Installation Guide

Electronic controller

080R9340

MCX15B2/20B2

General features:

MCX15B2/MCX20B2 is an electronic controller that stands on the top of the MCX range,

thanks to the large number of its inputs and outputs, the enhanced CPU capabilities and

connectivity features.

It holds all the typical functionalities of MCX controllers: programmability, connection to the

CANbus local network, up to two Modbus RS485 serial interfaces with galvanic isolation.

Furthermore, it is fitted with an ultra wide range (24/110/230 V AC) power supply in the

same product variant, with USB and Ethernet connection for embedded Web server and IP

protocols management.

It is available in several models, with or without graphic LCD display and with 15 or 20 digital

output.

MC X15B2 MCX20B2

ANALOG INPUTS

NTC, 0/1 V, 0/5 V, 0 / 10 V PT1000, selectable via software 4 6

Universal NTC, Pt1000, 0/1 V, 0/5 V, 0/10 V, ON/OFF, 0/20 mA, 4/20 mA, selectable via

software

Total number 10 16

DIGITAL INPUTS

Voltage free contact/24V AC sensing 18 18

24/230 V AC optoinsulated 4 4

Total number 22 22

ANALOG OUTPUTS

0/10 V DC optoinsulated 6 6

0/10 V, PWM, PPM selectable via software 2 2

Total number 6 6

DIGITAL OUTPUTS

SPDT relay 16 A (changeover contacts) 2 2

SPST relay 5 A (normally open contacts) 13 18

Total number 15 20

OTHERS

Power supply 24-110-230 V AC / 40-230 V DC • •

Connection for programming key and for remote display and keyboard • •

Buzzer - RTC clock • •

Modbus RS485 serial interface x1 x2

CANbus • •

Ethernet for Webserver/Modbus TCP • •

USB for firmware/application software update and datalogging • •

Dimensions (DIN modules) 16 16

Mounting DIN rail DIN rail

AN320819413085en-000401

6 10

© Danfoss | DCS (vt) | 2020.10

AN320819413085en-000401 | 1

General features and warnings

Plastic housing features

• DIN rail mounting complying with EN 60715

• Self extinguishing V0 according to IEC 60695-11-10 and glowing/hot wire test at 960 °C according to IEC 60695-2-12

• Ball test: 125 °C according to IEC 60730-1. Leakage current: ≥ 250 V according to IEC 60112

Other features

• Operating conditions CE: -20T60 / UL: 0T50, 90% RH non-condensing

• Storage conditions: -30T80, 90% RH non-condensing

• To be integrated in Class I and/or II appliances

• Index of protection: IP40 only on the front cover

• Period of electric stress across insulating parts: long

• Suitable for use in environments with degree of pollution 2

• Category of resistance to heat and fire: D

• Immunity against voltage surges: category II, category III for versions without display

• Software class and structure: class A

Compliance

CE mark

This product is designed to comply with the following EU standards:

• Low voltage directive LVD 2014/35/EU:

– EN60730-1: 2011 (Automatic electrical control for household and similar use. General requirements)

– EN60730-2-9: 2010 (Particular Requirements for Temperature Sensing Controls)

• Electromagnetic compatibility EMC directive 2014/30/EU:

– EN 61000-6-3: 2007 +A1: 2011 (Emission standard for residential, commercial and light-industrial environments)

– EN 61000-6-2: 2005 (Immunity for industrial environments)

• RoHS directive 2011/65/EU and 2015/863/EU:

– EN50581: 2012

UL approval:

• UL file E31024

General warnings

• Every use that is not described in this manual is considered incorrect and is not authorised by the manufacturer

• Verify that the installation and operating conditions of the device respect the ones specified in the manual, specially concerning the

supply voltage and environmental conditions

• This device contains live electrical components therefore all the service and maintenance operations must be performed by qualified

personnel

• The device can’t be used as a safety device

• Liability for injury or damage caused by the incorrect use of the device lies solely with the user

Installation warnings

• Mounting position recommended: vertical

• The installation must be executed according the local standards and legislations of the country

• Always operate on the electrical connections with the device disconnected from the main power supply

• Before carrying out any maintenance operations on the device, disconnect all the electrical connections

• For safety reasons the appliance must be fitted inside an electrical panel with no live parts accessible

• Don’t expose the device to continuous water sprays or to relative humidity greater than 90%.

