Page 1

DESCRIPTION

The MCW102A and MCW102C Time Proportional Rotary Position Controllers provide automatic grade control on paving,

curbing and planing machines. The Controller uses a follower arm

riding on a stringline or a ski riding on the prepared surface as a

grade reference. The controllers activate solenoid valves to

position a screed, form cutting drum, or steer cylinder.

The MCW102A and C are time proportional devices having valve

on - time proportional to grade error. This feature causes the

output to the solenoid to be on a greater percentage of the time for

larger grade deviations, allowing greater sensitivity to grade

deviations than would otherwise be possible. The “A” model is

ground-side switched and the “C” model is high-side switched.

FEATURES

MCW102A,C

Time Proportional Rotary Position Controller

BLN-95-9048 Issued: March 1995

• Non-contacting sensing element for long life

• Fully burned-in components for added reliability

• Bright up/down lights for easy nulling

• Adjustable deadband sensitivity

• Run/Standby switch for manual or automatic control

• Reverse polarity and short circuit protection

ORDERING INFORMATION

SPECIFY

1. Model Number MCW102A1005 (ground-side switching)

Model Number MCW102C1002 (high-side switching)

2. Valve load to be driven

3. Accessories

4. Service parts

ACCESSORIES

1. KG04003, Right Angle Grade Follower

With breakaway joint. For grade applications only.

Follows a stringline. Also used with skate assembly, or

skate and ski assembly for following hard reference

surface.

2. K09274, Right Angle Grade Follower Less Sensing Arm

For grade applications utilizing the skate and/or skate

and ski assembly. Same as part number KG04003

above, but without the sensing arm and breakaway joint.

3. KG06001, Skate Assembly

For grade applications. Used with right angle grade

follower (part number K09274) on hard reference sur-

face.

• Rugged aluminum housing

• Withstands high vibration and shock

• Moisture and corrosion resistant

• Easy to mount

• Adjustable tracking force

4. KG02001, Ski Assembly

For grade applications. Used with right angle grade

follower (part number K09274), and skate assembly

(part number KG06001) on hard reference surface.

5. Cable Assemblies:

KW01013 – Two-foot coiled cable that extends to ten

feet. Has right angle connector on one end and straight

connector on the other to make connections between

the MCW102 and Bendix Type No. MS3102A18-1P

plug (part number K03989).

KW01035 – Two-foot coiled cable that extends to ten

feet. Has right angle connector on one end and straight

connector on the other to make connections between

the MCW102A and the paving machine bulkhead.

STRAIGHT 90°

CONNECTOR CONNECTOR

AA

BB

CE

DF

EC

FD

© Danfoss, 2013-09 BLN-95-9048 1

.

.

Page 2

ORDERING INFORMATION

KW01015 – Two-foot coiled cable that extends to ten

feet. Has two straight connectors to make connections

between the MCW102C and the paving machine bulk-

head.

KW01034 – Two-foot coil cable that extends to ten feet,

has right angle connector on one end and straight

connector on the other end to make connections between the MCW101 and paving machine bulkhead.

STRAIGHT 90°

CONNECTOR CONNECTOR

AA

BB

(continued)

FE

EF

6. K00702 Lens (service part)

7. K03891 Lamp (service part)

TECHNICAL DATA

ELECTRICAL

SUPPLY VOLTAGE

12 volts

0.5 amps

Does not include output current to load.

MAXIMUM OUTPUT CURRENT @ 14 VDC SUPPLY

2.5 amp with 5 ohm load

The MCW102A has ground-side switching

The MCW102C has high-side switching

MAXIMUM REVERSED POLARITY VOLTAGE

50 Vdc for 5 minutes

SHORT CIRCUIT PROTECTION

The controllers are protected against short circuits

across the valve coil as well as shorts between the

outputs and ground. A short circuit is defined as 1 ohm

maximum resistance for 5 minutes maximum.

LOAD DUMP

Protected against load dump per SAE J2.20.97

MECHANICAL

Physical stops limit the rotation to approximately ± 23° from

null.

ENVIRONMENTAL

OPERATING TEMPERATURE

-18° to 65° C (0° to 150° F)

STORAGE TEMPERATURE

-30° to 65° C (-22° to 150° F)

HUMIDITY

After being placed in a controlled atmosphere of 95%

humidity at 38° C for 10 days, the controller will perform

within specification limits.

RAIN

The controller will withstand exposure to a 15 minute

shower with cold water after reaching the maximum

storage temperature.

VIBRATION

Withstands a vibration test designed for mobile equipment controls consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the three axes.

2. Resonance dwell for one million cycles for each

resonant point in each of the three axes.

