Page 1

MCW100C, MCW100E

Time Proportional Rotary Position Controller

BLN-95-9013-1Issued: March 1995

DESCRIPTION

The MCW100C,E Time Proportional Rotary Position Controller provides

automatic grade or steering control of paving, trenching and curbing machines. The Controller uses a wand follower to sense the grade level or

steering command from a stringline or flat surface.

Two modules are housed in the case of the Controller. The grade sensing

module electromagnetically measures the machine's deviation from a grade

reference. The amplifier module receives the signal from the sensor module

and produces a voltage output to drive solenoid valves which, on a typical

paving machine, operate lift cylinders. Within the amplifier's proportional

band, the percent of time the output is on is proportional to the grade error. The

MCW100C,E may be used together with the MCW101 Time Proportional

Level Controller to control both parameters simultaneously.

FEATURES

• May be mounted on either side of machine

• Adjustable tracking force

• Dual UP/DOWN lamps show deviation from setpoint in

RUN and STANDBY modes

• Adjustable deadband varies sensitivity

• Run/Standby switch permits operator to switch to

manual control

ORDERING INFORMATION

ACCESSORIES

1. STEERING FOLLOWER

Straight tubular follower, 16 inches long overall with

breakaway joint. For steering only. Part number

KG07002.

2. RIGHT ANGLE GRADE FOLLOWER

With breakaway joint. For grade applications only. Follows a stringline. Also used with skate assembly, or

skate and ski assembly for following hard reference

surface. Part number KG04003.

3. RIGHT ANGLE GRADE FOLLOWER LESS SENSING

ARM

For grade applications utilizing the skate and/or skate

and ski assemblies. Same as Part number KG04003,

above, but without the sensing arm and breakaway joint.

Part number K09274.

4. SKATE ASSEMBLY

For grade applications. Use with right angle grade follower (Part number K09274) on hard reference surface

Part number KG06001.

5. SKI ASSEMBLY

For grade applications. Used with right angle grade

• Flexible joint on follower prevents breakage

• Rugged aluminum housing

• 12 Vdc or 24 Vdc supply voltage

• Reverse polarity and short circuit protected

• Moisture and corrosion resistant

• Withstands vibration and shock

follower (Part number K09274), and skate assembly

(Part number KG06001) on hard reference surface. Part

number KG02001.

6. CABLE ASSEMBLY

KW01015 two-foot coiled cable that extends to ten feet

(3 meters). Has right angle connector on one end

and straight connector on the other end to make

connections between the MCW100C,E and Bendix

Type No. MS3102A18-1P plug. (Part number K03989).

SERVICE PARTS

1. AMPLIFIER MODULE

Removable modular amplifier can be exchanged with

other voltage compatible grade controllers:

Part Number K02910 (12 volt, MCW100C)

K02911 (24 volt, MCW100C)

K10654 (12 volt, MCW100E)

K10655 (24 volt, MCW100E)

2. K00702 Lens

3. K00706 Lamp (12 volt models)

K00707 Lamp (24 volt models)

4. K00665 RUN/STANDBY Switch

©Copyright 2001, Danfoss (US) Company.

1

All rights reserved. Contents subject to change.

Page 2

ORDERING INFORMATION (

CONTROLLER SUPPLY VOLTAGE TYPE OF OUTPUT

MCW100C1007 12 Vdc Ground side switching

MCW100C1015 24 Vdc Ground side switching

MCW100E1005 12 Vdc High side switching

MCW100E1013 24 Vdc High side switching

TECHNICAL DATA

continued)

OPERATING VOLTAGE

12 Volt Model: 11 to 15 Vdc

REVERSE POLARITY PROTECTION

200 Vdc, maximum

24 Volt Model: 22 to 30 Vdc

SHORT CIRCUIT PROTECTION

SUPPLY CURRENT

Full, with 0.5 Ω maximum resistance

0.6 A, maximum, not including output current to the valve

TIME PROPORTIONAL OUTPUT FREQUENCY

MAXIMUM VOLTAGE DROP (3 A load current)

