Page 1

DESCRIPTION

FEATURES

MCV106A

Hydraulic Displacement Control

ORDERING INFORMATION

Danfoss

TABLE A. INFORMATION NECESSARY TO SPECIFY

THE HDC.

MCV106A X 9 XX

DEVICE IDENTITY

CONFIGURATION

MODEL

MODULATING PRESSURE RANGE

1. DEVICE IDENTITY

2. CONFIGURATION

MODEL PRESSURE ANNULAR

CODE LIMITER OR CONTROL

PRESSURE

OVERRIDE

Pumps

Pressure

Danfoss .

Danfoss (pressure limiting is

spool); the

through

6

© Danfoss, 2014-05 11152454 • Rev AA • May 2014 1

3. MODEL

Page 2

ORDERING INFORMATION

(continued)

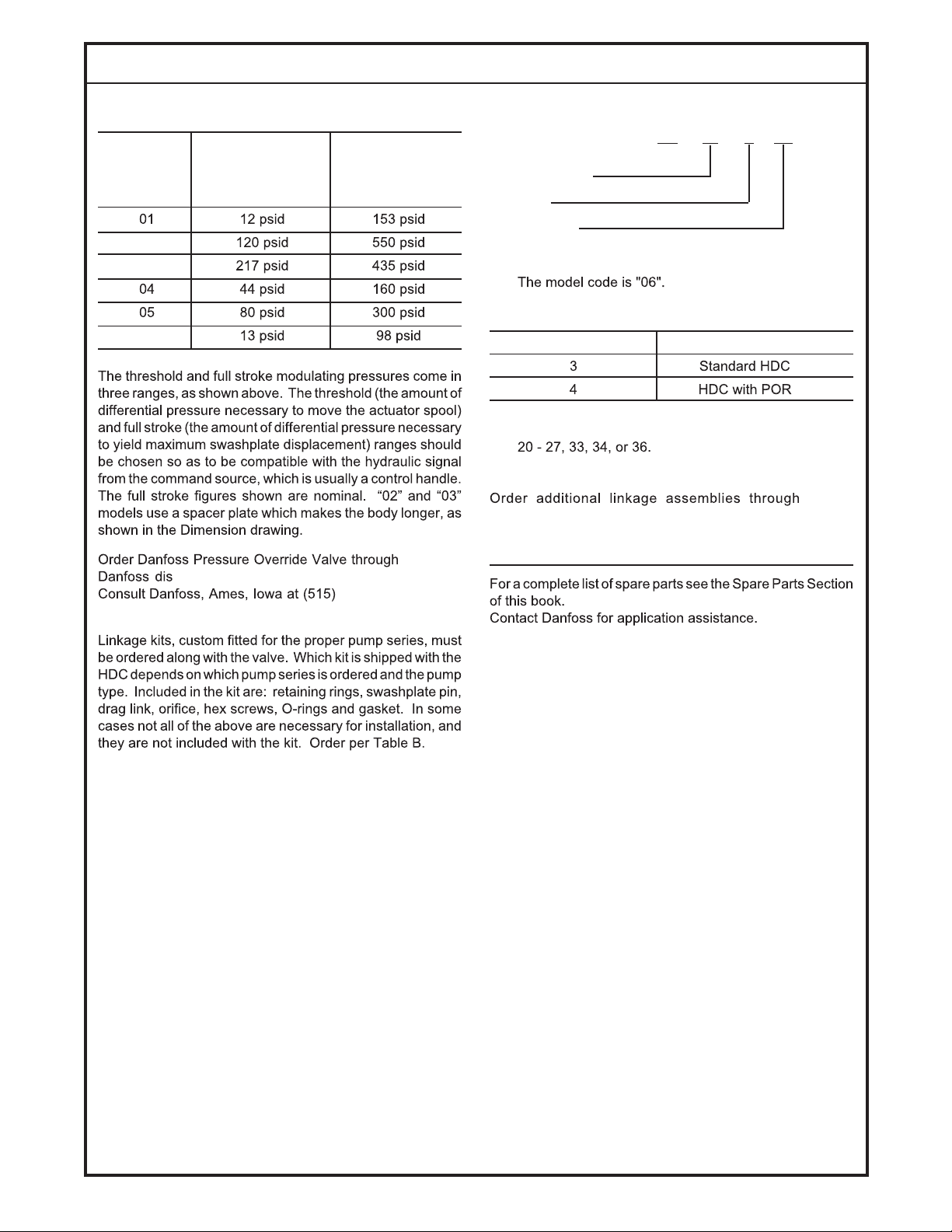

4. MODULATING PRESSURE RANGE

MODEL DIFFERENTIAL DIFFERENTIAL

CODE THRESHOLD FULL-STROKE

PRESSURE MODULATING

PRESSURE

02

03

06

TABLE B. LINKAGE KIT ORDERING INFORMATION.

