Page 1

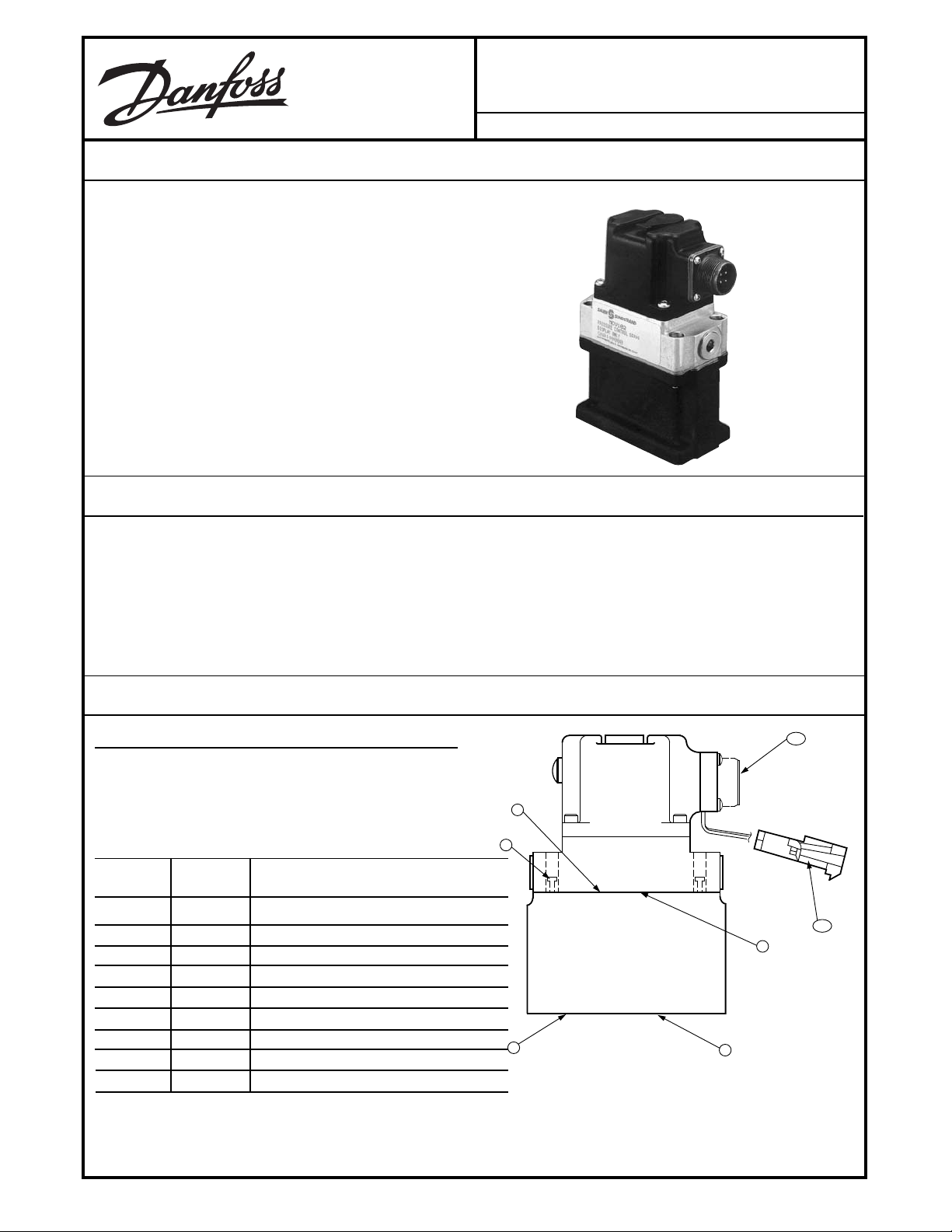

DESCRIPTION

The MCV102A Pressure Control Servovalve (PCS) is a twostage, fourway, closed loop electrohydraulic servovalve that

provides an output differential pressure in response to a low

power electrical input signal. The PCS consists of a closed

loop Pressure Control Pilot Valve and a closed loop pressure

control boost stage valve. The boost stage valve features a

unique double-spool arrangement that has significant cost

and functional advantages over conventional single-spool

deigns.

