Page 1

Working in partnership

Product Sheet

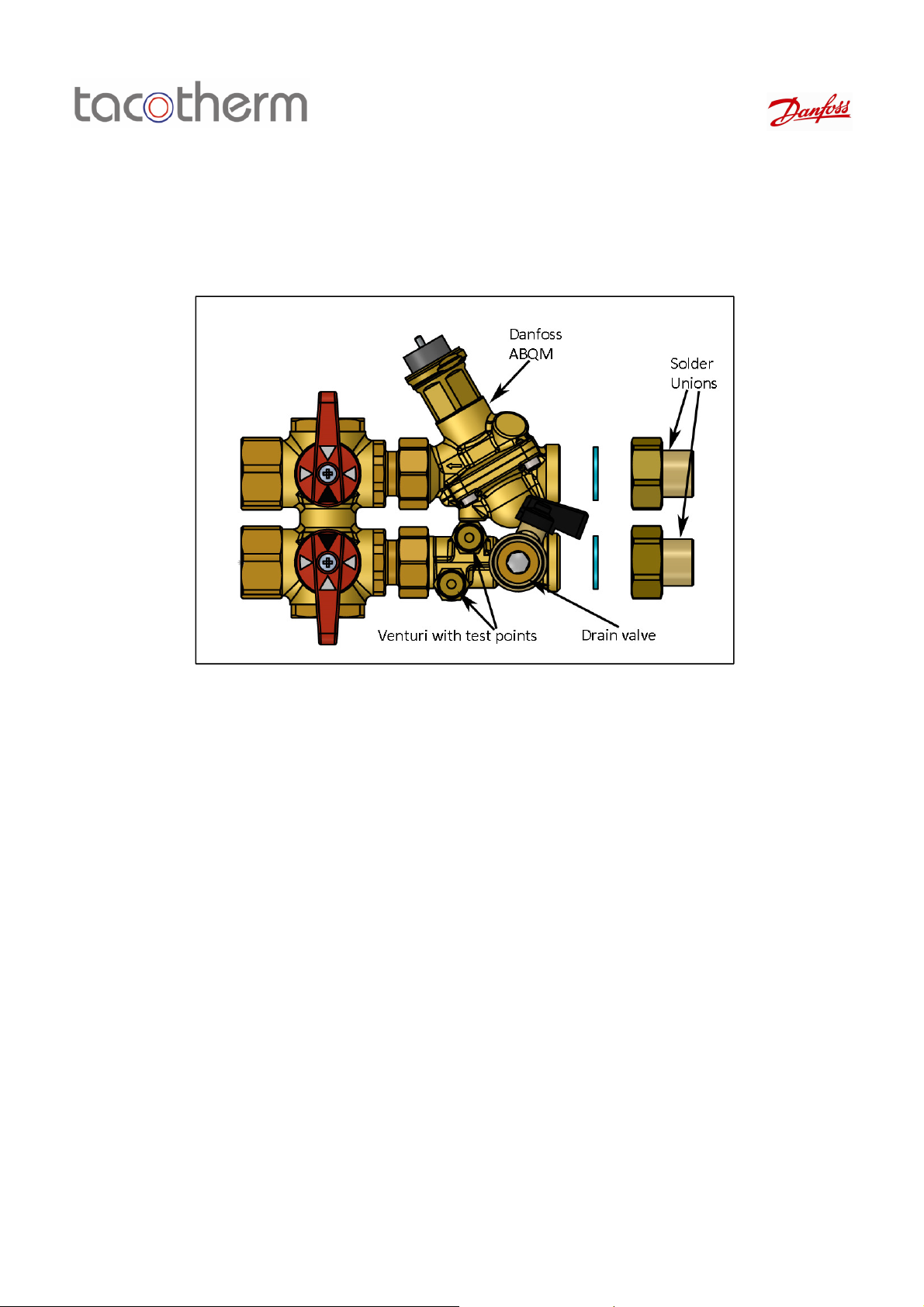

Pre-Fabricated Flushing Bypass Assembly for Terminal Applications

Mini-Flush 40

with

Description

Miniflush 40 is a pre-fabricated, flushing bypass arrangement for balance, control, isolation, and

operation of terminal devices. It is designed for use with fan coil units, chilled beams, and other

terminal devices, where flow is controlled via a pressure independent control valve, and isolation,

drain, flushing bypass, and flow measurement is required.

