Page 1

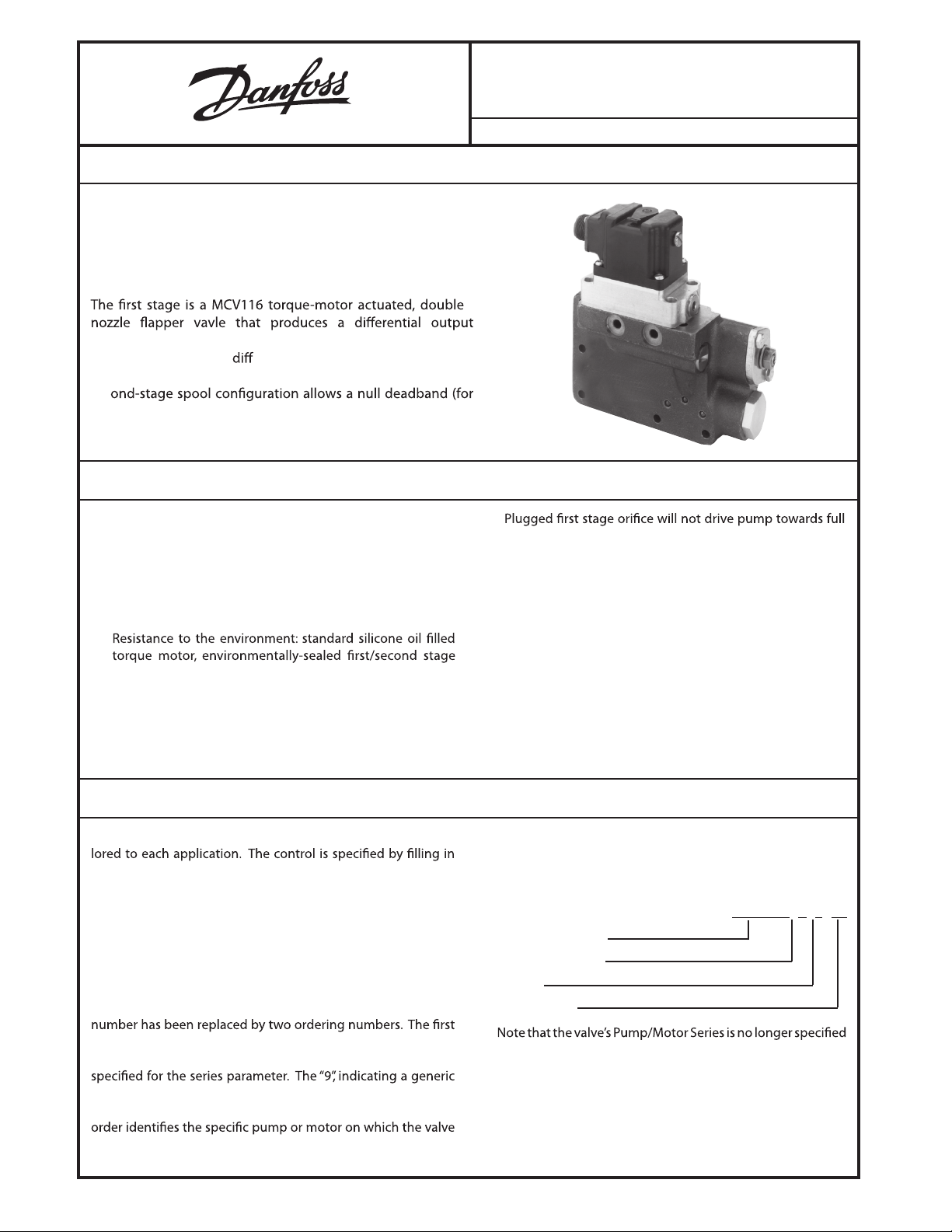

MCV104A

Electrical Displacement Control

DESCRIPTION

The MCV104A Electrical Displacement Control (EDC) is a

two-stage electrohydraulic pump stroke control which uses

a mechanical feedback to establish closed-loop control of the

swashplate angle of Sauer-Danfoss Series 2X and 3X pumps.

-

pressure proportional to the applied electrical signal. The

second stage uses the

spool arrangement and port oil to the pump servocylinders. The

sec

machine safety) in the pump’s output while maintaining

optimum dynamic response to control commands.

erential pressure to drive its double

FEATURES

•

Single command source can be used to control both

hydrostatic pump and motor.

• Servo control deadband independent of signal null deadband: offers safety combined with accurate and responsive

control.

K07116

•

stroke.

• First and second stages can be individually replaced.

• Swashplate movement can be visually detected.

Issued: November 2003

•

interface, full environmental testing.

• Minimum long term null shift.

• Pilot supply screens in series, upstream screen is externally

serviceable.

ORDERING INFORM ATION

A range of options to the basic EDC allows it to be custom-tai-

each slot of the two order numbers, as shown in Tables A and

B. Consult Sauer-Danfoss, Minneapolis, MN, with further questions.

Previous to September, 1985, Electrical Displacement Controls

(EDC’s) and Hydraulic Displacement Controls (HDC’s) were sold

with appropriate linkage assemblies installed for the various

pump options. In order to simplify the inventory process, and

thereby provide faster delivery to customers, this single ordering

number, as described further in the scheme outlined in Table A,

remains the same - the only change being that a “9” is always

valve without linkage, allows the EDC or HDC to be mounted on

any pump or motor. The second number to be included with the

• Single or dual coil torque motor.

• 4 to 20 mA control option.

• Intrinsically safe control option for hazardous atmosperic

environments.

TABLE A. INFORMATION NECESSARY TO SPECIFY

THE EDC

MCV104A

DEVICE IDENTITY

CONFIGURATION

SERIES*

PILOT STYLE

*

in the series slot for the control’s order number; A “9” indicates

a generic control.

X 9 XX

is to be mounted. This in turn determines the components of

the mounting kit, including the appropriate link.

