Page 1

Operating Guide

VLT® Motion Control Tool MCT 10

vlt-drives.danfoss.com

Page 2

Page 3

VLT® Motion Control Tool MCT 10

Operating Guide

Contents

1

Introduction 10

1.1

Purpose of this Operating Guide 10

Manual and Software Version 10

1.2

Intended Use 10

1.3

1.4

System Requirements 11

1.5

Software Modules 11

1.5.1

Features of the VLT® Motion Control Tool MCT 10 11

1.6

Versions 12

1.7

Further Information 13

Safety 14

2

Safety Symbols 14

2.1

Safety Precautions 14

2.2

Contents

Installation and De-installation 16

3

Introduction 16

3.1

3.1.1

Starting the Installation Program 16

3.1.2

Selecting the Software Language 16

3.1.3

Uninstalling the Software 16

4

Set-up of Communication 17

4.1

Communication Options 17

4.2

Manual Fieldbus Configuration 17

4.3

Automatic Scan 18

4.3.1

Scan Range Configuration 18

4.3.2

Scan Network 19

4.4

Set Up the Drive with RS485 Data Communication 19

4.4.1

Configuring the Fieldbus 19

4.4.2

USB Data Communication 20

4.5

Set-up of Soft Starter 20

4.5.1

Serial Configuration 21

4.5.2

Importing/Exporting Parameter Files, MCD 600 22

4.6

PROFIBUS DP-V1 Communication 24

4.6.1

Configuring PROFIBUS DP-V1 24

4.6.2

DP-V1 Connection and PG/PC Interface 25

4.6.3

PROFIBUS Multitelegrams 28

4.7

Ethernet-TSC Data Communication 28

4.7.1

Ethernet-TSC Configuration 28

AQ283728700891en-000201/130R0466 | 3Danfoss A/S © 2021.09

Page 4

VLT® Motion Control Tool MCT 10

Operating Guide

4.7.2

Wink Drive 32

4.7.3

Advanced 33

5

Parameter Set-up 35

5.1

Introduction 35

5.2

User Interface 35

5.2.1

Display 35

5.2.2

Network and Project Folders 36

5.2.3

Other Folders 37

5.3

Setting Up Drives and Folders 38

5.3.1

Inserting a New Folder 38

5.3.2

Setting Up Drives, Active Filters, or Soft Starters 38

5.3.3

Setting Up Low Harmonic Drives 39

5.3.4

All Parameters Folders 40

5.3.5

Array Parameters 41

Contents

5.3.6

Sorting 42

5.4

Customized Views 42

5.4.1

Customize Parameter View Settings 43

5.4.2

Customize Background Color 43

5.4.3

Customize Parameter View 44

5.4.4

Filtering Parameters 45

5.4.5

Customize Columns 45

5.5

Parameter Edit 46

5.6

Comparison of Parameters 48

5.7

Compare Multiple Drives 49

5.8

View Change Log 51

5.9

Read Drive Operation Status 53

6

Operation 54

6.1

Reading and Writing Parameters 54

6.1.1

Read From Drive Settings 54

6.1.2

Write to Drive Settings 55

6.1.3

Communication Fault Tolerance 55

6.2

Connection Properties 56

6.3

Read from Drive 56

6.3.1

Changing the PROFINET Host Name 58

6.4

Write to Drive 59

6.5

Write to Multiple Drives 60

6.6

Poll 62

AQ283728700891en-000201/130R04664 | Danfoss A/S © 2021.09

Page 5

VLT® Motion Control Tool MCT 10

Operating Guide

6.6.1

6.6.2

6.6.3

6.7

Changing the Set-up of a Field Device 64

6.8

Save Changes to a Hard Disk 64

6.8.1

6.8.2

6.9

Import of Older Dialog Files 65

6.10

Printing 66

6.11

Update Database Information 67

6.12

Update Drives Firmware Support in MCT 10 Set-up Software 69

6.13

Software Compatibility 70

6.13.1

6.14

Conversion Wizard 71

Contents

Stop Polling 62

Resume Polling 63

Using Smart Polling (Intelligent Scan Frequency) 63

Recoding Online Changes 64

Archive/Unarchive 65

Mapping to Compatible Firmware 70

6.14.1

Conversion 71

6.14.2

VLT to FC Series Converter Function 71

6.14.3

FC to FC Conversion 73

6.14.4

Conversion Tables Manager 73

7

Diagnostics 80

7.1

Alarm, Warning, and Fault Log Readout 80

7.2

Localization of Alarms and Warnings 80

7.3

Storing Alarms/Warnings in Project Files 81

7.4

