Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

VLT® Factory Tool MCT 21

www.danfoss.com/drives

Page 2

Page 3

Contents Operating Instructions

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Further Information

1.3 Product Overview

1.4 Document and Software Version

2 Safety

2.1 Safety Symbols

2.2 Qualified Personnel

2.3 Safety Precautions

3 Installation and Set-up

3.1 Installation

3.2 De-installation

3.3 Set-up

4 Workflow

4.1 Interaction of Engineering Tool and Technician Tool

3

3

3

3

3

4

4

4

4

6

6

6

6

7

7

4.2 Workflow Engineering Tool

4.3 Workflow Technician Tool

5 Engineering Tool Functions

5.1 Project

5.1.1 Create a Project 10

5.1.2 New Project - Create from Database 10

5.1.3 New Project - Read from Drive 12

5.1.4 Open Project 12

5.1.5 Search Project 13

5.1.6 Create Order 13

5.1.7 Copy Project 15

5.1.8 Upgrade a Project to New Firmware 16

5.2 Motor Database

5.3 Motor Library

5.3.1 Common Motor Library 19

5.3.2 Export Library 21

5.3.3 Copy the Common Motor Library 21

8

9

10

10

17

19

5.4 SIVP (Specific Initial Values and Protection)

5.4.1 Define the SIVP 22

5.4.2 SIVP Examples 24

5.4.3 Copy SIVP Library 25

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 1

22

Page 4

Contents Operating Instructions

5.5 Tests

5.5.1 Create Test 25

5.5.2 Edit Test 26

5.5.2.1 Commands 26

5.5.2.2 Editing Procedure 27

5.5.3 Control Word according to FC Profile (CTW) 28

5.5.4 Definition of Reference 30

5.5.5 Select and Run Test, View Test Report 30

5.5.6 Remove Test 30

5.5.7 Copy Test 31

5.6 Settings Menu

5.6.1 General Settings 32

5.6.2 Drive Communication 32

6 Technician Tool Functions

6.1 Project

6.1.1 Open a Project 33

6.1.2 Project View 33

25

32

33

33

6.2 Motor Database

6.3 SIVP

6.4 Tests

Index

6.1.3 Project Review and Adjustments 33

6.1.4 Create an Order 34

6.1.5 Write to Frequency Converter 34

6.1.6 Compare 35

35

35

6.3.1 Select 35

6.3.2 Write to Frequency Converter 35

35

6.4.1 Test and Documentation 35

37

2 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 5

Introduction

1 Introduction

Operating Instructions

1

1

1.1 Purpose of the Manual

This manual provides basic knowledge required to use the

VLT® MCT 21 Factory Tool with VLT® DriveMotor FCP 106

and FCM 106 frequency converters.

Familiarity with the following is assumed:

MS®-WindowsTM at user level.

•

Set-up, process knowledge, and operation of

•

frequency converters.

Connection, set-up, and use of communication

•

equipment.

Familiarity with the PC or PLC master of the

•

system.

Issues regarding hardware or software produced by other

manufacturers are beyond the scope of this manual, and

are not the responsibility of Danfoss.

The manual does not provide detailed information

regarding:

Specific applications

•

Possible solutions

•

Related parameter combinations in the set-up

•

and use of a frequency converter.

1.3

Product Overview

1.3.1 Intended Use

The MCT 21 Factory Tool enables the creation of factory

settings and testing of the frequency converter in the

factory. The software comprises 2 tools:

Engineering Tool

•

Technician Tool

•

For details of the interaction of these tools, refer to

chapter 4.1 Interaction of Engineering Tool and Technician

Tool.

System Requirements

1.3.2

Supported operating systems:

Windows 7 (32 bit) Service Pack 1

•

Windows 7 (64 bit) Service Pack 1

•

Windows XP (32 bit) Service Pack 3

•

Additional system requirements:

Minimum screen resolution: 1024 × 768

•

Minimum physical memory: 256 MB

•

Communication bus: Danfoss FC protocol on

•

RS-485

VLT® is a registered trademark.

1.2

Further Information

Literature available:

VLT® DriveMotor FCP 106 and FCM 106 Operating

•

Instructions

VLT® DriveMotor FCP 106 and FCM 106

•

Programming Guide

VLT® DriveMotor FCP 106 and FCM 106 Design

•

Guide

The full range of manuals, instructions, and software

downloads is available at:

http://www.danfoss.com/BusinessAreas/DrivesSolutions

Prerequisite installed software:

VLT® Motion Control Tool MCT 10 software. MCT

•

21 Factory Tool uses the parameter database

from MCT 10.

1.4

Document and Software Version

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the document version and the corresponding MCT 21

Factory Tool software version.

Edition Remarks

MG10X1 New document 1.20 and later versions

Table 1.1 Document and Software Version

MCT 21 Factory Tool software

version

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 3

Page 6

Safety

Operating Instructions

2 Safety

22

2.1 Safety Symbols

The following symbols are used in this document:

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.2 Qualified Personnel

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the troublefree and safe operation of the frequency converter. Only

qualified personnel are allowed to install or operate this

equipment.

Qualified personnel are defined as trained staff, who are

authorised to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Additionally, the personnel must be familiar

with the instructions and safety measures described in

these operating instructions.

2.3

Safety Precautions

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input power. Failure to perform

installation, start up, and maintenance by qualified

personnel could result in death or serious injury.

Only qualified personnel are permitted to

•

perform installation, start up, and maintenance.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

DC power supply, or load sharing, the motor can start at

any time. Unintended start during programming, service,

or repair work can result in death, serious injury, or

property damage. The motor can start with an external

switch, a fieldbus command, an input reference signal

from the LCP or LOP, via remote operation using a

software tool, or after a cleared fault condition.

To prevent unintended motor start:

Disconnect the frequency converter from mains.

•

Press [Off/Reset] on the LCP before

•

programming parameters.

Ensure the frequency converter, motor, and any

•

driven equipment are fully wired and

assembled when the frequency converter is

connected to AC mains, DC power supply, or

load sharing.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors,

which can remain charged even when the frequency

converter is not powered. Failure to wait the specified

time after power has been removed before performing

service or repair work could result in death or serious

injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link power

•

supplies, including battery back-ups, UPS, and

DC-link connections to other frequency

converters.

Disconnect or lock the PM motor.

•

Wait for the capacitors to discharge fully before

•

performing any service or repair work. The

duration of waiting time is specified in

Table 2.1.

Minimum waiting

[kW]

1)

time

(min)

Voltage

[V]

3x400 0.55–7.5 4

High voltage can be present even when the warning LED

Power range

indicator lights are off.

Table 2.1 Discharge Time

1) Power ratings relate to normal overload (NO).

4 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 7

Safety Operating Instructions

WARNING

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

Ensure that only trained and qualified

•

personnel perform installation, start up, and

maintenance.

Ensure that electrical work conforms to national

•

and local electrical codes.

Follow the procedures in this manual.

•

WARNING

UNINTENDED MOTOR ROTATION

WINDMILLING

Unintended rotation of permanent magnet motors can

result in serious injury or equipment damage.

Ensure that permanent magnet motors are

•

blocked to prevent unintended rotation.

WARNING

LEAKAGE CURRENT HAZARD

Follow national and local codes regarding protective

earthing of equipment with a leakage current exceeding

3.5 mA. Frequency converter technology implies high

frequency switching at high power. This switching

generates a leakage current in the ground connection. A

fault current in the frequency converter at the output

power terminals can contain a DC component which can

charge the filter capacitors and cause a transient ground

current. The ground leakage current depends on various

system configurations including RFI filtering, screened

motor cables, and frequency converter power. EN/IEC

61800-5-1 (Power Drive System Product Standard)

requires special care because the leakage current

exceeds 3.5 mA. See EN 60364-5-54 paragraph 543.7 for

further information.

Ensure correct grounding of the equipment by

•

a certified electrical installer.

