Page 1

Data Sheet

Thermostatic Expansion Valves

Type TR6

The TR6 series is a hermetic design which is

developed with features especially for use in

applications such as:

• Residential air conditioning systems

• Split systems

• Roof top units

• Heat pumps

• Chillers

• Light commercial air conditioning systems

The TR6 design incorporates a forged brass

body with the entire power element, including

the capillary tube and bulb, fabricated from

stainless steel. All valves are designed with

balanced port which reduces the inuence

from varying condensing pressures. The valves

can be delivered with special connections and

ttings both at the inlet, outlet, and the

equalizer connection.

AI318728845972en-000401

Page 2

Thermostatic Expansion Valves, Type TR6

Features

• Compact size - hermetic design, straightway conguration with external equalization

• Refrigerants & rated capacities ranging up to

◦ R22/R407C: 23.6 kW / 6.7 TR

◦ R410A: 24.5 kW / 7 TR

• Laser-welded power element

◦ Longer diaphragm life

◦ High corrosion resistant

• Stainless steel capillary tube

◦ Tolerates more bending for easier installation and longer life

◦ High strength and vibration resistance

• Stainless steel bulb

◦ Self aligning

• Balance port design

• A complete program with and without internal check valve

• Internal check valve design with low pressure drop in reverse ow

• Adjustable or non-adjustable superheat, for customer specic factory setting

• Bleed function available

• Solder, chatle and aeroquip connections

• With external equalization

• UL listed, le SA7200

• Anti-hunt bulb charge

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 2

