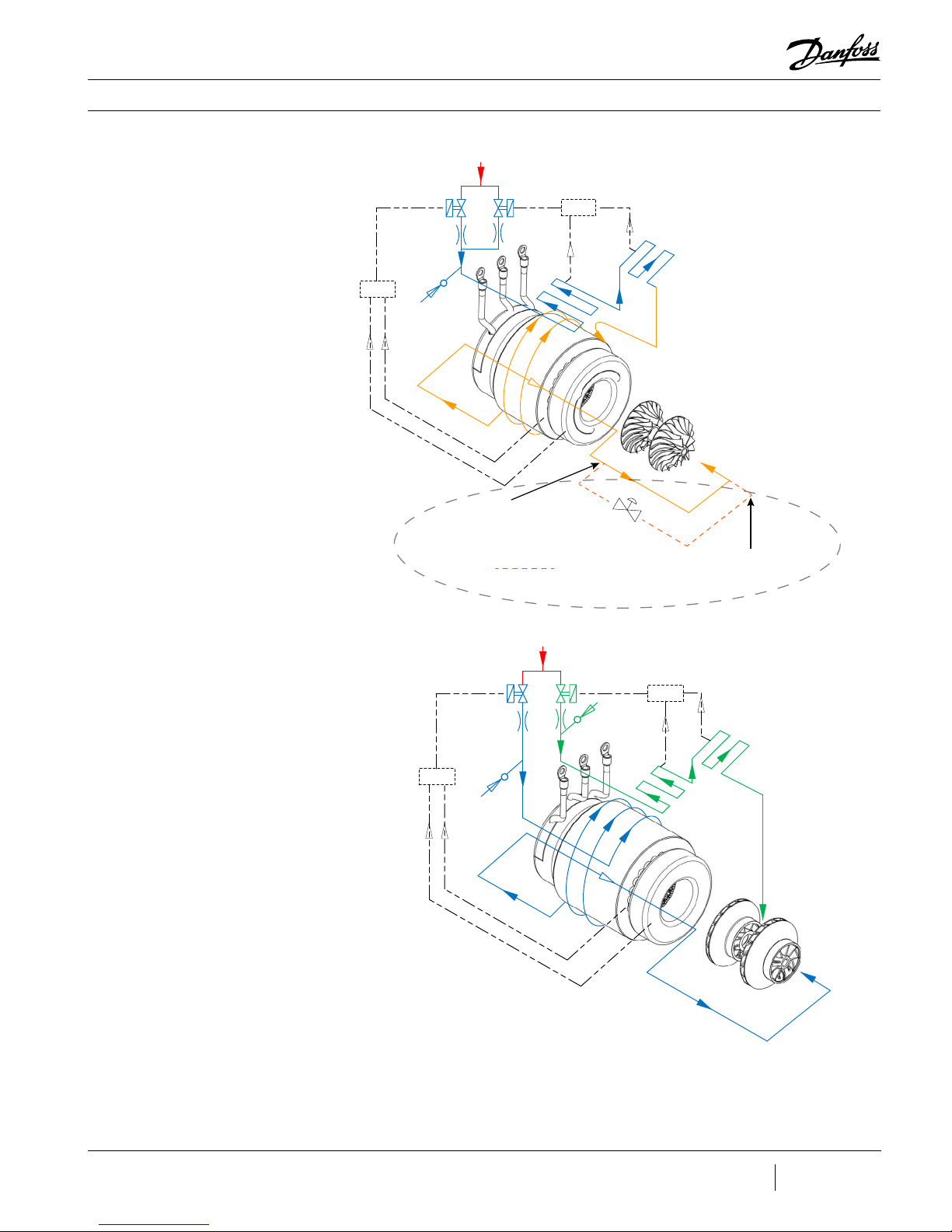

Figure 3-1 - Compressor Fluid Path TG230 / TT300 ....................................................................................................................... 19

Figure 3-2 - Compressor Fluid Path ( TG310, TT350, TG390, TT400, TG520, and TT700) ................................................... 20

Figure 3-3 - Compressor Cooling Circuit (TG230 / TT300) .......................................................................................................... 21

Figure 3-4 - Compressor Cooling Circuit (TT300 Split-Cooling, TG310, TT350, TG390, TT400, and TG520) .............. 21

Figure 3-5 - Compressor Control System Functional Block Diagram ...................................................................................... 22

Figure 3-6 - Magnetic Bearing Conguration .................................................................................................................................. 26

Figure 3-7 - Magnetic Bearing Control System ...............................................................................................................................27

Figure 4-1 - Typical Control Wiring ...................................................................................................................................................... 28

Figure 4-2 - ModBus Grounding Diagram ........................................................................................................................................ 28

Figure 4-3 - I/O Wiring Specications ................................................................................................................................................. 30

Figure 4-4 - Compressor I/O Board ...................................................................................................................................................... 31

Figure 4-5 - Compressor I/O Board Installation .............................................................................................................................. 31

Figure 6-1 - Typical Ground Connections ......................................................................................................................................... 41

Figure 8-1 - Operating Envelope, TT300 and TG230 ..................................................................................................................... 45

Figure 8-2 - Operating Envelope, TT300 and TG230 (Medium Temperature Compressor) ............................................. 46

Figure 8-3 - Operating Envelope, TT350 and TG310 ..................................................................................................................... 47

Figure 8-4 - Operating Envelope, TT400 and TG390 .....................................................................................................................48

Figure 8-5 - Operating Envelope, TT700 and TG520 .....................................................................................................................49

Figure 13-1 - Centrifugal Performance Dynamics..........................................................................................................................62

Figure 14-1 - Typical Refrigeration Piping Schematic ................................................................................................................... 63

Figure 14-2 - Typical Refrigeration Piping Schematic With Staging and Load Balancing Valve .................................... 64

Figure 14-3 - Typical Refrigeration Piping Schematic With Flash Tank Economizer .......................................................... 65

Figure 14-4 - Typical Refrigeration Piping Schematic With Sub-Cooler Circuit Economizer .......................................... 66

Figure 14-5 - Typical Refrigeration Piping Schematic Using Motor-Cooling Pressure Regulating Valve

(Medium Temperature Compressors Only) ............................................................................................................ 67

Figure 14-6 - Typical Refrigeration Piping Schematic With Multiple DX Evaporators ....................................................... 68

Figure 14-7 - Typical Refrigeration Piping Schematic Using Multiple Compressors on a Common Circuit

With a Flooded Evaporator ........................................................................................................................................... 69

Figure 16-1 - Suction/Front View All Models ................................................................................................................................... 75