The PCS has been designed with an output dynamic

response bandwidth sufficient for most high performance

servo control applications. The valve may be used to directly

control cylinders, to control output forces, or as a first stage

to pilot operated high flow main control valves of 40 gpm to

400 gpm flow rates.

FEATURES

MCV102A

Pressure Control Servovalve

BLN-95-8963-4 Issued: October 1998

• Null shift stability over a wide temperature and pressure

range

• Constant pressure gain regardless of supply pressure,

return pressure and load flow demand changes

• Independent dual spool operation maximizes load flow

output while maintaining proper differential pressure

ORDERING INFORMATION

SPECIFY

• MCV102A1006 (PCS with Packard Connector)

• MCV102A1014 (PCS with MS Connector)

• MCV102A2103 (PCS dual coil MS Connector)

SPARE PARTS

ITEM

NUMBER

1 K01314 Device MS Connector

2 K08106 Mating MS Connector (Bag Assembly)

3 K03377 Device Connector 2-Pin (Unassembled)

4 K03383 Mating Connector 2-Pin (Unassembled)

5 K00829 O-Ring (.364 ID x .070)

6 K00834 O-Ring (1.24 ID x .070)

7 K00830 O-Ring (.43 ID x .070)

8 K04793 Socket head cap screw 10 - 32 X 3/4

9 K00832 0-Ring (.551 ID x .070)

PART

NUMBER DESCRIPTION

• Compatible with standard 10 micron nominal filtration

• Pilot stage manual operator allows hydraulic operation

to be verified without electrical signal

• Configured for direct manifold mounting

• GM Packard or MS Connector available

1,2

9

8

3,4

5

7

6

1320A

Location of Spare Parts Item Number.

Mounting manifolds may be made available upon customer request.

© Danfoss, 2013-09 BLN-95-8963-4 1

Page 2

TECHNICAL DATA

ELECTRICAL

RATED FULL PRESSURE CURRENT

See Two Spool, Pressure Control, Static Gain (Single Coil).

±150 mA (single coil ) (23 ohm)

±200 mA (dual coil) (19 and 15.5 ohm)

Maximum input signal is ±250 mA, which will increase

PCS output differential pressure range to approximately

1.2 times that obtained at rated input signal at rated

supply pressure.

COIL RESISTANCE @ 24° C (76° F)

23 ohms (single coil)

19 ohms and 15.5 ohms (dual coil)

COIL INDUCTANCE

.14 Henries (single coil)

.062 Henries (19 ohms, dual coil),

.047 Henries (15.5 ohms, dual coil)

MAXIMUM CONTINUOUS VOLTAGE

7.5 Vdc at 93.3° C (200° F)

HYDRAULIC

FLUID

Petroleum based standard. Other with compatible seals

OIL VISCOSITY

40 - 20,000 SSU

FLUID AND AIR OPERATING TEMPERATURE RANGE

-40° to 104° C (-40° to 220° F)

FLUID AND AIR RATED TEMPERATURE RANGE

-29° to 104° C (-20° to 220° F)

ENVIRONMENTAL

SHOCK

50 G's for 11 milliseconds. Three shocks in both

directions of the three mutually perpendicular axes for a

total of 18 shocks.

VIBRATION

Withstands a vibration test designed for mobile

equipment controls consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the three axes.

2. Resonance dwell for one million cycles for each

resonance point in each of the three axes.

Subject to acceleration levels of 1 to 46 G's.

Acceleration level varies with frequency.

HUMIDITY

After being placed in a controlled atmosphere of 95%

humidity at 49° C (120° F) for 10 days, the PCS will

perform within specification limits. Meets MIL-STD810B.