Avoid exposure to corrosive or pollutant gases, natural elements, environments where explosives or mixes of flammable gases are

present, dust, strong vibrations or shock, large and rapid fluctuations in ambient temperature that in combination with high humidity

can condensate, strong magnetic and/or radio interference (e.g. transmitting antennae)

• When connecting loads beware of the maximum current for each relay and connector

• Use cable ends suitable for the corresponding connectors. After tightening the screws of connectors, slightly tug the cables to check

their tightness

• Use appropriate data communication cables. Refer to the Installation Guide “MCX hardware network specification” for the kind of cable

to be used and setup recommendations

• Reduce the path of the probe and digital inputs cables as much as possible, and avoid spiral paths enclosing power devices. Separate

from inductive loads and power cables to avoid possible electromagnetic noises

• Avoid touching or nearly touching the electronic components fitted on the board to avoid electrostatic discharges

• The product is not suitable to be exposed directly to the Internet

2 | AN320819413085en-000401

© Danfoss | DCS (vt) | 2020.10

Technical specifications

Power supply

• 21 – 265 V AC, 50/60 Hz. Maximum power consumption: 15 W. Insulation between power supply and the extra-low voltage: reinforced

• 40 – 230 V DC

I/O TYPE NUM SPECIFICATIONS

Analog

inputs

Digital

inputs

NTC

0 / 1 V

0 / 5 V

0 / 10 V

PT1000

ON/OFF

0 / 20 mA

4 / 20 mA

Auxiliary Supplies 15 V+ and 5 V+

16 (MCX20B2)

10 (MCX15B2)

10 (MCX20B2)

6 (MCX15B2)

Total number: 16 on MCX20B2; 10 on MCX15B2

Analog Input type selectable via software

Max 13.5 V input voltage

Do not connect voltage sources without current limitation (overall 80 mA)

to analog inputs while unit is not powered

Open circuit HW diagnostics available for all analog inputs

AI1 to AI16 on MCX20B2

AI1 to AI10 on MCX15B2

NTC, default 10 kΩ at 25 °C, Beta 3435

0/xV type: impedance is greater than 1 MΩ

AI1 to AI6, AI11 to AI14 on MCX20B2

AI1 to AI6 on MCX15B2

100 Ωs as measuring resistance for current measurements.

The inputs can be used to sense voltage free contacts with contact

cleaning current 10 mA

5 V+ max: 200 mA (total on all outputs)

15 V+ max: 200 mA (total on all outputs)

All power outputs are protected against short circuit and have an

automatic recovery from overload condition.

Total number: 22

Digital Input type selectable via software between 24 V AC or voltage free

Analog

outputs

Voltage free contacts

or 24 V AC

24 V opto-insulated 4 DI1, DI2, DI3, DI4

230 V opto-insulated 4 DIH1, DIH2, DIH3, DIH4

0 / 10 V 6 AO1, AO2, AO3, AO4, AO5, AO6

PWM-PPM 2 AO5, AO6

18 DI5 to DI22

As the inputs are not isolated, caution has to be used when applying 24

V AC: the same polarity of the supply MUST always be used on COM/GND

connection.

Counting function with max frequency of 16.6 Hz (30 ms minimum pulse

time)

Inputs opto isolated, 24 V AC 50/60 Hz or 24 V DC

Rated current: 5 mA @24 V AC

Inputs opto isolated, 86 – 265 V AC / 50/60 Hz

Reinforced isolation

Rated current: 2,5 mA @ 265 V AC

Note: when the 230 V AC DH1 input is used, the corresponding 24 V DI1

input is not available anymore; the same for the couple of inputs DIH2

and DI2, DIH3 and DI3, DIH4 and DI4

Total number: 6

Analog Outputs 0/10 V, galvanically isolated, minimum load 1K Ω (10 mA)

for each output

Asynchronous PWM

Voltage output: max VLO= 0.6 V, min VHI= 6.5 V

Frequency range 15Hz…1kHz

Synchronous PWM and PPM

Voltage output: max VLO= 0.6 V, min VHI= 6.5 V

Frequency: Mains frequency x2

© Danfoss | DCS (vt) | 2020.10

AN320819413085en-000401 | 3

Digital

output

Communication interface

Interface Use Connector label Technical data

CANbus Fieldbus for connection to user

USB device Prepared for future use USB-DEV Plug: Type Mini B

USB host For connection to Flash drive

RS485-1

RS485-2 (MCX20B2 only)

Ethernet For web server functionality,

Relay 20 (MCX20B2)

15 (MCX15B2)

interfaces, MCX controllers, service

tools etc.

for application software update,

datalogging and service

Communication bus to BMS (e.g.

Modbus slave), service tools, smart

devices (e.g. Modbus master)

RS485-1 can be polarized as master

from the application

integration (e.g. Modbus TCP)

NOTICE! Do not route cable outside

of buildings.