Figure 16-2 - Service Side View All Models ....................................................................................................................................... 76

Figure 16-3 - Discharge Side View ....................................................................................................................................................... 76

Figure 16-4a - Center of Gravity ........................................................................................................................................................... 77

Figure 16-4b - Center of Gravity ........................................................................................................................................................... 78

Figure 16-5 - Discharge Port Details (TT300 and TG230) ............................................................................................................ 79

Figure 16-6 - Discharge Port Details (TT350 and TG310) ............................................................................................................ 80

Figure 16-7 - Discharge Port Detail (TT400 and TG390) .............................................................................................................. 80

Figure 16-8 - Discharge Port Detail (TT700 and TG520) .............................................................................................................. 81

Figure 16-9 - Suction Port (All Models) .............................................................................................................................................. 82

Figure 16-10 - Suction Port Detail DD (All Models) ....................................................................................................................... 83

Figure 16-11 - Suction Port Detail DD (TT700 and TG520) ......................................................................................................... 83

Figure 16-12 - TT300 Flange Footprint Details ................................................................................................................................ 84

Figure 16-13 - TT350, TG310, TG390, and TT400 Flange Footprint Details ........................................................................... 84

Figure 16-14 - TT700 and TG520 Flange Footprint Details ......................................................................................................... 85

Figure 16-15 - Motor Cooling Fitting ..................................................................................................................................................86

Figure 19-1 - Anti-Vibration Bracket ................................................................................................................................................... 91

Figure 20-1 - Rigging Set-up .................................................................................................................................................................. 93

Figure 20-2 - Mounting Base (TT and TG series) ............................................................................................................................. 94

Figure 20-3 - Incorrect Compressor Mounting Pad Installation ............................................................................................... 94

Figure 20-4 - Correct Compressor Mounting Pad Installation ................................................................................................... 95

Figure 20-5 - Motor-Cooling Connection and Access Port ......................................................................................................... 96

Figure 20-6 - Compressor I/O Board Connections ......................................................................................................................... 97

Figure 20-7 - Interlock and Motor Speed Connections ................................................................................................................ 98

Figure 20-8 - Interlock Circuit Tests .....................................................................................................................................................99

Figure 20-9 - Typical Electrical Connections .................................................................................................................................. 100

Figure 20-10 - Ground Post Nuts ........................................................................................................................................................101

Figure 20-11 - Compressor AC Input Terminals ............................................................................................................................101

Figure A-1 - Line Reactor Connections ............................................................................................................................................104

Figure B-1 - Interconnection Layout .................................................................................................................................................106

Figure B-2 - Grounding Diagram ........................................................................................................................................................106

Page 6 of 108

M-AP-001-EN Rev. N

Page 7

Proprietary Notice

Copyright, Limitations of Liability and Revision Rights.

This publication contains proprietary information to Danfoss Turbocor Compressors (DTC).

By accepting and using this manual, the user agrees that the information contained herein

is utilized solely for operating DTC equipment or third party vendor equipment intended for

communication with DTC equipment over a serial communication link. This publication is

protected under the Copyright laws of the United States of America (USA) and most other

countries. The publication of this Guide is owned by DTC and is published as the most recent

revision as indicated on the Title page of this document. This document is for use by DTC

customers only; any use beyond the intended usage of this document is prohibited.

Tests have demonstrated that equipment will function as designed if the installation if

performed in accordance with the guidelines provided in this guide. However, DTC does not

guarantee the equipment performance will work in every physical, hardware or software

environment.

The guidelines provided in this manual are “AS-IS”, with no warranty of any kind, either

express or implied including; without limitation, any implied warranties of condition,

uninterrupted use, merchantability or tness for a particular purpose.

In no event shall DTC be liable for direct, indirect, special, incidental or consequential

damages arising out of the manufacture, use, or the inability to manufacture or use

information contained in this manual, even if advised of the possibility of such damages. In

particular, DTC is not responsible for any costs, including but not limited to those incurred as

a result of lost prots or revenue, loss of damage or equipment, loss of computer programs,

loss of data, the costs to substitute these, or any claims by third parties. In any event, DTC’s

total aggregate liability for all damages of any kind and type (regardless of whether based in

contract or tort) shall not exceed the purchase price of this product.

DTC reserves the right to revise this publication at any time and to make changes to its

contents without prior notice or any obligation to notify former or present users of such

revisions or changes.

Danfoss Turbocor Compressors Inc.

1769 East Paul Dirac Drive Tallahassee,

Florida 32310

USA

Phone 1-850-504-4800

Fax 1-850-575-2126

http://turbocor.danfoss.com

M-AP-001-EN Rev. N

Page 7 of 108

Page 8

THIS PAGE INTENTIONALLY LEFT BLANK

Page 8 of 108

M-AP-001-EN Rev. N

Page 9

Introduction

1 Introduction

1.1 Scope

Table 1-1 - Application

Manual Applicability

This Applications and Installation Manual is intended to be a guide for application data/

installation procedures specic to Danfoss Turbocor compressors. It is not intended to

inform on fundamental safety, refrigeration and electrical design skills. It is assumed and

presumed that persons using this manual are appropriately certied and have detailed

knowledge, experience and skills in respect to designing for and working with high pressure

refrigerants and medium voltage electrical components (to 1 KV high power AC & DC) as

well as complex control systems.

Some potential safety situations may not be foreseen or covered in this guide. Danfoss

Turbocor Compressors (DTC) assumes personnel using this manual and working on DTC

compressors are familiar with, and carry out all safe work practices necessary to ensure

safety for personnel and equipment.

This manual is designed for use with BMCC

software, Version 4.0.0 and later.

Manual Release Date BMCC Firmware Versions

M-AP-001-XX Rev E September 2013 CC 2.3.1213

M-AP-001-XX Rev L October 2016 CC 3.1.4

M-AP-001-XX Rev M November 2017 CC 4.0 and later

M-AP-001-XX Rev M.1 November 2017 CC 4.1 and later

M-AP-001-XX Rev N May 2018 CC 4.1 and later

1.2 Organization of

this Manual

This Applications and Installation Manual is divided into the following sections:

1. Overview of the TT/TG series compressors - provides an overview of the Twin-Turbo

and Total-Green (TT and TG) series compressors, including an introduction to the

compressor.

2. Compressor Module - provides details on the Compressor Module of the compressor,

including product capacity and application range, maximum pressure alarm and fault

limits.

3. System Design Guidelines - provides basic guidelines and requirements for the design

and manufacture of R134a, R513a, and R1234ze(E) systems equipped with DTC TT/TG

series compressors.

4. Installation Guidelines - describes application/installation procedures specic to

Danfoss Turbocor TT/TG compressors.