Grounding must be reinforced in one of the

•

following ways:

- Ensure the ground wire has a crosssection of at least 10 mm2, or

- Ensure 2 separate ground wires, both

complying with the dimensioning

rules, are used.

NOTICE

HIGH ALTITUDES

For installation at altitudes above 2000 m, contact

Danfoss regarding PELV.

WARNING

DC CURRENT RISK

This product can cause a DC current in the protective

conductor. Failure to follow the precautions can lead to

personal injury or property damage.

Take the following precautions:

Where a residual current device (RCD) is used

•

for extra protection, use only an RCD of Type B

(time delayed) on the supply side of this

product.

Protective earthing of the frequency converter

•

and the use of RCDs must always follow

national and local regulations.

WARNING

GROUNDING HAZARD

For operator safety, it is important to ground the

frequency converter properly in accordance with national

and local electrical codes, as well as the instructions in

this manual. Ground currents are higher than 3.5 mA.

Failure to ground the frequency converter properly could

result in death or serious injury.

It is the responsibility of the user, or certified electrical

installer, to ensure correct grounding of the equipment

according to national and local electrical codes and

standards.

Follow all local and national electrical codes to

•

ground electrical equipment properly.

Establish proper protective grounding for

•

equipment with current higher than 3.5 mA.

A dedicated ground wire is required for input

•

power, motor power, and control wiring.

Use the clamps provided on the equipment for

•

proper ground connections.

Do not ground one frequency converter to

•

another in a daisy chain fashion.

Keep the ground wire connections as short as

•

possible.

Use high-strand wire to reduce electrical noise.

•

Follow the motor manufacturer wiring

•

requirements.

2 2

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 5

Page 8

Installation and Set-up Operating Instructions

3 Installation and Set-up

3.1 Installation

33

Prerequisite: MCT 10 Set-up Software is installed.

To install the MCT 21 Factory Tool,

1.

Run the file MCT 21 Factory Tool Setup x.x.exe,

where “x.x” refers to the software version. No key

is required.

2. Select during installation:

2a Technician Tool, and/or

2b Engineering Tool

3. Open the programme.

3.3.2 Serial Fieldbus Communication

To set up serial fieldbus communication with the

frequency converter, refer to chapter 5.6.2 Drive Communi-

cation.

3.2 De-installation

NOTICE

De-installation procedure for a Windows operating

system:

1.

Select Start.

2.

Select Settings.

3.

Select Control Panel.

4.

Double-click Programs and Features.

5. Select MCT 21 Factory Tool software.

6.

Select Uninstall.

3.3

Set-up

3.3.1 General Settings

For detailed information regarding general settings, refer

to chapter 5.6.1 General Settings.

Open the MCT 21 Factory Tool software.

•

The first time the program runs, the New Project

•

dialog appears. For more information, see

chapter 5.1.2 New Project - Create from Database.

Go to [Settings → General Settings].

•

In the General Settings dialog:,

•

Set the application and parameter

-

languages.

Set the OEM password.

-

NOTICE

PASSWORD MATCH

Note that data can be password-protected in the

frequency converter. Set the OEM password to match the

frequency converter password. Otherwise no access is

granted.

6 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 9

Workflow

Operating Instructions

4 Workflow

4.1 Interaction of Engineering Tool and

Technician Tool

The MCT 21 Factory Tool software comprises 2 tools which

interact:

Engineering Tool

•

Technician Tool

•

Develop projects and tests in the Engineering Tool before

implementation in the Technician Tool.

Engineering Tool - Development

The Engineering Tool is intended for use by engineers in

developing projects and tests for planning factory

implementation of frequency converter default settings.

The engineer uses the Engineering Tool to:

Create projects.

•

Set up default parameter settings for OEM

•

production.

Create, design, and verify tests.

•

Manage passwords, motor database, general

•

settings, and communication with the frequency

converter.

Process orders received.

•

Access change and test logs.

•

For Engineering Tool workflow, refer to

chapter 4.2 Workflow Engineering Tool.

For details of Engineering Tool functions, refer to

chapter 5 Engineering Tool Functions.

Technician Tool - Implementation

The Technician Tool is intended for use by technicians

working in the production line. The technician is familiar

with how to assemble the frequency converter and motor.

The technician uses the Technician Tool to:

Create custom set-ups for the frequency

•

converter.

Configure the frequency converter with new

•

settings.

Select and run tests.

•

Manage communication with the frequency

•

converter.

The technician uses projects and tests developed in the

Engineering Tool.

For Technician Tool workflow, refer to chapter 4.3 Workflow

Technician Tool.

For details of Technician Tool functions, refer to

chapter 6 Technician Tool Functions.

4 4

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 7

Page 10

Workflow Operating Instructions

4.2 Workflow Engineering Tool

44

Illustration 4.1 Engineering Tool Workflow

For details of each step refer to the following:

Chapter 5.1.1 Start

•

Chapter 5.1.1 Create a Project

•

Chapter 5.1.4 Open Project and chapter 5.1.5 Search Project

•

Chapter 5.4.1 Define the SIVP

•

Chapter 5.2.1 Define a Motor Database

•

Chapter 5.3.1 Common Motor Library

•

Chapter 5.3.2 Common Motor Library Management

•

Chapter 5.5.5 Select and Run Test, View Test Report

•

Chapter 5.5.1 Create Test and chapter 5.5.2 Edit Test

•

8 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 11

Workflow Operating Instructions

4.3 Workflow Technician Tool

4.3.1 Overview of Workflow

4 4

Illustration 4.2 Technician Tool Workflow

For details of each step refer to the following:

Step 1: chapter 6.1.2 Project View

•

Step 2 (optional): chapter 6.1.3 Project Review and Adjustments

•

Alternative to Step 2: chapter 5.1.6 Create Order

•

Step 3: chapter 6.1.5 Write to Frequency Converter

•

Step 4 (optional): chapter 6.1.6 Compare

•

Step 5: chapter 6.4.1 Test and Documentation

•

Programme the next frequency converter with the same settings: see chapter 5.3.1 Common Motor Library

•

A test report is created: see

•

chapter 5.5.5 Select and Run Test, View Test Report

-

chapter 6.4.1 Test and Documentation

-

Details are stored in a log file: see chapter 5.5.5 Select and Run Test, View Test Report.

•

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 9

Page 12

Engineering Tool Functions Operating Instructions

5 Engineering Tool Functions

5.1 Project

Create a Project

5.1.1

Initial start

At initial startup of the Engineering Tool, the New Project

dialog opens, see Illustration 5.1. No projects have

previously been created. For details of how to create a

new project, go to chapter 5.1.1 Create a Project.

55

Illustration 5.1 New Project Dialog

A project contains a set of motors and tests available for

use by the technician. Use the Engineering Tool to create a

project.

There are 2 starting points for creating a new project:

Based on an MCT 10 database. Follow the steps

•

in chapter 5.1.2 New Project - Create from

Database.

Based on a project stored in a frequency

•

converter. Follow the steps in chapter 5.1.3 New

Project - Read from Drive.

When all the steps are completed, the new project opens

in project view. See chapter 5.1.6 Project View.

New Project - Create from Database

5.1.2

To create a new project based on the MCT 10 database:

1.

Select Projects in the menu bar.

2. Via the dropdown menu, go to [Projects → New

Project → Create from database], as shown in

Illustration 5.3.

Subsequent start

At subsequent startup of the Engineering Tool, the Search

dialog opens, see Illustration 5.2. Use the dialog to search

for existing projects. For more information go to

chapter 5.1.5 Search Project.

Illustration 5.2 Search Dialog

Illustration 5.3 Path for New Project Based on MCT 10

Database

10 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 13

Engineering Tool Functions Operating Instructions

3.

The New Project dialog opens, see Illustration 5.4.

Illustration 5.4 New Project Dialog

4.