Connect only to IT equipment

compliant with EN 60950 or EN

62368 (Information technology

equipment. Safety. General

requirements)

Concerning the insulation distance there are three groups of relays:

• group 1: relays 1 to 8

• group 2: relays 9 to 13

• group 3: relays 14 to 20

Insulation between relays of the same group: functional

Insulation between relays of different groups: reinforced

Insulation between relays and the extra-low voltage parts: reinforced

Total current load limit: 65 A

C1-NO1 to C13-NO13, C16-NO16 to C20-NO20 on MCX20B2

C1-NO1 to C13-NO13 on MCX15B2

Normally open contact relays 5 A

Characteristics of each relay:

– 5 A 250 V AC for resistive loads - 100,000 cycles

– 3 A 250 V AC for inductive loads - 100,000 cycles with cos(phi) = 0.4

– UL: 3 A resistive, 250 V AC, 100,000 cycles; 1/8 hp, 125/250 V AC,

30,000 cycles; C300 pilot duty, 125/250 V AC, 30,000 cycles

C14-NO14-NC14, C15-NO15-NC15

Changeover contact relays 16 A

Characteristics of each relay:

– 7 A 250 V AC for resistive loads - 100,000 cycles

– 3.5 A 250 V AC for inductive loads - 230,000 cycles with cos(phi) = 0.4

– UL: NO contact: 6 A resistive, 240 V AC, 30.000 cycles; 1/2 hp, 240

V AC, 30.000 cycles; 470 VA pilot duty, 240 V AC, 30.000 cycles. NC

contact: 6 A resistive, 6.000 cycles

C3 NO3 to C6 NO6

Optionally they can be solid state relays

Characteristics of each relay:

15-280 Vrms, 0.5 A

UL: 0.5 A resistive, 240 V AC, 30,000 cycles

CAN

CAN-RJ

USB-H Plug: Type A

RS485-1

RS485-2

ETHERNET Interface type: 10 BASE-T and 100 BASE-TX, IEEE

Physical layer according to ISO 11898-2 High

Speed CAN bus

Frame format according to CAN 2.0B specification

Transceiver not isolated (power supply has

reinforced isolation)

Physical layer according to EIA 485 Ref3

Provide 500 V peak transient galvanic isolation

802.3.

MDI-X (Automatic medium-dependent interface

crossover)

