Page 1

User Guide

MCX-RTU

Rooftop unit

Page 2

User Guide | MCX-RTU Rooftop

Contents

Document history ........................................................................3

Product Introduction...................................................................3

Ordering .......................................................................................3

Specifications ...............................................................................4

Approvals .....................................................................................4

Installation ...................................................................................5

Connections .................................................................................6

Network Topology .......................................................................8

Sequence of Operation ...............................................................9

Cooling Mode ..................................................................................... 9

Heating Mode ...................................................................................10

Dehumidification Mode................................................................10

CO2 Mode ..........................................................................................11

DOAS Mode ....................................................................................... 11

Status Screens ............................................................................12

Configuration .............................................................................14

Overrides ....................................................................................24

Schedule Enable ........................................................................25

How it works .....................................................................................25

Backup / Restore ........................................................................26

Purpose ............................................................................................... 26

How it works .....................................................................................26

Using More Than One Zone Sensor ..........................................26

Data Logging .............................................................................27

How it works .....................................................................................27

Broadcast Configuration ...........................................................28

How it works .....................................................................................28

Configure Sensors ...........................................................................28

Configure Schedules ......................................................................28

Configure Load Shed .....................................................................28

AK-SM 800 MCX-RTU Commission ...........................................29

IO List ..........................................................................................34

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 2

Page 3

User Guide | MCX-RTU Rooftop

Document history

Product Introduction

Version Init. Date Description

1.00 FF 12/01/15 Initial MCX-RTU User Guide

1.04 FF 7/31/2018 Firmware v1.04 Update

Ordering

The MCX-RTU controller is a complete solution for controlling a small to medium sized commercial rooftop unit. The controller provides energy efficient control of the rooftop while maintaining designed comfort levels and safety of the controlled space. It is also designed to complement the Danfoss full store control via the connection to the AK-SM 800 series front end.

Type Function Application Code no.

MCX-RTU Controller for small to medium sized

rooftops

MCX08M2 Optional additional IO for MCX-RTU IO Expansion 080G0307

MMIGRS2 Optional Remote Display Remote Display 080G0294

Rooftop Controller 080G0304

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 3

Page 4

User Guide | MCX-RTU Rooftop

Specifications

Supply Voltage

85 – 265 V AC, 50/60 Hz Maximum power consumption: 27 W, 48 VA insulation between power

supply and the extra-low voltage: reinforced

Modbus

It is important that the installation of the data communication cable be installed correctly.

Remember to terminate each end of the bus. EIA485 Rated cable must be used.

See separate literature No. RC8AC902.

DO - Digital outputs, 15 pcs. DO1 – DO15

DO1 - DO15, all are mechanical relays, no solid state relays

AO - Analog output, 6 pcs. AO1 – AO6

Outputs are 0 – 10 V DC by default

AI - Analog Inputs, 14 pcs. AI1 – AI14

All temperature sensors default to PT1000, Pressure transducers default to .5 – 4.5 V DC

ratiometric with 5 V DC supply. All other inputs are 0 – 5 V DC by default

DI - Digital switch inputs DI1 – DI17

All Dry contacts except DI17 (24 V AC or 230 V AC driven)

AK-SM 800 Firmware required to interface with the MCX-RTU must be VG8.033 or greater and

StoreView Desktop version 1.13 or greater must be used for remote access.

Approvals

EU Declaration of Conformity

This product is in conformity with the following directive(s), standard(s) or other normative

document(s), provided that the product is used in accordance with our instructions.

EMC directive 2014/30/EU

By fulfilling the requirements in the following standards

EN 61000-6-4: 2007 + A1: 2011 Generic standards. Emissions standard for industrial environments

EN 61000-6-2: 2005 Generic standards. Immunity for industrial environments

and

LVD directive 2014/35/EU

By fulfilling the requirements in the following standards

EN60730-1: 2011 Automatic electrical controls for household and similar use. General

requirements

EN60730-2-9: 2010 Particular Requirements for Temperature Sensing Controls

and

RoHS Directive 2011/65/EU

By fulfilling the requirements in the following standards

EN 50581:2012

UL Approval

UL file: E31024

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 4

Page 5

User Guide | MCX-RTU Rooftop

110

60

Danfoss

80G8044.01

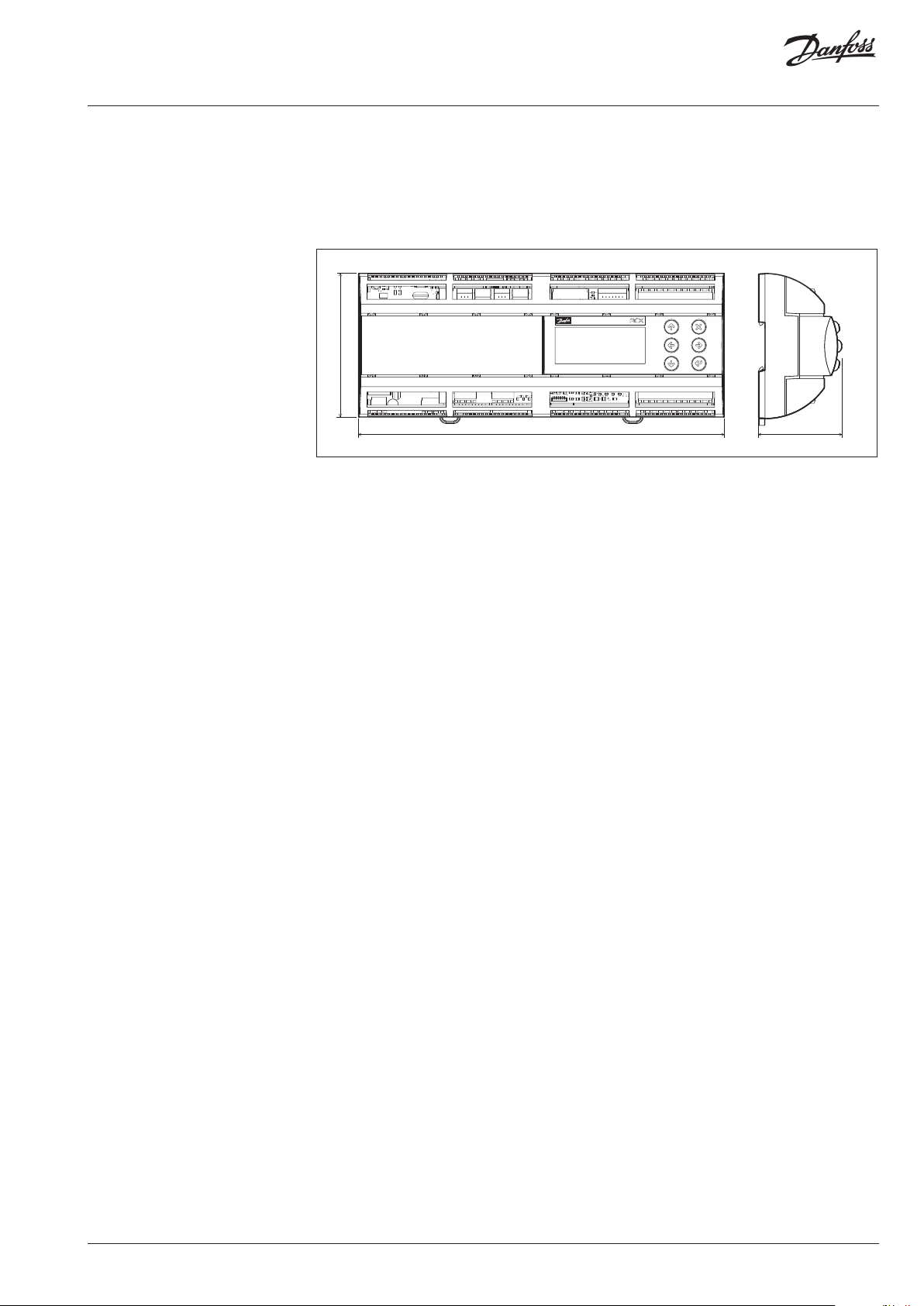

Installation

The MCX-RTU is mounted on a DIN rail with enough room to easily connect power and other

interface wires.

This image provides the dimensions of the MCX-RTU controller for determining space for

mounting. Make sure that you allow enough space for easy routing of the required interface

cables for power, inputs and outputs.

280

63

The MCX-RTU must be mounted in a space that meets the environmental standards named in

the specification section of this document.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 5

