Page 1

DESCRIPTION

The MCV115 Series 90 Hydraulic Displacement Control

(HDC) is a hydromechanical pump stroke control which uses

mechanical feedback to establish closed loop control of the

swashplate angle of Danfoss Series 90 pumps.

The first stage, provided by the customer, produces a differential pressure to the HDC. The second stage uses the

differential pressure to drive its unique spool arrangement

and port oil to the pump servo cylinders. The second stage

spool configuration allows a null deadband (for machine

safety) in the pump's output while maintaining optimum

dynamic response to control commands.

FEATURES

MCV115

Hydraulic Displacement Control - PV

Series 90

BLN-95-9039-1 Issued: December 1992

• Servo control deadband independent of signal null

deadband; offers safety combined with accurate and

responsive control

ORDERING INFORMATION

The MCV115 HDC is ordered through the following part

number scheme:

MCV115 X XX XX

CONFIGURATION

PUMP CATEGORY

(frame/linkage size)

PRESSURE RANGE

CONFIGURATION

A Standard control

B Annular control (not available on 30, 42 or 55 cc

pumps)

PUMP CATEGORY

05 30, 42, 55 cc

07 75 cc

10 100 cc

13 130 cc (with short pin)

18 180 cc

• Fully tested to resist the off road environment

• Minimum long term null shift

PRESSURE RANGE

01 1.1 - 6.7 bar

02 1 - 11 bar

03 3 - 11 bar

04 8 - 16.5 bar

05 0.8 - 4.6 bar

06 5 - 15 bar

The pressure ranges available for the HDC are:

MCV115 PRESSURE

PART NUMBER RANGE COMMENTS

AXX01, BXX01 1.1 - 6.7 bar Same Pressure Range

(16 - 98 psi) as MCV112

AXX02, BXX02 1 - 11 bar Same Pressure Range

(15 - 160 psi) as MCV112

AXX03, BXX03 3 - 11 bar Same Pressure Range

(44 - 160 psi) as MCV112

AXX04, BXX04 8 - 16.5 bar Not available as

(116 - 239 psi) MCV112

AXX05, BXX05 0.8 - 4.6 bar Same Pressure Range

(11 - 66 psi) as MCV114's

lower range

AXX06, BXX06 5 - 15 bar Not available as

(73 - 218 psi) MCV112

© Danfoss, 2013-09 BLN-95-9039-1 1

.

.

Page 2

ORDERING INFORMATION

(continued)

HDCs ordered separate from the pump must have mounting kits ordered separately. The following table shows the pump/

kit relationships.

30/55 cc PUMP KIT (KIT NUMBER KK12655)

PART NUMBER QUANTITY DESCRIPTION

K11419 1 Gasket

9007314-0611 6 Screw

42 cc PUMP KIT (KIT NUMBER KK12642)

PART NUMBER QUANTITY DESCRIPTION

K11419 1 Gasket

9007314-0611 6 Screw

K09123 1 Seal Washer

TECHNICAL DATA

Some specifications apply to all HDCs. Others will vary

based on the MCV115 number scheme, as outlined in the

Ordering Information section.