Wire lengths

Interface Max wire length (m) Max. baudrate (bps) Min. wire size

Ethernet 100 10/100 M

CANbus 1000

500

250

80

30

RS485 1000 125 K AWG22

Signal wiring 30

4 | AN320819413085en-000401

50 K

125 K

250 K

500 K

1 M

AWG18

AWG22

AWG24

AWG26

AWG26

© Danfoss | DCS (vt) | 2020.10

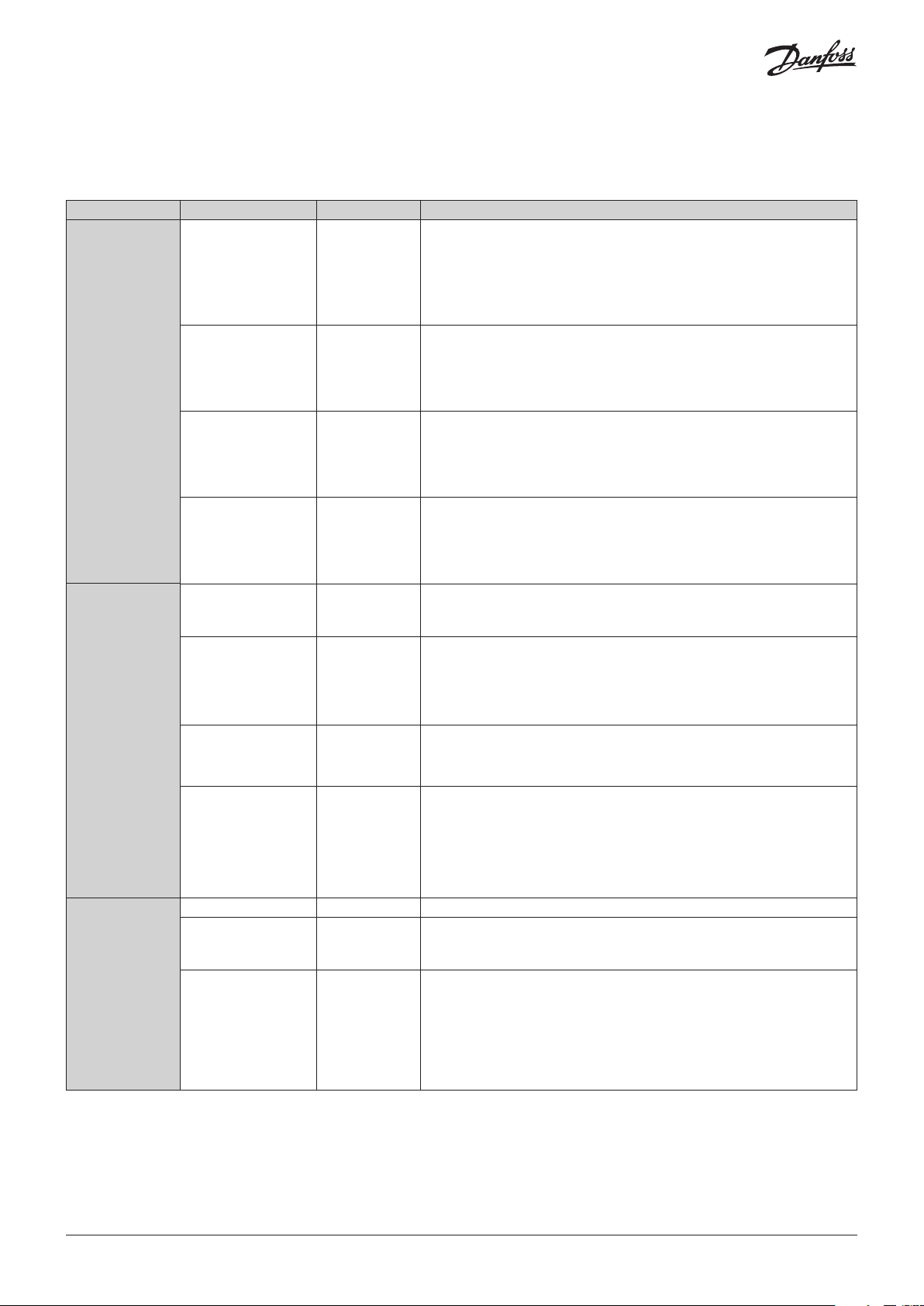

Connection diagram

L

TOP BOARD

MCX20B2 only

N

BOTTOM BOARD

230 V or 24 V DIGITAL INPUT

(DI1 - DI4)

N

L

VOLTAGE FREE or 24 V DIGITAL INPUT

(DI5 - DI22)

24 V230 VOR OR

24 V

SELV

e.g. DIGITAL INPUT 5e.g. DIGITAL INPUT 1

N

L

24 VVOLTAGE FREE

24 V SELV

*)

© Danfoss | DCS (vt) | 2020.10

*)

NOTE: connection has to be made on the first and

last local network units, make the connection as

close as possible to the connector

AN320819413085en-000401 | 5

Connection

Connectors Type Dimensions

Top Board

Digital input 1 connector 3 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital output 14-15 connector 6 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital output 16-20 connector (MCX20B2) 10 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Analog input 11-14 connector (MCX20B2) 7 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Analog input 15-16 connector (MCX20B2) 4 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital input 2 connector 3 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital input 3 connector 3 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital input 4 connector 3 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital input 5-8 connector 5 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital input 9-13 connector 6 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital input 14-17 connector 5 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital input 18-22 connector 6 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Bottom Board

Digital output 1-5 connector 10 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital output 6-8 connector 6 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Ethernet connector 8 / 8 way RJ 45 plug type

USB host connector USB Type A

Analog input 1-6 connector 11 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Analog input 7-10 connector 6 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Power supply connector 2 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Digital output 9-13 connector 10 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

Analog output 1-6 connector 8 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

RS485 -2 connector 3 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

RS485-1connector 3 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

CAN connector 4 way screw plug-in connector type • pitch 5 mm

• section cable 0.2 – 2.5 mm²

CAN-RJ connector 6/6 way telephone RJ12 plug type

USB DEV connector USB Mini B

6 | AN320819413085en-000401

© Danfoss | DCS (vt) | 2020.10

Dimensions

LCD Display No Display

User interface

LCD Display

display mode: STN blue transmissive

back-light: white LED back-light adjustable via software

display format: 128 x 64 dots

active visible area : 58 x 29 mm

contrast: adjustable via software

Keyboard

number of keys: 6

keys function is settled by the application software

Display settings adjustment

Setting of the LCD display like contrast and brightness might need to be adjusted due to external ambient factors. Press and release

simultaneously the Enter and X key after power ON to access the BIOS menu and select the DISPLAY menu. Use UP and DOWN arrow

keys to adjust the contrast or the brightness of the display at the desired level.

Product part numbers

Description Code No.

MCX15B2, RS485, S 080G0327

MCX15B2, LCD, RS485, S 080G0328

MCX20B2, 2xRS485, I (12 pieces) 080G0329

MCX20B2, LCD, 2xRS485, S 080G0330

MCX20B2, LCD, 2xRS485, I (12 pieces) 080G0331

MCX20B2, LCD, 4 SSR, 2xRS485, S 080G0332

Note: single pack codes (S) include standard kit connectors,

industrial pack codes (I) don’t include standard kit connectors

Accessories part numbers

Description Code No.

