Page 1

Replacement Parts Sheet

3

3

3

3

3500 Annapolis Lane North, Minneapolis, MN 55447 • Phone: (763) 509-2084 • FAX: (763) 559-0108

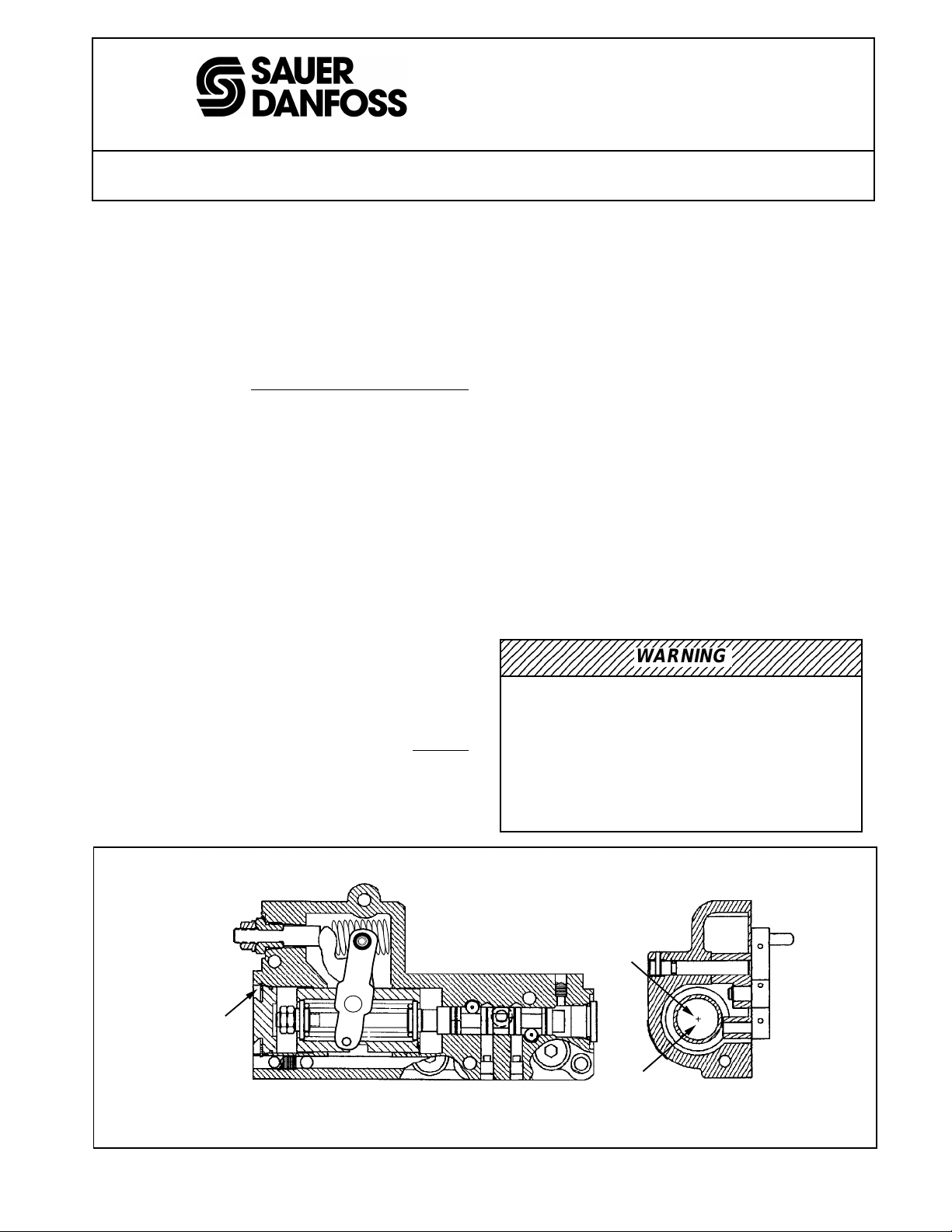

Service for the MCV115 HDC, Series 90 PV

This procedure covers the proper removal and installation of

those internal piece parts as outlined in the following steps.