Handling the Alarms and Warnings Loggings 81

7.5

The Scope Function 81

7.5.1

Activating the Scope - MCT 10 Set-up Software 82

7.5.2

Configuring the PC Polling Channel 83

7.5.3

PC Polling Channel Properties 85

7.5.4

Reuse of PC Polling Channel Settings 87

7.5.5

Configuring the Drive Real-time Channel 88

7.5.6

Using Advanced Triggers 90

7.5.7

Drive Real-time Channel Properties 92

7.5.8

Communication Control 93

7.5.9

Additional Functionality 93

7.5.10

Scope Storage 94

7.6

Export Log Files 95

8

Plug-ins 97

8.1

Smart Logic Controller Plug-in 97

AQ283728700891en-000201/130R0466 | 5Danfoss A/S © 2021.09

Page 6

VLT® Motion Control Tool MCT 10

Operating Guide

8.2

Time-based Actions and Preventive Maintenance Plug-ins 97

8.2.1

8.2.2

8.2.3

8.3

Motor Plug-in 100

8.3.1

8.3.2

8.3.3

8.3.4

8.4

Multi-motor Plug-in 105

8.4.1

8.4.2

8.4.3

8.4.4

Contents

Clock Functions 97

Preventive Maintenance 98

Timed Actions 99

Asynchronous Motors 102

PM Non-salient SPM 102

PM Salient IPM 103

SynRM 105

Defining Normal Operation Curve 106

Threshold 106

Coefficients 107

Modified Curves 107

8.5

Cascade Controller Plug-in 107

8.5.1

The Preconditions Tab 108

8.5.2

The Set-up Tab 111

8.5.3

The System Optimizing Tab 116

8.5.4

The Service Tab 117

8.5.5

Extended Cascade Controller Options 120

8.6

Drive File Manager Plug-in 125

8.6.1

Customer-specific Initialization Values - CSIV 125

8.6.2

Creating New CSIV Files 126

8.6.3

Configuration of CSIV Files 127

8.6.4

Drive File Manager 129

8.7

Functional Safety Configuration Plug-in 131

8.7.1

Introduction 131

8.7.2

Access 132

8.7.3

Safe Plug-in Interface 133

8.7.4

Configuration 147

8.7.5

Commissioning 152

8.7.6

Operation 154

8.8

Status Plug-in 156

8.9

Drive Control Plug-in 158

8.9.1

Launching the Drive Control Plug-in 160

8.9.2

Setting the Control Word 161

8.9.3

Start Drive Control 162

8.9.4

Changing Control Word Bits 165

AQ283728700891en-000201/130R04666 | Danfoss A/S © 2021.09

Page 7

VLT® Motion Control Tool MCT 10

Operating Guide

8.9.5

8.9.6

8.10

Decoder Plug-in 167

8.10.1

8.11

Condition-based Monitoring (CBM) Plug-in 168

8.11.1

8.11.2

8.11.3

8.11.4

8.11.5

8.11.6

Contents

Changing the Reference 166

Open Drive Control Plug-in 166

Starting the Decoder Plug-in 167

Home Page 171

Speed Range Page 172

Speed Steps Configuration Page 175

8.11.3.1

8.11.3.2

8.11.3.3

Sensor Configuration Page 179

Auto-configuration Setup Page 184

Baseline Progress Page 185

Baseline Run 175

Online Baseline 176

All Baseline Types 177

8.11.6.1

8.11.6.2

8.11.6.3

8.11.7

Thresholds Page 188

8.11.7.1

8.11.7.2

8.11.7.3

8.11.7.4

8.11.8

Monitoring Page 205

8.12

Service Log 213

9

Support of VLT® Wireless Communication Panel LCP 103 214

9.1

Introduction 214

9.1.1

Using LCP 103 with MCT 10 Set-up Software Basic Version 214

9.1.2

Using LCP 103 with MCT 10 Set-up Software Advanced Version 214

10

VLT® Software Customizer 216

Baseline Run 185

Online Baseline 186

All Baseline Types 187

Thresholds Generation 198

Numeric Parameters Editing 202

Choice List Parameters Editing 203

Thresholds Page when Auto-configuration is Selected 204

10.1

Introduction 216

10.1.1

Activation Key 217

10.1.2

Disclaimer 218

10.2

SplashScreen 219

10.2.1

Creating New from Blank 219

10.2.2

Selecting from Library 220

10.2.3

Import 220

10.3

LanguageChanger 223

AQ283728700891en-000201/130R0466 | 7Danfoss A/S © 2021.09

Page 8

VLT® Motion Control Tool MCT 10

Operating Guide

10.3.1

10.3.2

10.3.3

10.3.4

10.3.5

10.4

InitialValues 229

10.4.1

10.4.2

10.4.3

10.4.4