M-AP-001-EN Rev. N

Page 9 of 108

Page 10

Introduction

1.3 Document Symbols

The following symbols are used in this document.

NOTE: Indicates something to be noted by the reader.

NOTE

DANGER: Indicates an essential operating or maintenance procedure, practice, or

condition, which, if not strictly observed, could result in serious injury to or death of

personnel or long-term health hazards.

• • • DANGER • • •

WARNING: Indicates an essential operating or maintenance procedure, practice, or

condition which, if not strictly observed, could result in serious damage or destruction

of equipment.

• • • WARNING • • •

CAUTION: Indicates an essential operating or maintenance procedure, practice, or

condition which, if not strictly observed, could result in damage to equipment or potential

problems in the outcome of the procedure being performed.

• • • CAUTION • • •

Page 10 of 108

M-AP-001-EN Rev. N

Page 11

Introduction

1.4 Denitions

Table 1-2 - Denitions

Acronym / Term Denition

Alarms

AHRI Air-Conditioning, Heating, and Refrigeration Institute (www.ari.org; www.ahrinet.org)

ASHRAE

ASIC Application-Specic Integrated Circuit

ASTM American Society for Testing and Materials (www.astm.org)

Axial Bearing Bearing that controls the horizontal movement (Z axis) of the motor shaft

Backplane

Balance Piston

BMCC

Bus Bars Heavy-gauge metal conductors used to transfer large electrical currents

Capacitor A passive component that stores energy in the form of an electrostatic eld

Cavity Sensor

CE

Choke

Compression

Ratio

CSA Canadian Standards Association (www.csa.ca)

DC Bus

DC Capacitor

Assembly

DC-DC Converter

Dielectric

Diuser

Diode A two-terminal device between which current may ow in one direction only

Down-Trip Voltage

D-Sub

DTC Danfoss Turbocor compressors Inc.

EEPROM

EER Energy Eciency Ratio

Alarms indicate a condition at the limit of the normal operating envelope. compressor

alarms will still allow the compressor to run, but speed is reduced to bring the alarm

condition under the alarm limit.

American Society of Heating Refrigeration and Air-Conditioning Engineers (www.ashrae.

org)

A PCB for the purpose of power and control signal transmission. Many other components

connect to this board.

Component within the compressor that provides primary counter to impeller thrust.

Impeller thrust is trimmed by the axial bearing.

Bearing Motor compressor Controller. The BMCC is the central processor board of the

compressor. Based on its sensor inputs, it controls the bearing and motor system and

maintains compressor control within the operating limits.

NTC temperature sensor located behind the Backplane for the purpose of sensing motorcooling vapor temperature. Provides overheat protection to motor windings.

Conformance European. The CE marking (also known as CE mark) is a mandatory

conformity mark on many products placed on the single market in the European Economic

Area. The CE marking certies that a product has met EU health, safety, and environmental

requirements, which ensure consumer safety.

Denitive point on compressor map where mass ow rate is at maximum for compressor

speed and lift conditions.

The absolute discharge pressure divided by the absolute suction pressure

High DC voltage simultaneously connected to multiple compressor components via

metallic bus bars, including the capacitors

An assembly of four DC capacitors, four bleeder resistors, and positive and negative bus

bars

DC-DC converters supply and electrically isolate the high and low DC voltages that are

required by the control circuits. When the compressor is switched on, the High-Voltage

(HV) DC-DC Converter receives its 15VAC supply from the Soft-Start Board. Once the DC

bus voltage has risen to a pre-determined level, the HV DC-DC Converter’s onboard circuits

are powered by the DC bus (460-900VDC). The HV DC-DC Converter delivers +24VDC (with

respect to 0V) to the Backplane, and HV+ (+250VDC with respect to HV-) to the magnetic

Bearing Pulse Width Modulation (PWM) Amplier via the Backplane.

A dielectric is a nonconducting substance. Although “dielectric” and “insulator” are

generally considered synonymous, the term “dielectric” is more often used when

considering the eect of alternating electric elds on the substance while “insulator” is

more often used when the material is being used to withstand a high electric eld.

Part of a centrifugal compressor in the uid module that transforms the high-velocity, lowpressure gas exiting the impeller into higher-pressure, low-velocity gas discharged into the

condenser.

A voltage threshold where, if the incoming AC voltage drops below it, the SCRs will shut

down

A type of connector/plug (male and female) for control wiring. The RS-232 and large

connectors on either side of the I/O cable are both types of D-Sub connectors.

Electrically Erasable Programmable Read Only Memory. A small chip holds bits of data code

that can be rewritten and erased by an electrical charge, one byte at a time. EEPROM data

cannot be selectively rewritten; the entire chip must be erased and rewritten to update its

contents.

M-AP-001-EN Rev. N

Page 11 of 108

Page 12

Introduction

Acronym / Term Denition

EMC Electromagnetic Compatibility

EMF Electromotive Force

EMI Electromagnetic Interference

EMI Filter A circuit or device that provides electromagnetic noise suppression for an electronic device

EPC Extended Performance Compressor

ETL ETL Testing Laboratories, now a mark of Intertek Testing Services

EXV

Event Log

Faults (Critical)

Faults (Non-Critical)

Feedthrough

FIE Fully Integrated Electronics version of the compressor.

FLA Full Load Amps

Generator Mode

Genlanolin

Harmonics

HFC Hydrouorocarbon

HFC-134a A positive-pressure, chlorine-free refrigerant having zero ozone depletion potential.

Hermetic Motor A motor that is sealed within the refrigerant atmosphere inside the compressor.

ICD Integrated compressor Design

IEEE Institute of Electrical and Electronic Engineers (www.ieee.org)

IGBT Insulated Gate Bipolar Transistor. See Inverter.

IGV

Impeller

I/O Board

Inverter

IPLV Integrated Part Load Value

LBV

Electronic Expansion Valve. Pressure-independent refrigerant metering device driven by

electrical input

A record of events occurring during the compressor’s lifecycle, indicating when events and

faults occur and in what order. The event log is held in the BMCC.

Critical faults indicate an intolerable or unsafe condition that will result in equipment

failure if unchecked. They will cause the compressor controller to reduce speed and shut

down the system within 60 seconds. This type of fault requires a manual reset. Critical faults

include: Discharge Pressure Fault, 3-Phase Over-Current Fault, and Lock Out Fault. If any

of the following faults occur three times within a 30-minute period, they also will require

a manual reset: Inverter Temperature Fault, Cavity Temperature, SCR Temperature Fault,

Motor High Current Fault, and Motor back EMF is low.