Page 3

Danfoss

R64-1822.12

A

B

C

D

E

A

BCD

E

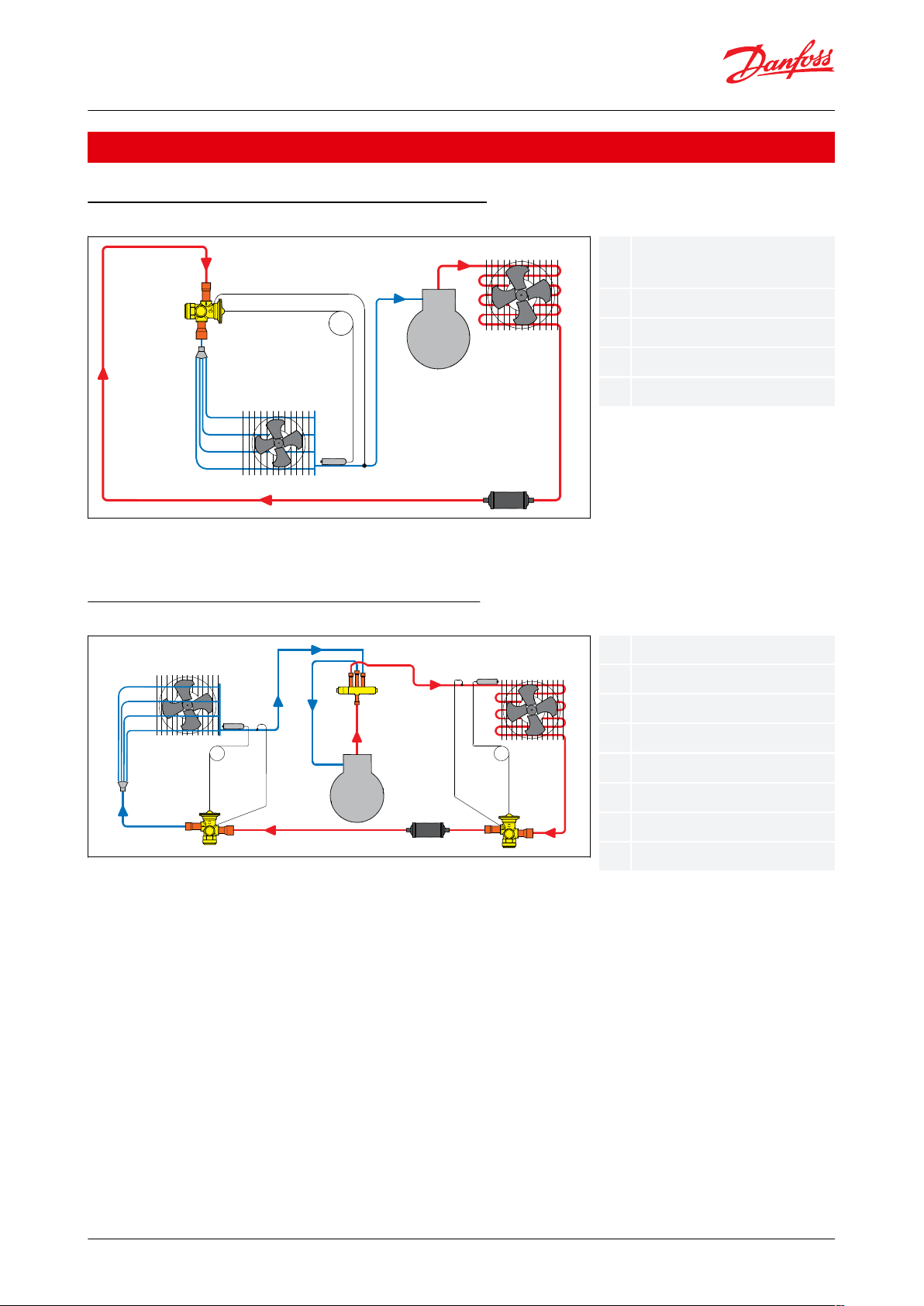

TR6 with / without internal

check valve

RD Distributor

Compressor

Outdoor coil

DCL/DML

Danfoss

R64-1823.13

A

B

C

D

E

F

H

G

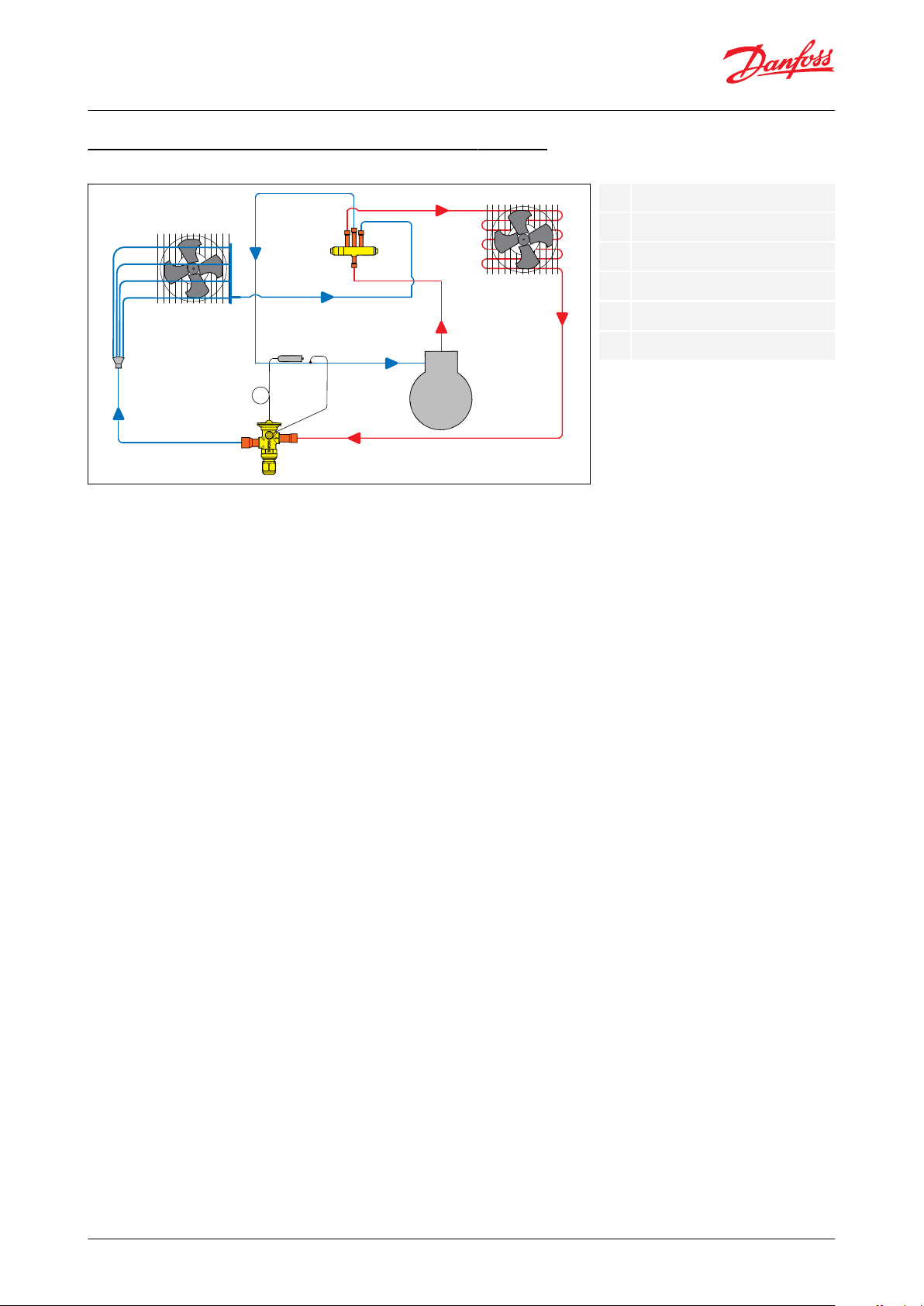

ABCDEFGHRD Distributor

Indoor coil

TR6 with internal check valve

4-way valve

Compressor

DCB/DMB

TR6 with internal check valve

Outdoor coil

Thermostatic Expansion Valves, Type TR6

Application

Traditional air conditioning system, cooling only

Figure 1: Traditional air conditioning system, cooling only

Illustrates the diagram of a traditional air conditioning system where the TR6 is controlling liquid injection in one

direction only.

Traditional air conditioning / heat pump system

Figure 2: Traditional air conditioning / heat pump system

Illustrates a split air conditioning / heat pump system with two thermostatic expansion valves, one for cooling mode

and one for heating mode. The thermostatic expansion valves each has a built-in check valve, which has the

function of preventing ow in one direction and allowing the ow in the opposite direction. It means that one

thermostatic expansion valve is controlling liquid injection into the indoor coil while the other thermostatic

expansion valve is bypassing the metering device with the open check valve.

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 3

Page 4

Danfoss

R64-1824.13

A

B

C

D

E

F

ABCDEFRD Distributor

Indoor coil

TR6 without check valve

4-way valve

Compressor

Outdoor coil

Thermostatic Expansion Valves, Type TR6

Simplied air conditioning / heat pump system (bi-ow)