06

KK XXX

PRODUCT TYPE

KIT TYPE

PUMP SERIES

1. PRODUCT TYPE

2. KIT TYPE

MODEL CODE DESCRIPTION

3. PUMP SERIES

Danfoss.

SPARE PARTS

tributors.

further information.

239-6000 for

© Danfoss, 2014-05 11152454 • Rev AA • May 2014 2

Page 3

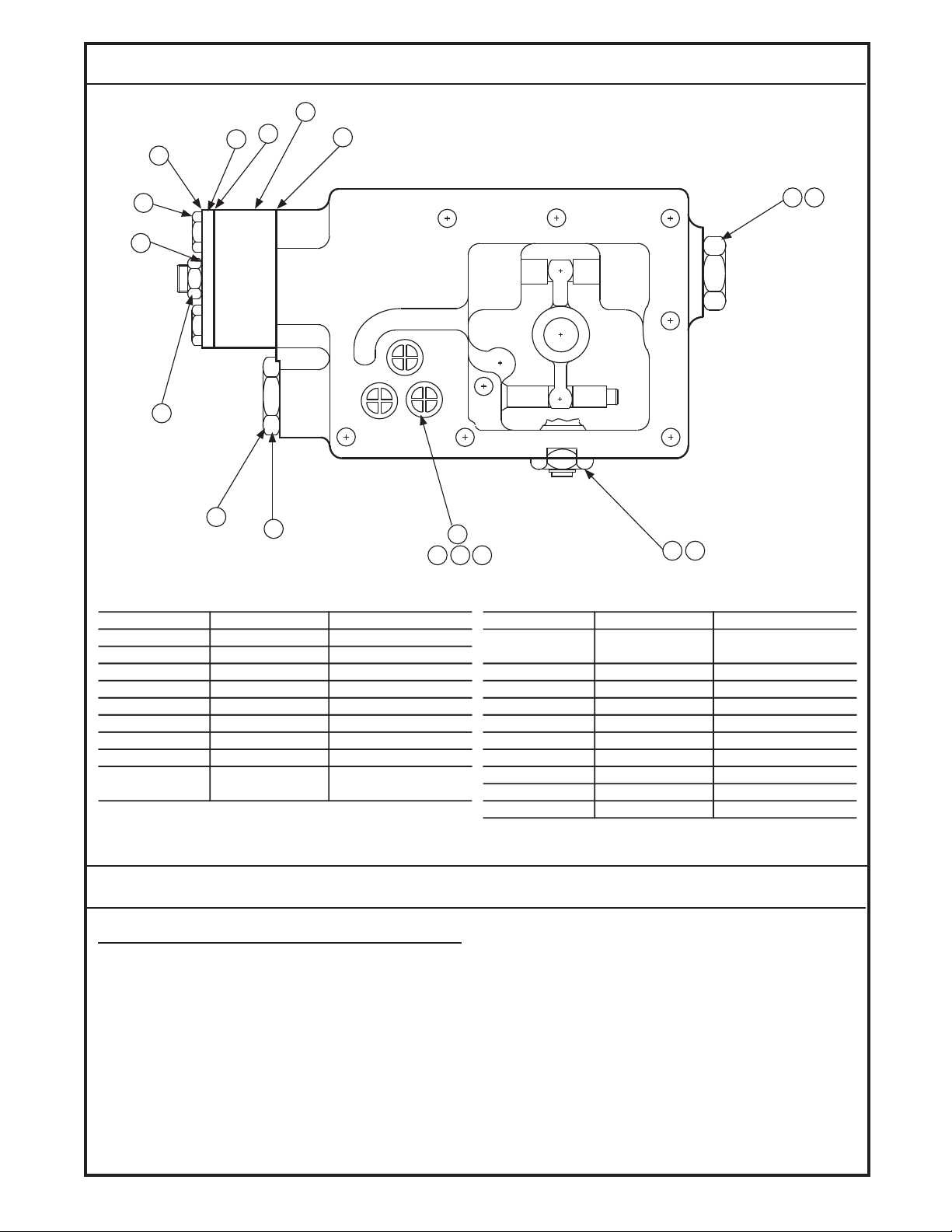

SPARE PARTS

15

10

4

3

14

9

13

8

7

ITEM NUMBER PART NUMBER DESCRIPTION

3 K08621 Cover, Null adjust

9 K07035 Screw, 1/4-20 X 1.5

6

teksaG33180K4

neercS retliF82170K5

gniR-O11070K6

gulP82070K7

23-8/3 ,tuN00070K8

(Spacer models)

5

16 17 18

11 12

1 2

1379

ITEM NUMBER PART NUMBER DESCRIPTION

57.0 X 02-4/1 ,wercS43070K9gniR-O90070K1

)sledom recapS noN(gnihsuB06170K2

10 K07181 Spacer

11 K07159 Plug

12 K07010 O-ring

13 K08387 3/8 Seal washer

14 K08132 Gasket (spacer models)

15 K08601 1/4” Seal washer

16 K07182 HDC gasket

17 K07006 Port O-ring

18 K07136 Orifice

TECHNICAL DATA

HYDRAULIC

OIL VISCOSITY

- 40° to 121° C (-40° to 250° F) operating range

OIL TEMPERATURE

40° TO 121° C (-40 ° TO 250 ° F) operating range

21° to 82 ° C (70° to 180° F) rated performance range 2X Series

21° to 104 ° C (70° to 220 ° F) rated performance range

- 3X Series

MINIMUM SYSTEM FILTRATION

= 2 or better (10 micron nominal)

B

10

© Danfoss, 2014-05 11152454 • Rev AA • May 2014 3

RATED CASE OPERATING PRESSURE

40 psi.

OPERATING CHARGE PRESSURE

150 - 600 psi above case pressure

FLOW RATING

0.7 to 1.1 gpm (std.), 1.2 gpm minimum (annular) total

at saturation with cylinder ports connected and 200 psi

supply pressure.

Page 4

DIMENSIONS

1170B

Dimensions of the MCV106A in Millimeters (Inches).

© Danfoss, 2014-05 11152454 • Rev AA • May 2014 4

Page 5

THEORY OF OPERATION

The HDC uses a unique double spool arrangement that

serves to separate the null deadband from the feedback,