Faults indicate an intolerable or unsafe condition that will result in equipment failure if

unchecked. They will cause the compressor controller to reduce speed and shut down the

system within 60 seconds. This type of fault has an automatic reset.

An insulated conductor connecting two circuits on opposite sides of a barrier such as a

compressor housing or PCB.

A function of the compressor where the stator becomes a generator, creating sucient

power to allow for the shaft to graduate slowly and drop onto the touchdown bearings

safely. This occurs when the inverter has insucient power to sustain safe and normal

operation and is typically due to a loss of power.

A type of grease. In certain climates where the dew point falls below the operating

temperature of some of the electronic components, it is necessary to apply Genlanolin to

certain parts of the compressor to prevent moisture accumulation.

Harmonics are multiples of the fundamental frequency distortions found in electrical

power, subjected to continuous disturbances.

Inlet Guide Vanes. The IGV assembly is a variable-angle guiding device that pre-rotates

refrigerant ow at the compressor intake and is also used for capacity control. The IGV

assembly consists of movable vanes and a motor. The vane angle, and hence, the degree of

pre-rotation to the refrigerant ow, is determined by the BMCC and controlled by the Serial

Driver. The IGV position can vary between approximately 0-percent and 110-percent open.

Rotating part of a centrifugal compressor that increases the pressure of refrigerant vapor

from the lower evaporator pressure to the higher condenser pressure.

Input/Output Board facilitating a connection between the compressor controller and/

or PC and the compressor. It allows the user to control the compressor and allows the

compressor to return status and sensor information to the user. Also known as the

Compressor Interface Module (CIM).

The Inverter converts the DC bus voltage into an adjustable frequency and adjustable

amplitude, three-phase simulated AC voltage.

Load Balance Valve. A modulating valve that can be installed to bypass discharge gas to the

inlet of the evaporator to provide gas ow at certain conditions such as startup, surge, and

further unloading of the compressor.

Page 12 of 108

M-AP-001-EN Rev. N

Page 13

Introduction

Acronym / Term Denition

LED Light-Emitting Diode

Levitation

Line Reactor

LLSV Liquid Line Solenoid Valve

LR Line Reactor

LRA Locked Rotor Amps

Mid Bus

Modbus

Monitor Program

MOP Maximum Operating Pressure

Motor Back EMF

NEC National Electric Code (www.necplus.org)

Nm Newton meter. A unit of torque. 1 Nm = 0.738 pound-force foot (lbf/f).

NTC

OEM Original Equipment Manufacturer

Open Impeller A compressor impeller with exposed vanes similar to a boat propeller or turbocharger.

PCB Printed Circuit Board

Permanent Magnet

Motor

PLC Programmable Logic Controller

Pressure Ratio See “Compression Ratio”

Proximity Sensor

PWM Pulse Width Modulation

Radial Bearing Bearings that control the position of the shaft on the X and Y axis.

Rectier A rectier is an electrical device that converts AC current to pulsating DC current.

Resistor

RMA Return Material Authorization

SCR

Serial Driver

SDT Saturated Discharge Temperature

SEER Seasonal Energy Eciency Ratio

The elevation or suspension of the compressor shaft by the magnetic eld created by the

magnetic bearings.

A transformer-like device designed to introduce a specic amount of inductive reactance

into a circuit. When this occurs, it limits the change in current in the line, which in turn

lters the waveform and attenuates electrical noise and harmonics associated with an

inverter/drive output.

A connection between the capacitors allowing them to be connected in series and in

parallel simultaneously. Two capacitors in a series make up the DC- and two in a series

make up the DC+, and those two sets of two are connected in parallel.

A serial communications protocol published by Modicon in 1979 for use with its

programmable logic controllers (PLCs). It has become a de facto standard communications

protocol in industry, and is now the most commonly available means of connecting

industrial electronic devices. Modbus allows for communication between many devices

connected to the same network, for example a system that measures temperature and

humidity and communicates the results to a computer.

A software program provided by DTC that can be downloaded to a PC or laptop computer

to monitor, regulate, control or verify the operation of a compressor.

Back electromotive force is a voltage that occurs in electric motors where there is relative

motion between the armature of the motor and the external magnetic eld and is also

a parameter used to evaluate the strength of the permanent magnets of the shaft. One

practical application is to use this phenomenon to indirectly measure motor speed as well

as estimate position.

Negative Temperature Coecient. Refers to thermistor characteristic. Decrease in

temperature results in a rise in resistance (ohms).

A motor that has permanent magnetism as opposed to electromagnetism

Sensors that are able to detect the presence of nearby objects without any physical

contact. A proximity sensor often emits an electromagnetic or electrostatic eld, or a beam

of electromagnetic radiation (infrared, for instance), and looks for changes in the eld or

return signal.

A resistor is an electrical component that limits or regulates the ow of electrical current in

an electronic circuit.

Silicon-Controlled Rectier. The SCR is a four-layer, solid-state device that controls current

and converts AC to DC.

A PCB plug-in responsible for the operation of the IGV stepper motor and optional

expansion valves. It contains four relays for the solenoid valves, compressor status and

compressor run status respectively.

M-AP-001-EN Rev. N

Page 13 of 108

Page 14

Introduction

Acronym / Term Denition

Shaft Orbit The path travelled by the compressor shaft relative to the bearing magnetic centers

Shrouded Impeller An impeller with boxed in, or “shrouded,” impeller blades, as opposed to an open impeller.

SIE Semi-Integrated Electronics version of the compressor.

Single-Stage

Centrifugal

compressor

Snubbers

Soft-Start Board /

SoftStarter

SST Saturated Suction Temperature

Surge

Thrust Bearing

Ton The basic unit for measuring the rate of heat transfer (12,000 BTU/H; 3.516 kw/H)

Touchdown

Bearings

TT Twin Turbine

Two-Stage

Centrifugal

compressor

TXV

UL Underwriters Laboratories (www.ul.com)

Up-Trip Voltage When the DC- bus reaches the up-trip voltage, the SCRs will be gated open continuously

VAC Volts Alternating Current

Vaned Diuser

Vaneless Diuser Similar to a Vaned Diuser, except that it does not possess any de-swirl vanes

VDC Volts Direct Current

VFD Variable Frequency Drive

Type of centrifugal compressor having one impeller.

Capacitors responsible for eliminating electrical noise/harmonics from the DC Bus before it

reaches the IGBT

The Soft-Start Board limits in-rush current by progressively increasing the conduction

angle of the SCRs. This technique is used at compressor startup while the DC capacitors are

charging up. The Soft-Start Board takes as input a 3-phase voltage source at 50/60Hz from

the input terminal and a DC voltage signal from the SCR output. In turn, it outputs pulses

to the SCR and provides power to the High-Voltage (HV) DC-DC Converter. All voltages

from the Soft-Start Board are with respect to the positive DC bus and not the compressor

ground.