Figure 3: Simplied air conditioning / heat pump system (bi-ow)

Illustrates a packaged air conditioning / heat pump system with a short distance between the indoor and outdoor

heat-exchangers. The two TR6 valves from g 6 can be replace by one TR6 valve without internal check valve,

making use of the bi-ow feature of this thermostatic expansion valve. The single valve is controlling the liquid

injection in both directions. The normal ow direction marked with an arrow on the valve body should be used for

the primary function, i.e. cooling or heating.

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 4

Page 5

Thermostatic Expansion Valves, Type TR6

Product specication

Technical data

Max. operating temperature

• Thermostatic element:

◦ R22 / R407C: max. 100°C / 212°F

◦ R410A: max. 100°C / 212°F

• Valve body:160 °C / 320 °F

Max. working pressure PS / MWP

49 bar / 711 psig

Valve program

Standard versions

Refrigerants:

R22 / R407C and R410A

Operating range:

-10 to 15°C / 15 to 60°F

Setting:

• Fixed setting:

◦ Static superheat in accordance with customers' specications

• Adjustable setting:

R22 / R407C

Factory static superheat of 4 K / 7.2 °F

R410A

Factory static superheart of 3 K / 5.4 °F

Packing

Single or Multipack

Industrial Pack for OEM specic valves only

Versions:

All valves are in straightway versions with or without internal check valve

Standard connections:

Inlet solder

Equalizer capillary tube ¼ in. are; 24.3 in. length

Capillary tube length: 800 mm / 31.5 in.

3

⁄8 in. ODF x Outlet solder 3⁄8 in. ODF

Options on request

Capillary tube lengths(approx.):

450 mm / 17.7 in.