Enter or select project details, see Illustration 5.5:

4a Project name

4b Frequency converter (“Drive series”)

4c Power size

4d Voltage

4e Basic SW version

4f Parameter language

Click on [Create Project]

5.

The Project Info dialog opens. Enter further details

of the project, as shown in the example, see

Illustration 5.6.

Illustration 5.6 Project Info Dialog

NOTICE

There are 2 dialogs containing information about the

customer and the order: Project Info (see Illustration 5.6)

and Test Drive and Motor (see Illustration 5.37). Ensure

the data in both dialogs are consistent.

NOTICE

To adapt the Project Info content subsequently, ensure

the original file is preserved, not overwritten. Use Save

As when adapting content to a different project.

5 5

6. Click on [Save].

7. The new project opens.

8. A confirmation message appears, stating that the

new project is now created, see Illustration 5.7.

Illustration 5.7 Project Created

Illustration 5.5 New Project, Selection Drop Down Menu

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 11

Page 14

Engineering Tool Functions

Operating Instructions

5.1.3 New Project - Read from Drive

Use of an existing project stored in a frequency

converter

To import an existing project from a frequency converter

to MCT 21 Factory Tool, use Read From Drive. The Read

From Drive function enables project transfer from the

frequency converter memory to the PC.

NOTICE

PASSWORD MATCH

Note that data may be password protected in the

55

frequency converter. Set the MCT 21 Factory Tool

password defined in [Settings → General Settings], to be

identical with the frequency converter password.

Otherwise no access is granted.

To create the project:

1.

Select Projects in the menu bar.

2. Via the dropdown menu, go to [Projects → New

Project → Read From Drive]. See the dropdown

menu in Illustration 5.3.

3.

The Read From Drive dialog opens, see

Illustration 5.8.

6. The data transfers from the frequency converter

to MCT 21 Factory Tool, and the new project

opens.

When selecting Read from Drive, a commutation must be

established. Then project information can be extracted

from the frequency converter. See the note on password

match requirements.

5.1.4 Open Project

To open an existing project, go to [Projects → Open

Project]. The browser opens. Select the project in the

folder structure, and click [Open]. The Project Info dialog

opens, see Illustration 5.9.

Illustration 5.8 Read From Drive

4. If communication with the frequency converter is

not possible, click Configure Communication, to

adjust the settings. To access the communication

configuration later, go to [Settings → Drive

Configuration].

5. Click [Read From Drive].

Illustration 5.9 Open Project, Project Info Dialog

The Project Info dialog differs from that for a new project.

For an existing project, the Project Info dialog contains a

[Save As] button. Use [Save As] to create a new project on

the basis of a copy of an existing project.

When changing the Project Info settings, use the [Save As]

button to ensure the existing project is not overwritten.

When entering new settings, clicking on [Save] will cause

the previous settings to be overwritten, and the previously

existing project will be deleted.

12 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 15

Engineering Tool Functions Operating Instructions

5.1.5 Search Project

Access the search dialog via [Menu → Search Project].

Illustration 5.11 Project View: Example of New Project

Illustration 5.10 Search Dialog

Use the Search dialog to find an existing project. The

existing projects originate from the Engineering Tool, see

chapter 5.1.1 Create a Project.

Search for all projects

To display a list of all existing projects:

1. Click on [Show All].

2. The search results are displayed in the field

Search Result.

Search with filter

To display a list containing only a selection of the existing

projects:

1. Set the search criteria

1a To search for a specific project, use the

fields Customer Name and Application

Name.

1b To filter for specific properties of the

frequency converter or motor, fill out

the fields under Drive Information and

Motor Information.

2. Click on [Search project].

3. The search results are displayed in the field

Search Result.

The new project opens in the project view, see example in

Illustration 5.11.

The project name appears in the horizontal menu bar. In

the example the project name is Database, see

Illustration 5.11.

The left panel contains the project structure, for setting up

and accessing data in the project. Unfold the structure to

view the elements:

Motors

•

SIVP

•

Test

•

Initially there is no data in the project , so the 3 elements

have the suffixes Empty and 0.

To enter and import data into the project, see:

Chapter 5.2.1 Motor Database

•

Chapter 5.4 SIVP (Specific Initial Values and

•

Protection)

Chapter 5.5.1 Create Test

•

Chapter 5.1.6 Create Order

•

Create Order

5.1.6

A third way to create a project, is via an order file. The

order file specifies project data, including SIVP parameters

and motor database. To create the order, use an external

order handling tool.

Orders

MCT 21 Factory Tool monitors the order folders. The

location of the order folder is specified under General

Settings, see chapter 5.6.1 General Settings. New orders are

indicated in the menu bar, as shown in Illustration 5.12.

5 5

Illustration 5.12 New Order shown in Menu Bar

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 13

Page 16

Engineering Tool Functions Operating Instructions

Unprocessed Orders

When a user places an order file, it is listed in [Orders →

Unprocessed Orders], see Illustration 5.13.

Processed Orders

Processed orders are listed in [Orders → Processed Orders],

see Illustration 5.15.

55

Illustration 5.13 Unprocessed Orders Dialog

To select and open the order,

1.

Mark the checkbox under Select

2. Click on [Process]

3. When processing the order, the order converts

into a project, which can be saved to the

frequency converter, see Illustration 5.14.

Illustration 5.15 Processed Orders Dialog

Order file

An order file of processed orders is maintained in the

Order folder. The location of the order folder is specified

under General Settings, see chapter 5.6.1 General Settings.

For the structure of the order file, see Table 5.1.

Content

1)

Comment

Line

1 Order number Mandatory item

Illustration 5.14 Order Converts into Project: Project Info

Dialog

2 OEM name Optional item, can be

empty.

3 OEM type code Optional item, can be

empty.

4 OEM identity Optional item, can be

empty.

5 OEM application name Optional item, can be

empty.

6 Customer name Optional item, can be

empty.

7 Drive series Mandatory item: FCP106 or

FCM 106

8 Drive software If empty, reverts to default

(most recent software

version).

9 Drive power Mandatory item. Example:

1.50

10 Drive voltage Mandatory item. Example:

380-480

11 Language If empty or invalid, reverts

to default (English).

12 Master file Optional item, can be

empty.

The master file is an MCT 21

file containing for example

MotorDB, Pump DB, and

SIVP (or parts of it).

13 Number of parameters

defined in the following

lines

-

14 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 17

Engineering Tool Functions Operating Instructions

Line

x Parameter ID, Array index,

y Order file status 0 = processed

Table 5.1 Structure of an Order File

1) Value separator is defined as - or ; or |.

1)

Content

Setup, Value, Read-Only,

Visibility – it can be empty.

Comment

Optional item, can be empty

If Parameter ID is already in

use by master file, it

overwrites its value.

1 = unprocessed

Note that text starting with /* and ending with */ will be

ignored, and can be used for comments. See Table 5.2 for

an order file example.

Line

1 Test Order 1 /*ORDER NUMBER – it must exist*/

2 OrderName /*OEM NAME – it can be empty also*/

3 A412 /*OEM TYPE CODE – it can also be empty*/

4 TEST /*OEM IDENT– it can also be empty*/

5 MCT21 /*APPLICATION NAME – it can also be empty*/

6 Danfoss /*CUSTOMER NAME– it can also be empty*/

7 FCP106 /*DRIVE SERIES – it must exist*/

8 01.10 /*SW Version. If empty it will take the latest

9 1.50 /*drive power – must exist*/

10 380-480 /*Voltage – must exist*/

11

12 English /*parameter language if empty or wrong it

13 /*MCT21 file from where we can extract MotorDB file,

14 3 /*Number of parameters – can be zero*/

x 1;0;2;1;1;1 /*Parameter ID, Array index, Setup, Value,

x 100;0;1;3;0;1 /*parameter is Configuration Mode, array

x 207;0;1;8.5;1;1 /*parameter is Parking Time, array index

y 1 /* Order is unprocessed */

1)

Content

one*/

must default to */

Pump DB location, and SIVP file – can be empty –

called master file*/

Read-Only, Visibility – it can be empty. In case of

Parameter ID already in use by master file, it

overwrites it’s value.*/

index 0, setup 1, value 3 (Closed Loop), will be read

and write, and not visible*/

0, setup 2, value 8.5, will become read-only and not

visible*/

5.1.7

Copy Project

Copy all project data

To copy all project data from one PC to another:

1. Open Windows Explorer.

2. Open the project folder.

2a To find the project folder go to [Menu

→ General Settings].