Run from 1 g to 8 g’s. Acceleration level varies with

frequency.

SHOCK

50 g for 11 milliseconds. Three shocks in both directions

of the three mutually perpendicular axes for a total of 18

shocks.

DIMENSIONS

See the Dimensions Drawing.

2

BLN-95-9048

Page 3

DIMENSIONS

Dimensions of the MCW102A, C in Millimeters (Inches).

1304

3

BLN-95-9048

Page 4

TECHNICAL DATA

(continued)

PERFORMANCE

TEST CONDITIONS

SUPPLY: 14 Vdc

LOAD: 5 ohm minimum

DEADBAND: Maximum (full ccw)

RUN/STANDBY SWITCH: Run

TEMPERATURE: 25° C

Shaft rotation measured at end of 4.25 inch long horizontal arm. (Equivalent to a standard 6 inch long sensing

arm trailing at 45°).

MAXIMUM TORQUE

6.0 in-gms required to rotate the shaft from either side of

null to the stop.

NULL CENTERING

With the shaft roll pin centered between the stops,

electrical null will occur within ± 0.37 inches.

MAXIMUM TEMPERATURE NULL SHIFT

0.15 inch vertical deflection over the range from 0° to 50°

C (32° to 122° F). A larger null shift may occur over a

greater temperature span. It is recommended that the

user re-null the Controller each morning before using.

See the Adjustment section.

PHASING

Facing the hub with the lamps up, a clockwise shaft

rotation will make pin F positive with respect to pin E.

The right lamp will come on.

PROPORTIONAL BAND

.33 ± .08 inches

FREQUENCY OF OUTPUT PULSES

MCW102A1005 3 ± 1 Hz

MCW102C1002

MCW102C1011

MCW102A1013 4.5 ± 1 Hz

MINIMUM OUTPUT PULSE WIDTH

MCW102A1005 37 ± 12 ms

MCW102C1002

MCW102C1011

MCW102A1013 50 ± 12 ms

DEADBAND ADJUSTMENT

Overlap to a minimum of 0.12 inches

NULL POINT STABILITY

Changes in supply voltage from 11 to 15 Vdc will not

change the null point more than 0.02 inches.

RUN/STANDBY SWITCH

On Standby, output will be 0 ± 1 mA.

THEORY OF OPERATION

Both the MCW102A and MCW102C Controllers consist of

two stages: a sensor input and an amplifying/controlling

section. See the MCW102A and MCW102C Block Diagrams.

The sensor input section accepts steering or grade information through either a right angle or straight tube follower.

Right angle followers are used to sense grade and are either

tubular (for stringlines) or skate and ski (for firm reference

surfaces). As the reference is raised or lowered the hub shaft

is rotated so that the follower maintains contact.

As the hub shaft turns, it rotates a U-shaped magnet that is

attached inside the device housing. A non-contact sensor is

mounted to the housing between the poles of the magnet,

and as the angle of the flux lines passing through the sensor

changes with the follower, the voltage from the sensor varies.

The timed output voltage is proportional to the angle of

rotation over the sensing range.