© Danfoss, 2013

K07116 • Rev AB • September 2013

1

Page 2

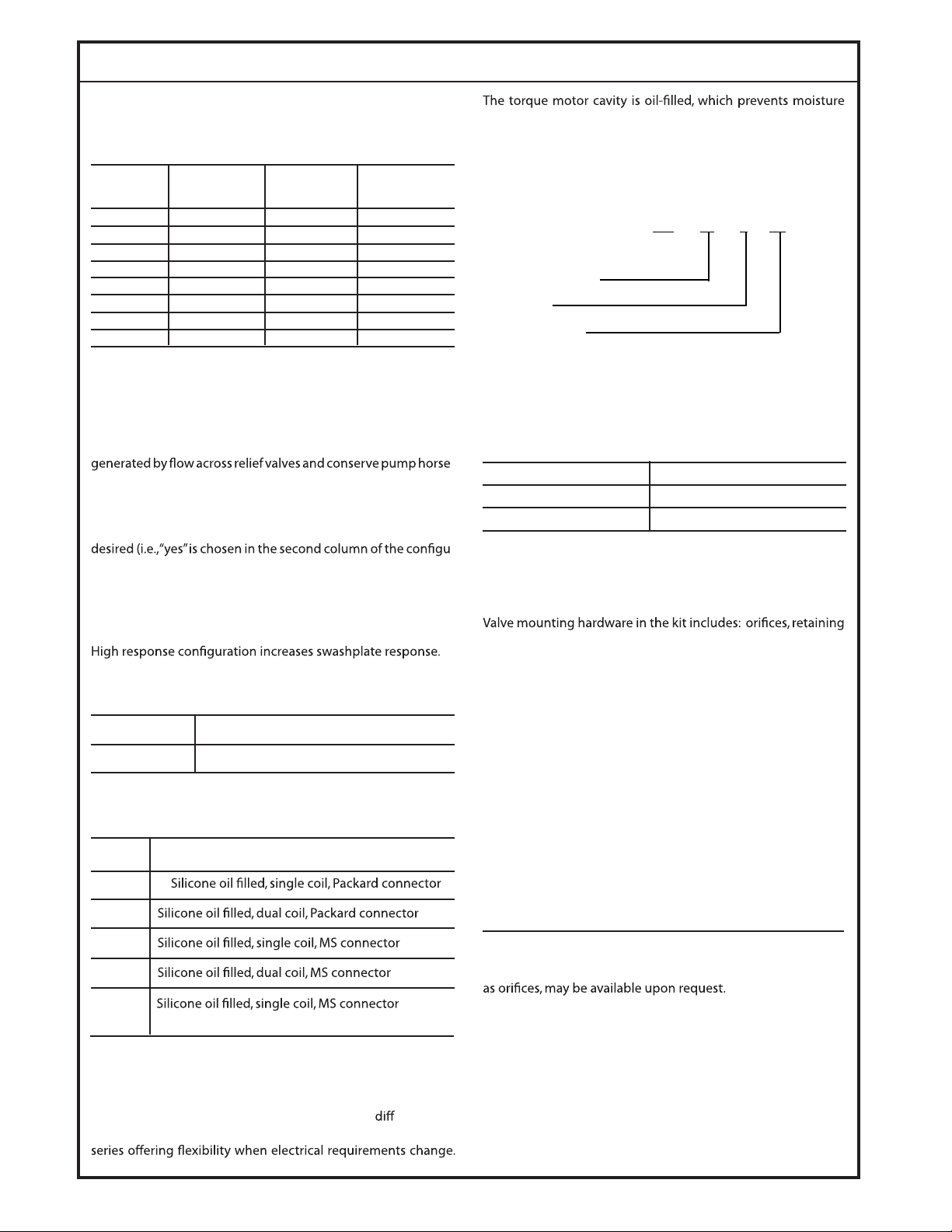

ORDERING INFORMATION (continued)

DEVICE IDENTITY

This is the basic EDC. The model code is MCV104A.

CONFIGURATION

MODEL

CODE

1

2

3

4

5

6

7

8

* Pressure Override Only

PRESSURE

OVERRIDE

Yes

Yes

No

Yes

Yes

HIGH

RESPONSE

Yes

Yes

No

Yes

Yes

SERVO

PORTS

Yes

Yes

Yes

Yes

No

from condensing on the inside during extreme temperature

changes. Dual coil valves have all four pin connections active.

See the Wiring section.

TABLE B. INFORMATION NECESSARY TO SPECIFY THE KIT ASSEMBLY.

PRODUCT TYPE

KIT TYPE

PUMP SERIES

KK

04

XXX

The pressure override and pressure limiter accomplish the

same function - they shift the pump swashplate toward neutral

when system pressure exceeds a preset threshold. They thus

limit maximum system pressure, protect components from heat

power. Pressure override is available only for Series 2X pumps,

and pressure limiting is available only for 3X pumps. Pressure

limiting and annular control are not available together. If the

model code chosen indicates that pressure override function is

ration parameter, above). The pressure override valve must be

obtained through Sauer-Danfoss, Ames, IA. The pressure limiting

feature is inherent in the design of the MCV104 when applied

with the 3X pump.

SERIES

MODEL

9 Any Pump, Less Linkage

The model code is “9”.

PILOT STYLE

MODEL DESCRIPTION

22

DESCRIPTION

PRODUCT TYPE

The model code is "04".

KIT TYPE

MODEL CODE DESCRIPTION

1 Standard EDC

2 EDC with POR

-

PUMP SERIES

20 - 27, 33, 34, or 36.

ring, drag link, spacer plate, swashplate pin, link and ball assembly, hex screws, O-rings and gaskets. In some cases not all the

above are necessary for installation and they are not included

in the kit.

Several Sauer-Danfoss variable pumps come without premounted controls. These pumps will need additional mounting

hardware that generally accompanies the control in order to

accomodate the EDC. The pump numbers are: 34-2035, 34-2060,

34-2080, 36-2047, 36-2056, 36-2081, 36-2082.

If you wish to mount an EDC on one of these pumps, order a

K07015 (9004700-1212) roll pin, a 9004875-0020 straight pin

and a 9340301 (for Series 34 pumps) or 9360354 (for Series 36

pumps) drag link.

23

26

27

40

(4-20 mA)

It may be preferred to apply the dual coil versus the single coil

EDC. The dual coil allows two command sources to be combined

at the torque motor, the resulting signal being the

tween the two. Dual coil models can be connected in parallel or

© Danfoss, 2013

SPARE PARTS

See the Spare Parts Section of this book for a

available for the MCV104. Other non-standard spare parts, such

Order Sauer-Dan foss Pre ssure O verride Valve throug h

Sauer-Danfoss, Ames, IA (515) 239-6000 or Sauer-Danfoss

Distributors.

Order the EDC either factory installed on pumps or as an individual control.