MCX20B2 CONNECTORS KIT 080G0404

© Danfoss | DCS (vt) | 2020.10

AN320819413085en-000401 | 7

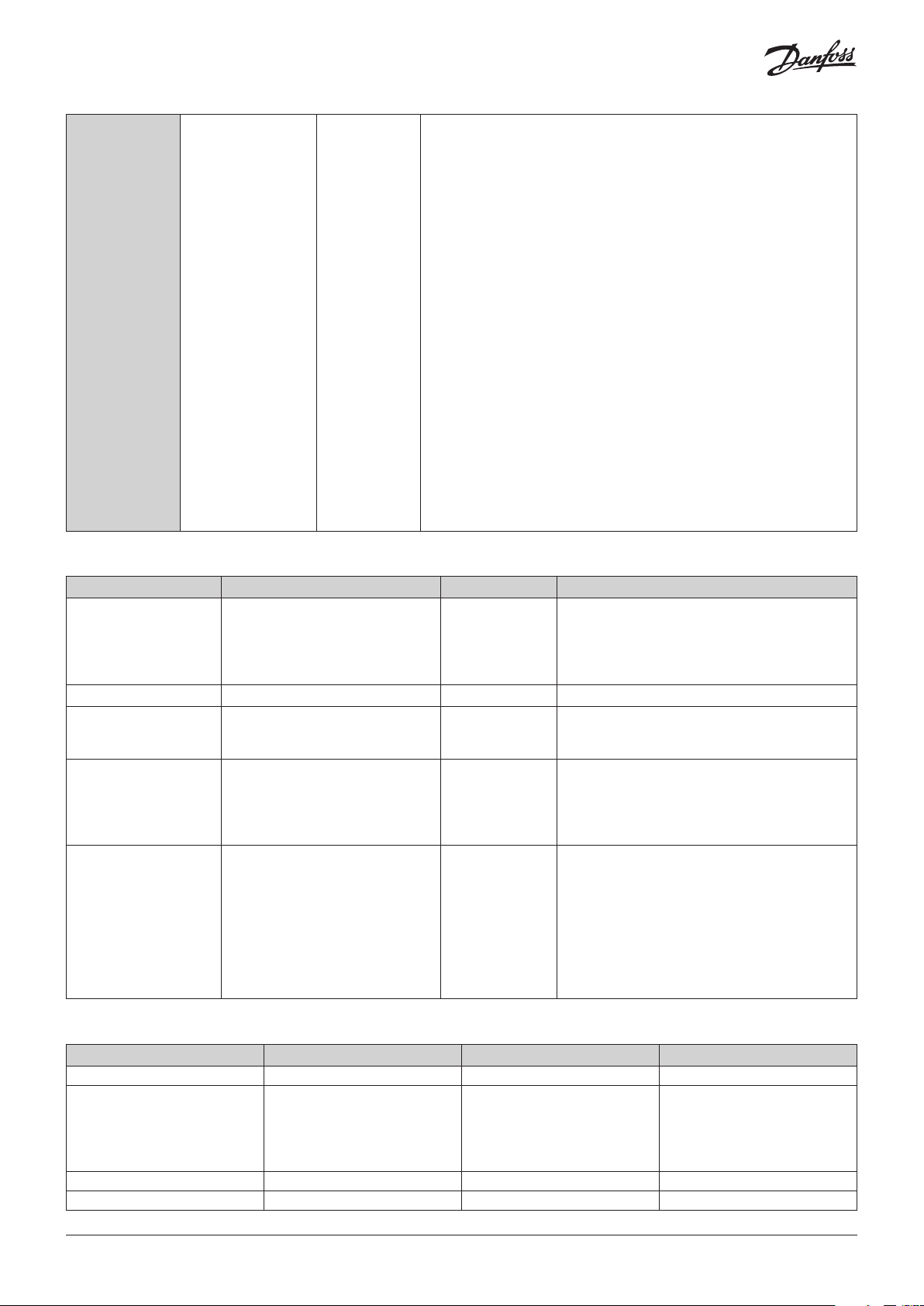

Replacement of MCX15B-20B with MCX15B2-20B2 through wiring kit

MCX15/20B2

11

From the unit to MCX15/20B

You can replace MCX15/20B with an equivalent model of MCX15/20B2. The same application software runs on both versions

without any change and the universal power supply (24 V AC - 110 V AC - 230 VAC) of MCX15/20B2 facilitates the selection of the

equivalent model.