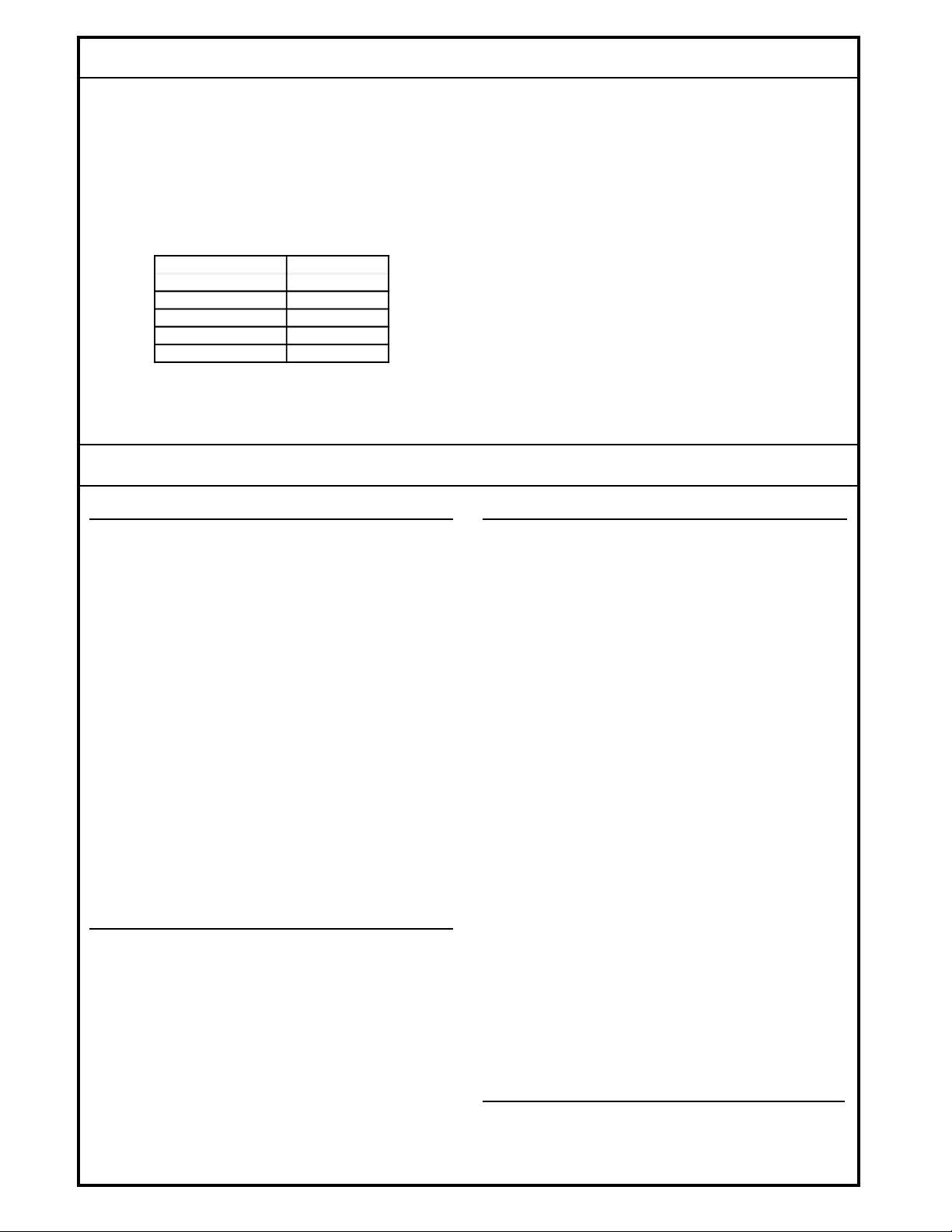

The amplifier sums the error signal from the sensor with a 3

Hz triangular wave to effect the time proportioning. See the

Triangular Wave drawing.

The sum is compared to an upper and lower reference

voltage to drive the output. The separation between the

references (the deadband) is adjustable through a trim potentiometer on the front panel. At minimum sensitivity (wide

deadband), a ± 0.06 inch (six inch grid arm at a 45° angle)

error signal will produce valve drive. At maximum sensitivity

(narrow deadband), both valve drives occur at the peaks of

the triangular waves, even when the system receives no

error signal. Two front-panel incandescent lamps light as the

valve drive trigger is activated.

TRIANGULAR WAVE

DEADBAND

ADJUST

UP

VALVE

ON

OFF NULL

NULL

ERROR

SIGNAL

DOWN

VALVE

ON

1150A

Triangular Wave Summed With Error Voltage In Null

(Solid Line) And Off Null (Broken Line) Conditions.

4

BLN-95-9048

Page 5

MCW102A BLOCK DIAGRAM (Ground Side Switching)

3 Hz

V

t

+

∑

+

V

t

HALL EFFECT

SENSOR

VOLTAGE

FUSE

-+

BATTERY

REGULATOR

V

V

t

t

MCW102C BLOCK DIAGRAM (High Side Switching)

3 Hz

V

t

DEADBAND

POTENTIOMETER

1741

FUSE

BATTERY

+

∑

+

HALL EFFECT

SENSOR

VOLTAGE

REGULATOR

V

-+

t

V

t

DEADBAND

POTENTIOMETER

V

t

1742

5

BLN-95-9048

Page 6

MOUNTING

Determine the mounting location, and drill a 9/16-inch (14

mm) hole for the mounting stud. Remove the nut and

lockwasher. Mount the MCW102 with the shaft horizontal.

Tighten the nut against the lockwasher, but not too tightly,

since it must be loosened in the adjustment procedure.

Attach the appropriate follower to the hub. Note the guide

hole location and direction of travel.

WIRING

All wiring connections are made through a 10 Pin MS Connector located on the end of the front panel of the device. A

two-foot coiled cable that extends to ten feet is available with

plugs for easy connection and removal. A straight plug is

provided on one end and a right angle plug on the other (part

ADJUSTMENT

1. Place the Run/Standby switch on Standby.

2. Loosen deadband potentiometer locknut.

3. Turn the deadband potentiometer fully counterclockwise to minimum deadband.

4. Apply electrical power to the system. Hydraulic power is

not necessary at this time.