10.5

SmartStart 233

10.5.1

10.5.2

10.5.3

Contents

New from Blank 224

Search Filter 227

Advanced Settings 228

Audit 229

Markings 229

Creating New from Blank 230

Removing Parameters 232

Saving the CSIV File 232

Validation of Parameters During Import 233

Creating New from Blank 235

Create Diagram 239

Create Parameter Screen 240

10.5.4

Link Screens 243

10.5.5

Branching 246

10.5.6

Junction 248

10.6

Writing to Drive 248

10.6.1

Preserve Original vs. Wipe Original 249

10.7

Testing in Simulator 250

10.7.1

Installing the Simulator 251

11

Tool Calling Interface (TCI) 253

11.1

Introduction 253

11.2

Installing the GSD/GSDML File 253

11.3

Creating a Project in TIA 253

11.4

Use Cases 254

11.4.1

Doing the Initial Connection 254

11.4.2

Configuring the TCI 255

12

SyncPos 257

12.1

SyncPos Handling 257

12.2

Programs and Configuration File 257

12.2.1

Programs 257

12.2.2

Viewing the Configuration File 257

12.2.3

Importing and Exporting a Configuration File 257

12.2.4

Editing and Saving a Configuration File 258

12.2.5

Importing Program Files 259

12.2.6

Setting a Program to Auto Start 260

AQ283728700891en-000201/130R04668 | Danfoss A/S © 2021.09

Page 9

VLT® Motion Control Tool MCT 10

Operating Guide

12.2.7

Editing Source Code 261

12.2.8

Saving and Exiting Program 261

12.3

SyncPos Read From Drive 262

12.4

SyncPos Write to Drive 263

13

Troubleshooting 265

13.1

Save Error Dialog 265

13.2

Common Problems and Solutions 266

13.2.1

Changes are not Saved to PC 266

13.2.2

Error Message While Installing MCT 10 Set-up Software 266

13.2.3

Error Message Communication Failed 266

13.2.4

Communication Errors 267

13.2.5

Help 268

13.3

Safe Plug-in 268

13.3.1

Troubleshooting Communication Errors 268

Contents

13.3.2

Troubleshooting CRC Errors 268

13.3.3

Warnings and Alarms 269

AQ283728700891en-000201/130R0466 | 9Danfoss A/S © 2021.09

Page 10

Edition

Remarks

Software version

AQ283728700891, version 0201

Upgrade to new software version. Support of Multiple Drive Handling, Wireless Direct, and Condition-based Monitoring.

5.3

VLT® Motion Control Tool MCT 10

Operating Guide

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This manual provides basic knowledge required to use the MCT 10 Set-up Software with Danfoss drives. Familiarity with the following is assumed:

•

MS®-Windows™ at user level.

•

Set-up, process knowledge, and operation of drive.

•

Use of and linkage with communication equipment.

The manual does not provide any detailed information regarding specific applications or possible solutions and related parameter

combinations in the set-up and use of a drive. Refer to the operating guide and design guide of the drive. Any update of the manual

and instructions related to the MCT 10 Set-up Software is available at www.danfoss.com.

Familiarity with the PC or PLC master of the system is assumed. Issues regarding hardware or software produced by other manufacturers are beyond the scope of this manual and are not the responsibility of Danfoss.

Refer to the appropriate manuals for more information about master-to-master communication, or communication to a non-Danfoss slave.

1.2 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

1.3 Intended Use

The MCT 10 Set-up Software enables full system configuration and control. With MCT 10, it is possible to monitor the entire system

more efficiently for faster diagnosis and better preventive maintenance.

MCT 10 is designed as an interactive commissioning tool for quick and easy commissioning of the following drive series:

•

VLT® 2800.