giving both safety against null drift and quick dynamic response to command changes.

The command signal for the MCV106A is usually a remote

hydraulic control handle, as shown in the Block Diagram,

although other pressure sources could be used. The handle

modulates charge pressure from the pump (or another

source) so as to apply a proportional differential pressure

across the C1 and C2 input ports.

The HDC’s null adjust is factory set with the modulating

spring compressed to the equivalent of the threshold pressure (see Technical Data section), depending on the output

characteristics of the command source, representing the

differential pressure required to move the actuator spool one

direction or the other. This is a factory setting that defines the

width of the actuator spool deadband and cannot be changed

in the field. By tightening or loosening the null adjust screw,

the fixed deadband is moved toward or away from a symmetrical neutral position.

As differential control pressure (C1 - C2) rises beyond the

deadband, the actuator spool moves in one direction or the

other, pivoting the crosslink about its center. The pivoting

crosslink pushes or pulls the porting spool in the opposite

direction of the actuator

moved far enough to open A or B to charge pressure, oil is

ported to the pump servocylinders to move the swashplate.

As the swashplate moves, the feedback link follows, pivoting

the crosslink about the stationary end of the actuator spool,

driving the porting spool back toward its neutral position.

Because the feedback signal is entered into the control loop

after the command has been input, response time and

accuracy are enhanced.

INTERNAL WORKINGS SCHEMATIC OF THE MCV106A

spool. When the porting spool has

1171B

Control Handle Supply Pressure May Also Be Provided By an Auxiliary Pilot Pump.