2b The project folder is displayed in the

field Projects folder, as shown in

Illustration 5.16.

2c The default project folder is

C:\ProgramData\Danfoss Power

Electronics\MCT21 Factory Tool\Projects\.

3. Copy the entire project folder content to a

suitable storage media, for example a USB stick.

4. Open the test folder.

4a To find the test folder, go to [Menu →

General Settings].

4b The test folder is displayed in the field

Tests folder, as shown in Illustration 5.16.

4c The default test folder is:

C:\ProgramData\Danfoss Power

Electronics\MCT21 Factory Tool\Projects\.

5. Copy the entire test folder content to a suitable

storage media, for example a USB stick.

6. Move the media to the destination PC.

7. Copy the files from the source project and test

folders to the corresponding folders on the

destination PC.

5 5

Table 5.2 Example of an Order File

1) Value separator is defined as - or ; or |.

Illustration 5.16 General Settings Dialog, showing the Projects

Folder

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 15

Page 18

Engineering Tool Functions Operating Instructions

5.1.8 Upgrade a Project to New Firmware

When new frequency converter firmware is released, a

project may require upgrade to the new firmware.

There are 2 methods to upgrade a project to new

firmware.

Upgrade method 1

1. Create a new project with the new firmware.

2. Import the motors.

55

3. Import the .siv files from the old project.

4. Select the required tests.

5. The new project is now ready for use.

For more information, see chapter 5.1.1 Create a Project.

Upgrade method 2

1. Open Windows Explorer.

2. Open the project folder.

2a To find the project folder go to [Menu

→ General Settings].

2b The project folder is displayed in the

field “Projects folder”, as shown in

Illustration 5.16.

2c

The default project folder is C:

\ProgramData\Danfoss Power Electronics

\MCT21 Factory Tool\Projects\.

3. Create a copy of the project file. The project file

has the suffix .xml.

4. Open a new file in the text editor.

5. In the text editor, change the content of the tag

<BasicSoftwareVersion>1.10</BasicSoftwareVersion> to the new firmware version, as shown

in Illustration 5.17.

6. Save and close the text editor file.

7. The project is now upgraded to the new firmware

version, and is ready for use.

Illustration 5.17 Basic Software Version Tag in the Text Editor

16 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 19

Engineering Tool Functions

Operating Instructions

5.2 Motor Database

For each project, define a motor database, see Illustration 5.18.

To populate the motor database, import motors from the motor library, see chapter 5.3 Motor Library. For more information,

refer to chapter 5.2 Motor Database.

5 5

Illustration 5.18 Project Motor Database

To view motors available to a project, open the Motor Database:

1.

Go to the Project Viewvia [Projects → Open Project] or [Projects → New Project].

2.

Click the Motors element in the project structure.

The Project Motor Database dialog opens, see Illustration 5.19.

Illustration 5.19 Project Motor Database

The Project Motor Database dialog displays a list of motors available to the project, including details of motor characteristics.

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 17

Page 20

Engineering Tool Functions Operating Instructions

Add a motor to the database

To add a motor to the motor database:

1.

Open the Common Motor Library. For instructions see chapter 5.3.1 Common Motor Library.

2.

Open the Project Motor Database dialog, see Illustration 5.19.

3.

Click [Motor Library]. The Common Motor Library dialog opens.

4.

Select motors from the Common Motor Library. For more information, refer to chapter 5.3.1 Common Motor Library.

5. Place a checkmark to select which motors to add to the project.

6. Click [Copy motor(s) to project].

7. Click [Save].

55

Illustration 5.20 Project Motor Database

Remove a motor from the database

To remove a motor from the Project Motor Database:

1. Click on [Remove] for the motor in the list.

2. Click on [Save].

18 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 21

Engineering Tool Functions Operating Instructions

5.3 Motor Library

5.3.1 Common Motor Library

The Common Motor Library contains a list of all motors available for use in all projects, including motor characteristics for

each. Use the Common Motor Library to find suitable motors for each project, and import them into the project.

5 5

Illustration 5.21 Motor Library, Example

Open the Common Motor Library

To open the Common Motor Library,

1. In the menu bar, go to [Tools → Common Motor Library.]

2.

The Management Common Motor Library dialog opens, see Illustration 5.21.

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 19

Page 22

Engineering Tool Functions Operating Instructions

Create a new motor

To add a motor to the Common Motor Library:

1. Select [Add New Motor].

2.

The Create New Motor dialog opens, see Illustration 5.22.

3. The dialog contains preselected data, which are based on the MCT 10 database. Depending on the motor type,

some fields are not accessible.

4. Select and/or enter the type and characteristics of the motor, then save.

55

Illustration 5.22 Create New Motor Dialog, Example

20 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 23

Engineering Tool Functions Operating Instructions

Alternative method to add a motor to the Common Motor

Library:

1. Select [Library Import].

2. Select the library for import.

3. Click [Open].

Edit the motor

To change the motor data for a motor already listed in the

Common Motor Library:

1. Check the check box for the motor.

2. Click [Edit].

3. Enter the changes, then click [Save].

Delete a motor

To delete a motor or group of motors from the Common

Motor Library:

1. Check the check box for the motor, or for several

motors.

2. Click [Delete Motor(s)].

3. Click [Save].

Export Library

5.3.2

Copy the Common Motor Library

5.3.3

To copy the Common Motor Library from one PC to

another:

1.

Open the Common Motor Library via the menu

[Tools → Common Motor Library].

2.

The Management Common Motor Library dialog

opens, see Illustration 5.21.

3. Click [Library Export] and export the database to

suitable media (for example, a USB stick).

4. Move the media to the destination PC.

5.

On the destination PC, open the Common Motor

Library via the menu [Tools → Common Motor

Library].

6. Click [Library Import] and import the database

from the media.

7. Click [Save].

8.

The Common Motor Library is now stored on the

destination PC.

5 5

Via Menu it is possible to export the Common Motor

Library, which can then be imported to another PC.

To export a motor or group of motors to a project,

1. Check the check box for the motor(s).

2. Click [Library Export].

3. Enter file name.

4. Click [Save].

5. If any motor parameters are incompatible with

the frequency converter, they are marked red.

Correct them.

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 21

Page 24

Engineering Tool Functions Operating Instructions

5.4 SIVP (Specific Initial Values and Protection)

5.4.1 Define the SIVP

Use the SIVP tool to define the factory default settings and attributes of parameters in each project:

Read/write

•

Read only

•

Hidden

•

.

55

Open SIVP

To open SIVP:

1.

Go to the Project View via [Projects → Open Project] or [Projects → New Project].

2. Unfold the project structure.

3. Click on the SIVP element in the project structure.

4.

The SIVP dialog opens, see Illustration 5.23.

Illustration 5.23 SIVP Dialog, Example

22 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 25

Engineering Tool Functions

Operating Instructions

SIVP, left panel

The SIVP dialog displays a list of all available parameters

with their default settings.

1. Click on the parameter group name in the left

panel.

2. The parameters within the group are displayed in

the centre panel.

SIVP, right panel

The SIVP dialog displays a list of available parameters with

default settings. The status fields in the right-hand panel

show lists of:

Changed parameters

•

Parameters which are visible for technician (VFT),

•

in the Technician Tool.

To import parameter settings from other projects, click

[Import].

To save parameter settings, click [Save].

SIVP, centre panel

Set the desired status for use of each parameter in the

frequency converter, as shown in Table 5.3.