•

VLT® 4000.

•

VLT® 5000.

•

VLT® 6000.

•

VLT® 8000.

•

VLT® Micro Drive FC 51.

•

VLT® HVAC Basic Drive FC 101.

•

VLT® HVAC Drive FC 102.

•

VLT® Refrigeration Drive FC 103.

•

VLT® AQUA Drive FC 202.

•

VLT® Midi Drive FC 280.

•

VLT® AutomationDrive FC 301/FC 302.

•

VLT® AutomationDrive FC 360.

•

VLT® Decentral Drive FCD 302.

•

VLT® DriveMotor FCM Series.

•

VLT® Compressor Drive CD 302.

•

VLT® Compressor Drive CDS 302.

•

VLT® Compressor Drive CDS 303.

•

VLT® Soft Starter MCD 500.

•

VLT® Soft Starter MCD 600.

AQ283728700891en-000201 / 130R046610 | Danfoss A/S © 2021.09

Page 11

VLT® Motion Control Tool MCT 10

Operating Guide

•

VLT® Advanced Active Filter AAF 005.

•

VLT® Advanced Active Filter AAF 006.

Use cases of the MCT 10:

•

For planning a new communication network offline. The MCT 10 contains a complete database with all Danfoss Drives products.

•

For commissioning drives online.

•

For easy replacement of drives.

•

For easy expansion of networks with more drives.

•

For back-up of parameter settings of drives in a communication network.

•

The MCT 10 supports PROFIBUS DP-V1 communication via a master class 2 connection. This connection eliminates the need for

an extra communication network.

The communication framework part of MCT 10 is handling the control of the fieldbuses. It provides enhanced capabilities allowing

multiple concurrent fieldbus communication. Several fieldbuses can be configured and combined in the same network within MCT

10.

Introduction

N O T I C E

If several fieldbuses are created with the same type, make sure that they are configured with different scan ranges.

1.4 System Requirements

To use the VLT® Motion Control Tool MCT 10, the IBM-compatible computer must meet the following minimum system requirements:

4 GB of available space on the hard drive.

•

MCT 10 runs on Windows™ 10 32/64-bit editions.

1.5 Software Modules

The VLT® Motion Control Tool MCT 10 Set-up Software is supplied in 2 modules:

•

MCT 10 Set-up Software for:

-

Setting the drive parameters.

-

Copying parameter sets to and from a drive.

-

Documentation/printout of set-up, including diagrams.

-

Servicing and fault analysis.

•

APoss program for creating APoss programs.

1.5.1 Features of the VLT® Motion Control Tool MCT 10

•

Project-oriented PC tool, 1 tool for all drive series.

•

Links to all Windows applications possible.

•

Supports Siemens CP PCMCIA-and PCI cards for PROFIBUS DP-V1 master class 2 connection.

•

Supports standard interfaces: COMx, USB, RS232 (Flux).

•

Siemens PG/Field PGs already have the required hardware.

•

View is highly individually configurable.

•

Downwards compatibility with Dos-Dialog (*.mnu) and WinDialog (*.vlt).

•

Windows™ Explorer-like interface for quick and easy start-up and navigation.

•

Wireless Direct.

AQ283728700891en-000201 / 130R0466 | 11Danfoss A/S © 2021.09

Page 12

e30bt513.12

PC (Master)

USB to RS485 converter

#1

#2

#3 #126

Version supports

MCT 10 Set-up Software

Advanced

MCT 10 Set-up Software Basic

Drives per project

Unlimited

4

FC protocol

✓

✓

Functional safety

✓

✗

USB

✓

✓

PROFIBUS DP-V1

✓

✓

PROFIBUS DP-V1 handling multiple Danfoss nodes concurrently

✓ (limited performance)

✗

Ethernet-TSC

✓

✓

Logging and scope function

8 channels

2 channels

Real-time logging from a drive

4 channels

✗

Alarm display

✓

View only

VLT® Motion Control Option MCO 305

✓

✓

Graphical smart logic control

✓

✓

VLT® 5000 to FC 302, VLT® 6000 to FC 102, and VLT® 2800 to FC 280 conversion wizards

✓

✓

VLT® Motion Control Tool MCT 10

Operating Guide

Introduction

Illustration 1: Connect up to 126 Nodes with a Repeater and up to 31 Nodes without Repeater

1.6 Versions

VLT® Motion Control Tool MCT 10 is available in 2 versions:

•

MCT 10 Set-up Software Basic is available free of charge. Download the program from www.danfoss.com - select VLT® Motion

Control Tool MCT 10.