erence be-

K07116 • Rev AB • September 2013

list of

spare parts

2

Page 3

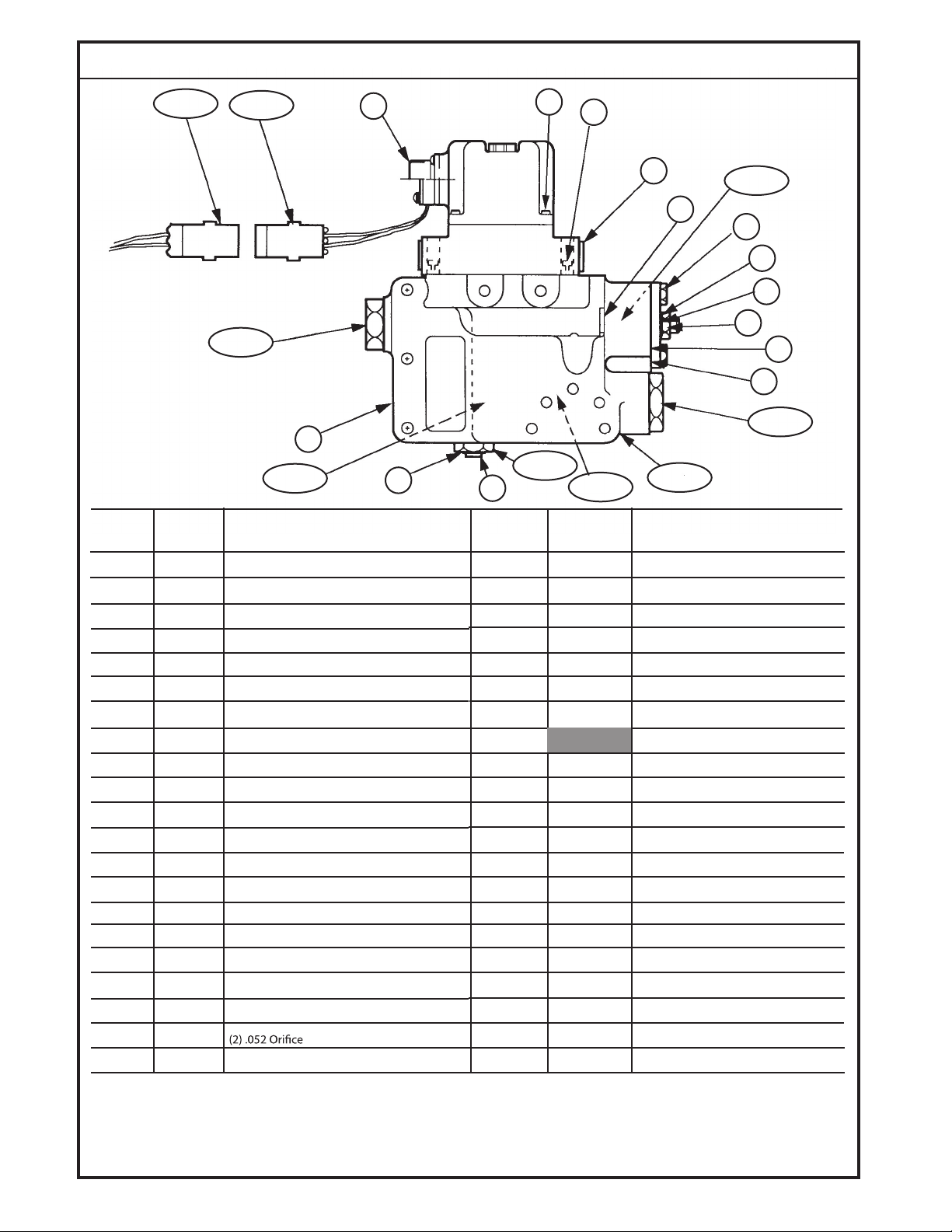

SPARE PARTS

1 - 2 3 - 4

5

29

6

7

30 - 32

8

9

10

11

12

27 - 28

13

14

15 - 16

26

36 - 42

ITEM PART ITEM PART

NUMBER NUMBER (QUANTITY) DESCRIPTION NUMBER NUMBER (QUANTITY) DESCRIPTION

1 K03383 (1) Mating Connector 2-Pin (Unassembled) 22 K07182 (1) EDC Gasket

2 K03384 (1) Mating Connector 4-Pin (Unassembled) 23 K07160 (1) Linkage Bushing

3 K03377 (1) Device Connector 2-Pin (Unassembled) 24 K07009 (1) O-Ring, (1) Linkage Bushing

4 K03378 (1) Device Connector 4-Pin (Unassembled) 25 K02611 (1) Snap Ring

5 K08106 (1) Bag Assembly (Mating Connector) 26 K04448 (1) Plug

6 K07055 (4) #10-24 X 5/8 Socket Head Cap Screw 27 K07159 (1) Plug

7 K01291 (2) Plug 28 K07010 (1) O-Ring for Item 27

8 K22582 (1) Filter Assembly 29 CAUTIO N (4) Do Not Remove Cover Screws

9 K07034 (2) Screw, Neutral Adjust Cover 30 K02361 (1) Piston Pack 14-85 mA

10 K08387 (1) Seal Washer 31 K15631 (1) Piston Pack 4-20 mA

11 K10911 (1) Seal Washer Retainer 32 K07008 (1) O-Ring Piston Pack

12 K07000 (1) #3/8-32 Nut, Neutral Adjust Lock 33 K07005 (1) O-Ring Link Shaft

13 K08133 (1) Gasket Neutral Adjust Cover 34 K07151 (1) Spool Standard

14 K07158 (1) Neutral Adjust Cover 35 K07150 (1) Spool High Response

15 K07028 (1) Plug 36 K03272 (1) Link & Ball Assembly, 20 Frame

16 K07011 (1) O-Ring For Item 15 37 K03273 (1) Link & Ball Assembly, 21/22 Frame

17 K07163 (1) Spacer - SS 20 38 K03274 (1) Link & Ball Assembly, 23 Frame

18 K07164 (1) Spacer - SS 26 39 K03275 (1) Link & Ball Assembly, 24 Frame

19 K07128 (3) Port Screens 40 K03276 (1) Link & Ball Assembly, 25 Frame

20 K07136 41 K03277 (1) Link & Ball Assembly, 26 Frame

21 K07006 (3) O-Ring For Ports 42 K03278 (1) Link & Ball Assembly, 27 Frame

25

33

23 - 24

34 - 35

17 - 22

1238F

For items 17, 18, 20, 21, 22, 25 and 36-42 it is recommended to purchase the appropriate installation kit ensuring the necessary items

for a complete EDC installation.

Item 30 is used for the 14-85 mA models.

Item 31 is used for the 4-20 mA models.

© Danfoss, 2013

K07116 • Rev AB • September 2013

3

Page 4

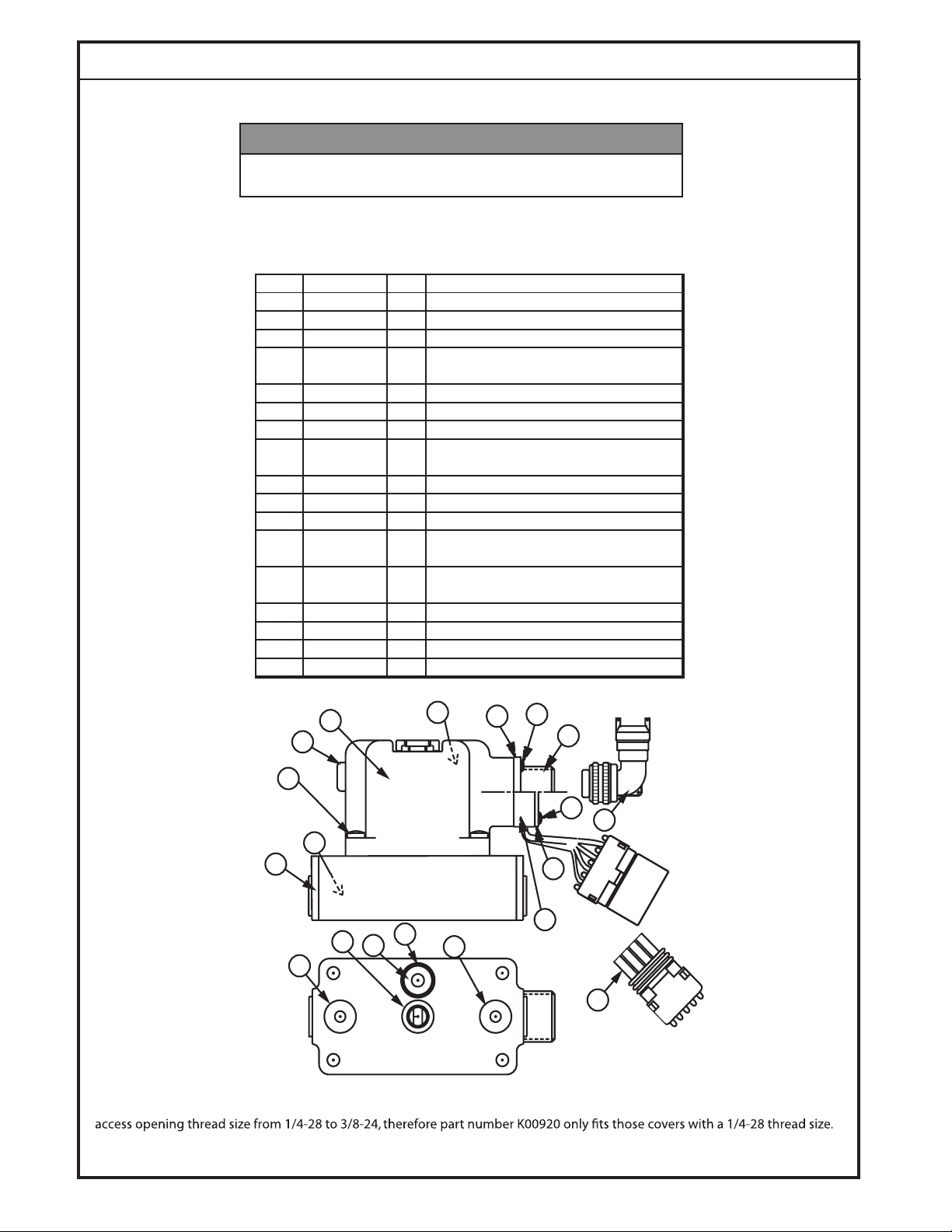

SERVICE PARTS

WARNING

Regarding Service Parts List, Item 3:

DO NOT Remove Cover Screws unless replacing cover.