f = 3 Hz ± 1 Hz

3.5 Vdc

MINIMUM PULSE WIDTH

CURRENT OUTPUT

t = 37 ms ± 12 ms

3 A, maximum

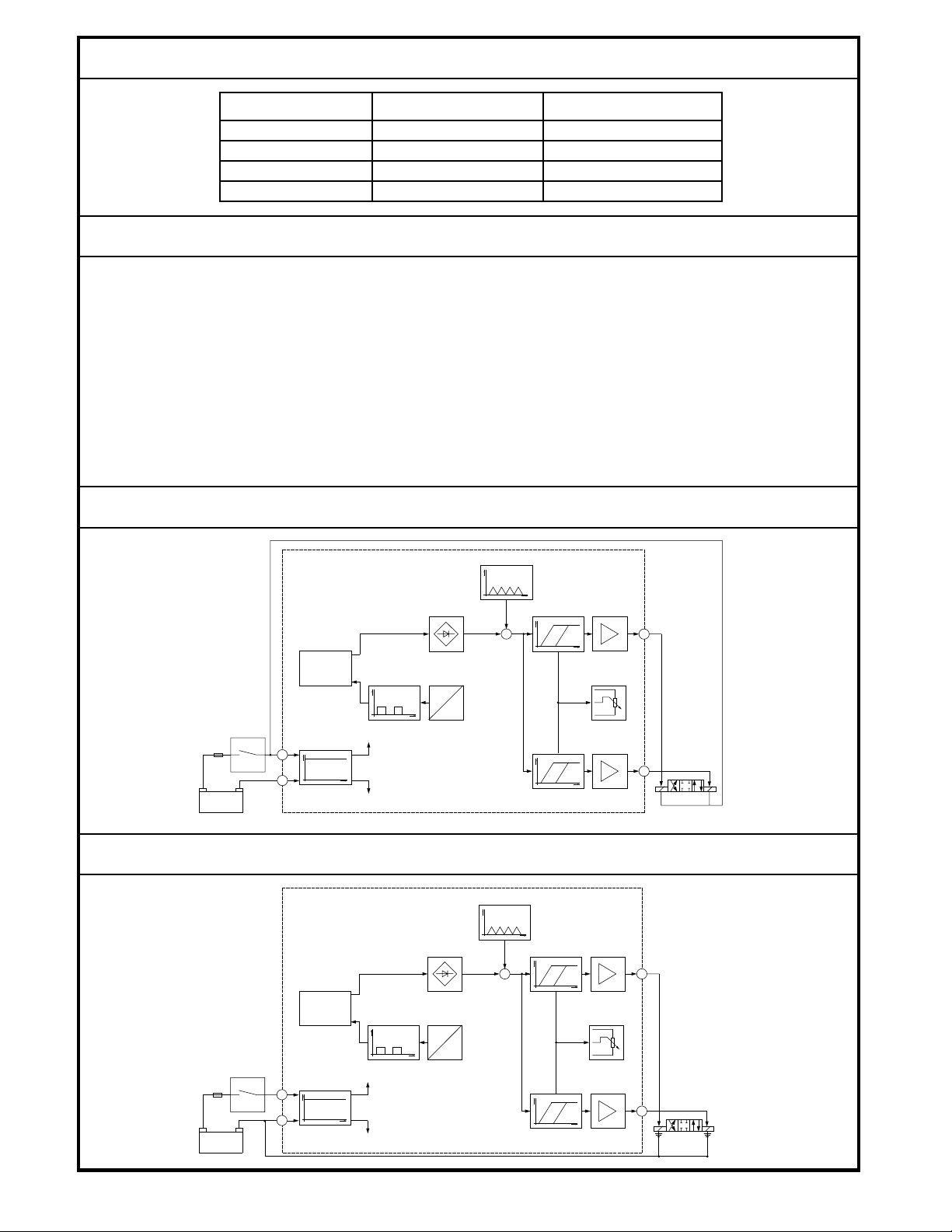

BLOCK DIAGRAM MCW100C - Ground Side Switching

V

3 Hz

t

+

V

+

Microsyn

-

V

440 Hz

f

V

t

t

potentiometer

Sensitivity

F

+

-

Battery

Voltage regulator

V

t

BLOCK DIAGRAM MCW100E - High Side Switching

V

3 Hz

+

-

+

Microsyn

BLN-95-9013

V

F

+

-

Battery

Voltage regulator

V

t

440 Hz

f

V

t

2

V

t

1812

t

V

t

Sensitivity

potentiometer

V

t

1842

Page 3

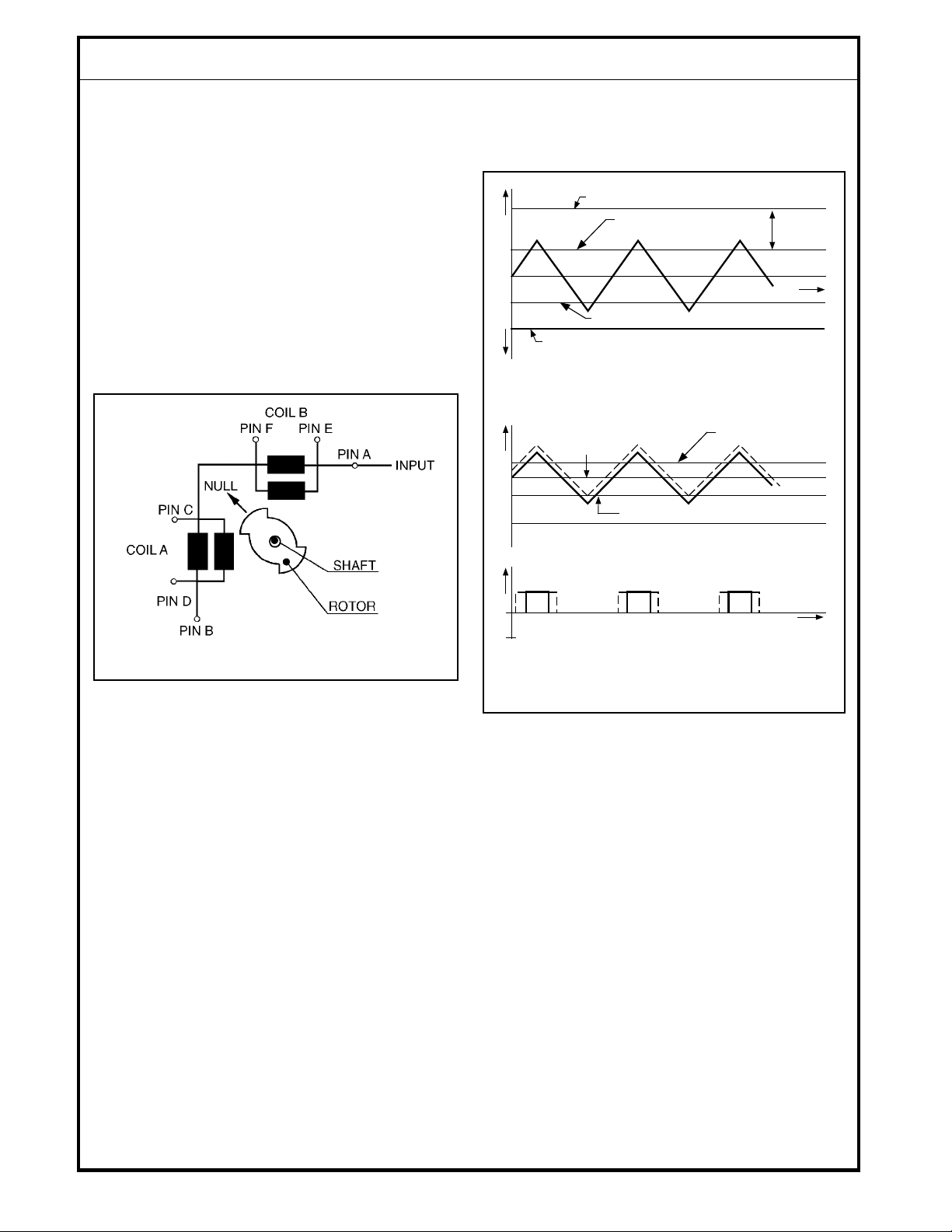

THEORY OF OPERATION

The MCW100C,E Time Proportional Grade Controller consists of a grade-sensing transducer and an amplifier. The

sensor and amplifier are housed in a single aluminum channel and can be removed easily for repair or replacement.

They are connected with a MS-connector.

Steering and grade information is sent to the Controller

through either a right angle or straight tube follower. Right

angle followers are used to sense grade and are either

tubular (for stringlines) or skate and ski (for firm reference

surfaces). Straight followers are used to sense a steering

path and are tubular. As the reference is raised or lowered left or right for steering - the transducer shaft is rotated so that

the follower maintains contact.