•

MCT 10 Set-up Software Advanced can be purchased using ordering number 130B1000.

Table 1: Features of the Basic and Advanced Versions

AQ283728700891en-000201 / 130R046612 | Danfoss A/S © 2021.09

Page 13

Version supports

MCT 10 Set-up Software

Advanced

MCT 10 Set-up Software Basic

FC to FC conversion wizard

✓

✓

Import 3000.XLS to FC 302

✓

✗

Motor database

✓

✗

VLT® Extended Cascade Controller MCO 101

✓

✗

Drive file system

✓

✗

VLT® Wireless Control Panel LCP 103

✓

✓

Status plug-in

✓

✓

Drive plug-in

✓

✗

VLT® Software Customizer

✓

✗

VLT® Motion Control Tool MCT 10

Operating Guide

1.7 Further Information

The following manuals related to VLT® Motion Control Tool MCT 10 are available:

•

VLT® PROFIBUS DP-V1 MCA 101 Installation Guide.

•

Design guides for the relevant drives.

Refer to www.danfoss.com/en/about-danfoss/our-businesses/drives/ for more information.

It is also possible to find video training material on this site for operating the MCT 10.

Introduction

AQ283728700891en-000201 / 130R0466 | 13Danfoss A/S © 2021.09

Page 14

VLT® Motion Control Tool MCT 10

Operating Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example messages relating to property damage).

Safety

2.2 Safety Precautions

W A R N I N G

HIGH VOLTAGE

AC drives contain high voltage when connected to AC mains input , DC supply , or load sharing. Failure to perform installation,

start-up, and maintenance by qualified personnel can result in death or serious injury.

Only qualified personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to the AC mains, DC supply, or load sharing, the motor may start at any time, causing risk of death,

serious injury, and equipment, or property damage. The motor may start by activation of an external switch, a fieldbus command,

an input reference signal from the LCP or LOP, via remote operation using MCT 10 Set-up software, or after a cleared fault condi-

tion.

Press [Off] on the LCP before programming parameters.

-

Disconnect the drive from the mains whenever personal safety considerations make it necessary to avoid unintended motor

-

start.

Check that the drive, motor, and any driven equipment is in operational readiness.

-

AQ283728700891en-000201 / 130R046614 | Danfoss A/S © 2021.09

Page 15

VLT® Motion Control Tool MCT 10

Operating Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully before performing any service or repair work. The discharge time is specified in the

-

drive operating guides.

Use a measuring device to make sure that there is no voltage, before opening the drive or performing any work on the ca-

-

bles.

AQ283728700891en-000201 / 130R0466 | 15Danfoss A/S © 2021.09

Page 16

e30bt514.14

VLT® Motion Control Tool MCT 10

Operating Guide

Installation and De-installation

3 Installation and De-installation

3.1 Introduction

The VLT® Motion Control Tool MCT 10 Software and SyncPos modules are installed via a multilingual, self-explanatory installation

program.

3.1.1 Starting the Installation Program

Procedure

1.

Run VLT_MCT10_Vx.xx.msi.

2.

Follow the instructions of the installation program.

When the installation process is complete, the MCT 10 Set-up Software can be found on the following path:

Illustration 2: Path for MCT 10 Set-up Software

3.1.2 Selecting the Software Language

The Danfoss default language is English. If another language is selected, it becomes the new default.

Procedure

1.

Select Options from the main menu, then select Select Language.

2.

Select the wanted language from the scrollbar and click OK.

N O T I C E

Changing the language affects the parameter language. If an external LCP is connected to the drive, the change of lan-

guage version does not affect the language in the display.

3.

Close and restart MCT 10 to activate the language setting.

3.1.3 Uninstalling the Software

N O T I C E

The following procedure is only valid for Windows operating systems.

Procedure

1.

Select Start.

2.

Select Settings.

3.

Select Control Panel.

4.

Double-click Remove/Add Programs.

5.

Select Remove.