Page 6

User Guide | MCX-RTU Rooftop

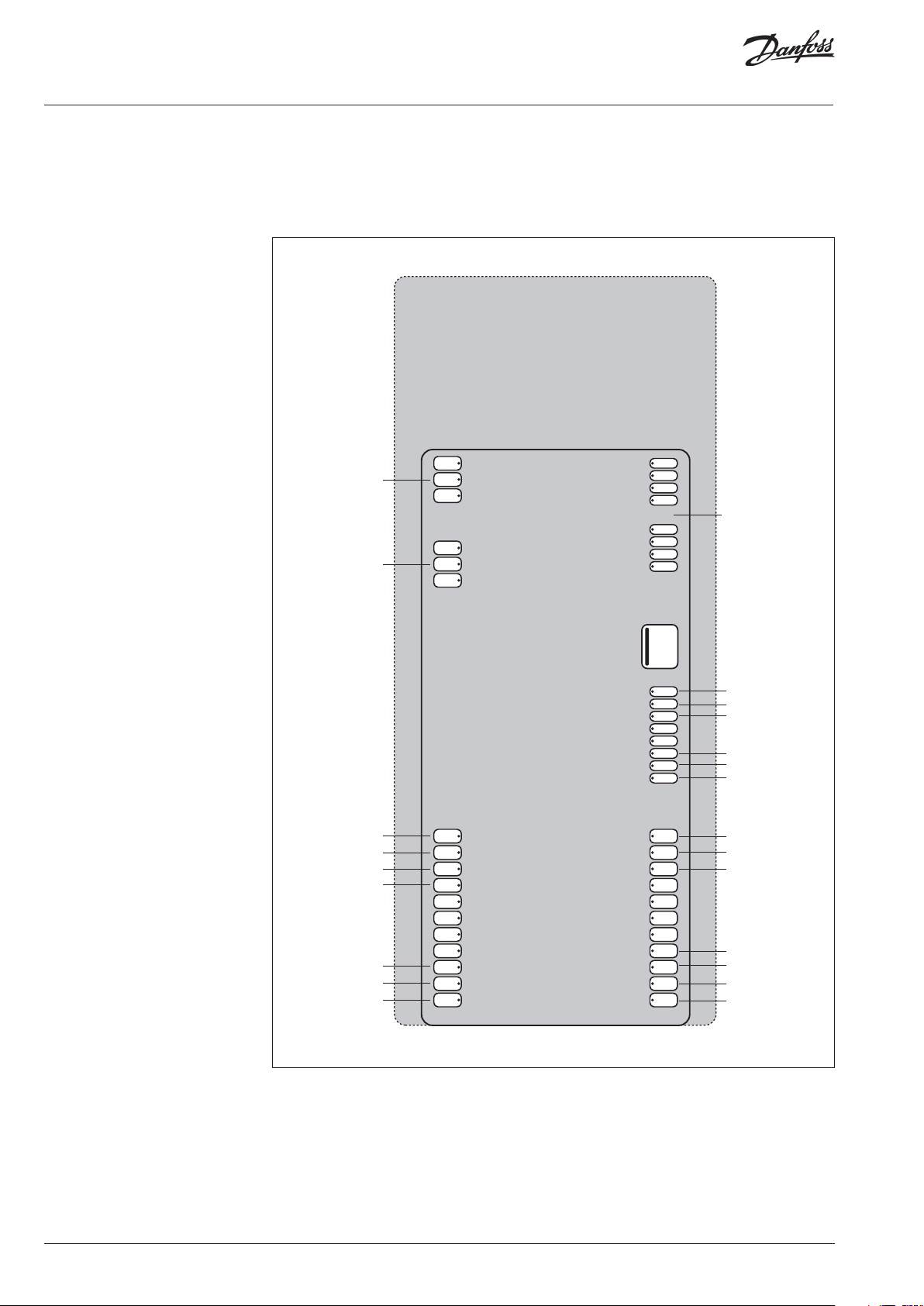

Connections

Wiring Diagram MCX 152V - top and bottom

COM 1

AK-SM 800

Modbus connection

VLT Drive

Modbus connection

D1 +

D1 -

COM 2

D2 +

D2 -

RS485-1

RS485-2

MCX152V - TOP

MOTOR 2

MOTOR 1

STEPPER

STEPPER

ST2 4

ST2 3

ST2 2

ST2 1

ST1 4

ST1 3

ST1 2

ST1 1

Not used

Mixed Air (PT1000)

Outdoor Temp (PT1000)

Light Level (5VDC)

Compr. 1 Press (5VDC)

Compr. 2 Press (5VDC)

Compr. 3 Press (5VDC)

Compr. 4 Press (5VDC)

AI 8

AI 9

AI 10

AI 11

5V+

15V+

COM

COM

AI 12

AI 13

AI 14

ANALOG INPUT 8-14

MEMORY CARD ANALOG OUTPUT 1-6 ANALOG INPUT 1-7

AO 6

AO 5

AO 4

COM

AO 3

AO 2

AO 1

COM

COM

COM

15V+

AI 7

AI 6

AI 5

5V+

AI 4

AI 3

AI 2

AI 1

SD/MMC

Damper AO

VS compressor 4

VS compressor 3

VS compressor 2

VS compressor 1

Fan AO

DP Outside/Mixed Air

Zone CO2 (0-5V DC)

Outdoor RH (0-5V DC)

Zone RH (0-5V DC)

Return Air (PT1000)

Supply Air (PT1000)

Zone Temp(PT1000)

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 6

Page 7

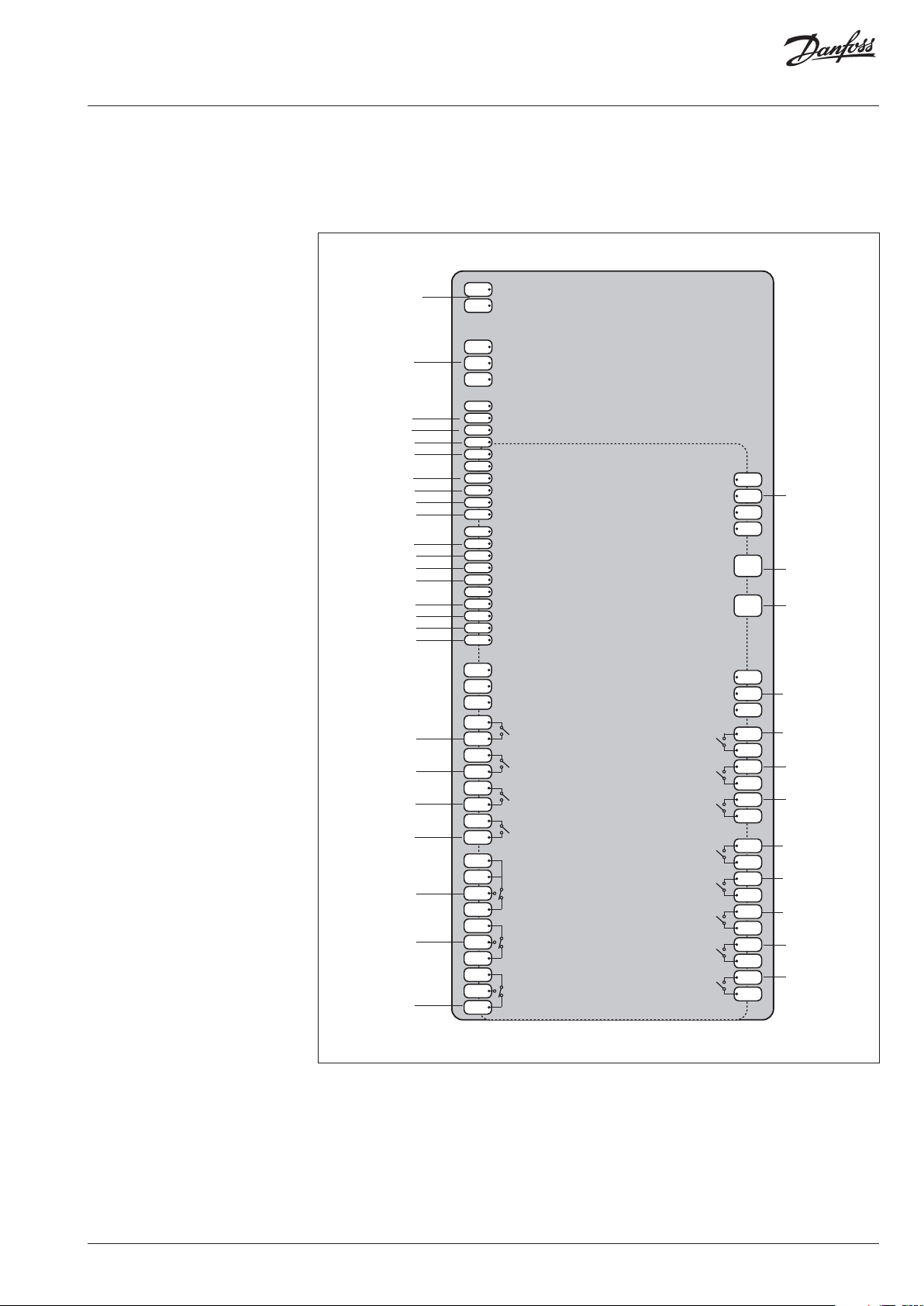

SD/MMC

RS485-2

D2 +

D2 -

MEMORY CARD ANALOG OUTPUT 1-6 ANALOG INPUT 1-7

ANALOG INPUT 8-14

ST1 2

ST1 1

AO 6

AO 5

AO 4

COM

AO 3

AO 2

AO 1

COM

COM

COM

15V+

AI 7

AI 6

AI 5

5V+

AI 4

AI 3

AI 2

AI 1

COM

COM

15V+

AI 14

AI 13

AI 12

5V+

AI 11

AI 10

AI 9

AI 8

User Guide | MCX-RTU Rooftop

Wiring Diagram MCX 152V - top and bottom

Input Voltage

110-230 V AC

Stepper Backup

NOT USED

Fan Proof

Phase Loss

Shutdown 1

Shutdown 2

Fan Drive Fault

Compr 1 Drive Fault

Compr 2 Drive Fault

Compr 3 Drive Fault

Compr 4 Drive Fault

Filter Clogged Fault

Damper Override

Title 24

Schedule Override

Cool 1 Proof

Cool 2 Proof

Cool 3 Proof

Reheat (N.O.)

Damper (N.O.)

Heat Reclaim 1 (N.O.)

Heat Reclaim 2 (N.O.)

Heat Pump (N.O.)

Fan Low Speed (N.O.)

Fan High Speed (N.C.)