975 mm / 38.4 in.

Options for Connections:

Inlet/Outlet:

Inlet: Solder ODM

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 5

3

⁄8 in., solder ODF 3⁄8 in., solder ODF ½ in., Chatle male 5⁄8 in. and aeroquip male 5⁄8 in.

Page 6

A

D

B

E

C

F

G

H

ABCDEFGHValve type

Code number

Evaporating temperature range in °C

Refrigerant

Rated capacity Qnom in Tons of refrigeration

Evaporating temperature range in °F

Max. working pressure in bar and psig

Date making (BC=Mexico, week 49, year 2017, weekday

D=Thursday)

X

Y

XYDp (psi)

Mass ow lb/h

Thermostatic Expansion Valves, Type TR6

Outlet: Solder ODF

female

5

⁄8 in., short and long tail.

3

⁄8 in., solder ODF ½ in., solder ODF 5⁄8 in., chatle female ¾ in., short and long tail, aeroquip

Equalizer:

Copper capillary tube size (approx.): Ø

1

⁄8 in.

Available congurations:

Solder ODM

1

⁄8 in., lengths 9.5 in., 16.9 in., 24.3 in., 31.7 in.

Solder ODF ¼ in., lengths 31.7 in. and 39.1 in.

Flare nut ¼ in., lengths 9.5 in., 16.9 in., 24.3 in., 31.7 in.

Identication

Figure 4: Main valve data example:

Essential valve data is given on the power element.

Check valve capacity

Figure 5: Internal check valve for orice bypass in reverse ow (ow rate as a function of pressure dierential)

TC= 32 °C / 90 °F

TI= 24 °C / 75 °F

Valve selection based on capacity calculation

As for extended capacity calculations and valve selection based on capacities and refrigerants, please refer to

Coolselector®2. Rated and extended capacities are calculated with the Coolselector®2 calculation engine to ARI

standards with the ASEREP equations based on laboratory measurements of selected valves.

Download Coolselector®2 for free at coolselector.danfoss.com.

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 6

Page 7

123456789

TR6 with xed setting

TR6 with adjustable setting

4

9

6

8

2

7

3

5

1

Bulb

Thermostatic element

Push pin seal

Balanced port

Check valve

Setting spindle for adjustment of static superheat

(SS)

Equalizer

Inlet connection

Outlet connection

Thermostatic Expansion Valves, Type TR6

Design and function

Table 1: Design and function

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 7

Page 8

SSOSOSH

Static superheat

Opening superheat at nominal/ rated capacity

SS + OS = Operating superheat

Danfoss

67U02.10

45.5 mm / 1.79 in.

46.3 mm / 1.82 in.

7.5 mm /

0.30 in.

35.5 mm /

1.40 in.

29.4 mm /

1.16 in.

Danfoss

67U03.10

47 mm / 1.85 in.

40.5 mm / 1.59 in.

Ø14.35 mm /

0.565 in.

22.7 mm /

0.89 in.

Thermostatic Expansion Valves, Type TR6

Figure 6: Static/opening superheat graph

The central push pin is sealed with a robust seal (pos. 3) that ensures maximum tightness and minimum friction

through the lifetime of the valve.

The balanced port (pos. 4) ensures minimal superheat changes when condensing pressure varies. This feature

makes the valve ideal for bi-ow operation.

Static superheat (SS) can be adjusted with the setting spindle (pos. 6).

Example

Static superheat

SS = 4 K / 7.2 °F (factory setting)

or according to customer specication

Opening superheat at nominal/ rated capacity OS = 4 K / 7.2 °F

Opening superheat is dened as the required superheat to open the valve to nominal capacity

Dimensions and weights

Fixed setting

Table 2: Fixed setting

Weight 0.305 kg, 0.672 lbs

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 8

Page 9

Danfoss

67U05.10

45.5 mm / 1.79 in.

46.3 mm / 1.82 in.

7.5 mm /

0.30 in.

43.1 mm / 1.70 in.

29.4 mm /

1.16 in.

Danfoss

67U06.10

47 mm / 1.85 in.

Ø14.35 mm /

0.565 in.

48.1 mm / 1.89 in.

22.9 mm /

0.90 in.