5 5

Field Set status Comment

VFT Check this box for VFT

(visible for technician)

functionality.

Set-up 1 Enter a value or select

from the drop-down

menu.

Set-up 2 Enter value or select from

the drop-down menu.

Unit Enter the unit. Where applicable, the unit

Not

visible

Read

only

Check this box to make

the parameter invisible in

the frequency converter.

Check this box to remove

write access to the

parameter in the

frequency converter.

When a parameter is

marked as VFT, the

parameter settings are

visible and can be

changed in the Technician

Tool.

The selected value

becomes the factory

setting in the frequency

converter, activated after

frequency converter reset.

-

of the parameter is

displayed.

The selected parameter is

no longer displayed in the

LCP.

In the LCP, the selected

parameter is displayed,

but the settings cannot

be changed.

Table 5.3 SIVP Centre Panel

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 23

Page 26

Engineering Tool Functions Operating Instructions

5.4.2 SIVP Examples

55

Illustration 5.24 SIVP All Parameters

Illustration 5.25 Example: SIVP Parameter Group 2

24 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 27

Engineering Tool Functions Operating Instructions

5.4.3 Copy SIVP Library

To copy the SIVP Library from one PC to another:

1. Open Windows Explorer.

2. Open the project folder.

2a To find the project folder go to [Menu

→ General Settings].

2b The project folder is displayed in the

field Projects folder, as shown in

Illustration 5.26.

2c

The default project folder is C:

\ProgramData\Danfoss Power Electronics

\MCT21 Factory Tool\Projects\.

3.

Select the required SIVP file (suffix .siv) and copy

it to a suitable media (for example, a USB stick).

4. Move the media to the destination PC.

Illustration 5.27 SIVP Dialog

5.5 Tests

A test comprises a sequence of actions, testing the

interaction of the frequency converter and the motor.

The Engineering Tool offers the following test functionalities:

Create test

•

Edit test

•

Run test

•

View test results

•

Remove test

•

1) The Run test and View test results functions are the same

for the Engineering Tool and the Technician Tool.

1)

1)

5 5

Illustration 5.26 General Settings Dialog, showing the Projects

Folder

5. On the destination PC, open the SIVP dialog as

shown in chapter 5.4.1 Define the SIVP.

6.

In the SIVP dialog (Illustration 5.27), click on

[Import], to import SIVP.

7. Click on [Save].

8. The SIVP Library is now stored on the destination

PC.

Create Test

5.5.1

To create a new test:

1. In the menu bar, go to [Tools → Common Test

Database].

2.

The Test Database dialog opens, see

Illustration 5.28.

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 25

Page 28

Engineering Tool Functions

Operating Instructions

The following commands are available within each test

step, to activate and monitor the frequency converter:

Initialise drive

•

Read

•

Write

•

Wait

•

Write Control Word

•

For more information refer to chapter 5.5.2 Edit Test.

55

5.5.2 Edit Test

Before editing a test, it is necessary to understand:

Range of commands available, see

•

chapter 5.5.2.1 Commands.

Predefined commands, see chapter 5.5.1 Create

•

Test.

How to edit, see chapter 5.5.2.2 Editing Procedure.

•

Illustration 5.28 Test Database Dialog

Commands

Initialise drive

•

Read

•

Write

•

Wait

•

Write Control Word

•

3. Click on [Add New Test].

4.

The New Test dialog opens, see Illustration 5.29.

The new test contains several predefined initial steps by

default, see Illustration 5.29. The predefined initial steps

activate a function which monitors the communication

between the PC and the frequency converter. If communication fails, these steps ensure that the frequency

converter stops automatically. Therefore, consider possible

negative impact on the test before changing or removing

the predefined steps in the sequence.

Illustration 5.29 Create Test, Predefined Steps

5.5.2.1

The following commands are available within each test

step, to activate and monitor the frequency converter:

View the available commands via the drop down menu, as

shown in Illustration 5.30.

Write enables change of a parameter value, for example

preset references or ramp times.

Wait tells the tool to wait for a specified time or condition

before executing the next step. For example, using the

wait command, the tool can wait until a motor has

accelerated to a certain speed before performing the next

command. Note: Enter the time in ms (1000 ms = 1 s).

Read tells the tool to fetch a value from a parameter. The

test fails if a read function does not match the defined

value. For example, in Illustration 5.31, the language

selection must be English. If it is not English, the test will

be marked as failed.

Write Control Word consists of a control word and a

reference value. For details see chapter 5.5.3 Control Word

according to FC Profile (CTW).

26 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 29

Engineering Tool Functions Operating Instructions

WARNING

UNINTENDED START

Depending on the settings of the frequency converter,

editing a command can start the motor. Unintended

start during programming can result in death, serious

injury, or property damage. To prevent unintended

motor start:

Disconnect the frequency converter from mains.

•

Press [Off/Reset] on the LCP before editing a

•

command.

Ensure the frequency converter, motor, and any

•

driven equipment are fully wired and

assembled when the frequency converter is

connected to AC mains, DC power supply, or

load sharing.

5.5.2.2

To edit a test:

Editing Procedure

1. Use the checkmark to select the test from the list,

see Illustration 5.32.

2. Click on [Edit].

3.

The Edit Test dialog opens, see Illustration 5.33.

5 5

Illustration 5.30 Create Test, Commands Available

Illustration 5.31 Create Test, Write Command

Illustration 5.32 Select Test for Editing

4. To view the sub-steps for each predefined

process, click on [+], as shown in Illustration 5.33.

5.

The sub-steps unfold as shown in Illustration 5.34.

Illustration 5.33 Edit Test

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 27

Page 30

Engineering Tool Functions

55

Illustration 5.34 Example: Process Step Expanded to show Substeps

Operating Instructions

Bit Bit value=0 Bit value=1

00 Reference value External selection lsb

01 Reference value External selection msb

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05 Hold output frequency Use ramp

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data valid

11 No function Relay 01 active

12 No function Relay 04 active

13 Parameter set-up Selection lsb

14 Parameter set-up Selection msb

15 No function Reverse

6. Enter a new command by defining each of the

fields Action, ID (parameter number), Name

(parameter name).

7. Click [Save].

8. Continue to enter each new command. Click

[Save] after each one.

9. When all new commands are completed, click

[Execute]. The test is saved.

10.

The dialog closes and returns to the Test Drive

and Motor dialog (shown in Illustration 5.32).

Control Word according to FC Profile

5.5.3

(CTW)

To select FC protocol in the control word, set 8-10 Control

Word Profile to [0] Frequency converter profile . The control

word is used to send commands from a master (PLC or PC)

to a follower (frequency converter).

Table 5.4 Bit Values for FC Control Word

Explanation of the control bits

Bits 00/01 Reference value

Bits 00 and 01 are used to choose between the 4 reference

values, which are pre-programmed in 3-10 Preset Reference

according to Table 5.5.

NOTICE

In 8-56 Preset Reference Select a selection is made to

define how bit 00/01 gates with the corresponding

function on the digital inputs.

Bit 01 Bit 00 Programmed

ref. value

0 0 1

0 1 2

1 0 3

1 1 4

Table 5.5 Programmed Reference Values for Bits

Bit 02, DC brake

Bit 02=0 - leads to DC braking and stop. Braking current

and duration are set in 2-01 DC Brake Current and 2-02 DC

Braking Time.

Bit 02=1 - leads to ramping.

Bit 03, Coasting

Bit 03=0 - causes the frequency converter to immediately

coast the motor to a standstill.

Bit 03=1 - enables the frequency converter to start the

motor if the other starting conditions have been fulfilled.

Parameter

[0] 3-10 Preset Reference

[1] 3-10 Preset Reference

[2] 3-10 Preset Reference

[3] 3-10 Preset Reference

28 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 31

Engineering Tool Functions

Operating Instructions

NOTICE

In 8-50 Coasting Select a selection is made to define how

bit 03 gates with the corresponding function on a digital

input.