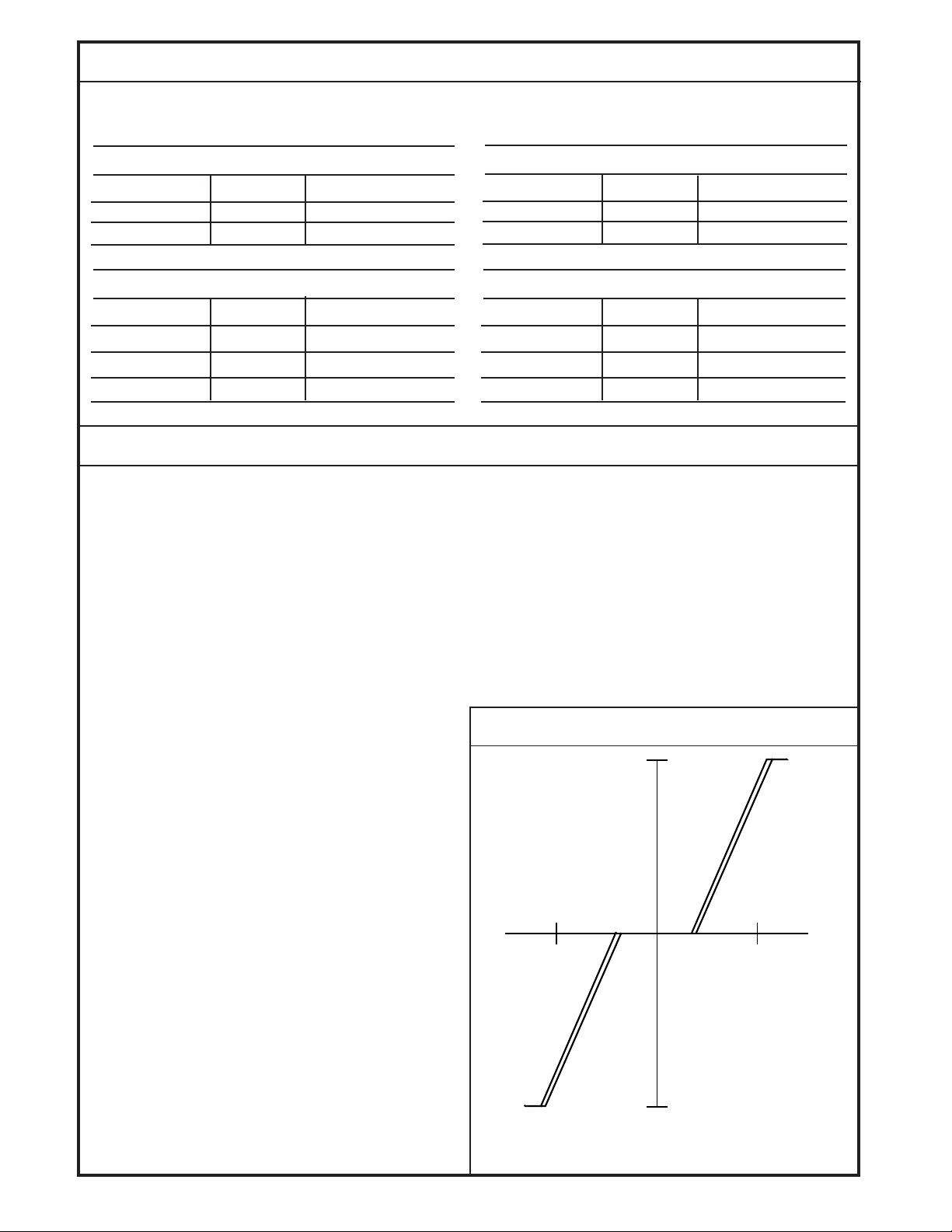

THRESHOLD

See Pressure Range in the Ordering Information section. Defined as the center of hysteresis extracted to the

pump start stroke.

DEADBAND

Twice the threshold, ±7% of the rated pressure.

RATED PRESSURE

See Pressure Range, in the Ordering Information sec-

tion. Tolerance is ±10%. Defined as the pressure

required to reach rated pump output. Maximum pressure is 500 psid above rated pump case pressure. See

the Input Pressure Vs. Swashplate Angle Curve.

75/100/130 cc PUMP KIT (KIT NUMBER KK12675)

PART NUMBER QUANTITY DESCRIPTION

K11420 1 Gasket

9007314-0611 6 Screw

180 cc PUMP KIT (KIT NUMBER KK12618)

PART NUMBER QUANTITY DESCRIPTION

K11419 1 Gasket

9007314-0611 6 Screw

K09123 1 Seal Washer

TIME RESPONSE (Maximum)

1.0 seconds (0 to full stroke) (pressure limited valves)

2.0 seconds (full to full stroke) (pressure limited valves)

0.30 seconds (0 to full stroke) (non-pressure limited

valves)

0.40 seconds (full to full stroke) (non-pressure limited

valves)

SENSITIVITY

The valve will respond to a 2% change in input pressure

throughout the rated pressure range except for the

deadband region.

INPUT PRESSURE VS. SWASHPLATE ANGLE

17°

HYSTERESIS (Maximum)

7% of rated pressure. Measured on the hysteresis curve

generated at a frequency of 0.01 Hz with an excursion of

± rated pressure. The hysteresis measurement will be

made between 1 and 16 degrees of swash angle.

SYMMETRY

Input current required to reach rated output in each

direction must be equal within 15%.

LINEARITY

10% maximum of swashplate angle change between

any two points except within 1° of neutral.

RETURN TO NEUTRAL

The spool will return to neutral if the input differential

pressure signal is zero and mechanical feedback is

present.

OPERATING CHARGE PRESSURE

300 psi above case pressure (nominal).

BLN-95-9039-1

SWASHPLATE ANGLE

10

DELTA BAR

10

17°

Input Delta Pressure Vs. Swashplate Angle for the

MCV115 (Typical).

2

1637

Page 3

THEORY OF OPERATION

The HDC uses a unique spool-barrel-feedback arrangement

that serves to separate the null deadband from the feedback,

giving both safety against null drift and quick dynamic response to command changes. The barrel contains the spring

which provides the matching requirements for differential

pressure rating to output swashplate angle rating. The barrel

is driven directly by the feedback linkage from the swashplate.