Key features include:

• A compact, pre-fabricated design

• Factory pressure tested assembly

• Each assembly is labelled with FCU location and Miniflush 40 instructions

• High flow DN15 option for direct connection to CHW terminals with flows up to 0.315 l/s

• Low flow option for LTHW flow rates down to 0.008 l/s

• Left and right handed versions to prevent clashes within the fan coil

• A wide range of connection options, including BSP, compression, and solder connections to the

coil

• Danfoss AB-QM pressure independent control valve for balance at full or partial loads

• A comprehensive compatible range of actuators to enable it to be connected to a building

management system or other controller

• Flow mounted drain for flushing and quick drain-downs

• Flow measurement function in all sizes

Tacotherm Ltd, Unit 40, Hampshire Business Park, Brunel Road, Totton, Ha mpshire, SO40 3SA, UK.

T: 02380 663163 E: sales@tacotherm.co.uk

Tacotherm accept no liability for possible errors in this product sheet. Tacothermr eserve the right to alter this product without notice. This product us supplied by Tacotherm Limited

Page 2

Working in partnership

Connection

with

Product Sheet Pre-Fabricated Terminal Assembly Type: Mini-Flush 40

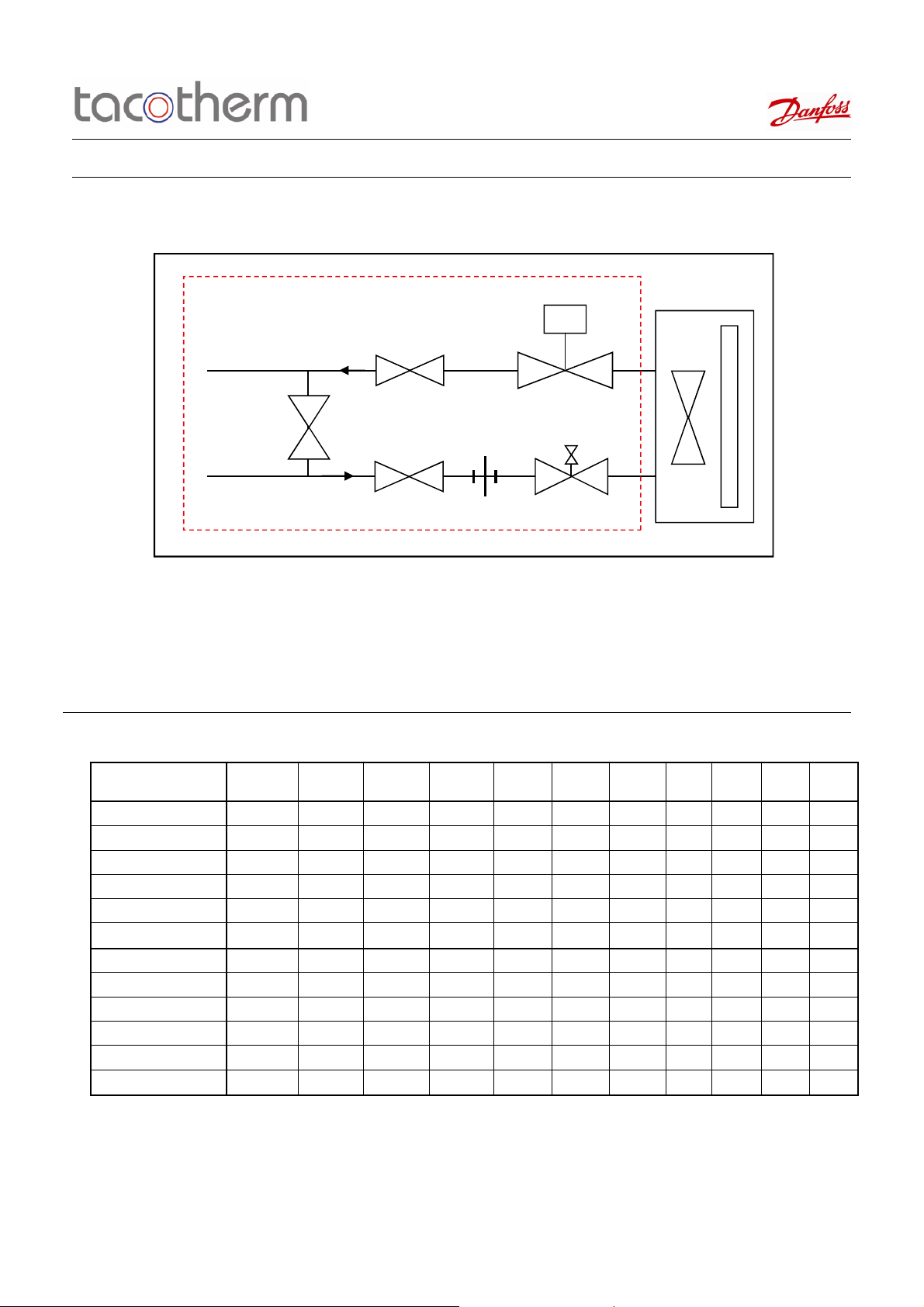

Schematic and Design

AB-QM

IV

IV (NC)

IV

Schematic Symbol Guide

AB-QM -Pressure Independent Control Valve (actuator supplied separately)

DOC -Drain point

IV -Isolation valve

MS -Measuring station

Ordering

Type

Miniflush 40 10LF 0.3 Left Handed 150 60 30 0.3

Miniflush 40 15LF 0.6 Left Handed 275 90 60 0.6

Miniflush 40 15LF 0.9 Left Handed 275 230 90 0.9