Bit 04, Quick stop

Bit 04=0 - causes a quick stop, ramping the motor speed

down to stop via 3-81 Quick Stop Ramp Time.

Bit 04=1 - the frequency converter ramps the motor speed

down to stop via 3-42 Ramp 1 Ramp Down Time or

3-52 Ramp 2 Ramp Down Time.

Bit 05, Hold output frequency

Bit 05=0 - causes the present output frequency (in Hz) to

freeze. The frozen output frequency can only be changed

with the digital inputs (5-10 Terminal 18 Digital Input to

5-15 Terminal 33 Digital Input) programmed to Speed up

and Speed down.

Bit 05=1 - use ramp.

NOTICE

If Freeze output is active, stop the frequency converter

with:

Bit 03 Coasting stop

•

Bit 02 DC braking

•

Digital input (5-10 Terminal 18 Digital Input to

•

5-15 Terminal 33 Digital Input) programmed to

DC braking, Coasting stop, or Reset and coasting

stop.

Bit 06, Ramp stop/start

Bit 06=0 - causes a stop, in which the motor speed is

ramped down to stop via the selected Ramp down

parameter.

Bit 06=1 - permits the frequency converter to start the

motor if the other starting conditions have been fulfilled.

NOTICE

In 8-53 Start Select a selection is made to define how bit

06 Ramp stop/start gates with the corresponding

function on a digital input.

Bit 09, Selection of ramp 1/2

Bit 09=0 - ramp 1 is active (3-40 Ramp 1 Type to 3-47 Ramp

1 S-ramp Ratio at Decel. Start).

Bit 09=1 - ramp 2 (3-50 Ramp 2 Type to 3-57 Ramp 2 Sramp Ratio at Decel. Start) is active.

Bit 10, Data not valid/data valid

Is used to tell the frequency converter whether it should

use or ignore the control word.

Bit 10=0 - the control word is ignored.

Bit 10=1 - the control word is used. This function is

relevant because the control word is always contained in

the telegram, regardless of which type of telegram is used.

Therefore, the control word can be turned off if it is not

required when updating or reading parameters.

Bit 11, Relay 01

Bit 11=0 - relay 01 not activated.

Bit 11=1 - relay 01 activated, provided Control word bit 11

has been chosen in 5-40 Function Relay.

Bit 12, Relay 04

Bit 12=0 - relay 04 has not been activated.

Bit 12=1 - relay 04 has been activated, provided Control

word bit 12 has been chosen in 5-40 Function Relay.

Bit 13/14, Selection of set-up

Bits 13 and 14 are used to choose from the 4 menu setups according to Table 5.6:

The function is only possible when Multi-Set-ups is selected

in 0-10 Active Set-up.

Set-up Bit 14 Bit 13

1 0 0

2 0 1

3 1 0

4 1 1

Table 5.6 Selection of Set-up

NOTICE

In 8-55 Set-up Select a selection is made to define how

bit 13/14 gates with the corresponding function on the

digital inputs.

5 5

Bit 07, Reset

Bit 07=0 - does not cause a reset.

Bit 07=1 - causes the reset of a trip. Reset is activated on

the signals leading edge, that is, when changing from logic

0 to logic 1.

Bit 08, Jog

Bit 08=0 - no function.

Bit 08=1 - 3-19 Jog Speed [RPM] determines the output

frequency.

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 29

Bit 15 Reverse

Bit 15=0 - no reversing.

Bit 15=1 - reversing.

Page 32

Engineering Tool Functions

NOTICE

The control word cannot overrule settings in the

frequency converter. For example, when the frequency

converter is stopped via the LCP or a digital input

(coast), it will not accelerate when sending a start

command via bus.

Examples

CTW Action

047C Start motor

55

043C Stop

847C Start reversing

046C Quickstop

007C No function (bit 10=0)

Table 5.7 Examples

Definition of Reference

5.5.4

Operating Instructions

3.

The Test Drive and Motor dialog opens, see

Illustration 5.37.

4. Use the checkmark to select the test(s) from the

list.

5. Click [Run].

6. Click [Results] to view the test report.

Illustration 5.35 Definition of Reference

Illustration 5.36 Minimum and Maximum Reference

5.5.5 Select and Run Test, View Test Report

Run a single test, or several tests

To run a single test, or a group of tests:

1. Go to the project view. For more information, see

chapter 5.1.4 Open Project.

2. In the left panel click on [Test] in the project

structure.

Illustration 5.37 Test Drive and Motor Dialog

Run all tests

To run all tests:

1. Follow steps 1, 2, and 3 above.

2. In the left panel click on [Test] in the project

structure.

3. Click [Run All Tests].

4. Click [All Test Results] to view the test report.

Remove Test

5.5.6

To remove a test or tests from a project:

1. Go to the project view. For more information, see

chapter 5.1.4 Open Project.

2. In the left panel click on [Test] in the project

structure.

3.

The Test Drive and Motor dialog opens, see

Illustration 5.37.

4. Use the checkmark to select the test(s) from the

list.

5. Click on [Remove].

30 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 33

Engineering Tool Functions

6. The test or tests are now removed from the

project. Confirm by checking the list of tests in

the Test Drive and Motor dialog.

Operating Instructions

5.5.7 Copy Test

1. Open Windows Explorer.

2. Open the test folder.

2a To find the test folder go to [Menu →

General Settings].

2b The test folder is displayed in the field

Tests folder, as shown in Illustration 5.38.

2c

The default test folder is C:\ProgramData

\Danfoss Power Electronics\MCT21 Factory

Tool\Projects\.

5 5

Illustration 5.38 General Settings Dialog, showing Tests Folder

3. Select the desired test file (suffix “.Test”) and copy

it to a suitable media (e.g. USB stick).

4. Move the media to the destination PC.

5. On the destination PC, copy the test to the test

folder path specified in the General Settings

dialog (see Illustration 5.38).

6. The test is now available for selection in the

Engineering Tool and the Technician Tool on the

destination PC.