© Danfoss, 2014-05 11152454 • Rev AA • May 2014 5

Page 6

PERFORMANCE

MODULATING RANGE

141 psid (MCV106AXX01)

430 psid (MCV106AXX02)

218 psid (MCV106AXX03)

116 psid (MCV106AXX04)

220 psid (MCV106AXX05)

85 psid (MCV106AXX06)

MAXIMUM HYSTERESIS

4% of modulating range when cycled at .01 Hz

THRESHOLD PRESSURE

12 ± 6.4 psid (MCV106AXX01)

120 ± 15.5 psid (MCV106AXX02)

217 ± 8.1 psid (MCV106AXX03)

44 ± 4.6 psid (MCV106AXX04)

80 ± 8.1 psid (MCV106AXX05)

13 ± 3.5 psid (MCV106AXX06)

SENSITIVITY

A 1%-of-modulating-range change in output differential

pressure will cause a detectable output change.

NEUTRAL LEAKAGE

.10 gpm maximum std., .18 gpm maximum annular

across the valve with 145 - 160 SUS oil @ 38 ° C

(100 ° F)

RESPONSE TIME

See Table C.

DIMENSIONS

See the Dimension drawing.

TABLE C.

MAXIMUM RESPONSE TIME IN SECONDS, OF STANDARD (NON-ANNULAR, NON ORIFICE), ANNULAR AND

.052 ORIFICED HDC'S. CHARGE PRESSURE IS LESS

THAN 250 PSI. RETURN TO NEUTRAL TIMES ARE APPROXIMATELY 60% OF FULL TO FULL.

SERIES TYPE FULL TO FULL

20

20

20

21

21

21

22

22

22

23

23

23

24

24

24

25

25

25

26

26

26

27

27

27

33, 34

33, 34

33, 34

36

36

36

STANDARD

ORIFICED

ANNULAR

STANDARD

ORIFICED

ANNULAR

STANDARD

ORIFICED

ANNULAR

STANDARD

ORIFICED

ANNULAR

STANDARD

ORIFICED

ANNULAR

STANDARD

ORIFICED

ANNULAR

STANDARD

ORIFICED

ANNULAR

STANDARD

ORIFICED

ANNULAR

STANDARD

ORIFICED

ANNULAR

STANDARD

ORIFICED

ANNULAR

.6

1.9

.4

.7

2.1

.5

1.0

2.9

.7

1.0

3.0

.7

1.6

5.0

1.1

1.9

5.7

1.3

4.3

13.0

3.0

4.9

15.1

3.4

.9

1.8

.5

1.4

2.8

.8

ENVIRONMENTAL

SHOCK

50 g for 11 milliseconds. Three shocks in both directions

of the three mutually perpendicular axes for a total of 18

shocks.

VIBRATION

Withstands a vibration test designed for mobile equipment controls consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the three axes.

© Danfoss, 2014-05 11152454 • Rev AA • May 2014 6

2. Resonance dwell for one million cycles for each

resonance point in each of the three axes.

Subject to acceleration levels of 1 g to 46 g. Acceleration

level varies with frequency.

Page 7

INSTALLATION

WARNING

Danfoss .

TABLE D.

TABLE D CORRELATES THE PUMP SERIES NUMBER

WITH THE SERIES NUMBER STAMPED ON THE SIDE OF

THE FEEDBACK LINK PROTRUDING FROM THE CONTROL.

SERIES LINK MARKING

23 23

bers.

MOUNTING

pump.

REMOVING THE OLD HARDWARE

26 26

SWASHPLATE DRAG LINK

1124B

Swashplate Drag Link/Control Feedback Link Connection Between Original Control and Pump.

© Danfoss, 2014-05 11152454 • Rev AA • May 2014 7

Page 8

MOUNTING THE NEW HARDWARE

1. Re-check the series number on the control feedback link

to ensure that it is compatible with the pump. Follow the

procedure outlined below to install the linkage:

A. Unscrew the bushing, using care not to damage its

O-ring. See the Parts Location photograph.

B. Install the new linkage assembly shaft through the

swashplate feedback shaft hole. Place the ball in

the crosslink ball cavity.

C. Lubricate the shaft O-ring and replace the bushing

over the shaft. Torque to the body (10 - 15 footpounds) so that the feedback shaft extends through

the bushing.

D. Install the retaining ring in the groove on the shaft.

2. Align one end of the replacement drag link with the holes

in the swashplate link arms.