L

N

COM

+ BATT

15V+

COM

DI 1

DI 2

DI 3

DI 4

COM

DI 5

DI 6

DI 7

DI 8

COM

DI 9

DI 10

DI 11

DI 12

COM

DI 13

DI 14

DI 15

DI 16

DI 18H

DI 18

COM 18

C 9

NO 9

C 10

NO 10

C 11

NO 11

C 12

NO 12

C 13

C 13

NO 13

NC 13

C 14

NO 14

NC 14

C 15

NO 15

NC 15

SUPPLY

POWER

STEPPER BACKUP

DIGITAL INPUT 1-8 DIGITAL INPUT 9-16

DIGITAL INPUT 18

DIGITAL OUTPUT 9-12 DIGITAL OUTPUT 13-15

MCX152V- BOTTOM

COM

CANCAN-RJ

CANL

CANH

R120

CAN-RJ

ETHERNET DIGITAL INPUT 17

ETH

COM 17

DI 17

DI 17H

NO 8

DIGITAL OUTPUT 6-8

NO 7

NO 6

NO 5

DIGITAL OUTPUT 1-5

NO 4

NO 3

NO 2

NO 1

Danfoss

80G8043.02

Optional IO

Expansion

Optional Remote Display

Not Used

Cool 4 Proof

Aux Heat 4 (N.O.)

C 8

Aux Heat 3 (N.O.)

C 7

Aux Heat 2 (N.O.)

C 6

Aux Heat 1 (N.O.)

C 5

Cool 4 (N.O.)

C 4

Cool 3 (N.O.)

C 3

Cool 2 (N.O.)

C 2

Cool 1 (N.O.)

C 1

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 7

Page 8

User Guide | MCX-RTU Rooftop

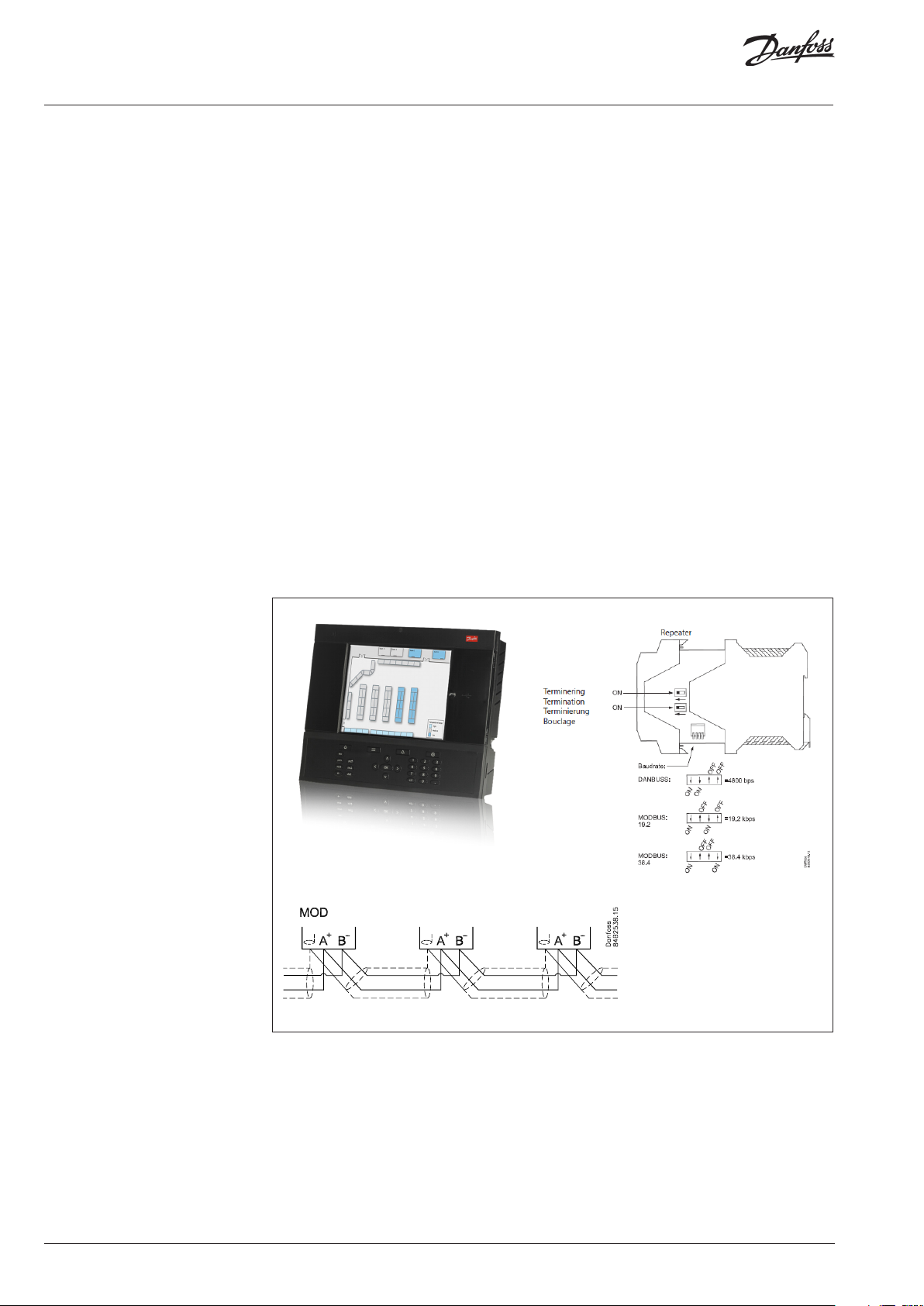

Network Topology

The network cable must be EIA485 rated. The cable is connected from controller to controller, and no branches (stars) are allowed on the cable. If the cable length exceeds 1200 meters

(1312 yards) a repeater must be inserted. One repeater must be added for every 32 controllers.

If the data communication cable runs through an electrically noisy environment which impairs

the data signal, one or more repeaters must be added to stabilize the signal. When configuring

Modbus devices on the control bus, the highest device address that can be used is 120 (max 120

Modbus control devices in total). The wires are looped from device to device and must observe

polarity. A is connected to A and B is connected to B. The shield must be connected and complete a path from the device, all controllers, any repeaters finally landed on the ground/shield

terminal at the AK-SM 800. The shield must not be connected to earth ground except at the AKSM 800. At the AK-SM 800 the shield must be attached to the shield terminal and then extended

to an external earth ground. See AK-SM 800 User Guide for system 485 wiring instructions.

The maximum number of MCX-RTU is dependent on which AK-SM 800 is used.

The AK-SM 880 (080Z4008 and 080Z4009) may use a maximum of 45 MCX-RTU controllers.

The AK-SM 820 (080Z4004) may use a maximum of 10 MCX-RTU controllers.

The AK-SM 800 User Manual can be found at:

http://food-retail.danfoss.com/knowledge-center/software/ak-sm-800/

Be sure to configure the Modbus repeater AKA 222 (code#084B2240) to the correct baud rate.

MCX-RTU baud rate must be set to 38.4 K when used with the AK-SM 800. MCX-RTU cannot be

on the same 485 bus with SLVs.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 8

Page 9

User Guide | MCX-RTU Rooftop

Sequence of Operation

Cooling Mode

The Controller is in Cooling Mode when the Zone Temperature is above Cool1 Target minus two

times the programmed Cool Range. At this point Free Cooling will be active if the Damper and

Free Cooling are enabled. The Damper will modulate to maintain the Supply Air or Mixed Air

target temperature. Free Cooling is enabled when Zone Enthalpy is above Outdoor Enthalpy and

the above conditions are met. Free Cooling will lockout if the Outdoor Enthalpy, Temperature or

Relative Humidity are above their specific lockout values.

The Cooling stages will become active when the Zone Temperature is above Cool1 Target minus

the Cool Range. Before any cooling stages are activated, the fan must be proofed by either a

digital input or analog input to insure the fan is operational. The method of operation depends

on the Cooling stages configuration. It is required for the previous stage of Cooling be ON prior

to the next stage activating.

If all Cooling stages are configured to use Relay Outputs, then the stages will turn on at Cool

Target plus the Range and off at Cool Target minus the Range. Each stage has a Target, PreDelay

and PostDelay. PreDelay is the delay period once the conditions have been met for the stage to

activate. PostDelay is the period the output will stay on once the conditions have been met for

the stage to deactivate.

If any cooling stages are configured to use an Analog Output, the sequence of operation changes. All stages that use an Analog Output must precede stages that use Relay Outputs. In this

configuration, the first stage will start when the Zone Temperature reaches the Cool 1 Target

minus the Range. The Analog Output will be set to the Min Compr1 Speed. The speed ramps to

100% when the Zone Temperature reaches the Cool 1 Target plus the Range. When Zone Temperature reaches the Cool 2 Target minus the Range the second stage activates, and the first stage

reduces to Min Compr1 Speed. If the second stage uses an Analog Output, then the output will

use the same value used by Cool Stage 1. If there are more than 2 stages, Min Compr Speed will

adjust so the total cooling capacity will equal the maximum capacity of the previous cooling

stage. All the Cooling Analog Outputs will always be in sync as they rise.

Fan control during Cooling Mode depends on the type of fan controlled. For Single Speed Fan,

the fan will be ON whenever there is a demand for cooling. If the fan is configured for continuous operation, then the fan runs all the time. For Two Speed Fan, the fan will be on high

speed whenever there is a demand for cooling. If the fan is configured for continuous operation,

the fan will switch to Low Speed with no demand for cooling. If the fan is configured for On

Demand, the fan switches off when there is no demand for cooling. For Variable Speed Fan, the

fan modulates to maintain the Cooling Supply Air Target with a demand for cooling. If the fan

is configured for continuous operation the fan modulates to the Cool Min Fan Speed with no

demand for cooling. If the fan is configured for On Demand, and there is no demand for cooling,

the fan either modulate to Cool Min Fan Speed or turns OFF, depending on setting of the Fan

Control Demand parameter.

Note: On DOAS units with more than 2 stages of cooling, the first two stages turn ON together.