PERFORMANCE

LOAD FLOW CURVE

See Two Spool, Pressure Control, Load-Flow Curve

(Single Coil).

SUPPLY PRESSURE

1000 psi maximum

500 psi rated

150 psi minimum

RETURN PRESSURE

Atmospheric to 300 psi

SUPPLY FILTRATION

10 micron nominal recommended

RATED OUTPUT DIFFERENTIAL PRESSURE AT 500 PSI

SUPPLY PRESSURE

±225 psid (23 ohms, single coil)

±156 psid (19 and 15.5 ohms, dual coil)

With output ports blocked

RATED OUTPUT FLOW RATE

6.6 gpm minimum (single coil)

With an output load pressure of 175 psid

.7 gpm minimum (dual coil)

With an output load pressure of 100 psid

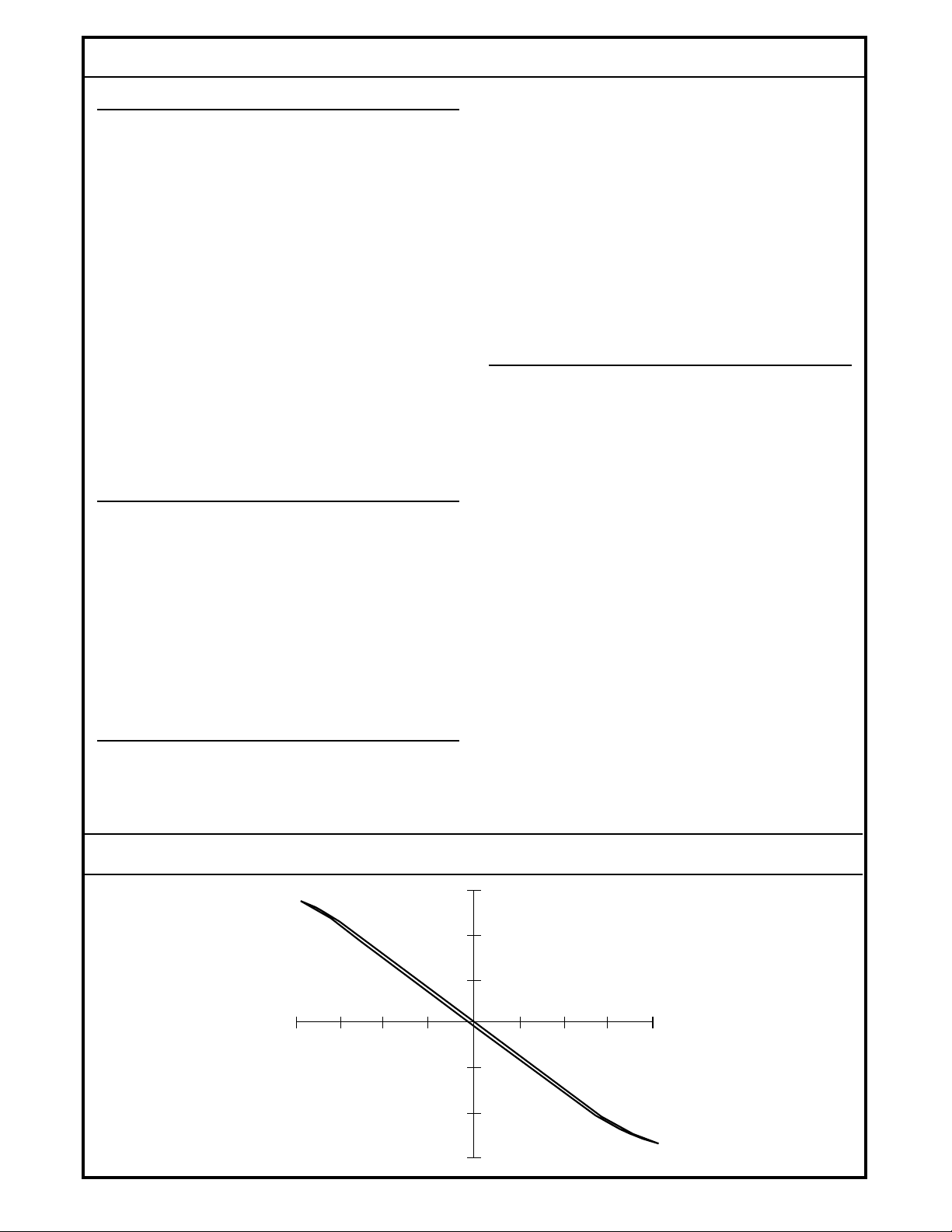

TWO SPOOL, PRESSURE CONTROL, STATIC GAIN (SINGLE COIL)

300

200

100

50 100 150 200

CURRENT INPUT (mA)

100

200

300

2

BLN-95-8963-4

OUTPUT

DIFFERENTIAL

PRESSURE (psid)

200 150 100 50

1253A

Page 3

TECHNICAL DATA (continued)

NEUTRAL LEAKAGE

1.2 gpm maximum

Consisting of pilot stage valve quiescent flow plus boost

stage neutral leakage

LINEARITY

Within 5% of rated signal, maximum

Pressure linearity is the deviation from the best straight

line pressure gain curve in either direction expressed as

a percentage of rated input signal. Null region (±4%

OUTPUT PORT NULL PRESSURE

0 psid

With supply pressure at 500 psi above return pressure,

each output port pressure will be 115 psi nominal