(See Figures 1 and 2 for reference).

1. Remove the HDC from the pump, use a 5 mm socket hex

head and place it on a firm surface with the internal

workings facing up.

2. Locate the neutral adjust nut. Use an 11/16 hex wrench,

back out the neutral adjust assembly all the way and

remove from body.

Be careful not to disturb the locknut.

This will help ensure a positive pump neutral when

reinstalling this assembly.

3. Lift link/main adjust assembly away from housing. The

slider block may drop away from the link pin. Also, the

spring(s) in the housing should stay in place (30/55 cc,

one spring only; 75/180 cc, two springs).

4. Locate the large snap-ring. The cavity above the snapring should be cleaned of debris. Tap lightly with a

hammer on the plug below the snap-ring. This will relieve

the force when removing the snap-ring.

5. Using a snap-ring pliers, remove the snap-ring. Place a

blade screw driver under the lip of the plug and apply an

outward force at several points until plug is removed.

This will expose the Spool/Barrel Assembly (SBA). Now

place the HDC on end and grab hold of the two hex nuts

that are part of the SBA and pull out of housing.

6. Reassemble with the HDC on end. Gently lower the new

SBA into housing. If the SBA becomes stuck

GENTLY

tap into place.

7. Install new plug and snap-ring. All SBAs are shipped

with new plugs indicating the pressure range which is

stamped on the outside of the plug. Be sure that plugs

stay with their respective SBA, as this is the only means

of identifying the SBA pressure range.

8. Re-assemble the slider block onto the link pin as shown.

Place the link/main adjust assembly into the housing

while positioning the slider block flats into the barrel slot.

9. Install the neutral adjust assembly, making sure that the

spring(s) fall in place. While threading the neutral adjust

assembly into the housing, it will be necessary to assist

the main adjust by applying force in the direction as

shown. Keep applying this force while installing the main

adjust assembly until the O-ring contacts the housing.

Torque the main adjust nut to 30 ft·lb.

10. To ensure proper assembly, hold the feedback pin and

move side-to-side. It should move freely from stop to

stop, approximate.y 1/8 inch, before spring force is felt.

11. To install new control, align feedback pin to pump link.

Then carefully lower control onto pump.

12. Before installing mounting screws, check that control is

completely down on gasket. Install mounting screws

and tighten to 10 to 12 ft·lb.

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

WARNING

To adjust neutral requires operating the pump. Take

the necessary safety precautions. If the linkage is not

properly engaged maximum system pressure may occur

upon start up, and the machine may move. Ensure that

all personnel are not in a position to be injured should the

machine move. The EDC neutral position is critical to

ensure no machine movement upon start-up. Ensure

lock nut is tight (10 ft·lb).

HYDRAULIC DISPLACEMENT CONTROL (HDC)

SNAP RING

* Note: The pressure range is called out in the last two digits of the HDC P/N.

Figure 1.

RP-9601M

K20984

1

PRESSURE

RANGE

STAMPING

PLUG

Date: January 10, 1996

©Copyright 2000, Sauer-Danfoss (US) Company.

All rights reserved. Contents subject to change.