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 31

Page 34

Engineering Tool Functions Operating Instructions

5.6 Settings Menu

Drive Communication

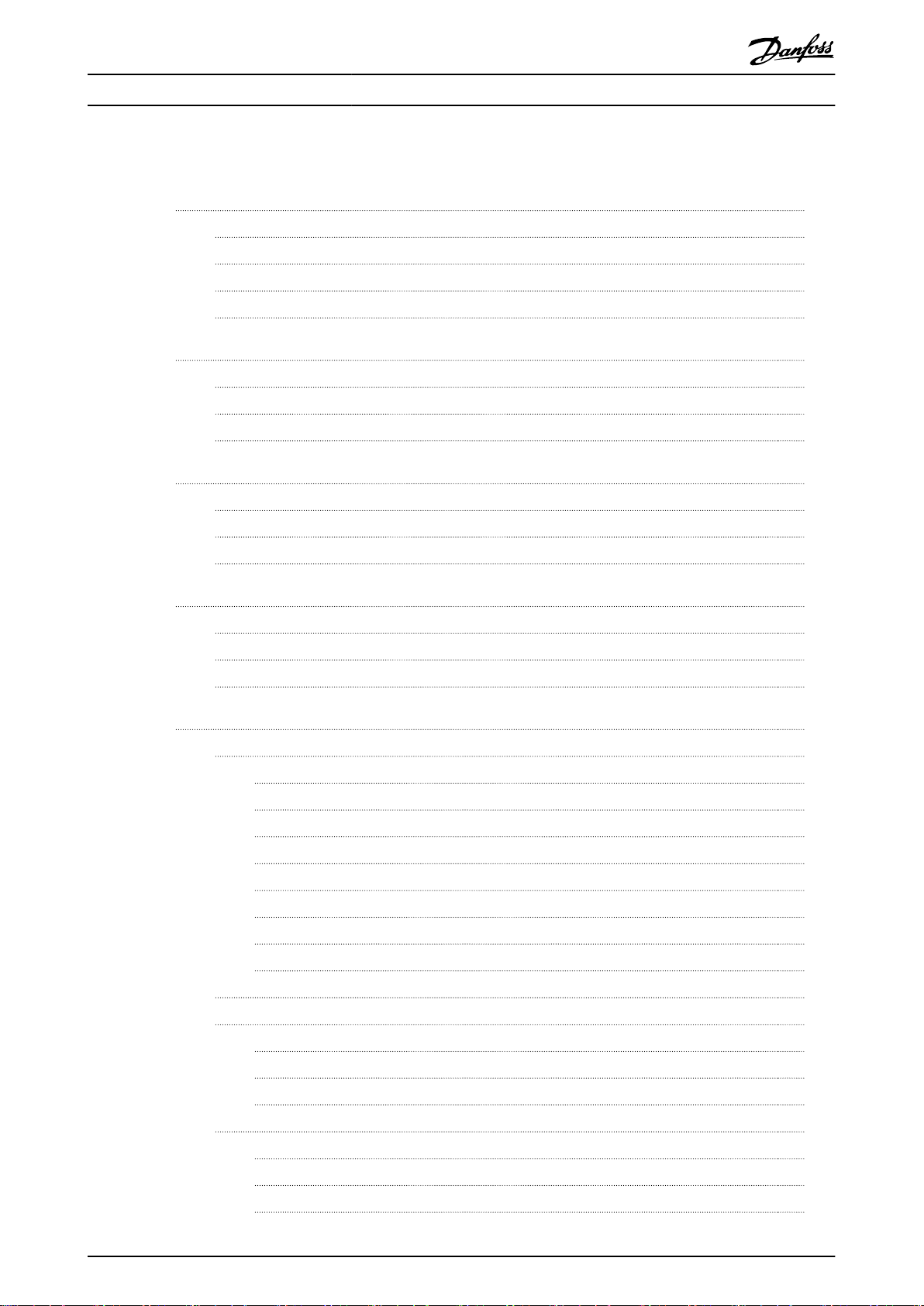

5.6.2

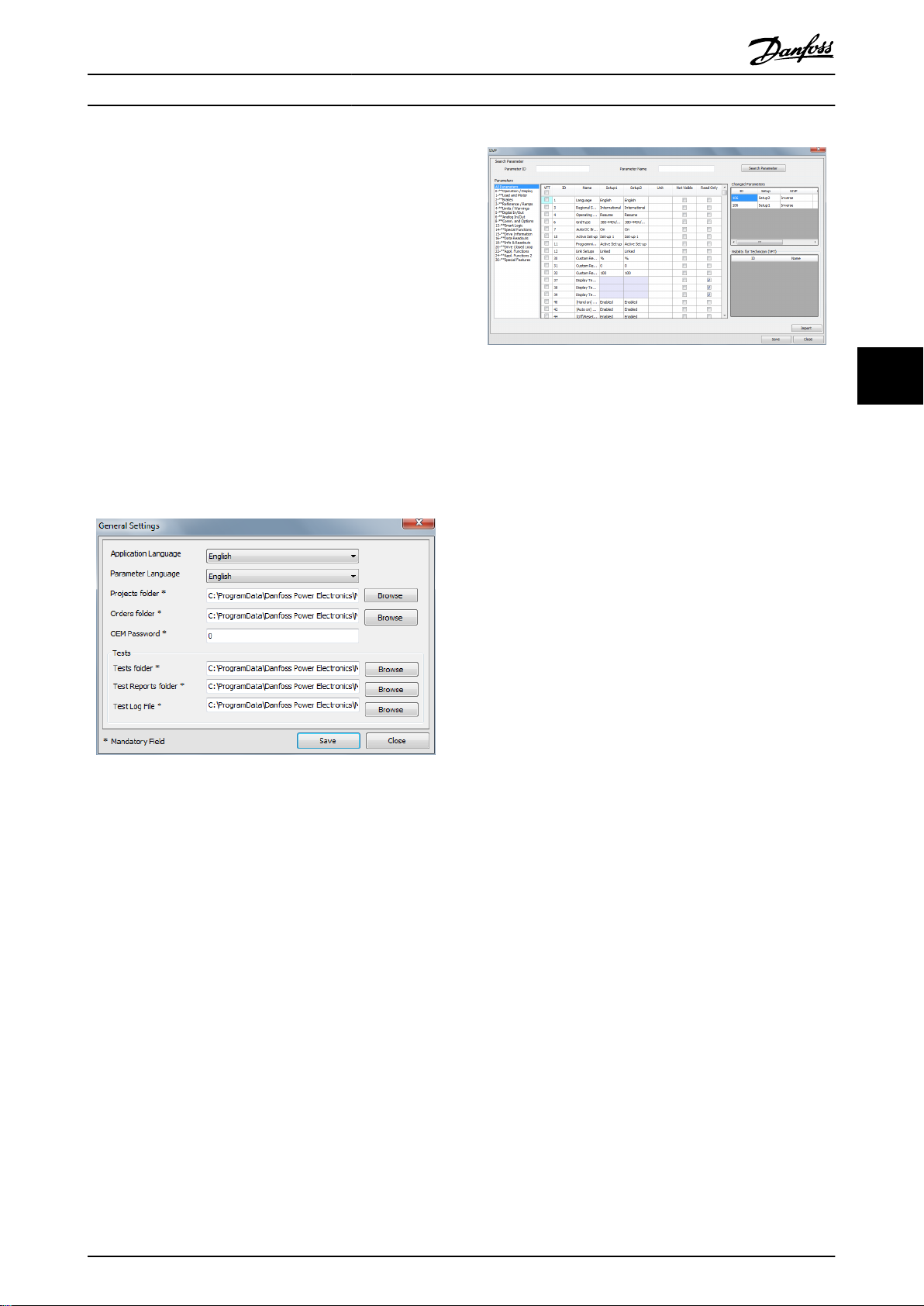

5.6.1 General Settings

To access General Settings:

1.

Click Settings in the menu bar, see

Illustration 5.39.

2.

Select General Settings in the dropdown.

3.

The dialog opens, see Illustration 5.40.

To access serial fieldbus communication settings for the

frequency converter:

1.

Click Settings in the menu bar, see

Illustration 5.39.

2.

Select Drive Communication in the dropdown.

3.

The Serial Fieldbus Configuration dialog opens, see

Illustration 5.41.

55

Illustration 5.39 General Settings

Use the General Settings dialog to set up preferences for:

Language of the tool user interface (English or

•

German).

Language for displaying parameters (English,

•

German, French, Danish, Spanish, or Italian).

Folder location to store projects.

•

OEM password definition.

•

Tests:

•

Folder location to store test procedures.

-

Folder location to store test reports.

-

Folder location to store test log files.

-

Illustration 5.41 Serial Fieldbus Configuration, Communication

Settings

Procedure:

1. Enter the required settings. As a minimum, select

Port and enter Address. The other settings are

optional.

2. Click [Configure] to save the settings.

3. Click [Test Configuration] to check the settings

function correctly.

4. Click [Cancel] to delete the settings.

Illustration 5.40 General Settings Dialog

32 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 35

Technician Tool Functions

Operating Instructions

6 Technician Tool Functions

6.1 Project

6.1.1 Open a Project

At the start-up of the Technician Tool, the Search dialog

opens, see Illustration 5.10. The dialog is also accessible via

[Menu → Search Project].

6 6

Illustration 6.1 Search Dialog

Use the Search dialog to find an existing project. The

existing projects originate from the Engineering Tool, see

chapter 5.1.1 Create a Project.

To search for a project, refer to the instructions in

chapter 5.1.5 Search Project.

Open a project

To open a project in the Search Result dialog:

1. Double-click on the project, or

2. Use the check box to mark the required project,

and click [Open]

3.

The Project View dialog opens.