Service Parts List.

ITEM P/N QTY DESCRIPTION

1 K01291 2 SAE-6 Plugs

2 K07067 4 PCP Mounting Screws

3 K02264 4 PCP Cover Screws

4 K26275 1 3/8-24 PCP Null Access Screw

K00920 1 1/4-28 PCP Null Access Screw

5 K28475 1 PCP Cover Kit

6 K21436 1 Silicone Oil Kit 4000 cs

7 K04790 1 Connector O-ring

8 K08687 4 Connector Screw for MS

9 K01314 1 Connector MS

10 K08688 4 Connector Screw for Packard

11 K08106 1 Mating Electrical Connector MS

12 K08014 1 Feed Through Assy Cover Plate

13 K07533 1 Feed Through Assy 4-pin Packard W-P

K24223 1 Feed Through Assy 4-pin Deutsch

14 K03384 1 Mating Electrical Packard W-P 4-pin

K23511 1 Mating Electrical Deutsch 4-pin

15 K00829 2 O-ring Control Port

16 K00830 1 O-ring Return Port

17 K08573 1 Filter Assy with O-rings

18 K08493 1 O-ring Pressure Port

5

6

4

8

7

9

3

10

11

2

1

12

13

17

18

15

16

15

14

3001B

Note: The Deutsch electrical connectors are not shown. See Item 4, a change was made in January 2000 that increased the null

See Item 5, the preferred part number K28475 includes the cover, gaskets, null access screw, and all the cover seals.

© Danfoss, 2013

K07116 • Rev AB • September 2013

4

Page 5

TECHNICAL DATA

+A

+A

+A

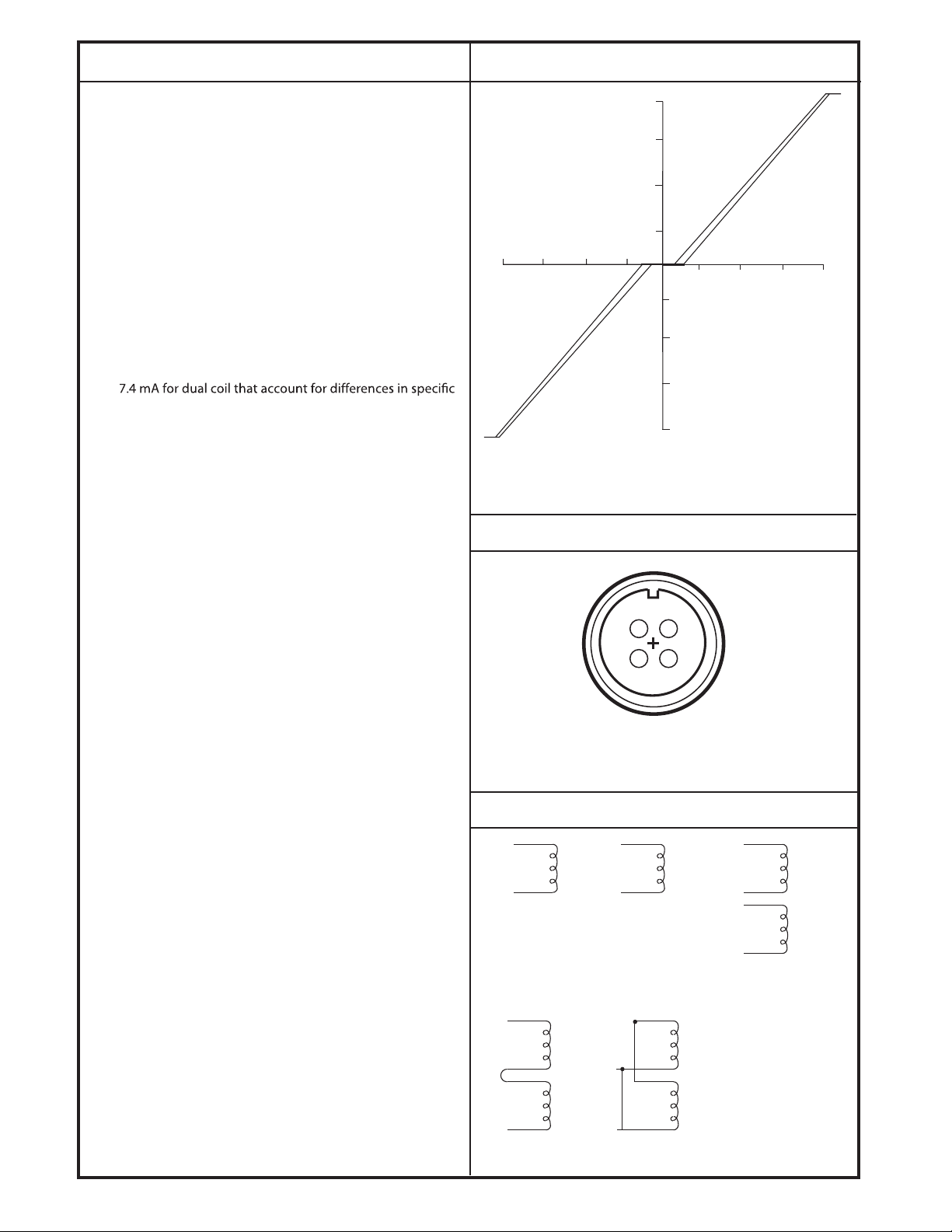

CURRENT VS. SWASHPLATE ANGLE

ELECTRICAL

NOMINAL START CURRENT

18∞

15∞

± 11 mA (single coil)

± 16 mA (using one of the dual coils)

± 8 mA (using the dual coils in series)

10∞

± 16 mA (using the dual coils in parallel)

± 6.25 mA (low current models)

NOMINAL FULL STROKE CURRENT

(See Current vs. Swashplate Angle and Wiring Schemes)

85 ± 12 mA (single coil)

125 ± 18 mA (using one of the dual coils)

80 mA 60 mA 40 mA 20 mA

INPUT CURRENT (MA)

5∞

SWASHPLATE ANGLE (DEGREES)

20 mA 40 mA 60 mA 80 mA

5∞

62 ± 9 mA (using the dual coils in series)

125 ± 18 mA (using the dual coils in parallel)

10∞

18 ± 1.5 mA (low current models)

Current tolerances include ± 5 mA for single coil and ±

15∞

pump series’. For sizing drive sources, use 100 mA in computations for single coil EDC’s.

COIL RESISTANCE @ 24° C (76° F)

23 ohms (single coil)

19.5 ohms (A, B Terminals),

15.5 ohms (C, D Terminals) (dual coil)

650 ohms (low current models)

Current Vs. Swashplate Angle for the MCV104A.

Single-Coil Load Pressure is 3000 PSI and Current Input is 0.01

Hz.