Miniflush 40 15 2.1 Left Handed 450 450 230 2.1

Miniflush 40 15HF 4.0 Left Handed 1135 600 450 4.0

Miniflush 40 15HF 5.6 Left Handed 1135 1135 600 5.6

Miniflush 40 10LF 0.3 Right Handed 150 60 30 0.3

Miniflush 40 15LF 0.6 Right Handed 275 90 60 0.6

Miniflush 40 15LF 0.9 Right Handed 275 230 90 0.9

Miniflush 40 15 2.1 Right Handed 450 450 230 2.1

Miniflush 40 15HF 4.0 Right Handed 1135 600 450 4.0

Miniflush 40 15HF 5.6 Right Handed 1135 1135 600 5.6

Position on

Terminal

Nominal Valve

Flow Rate l/h

Recommended

Q Max (l/h)

Recommended

Q Min (l/h)

MS

Orifice kVs

DOC

Connection

Size

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

3/4" x 15 or

22mm

Connection

Type

Pipework

Internal

Threaded

Internal

Threaded

Internal

Threaded

Internal

Threaded

Internal

Threaded

Internal

Threaded

Internal

Threaded

Internal

Threaded

Internal

Threaded

Internal

Threaded

Internal

Threaded

Internal

Threaded

Actuator

Type

Terminal

Modulating

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Solder AME 110NL AMV 110NL TWA-Z

Type

Actuator

Type

3-Point

Actuator

Thermic

Type

Notes:

-The recommended flow rates are to enable accurate measurement of flow

-Actuators need to be ordered separately

-Options are available for connection to the pipework and terminal. Please discuss with your representative prior to ordering

Tacotherm Ltd, Unit 40, Hampshire Business Park, Brunel Road, Totton, Ha mpshire, SO40 3SA, UK.

T: 02380 663163 E: sales@tacotherm.co.uk

Tacotherm accept no liability for possible errors in this product sheet. Tacothermr eserve the right to alter this product without notice. This product us supplied by Tacotherm Limited