AQ283728700891en-000201 / 130R046616 | Danfoss A/S © 2021.09

Page 17

e30bt631.11

VLT® Motion Control Tool MCT 10

Operating Guide

Set-up of Communication

4 Set-up of Communication

4.1 Communication Options

Drives in the VLT® HVAC Drive FC 102, VLT® AQUA Drive FC 202, and VLT® AutomationDrive FC 302 series are equipped with a USB

port. Communication from a PC can be established using a standard A–B male-to-male USB cable connected to the drive. No extra

hardware or bus configuration is required. If the PC is equipped with more than 1 USB port, several drives can be connected. The

USB bus is automatically added to the network bus list.

Establish a hardwired connection through:

•

Standard built-in RS485, or

•

USB port.

The USB interface socket allows devices to be connected and disconnected using hot swapping. When connecting a drive using

USB, MCT 10 Set-up Software automatically adds on to the bus list.

If the VLT® PROFIBUS DP-V1 MCA 101 or the VLT® EtherNet/IP MCA 121 option is mounted in the drive, establish the connection

through:

•

PROFIBUS master class 2 connection (MSAC 2), or

•

Ethernet-based network.

N O T I C E

Connect soft starters either via a USB cable or via ethernet.

N O T I C E

RISK OF DAMAGE TO PC USB HOST CONTROLLER

When connecting the PC to the drive through the USB cable, there is a risk of damaging the PC USB host controller.

Follow the recommendations for grounding described in the Operating Guide for the relevant drive.

-

Use a USB isolator with galvanic isolation to protect the PC USB host controller from ground potential differences when con-

-

necting the PC to a drive through a USB cable.

Do NOT use a PC power cable with a ground plug when the PC is connected to the drive through a USB cable.

-

Communication from a PC can be established via RS232 to RS485 converters or via USB to RS485 converters.

Illustration 3: Communication from a PC

4.2 Manual Fieldbus Configuration

After installation, configure the non-plug-and-play networks via the fieldbus configuration dialog.

Procedure

1.

Start the MCT 10 Set-up Software.

2.

Select Network.

AQ283728700891en-000201 / 130R0466 | 17Danfoss A/S © 2021.09

Page 18

e30bt622.12

e30bt630.13

VLT® Motion Control Tool MCT 10

Operating Guide

3.

Right-click Network and select Add/Remove/Configure Buses.

Illustration 4: Refreshing the Fieldbus List

4.

Add, remove, or configure the properties for the connected buses.

Set-up of Communication

Illustration 5: Fieldbus Configuration

5.

Scan the network for active drives to make MCT 10 indicate available drives on the non-plug-and-play fieldbuses.

4.3 Automatic Scan

Only the USB fieldbus is scanned automatically when a drive is connected to the PC. For non-plug-and-play fieldbuses, scan manually for active drives.

4.3.1 Scan Range Configuration

Enter the preferred scan setting by right-clicking SerialCom and then selecting Configure Driver.

Adding a standard bus RS485 or PROFIBUS to the network tree configures the scan range to scan the entire address range. The

Ethernet-TSC bus is added using the current IP address settings.

The fieldbus scan range can be configured in several ways:

•

Right-click the Fieldbus icon in the network tree and select Configure Bus.

•

Mark the Fieldbus icon in the network tree and select Configure under Communication in the main menu bar.

•

Open the Fieldbus Configuration dialog, right-click the Network icon, and select Add/Remove/Configure Buses.

Open from the Windows panel.

•

AQ283728700891en-000201 / 130R046618 | Danfoss A/S © 2021.09

Page 19

e30bt495.14

Scan network icon

e30bt496.12

VLT® Motion Control Tool MCT 10

Operating Guide

Illustration 6: Scan Network Icon

Set-up of Communication

4.3.2 Scan Network

Scan a fieldbus in 3 ways:

•

Right-click the Fieldbus icon in the network tree and select Scan Bus for active drives.

•

Mark the Fieldbus icon in the network tree and select Scan/Refresh under Communication in the main menu bar.

•

Mark the Fieldbus icon in the network tree and select the Scan icon on the toolbar.

The Scanning for Drives window appears and indicates the progress of the scan.

Illustration 7: Progress of Network Scanning

4.4 Set Up the Drive with RS485 Data Communication

All drives can be configured to 300, 1200, 4800, 9600 (default), 19200, 38400, 57600, or 115200 baud. The serial configuration is

always configured with:

•

8 data bits.

•

1 stop bit.

•

Even parity.