CONNECTION DIAGRAM

18∞

1141

COIL RESISTANCE @ 104° C (220° F)

29 ohms (single coil)

24.7 ohms (A, B Terminals),

19.7 ohms (C, D Terminals) (dual coil)

800 ohms (low current models)

COIL INDUCTANCE

.14 henries (single coil)

D

C

A

B

.062 henries (A, B Terminals),

.047 henries (C, D Terminals) (dual coil)

MAXIMUM CONTINUOUS VOLTAGE @ 93.3° C(200° F)

• 7.5 Vdc for single coil models with the exceptionof those

low current models

Pin Orientation of 4-pin, 90° MS Mating Connector. Part

No. MS3108E-14 S-2S (Sauer-Danfoss Kit No. K08106).

1276

• 14 Vdc for dual coil models in series

• 7.5 Vdc for dual coil models when only one coil or both coils

in parallel are used

WIRING SCHEMES

• 24 Vdc for low curent models.

The EDC is designed to be controlled from a dc current source or

voltage source. Pulse width modulation (PWM) is not required.

But if a PWM signal is used, avoid a carrier frequency <200 Hz.

Do

use a pulse current of more than 120% of that required

not

for full output.

700

Ω

B

SINGLE COIL 20 MA

WITH 15 VDC

INPUT AT FULL STROKE.

(LOW CURRENT MODEL)

24

Ω

B

SINGLE COIL 85 MA

WITH 2.0 VDC

INPUT AT FULL STROKE.

HYDRAULIC

USING ONE OF THE TWO DUAL COILS

OIL VISCOSITY

40 - 6000 SSU

A

+

+

125 MA WITH 1.9 VDC (C, D COIL) OR

2.4 VDC (A, B COIL)

INPUT AT FULL STROKE.

A

19.5

Ω

B

+C

15.5

Ω

D

,

OIL TEMPERATURE

- 40° C (- 40° F) minimum

+ 104° C (+220° F) maximum continuous

+ 116° C (+240° F) maximum intermittent

B

C

35 Ω

(TOTAL

RESISTANCE)

B

C

9 Ω

(TOTAL

RESISTANCE)

AMBIENT OPERATING TEMPERATURE

- 40° to 93° C (- 40° to 200° F)

© Danfoss, 2013

D

DUAL COILS IN SERIES,

62 MA WITH 2.2 VDC

INPUT AT FULL STROKE.

K07116 • Rev AB • September 2013

D

DUAL COILS IN PARALLEL,

125 MA WITH 1.1 VDC

INPUT AT FULL STROKE.

1300

5

Page 6

DIMENSIONS

190,5 [7.50]

S

First stage

econd stage

Packard

connector

assembly

191,0 [7.52]

2 connector

options shown

1

MS connector

Manual operator

Null adjust access screw

Intrinsically safe device

enclosure grounding terminal

Sae J514C —6 (ref. 9/16—18 UNF—2b)

Pilot pressure guage port

(2 places)

Null adjust

Null adjust lock nut

Externally serviceable second

stage inlet screen

Swashplate feedback shaft

190,5 [7.50]

70,6 [2.78]

1

PhasingPositive voltage to either red lead (Pins B or D on either

the Packard or MS Connector; or pins 2 or 4 of the Duetsch Connector)

produces a pressure rise at Output Port-C2.

1122G

Dimensions of the MCV104A in Millimeters [Inches]. Table of

Mounting Bolt Dimensions, Quantity and Part Number by Pump Series.

33, 34, 36 SERIES EDC

27 SERIES EDC W/POR

-

-

4

-

-

3

27 SERIES EDC

-

-

-

-

2

5

-

-

-

-

2

5

26 SERIES EDC W/POR

26 SERIES EDC

4

-

3

-

-

-

-

24, 25 SERIES EDC W/POR

-

-

2

-

-

-

5

4

-

-

-

-

-

-

-

3

24, 25 SERIES EDC

21, 22, 23 SERIES EDC W/POR

21, 22, 23 SERIES EDC

-

-

-

-

-

-

-

4

-

-

2

-

-

-

5

3

20 SERIES EDC W/POR

-

-

-

-

-

4

-

-

-

-

2

-

-

3

5

-

20 SERIES EDC

-

1/4 - 20 X 5 1/4 LG

1/4 - 20 X 4 1/2 LG

-

-

1/4 - 20 X 4 LG

-

1/4 - 20 X 3 3/4 LG

2

1/4 - 20 X 3 1/4 LG

-

1/4 - 20 X 3 LG

5

1/4 - 20 X 2 1/2 LG

-

1/4 - 20 X 2 1/4 LG

SE RI ES DIM "C" DIM "D"

20

21

22

23

24

25

26

27

33

34

36

9.25

9.73

10.29

10.54

12.22

13.30

14.05

15.16

9.54

9.54

10.36

1.35

1.83

2.39

2.64

4.32

5.40

6.15

7.26

1.64

1.64

2.46

DIM "E" DIM "F"

6.97

7.23

7.23

7.67

8.17

8.67

9.74

9.68

7.23

7.23

7.48

4.23

4.64

4.75

5.16

5.51

5.89

6.33

7.10

4.42

4.42

4.75

DIM "F "

3.67

3.26

3.15

2.74

2.39

2.01

1.57

.8 0

3.48

3.48

3.15

© Danfoss, 2013

K07116 • Rev AB • September 2013

6

Page 7

THEORY OF OPERATION

A command source supplies a dc current signal to the pilot stage

of the Electrical Displacement Control. See Internal Workings

Schematic. The input current commands the pilot’s torque motor

stage, a bridge network consisting of an armature mounted on

Two permanent magnets polarized in parallel and a connecting

plate form a frame for the magnetic bridge. At null the armature

is centered in the air gap between the magnet’s opposing poles

by the equivalence of their magnetic forces and the null-adjust

centering springs. As the input current increases, the end of the

armature becomes biased either north or south, depending on

the direction of the current. The resulting armature movement

is determined by the current, the spring constant, and the differential pressure feedback forces, explained next.

toward the other, a erential control pressure results, the high

torque output from the motor equals the torque output from

the pressure feedback, the pilot system is equilibrium. It is this

pressure feedback that makes the pilot a stand-alone closedloop pressure control valve.

The second stage of the EDC uses a unique double spool arrangement that serves to separate the null deadband from the

feedback, giving both safety against null drift and quick dynamic

response to command charges.

erential pressure required to move the actuator spool one

band is moved toward or away from the “A” control port.

erential control pressure (C1-C2) rises beyond the 12 psi

As

deadband, the actuator spool moves in one direction or the other, pivoting the crosslink about its center. The pivoting crosslink

pushes or pulls the porting spool in the opposite direction of the

actuator spool. When the porting spool has moved far enough

to open A or B to supply pressure, oil is ported to the pump servocylinders to move the swashplate. As the swashplate moves, the

drag linkage follows, pivoting the crosslink about the stationary

end of the actuator spool, driving the porting spool back to its

neutral position. Because the feedback

control loop a

and accuracy are enhanced.

.llun ta si metsys eht nehw pord erusserp lanimon a sedivorp

Input phasing is such that, when facing the input shaft of the

pump and rotation is clockwise, current input to the Red (B)

lead or MS connector pin will produce a pressure rise at the “A”

pump.

When the MCV107A Hydraulic Displacement Control - MV is

used on a motor in conjunction with the pump-mounted EDC,

a single electrical command can be used to control both devices.