Illustration 6.2 Project View Dialog

Alternative - Order file

MCT 21 Factory Tool monitors the order folder specified in

General Settings. When a user places an order file there, it

is flagged in the menu bar, see Illustration 6.3. The order

file specifies SIVP parameter, motor database and so on.

Illustration 6.3 Order Flag in the Menu Bar

After processing the order, the information transfers to a

project. Handle this project in the same way as any other

project, see Illustration 6.2.

Project View

6.1.2

Project View Dialog

The project opens in Project View, see Illustration 6.2. After

opening the project, the following actions are available in

the left-hand panel in the Project View dialog:

Project Info

•

Write to Drive

•

Compare

•

Test

•

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 33

Project Review and Adjustments

6.1.3

Project Info

In the Project View dialog (Illustration 6.2) go to [MCT21 File

→ Project Info] to read project data:

Project details

•

Drive Information

•

Motor Information

•

Page 36

Technician Tool Functions Operating Instructions

SIVP parameters. Only SIVP parameters indicated

•

in the Engineering Tool as VTF (Visible to Factory

Tool) are visible in the Factory Tool dialog. The

technician can only edit these parameters. Other

parameters are not visible or editable by the

technician.

Edit the project

If required, edit the project in the Project Info dialog as

follows:

Adapt the entries in the dialog fields.

•

Click [Save] to overwrite a project with changes.

•

Click [Save as] to create a new project with

•

changes.

66

If no editing is required, click [Continue] to leave

everything unchanged. The Project View opens.

Create an Order

6.1.4

To create an order, refer to chapter 5.1.6 Create Order.

Write to Frequency Converter

6.1.5

To write data to the frequency converter, in the project

view go to [MCT21 File → Write to Drive] as shown in

Illustration 6.2.

The dialog Write SIVP and Selected Motors to Drive opens,

see Illustration 6.4. In the dialog,

View and edit communication settings

•

Select a pump table for the sensorless pump

•

function

View a summary of the project including motor

•

data, adjusted parameters

Transfer project data to the frequency converter

•

Illustration 6.4 Write SIVP and Selected Motors to Drive

34 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 37

Technician Tool Functions

To transfer the project data to the frequency converter,

click [Write to Drive].

If an error arises during data transfer, click [Recover From

Boot Mode]. Possible errors are power loss and communication failure.

Operating Instructions

6.1.6 Compare

Use the Compare function to check whether data are

successfully transferred from the PC to the frequency

converter.

In the project view, go to [MCT 21 File → Compare].

6.2 Motor Database

In the Technician Tool, use the motor database to select

motors and to write to the frequency converter.

For more information, refer to chapter 5.2 Motor Database.

6.3 SIVP

6 6

Illustration 6.5 Test Drive and Motor

6.3.1 Select

In the Technician Tool, use the SIVP to select parameters

and write to the frequency converter.

For more information, refer to chapter 5.4 SIVP (Specific

Initial Values and Protection).

Write to Frequency Converter

6.3.2

To write SIVP to the frequency converter, refer to the

instructions in chapter 6.1.5 Write to Frequency Converter.

6.4

Tests

6.4.1 Test and Documentation

Test

To verify that a frequency converter is operating correctly,

run a defined test. The result is documented.

To run a test or tests:

1.

Open Project View.

2. Go to [MCT21 File → Test].

3.

The Test Drive and Motor dialog opens, see

Illustration 6.5.

4. Follow the steps in the following sections to run

a test or tests.

Test Information field

In the section Test Information, use the fields Tester Name

and Comment to document details about the test. For

example, enter the code number in the Comment field.

Run Test

To start a dedicated test:

Use the check boxes under the heading Select, to

•

select the test or tests.

Click [Run].

•

The selected test(s) runs.

•

To run all available tests:

Click [Run all Tests].

•

The tests run.

•

Documentation - test result

The test result is saved in a pdf file.

Name the PDF file in the format Type code + drive serial

number + date.

Documentation - test log

The output of the test is the test log, in csv file format.

The following test details are stored in the test log:

Date

•

Time

•

Order number

•

Customer name

•

Name tester

•

Drive type (15–46)

•

Serial number (15–51)

•

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 35

Page 38

Technician Tool Functions Operating Instructions

.Siv file name

•

Comment

•

Result (pass or not passed)

•

Test report path (path with .PDF file name where

•

report was created)

66

36 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 39

Index Operating Instructions

Index

C

Communication

Serial fieldbus................................................................................ 6, 32

Set-up..................................................................................................... 6

Create project........................................................................................ 10

D

De-installation.......................................................................................... 6

Dialog

General settings........................................................................... 6, 32

New project................................................................................... 6, 10

Project info.................................................................................. 11, 34

Read from drive................................................................................ 12

Search................................................................................................... 10

Test drive and motor...................................................................... 11

Write SIVP and selected motors to drive................................. 34

Discharge time......................................................................................... 4

Document version.................................................................................. 3

E

Engineering tool................................................................................. 7, 8

F

FC profile

Control bits......................................................................................... 28

Control word...................................................................................... 28

Example............................................................................................... 30

G

General settings.................................................................................... 32

H

High altitude............................................................................................. 5

High voltage............................................................................................. 4

Motor

Add to database............................................................................... 18

Common motor library.................................................................. 19

Copy library........................................................................................ 21

Database...................................................................................... 17, 35

Library management...................................................................... 19

Remove from database.................................................................. 18

Write to drive..................................................................................... 34

O

Order......................................................................................................... 13

Order file

Example............................................................................................... 15

Flag........................................................................................................ 33

Order folder........................................................................................ 33

Structure.............................................................................................. 15

P

Password

Frequency converter......................................................................... 6

OEM......................................................................................................... 6

PELV............................................................................................................. 5

Project

Copy all data...................................................................................... 15

Edit........................................................................................................ 34

Existing................................................................................................ 12

Folder................................................................................................... 15

Info........................................................................................................ 33

New....................................................................................................... 10

New, create from database.......................................................... 10

New, read from drive...................................................................... 12

Open.............................................................................................. 12, 33

Search............................................................................................ 13, 33

Search with filter.............................................................................. 13

Upgrade to new firmware............................................................. 16

View...................................................................................................... 13

Write to drive..................................................................................... 34

Project structure................................................................................... 13

Project view............................................................................................ 13

Purpose of the manual.......................................................................... 3

I

Installation................................................................................................. 6

Intended use............................................................................................. 3

Q

Qualified personnel................................................................................ 4

R

L

Leakage current....................................................................................... 5

Links............................................................................................................. 3

M

MCT 10...................................................................................................... 10

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 37

Reference................................................................................................. 30

Removal...................................................................................................... 6

Residual Current Device....................................................................... 5

S

Set-up.......................................................................................................... 6

Page 40

Index Operating Instructions

SIVP

Definition............................................................................................ 22

Example............................................................................................... 24

In Technician Tool............................................................................ 35

Library.................................................................................................. 25

Software version...................................................................................... 3

Specific initial values and protection............................................ 22

System requirements............................................................................ 3

T

Technician tool............................................................................. 7, 9, 33

Test

Copy...................................................................................................... 31

Create................................................................................................... 25

Documentation................................................................................ 35

Edit........................................................................................................ 26

Log......................................................................................................... 35

Remove................................................................................................ 31

Report............................................................................................ 30, 35

Run................................................................................................. 30, 35

Select.................................................................................................... 30

U

Unintended motor rotation................................................................ 5

Unintended start.............................................................................. 4, 27

W

Windmilling............................................................................................... 5

Workflow........................................................................................... 7, 8, 9

38 Danfoss A/S © Rev. 2014-06-09 All rights reserved. MG10X102

Page 41

Index Operating Instructions

MG10X102 Danfoss A/S © Rev. 2014-06-09 All rights reserved. 39

Page 42

www.danfoss.com/drives

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property

of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

www.danfoss.com/drives

130R0549 MG10X102 Rev. 2014-06-09

*MG10X102*

Loading...

Loading...