The transducer transforms this shaft rotation into an electrical

signal through the rotor/stator interaction. (See Figure 1.)

The secondary voltages are demodulated in the amplifier to

power a bridge network. A 3 Hz triangular wave is summed

with the error signal, defined by the difference between the

voltages, to effect the time proportioning. (See Figure 2.)

min. sensitivity

max. sensitivity

0

max. sensitivity

min. sensitivity

no output signal to the solenoid valve

0

error

upper trigger level

adjust

sensitivity

t

lower trigger level

upper trigger level

1814

Figure 1.

A 440 Hz square wave from the amplifier is applied to the

primaries of coils A and B. The stator position with respect to

the rotor determines the voltages from the coil secondaries.

output signal to the solenoid valve

0

Figure 2.

t

1815

The sum is compared to a reference voltage by two Schmitt

triggers, which drive the solenoids. As the slope sensor

rotates, the triangular wave moves up or down with respect

to zero error signal. When the triangle crosses the upper or

lower trigger level the output signal is turned on. When a

Remote Setpoint is used, the difference between the voltages is kept proportional to the commanded slope. The

separation between the reference voltages (the deadband)

is adjustable through a trim potentiometer in the front panel.

At minimum sensitivity (maximum deadband), a 0.4% slope

error signal will fire the triggers. At maximum sensitivity

(minimum deadband), both triggers will fire alternately at the

peaks of the triangular waves, even when the system is level.

The sensitivity adjustment controls the difference between

the upper and lower trigger from overlap to 0.5% slope.