With the balance of the stages turning ON sequentially.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 9

Page 10

User Guide | MCX-RTU Rooftop

Heating Mode

The Controller is in Heating Mode when the Zone Temperature is below Cool1 Target minus 2x

the Cool Range. Before any heating stages are activated, the fan must be proofed by either a

digital input or analog input to insure the fan is operational.

The first type of heating is Heat Reclaim. The first stage of Heat Reclaim will turn on when the

Zone Temperature is below Heat Reclaim 1 Target minus the Heat Reclaim Range. The first stage

of Heat Reclaim will turn off when the Zone Temperature is above Heat Reclaim 1 Target plus

the Heat Reclaim Range. This occurs for each stage of Heat Reclaim. Each stage has their own

Target, PreDelay and PostDelay. PreDelay is the delay period once the conditions have been met

for the stage to activate. PostDelay is the period the output will stay on once the conditions have

been met for the stage to deactivate. It is required that the previous stage of Heat Reclaim be

ON prior to the next stage activating.

The first type of heating is the Aux Heat. The first stage of Aux Heat will turn on when the Zone

Temperature is below Aux Heat 1 Target minus Aux Heat Range. The first stage of Aux Heat

will turn off when the Zone Temperature is above Aux Heat 1 Target plus Aux Heat Range. This

will occur for each stage of Aux Heat. Each stage has its own Target, PreDelay and PostDelay.

PreDelay is the period the output delays once the conditions have been met for the stage to

activate. PostDelay is the period the output will stay on once the conditions have been met for

the stage to deactivate. It is required that the previous stage of Aux Heat be ON prior to the next

stage activating.

Fan control during Heating Mode depends on the type of fan being controlled. For Single Speed

Fan, the fan will be on whenever there is a demand for heating. If configured for continuous

operation, then the fan will run all the time. For Two Speed Fan, the fan will be on high speed

whenever there is a demand for heating. If the fan is configured for continuous operation, the

fan switches to Low Speed when there is no demand for heating. If the fan is configured for

On Demand, the fan will switch OFF when there is no demand for heating. For Variable Speed

Fan, the fan modulates to maintain the Aux Heat Supply Air Target when there is a demand for

heating. If the fan is configured for continuous operation the fan modulates to the Heat Reclaim/

Aux Heat Min Fan Speed with no demand for heating. If the fan is configured for On Demand,

and there is no demand for heating the fan either modulates to Heat Reclaim/Aux Heat Min Fan

Speed or turns OFF depending on the setting of the Fan Control Demand parameter.

Dehumidification Mode

The Controller is in Dehumidification Mode when the Zone RH or Dewpoint is above Dehumidification 1 Target plus the Dehumidification Range. Before any dehumidification stages are

activated, the fan must be proofed by either a digital input or analog input to insure the fan is

operational.

If all Cooling stages are configured to use Relay Outputs, then the Dehumidification stages turn

on when the Zone Relative Humidity or Zone Dewpoint is above the Dehumidification Target

plus the Range and off at Dehumidification Target minus the Range. Each stage has its own Target, PreDelay and PostDelay. PreDelay is the delay period once the conditions have been met for

the stage to activate. PostDelay is the period the output stays on once the conditions have been

met for the stage to deactivate.

If any of the Cooling stages are configured to use Analog Outputs, then the Dehumidification

stages use a modulating capacity method. The Dehumidification Mode is enabled when the

Zone RH or Dewpoint is above Dehumidification 1 Target plus the Dehumidification Range.

Once the Dehumidification Mode is enabled the first stage compressor turns on and modulates

to maintain the Compressor 1 Target Pressure. Each stage has its own Target and Range used to

enable that stage of Dehumidification. If the compressor uses an Analog Output, then the compressor modulates to the compressor target pressure. If the compressor uses a Relay Output,

then the compressor is turned ON while the stage is enabled. The Dehumidification PreDelay

and PostDelay is only used to determine when the Dehumidification Stage is enabled. It does

not control the compressors directly.

Fan control during Dehumidification Mode depends on the type of fan being controlled. For

Single Speed Fan, the fans ON whenever there is a demand for dehumidification. If the fan is

configured for continuous operation, the fan will run all the time. For Two Speed Fan, the fans on

high speed whenever there is a demand for dehumidification. If the fan is configured for continuous operation, the fan switches to Low Speed with no demand for dehumidification. If the fan

is configured for On Demand, the fan switches OFF when there is no demand for dehumidificati-

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 10

Page 11

User Guide | MCX-RTU Rooftop

on. For Variable Speed Fan, the fan will run at Cooling Max Fan Speed until all stages of dehumidification are running at 100% capacity for the time specified in the Max Capacity Period setting.

Once this occurs, the fan modulates trying to lower the compressor capacity to 98%. If the fan

is configured for continuous operation the fan modulates to the Cool Min Fan Speed with no

demand for dehumidification. If the fan is configured for On Demand, and there is no demand

for dehumidification, the fan will either modulate to Cool Min Fan Speed or turn OFF depending

on the setting of the Fan Control Demand parameter.

CO2 Mode

The CO2 Mode is for health and safety of everyone in the facility. CO2 Mode has priority over all

other modes. And there are no lockouts to effect operation.

CO2 control requires an Analog Output to control the damper. The damper activates when the

Zone CO2 level reaches CO2 Target minus the CO2 Range. The damper modulates proportionally

between the CO2 Target minus the CO2 Range and CO2 Target plus the CO2 Range.

DOAS Mode

DOAS Mode is a combination of all the above modes.

DOAS Mode is controlled by the value for C23 under Setup Options. If set to yes, then the operation is as follows.

Fan Speed is fixed to the value set by parameter FN7 – OvrdFanSpeed(Parameters->Fan)

Outdoor Temperature and Outdoor Relative Humidity are used in place of both the Zone Temperature and Zone Relative Humidity for the Cooling/Heading/Dehumidification modes.

The Damper is set to the DM0(Damper Ovrd Value) value and does not modulate. This value will

typically be set to 80%. Note that if this value is less than 100%, and CO2 Mode is calling for the

Damper to open more, then the Damper will open to the value requested by the CO2 mode.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 11

Page 12

User Guide | MCX-RTU Rooftop

Status Screens

Main Status Screen

What the keys do on the Main Status Screen

Enter – Parameter Screen

ESC – Current Alarms

Down Arrow – Current Sensor Values

Left Arrow – Broadcast Sensor Values Received

Access Current Sensor Values from Main Status Screen using the Down Arrow button.

Current Sensor Screen

Sensor Error Values

20000 = Sensor Open

20001 = Sensor Short

20002 = Broadcast Value Not Updating

20003 = Sensor Disabled

ZNTP – Zone Temp ZNRA – Return Air Temp

ZNRH – Zone RH OTTP – Outdoor Temp

ZNET – Zone Enthalpy OTRH – Outdoor RH

ZNDP – Zone Dewpoint OTET – Outdoor Enthalpy

ZNC2 – Zone CO2 Level OTDP – Outdoor Dewpoint

ZNSA – Supply Air Temp OCO2 – Outdoor CO2

ZNMA – Mixed Air Temp Cmp1 – Compr 1 Suction Pressure

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 12

Page 13

User Guide | MCX-RTU Rooftop

Access Broadcast Sensor Values from the Main Status Screen using the Left Arrow button.

Broadcast Sensor Screen

This screen shows the values that have been received via the broadcast from the AK-SM 800. The

sensors that start with RH and CO2, are just that.

Then you have the three outdoor sensors. The two values at the bottom right are

SCHD(Schedules – bit mask) and LDSH(Load Shed Value)

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 13

Page 14

User Guide | MCX-RTU Rooftop

Configuration

The configuration screens are accessed by pressing the Enter button (lower right button) on the

controller.

Select Login and enter the password( default: 300) for the following screen. Note that every time

the Main Status Screen is visible the password entered is cleared and must be reentered to access

the password protected items.

Select Service and then Serial Settings to edit the communication Address of the control.

Press enter to put controller in Edit mode, then use the Up/Down arrows to edit. Press enter to

save.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 14

Page 15

User Guide | MCX-RTU Rooftop

To configure the controller, go to the Setup Options menu and make selections for your installation. Below is a list of the Setup Options along with their definitions.

OPT Setup Options Function Default Units

C01 Fan Type Select Fan Type – Single Speed, Two Speed or

C02 Fan Control Open Select fan operation during Open periods –

C03 Fan Control Closed Select fan operation during Closed periods –

C04 Fan Proof Select Disable, DI or CT DI

C05 Monitor phase loss Select No or Yes Yes

C06 Cool Stages Select number of cooling stages(0-4) 2

C07 CL1 Stage Size Set size of cooling stage(0.0 – 2000.0) 1000.0

C08 CL1 Stage Type Select RO or AO AO

C09 CL2 Stage Size Set size of cooling stage(0.0 – 2000.0)

C10 CL2 Stage Type Select RO or AO RO

C11 CL3 Stage Size Set size of cooling stage(0.0 – 2000.0)

C12 CL3 Stage Type Select RO or AO RO

C13 CL4 Stage Size Set size of cooling stage(0.0 – 2000.0)