Page 3

Working in partnership

with

Product Sheet Pre-Fabricated Terminal Assembly Type: Mini-Flush 40

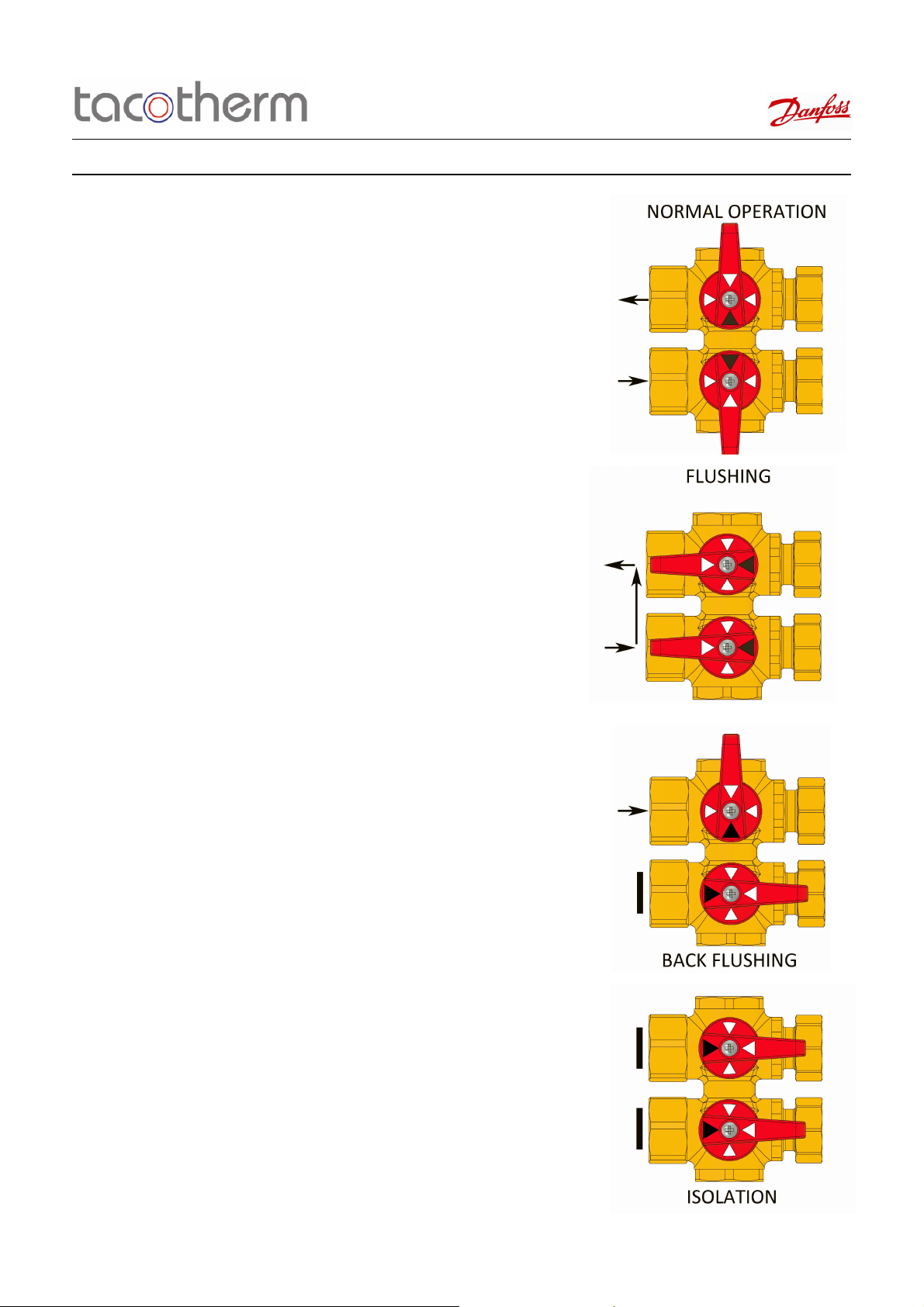

Operational Modes

Normal Operation

This is the supply operation of the Mini-flush,

with flow going through terminal, and out

through the return, back to the system.

The AB-QM valve will balance by limiting the

flow to the coil, and the actuator will control

flow as per the temperature requirement.

Flushing

During system flushing, the terminal will be

isolated, but a flow around the main system is

required. To enable bypassing we have

positioned a flushing bypass within the Miniflush assembly, which can open a link between

flow and return, to enable mainline system

flow for flushing.

Back Flushing

To enable flushing through the terminal, the

return can be opened, with the flow and

bypass isolation valves closed. The drain is

then opened, to allow flow through the coil,

and any coil debris will be released through

the flow side drain point.

Isolation

For a variety of reasons, it may be required to

completely isolate the terminal. For this we

can isolate the flow and return, and close the

bypass, to remove all flow through the coil

and bypass.