See the Internal Workings Schematic.

The HDC's null adjust is set with a feedback spring to provide

an effective pressure-preload threshold, which is the amount

of differential pressure required to move the spool one

direction or the other. By tightening or loosening the main null

adjust screw, the fixed deadband is adjusted to the pump to

create the pump stroking start differential pressures.

As differential control pressure input from the external source

rises beyond the threshold, the spool moves in one direction

or the other, opening one of the control ports to charge

pressure, which ports oil to one of the pump servocylinders

to move the swashplate. As the swashplate moves, the drag

INTERNAL WORKINGS SCHEMATIC

linkage follows, moving the barrel in the opposite direction of

the spool input motion, driving the spool back to its neutral

position through the feedback spring within the barrel.

The HDC is a removable module from the main pump

housing such that no internal hardware changes are required

to the basic unit to switch from a manual to a hydraulic

displacement control. It will, however, be necessary to add

a charge check orifice, spring and retainer (which are part of

the pump assembly). The 90 Series HDC is comprised of

several physical sizes of controls to meet the requirements

of all the pump sizes. High response HDCs are not compatible with pressure limiters. This is a limit set by the design of

the pressure limiters within the pump.

Loose parts will be captive so there is no danger of them

falling into the pump during servicing. Control pressure ports

(from the external hydraulic input device) will be provided on

the boost stage as SAE-6 straight thread O-ring ports located

on the HDC's surface opposite the pump mounting surface.

MCV115

PUMP

HYDRAULIC CONTROL

VALVE

P

s

LINKAGE

P

t

P

t

AB

Schematic of the MCV115.

SWASHPLATE

1636

3

BLN-95-9039-1

Page 4

DIMENSIONS FOR 30, 42, AND 55 CC PUMPS

4,57 (0.180)

61,21 (2.410)

9/16-18 SAE STR. THD.

CONTROL PRESSURE INLET

60,45

(2.380)

7,11 DIA (6)

(0.280 DIA)

INSTALL SEAL WASHER HERE

ON 42 cc DEVICES

O-RING BOSS

2 PORTS

60,45

(2.380)

75,7

(2.98)

153,42 (6.040)

174,75 (6.880)

147,7 (5.814)

(0.236)

99,06 (3.90)

131,06 (5.160)

Dimensions in Millimeters (Inches).

6,0

72 (2.834)

44,7 (1.760)

30,99

(1.220)

13,97 (0.550)

11,94 (0.470)

NEUTRAL

ADJUST

41,66

(1.640)

81,28

(3.20)

6,35

(0.250)

94,49

(3.720)

1634

DIMENSIONS FOR 75 - 180 CC PUMPS

61,21

(2.410)

9/16-18 SAE STR. THD.

CONTROL PRESSURE INLET

70,61

(2.780)

7,11 DIA (6)

(0.280 DIA)

INSTALL SEAL WASHER

HERE ON 180 cc DEVICES

O-RING BOSS

2 PORTS

7 (0.275)

(2.63)

169,67 (6.680)

188,72 (7.430)

Dimension in Millimeters (Inches).

67

141,22 (5.560)

153 (6.023)

3,5

(0.137)

86,0 (3.385)

108,46 (4.270)

10,2 (0.40)

49,78 (1.960)

7,37 (0.290)

10,92

(0.430)

NEUTRAL

ADJUST

55,37

(2.180)

36,07

(1.420)

11,94 (0.470)

69,6

(2.740)

89,41

(3.520)

8,89

(0.350)

107,44

(4.230)

1635

BLN-95-9039-1

4

Page 5

ENVIRONMENTAL

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

TEMPERATURE

The valve will be functional and undamaged at oil

temperatures of –40° to 250° F (–40° to 121° C) with oil

viscosities from 40 to 6000 SUS. The valve will meet

performance specifications with oil temperatures of 70°

to 180° F (21° to 82° C).

SHOCK

50 g for 11 milliseconds. Three shocks in both directions

of the three mutually perpendicular axes for a total of 18

shocks.

VIBRATION

Withstands a vibration test designed for mobile equipment controls mounted on hydrostatic transmissions

consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the three axis.

TO INSTALL THE NEW CONTROL

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

Exercise care when placing the valve on a surface before

mounting on a transmission. Dropping or otherwise forcefully setting the valve down may damage the pin.

WARNING

2. Resonance dwell for one million cycles for each

resonance point in each of the three axis.

Run from 1 g to 46 gs. Acceleration levels vary with

frequency.

FILTRATION

The system hydraulics shall have 10 micron or better

filtration. The pump will contain screen filters near the

interface to the HDC at the charge port and control ports.