signal) pressure gain may vary from 50 to 200% of

nominal pressure gain due to boost stage null

adjustment. Pressure linearity in each direction is

specified from 4% to 90% input signal with a constant

pressure drop across the valve.

THRESHOLD

Less than 1% of rated input signal

SYMMETRY

Will not exceed 5% in each direction

HYSTERESIS

5% of rated input signal, maximum

Symmetry is the difference in output differential

pressure in each direction at rated input signal

expressed as a percentage of the mean output

differential pressure.

TWO SPOOL, PRESSURE CONTROL, LOAD-FLOW CURVE (SINGLE COIL)

LOW PRESURE VERSION

Pressure control servovalve

Supply pressure: 500 psi

LOAD-FLOW (P-Q) CURVE - PCS

10

FLOW (gpm)

8

175 mA

150 mA

200 mA

250 mA

225 mA

TECHNICAL DATA (continued)

PRESSURE NULL SHIFT

< ±1.5% (23 ohms, single coil)

< ±1.0% (19 and 15.5 ohms, dual coil)

TEMPERATURE NULL SHIFT

< ±3 psid (23 ohms, single coil)

< ±2 psid (19 and 15.5 ohms, dual coil)

125 mA

100150200250

100 mA

75 mA

6

4

2

25 mA

50

2

50 mA

25 mA

4

6

8

10

75 mA

50 mA

50 100 150 200 250

100 mA

125 mA

150 mA

175 mA

200 mA

225 mA

250 mA

1254A

by a current driver-type amplifier. The oil trapped

between the two output ports does not exceed .4 cubic

inches. See Two Spool, Pressure Control, Dynamic

Response.