C14 CL4 Stage Type Select RO or AO RO

C15 Heat Reclaim

Stages

C16 Aux Heat Stages Select number of Aux Heat Stages(0-4) 2

C17 Use Gas Heat Does Aux Heat use Gas Heat(Yes/No) Yes

C18 Enable Dehumidi-

fication

C19 Control Dehumid onSelect Control Dehumidification with RH sensor

C20 Reheat Cntl Reheat Control(No, AuxRly,HeatReclaim,Both) HtRclm

C21 Reheat Cntrl

Sensor

C22 Enable Damper Enable Damper using(Disable, DO, or AO) AO

C23 Enthalpy Cntl Enable Enthalpy Control(Yes/No) Yes

C24 Free Cooling Enable Free Cooling(Disable/Enable) Enable

C25 CO2 Option Select CO2 Damper Control(Disable, Monitor,

C26 Damper Cntrl

Sensor

C27 Enable HP Valve Enable Heat Pump Valve in None, Heat or Cool

C28 Fan Control De-

mand

C29 Fan AO Type Select AO Range for Fan(0-5,1-5,0-10,2-

C30 Compr1 AO Type Select AO Range for Cool1(0-5,1-5,0-10,2-

C31 Compr2 AO Type Select AO Range for Cool2(0-5,1-5,0-10,2-

VariSpeed

Continuous or on Demand

Continuous or on Demand

Select number of Heat Reclaim Stages(0-4) 2

Enable Dehumidification(Yes/No) Yes

or CalcDP

Select Reheat Control Sensor(SupplyAir/ZoneTemp)

Control)

Select Damper control sensor(SupplyAir/MixedAir)

Mode

For VS Fan, set fan to Off or Min when no

demand

10,Custom)

10,Custom)

10,Custom)

VS Fan

Continuous

Demand

CalcDP

SplyAir

Control

SplyAir

None

Min

0-10 vdc

1-5 vdc

1-5 vdc

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 15

Page 16

User Guide | MCX-RTU Rooftop

OPT Setup Options Function Default Units

C32 Compr3 AO Type Select AO Range for Cool3(0-5,1-5,0-10,2-

C33 Compr4 AO Type Select AO Range for Cool4(0-5,1-5,0-10,2-

C34 Damper AO Type Select AO Range for Damper(0-5,1-5,0-10,2-

C35 Custom AO Min Set Min VDC for Custom AO(0.0-10.0vdc) 1.5 vdc

C36 Custom AO Max Set Max VDC for Custom AO(0.0-10.0vdc) 5.0 vdc

C37 Ovrd Night Set-

back

C42 Invert Fan AO Invert Fan AO(Normal/Invert) Normal

C43 Invert Compr 1 AO Invert Compr1 AO(Normal/Invert) Normal

C44 Invert Compr 2 AO Invert Compr2 AO(Normal/Invert) Normal

C45 Invert Compr

10,Custom)

10,Custom)

10,Custom)

If Yes, then Night Setback can be

overridden(Yes/No)

Invert Compr3 AO(Normal/Invert) Normal

1-5 vdc

1-5 vdc

2-10 vdc

No

3 AO

C46 Invert Compr

Invert Compr4 AO(Normal/Invert) Normal

4 AO

C47 Invert Damper AOInvert Damper AO(Normal/Invert) Normal

C48 Zone RH Select Sensor for Zone

Local

RH(Disable,Local,GlobalRH1-5,Avg)

C49 Zone CO2 Select Sensor for Zone CO2(Disable,Local,

Local

GlobalCO2-1-5)

C50 Outdoor Temp Select Sensor for Outdoor

Local

Temp(Disable,Local,Global)

C51 Outdoor RH Select Sensor for Outdoor

Local

RH(Disable,Local,Global)

C52 Outdoor CO2 Select Sensor for Outdoor

Disable

CO2(Disable,Local,Global)

C40 Supply Air

Select Sensor for Supply Air(Disable,Local) Local

Sensor

C39 Return Air

Select Sensor for Return Air(Disable, Local) Local

Sensor

C38 Mixed Air Sensor Select Sensor for Mixed Air(Disable, Local) Local

C41 Zone Cntl Sensor Zone Control uses the Zone or Return Air

Zone

sensor

C53 HT/CL Ctrl Mode Select HT/CL Ctrl Mode(Standard/Supply

Standard

Air)

C54 Fan VLT Modbus Enable Fan VLT Modbus Control(Disable/

Disable

Enable)

C55 HTReset AO Type Select AO Range for HTReset AO(0-5,1-5,0-

0-10

10,2-10,Custom)

C56 Invert HTReset AOInvert HTReset AO(Normal/Invert)

© Danfoss | ADAP-KOOL® | 2018.11

C57 Zone Control Zone Sensor

Single

Config(Single;Average;High;Low)

C58 BldPress Sensor Select Sensor for Building Pressure

Local

Control(Disable;Local;Global)

C59 Condenser Cntl Enable AO Condenser Control(No/Yes) No

RS8KE102 | 16

Page 17

User Guide | MCX-RTU Rooftop

Next go to the Parameters menu for the screen below.

The table below shows all the parameters available to edit along with their definitions.

GEN Parameters >

General

y01 ON/OFF Master Switch (Off/On) On

y05 Temperature Units Select Temperature/Pressure Units (C/F)

y06 Reset Runtime/

Cycle

y07 Reset to Default Resets all settings to default values (No/Yes),

y08 Night Setback Can be used to put unit into night setback if

y27 Load Shed Value Current Load Shed value from front end. (Read

y28 Load Shed Set If Load Shed Value is above this setting, unit is

y26 Select Schedule If Load Shed Value is above this setting, unit is

y29 Select Title24 Select which schedule in the front end the unit

y09 Enable Alarms Master Alarm Enable (No/Yes) Yes

y10 Changeover Delay Set delay time between switching between

y02 Enable Expansion Enable Expansion Module (No/Yes) No

y11 Enable AI Filters Enable AI Filters (No/Yes) Yes

y12 Global AI Filter Set Global AI Filter Value (0, 2, 4, 16)

y13 Startup Delay Set power up delay before control starts. (5-600) 600 s

y14 MorningStartup-

Period

y15 Sensors Broadcast Number of sensors to broadcast (Read Only)

y16 Broadcast Sensor 1 Select which sensor to broadcast as sensor 1

y17 Broadcast Sensor 2 Select which sensor to broadcast as sensor 2

y18 Broadcast Sensor 3 Select which sensor to broadcast as sensor 3

y19 Broadcast Sensor 4 Select which sensor to broadcast as sensor 4

y20 Broadcast Sensor 5 Select which sensor to broadcast as sensor 5

Function Default Units

Also sets pressure to BAR when C used, PSI

when F used.

Reset Runtime/Cycle values (No/Yes), resets to

No once values are cleared

resets to No once values are set to default

Select Schedule is zero. (Day/Night)

Only)

placed in Load Shed Mode (0-4, zero disables

load shed)

placed in Load Shed Mode (0-4, zero disables

load shed)

will use for night setback.(0-16, zero disables

using front end schedule)

Heat and Cool mode. (0-60)

How many samples are used to average an AI

sensor.

Delay between Night Setback and Normal

Mode(0-360

None/ZnRH1-ZnRH5/ZnCO21-ZnCO25/OtdTp/

OtdRH/OtdCO2

None/ZnRH1-ZnRH5/ZnCO21-ZnCO25/OtdTp/

OtdRH/OtdCO2

None/ZnRH1-ZnRH5/ZnCO21-ZnCO25/OtdTp/

OtdRH/OtdCO2

None/ZnRH1-ZnRH5/ZnCO21-ZnCO25/OtdTp/

OtdRH/OtdCO2

None/ZnRH1-ZnRH5/ZnCO21-ZnCO25/OtdTp/

OtdRH/OtdCO2

F

No

No

Day

--

0

0

0

5 m

16

360 m

None

None

None

None

None

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 17

Page 18

User Guide | MCX-RTU Rooftop

GEN Parameters >

General

y21 Avg RH1 Select RH1 sensor for Average(None/Local/

y22 Avg RH2 Select RH2 sensor for Average(None/Local/

y23 Avg RH3 Select RH3 sensor for Average(None/Local/

y24 Not Used Not Used

y25 Not Used Not Used

y30 SelectExhaustFan Select Exhaust Fan Schedule(0-16) 0

y31 Aux RO 1 Schedule Select Aux RO 1 Schedule(0-16) 0

y32 Aux RO 2 Schedule Select Aux RO 2 Schedule(0-16) 0

y33 Aux RO 3 Schedule Select Aux RO3 Schedule(0-16) 0

y34 Aux RO 4 Sche-

Function Default Units

None

Glbl1-5)

None

Glbl1-5)

None

Glbl1-5)

Select Aux RO4 Schedule(0-16) 0

dule

y35 Enable Broadcast Enable Broadcast feature(No/Yes) Yes

y36 Night Shutdown Night Shutdown(No/Yes) No

y37 Enable Logging Enable Logging(No/Yes) No

y38 Logging Interval Set Logging Interval 1 m

FAN Parameters >

Function Default Units

Fan

FN1 Fan Off Delay Fan Off Delay (0-30) 2 m

FN2 Fan Proof Value Fan Proof Value (0.0-100.0)

2.0 a

Used with the Fan CT AI . If AI is above this

value the is ON

FN3 Min Fan Speed Min Fan Speed when in Fan Only Mode

30.0 %

(0.0-100.0)