This is done by “staging” the HDC so that the motor swashplate

starts to destroke just as the pump reaches full stroke. For further

information, see technical literature for the MCV107A.

fter the command has been input, response time

signal is entered into the

.degnahc eb tonnac dna dnabdaed loops rotautca eht fo htdiw

-

The second stage’s null adjust is set with the modulating spring

compressed to the equivalent of 12 psi, which is the amount of

INTERNAL WORKINGS SCHEMATIC, WITH OPTIONAL PRESSURE OVERRIDE

© Danfoss, 2013

Schematic of the Internal Workings of the MCV104A with Optional Pressure Override Valve.

Oil Paths Shown Externally for Clarity.

K07116 • Rev AB • September 2013

1302

7

Page 8

18

18

C

INTERNAL WORKINGS SCHEMATIC, WITHOUT OPTIONAL PRESSURE

Schematic of the Internal Workings of the MCV104A Without Optional Pressure Override Valve.

Oil Paths Shown Externally For Clarity.

TIME VS. SWASHPLATE ANGLE

High response Non-high response ED

1.0

.75

10

Swashplate angle (degrees)

.5.5.25

-10

-18

.25

.75

Time (second)

1.0

1.0

.75

10

Swashplate angle (degrees)

.5.5.25

-10

-18

.25

.75

Time (second)

1.0

Time vs. Swashplate Angle For Annular and Non-Annular EDCs, Run Full-To-Full With a Step Input. EDCs Run Into 1000 PSI Load

PERFORMANCE

RATED CASE AND OPERATING PRESSURE

40 psi

RESPONSE TIME

See Table C.

MAXIMUM HYSTERESIS

4% of peak to peak current excursion

NOMINAL FREQUENCY RESPONSE (Series 22 pump without

STEP RESPONSE

See Time vs. Swashplate Angle.

DIMENSIONS

See Dimensions and Pump Mounting.

1303

1301

© Danfoss, 2013

K07116 • Rev AB • September 2013

8

Page 9

PERFORMANCE ( continued)

TABLE C. MAXIMUM RESPONSE TIME IN SECONDS, OF STANDARD (NON-ANNULAR, NON ORIFICE), ANNULAR AND .052 ORIFICED EDCs.

CHARGE PRESSURE IS LESS THAN 250 PSI. RETURN TO NEUTRAL TIMES ARE APPROXIMATELY 60% OF FULL TO FULL.

SERIES

20

20

20

21

21

21

22

22

22

23

23

23

24

24

24

TYPE FULL TO FULL

STANDARD

ORIFICED

HIGH RESPONSE

STANDARD

ORIFICED

HIGH RESPONSE

STANDARD

ORIFICED

HIGH RESPONSE

STANDARD

ORIFICED

HIGH RESPONSE

STANDARD

ORIFICED

HIGH RESPONSE

1. 9

2. 1

1. 0

2. 9

1. 0

3. 0

1. 6

5. 0

1. 1

ENVI RONMEN TAL

SHOCK

50 g’s for 11 milliseconds. Three shocks in both directions

of the three mutually perpendicular axes for a total of 18

shocks.

SERIES TYPE FULL TO FULL

.6

.4

.7

.5

.7

.7

25

25

25

26

26

26

27

27

27

33, 34

33, 34

33, 34

36

36

36

STANDARD

ORIFICED

HIGH RESPONSE

STANDARD

ORIFICED

HIGH RESPONSE

STANDARD

ORIFICED

HIGH RESPONSE

STANDARD

ORIFICED

HIGH RESPONSE

STANDARD

ORIFICED

HIGH RESPONSE

1. 9

5. 7

1. 3

4. 3

13.0

3. 0

4. 9

15.1

3. 4

.9

1. 8

.5

1. 4

2. 8

.8

2. Resonance dwell for one million cycles for each resonance point in each of the three axes.

Subject to acceleration levels of 1 g to 46 g’s. Acceleration level

varies with frequency.

VIBRATION

Withstands a vibration test designed for mobile equipment

control consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the three axes.

WIRING

Two wiring styles are available: MS and Packard connectors. The

MS connector is Part Number K01314 (MS3102C14S-2P) and has

four pins, only two of which are used (A and B) for single coil

devices. See Connection Diagram for proper wire phasing and

pin locations. For both MS and Packard connectors, phasing is

such that a positive voltage on the Red wire (Pin B) will cause a

pressure rise at the C2 port for single coil valves.

Included in the mating Packard connector bag assembly (which

must be ordered separately) are:

1. 2 (or 4) 14 - 16 gauge sleeves

2. 2 (or 4) 18 - 20 gauge sleeves

3. 1 plastic housing

4. 2 (or 4) green cable seals (accept 2,

diameter)

5. 2 (or 4) gray cable seals (accept 2, 81-3, 49 mm wire

diameter)

6. 2 (or 4) blue cable seals (accept 3, 50-4, 21 mm wire

diameter)

See Ordering Information.

2-2, 8 mm wire

HUMIDITY

After being placed in a controlled atmosphere of 95%

humidity at 49° C (120° F) for 10 days, the EDC will perform

To assemble the female tower connector, use the following

directions:

1. Isolate the wires that extend from the command source to

the EDC.

2. Strip back the insulation 5.5 millimeters on both wires.

3. Push a ribbed cable seal over each of the wires with the

.pit eriw eht drawot slaes eht fo redluohs retemaid-rellams

should be 9.5 millimeters. Thus the insulation should just

protrude beyond the seal.

4. Select the larger of the two sets of pins, as measured at Dimension A (see Dimension A drawing), if using 14-16 gauge

wire. Choose the smaller if using 18-20 gauge. Place the

wire into the socket so that the seal edge is pushed through

and extends slightly beyond the circular tabs that hold it

in place. Crimp in the locations shown in Distance, Packard

Connector diagram with a Packard 12014254 crimp tool

available from your local Packard distributor.

© Danfoss, 2013

K07116 • Rev AB • September 2013

9

Page 10

WIRING ( continued)

5. The distance from the back of the tangs to the furthest rib

may not exceed 19.5 millimeters. See Distance, Packard

Connector diagram.

6. Manually insert the assembled wires into the back end

(large hole) of the plastic housing. Push until the wire detents with an audible click, then pull back slightly to ensure

proper seating. (Observe the proper phasing of the wires

when installing: Black wire to “A” hole, Red to “B”, Black to

“C” and Red to “D”.) Terminals may be removed from the

connector bodies with a Packard 12014012 removal tool.

DIMENSION A.

DIMENSION A

Dimension A For Selecting Correct Terminal.

DIS TANC E, PACK ARD CONNEC TOR

7. Swing the holder down into the detented position to trap

the wires in the housing. The third rib should be sealed into

the housing.

8. Plug the shroud connector from the valve into the tower

connector just constructed. They are sealed with a double

(or quadruple) plug seal over the double (or quadruple)

barrel of the tower assembly. The two connector halves

should detent into each other. See Connector Parts Identi-

1123

Distance From Tang to Third Rib of Packard Connector.

CONNEC TOR PARTS IDENTIFIE D, PACKARD CONNEC TOR

SIDE "B"

CABLE

SEALS

DOUBLE-PLUG SEAL

TOWER CONNECTOR

© Danfoss, 2013

K07116 • Rev AB • September 2013

1077A

RED

BLACK

SIDE "A"

SHROUD

CONNECTOR

1078A

10

Page 11

TROUBLESHOOTING STEPS

1.

pressure when applying an electrical signal, actuate the

take the necessary safety precautions in the event full output

pressure is reached. If output pressure is reached with the

manual operator the problem may be electrical, in which

case skip to step 5.