3

BLN-95-9013

Page 4

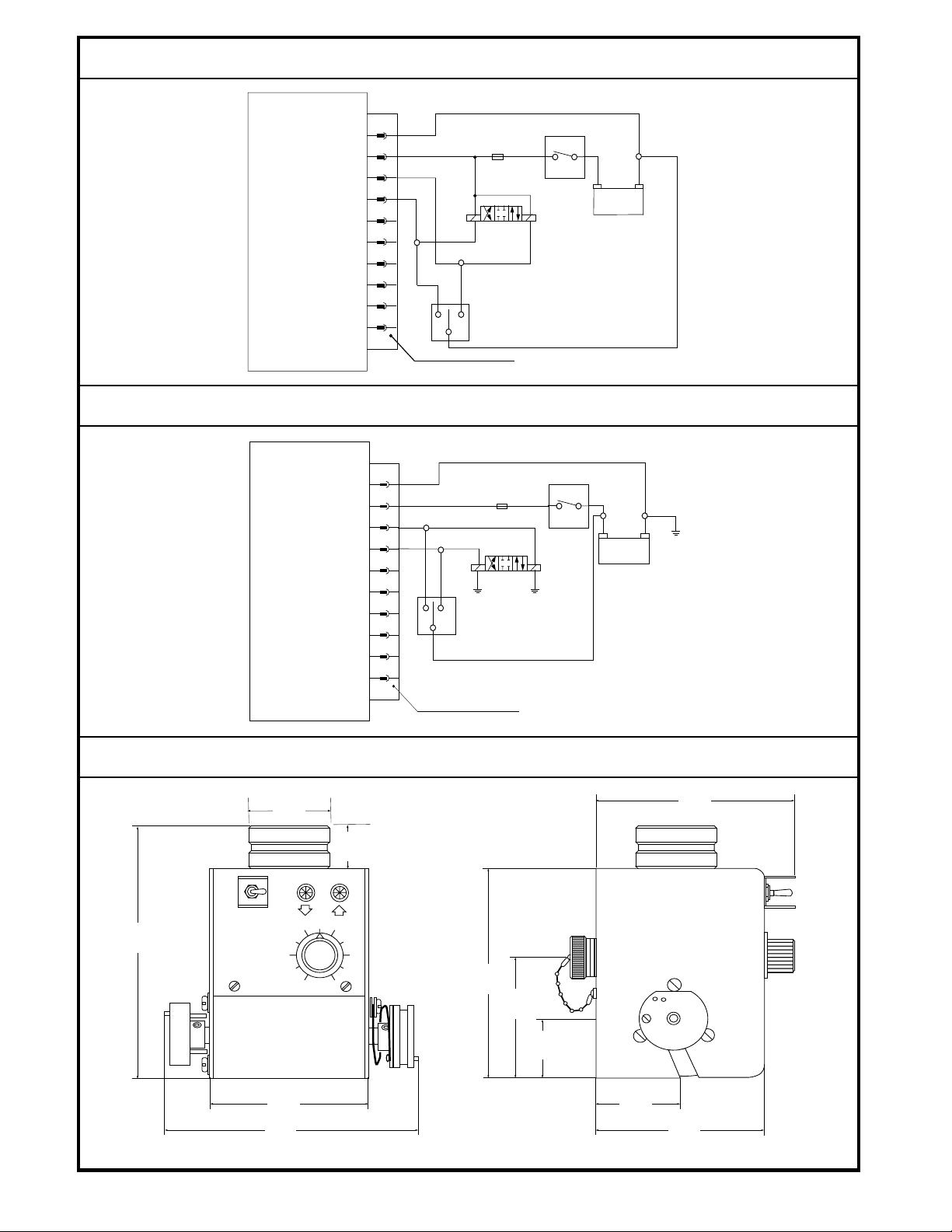

CONNECTION DIAGRAM MCW100C - Ground Side Switching

A

B

C

D

E

F

DOWN

G

H

I

DOWN

J

F

5A

BATTERY

UP

JOG

UP

-+

MS-CONNECTOR, 10-PIN

CONNECTION DIAGRAM MCW100E - High Side Switching

A

B

C

F

5A

D

E

F

G

H

DOWN UP

JOG

DOWNUP

I

J

MS-CONNECTOR, 10-PIN

DIMENSIONS

63,5

(2.5)

31,8

(1.25)

S

T

A

O

N

N

D

B

Y

46

S

190,5

(7.5)

E

N

S

I

T

2

I

V

I

T

Y

8

158,8

(6.25)

86,6

(3.4)

+

BATTERY

1816

-

1817

136,7

(5.44)

BLN-95-9013

117,1

(4.61)

188

(7.4)

39,4

(1.55)

Dimensions in Millimeters (Inches)

4

39,1

(1.54)

114

(4.5)

1818

Page 5

INSTALLATION - LOCATION

The MCW100C,E can be mounted on either side of the

machine, oriented according to the location of the reference

surface or stringline. It may be used with a right angle grade

follower, Part number KG04003, or straight tubular follower,

Part number KG07002.

The right angle follower may be attached to the MCW100C,E

hub horizontally, at a 45° angle downward, or at a 45°

upward. (See Figure 3.) The flat on the hub should be parallel

to the grade reference.

Figure 3.

1825

The follower may be attached at a 45° angle upward. (See

Figure 5.) and the follower should be positioned toward the

operator panel.

Figure 5.

1827

When the straight tubular follower is used for steering control

(see Figure 6), the MCW100C,E hub should be directly

above the stringline.

Note: When the right angle follower is

used, the transducer shaft must be mounted perpendicular

to the direction of travel. When the straight tubular follower is

used, the transducer shaft must be parallel with the direction

of travel.

The follower may be attached at a 45° angle downward.

(See Figure 4.)

Figure 4.

1826

Figure 6.

5

1828

BLN-95-9013

Page 6

INSTALLATION - MOUNTING

Attach the appropriate follower to the hub. Note the guide

hole location, and direction of travel. Guide holes in the

mounting bracket for the steering follower, Part number

KG07002, are located as shown (see Figure 7). The follower

may be attached to either hub. The right angle follower, Part

number KG04003, is used for grade applications.

BREAKAWAY JOINT

STEERING

LEFT HUB

GRADE

RIGHT

1

HUB

THE RIGHT HUB IS DEFINED AS THE ONE WITH

1

THE SPRING BIAS ADJUSTMENT THUMBSCREW

STEERING

RIGHT HUB

LEFT

HUB

1

952B

Figure 7.

A skate assembly (Part number KG06001) and ski assembly

(Part number KG02001) may be used with the right angle

follower (Part number KG04003) when a firm reference

surface is used. (See Figures 8 and 9.)

After the follower has been installed, adjust the spring on the

hub so the follower exerts a very light pressure on the

stringline or reference surface. Note that the flat of the hub is

parallel to the top of the case when the MCW100C,E is at null

position.

Figure 8.

1829

BLN-95-9013

Figure 9.