FN4 Fan PI Gain Fan PI Gain Value (0.0-100.0) 5.0

FN5 FanPIIntegrati-

Fan PI Integration Time (6-1000) 60

onTime

FN6 Building Press

Building Pressure Target(-1.00-1.00) 0.00

Target

FN7 OvrdFanSpeed Stage One Fan Speed if exhaust fan one

enabled

FN8 OvrdFanHigh Stage Two Fan Speed if exhaust fan two

enabled

FN9 Cond Target 1 Condenser Target 350 PSI bar/psi

FNA Cond Target 2 Condenser Target if Reheat enabled 400 PSI bar/psi

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 18

Page 19

User Guide | MCX-RTU Rooftop

COL Parameters >

Cool

Ct1 CL1 Target Cool 1 Target Temperature (10.0-40.0°C) 40.0 °C/°F

Cb1 CL1 PreDelay Cool 1 Pre Delay (0-240) 0 m

Ca1 CL1 PostDelay Cool 1 Post Delay (0-240) 0 m

Ct2 CL2 Target Cool 2 Target Temperature (10.0-40.0°C) 40.0 °C/°F

Cb2 CL2 PreDelay Cool 2 Pre Delay (0-240) 240 m

Ca2 CL2 PostDelay Cool 2 Post Delay (0-240) 240 m

Ct3 CL3 Target Cool 3 Target Temperature (10.0-40.0°C) 40.0 °C/°F

Cb3 CL3 PreDelay Cool 3 Pre Delay (0-240) 240 m

Ca3 CL3 PostDelay Cool 3 Post Delay (0-240) 240 m

Ct4 CL4 Target Cool 4 Target Temperature (10.0-40.0°C) 40.0 °C/°F

Cb4 CL4 PreDelay Cool 4 Pre Delay (0-240) 240 m

Ca4 CL4 PostDelay Cool 4 Post Delay (0-240) 240 m

CLr CL Range +/- Cool Range +/- (0.0-10.0K) 0.5 K/F

CL1 CL Ambient

Lockout

CL2 CL Lockout

Range +/-

CnS CL Night Setback Cool Mode Night Setback (0.0-30.0K) 0.6 K/F

Cs1 CL SupplyAir Cool Mode Supply Air Target for VS Fan

Cm1 CL Min Fan

Speed

Cm2 CL Max Fan

Speed

CC1 CL Min Compr 1

Speed

CC2 CL Min Compr 2

Speed

CC3 CL Min Compr 3

Speed

CC4 CL Min Compr 4

Speed

CLi PI Integ Time 120

CLg PI Gain 8.0

Cns CL Neutral SA 20.0 °C/°F

Rt1 HR1 Target Heat Reclaim 1 Target Temperature (10.0-

Function Default Units

Cool Mode Ambient Lockout (0.0-85.0°C) 15.6 °C/°F

Cool Mode Ambient Lockout Range +/(0.0-10.0K)

(0.0-100.0°C)

Cool Mode Min Fan Speed (0.0-100.0) 50.0 %

Cool Mode Max Fan Speed (0.0-100.0) 75.0 %

Cool Min Compressor 1 Speed (0.0-100.0) 5.0 %

Cool Min Compressor 2 Speed (0.0-100.0) 30.0 %

Cool Min Compressor 3 speed (0.0-100.0) 30.0 %

Cool Min Compressor 4 speed (0.0-100.0) 30.0 %

40.0°C)

1.1 K/F

15.0 °C/°F

22.2 °C/°F

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 19

Page 20

User Guide | MCX-RTU Rooftop

HRC Parameters >

Heat Reclaim

Rb1 HR1 PreDelay Heat Reclaim 1 Pre Delay (0-240) 240 m

Ra1 HR1 PostDelay Heat Reclaim 1 Post Delay (0-240) 240 m

Rt2 HR2 Target Heat Reclaim 2 Target Temperature (10.0-

Rb2 HR2 PreDelay Heat Reclaim 2 Pre Delay (0-240) 240 m

Ra2 HR2 PostDelay Heat Reclaim 2 Post Delay (0-240) 240 m

Rt3 HR3 Target Heat Reclaim 3 Target Temperature (10.0-

Rb3 HR3 PreDelay Heat Reclaim 3 Pre Delay (0-240) 240 m

Ra3 HR3 PostDelay Heat Reclaim 3 Post Delay (0-240) 240 m

Rt4 HR4 Target Heat Reclaim 4 Target Temperature (10.0-

Rb4 HR4 PreDelay Heat Reclaim 4 Pre Delay (0-240) 240 m

Ra4 HR4 PostDelay Heat Reclaim 4 Post Delay (0-240) 240 m

HRr HR Range +/- Heat Reclaim Range +/- (0.0-10.0K) 0.2 K/F

HR1 HR Ambient

Lockout

HR2 HR Lockout

Range +/-

RnS HR Night Set-

back

HRs HR SupplyAir Heat Reclaim Mode Supply Air Target for

Rm1 HR Min Fan

Speed

Rm2 HR Max Fan

Speed

HET Parameters >

Aux Heat

Ht1 HT1 Target Aux Heat 1 Target Temperature (10.0-

Hb1 HT1 PreDelay Aux Heat 1 Pre Delay (0-240) 240 m

Ha1 HT1 PostDelay Aux Heat 1 Post Delay (0-240) 240 m

Ht2 HT2 Target Aux Heat 2 Target Temperature (10.0-

Hb2 HT2 PreDelay Aux Heat 2 Pre Delay (0-240) 240 m

Ha2 HT2 PostDelay Aux Heat 2 Post Delay (0-240) 240 m

Ht3 HT3 Target Aux Heat 3 Target Temperature (10.0-

Hb3 HT3 PreDelay Aux Heat 3 Pre Delay (0-240) 240 m

Ha3 HT3 PostDelay Aux Heat 3 Post Delay (0-240) 240 m

Ht4 HT4 Target Aux Heat 4 Target Temperature (10.0-

Hb4 HT4 PreDelay Aux Heat 4 Pre Delay (0-240) 240 m

Ha4 HT4 PostDelay Aux Heat 4 Post Delay (0-240) 240 m

HTr HT Range +/- Aux Heat Range +/- (0.0-10.0K) 0.5 K/F

HT1 HT Ambient

Lockout

HT2 HT Lockout

Range +/-

Function Default Units

22.2 °C/°F

40.0°C)

20.0 °C/°F

40.0°C)

19.4 °C/°F

40.0°C)

Heat Reclaim Mode Ambient Lockout (0.0-

85.0°C)

Heat Reclaim Mode Ambient Lockout

Range +/- (0.0-10.0K)

Heat Reclaim Mode Night Setback (0.0-

30.0K)

VS Fan (0.0-100.0°C)

Heat Reclaim Mode Min Fan Speed (0.0-

100.0)

Heat Reclaim Mode Max Fan Speed (0.0-

100.0)

Function Default Units

40.0°C)

40.0°C)

40.0°C)

40.0°C)

Aux Heat Mode Ambient Lockout (0.0-

85.0°C)

Aux Heat Mode Ambient Lockout Range

+/- (0.0-10.0K)

37.8 °C/°F

1.1 K/F

2.8 K/F

30.6 °C/°F

50.0 %

75.0 %

20.8 °C/°F

20.3 °C/°F

18.9 °C/°F

18.3 °C/°F

37.8 °C/°F

1.1 K/F

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 20

Page 21

User Guide | MCX-RTU Rooftop

HnS HT Night Set-

back

Htd Gas Fan Delay OffGas - Fan Delay Off (0-600) 60 s

HTs HT SupplyAir Aux Heat Mode Supply Air Target for VS

Hm1 HT Min Fan

Speed

Hm2 HT Max Fan

Speed

HTi HT PI Integ Time

HTg Heat PI Gain

HUM Parameters >

Dehumd

Dt1 DH1 Target Dehumidification 1 Target Temperature

Db1 DH1 PreDelay Dehumidification 1 Pre Delay (0-240) 240 m

Da1 DH1 PostDelay Dehumidification 1 Post Delay (0-240) 240 m

Dt2 DH2 Target Dehumidification 2 Target Temperature

HUM Parameters >

Dehumd

Db2 DH2 PreDelay Dehumidification 2 Pre Delay (0-240) 240 m

Da2 DH2 PostDelay Dehumidification 2 Post Delay (0-240) 240 m

Dt3 DH3 Target Dehumidification 3 Target Temperature

Db3 DH3 PreDelay Dehumidification 3 Pre Delay (0-240) 240 m

Da3 DH3 PostDelay Dehumidification 3 Post Delay (0-240) 240 m

Dt4 DH4 Target Dehumidification 4 Target Temperature

Db4 DH4 PreDelay Dehumidification 4 Pre Delay (0-240) 240 m

Da4 DH4 PostDelay Dehumidification 4 Post Delay (0-240) 1000 m

DHr DH Range +/- Dehumidification Range +/- (0.0-10.0K) 10.0

DH1 DH Ambient

Lockout

DH2 DH Lockout

Range +/-

DnS DH Night Set-

back

DrT DH Reheat

Target

DrR DH Reheat

Range +/-

DH3 Max_Capacity

Period

Dp1 Cp1 Press Target Dehumidification Compr 1 Pressure Target

Aux Heat Mode Night Setback (0.0-30.0K) 0.0 K/F

30.6 °C/°F

Fan (0.0-100.0°C)

Aux Heat Mode Min Fan Speed (0.0-100.0) 50.0 %

Aux Heat Mode Max Fan Speed (0.0-100.0) 75.0 %

Function Default Units

100.0

(10.0-40.0°C)

100.0

(10.0-40.0°C)

Function Default Units

100.0

(10.0-40.0°C)

100.0

(10.0-40.0°C)

Dehumidification Mode Ambient Lockout

(0.0-85.0°C)

Dehumidification Mode Ambient Lockout

Range +/- (0-10.0K)

Dehumidification Mode Night Setback

(0.0-30.0K)

Dehumidification Reheat Target (0.0-

40.0°C)

Dehumidification Reheat Range +/- (0.0-

30.0K)

Period for compressors at max capacity

before VS Fan will modulate. (0-60)

(0.0-100.0)