2. If the manual operator fails to achieve full output in both

directions, ensure a minimum pump charge pressure.

within the PCP such as a lodged particle. Move to step 3

and check for the proper internal pressure reactions.

3. Checking the PCP internal pressures at neutral (null) and

with a full rated electrical command can help isolate a

problem. First shut

the hydraulic system then locate

the two #6 SAE plugs in the sides of the PCP and place a

0-500 psi gage into each of these control ports. Once the

gages are in place start the system. The gage reading will

rise to approximately 40 ± 75 psi. If below 40 psi ensure

Readings should be within 10 psi or less of each other with

no command signal (i.e., 55 and 64 psi). If greater than 15

psi of each other replace the PCP. If the problem is a pump

creep in one direction and the gage readings are relatively

close to within 10 psi of each other, restoring the PCP null

is an option, proceed to step 4. Observe the gage readings

while stroking the valve manually, then stroke it electrically.

If either case fails to reach the proper minimum

erential

pressure (psid) level replace the PCP.

4. To restore the PCP null requires the hydraulic system to

be running and a gage in each control port. Locate and

remove the null access screw, a small amount of silicone

oil will likely escape fr

om this opening which is acceptable.

Then insert a 3/32 allen wrench just beyond this opening

into the adjustment set screw and very slowly adjust CW

and/or CCW until gages are reading the same. Replace the

5. Checking for the proper electrical voltage or current requires

a Volt Ohm Meter (VOM). Check voltage set meter to the

Volt dc scale and place meter leads across the two wires

going to the PCP coil. Voltage requirements may vary from

one PCP model to another:

2.0 to 2.5 volts for single coil 14 to 85 mA models

2.0 to 3.0 volts for dual coil 22 to 130 mA models

4.0 to 15.0 volts for single coil 4 to 20 mA models

When checking current, place the VOM in series between the

electrical controller and the valve. Set the meter to the dc

amp scale and set the range to read mAs. The current level

should reach the minimum. If the proper internal pressures

are reached with the

Step

1), there is likely a problem with the second stage the

electrical signal (see Troubleshooting

PCP is mounted to and it should be replaced.

Manual operator

Null adjust access screwremove screw, make null

adjustment with 3/32 inch

kex key, replace screw

C1

C2

CAUTION

control (EDC), pump or motor, do not adjust the pilot null. Adjust the

second stage valve null.

3002

© Danfoss, 2013

K07116 • Rev AB • September 2013

11

Page 12

INS TAL LATION

A highly reliable connection between the swashplate and the

drag link is necessary for safe operation. An unreliable connec-

Series 3X pumps meet this requirement, but all Series 2X units

not already equipped with an EDC or Hydraulic Displacement

and E-rings used to attach the original drag link. Series 20 and

26 models require a spacer plate between the control and the

pump housing.

Series 21, 22 and 27 pumps with MDCs require changing of the

pump Drag Link before mounting EDC.

Series 3X pumps with Serial Number of 82-34-00000 or greater

units have a clearance notch cast into the swashplate that

provides additional room for link movement. Series 3X pumps

Danfoss.

Prior to mounting any control on a pump, ensure that both the

control and the control feedback link are correct for the pump

as evidenced by the series number stamped on the link and

the part number labeled on the control body. See Table D and

Warning.

TABLE D. TABLE D CORRELATES THE PUMP SERIES NUMBER WITH

THE SERIES NUMBER STAMPED ON THE SIDE OF THE CONTROL

.lortnoc fo ssol gnitluser a htiw kcabdeef fo ssol ni tluser yam noit

FEEDBACK LINK PROTRUDING FROM THE CONTROL.

SERIES LINK MARKING

20, 20 (1/4 spacer)

21, 22 21, 22

23 23

24 24

25 25

26 26 (1 1/2 spacer)

27 27

33, 34, 36 33, 34, 36

WARNING

Exercise care when placing the valve on a surface before

mounting on a transmission. Dropping or otherwise forcefully setting the valve with the linkage down may break the

crosslink, resulting in a lack of response to command.

MOUNTING

Follow the procedure outlined below to attach the EDC to the

pump.

REMOVING THE OLD HARDWARE

1. Thoroughly clean all external surfaces of the pump and

control with steam or solvent. Blow dry.

2. Remove the existing control from the pump by removing

the nine hex head screws from the housing. Slip the pin on

the control linkage out of the end of the swashplate drag

link. See Swashplate Drag Link diagram.

3.

which the control was mounted.

4. Remove the E-ring from the inside end of the connecting

pin. Use caution not to drop the E-ring into the housing

during the removal. See Pin Connection diagram.

5. Remove the pin from the swashplate drag link and swashplate through the case drain port using a magnet or other

tool. Remove the drag link. On some models it may be

necessary to hold the swashplate off neutral to align it with

the case drain hole. See Swashplate Location diagram.

SWASHP LATE D R AG LINK

1124B

Swashplate Drag Link/Control Feedback Link

Connection Between Original Control and Pump.

© Danfoss, 2013

K07116

• Rev AB • September 2013

12

Page 13

PIN CONNECTION

DRAG LINK

REMOVE "E" RINGS,

PIN AMD DRAG LINK

SWASHPLATE LOCATION

1125C

Pin Connection to Swashplate.

Shown Disassembled for Clarity.

MOUNTING (continued)

MOUNTING THE NEW HARDWARE

1. Recheck the series number on the control feedback link to

ensure that it is compatible with the pump. If the control is

an MCV104X9XX (i.e., control less linkage assembly), follow

the procedure outlined below to install the linkage. See

Parts Location diagram.

A. Unscrew the bushing, using care not to damage its

O-ring. See Swashplate Location diagram.

B. Install the new linkage assembly shaft through the

swashplate feedback shaft hole. Place the ball in the

crosslink ball cavity.

WARNING

The control and feedback link must have the proper identi-

improper control feedback link can result in a control failure

which can cause the pump swashplate to move to full angle

and remain there independent of signal input.

Do not attempt to install an EDC on a pump for which it

was not originally designed without changing the link-andball assembly. Merely changing the swashplate drag link

is inadequate. See Ordering Information for the necessary

link-and-ball assembly number. In no case should a valve

originally built for a Series 2X pump be used on a Series

3X pump.

1126B

Location of Swashplate Assembly in Pump Housing.

C. Lubricate the shaft O-ring and replace the bushing

over the shaft. Torque to the body (10 - 15 foot pounds)

so that the feedback shaft extends through the bushing.

D. Install the retaining ring in the groove on the shaft.

2. Align one end of the replacement swashplate drag link with

the holes in the swashplate link arms.

3.

the drag link in the swashplate clevis. It will be necessary

the clevis.

4. Install the retaining ring by forcing it onto the tapered end

.tfahs nip eht no evoorg eht otni skcol ti litnu nip eht fo

Again, use caution not to drop any components into the

pump housing.

5. Install the supplied spacer between the control and the

pump housing. If the pump is a 20 Series, the spacer is

one-quarter inch thick; if it is a 26 Series, the spacer is 1 1/2

inch thick. Other series’ do not require a spacer. One gasket

and 3 O-rings must be installed on the under side of the

spacer.

6.

with the pressure override valve, only one .042-inch diam-

© Danfoss, 2013

the EDC.) Install 3 O-rings and a gasket. If a spacer is used,

there should now be 6 O-rings and 2 gaskets in place.

7. Engage the pin on the control in the drag link and swing

the control into place against the pump housing. The drag

Install the seven mounting screws and tighten to 10-11 foot

pounds of torque.