Thermostatic Expansion Valves, Type TR6

Adjustable setting

Table 3: Adjustable setting

Weight 0.361 kg; 0.795 lbs

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 9

Page 10

Danfoss

R64-1825.11

t

l

t

e

p

e

B

A

C

ABC

TR6

RD Distributor

Compressor

Valve type

Orice no.

Rated capacity

Connections solder ODF

Code no.

Multi pack

(1)

R410A

(2)

R407C

R22

Inlet x Out‐

let [in.]

Pressure

equalization

[in.]

[KW]

[TR]

[KW]

[TR]

[KW]

[TR]

TR63––9.8

2.8113.1

3⁄8 × 3⁄8

1⁄4

067L5855

TR64––13.8

3.9

15.5

4.4

3⁄8 × 3⁄8

1⁄4

067L5856

TR65––16.4

4.7

18.4

5.2

3⁄8 × 3⁄8

1⁄4

067L5857

TR66––17.4

4.9

19.6

5.6

3⁄8 × 3⁄8

1⁄4

067L5858

TR67––20.9623.8

6.8

3⁄8 × 3⁄8

1⁄4

067L5859

TR6311.3

3.2––––

3⁄8 × 3⁄8

1⁄4

067L5955

TR6415.9

4.5––––

3⁄8 × 3⁄8

1⁄4

067L5956

TR6519

5.4––––

3⁄8 × 3⁄8

1⁄4

067L5957

TR6620.2

5.8––––

3⁄8 × 3⁄8

1⁄4

067L5958

TR6724.57––––3⁄8 × 3⁄8

1⁄4

067L5959

Thermostatic Expansion Valves, Type TR6

Ordering

R22 / R407C and R410A

Figure 7: Adjustable setting

Table 4: R22 / R407C and R410A

(1)

(1)

Kit part numbers consist of a valve, bulb strap, insulation tape, installation guide, and the following connectors:

Kit part numbers consist of a valve, bulb strap, insulation tape, installation guide, and the following connectors:

1 Chatle female 3⁄4 in. connector

1 Chatle female 3⁄4 in. connector

1 Aeroquip female 5⁄8 in. connector

1 Aeroquip female 5⁄8 in. connector

1 Flare 3⁄8 in. connector

1 Flare 3⁄8 in. connector

(2)

(2)

The rated capacity is based on:

The rated capacity is based on:

Evaporating temperature te : 4.4 °C / 40 °F

Evaporating temperature te : 4.4 °C / 40 °F

Condensing temperature tc : 38 °C / 100 °F

Condensing temperature tc : 38 °C / 100 °F

Refrigerant temperature ahead of valve tl : 37 °C / 98 °F

Refrigerant temperature ahead of valve tl : 37 °C / 98 °F

Temperature range = -10 to 15 °C / 15 to 60 °F = 4 K / 7.2 °F

TR6 with xed superheat setting are available upon request.

Single pack = 1 valve kit in a box

Industrial pack = 12 pieces in one box

Sizing

Figure 8: Sizing

Example:

Refrigerant=R410A

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 10

Page 11

Thermostatic Expansion Valves, Type TR6

Evaporating temperature=(te=45 °F;pe=131 psig)

Condensing temperature =(tc=110 °F;pc=368 psi

Liquid line tl= 100 °F

pressure drop in liquid line, drier and distributor system Dp2+ Dp1=35 psi

Pressure drop in valve Dp = 368 - 131 - 35 = 202 psi

Subcooling Δtsub = tc – tl=10 °F

Evaporator capacity = 4.0 TR

Correction factor from table= 1.02

The corrected evaporator capacity then becomes 4.0 × 1.02 = 4.08 TR

As the selected valve must be equal to or slightly larger than the corrected evaporator capacity of 4.08 TR, the TR6

with orice 4 would be a suitable choice. Reference table below for rated capacities.

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 11

Page 12

File name

Document type

Document topic

Approval authority

067U9601 Vr.AB

Manufacturers Declaration

China RoHs

Danfoss

Thermostatic Expansion Valves, Type TR6

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 5: Declaration for TR6

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 12

Page 13

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI318728845972en-000401 | 13

Loading...

Loading...