100.0 °C/°F

10.0 K/F

30.0

40.0 °C/°F

30.0 K/F

2 m

8.2 bar/psi

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 21

Page 22

User Guide | MCX-RTU Rooftop

HUM Parameters >

Dehumd

Dp2 Cp2 Press Target Dehumidification Compr 2 Pressure Target

Dp3 Cp3 Press Target Dehumidification Compr 3 Pressure Target

Dp4 Cp4 Press Target Dehumidification Compr 4 Pressure Target

Gn1 Cp1 PI Gain Dehumidification Compr 1 PI Gain (0.0-

It1 Cp1 Integ Time Dehumidification Compr 1 Integration

Gn2 Cp2 PI Gain Dehumidification Compr 2 PI Gain (0.0-

It2 Cp2 PI Integ

Time

Gn3 Cp3 PI Gain Dehumidification Compr 3 PI Gain (0.0-

It3 Cp3 PI Integ

Time

Gn4 Cp4 PI Gain Dehumidification Compr 4 PI Gain (0.0-

It4 Cp4 PI Integ

Time

DMP Parameters >

Damper Config

DM1 DAM Min Open Damper Min Open (0.0-100.0) 7.0 %

DM2 DAM Max Open Damper Max Open (0.0-100.0) 100.0 %

DM3 DAM Air Target Damper Free Cooling Supply/Mixed Air

DM4 High Amb Temp

Lockout

DM5 High Otdr RH

Lockout

DM6 High Otdr En-

thalpyLockout

DM7 DM Min Fan

Speed

DM8 DM Max Fan

Speed

DMa Damper PI Gain Damper Free Cooling Pi Gain (0.0-100.0) 5.0

DMi Damper PI Integ

Time

Dc1 CO2 Target Damper CO2 Target (0-2000) 900 ppm

Dc2 CO2 Range +/- Damper CO2 Range +/- (0-200) 50 ppm

DM0 Ovrd Value 80.0 %

ALM Parameters >

Alarm Config

S01 Fan Proof Delay Fan Proof Alarm Delay (0-15) 5 s

S02 Zone - High

Temp

Function Default Units

8.2 bar/psi

(0.0-100.0)

8.2 bar/psi

(0.0-100.0)

8.2 bar/psi

(0.0-100.0)

10.0

100.0)

120

Time (5-1000)

10.0

100.0)

Dehumidification Compr 2 Integration

Time (5-1000)

100.0)

Dehumidification Compr 3 Integration

Time (5-1000)

100.0)

Dehumidification Compr 4 Integration

Time (5-1000)

Function Default Units

Target (0.0-40.0)

Damper Free Cooling High Ambient Lockout (0.0-100.0)

Damper Free Cooling High Outdoor RH

Lockout (0.0-100.0)

Damper Free Cooling High Enthalpy Lockout (0.0-100.0)

Damper Min Fan Speed (0.0-100.0) 30.0 %

Damper Max Fan Speed (0.0-100.0) 75.0 %

Damper Free Cooling PI Integration Time

(5-1000)

Function Default Units

Zone Temp High Alarm (0.0-40.0) 30.0 °C/°F

120

10.0

120

10.0

120

18.0 °C/°F

25.0 °C/°F

80.0 %

60.0

60

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 22

Page 23

User Guide | MCX-RTU Rooftop

ALM Parameters >

Alarm Config

S03 Zone - Low Temp Zone Temp Low Alarm (0.0-40.0) 5.0 °C/°F

S04 Zone - Delay Zone Temp Delay (0-240) 240 m

S05 CO2 - High Level CO2 High Alarm (0-2000) 1000 ppm

S06 CO2 - Delay CO2 Alarm Delay (0-240) 15 m

S07 Fan High Run-

time

S08 Fan High Cycle Fan High Daily Cycles (0-1000) 1000

S09 Cool1 High

Runtime

S10 Cool1 High Cycle Cool 1 High Daily Cycles (0-1000) 1000

S11 Cool2 High

Runtime

S12 Cool2 High Cycle Cool 2 High Daily Cycles (0-1000) 1000

S13 Cool3 High

Runtime

S14 Cool3 High Cycle Cool 3 High Daily Cycles (0-1000) 1000

S15 Cool4 High

Runtime

S16 Cool4 High Cycle Cool 4 High Daily Cycles (0-1000) 1000

S17 Heat1 High

Runtime

S18 Heat1 High Cycle Heat 1 High Daily Cycles (0-1000) 1000

S19 Heat2 High

Runtime

S20 Heat2 High Cycle Heat 2 High Daily Cycles (0-1000) 1000

S21 Heat3 High

Runtime

S22 Heat3 High Cycle Heat 3 High Daily Cycles (0-1000) 1000

S23 Heat4 High

Runtime

S24 Heat4 High Cycle Heat 4 High Daily Cycles (0-1000) 1000

Function Default Units

Fan High Daily Runtime (0-1500) 1500 m

Cool 1 High Daily Runtime (0-1500) 1500 m

Cool 2 High Daily Runtime (0-1500) 1500

Cool 3 High Daily Runtime (0-1500) 1500 m

Cool 4 High Daily Runtime (0-1500) 1500 m

Heat 1 High Daily Runtime (0-1500) 1500 m

Heat 2 High Daily Runtime (0-1500) 1500 m

Heat 3 High Daily Runtime (0-1500) 1500 m

Heat 4 High Daily Runtime (0-1500) 1500 m

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 23

Page 24

User Guide | MCX-RTU Rooftop

Overrides

Overrides OV1 and OV2, are used to enable Night Setback and Title24 modes.

Overrides OV3 – OV8 are used to place the specific features (as shown below) in manual operation. The override value will be displayed by stage, %, OFF, ON, etc. For analog outputs a value of

zero shuts down the feature and 100 will enable 100% of the feature overridden.

OV0 Service > Over-

rides

OV1 Override Night-

Setback

OV2 Override Title24 Override Title24 – Enables Title24(Off/On) Off

OV3 Override Fan Override Fan(Auto/Override) Auto

OV4 Override Fan % Sets Speed of Fan when in Override(0.0 –

OV5 Override Dam-

per

OV6 Override Cooling Override Cooling(Auto/Off/Stg1/Stg2/

OV7 Override Heat

Reclaim

OV8 Override Aux

Heat

OV9 Override Time-

out

Function Default Units

Override Night Setback – Enables Night

Setback(Off/On)

100.0)

Override DamperAuto/

Off/25%/50%/75%/100%)

Stg3/Stg4/All On)

Override Heat Reclaim(Auto/Off/Stg1/

Stg2/Stg3/Stg4/All On)

Override Aux Heat(Auto/Off/Stg1/Stg2/

Stg3/Stg4/All On)

Override Timeout – Removes override after

so much time (0-30)

Off

0.0 %

Auto

Auto

Auto

Auto

0 m

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 24

Page 25

User Guide | MCX-RTU Rooftop

Schedule Enable

How it works

On the AK-SM 800, select the MCX-RTU to assign a schedule and select the Schedule tab.

(Note: it is preferred to set up schedules under configuration -> Refrigeration -> Schedules – see

page 28)

If no schedule has been setup, you will see a screen, similar to the one below. If there is no schedule the MCX-RTU will follow the configuration of the unit.

To add a schedule, double click on the “Num of schedules” and set the number of schedules.

Each schedule allows programming a Start and Stop time.

© Danfoss | ADAP-KOOL® | 2018.11

This On/Off Schedule will completely shutdown the MCX-RTU between midnight and 9:45 AM.

This Eco/Com Schedule will place the MCX-RTU in night setback from 10:00pm to 6:45am.

RS8KE102 | 25

Page 26

User Guide | MCX-RTU Rooftop

Backup / Restore

Using More Than One

Zone Sensor

Purpose

Allows the user to backup/restore the parameters in the MCX-RTU to a SD card.

How it works

The Backup/Restore feature menu items are located in the Service Menu.

Backup - After you have inserted a SD card into the MCX-RTU, go to the Service Menu and select

Backup. Allow a minute for the backup to complete. The backup file is saved to the SD card with

the Modbus address of the MCX-RTU as part of the name.

Restore – Insert a SD card that has a backup file on the card. Go to the Service Menu and select

Restore. Allow a minute for the restore to complete.

Note: There is no indication when the backup/restore are complete.

To use more than one zone sensor for a MCX-RTU, use parameter C57(Zone Control).

The allowed settings for this parameter are

Single – Only uses a single sensor for control

Average – Uses the average of 2 to 3 sensors for control

Low – Uses the lowest value of 2 to 3 sensors for control

High – Uses the highest value of 2 to 3 sensors for control

To add sensors to the configuration change the function of an unused analog input to either

Zone Temp 2 or Zone Temp 3. To change the function, go to Service->IO Config located in the

MCX-RTU menu. Then select an unused AI point and edit the FUNC to “Zone Temp 2” or “Zone

Temp 3” and set sensor type/min/max values to PT1000/-22.0/338.0.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 26

Page 27

User Guide | MCX-RTU Rooftop

Data Logging

How it works

Logs the list of points below using the logging interval.). The parameter is located at Parameters>General. Set y37(Logging Interval) to the frequency of logging and y36(Enable Logging). to

Yes to start the logging.

Data Log Points

1. Zone 1 Zone 1 Sensor

2. Zone 2 Zone 2 Sensor(if used)

3. Zone 3 Zone 3 Sensor(if used)

4. ZoneTemp Zone Temp used for control

5. ZoneRH ZoneRH(may be local or global sensor)

6. ZoneDewpoint Calculated Zone Dewpoint

7. SupplyAir Supply Air Sensor

8. ReturnAir Return Air Sensor

9. MixedAir Return Air Sensor

10. OutdoorAir Outdoor Air Sensor(may be local or global sensor)

11. OutdoorRH Outdoor RH Sensor(may be local or global sensor)

12. OutdoorDewpoint Calculated Outdoor Dewpoint

13. GlobalSchedules Bit map of the first 16 refrigeration schedules

14. AlarmStatus Alarm Status

15. Mode MCX-RTU Mode

16. EffSetp Calculated Setpoint(heat or cool setpoint depending on

mode)

17. FanOut Fan Control Output

18. FanFail Fan Proof not on when FanOut is ON.

19. PhaseLoss On means PhaseLoss is good

20. ShutdownFlag One of the shutdown DI’s is active

21. CoolHeatModeGlobal What is the control mode(0 = Cool, 1 = Heat)

22. NightSetback Night Setback is active

23. SystemOnOff Master Switch Status

24. CoolStatus1 Cool 1 Status

25. CoolStatus2 Cool 2 Status

26. CoolStatus3 Cool 3 Status

27. CoolStatus4 Cool 4 Status

28. AuxHeatStatus1 Aux Heat Status 1

29. AuxHeatStatus2 Aux Heat Status 2

30. FanStatusAO Fan AO Status – 0-100%

31. DamperStatusAO Damper AO Status – 0-100%

32. GlobalOutdoorTemp Value of Global Outdoor Temp

The Data Log file may be converted to an Excel file by using the DecodeLog converter program.