After the follower has been installed, adjust the spring on the

hub so the follower exerts a very light pressure on the

stringline or reference surface.

A skate assembly, part number KG06001, and ski assembly,

part number KG02001, may be used with the right angle

follower, part number KG04003 when a firm reference surface is used. When using these devices, hub spring tension

is comparatively unimportant.

number KW01013), or two straight plugs (part number

KW01014). Use an MS3102A18-1P connector (part number

K03989) on the machine for cable connections. See the

MCW102A and MCW102C Connection Diagrams.

6. Turn the potentiometer back approximately 1/4 turn.

7. Turn on the hydraulic power and place the Run/Standby

switch on Run.

8. Observe the response of the machine. If it oscillates

when returning to null, turn the potentiometer clockwise.

If the machine slowly approaches null but stops short,

turn the potentiometer counterclockwise.

5. With the equipment at the correct grade position, adjust

the vertical position of the MCW102 until the lights are

blinking for the same amount of time, or until an equivalent angular deflection causes the lamps to fire. Lock the

controller in place.

TROUBLESHOOTING

Keep the following facts in mind while troubleshooting

the system:

• The lights will indicate deviations whenever power is

applied to the MCW102, regardless of the Run/Standby

switch position.

• In the Run position, amplifier output is connected to the

solenoid. In the Standby position, it is not.

• If the deadband potentiometer is turned fully clockwise

(maximum deadband), a large deviation will be needed

to command an output to the solenoid.

• Preliminary checks should include examination of the

cables and leads for damaged or broken wire. Examine

areas where shorting may occur. Check the power

supply to be sure it is greater than 11 volts.

9. Tighten locknut on deadband potentiometer.

1. Check for free rotation, proper spring loading and tightness in all sensor grid parts.

2. Unhook the MCW102 cables and manually operate the

solenoids to check for correct operations. Re-connect

the cables.

3. Check the lights when the controller is in the Standby

mode. Vary the machine position manually and note the

indication. One light and then the other should glow as

the conditions are reversed.

4. If another controller is available, set it on the same

surface as the other and plug the MS connector into the

replacement unit. Check system operation. If the

problem disappears, the controller is defective. Substitute the replacement and return the old device as

outlined in the Ordering Information.

6

BLN-95-9048

Page 7

MCW102A CONNECTION DIAGRAM

MCQ/Q625

REMOTE SETPOINT

ABCD

A

B

C

D

E

F

AMPLIFIER

MCW101B1006

SLOPE CONTROLLER

A

B

LEFT

SIDE

C

KW01034 SLOPE CABLE

D

RUN

STANDBY

(NO LEFT/RIGHT SWITCH)

ON

OFF

UP

DOWN

+ 12 V

5A

LEFT

SOLENOID

VALVE

+12 VDC

AMPLIFIER

STANDBY

MCW102A1005

GRADE CONTROLLER

HUB LEFT

ON

5A

RIGHT

SOLENOID

VALVE

OFF

UP

DOWN

RUN

+12 V

UP

DOWN

RIGHT

SIDE

A

B

C

D

E

F

A

B

C

D

KW01035 GRADE CABLE

E

F

JOG

UP

DOWN

PAVING MACHINE

UP

DOWN

JOG

E

F

MCW102A Used in a Grade and Slope System with Ground-Side Switching and Four Pin Machine Connection.

7

BLN-95-9048

1743

Page 8

MCW102C CONNECTION DIAGRAM

Q625A1136

REMOTE SETPOINT

ABCD

A

AMP LIFIE R

AMP LIFIE R

A

RUN

STANDBY

MCW101A1023

SLOP E CO NT ROLLER

A

B

C

D

DOWN

+12 V

GRADE

SLOPE

ON

OFF

UP

UP

DOWN

B

C

D

E

F

JOG

LEFT

SOLENOID

VALVES

KW01015

CABLE

5A

+12 VDC

RUN

STANDBY

MCW102C1002

GRADE CONT ROLLER

HUB TOWARD

OUTSIDE

ON

5A

RIGHT

SOLENOID

VALVES

JOG

OFF

UP

DOWN

UP

DOWN

+12 V

B

C

D

E

F

KW01015

CABLE

A

B

C

D

E

F

E

F

PAVI NG MACHINE

MCW102C Used in a Grade and Slope System with High-Side Switching and Six Pin Machine Connection.

8

1744

BLN-95-9048

Page 9

CUSTOMER SERVICE

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

DEVICE REPAIR

For devices in need of repair, include a description of the

problem, a copy of the purchase order and your name,

address and telephone number.

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH & Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: 49-4321-8710

Fax: 49-4321-871-184

9

BLN-95-9048

Loading...

Loading...