But there are the following differences that must be taken into consideration:

• The pinout is slightly different for some of the Input/Output (see below the suggested connection diagram)

• The NC (Normally Closed) signals for relay DO10, DO11, DO12 and DO13 are not available in MCX15/20B2. But they are

available for DO14 (as in MCX15B) (and for DO15 as in MCX15/20B). An external relay must be used if these signals are needed.

Alternatively, the application can be changed to take advantage of the additional NC14 signal of MCX20B2.

• The Analogue Outputs (AO) in MCX15/20B2 are internally powered, therefore you must not connect the L1 signal

• 24 V DC power supply is not supported by MCX15/20B2 (40 – 230 V DC)

• The Digital Inputs are both contact free and 24 V sensing in MCX15/20B2, but the DI common signals (DIC) in MCX15/20B2 are

internally connected, therefore you must ensure that DIC are connected to the same phase before the replacement.

For facilitating the replacement of MCX15/20B with B2, you can build a wiring kit following these instructions:

Wiring kit specifications:

Cables:

L = 200 mm H05V-K WHITE

DO: section = 1 mm²

DI: section = 0.5 mm²

AO: section = 0.5 mm²

Connectors:

Phoenix FKIC (or equivalent): Wire strip lenght = 10 mm

Phoenix MSTP (or equivalent): End sleeves = PKD 508/PKD 108 (Danfoss P/N: 080G0404, provided with MCX15/20B2 Single Pack)

D09-12

11 ways

1

D013

3 ways

Phoenix FKIC

Connector

(not provided)

Wiring kit (example)

Connector

provided with

MCX15/20B2

(Single Pack)

D09-13

10 ways

Danfoss

80G465

8 | AN320819413085en-000401

© Danfoss | DCS (vt) | 2020.10

From the unit to

Wiring kit

32

65

11

33

55

77

Connection diagram – from MCX20B to MCX20B2

MCX20B to be

replaced

DIGITAL OUTPUT

DO1-5

10 ways

DO6-8

6 ways

DO9-12

11 ways

1C9

2NO9

3NC10

4C10

5NO10

6NC11

7C11

8NO11

9NC12

10 C12

11 NO12

DO13

3 ways

1NC13

2C13

3NO13

Phoenix FKIC

1910762

1

2

3

4

5

6

7

8

9

10

11

Phoenix FKIC

1910681

1

2

3

Wiring Kit

direct connection

direct connection

DO9-13

10 ways

1)

1)

1)

1)

NOTE: an external relay must be

used if the NC contact is

needed. See the note at the end

of this guide.