Tacotherm Ltd, Unit 40, Hampshire Business Park, Brunel Road, Totton, Ha mpshire, SO40 3SA, UK.

T: 02380 663163 E: sales@tacotherm.co.uk

Tacotherm accept no liability for possible errors in this product sheet. Tacothermr eserve the right to alter this product without notice. This product us supplied by Tacotherm Limited

Page 4

Working in partnership

with

Product Sheet Pre-Fabricated Terminal Assembly Type: Mini-Flush 40

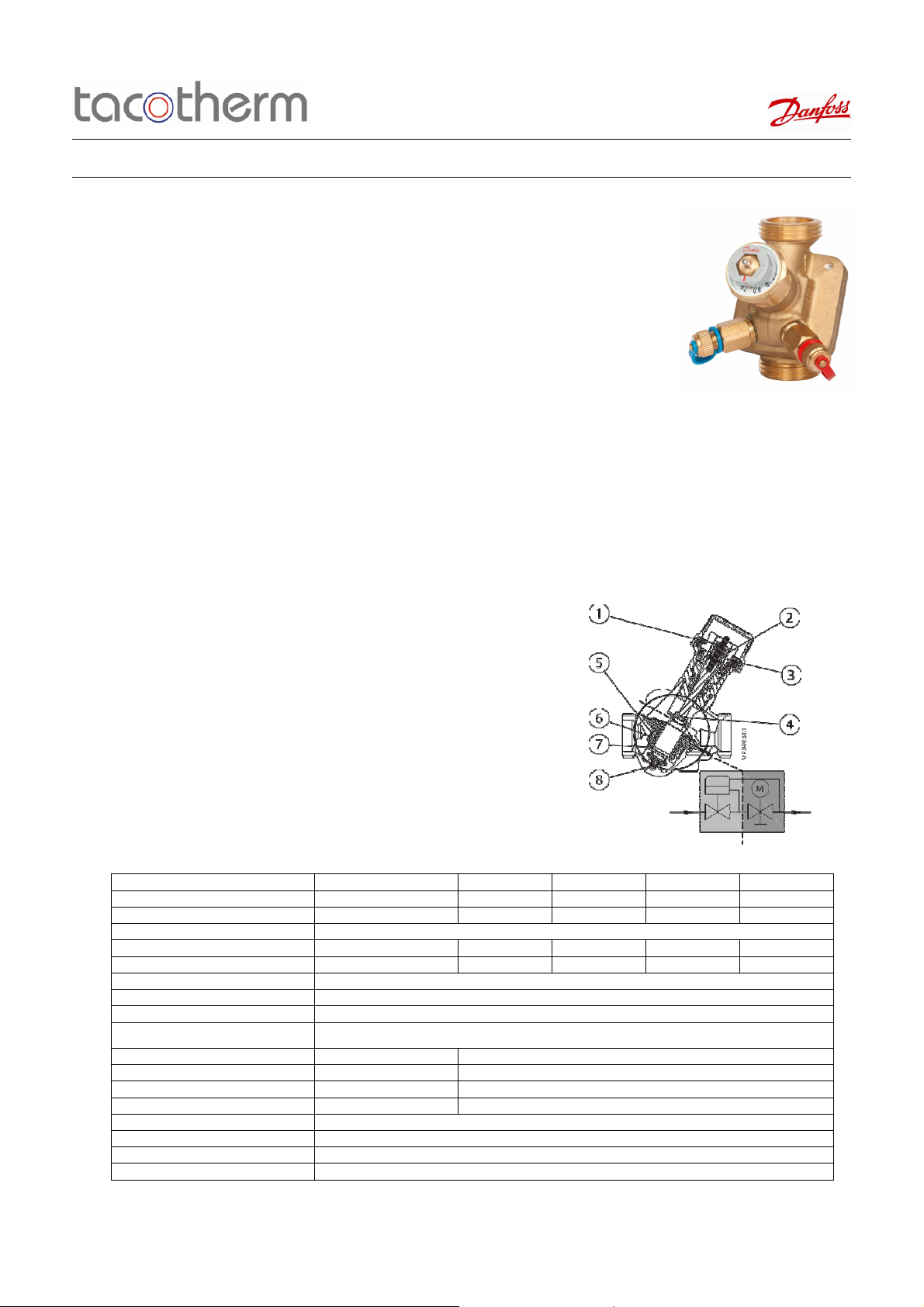

Pressure Independent Control Valve Specification

Description

The precise flow control performance of the AB-QM with a Danfoss actuator provides

increased comfort and superior Total Cost of Ownership because of savings made on:

• Efficient energy transfer and minimal pumping costs since there are no overflows at

partial loads because of the exact pressure independent flow limitation.