The condition at which the compressor cannot sustain the discharge pressure, allowing

refrigerant to temporarily and rapidly re-enter the compressor uid path, creating a

cavitating eect. This is an undesirable situation that should be avoided.

A bearing that absorbs the axial forces produced in a centrifugal compressor by the

refrigerant pressure dierential across the impeller.

Carbon races or ball bearing for the purpose of preventing mechanical interference

between the shaft and the magnetic bearings should they lose power or fail.

Type of centrifugal compressor having two impellers. The rst-stage impeller raises the

pressure of the refrigerant vapor approximately halfway from the cooler pressure to the

condenser pressure, and the second-stage impeller raises the pressure the rest of the

way. With a two-stage compressor, an interstage economizer may be used to improve the

refrigeration cycle eciency

Thermal Expansion Valve. A pressure-dependent refrigerant metering device that operates

independently and is controlled by temperature.

An assembly of plates with curved vanes that serve to slow, compress, and reduce

refrigerant rotation as it enters the second-stage impeller

* Danfoss Turbocor’s commitment to excellence ensures continuous product improvements.

* Subject to change without notice.

Page 14 of 108

M-AP-001-EN Rev. N

Page 15

Overview of the TT/TG Compressor

2 Overview of the

TT/TG Compressor

2.1 TT/TG Compressor

Nomenclature

Figure 2-1 - Compressor

Nomenclature

The TT/TG Centrifugal series of compressors is a group of compressors that covers the

nominal capacity range from 90 to 200 Tons (TT) and 70 to 150 Tons (TG) tons.

The TT/TG series of compressors are an oil free centrifugal design based on magnetic

bearing technology.

TT300 - G - 1 - ST - E - CE

Series

TT300

TT350

TT400

TT700

TG230

TG310

TG390

TG520

Voltage**

D: 380V / 3Ph / 60Hz

E: 380V / 3Ph / 50Hz

F: 575V / 3Ph / 60Hz

G: 460V / 3Ph / 60Hz

H: 400V / 3Ph / 50Hz

J: 400V / 3Ph / 60Hz

Options

ST: Standard

MT: Medium Temp

HL: High Lift

Refrigerant

1: R-134a

2: R-22

3: R-1234ze (E)

4: R513A

Unit Classication

CE: With CE Mark

NC: Non-conductive Coating

CH: China

Major Revision

N, P, C, A, D, E, F, G...etc.

2.2 Refrigerant Type

2.2.1 TG Series

Table 2-1 - Refrigerant Used

with Turbocor Compressors

The TT series compressors are totally oil-free and optimized for use with refrigerant R134a.

The TG series compressor is for use with R1234ze(E) refrigerant only.

ASHRAE standard 34 has classied this refrigerant as “R1234ze(E) with safety classication of

A2L”. ASHRAE Standard 34, 2010 Addendum 1 contains the change to the standard.

ASHRAE Standard 15 (Safety Standard) has sent out an initial public review document

outlining proposed changes to this standard to address 2L refrigerants.

Compressor Refrigerant

TT series R134a/R513A

TG series R1234ze(E)

NOTE

Do not use recycled refrigerant as it may contain oil, which can aect system reliability. The refrigerant should be pure

and stored in virgin containers.

NOTE

To ensure a reliable chiller system, all system components, most notably expansion valves, solenoid valves, and sensors, be

appropriate for application in oil free systems as determined by the component manufacturer. In addition, all chiller system

components exposed to refrigerant should be approved by their manufacturer for use with that refrigerant.

M-AP-001-EN Rev. N

Page 15 of 108

Page 16

Overview of the TT/TG Compressor

2.3 Environment

TT/TG Compressor Models

Figure 2-2 - Major

Components

The compressor should not be operated at an altitude higher than 3000m.

The compressor should be stored and operated within the following ambient temperature

ranges:

• Storage: -30°C to 70°C (-22°F to 158°F)

• Operation: -1°C to 52°C (30°F to 125°F).

• Mains Power Applied Non Operating Limit: -25°C (-13°F)

• Humidity: 0-95% Non Condensing

NOTE

• Contact Danfoss Turbocor for lower ambient temperature operations. Refer to “Operating Envelopes,” for details of the

operating conditions. These conditions are in line with the AHRI 540 Standard.

• All compressors/components should be protected from environments that could cause corrosion to exposed metals. For

outdoor installations, a weather-proof enclosure with vents is recommended to house the compressor.

• TT/TG compressors can operate below -1°C ambient if refrigerant circuit is maintained at a minimum of -1°C Saturated

temperature.

The TT/TG compressor, motor and power assemblies are packaged in design. 2.4 Configurations of the

Soft Start Board

SCRs

Inverter

DC-DC

Converter

Backplane

Serial Driver

Bearing Motor Compressor

Controller (BMCC)

PWM Amplifier

Page 16 of 108

M-AP-001-EN Rev. N

Page 17

Overview of the TT/TG Compressor

2.5 Compressor Module

This section provides a brief overview of the Compressor Module.

The Compressor Module is comprised of three (3) portions:

• Aerodynamics - The aerodynamics portion manages the compression of refrigerant

through the compressor from suction to discharge comprising centrifugal and IGV

technologies.

• Motor - The motor portion contains a direct-drive, high-efficiency, permanent-magnet

synchronous motor powered by pulse-width-modulating (PWM) voltage supply.

The high-speed variable-frequency operation that affords high-speed efficiency,

compactness and soft start capability. Motor cooling is by liquid refrigerant

injection.

• Electronics - The electronics is divided into two (2) sections: Power electronics

located on the top of the compressor including soft-start, DC-DC, SCR, capacitors

and inverter. Control electronics located on the side of the compressor including:

backplane, BMCC, serial driver and PWM.

M-AP-001-EN Rev. N

Page 17 of 108

Page 18

THIS PAGE INTENTIONALLY LEFT BLANK

Page 18 of 108

M-AP-001-EN Rev. N

Page 19

Functional Description

3 Functional Description

3.1 Main Fluid Path

Figure 3-1 - Compressor

Fluid Path TG230 / TT300

Compressor operation begins with a call for cooling from a chiller controller. The compressor

controller then begins compressor ramp-up.

The following paragraphs describe the ow of refrigerant from the intake to the discharge

port of the compressor (see Figure 3-1 and Figure 3-2).