Phoenix MSTB

(MCX20B2

connectors)Phoenix FKIC Wires

DO9-13

10 ways

1

C9

2

NO9

3

C10

4

NO10

5

C11

6

NO11

7

C12

8

NO12

9

C13

10

NO13

MCX20B2

board

DO1-5

DO6-8

DO9-13

Danfoss

80G466

Danfoss

DO14-16

7 ways

Phoenix FKIC

1910720

1C16 1

DO14-15

6 ways

80G467

2NO162 1NC15

3C15

4NO154 3NO15

5NC145 4NC14

6C14

C15

DO14-15

C14

7NO147 6NO14

DO17-20

8 ways

1C20

Phoenix FKIC

1910733

DO16-20

10 ways

C20

2NO202 2NO20

3C19

4NO194 4NO19

5C18

6NO186 6NO18

7C17

8NO178 8NO17

DIGITAL INPUT

DI1

3 ways

DI2

3 ways

DI3

3 ways

direct connection

direct connection

direct connection

C19

C18

C17

9

C16

10 NO16

DO16-20

DI1

DI2

DI3

DI4

3 ways

DI5-8

5 ways

© Danfoss | DCS (vt) | 2020.10

direct connection

direct connection

DI4

DI5-8

AN320819413085en-000401 | 9

11

DI9-13

55

54

54

ANALOGUE OU

11

22

33

44

DI9-12

Danf

80G468

5 ways

1DI9

Phoenix FKIC

1910704

6 ways

DI9

2DI102 2DI10

3DI113 3DI11

4DI124 4DI12

5DIC

DI13-16

5 ways

Phoenix FKIC

1910704

1DI131

DI13

6DIC

DI14-17

5 ways

DI9-13

2DI142 1DI14

3DI153 2DI15

4DI164 3DI16

5DIC

DI17

DI14-17

5DIC

DI17-20

5 ways

1DI171

Phoenix FKIC

1910704

DI18-22

6 ways

2DI182 1DI18

3DI193 2DI19

4DI204 3DI20

5DIC

DI21

DI18-22

5DI22

6DIC

DI21-22

4 ways

Phoenix FKIC

1910694

1DI211

2DI222

3DIC 3

4DIC 4

NOTE: the DIC signals in MCX20B2 are internally connected, therefore you

must ensure that DIC are connected to the same phase before the

replacement

ANALOG INPUT

AI1-6

11 ways

AI7-10

6 ways

AI11-14

7 ways

AI15-16

4 ways

TPUT

AO1-4

6 ways

Phoenix FKIC

1910717

1AO1

2AO2

3AO3

4AO4

5L15 5AO5

direct connection

direct connection

direct connection

direct connection

AO1-6

8 ways

AO1

AO2

AO3

AO4

AI1-6

AI7-10

AI11-14

AI15-16

AO1-6

6N16 6AO6

AO5-6

4 ways

1AO6 1

2AO5 2

3N13

4N14

Phoenix FKIC

1910694

NOTE: the AO signals in MCX20B2 are internally

powered, therefore you must not connect L1

7AOC

8AOC

oss

10 | AN320819413085en-000401

© Danfoss | DCS (vt) | 2020.10

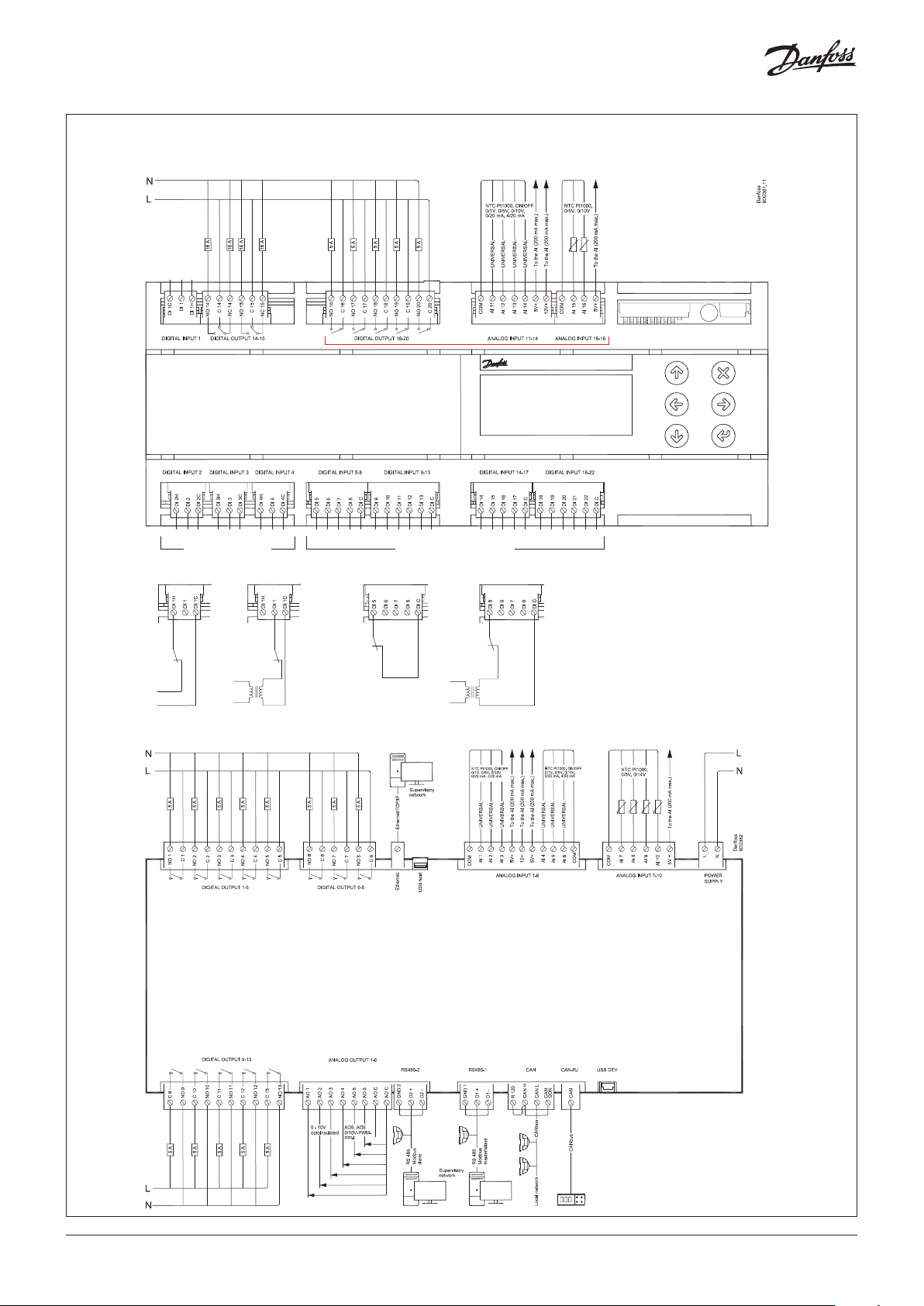

Connection diagram – from MCX15B to MCX15B2

42

75

08

21

Wiring Kit

From the unit to

Danf

80G469

MCX15B to be

replaced

(MCX15B2

connectors)Phoenix FKIC Wires

MCX15B2

board

DIGITAL OUTPUT

Phoenix MSTB

DO1-5

10 ways

DO6-8

6 ways

DO9-12

11 ways

Phoenix FKIC

1910762

1C91

2NO9 2

3NC103 1C9

1)