DIMENSIONS

See Dimensions

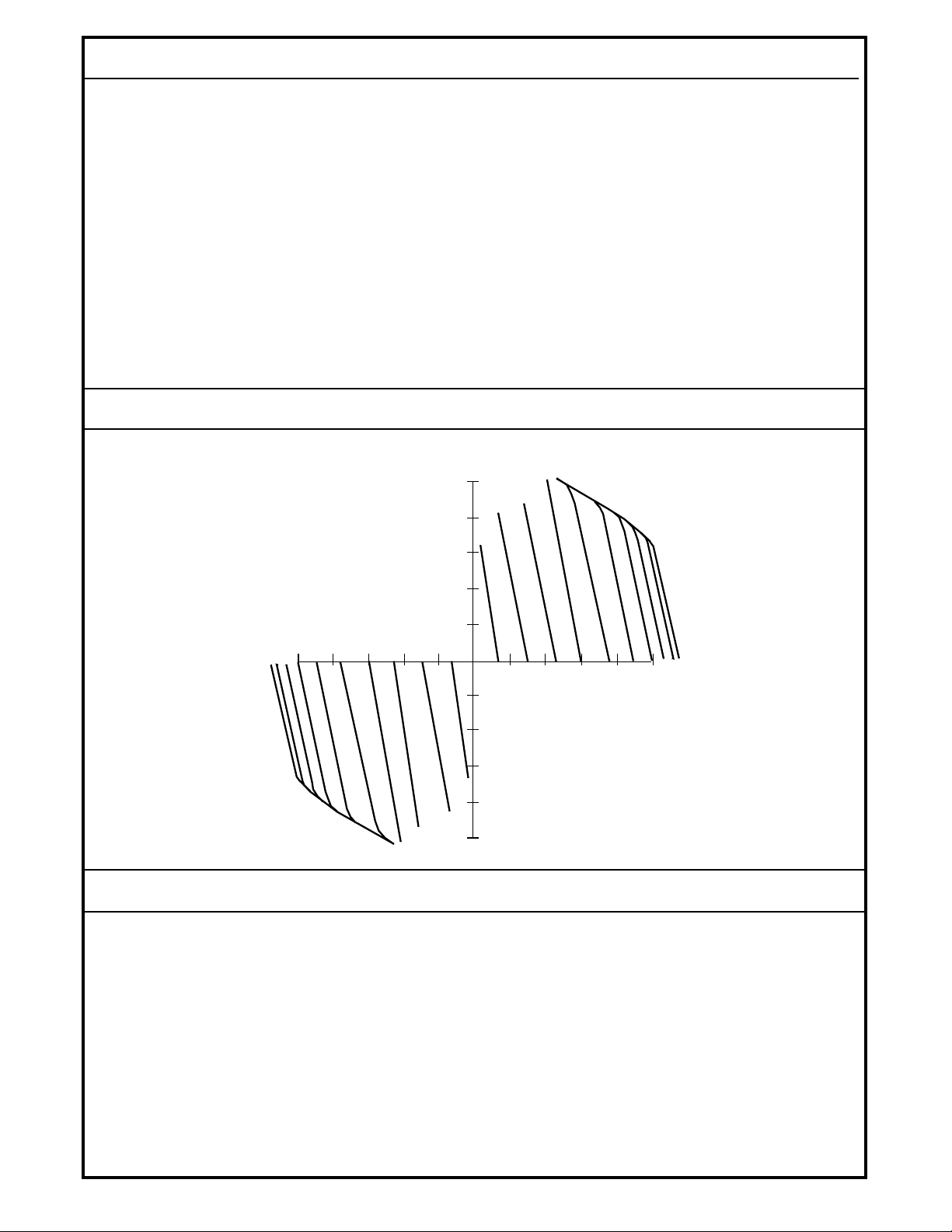

FREQUENCY RESPONSE

85 Hz minimum at -3db

70 Hz minimum at 90° phase lag

Specified at 500 psi supply pressure above return

pressure, blocked output ports and an input signal of

±30% to ±50% of rated input signal. The PCS is driven

3

BLN-95-8963-4

Page 4

TWO SPOOL, PRESSURE CONTROL, DYNAMIC RESPONSE

LOW PRESURE VERSION

Pressure control servovalve

±20 mA input

Supply pressure: 500 psi

Differential pressure output

6.00

BODE PLOT

0.00

-6.00

-12.00

-18.00

-24.00

20 x LOG MAGNITUDE

-30.00

– 10 100 1000

FREQUENCY (Hz)

0.00

-30.00

-60.00

-90.00

-120.00

-150.00

PHASE (DEGREES)

-180.00

– 10 100 1000

DIMENSIONS

FREQUENCY (Hz)

1255B

3/8 O.D. TUBE FITTING

O-RING PORT, PER SAE — J514

9/16 — 18 UNF (2) — PL.