The refrigerant enters the suction side of the compressor as a low-pressure, lowtemperature, super-heated gas. The refrigerant gas passes through a set of adjustable Inlet

Guide Vanes (IGVs) that are used to control the compressor capacity at low-load conditions.

The rst compression element the gas encounters is the rst-stage impeller. The centrifugal

force produced by the rotating impeller results in an increase in both gas velocity and

pressure. The high-velocity gas discharging from the impeller is directed to the secondstage impeller through de-swirl vanes. The gas is further compressed by the second-stage

impeller and then discharged through a volute via a diuser (a volute is a curved funnel

increasing in area to the discharge port. As the area of the cross-section increases, the volute

reduces the speed of the gas and increases its pressure). From there, the high-pressure/

high-temperature gas exits the compressor at the discharge port.

1st Stage

Impeller

Volute

Assembly

Discharge Port

Low - Pressure / Low Temperature Gas

Inlet Guide Vanes

(IGV)

High - Pressure / High Temperature Gas

2nd Stage Impeller

Vaned

Diffuser

M-AP-001-EN Rev. N

Page 19 of 108

Page 20

Figure 3-2 - Compressor

Fluid Path (TG310, TT350,

TG390, TT400, TG520, and

TT700)

Low - Pressure / Low Temperature Gas

Functional Description

Volute

Assembly

Discharge Port

High - Pressure /

High - Temperature

Gas

2nd Stage Impeller

Inlet Guide Vanes (IGV)

1st Stage Impeller

De-swirl Vanes

Vaneless Diffuser

3.2 Motor Cooling Liquid refrigerant is channelled at full condenser pressure from the main liquid line to the

compressor to cool the electronic, mechanical, and electromechanical components (see

Figure 3-3 and Figure 3-4).

• • • CAUTION • • •

A minimum operating pressure ratio of 1.5 is required to maintain adequate cooling of the compressor.

The sub-cooled refrigerant enters the compressor through two solenoid valves and

associated xed orices located behind the service access cover. The orices cause the

refrigerant to expand, thereby lowering its temperature. Both valves operate relative to the

temperature at the sensors that are located at the Insulated Gate Bipolar Transistor (IGBT)

Inverter and motor cavity. When the temperature at either sensor reaches a pre-determined

threshold, one solenoid valve opens. If the temperature increases to the point where it

equals a higher temperature threshold, the second solenoid valve opens.

From the outlet of the orices, the refrigerant is directed to the heatsink plate of the inverter

and then to the underside of the SCR heatsink. From there, the refrigerant passes through

grooves surrounding the motor stator. As the refrigerant ows through the grooves, it

vaporizes into a gas. At the coil outlet, the refrigerant gas is channeled back to the suction

inlet via the motor cavity, thereby cooling the rotor. All models with the exception of the

TT300 and TG230 use a split-cooling method where the motor and electronics portions are

cooled separately by refrigerant liquid.

Page 20 of 108

M-AP-001-EN Rev. N

Page 21

Functional Description

Figure 3-3 - Compressor

Cooling Circuit (TG230 /

TT300)

From Motor

Winding Temp.

Sensor

BMCC

Solenoid

A

From Motor

Cavity Tem p.

Sensor

Liquid

Refrigerant

Inlet

ORIFICEORIFICE

Cooling path

redirects outside of

the compressor

MT Only

Solenoid

B

IGBT

BMCC

From IGBT

Temp. Sensor

Pressure

Regula�ng

Valve

From SCR

Temp. Sensor

SCR

Motor/Rot or

cooling gas and

leakage

Cooling path re-enters

at the suc�on line of

the chiller

Figure 3-4 - Compressor

Cooling Circuit (TT300

Split-Cooling, TG310, TT350,

TG390, TT400, and TG520)

From Motor

Win ding T emp.

Senso r

BMCC

Solen oid

A

From Motor

Ca vit y Temp .

Senso r

OR IFI CE

Li quid

Refri gerant

Inl et

Solen oid

B

OR IFI CE

Fr om IG BT

Te mp. Sen sor

BMCC

IGB T

From SCR

Te mp. Sen sor

SCR

Motor/Rotor

coo li ng g as a nd

leak age

M-AP-001-EN Rev. N

Page 21 of 108

Page 22

Functional Description

3.3 Inlet Guide Vanes The Inlet Guide Vane (IGV) assembly is a variable-angle guiding device that is used for

capacity control. The IGV assembly consists of movable vanes and a motor. The vane

opening is determined by the BMCC and controlled by the Serial Driver. The IGV position can

vary between 0-110% where 0% is fully closed and 110% is fully open with the vanes at a 90°

angle.