4.4.1 Configuring the Fieldbus

When using an RS485 converter as the Advantech ADAM converter, MCT 10 Set-up Software indicates online drives available on the

fieldbus after scanning the bus.

N O T I C E

Protocol and advanced settings are for performance optimization and should normally not be changed.

Procedure

AQ283728700891en-000201 / 130R0466 | 19Danfoss A/S © 2021.09

Page 20

e30bt629.12

e30bt623.12

VLT® Motion Control Tool MCT 10

Operating Guide

1.

Open the Serial Fieldbus Configuration dialog box or right-click the appropriate fieldbus.

Illustration 8: Serial Fieldbus Configuration

2.

Set the COM port number.

Set-up of Communication

When using USB to RS485 converters, the actual COM port number can be identified from the device manager part of the

Windows control panel.

3.

Set the baud rate, parity, and the number of stop bits (must match the settings in the drive).

4.

Set the fieldbus scanning range to the available address to limit the time scanning for active drives.

5.

Press OK to activate settings or select to restore the default settings.

4.4.2 USB Data Communication

Illustration 9: Network Bus List

When the USB cable is disconnected, the drive connected via the USB port is removed from the network bus list.

4.5 Set-up of Soft Starter

Setting up connectivity to the VLT® Soft Starter MCD 500 and VLT® Soft Starter MCD 600 requires that the USB communication module is mounted on the soft starter. Communication from a PC can be established using a standard A–B male-to-male USB cable

connected to the USB communication module. If the PC is equipped with more than 1 USB port or a USB HUB, several soft starters

can be connected.

AQ283728700891en-000201 / 130R046620 | Danfoss A/S © 2021.09

Page 21

e30bt758.12

VLT® Motion Control Tool MCT 10

Operating Guide

Set-up of Communication

4.5.1 Serial Configuration

All soft starters can be configured to 300, 1200, 4800, 9600 (default), 19200, 38400, 57600, or 115200 baud. The serial configuration

is always configured with:

•

8 data bits.

•

1 stop bit.

•

No parity.

Illustration 10: Serial Configuration of Soft Starters

4.5.1.1 Configuring the Fieldbus

Procedure

1.

Add and configure the bus from the Fieldbus Configuration dialog.

If the bus is already added to the network, it can be reconfigured by right-clicking on the appropriate soft starter fieldbus.

2.

Set the COM port number. The actual COM port number can be identified from the device manager part of the control

panel.

3.

Set the baud rate, parity, and the number of stop bits (must match the setting in the soft starter).

4.

Reset to Default restores the general settings and fieldbus scanning to factory configuration values.

4.5.1.2 Using the Hilscher NetIdent Protocol

Use the tool for searching for devices and for identifying and changing IP addresses. The tool also has a filtering function.

Procedure

1.

Click the Tools menu.

AQ283728700891en-000201 / 130R0466 | 21Danfoss A/S © 2021.09

Page 22

e30bt980.12

VLT® Motion Control Tool MCT 10

Operating Guide

2.

Select Soft Starter Discover and Configuration Tool.

Set-up of Communication

Illustration 11: Selecting the Hilscher NetIdent Tool

3.

Select the soft starter for which the IP address should be configured.

4.

Click Configure.