4C10

5NO105 3C10

6NC116 4NO10

1)

7C11

8NO118 6NO11

9NC129 7C12

1)

10 C121

11 NO12 11 9C13

direct connection

direct connection

DO9-13

10 ways

NO9

C11

NO12

DO1-5

DO6-8

DO9-13

NO1310

DO13

3 ways

1NC131

2C13 2

3NO133

DO15

3 ways

1NC151

2C15

Phoenix FKIC

1910681

Phoenix FKIC

1910720

1)

NOTE: an external relay must be

used if the NC contact is

needed. See the note at the end

of this guide.

DO14-15

6 ways

NC15

3NO153 2C15

DO14

3 ways

1NC141

2C14 2

3NO143

Phoenix FKIC

1910720

4NC14

5C14

6NO14

3NO15

DO14-15

DIGITAL INPUT

DI1

3 ways

DI2

3 ways

DI3

3 ways

DI4

3 ways

DI5-8

5 ways

© Danfoss | DCS (vt) | 2020.10

direct connection

direct connection

direct connection

direct connection

direct connection

DI1

DI2

DI3

DI4

DI5-8

oss

AN320819413085en-000401 | 11

Phoenix FKIC

11

DI9-13

55

54

32

43

11

22

33

44

DI9-12

5 ways

1DI9

1910704

6 ways

DI9

2DI1 02 2DI10

3DI1 13 3DI11

4DI1 24 4DI12

5DIC

DI13-16

5 ways

1DI1 31

Phoenix FKIC

1910704

DI13

6DIC

DI14-17

5 ways

DI9-13

2DI142 1DI14

3DI153 2DI15

4DI164 3DI16

5DIC

DI17

DI14-17

5DIC

DI17-18

4 ways

1DI1 71

Phoenix FKIC

1910694

DI18-22

6 ways

2DI182 1DI18

3DIC

4DIC

NOTE: the DIC signals in MCX15B2 are

internally connected, therefore you must

DI19

DI20

4DI21

5DI22

6DIC

DI18-22

ensure that DIC are connected to the

same phase before the replacement.

ANALOGUE INPUT

AI1-6

11 ways

direct connection

AI1-6

AI7-10

6 ways

AI11-14

7 ways

AI15-16

4 ways

ANALOGUE OUTPUT

AO1-4

6 ways

Phoenix FKIC

1910717

1AO1

2AO2

3AO3

4AO4

5L15 5AO5

direct connection

direct connection

direct connection

AO1-6

8 ways

AO1

AO2

AO3

AO4

AI7-10

AI11-14

AI15-16

AO1-6

6N16 6AO6

AO5-6

4 ways

1AO6 1

2COM 2

3AO5 3

Phoenix FKIC

1910720

NOTE: the AO signals in MCX15B2 are

internally powered, therefore you

7AOC

8AOC

must not connect L1.

NOTE: AO5,6 are not isolated in

MCX15B, and the COM is in common

with other signals.

AO5,6 are isolated in MCX15B2, and the

reference is AOC.

12 | AN320819413085en-000401

Danfoss

80G470

© Danfoss | DCS (vt) | 2020.10

Phoenix FKIC

42

75

08

DO9-12

80G471

1

) External Relay connection diagram

(when the NC10, NC11, NC12, NC13 signals are needed).

Example for NC13

11 ways

1C91

2NO9 2

1910762

DO9-13

10 ways

3NC103 1C9

4C10

NO9

5NO105 3C10

6NC116 4NO10

7C11

C11

8NO118 6NO11

9NC129 7C12

10 C121

NO12

11 NO12 11 9C13

NO1310

DO13

3 ways

1NC131

2C13 2

Phoenix FKIC

1910681

External Relay

24 VAC

3NO133

DO9-13

Danfoss

© Danfoss | DCS (vt) | 2020.10

AN320819413085en-000401 | 13

Via San Giuseppe 38/G

Danf

already on order pro

All trademarks in this material are property of the respec

31015 Conegliano

(TV) Italy

Tel: +39 0438 336611

Fax: +39 0438 336699

info.mcx@danfoss.com

www.danfoss.com

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DCS (vt) | 2020.10

AN320819413085en-000401 | 14

Loading...

Loading...