3. Insert the press fit pin through the case drain port to trap

the drag link in the swashplate clevis. It will be necessary

to tap the pin into place until the head of the pin is flush

to the clevis.

SWASHPLATE LOCATION

4. Install the retaining ring by forcing it onto the tapered end

of the pin until it locks into the recess on the pin shaft.

Again, use caution not to drop any components into the

pump housing.

5. One .052 inch diameter orifice must be installed in each

servo port if reduced swashplate response is desired.

6. Engage the pin on the control in the drag link and swing

the control into place against the pump housing. The

drag link should be on the cylinder block side of the

swashplate. Install the seven mounting screws and

tighten to 10 - 11 foot-pounds of torque.

7. Connect the pipe or tubing from the control handle into

the C1 and C2 ports (9/16 - 18 UNF threads per SAE

J514). Phasing of the HDC is such that a pressure rise

at the C2 port causes a pressure rise at the A output port

of the pump, given a clockwise pump prime mover

rotation as viewed into the input shaft.

PIN CONNECTION TO SWASHPLATE

RAG LINK

1126B

Location of Swashplate Assembly in Pump Housing. Shown Disassembled for Clarity.

PARTS LOCATION

LINKAGE ASSEMBLY

SWASHPLATE FEEDBACK

SHAFT HOLE

Location of Parts When Installing a New Link and Ball

CROSSLINK BALL

CAVITY

BUSHING

RETAINING

RING

PUMP PORTS LOCATION

CASE

DRAIN PORT

CHARGE

PRESSURE

GAUGE

PORT

Location of Pump Ports.

Assembly.

1125C

11721173

© Danfoss, 2014-05 11152454 • Rev AA • May 2014 8

Page 9

PUMP NEUTRAL ADJUSTMENT

Use the following procedure to bring the Pump to neutral

once the Hydraulic Displacement Control has been mounted.

1. Install a 600 psi gauge into the charge pressure gauge

port on the pump. See Pump Ports Location photograph.

2. Using 1 9/16 - inch wrench, loosen the hex lock nut on

the null adjustment screw. See Dimensions drawing.

WARNING

To adjust neutral requires operating the pump. Take the

necessary safety precautions such as having unnecessary personnel stand away from the machine. Maximum

system pressure may occur upon start up, and the

machine may move. Ensure that the operator is not in

a position to be injured should the machine move.

3. Set the hydraulic control handle to neutral.

4. Start the prime mover and run at low idle.

5. Warm the system up for several minutes to bleed air.

6. Slowly increase the prime mover speed to rated rpm.

7. If the transmission operates as shown by motor shaft

rotation, reduce speed to idle. Using a 3/16 inch internal

hex wrench, slowly turn the null adjustment screw clockwise or counterclockwise until the transmission does not

operate. Repeat step 6. Note that charge pressure

should drop approximately 20 psi with forward or reverse stroking of the pump swashplate due to the shifting

of the shuttle valve in the motor manifold.

8. With a 3/16-inch internal hex wrench, slowly turn the null

adjustment screw clockwise until charge pressure begins to decrease. Then slowly turn the adjustment screw

counterclockwise, observing the angle of rotation, until

charge pressure decreases again (charge pressure will

rise in neutral and drop when going into stroke).

9. Turn the adjustment screw clockwise half the amount of

the turn observed in step 8. This should be the center of

neutral.

10. Hold the adjustment screw and securely tighten the hex

lock nut on the adjustment screw to 14 - 18 foot-pounds.

Note that if a motor is used which does not have a

manifold, neutral should be adjusted (steps 8 - 10) by

observing the motor output shaft rotation without a load.

11. Stop the prime mover.

12. Run the system briefly to ensure that it operates proportionally on both sides of the null command. Swashplate

movement can be verified by watching movement of the

swashplate feedback shaft, shown in the Dimension

Drawing.

CUSTOMER SERVICE

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (612) 509-2084

Fax: (612) 559-0108

DEVICE REPAIR

For devices in need of repair, include a description of the

problem, a copy of the purchase order and your name,

address and telephone number.

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH & Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: 49-4321-8710

Fax: 49-4321-871-184

© Danfoss, 2014-05 11152454 • Rev AA • May 2014 9

Loading...

Loading...