K07116 • Rev AB • September 2013

.etalphsaws eht fo edis kcolb rednilyc eht no eb dluohs knil

13

Page 14

PARTS LOCATION DRAWING

LINKAGE

ASSEMBLY

OPTIONAL ORIFICES (2)

SWASHPLATE FEEDBACK

SHAFT HOLE

PUMP NEUTRAL ADJUSTMENT

CROSSLINK

BALL

CAVITY

BUSHING

RETAINING

RING

1858

Location of Parts When Installing a New Link and Ball Assembly. Separate Assembly Parts

Shown for Information Only; Do Not Attempt to Disassemble.

1237B

Use the following procedure to bring the pump to neutral

once the Electrical Displacement Control has been mounted.

1. Install a 300 psi gauge into the charge pressure port on the

pump. See the Pump Port Location Drawing.

2. Using a 9/16-inch wrench, loosen the hex lock nut on the null

adjustment screw. See Dimensions and Pump Mounting.

3. Disconnect the elec trica l line at the connec tor.

4. Sta rt t he pri me mover an d run at low idle.

WARNING

To adjust neutral requires operating the pump. Take the

necessary safety precautions such as having unnecessary

personnel stand away from the machine. Maximum system

pressure may occur upon start up, and the machine may

move. Ensure that the operator is not in a position to be

injured should the machine move.

5. Warm

6. Slo

7. If the transmission operates as shown by motor shaft rota-

the system up for several minutes to bleed air.

wly increase the prime mover speed to rated RPM.

tion, reduce speed to idle. Using a 3/16-inch internal hex

wrench, slowly turn the null adjustment screw clockwise or

counterclockwise until the transmission does not .etarepo

Repeat Step 6.

9. Turn the adjustment screw clockwise half the amount of

the turn observed in Step 8. This should be the center of

neutral.

10. Hold the adjustment screw and securely tighten the hex

lock nut on the adjustment screw to 14 - 18 foot pounds.

Note that if a motor is used which does not have a manifold,

neutral should be adjusted (Steps 8 - 10) by observing the

motor shaft rotation without a load.

11. Stop the prime mover.

12. Reconnect the electrical line.

13.

por-

tionally on both sides of the null command. Swashplate

swashplate feedback shaft, shown in Dimensions and Pump

Mounting.

PUMP PORT LOCATION DRAWING

CASE

DRAIN

PORT

LOCKNUT

NULL

ADJUST

8. With a 3/16-inch internal hex wrench, slowly turn the null

adjustment screw clockwise until charge pressure begins

to decrease. Then slowly turn the adjustment screw counterclockwise, observing the angle of

rotation, until charge

pressure decreases again (charge pressure will rise approximately 20 psi in neutral and drop when going into stroke due

to the shifting of the shuttle valve in the motor manifold).

© Danfoss, 2013

CHARGE

PRESSURE

GAUGE

PORT

K07116 • Rev AB • September 2013

1143A

14

Page 15

REPLACING V7058 WITH MCV104 FOR S20 PV

Replacing the V7058A1296 hydrotransmission valve with the

MCV104 EDC valve is acceptable and often recommended. The

MCV104xxxxx can be mounted directly in place of the V7058

without changing the pump drag link. The EDC operates with

lower electrical current and voltage, therefore a 50 to 75 ohm 3

Watt resistor must be placed in series to the EDC. The current/

voltage used for the V7058 will be reduced from approximately

250 mA at 9.0 Volts to 130 mA at 2.6 Volts for dual coil EDC, and

90 mA at 2.3 Volts for single coil EDCs. If a single coil EDC is used,

select a 75 ohm 3 Watt resistor. When using a dual coil EDC, select

a 50 ohm 3 Watt resistor.

The electrical connection is accomplished through two wires wi

the V7058 or EDC. The EDC can be either a single coil (coil A/B)

or dual coil (coils A/B and C/D). If a dual coil EDC is used only the

A and B pin connections are required for operation.

fying the switching function for FWD and REV of the pump if just

a potentiometer is used, i.e., A/B coil for FWD and C/D for REV.

th

-

V7058

PARTS DESCRIPTION PART NUMBER

Resistor, 50-ohm 3-Watt (if using the dual coil model) K04139

Resistor, 75-ohm 3-Watt (if using the single coil model) K04144

ADDITIONAL PARTS (if needed)

EDC installation kit (i.e., 23 frame size and non-POR) KK04123

Mating electrical connector, if Packard for dual coil EDCs K03384

If the EDC is to be the standard or most common, but may

require the dual coil with the Packard connector

CROSS REFERENCE FOR SEREIES 20 EDC PART NUMBERS

CURRENT PART NUMBER REPLACES PART NUMBER

Description

MCV104A 5 9 2 2 Single Coil Packard MCV104A 1 or 5 0 thru 9 0 1 or 2

MCV104A 5 9 2 3 Dual Coil Packard MCV104A 1 or 5 0 thru 9 0 3 or 4

MCV104A 5 9 2 6 Single Coil MS MCV104A 1 or 5 0 thru 9 0 5 or 6

MCV104A 5 9 2 7 Dual Coil MS MCV104A 1 or 5 0 thru 9 0 7 or 8

MCV104A 6 9 2 2 Single Coil Packard MCV104A 2 or 6 0 thru 9 0 1 or 2

MCV104A 6 9 2 3 Dual Coil Packard MCV104A 2 or 6 0 thru 9 0 3 or 4

MCV104A 6 9 2 6 Single Coil MS MCV104A 2 or 6 0 thru 9 0 5 or 6

MCV104A 6 9 2 7 Dual Coil MS MCV104A 2 or 6 0 thru 9 0 7 or 8

MCV104A 7 9 2 2 Single Coil Packard MCV104A 3 or 7 0 thru 9 0 1 or 2

MCV104A 7 9 2 3 Dual Coil Packard MCV104A 3 or 7 0 thru 9 0 3 or 4

MCV104A 7 9 2 6 Single Coil MS MCV104A 3 or 7 0 thru 9 0 5 or 6

MCV104A 7 9 2 7 Dual Coil MS MCV104A 3 or 7 0 thru 9 0 7 or 8

MCV104A 8 9 2 2 Single Coil Packard MCV104A 4 or 8 0 thru 9 0 1 or 2

MCV104A 8 9 2 3 Dual Coil Packard MCV104A 4 or 8 0 thru 9 0 3 or 4

MCV104A 8 9 2 6 Single Coil MS MCV104A 4 or 8 0 thru 9 0 5 or 6

MCV104A 8 9 2 7 Dual Coil MS MCV104A 4 or 8 0 thru 9 0 7 or 8

MCV104

MCV104A5923

© Danfoss, 2013

K07116 • Rev AB • September 2013

15

Page 16

MOOG TO MCV104 CROSSOVER

ITEM MOOG P/N MCV104 P/N FEATURES

1 62-500B MCV104A5927

2 62-501B MCV104A7927 Pressure Override

3 62-502B MCV104A5927

4 62-504B MCV104A7927 Pressure Override

5 62-507B MCV104A1927 Servo Ports

6 62-509B MCV104A3927 Pressure Override & Servo Ports

7 62K518 MCV104A5932 Intrinsically Safe with FM approval

8 62-522B MCV104A4927 Pressure Override & Servo Ports & High Response

9 D062-512D,E, OR F MCV104A1927 Servo Ports

10 E062-562 MCV104A5927

11 D062-862D MCV104A5927

12 63-500 MCV104A5927

Note, the Moog 62-xxxx and 63-xxxx are the same.

© Danfoss, 2013

K07116 • Rev AB • September 2013

16

Loading...

Loading...