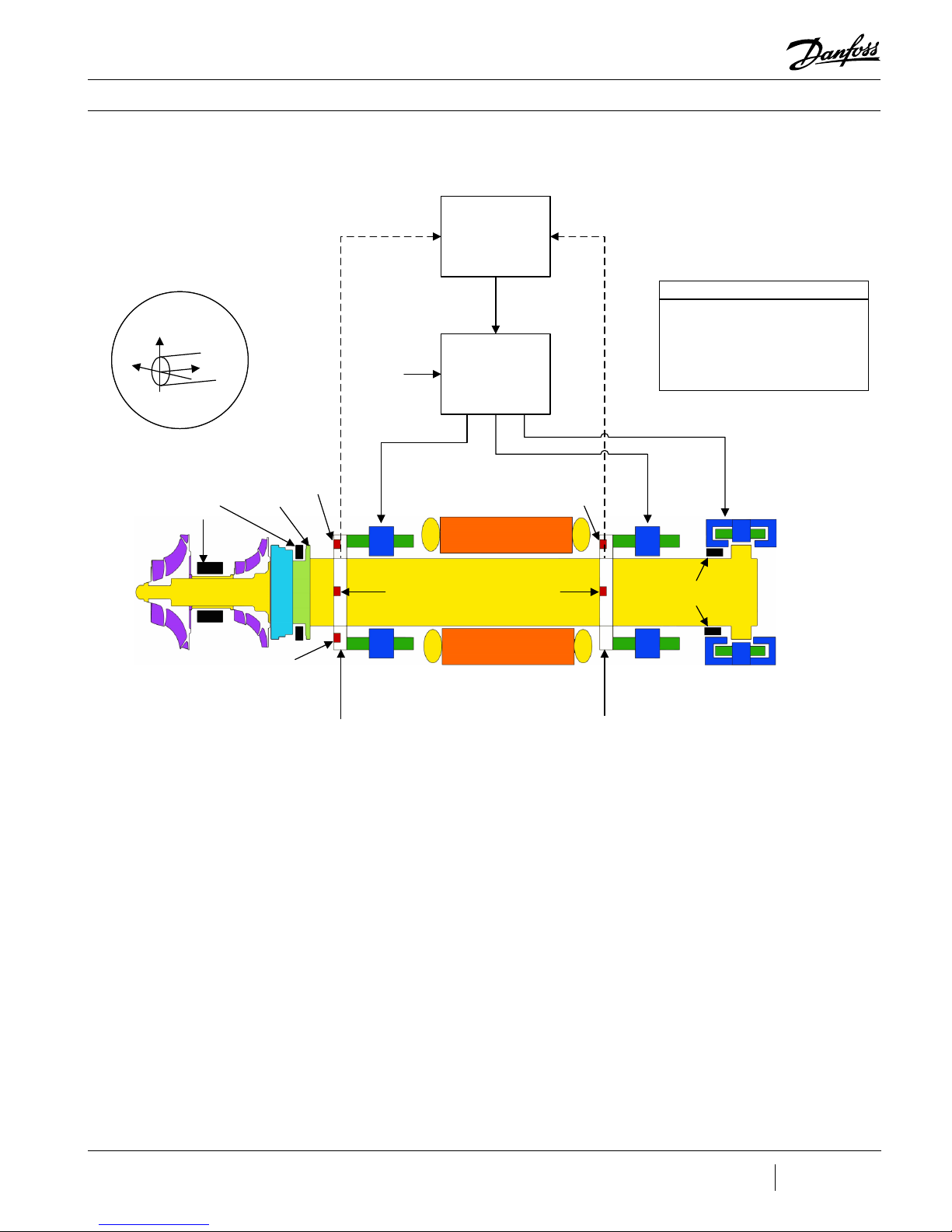

3.4 Compressor Control

Overview

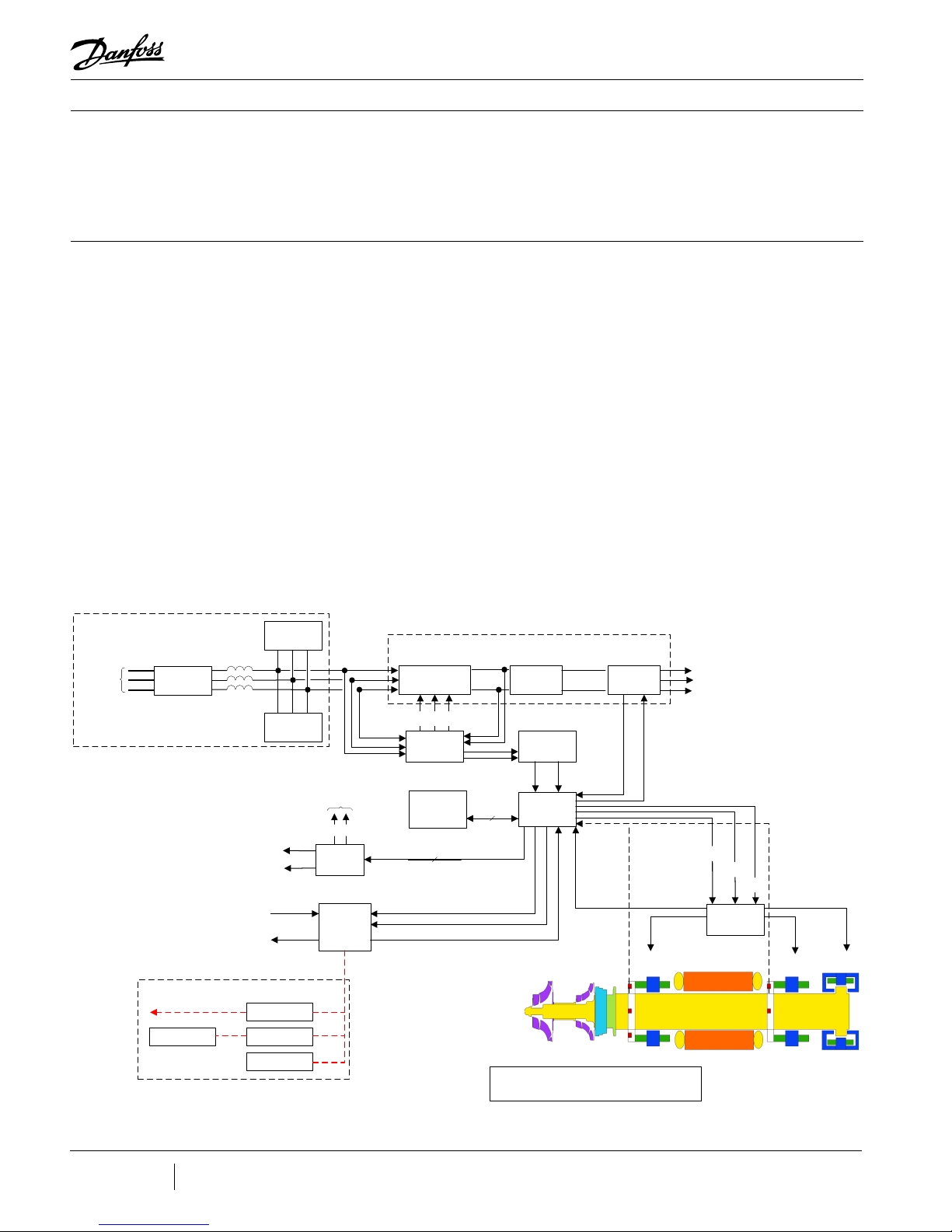

Figure 3-5 - Compressor

Control System Functional

Block Diagram

External Power Components

3-Phas e

380-57 5VAC

50/ 60 Hz

EMI/EMC

Fil ter

To Motor Cooling Solenoids

To IGV St eppe r Motor

RS-485 Comm s

to Chil ler or Buildi ng

Manag ement System

Int erne t

Com pres sor

Com pres sor

Figure 3-5 shows a functional block diagram of the compressor control and monitoring

system. Figure 3-7 displays the component locations. The major components include:

• Motor Drive

• Soft-Start Board

• Bearing Motor Compressor Controller (BMCC)

• Bearing PWM Amplifier

• Backplane

• Serial Driver

• HV DC-DC Converter

Su rge

Lin e

Rea ctor

Inputs

Outputs

Suppresso r

Ha rmoni c

Fil ter

Ex tern al Expa nsi on V al ves

+24V DC

+15V DC

0-10V DC

0-10V DC

Use r I nte rf ace

Cus tome r

Chiller Control

Com mun icati ons

Int erfa ce

Diagnostic

Te rmin al

3-Pha se

380-57 5VAC

50/60 Hz

+15V DC

Seria l

Dri ver

Modu le

Com pres sor

I/O

Boa rd

Half -Controlled

Rec tifie r

0-12 VD C

next (+ ) DC bus

Soft-S tart

Con tro ller

Bear ing

Motor

Com pres sor

Controller

(BMCC)