• Smaller pump investments and lower energy consumption as the pump head needed

is lower than in the traditional setup. With the built in test plugs it is easy to

troubleshoot and find the optimal setpoint for the pump.

• Reduced movements of the actuator since the built-in differential pressure controller

ensure the pressure fluctuations do not influence the room temperature.

• Achieving a stable temperature in a room leading to a lower average temperature at

the same comfort level.

• Minimal flow complaints, as the valve performs as designed, and has been tested by

BSRIA to demonstrate flow performance.

• Minimal blockage complaints, as the AB-QM diaphragm design has the advantage of

being ‘dirt tolerant’ unlike a cartridge type designed PICV.

• Trouble-free segmentation of the building project. When sections of a project are

finished they can normally not be handed over to the customer with a fully functional

HVAC installation. However the AB-QM with a Danfoss actuator will automatically

control the flow, even when other parts of the installation are still unfinished. It’s not

needed to adjust the AB-QM after finalisation of the project.

• Commissioning costs, the costs are close to zero because of a convenient setting

procedure without the need for flow charts, calculations or measuring equipment.

The AB-QM valves can be set to a precise design value even when the system is up

and running.

• Halved mounting costs as the AB-QM valve covers two functions, Balancing & Control

Operation of the AB-QM Balancing and Control Valve

Differential pressure controller DPC

The differential pressure controller maintains a constant differential pressure across the

control valve. The pressure difference ΔpCv (P2-P3) on th e membrane is balanced with

the force of the spring. Whenever the differential pressure across the control

valve changes (due to a change in available pressure, or movement of the control valve)

the hollow cone is displaced to a new position which brings a new equilibrium and

therefore keeps the differential pressure at a constant level.

Control valve Cv

The control valve has a linear characteristic. It features a stroke limitation function that

allows adjustment of the Kv value. The percentage marked on the scale equals the

percentage of 100 % flow marked on the pointer. Changing the stroke limitation is done

by lifting the blocking mechanism and turning the top of the valve to the desired position,

showed on the scale as a percentage. A blocking mechanism automatically prevents

unwanted changing of the setting.

PICV Technical Details

Size 10LF 15LF 15 15HF

Flow Range l/s Nom 0.042 0.076 0.125 0.315

Min 0.008 0.015 0.025 0.063

Standard Setting Range 20-100%

Starting Differential Pressure kPa 16 16 16 35

Max Differential Pressure Bar 6 6 6 6

Control Range 1:1000

Control Characteristic Linear/Logarithmic with actuator

Leakage Rate No visible leakage

Flow Medium

Pressure Rating PN 10 as Standard (16 is available on request)

Medium Temperature º C -10…+120

Storage and Transport Temp º C -40…70

Stroke mm 2.25

PICV Connection Union Threaded/Solder

Body Material DZR Brass

Membrane and O-Ring Material EPDM

Control Valve Cone Material CuZn40Pb3-CW614N

Water and water mixtures for closed heating and cooling systems according to plant type I for DIN EN14868

Tacotherm Ltd, Unit 40, Hampshire Business Park, Brunel Road, Totton, Ha mpshire, SO40 3SA, UK.