The program can be requested from Danfoss Tech Support.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 27

Page 28

User Guide | MCX-RTU Rooftop

Broadcast Configuration

How it works

The AK-SM 800 scans all the MCX-RTU controllers once a minute for any sensors setup to broadcast to all the controllers. If YES the AK-SM 800 requests the current sensor values from the

MCX-RTU controllers. Then the SM 800 broadcasts up to 14 sensor values to all the MCX-RTU

controllers in one message. Along with the sensor values a Load Shed Value and status for the

16 Schedules are broadcasted twice a minute. All the broadcast settings are within the MCX-RTU

parameters, there are no AK-SM 800 settings for this feature.

Configure Sensors

Select the Sensors to Broadcast. On each controller go to Parameters -> General. Then use

parameters y16, y17, y18, y19 and y20 to select the sensors that you want to share with the other

controllers. Note that each broadcast value may only be used once.

Select the Broadcast Sensors to use on each MCX-RTU controller. On each controller go to Setup

Options, then set parameters C48, C49, C50, C51 and C52. These parameters tell the controller

whether to use the Local sensor or the Global sensors. You can also use these parameters to disable the sensors.

Configure Schedules

The schedules used by the MCX-RTU are setup on the AK-SM 800. The schedule status of the first

16 schedules are broadcasted to all the MCX-RTU controllers. There is no assignment of individual MCX-RTU at the AK-SM 800. The schedule assignments are only configured in the MCX-RTUs.

The schedules at the AK-SM 800 are setup at Configuration->Control->Refrigeration->Schedules.

Even though the AK-SM 800 allows for a max of 100 schedules, only the first 16 schedules are

broadcast to the MCX-RTU controllers.

To select Schedule for Night Setback at the MCX-RTU go to Parameters->General. Edit setting

y26 to the schedule number to control Night Setback.

To select Schedule for Title24, go to Parameters->General. Edit setting y29 to the schedule

number you wish to use to control the Title24 option. The Title24 schedule places the controller

in Night Setback.

Configure Load Shed

To set Load Shed Setting, go to Parameters->General.

Edit settings y28 to the Load Shed value. If the Load Shed value that is broadcast from the AKSM 800 is greater than this value, the controller will use Night Setback settings.

See the AK-SM 800 User Manual for details on configuring the AK-SM 800 for Load Shedding.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 28

Page 29

User Guide | MCX-RTU Rooftop

AK-SM 800 MCX-RTU Commission

To commission a MCX-RTU controller on a AK-SM 800, use the following steps.

Connect to the AK-SM 800 using Storeview Desktop or a web browser and log in. Next go to

Configuration.

Next click on the HVAC Layout image.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 29

Page 30

User Guide | MCX-RTU Rooftop

This starts the Layout wizard. Click the Right Arrow on the upper right corner.

Enable the MODBUS-RS485 channel by selecting Disabled next to MODBUS-RS485 and change to

Enabled.

Click the arrow to advance to next screen

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 30

Page 31

User Guide | MCX-RTU Rooftop

Click the Scan button to start the scanning process.

Once scanning is complete a list of the HVAC controllers are displayed.

Click Right Arrow (upper right corner) to proceed.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 31

Page 32

User Guide | MCX-RTU Rooftop

Now add additional offline controllers or proceed. To add offline controllers, follow the instructions on the screen. Click the Right Arrow (upper right corner) to proceed.

View a summary of the HVAC controllers attached to the AK-SM 800. If correct click on the Right

Arrow (upper right corner) . If something is missing, click the Left Arrow (upper left corner) and

make changes.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 32

Page 33

User Guide | MCX-RTU Rooftop

Pop Up indicating completion using HVAC Layout Wizard.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 33

Page 34

User Guide | MCX-RTU Rooftop

IO List

I/O CONFIGURATION

AI ANALOG INPUTS Min Max Type

1 Zone Temperature -30.0°C 170.0°C PT1000

2 Supply Air -30.0°C 170.0°C PT1000

3 Return Air -30.0°C 170.0°C PT1000

4 Zone RH 0.0 % 100.0 % 0-5 V

5 Outdoor RH 0.0 % 100.0 % 0-5 V

6 Indoor CO2 0 ppm 2000 ppm 0-5 V

7 Building Pressure 0.0 100.0 0-5 V

8 Mixed Air -30.0°C 170.0°C PT1000

9 Outdoor Air -30.0°C 170.0°C PT1000

10 Light Level -1.00 1.00 00-5 V

11 Compr 1 Press 0.0bar 34.5 bar 0-5 V

12 Compr 2 Press 0.0 bar 34.5 bar 0-5 V

13 Compr 3 Press 0.0 bar 34.5 bar 0-5 V

14 Compr 4 Press 0.0 bar 34.5 bar 0-5 V

15 Aux AI 1 (Located on Expansion Module) 0.0 200.0 0-5 V

16 Aux AI 2 (Located on Expansion Module) 0.0 200.0 0-5 V

17 Aux AI 3 (Located on Expansion Module) 0.0 200.0 0-5 V

18 Aux AI 4 (Located on Expansion Module) 0.0 200.0 0-5 V

19 Aux AI 5 (Located on Expansion Module) 0.0 200.0 0-5 V

20 Aux AI 6 (Located on Expansion Module) 0.0 200.0 0-5 V

21 Aux AI 7 (Located on Expansion Module) 0.0 200.0 0-5 V

22 Outdoor CO2 (Located on Expansion Module) 0 2000 0-5 V

DI DIGITAL INPUTS Min Max Type

1 Fan Proof 0 1 N.O.

2 Phase Loss 0 1 N.C.

3 Shutdown 1 0 1 N.O.

4 Shutdown 2 0 1 N.O.

5 Fan Drive Fault 0 1 N.O.

6 Compr1 Drive Fault 0 1 N.O.

7 Compr2 Drive Fault 0 1 N.O.

8 Compr3 Drive Fault 0 1 N.O.

9 Compr4 Drive Fault 0 1 N.O.

10 Filter Clogged Fault 0 1 N.O.

11 Damper Override 0 1 N.O.

12 Title24 Override 0 1 N.O.

13 Schedule Override 0 1 N.O.

14 Cool 1 Proof 0 1 N.O.

15 Cool 2 Proof 0 1 N.O.

16 Cool 3 Proof 0 1 N.O.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 34

Page 35

User Guide | MCX-RTU Rooftop

DI DIGITAL INPUTS Min Max Type

17 Cool 4 Proof 0 1 N.O.

18 (Located on Expansion Module) 0 1 N.C.

19 (Located on Expansion Module) 0 1 N.C.

20 (Located on Expansion Module) 0 1 N.C.

21 (Located on Expansion Module) 0 1 N.C.

22 (Located on Expansion Module) 0 1 N.C.

23 (Located on Expansion Module) 0 1 N.C.

24 (Located on Expansion Module) 0 1 N.C.

25 (Located on Expansion Module) 0 1 N.C.

26 (Located on Expansion Module) 0 1 N.C.

AO ANALOG OUTPUTS Min Max Type

1 Fan AO 0 % 100 % 0-10 V

2 VS Compr 1 0 % 100 % 1-5 V

3 VS Compr 2 0 % 100 % 1-5 V

4 VS Compr 3 0 % 100 % 1-5 V

5 VS Compr 4 0 % 100 % 1-5 V

6 Damper AO 0 % 100 % 2-10 V

7 Not Available 0 % 100 % NO

8 Not Available 0 % 100 % NO

9 (Located on Expansion Module) 0 % 100 % NO

10 (Located on Expansion Module) 0 % 100 % NO

11 (Located on Expansion Module) 0 % 100 % NO

12 (Located on Expansion Module) 0 % 100 % NO

DO DIGITAL OUTPUTS Min Max Type

1 Cool 1 0 1 N.O.

2 Cool 2 0 1 N.O.

3 Cool 3 0 1 N.O.

4 Cool 4 0 1 N.O.

5 Aux HT 1 0 1 N.O.

6 Aux HT 2 0 1 N.O.

7 Aux HT 3 0 1 N.O.

8 Aux HT 4 0 1 N.O.

9 Reheat 0 1 N.O.

10 Damper 0 1 N.O.

11 HT RCLM 1 0 1 N.O.

12 HT RCLM 2 0 1 N.O.

13 Heat Pump 0 1 N.O.

14 Fan Low 0 1 N.O.

15 Fan High 0 1 N.C.

16 (Located on Expansion Module) 0 1 N.O.

17 (Located on Expansion Module) 0 1 N.O.

18 (Located on Expansion Module) 0 1 N.O.

19 (Located on Expansion Module) 0 1 N.O.

20 (Located on Expansion Module) 0 1 N.O.

21 (Located on Expansion Module) 0 1 N.O.

22 (Located on Expansion Module) 0 1 N.O.

23 (Located on Expansion Module) 0 1 N.O.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 35

Page 36

User Guide | MCX-RTU Rooftop

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | ADAP-KOOL® | 2018.11

RS8KE102 | 36

ADAP-KOOL®

Loading...

Loading...