+15V DC

+24V DC

Con tro l

Fee dbac k

+5 VDC

+15V DC

Con tro l

Fee dbac k

Motor Drive

1.3 5*V

in

0 VDC

460-85 3 VDC

15 V AC

+24V DC

+5 VDC

+15V DC

-15V DC

Con tro l

No te:

All vo ltage leve ls shown have t he foll owin g e rror tol erance:

460-85 3 VDC

DC Li nk

Ca pacit ors

0 VDC

DC/DC

Con ver ter

+

(+250 VDC)

HV

not HV

Backplane

DC (e xce pt the DC bu s): ±5%

AC : ±10 %

Con tro l

Fee dbac k

-

Con tro l

Fee dbac k

3-Phas e

Inv ert er

IGB T

+24V DC

Gat ing

Sign als

Sh aft Posi tion Out puts

2-3A

(Calibration)

Fr ont

Rad ial

Bear ing

V

Freq uency

a

(0-750H z)

V

b

AC Vo ltage

V

c

To Stator

+

HV

not HV

Bea rin g P WM

Varia ble

-

+17V DC

not HV

Amplifier

-

+5 VDC

Rear

Radial

Bear ing

(Calibration)

2-3A

(Calibration)

2-3A

Axial

Bear ing

Page 22 of 108

M-AP-001-EN Rev. N

Page 23

Functional Description

3.4.1 Motor Drive System Normally, AC power to the compressor remains on even when the compressor is in the idle

state. The compressor motor requires a variable-frequency three-phase source for variablespeed operation. The AC line voltage is converted into a DC voltage by Silicon-Controlled

Rectiers (SCRs). DC capacitors at the SCR output serve as energy storage and lter out the

voltage ripple to provide a smooth DC voltage. The Insulated Gate Bipolar Transistor (IGBT)

is an inverter that converts the DC voltage into an adjustable three-phase AC voltage. Pulse

Width Modulation (PWM) signals from the Bearing Motor compressor Controller (BMCC)

control the inverter output frequency and voltage. By modulating the on and o times of

the inverter power switches, three-phase variable sinusoidal waveforms are obtained.

If the power should fail while the compressor is running, the motor switches into generator

mode, thereby sustaining the capacitor charge. The rotor can then spin down safely in a

controlled sequence preventing damage to components.

3.4.2 Soft-Start Board The Soft-Start Board limits inrush current by progressively increasing the conduction angle

of the SCRs. This technique is used at compressor start-up while the DC capacitors are

charging up.

The soft-start function and the variable-speed drive combined limit the inrush current at

startup.

3.4.3 Bearing Motor

Compressor Controller

The hardware and software for the compressor controller and the bearing/motor controller

physically reside in the BMCC. The BMCC is the central processor of the compressor.

3.4.4 Compressor Control The Compressor Controller is continuously updated with critical data from external sensors

that indicate the compressor’s operating status. Under program control, the compressor

controller can respond to changing conditions and requirements to ensure optimum system

performance.

Figures 3-5 to Figure 3-7 shows how the controller responds to chiller demands.

3.4.5 Capacity Control One of the Compressor Controller’s primary functions is to control the compressor’s motor

speed and IGV position in order to satisfy load requirements and to avoid surge and choke

conditions. However, the majority of capacity control can be achieved via motor speed.

M-AP-001-EN Rev. N

Page 23 of 108

Page 24

Functional Description

3.4.6 Expansion Valve

Control

3.4.7 Motor/Bearing

Control

3.4.8 Monitoring

Functions

The on-board Electronic Expansion Valve (EXV) driver uses manual control only.

Depending on the application, a load balancing (hot gas bypass) valve can be manually

driven by the auxiliary EXV output. Load balancing allows the compressor to obtain lower

capacities at higher pressure ratios. The valve opens to lower the overall pressure ratio and

thereby reduces the lift, enabling the compressor to reduce speed/unload.

The magnetic bearing system physically supports a rotating shaft while enabling noncontact between the shaft and surrounding stationary surfaces. A digital bearing controller

and motor controller provide the PWM command signals to the Bearing PWM Amplier and

IGBT Inverter, respectively. The bearing controller also collects shaft position inputs from

sensors and uses the feedback to calculate and maintain the desired shaft position.

The compressor controller monitors more than 60 parameters, including:

• Gas pressure and temperature monitoring

• Line voltage monitoring and phase failure detection

• Motor temperature

• Line currents

3.4.9 Abnormal

Conditions

• External interlock

The compressor controller responds to abnormal conditions by monitoring:

• Surge RPMs

• Choke RPMs

• Power failure/phase unbalance

• Low/high ambient temperature

• High discharge pressure

• Low suction pressure

• Motor-cooling circuit failure (over temperature)

• Refrigerant loss

• Power supply

• Overcurrent

Page 24 of 108

M-AP-001-EN Rev. N

Page 25

Functional Description

3.4.10 Bearing PWM

Amplier

3.4.11 Serial Driver

3.4.12 Backplane

The Bearing PWM Amplier supplies current to the radial and axial magnetic bearing

actuators.

The PWM Amplier consists of high-voltage switches that are turned on and o at a high

frequency, as commanded by the PWM signal from the BMCC.

The Serial Driver module performs serial-to-parallel conversion on the stepper motor drive

signals from the BMCC. The module also contains four normally open relays under BMCC

control. Two of the relays drive the motor-cooling solenoids, and the other two are used

to indicate compressor fault status and running status. The status relays can be wired to

external control circuits.

The Backplane physically interconnects the on-board plug-in modules with the power

electronics, IGV stepper motor, motor-cooling solenoids, rotor position sensors, and

pressure/temperature sensors. The Backplane also features on-board, low-voltage DCDC converters for generating +15V, -15V, +5V, and +17V from an input of +24VDC. The

Backplane receives its +24VDC power input from the High-Voltage (HV) DC-DC Converter

mounted on the topside of the compressor.

The Backplane is also equipped with status-indicating LEDs. All LEDs are yellow except for

the alarm LED, which is green/red. Table 3-1 Backplane LEDs describes the LEDs functions.

Table 3-1 - Backplane LEDs

LED Function

+5V, +15V, +17HV,

+24V

Cool -H, Cool -L LEDs are lighted when their respective coil is energized.

Run LED is lighted when the shaft is spinning.

Alarm LED is green when in normal status, red when in alarm status.