951A

6

Page 7

WIRING

All wiring connections are made through an MS connector

located on the back of the unit . Although two connectors are

provided, only the larger, 10-pin connector is used. (See

Figure 1, page 3 of this document.) A two-foot coiled cable

that extends to ten feet is available with plugs for easy

ADJUSTMENT

1. Place the RUN/STANDBY switch on STANDBY.

2. Turn the deadband potentiometer fully counterclockwise to minimum deadband.

3. Apply electrical power to the system. Hydraulic power is

not necessary at this time.

4. With the equipment at the correct grade position, adjust

the position of the MCW100C until the UP/DOWN grade

lights are blinking for the same amount of time. Lock the

controller in place.

5. Move the follower up and down about 1/4" while observing the lights and increase the deadband setting (turn

clockwise) until both lights are off for about 1/16" of

movement. Usually this is about 1/4 turn clockwise.

6. Turn ON the hydraulic power and place RUN/STANDBY

switch on RUN.

7. Introduce a grade error into the system by either using

the machine JOG switch or by pushing down on the

follower.

removal, A straight plug is provided on one end, and a right

angle plug on the other. Order Part number KW01015. Use

Part number MS3102A18-1P (K03989) connector on the

control panel for cable connection.

TROUBLESHOOTING

The Grade Controller will provide extended, trouble-free

operation and should not need servicing under normal

operating conditions. If preliminary investigation of a

system malfunction indicates trouble in the

MCW100C,E the following facts should be kept in mind

to help determine the problem.

1. The lights will indicate deviations in grade whenever

power is applied to the MCW100C,E, regardless of the

Run/Standby switch position.

2. In the Run position, amplifier output is connected to the

solenoid. In the Standby position, it is not.

3. If the deadband potentiometer is turned fully clockwise

(maximum deadband), a large deviation will be needed

to command an output to the solenoid.

4. Preliminary checks should include examination of the

cables and leads for damaged or broken wire. Examine

areas where shorting may occur. Check the power

supply to be sure it is greater than 11 Vdc (22 Vdc on 24

volt models).

8. Observe the response of the machine. If it oscillates

when returning to null, the deadband is too small. Turn

the potentiometer clockwise. If the machine slowly

approaches null but stops short, the deadband is too

large. Turn the potentiometer counterclockwise.

9. Replace the screw to cover the deadband adjustment.

TROUBLE CHECK

1. With the RUN/STANDBY switch in the STANDBY position, operate the machine JOG switch in both directions

while noting operation of the solenoid. (The JOG switch

is wired separately.) If the solenoid operates in the

wrong direction, reverse the leads on the valve and

recheck. If the solenoid fails to operate, check for voltage

at the JOG switch terminals at the center-off position and

at the solenoid terminals when the switch is activated. If

proper voltage exists, replace the solenoid. If there is no

voltage, check the wiring.

2. Check the lights when the Grade Controller is in the

STANDBY mode. Use the JOG switch to vary machine

position and note the indication. One light and then the

other should glow as the conditions are reversed.

5. Should a bulb need replacement, unscrew the lens from

the panel. The bulb snaps out of its socket, but because

clearances are tight it may be impossible to remove by

hand. If a piece of 5/16" rubber tubing is available, it can

be pushed down over the bulb and pulled back to effect

removal. The replacements are 'DQIRVV PartQXPEHU

K00706 for 12 volt models and K00707 for 249ROW

models. The part can also be purchased through

other vendors as a number 161 (12 9olt) or number 656

(24 9olt) bulb.

3. Disconnect the power and output cable connector from

the MCW100C,E. Check voltage at the socket end of the

cable for at least 11 Vdc between sockets A and B. If

voltage does not exist across A and B, the cable or the

voltage supply is faulty.

4. Check the output voltage from C to ground and D to

ground.

5. If another Grade Controller is available, set it on the

same surface as the other and plug the MS connectors

into the replacement unit. Check system operation. If

the problem disappears, the Controller is defective.

Substitute the replacement controller in its place.

7

BLN-95-9013

Page 8

CUSTOMER SERVICE

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

DEVICE REPAIR

For devices in need of repair or evaluation, include a

description of the problem and what work you believe

needs to be done, along with your name, address and

telephone number.

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH & Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: 49-4321-8710

Fax: 49-4321-871355

BLN-95-9013

8

Loading...

Loading...