T: 02380 663163 E: sales@tacotherm.co.uk

Tacotherm accept no liability for possible errors in this product sheet. Tacothermr eserve the right to alter this product without notice. This product us supplied by Tacotherm Limited

Page 5

Working in partnership

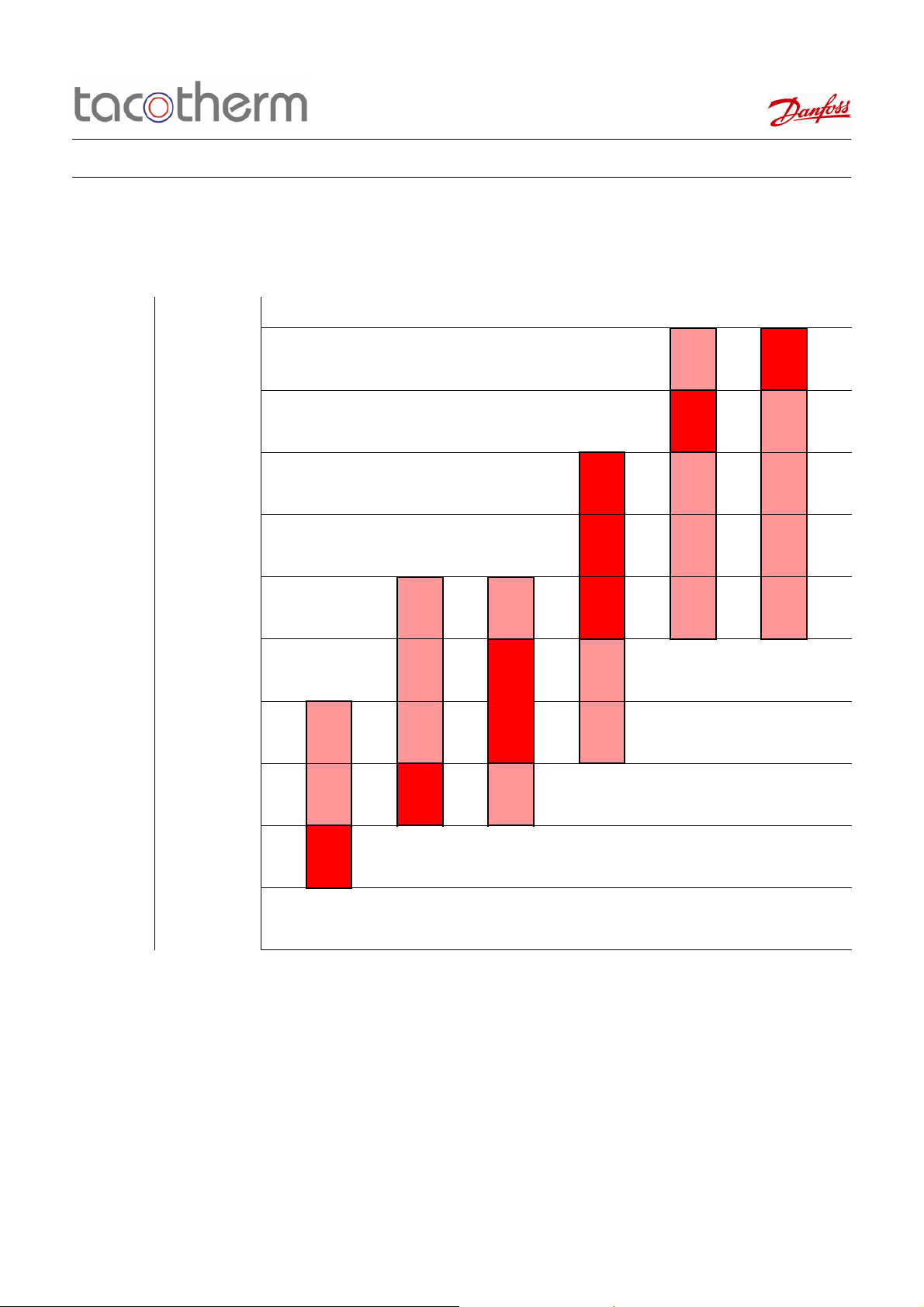

To select a manifold size take your required design flow rate. Find the flow points it falls between on the flow axis, draw

Where you have intersected a manifold in pink, you can select this manifold but it may not be the optimum selection for

with

Product Sheet Pre-Fabricated Terminal Assembly Type: Mini-Flush 40

Selection Chart

Flow Rate l/s Flow Rate l/h

0.32 1135

0.17 600

0.13 450

0.09 340

0.08 275

0.06 230

0.04 150

0.03 90

0.017 60

0.008 30

Orifice kVs: 0.3 0.6 0.9 2.1 4.0 5.6

Mini-Flush 10LF 15LF 15LF 15 15HF 15HF

This chart is for guidance only. Any selections must be checked with a Tacotherm representative before a final selection

Notes:

Tacotherm Ltd, Unit 40, Hampshire Business Park, Brunel Road, Totton, Ha mpshire, SO40 3SA, UK.