(PLUGS INSTALLED)

79,56

(3.12)

140,76 mm ±0.03

(5.52)

61,20

(2.4)

(0.35)

5,64 (DIA.)

(.221)

4 PL.

8,9

NULL

ADJUST

ACCESS

SCREW

85,6

(3.37)

MANUAL

OPERATOR

OPTIONAL MS

CONNECTOR

ELECTRICAL CONNECTOR:

HIGHER POTENTIAL AT

RED LEAD PRODUCES

FLOW OUT C2 TO LOAD,

BACK TO C1.

P = SYSTEM PRESSURE

S

P = RETURN PRESSURE

T

C = OUTPUT CONTROL PORT 1

1

C = OUTPUT CONTROL PORT 2

2

WEIGHT: 1.97 kg (4.33 lbs.)

6,1 (0.24)

19,05

(0.750)

34,9

(1.375)

38,1

(1.50)

116,53 mm ±0.03

(4.57)

BLN-95-8963-4

11,4

(0.450)

38,1

(1.50)

64,77

(2.55)

76,2

(3.0)

Dimensions of the MCV102A PCS in Millimeters (Inches).

4

1284A

Page 5

THEORY OF OPERATION

The MCV102A PCS uses a torque motor actuated, doublenozzle flapper pilot and a double-sliding spool boost stage.

See Internal Workings Schematic. The current input to the

pilot produces a proportional control output differential

pressure to the second stage. The differential pressure is

independent of supply pressure, return pressure and control

characteristics of the valve.

As the electrical input from the command source to the pilot

stage is varied, the pressure signals (P1 and P2) to the boost

stage change, with one increasing and the other decreasing.

This causes the spool to seek a new position, with the higher

INTERNAL WORKINGS SCHEMATIC

POLE

PIECE

AIR GAP

P

S

P1

P1

FLAPPER

ARMATURE

MAGNET

P2

COIL

POLE

PIECE

PIVOT

PLATE

P

S

P2

ORIFICE

NOZZLE

pressure spool moving down and the lower pressure spool

moving up. The new spool position is determined when a

change in the spool land varies the orifice size between

supply pressure and the appropriate work port (A or B),

resulting in a new work pressure (PA or PB). The work

pressure is fed back to the underside of the spool until it

equals the pilot pressure. Spool modulation (which acts like

dither) continues until, at equilibrium, the output differential

pressure is equal to the input differential pressure. Power is

boosted by retaining these pressures at a much higher flow

rate capability.

CONNECTION DIAGRAM

D

C

A

B

1276

P

T

P

Pa

Pa

PORT "A" PORT "B"

Pressure Control Servovalve,Two Spool Design.

P

LOAD

S

Pb

Pb

1292

S

WIRING

Two wiring styles are available: MS and GM Packard

Connectors. The MS Connector is part number MS3108E14S-2S (Danfoss Kit No. K08106) and has four

pins, two of which (A and B) are used. See Pin Orientation of

the Optional MS Connector, Part Number MS3108E-14S-2S

(Danfoss Kit No. K08106). The Packard Connector

a two pin connector. In both cases, phasing is such that

is

a positive voltage on the Red wire (Pin B) will cause a

pressure increase at the C2 port (see Dimensions).

Pin Orientation of 4-pin, 90° MS Mating Connector. Part

No. MS3108E-14S-2S (Danfoss Kit No. K08106).

The Packard Connector PCS includes a bag assembly for

the mating female connector half comprised of:

1. 2, 14-16 gauge sleeves

2. 2, 18-20 gauge sleeves

3. 1 plastic housing

4. 2 green cable seals

5. 2 gray cable seals

6. 2 blue cable seals

See Ordering Information.