FLUID

Automatic transmission fluid or hydraulic oil (Ref: Mobile DTE 24 or equivalent).

DIMENSIONS

See the Dimension drawings.

1. Place a new gasket on the pump housing. Ensure that

the control orifice and spring are in the proper position

in the control.

2. Engage the pin on the control into the mating hole in the

link attached to the swashplate. See the Linkage

Assembly and Port Locations photo.

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

WARNING

Do not put the MCV115X13XX HDC on an older model

pump. Consult factory for proper installation. Older style

pumps previously used MCV112 HDCs with a manifold

between the HDC and the 130 cc pump. Directlymounted MCV115s use a pin that is too short for older

pumps. Using them improperly will result in pump displacement without feedback signal to the HDC.

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

WARNING

Uncontrollable vehicle or load movement will occur upon

start-up if the control is installed without proper engagement of the control feedback link pin into the swashplate

link.

During control installation, feel for pin engagement by

tipping the control before installing the mounting screws.

The control will not tip more than 5° if the pin is engaged.

3. Ensure that the pin is engaged in the link by tilting the

control upwards from the narrower end. If the pin

catches in the link and allows only a slight upward tilt,

there is positive engagement. If the control swings up

freely, the pin is not properly aligned.

4. Position the control into place against the pump housing. Align the gasket. Install the cap screws (On 42 cc

and 180 cc pumps use the included seal washer per the

Dimension drawings.) and torque to 10-12 ft-lbs.

LINKAGE ASSY & PORT LOCATIONS

CASE DRAIN PORT

SYSTEM

PRESSURE

"B" GAUGE

PORT

CHARGE

PRESSURE

GAUGE PORT

Vehicle or load movement can also result from lack of or

improperly adjusted control neutral. Follow service

manual procedures for adjusting neutral after start-up.

Always raise the vehicle, or block the vehicle load, from

moving upon start-up.

SYSTEM

PRESSURE

"A" GAUGE PORT

Assembly of control linkage and location of pump ports

for the MCV115.

BLN-95-9039-1

5

1646

Page 6

PUMP NEUTRAL ADJUSTMENT

3

3

3

3

3

Use the following procedure to bring the pump to neutral once

the hydraulic displacement control has been mounted.

1. Install a 500 psi gauge into the charge pressure gauge

port on the pump. See the Linkage Assembly and Port

Locations photo.

2. Loosen the null adjust plug on the null adjust screw.

3. Start the prime mover and run at low idle.

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

WARNING

To adjust neutral requires operating the pump. Take the

necessary safety precautions, such as having unnecessary personnel stand away from the machine. Maximum

system pressure may occur upon start up, and the

machine may move. Ensure that the operator is not in a

position to be injured should the machine move.

4. Warm the system up for several minutes to bleed air.

5. Slowly increase the prime mover speed to rated rpm.

(Ensure that the input differential pressure is zero.)

6. If the transmission operates as shown by motor shaft

rotation, reduce speed to idle. Using a 4 mm internal hex

wrench, slowly turn the null adjustment screw clockwise

or counterclockwise until the transmission does not

operate. Repeat step 5. Note that charge pressure

should drop with forward or reverse stroking of the pump

swashplate due to the shifting of the shuttle valve in the

motor manifold. Slowly turn the null adjust screw

clockwise until charge pressure decreases.

7. With the hex wrench, slowly turn the null adjustment

screw counterclockwise, observing the wrench angle

rotation, until charge pressure decreases again (charge

pressure will rise in neutral and drop when going into

stroke).

8. Turn the adjustment screw clockwise half the amount of

the turn observed in step 7. This should be the center

of neutral.

9. Hold the adjustment screw and securely tighten the null

adjust plug to 3–5 ft-lbs. Note that if a motor is used that

does not have a manifold, neutral should be adjusted

(steps 7–9) by observing the motor shaft rotation without

a load.

10. Stop the prime mover.

11. Run the system briefly to ensure that it operates proportionally on both sides of null. Swashplate movement

can be verified by watching motor shaft rotation without

a load.

CUSTOMER SERVICE

NORTH AMERICA

ORDER FACTORY INSTALLED MCV115s ON PUMPS

FROM

Danfoss (US) Company

2800 East 13th Street

Ames, Iowa 50010

Phone: (515) 239-6000

Fax: (515) 239-6318

ORDER INDIVIDUAL MCV115s FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

DEVICE REPAIR

For devices in need of repair, include a description of the

problem, a copy of the purchase order and your name,

address and telephone number.

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH & Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: 49-4321-8710

Fax: 49-4321-871355

BLN-95-9039-1

6

Loading...

Loading...