T: 02380 663163 E: sales@tacotherm.co.uk

Tacotherm accept no liability for possible errors in this product sheet. Tacothermr eserve the right to alter this product without notice. This product us supplied by Tacotherm Limited

can be made

a line horizontally. Select the manifolds in red for optimum selection

accurate flow measurement and you may experience high orifice pressure loss. PICV flow control performance will not

be affected by selection within this range.

Page 6

Working in partnership

with

Product Sheet Pre-Fabricated Terminal Assembly Type: Mini-Flush 40

Pressure Independent Control Valve

Specification

Setting the AB-QM

The calculated flow can be adjusted easily without using special tools.

To change the presetting (factory setting is 100 %) follow the four

steps below:

① Remove the blue protective cap or the mounted actuator

② Raise the grey pointer

③ Turn (clock wise to decrease) to the new presetting

④ Press grey pointer back into lock position.

After click presetting is locked.

The presetting scale indicates values from 100 % flow to 0 %. Clock

wise turning would decrease the flow value while counter clock wise

would increase it.

If the valve is a DN 15 then the nom flow

= 450 l/h =100 % presetting. To set a flow of 270 l/h you have to set:

270/450 = 60 %.

Tacotherm recommends a presetting/flow from 20 % to 100 %.

Factory presetting is 100 %.

Verification of Flow Rate on Mini-Flush

To verify the flow rate, the following steps should be taken:

① Find the kVs of the measuring station on the orifice kVs chart

② Calculate the required pressure drop using the kVs and design flow rate, using the following formula:

Q=Kv x √∆P

Note Q=m3/h, ∆P=Bar

③ Plug a manometer into the test points on the measuring station

④ If you are getting the required pressure, you have the desired flow rate

A guide to the expected pressure losses can be found in the chart below:

Manifold Type

Miniflush 40 10LF 0.3 150 0.3 25.000 20.250 16.000 12.250 9.000 6.250 4.000 2.250 1.000

Miniflush 40 15LF 0.6 275 0.6 21.007 17.016 13.444 10.293 7.563 5.252 3.361 1.891 0.840

Miniflush 40 15LF 0.9 275 0.9 9.336 7.563 5.975 4.575 3.361 2.334 1.494 0.840 0.373

Miniflush 40 15 2.1 450 2.4 3.516 2.848 2.250 1.723 1.266 0.879 0.563 0.316 0.141

Miniflush 40 15HF 4 1135 4.0 8.051 6.522 5.153 3.945 2.899 2.013 1.288 0.725 0.322

Miniflush 40 15HF 5.6 1135 5.6 4.108 3.327 2.629 2.013 1.479 1.027 0.657 0.370 0.164

Nominal Flow Rate

l/h

Orifice Kvs Measuring Station Pressure Drop at PICV Setting (kPa)

100% 90% 80% 70% 60% 50% 40% 30% 20%

The highlighted cells, indicate the best settings for flow rate measurement

Tacotherm Ltd, Unit 40, Hampshire Business Park, Brunel Road, Totton, Ha mpshire, SO40 3SA, UK.

T: 02380 663163 E: sales@tacotherm.co.uk

Tacotherm accept no liability for possible errors in this product sheet. Tacothermr eserve the right to alter this product without notice. This product us supplied by Tacotherm Limited

Page 7

Working in partnership

with

Product Sheet Pre-Fabricated Terminal Assembly Type: Mini-Flush 40

DN15 Mini-Flush Dimensions

Tacotherm Ltd, Unit 40, Hampshire Business Park, Brunel Road, Totton, Ha mpshire, SO40 3SA, UK.

T: 02380 663163 E: sales@tacotherm.co.uk

Tacotherm accept no liability for possible errors in this product sheet. Tacothermr eserve the right to alter this product without notice. This product us supplied by Tacotherm Limited

Loading...

Loading...