1923

Page 2

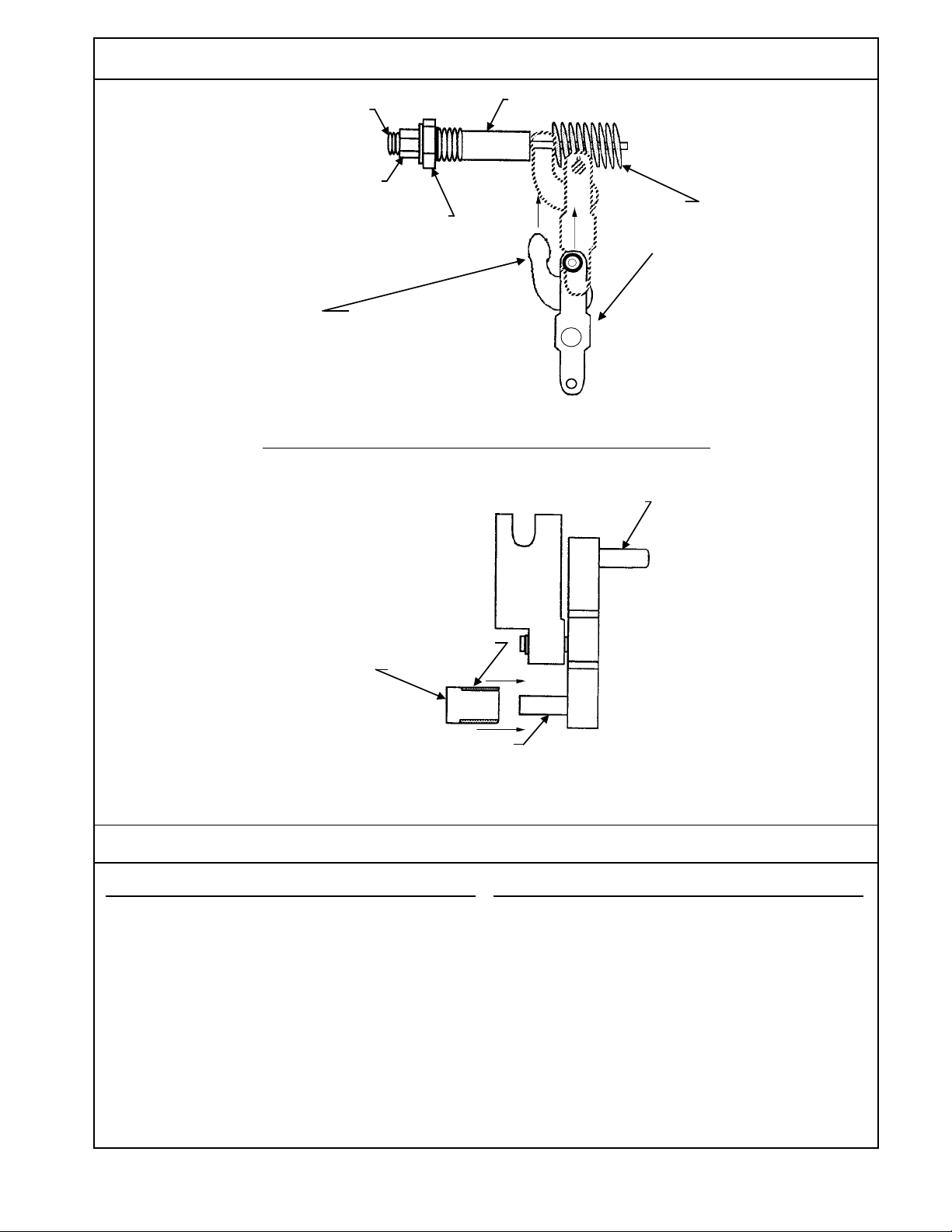

LINK/MAIN ADJUST ASSEMBLY

NEUTRAL ADJUST

SET SCREW

4 mm DIA.

LOCK NUT

13 mm DIA.

NEUTRAL ADJUST NUT 11/16

While installing the main adjust

assembly, apply force to this side

using a slotted screw driver.

NEUTRAL ADJUST ASSEMBLY

SPRINGS (2)

LINK/MAIN ADJUST

ASSEMBLY

FEEDBACK PIN

LINK/MAIN ADJUST

ASSEMBLY

RADIUS (4)

SLIDER BLOCK

FOR FURTHER ASSISTANCE CONTACT

NORTH AMERICA

Sauer-Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

MAIN

ADJUST

LINK PIN

LINK

Figure 2.

EUROPE

Sauer-Danfoss GmbH & Company

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: 49-4321-8710

Fax: 49-4321-871-184

1924

RP-9601M

K20984

2

Date: January 10, 1996

©Copyright 2000, Sauer-Danfoss (US) Company.

All rights reserved. Contents subject to change.

Loading...

Loading...