To assemble the female mating connector, use the following

directions:

1. Isolate the wires that extend from the command source

to the PCS.

2. Strip back the insulation 5.5 millimeters on both sides.

5

BLN-95-8963-4

Page 6

WIRING (continued)

3. Push ribbed cable seal over each of the wires with the

smaller-diameter shoulder of the seals toward the wire

tip. Select the pair of seals that fits tightly over the wires.

The distance from the tip of the wires to the first (nearest)

rib should be 9.5 millimeters. Thus the installation should

just protrude beyond the seal.

3. Push ribbed cable seal over each of the wires with the

smaller-diameter shoulder of the seals toward the wire

tip. Select the pair of seals that fits tightly over the wires.

The distance from the tip of the wires to the first (nearest)

rib should be 9.5 millimeters. Thus the installation should

just protrude beyond the seal.

4. Select the larger of the two sets of pins, as measured at

Dimension A (see Dimension A drawing), if using 14-16

gauge wire. Choose the smaller if using 18-20 gauge.

Place the wire into the socket so that the seal edge is

pushed through and extends slightly beyond the circular

tabs that hold it in place. Crimp in the locations shown

in Distance, Packard Connector diagram with a Packard

12014254 crimp tool available from your local Packard

distributor.

DIMENSION A.

5. The distance from the back of the tangs to the furthest

rib may not exceed 19.5 millimeters. See Distance,

Packard Connector diagram.

6. Manually insert the assembled wires into the back end

(large hole) of the plastic housing. Push until the wire

detents with an audible click, then pull back slightly to

ensure proper seating. (Observe the proper phasing of

the wires when installing: Black wire to “A” hole, Red to

“B”.) Terminals may be removed from the connector

bodies with a Packard 12014012 removal tool.

7. Swing the holder down into the detented tower

assembly. The two connector halves should detent into

each other. See Connector Parts Identified, Packard

Connector.

DIMENSION A

Dimension A For Selecting Correct Terminal.

DISTANCE, PACKARD CONNECTOR

CONNECTOR PARTS IDENTIFIED,

PACKARD CONNECTOR

CABLE

SEALS

SIDE "B"

DOUBLE-PLUG SEAL

TOWER CONNECTOR

RED

SIDE "A"

SHROUD

CONNECTOR

1123

BLACK

Distance From Tang to Third Rib of Packard Connector.

BLN-95-8963-4

1077A

1078A

Interlocked Connector Halves With Parts Identified.

Two Wire Connection Shown.

6

Page 7

START UP PROCEDURE

With the electrical connector at the PCS's pilot stage

disconnected, apply hydraulic power to the system. If the load

starts to drift, the PCS is off and will need adjustment. Use a

3/32 inch Allen wrench in the hole covered by the screw in the

pilot cover. Do not exceed more than one turn in either

THROUBLESHOOTING

The most common failure of the pressure control system is

sluggish or no response to electrical command from the

cylinder. If this is the case, follow the procedure below:

Jog the manual operator on the pilot valve. If the cylinder

response is over its full range, disconnect the connector on

the pilot stage. Use a voltohmeter to check the resistance

across pins A and B.

• If the coil resistance is between 22 and 30 ohms, (single

coil) check the resistance between each pin and the

case.

• If the coil resistance is less than 1000 ohms, the pilot coil

is bad and the valve should be replaced.

• If the coil resistance is greater than 1000 ohms, the PCS

is receiving a bad electrical signal. Check the command

source and the connecting cables.

• If the coil resistance is outside the 22 - 30 ohms (single

coil) range, the pilot is bad and the valve should be

replaced.

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

DEVICE REPAIR

For devices in need of repair or evaluation, include a

description of the problem and what work you believe

needs to be done, along with your name, address and

telephone number.

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH& Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: +49 4321 871-0

Fax: +49 4321 871-284

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

7

BLN-95-8963-4

Loading...

Loading...