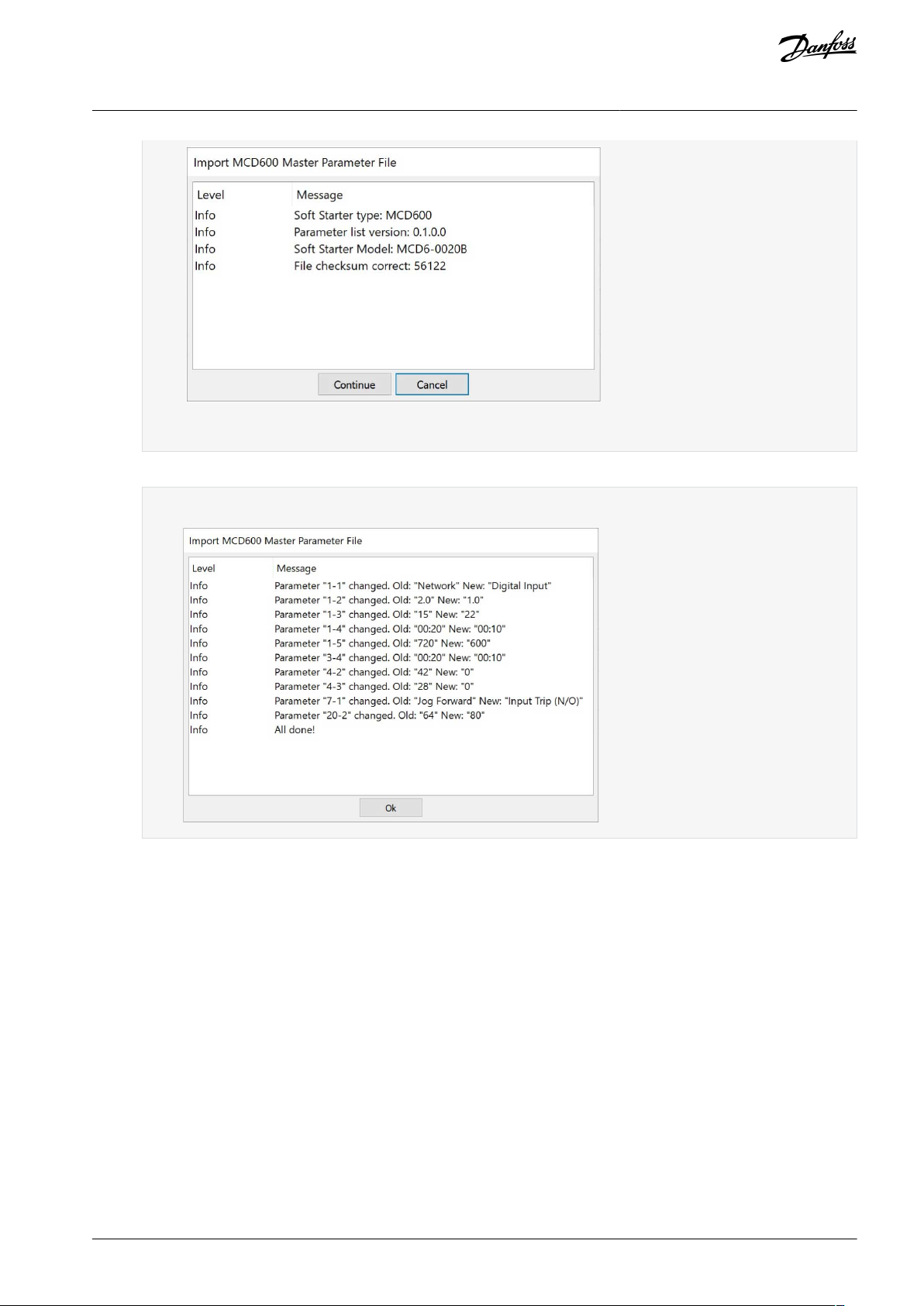

4.5.2 Importing/Exporting Parameter Files, MCD 600

With VLT® Soft Starter MCD 600, a parameter file (PAR file) can be exported from the soft starter to a USB stick and copied into VLT®

Motion Control Tool MCT 10. After changing the file in MCT 10, the PAR file can be copied back to the USB stick and applied to the

soft starter.

Procedure

Create an MCD 600 project soft starter.

1.

Right-click the project folder.

2.

3.

Select Import parameters.

From the dialog, select the file to import.

4.

A dialog opens showing information about the selected file.

AQ283728700891en-000201 / 130R046622 | Danfoss A/S © 2021.09

Page 23

e30bu310.12

e30bu311.12

VLT® Motion Control Tool MCT 10

Operating Guide

If the soft starter differs from the project, it shows up as an error or warning in this view, depending on the difference.

5.

Press Continue to apply the file.

A view, which shows all changed parameters, appears.

Set-up of Communication

6.

Click Ok to close the window.

7.

Right-click the project to export from MCT 10.

8.

Select the parameters to export.

9.

In the file selection dialog, select where to export the file to.

A dialog appears when the export is completed.

AQ283728700891en-000201 / 130R0466 | 23Danfoss A/S © 2021.09

Page 24

e30bu312.11

e30bt634.11

PCMCIA

DP-V1 card

DP-V1

#1

#2 #N

DP-V1

#1

#2 #N

Insertable

DP-V1 card

VLT® Motion Control Tool MCT 10

Operating Guide

Set-up of Communication

4.6 PROFIBUS DP-V1 Communication

Setting up PROFIBUS DP-V1 communication requires a VLT® PROFIBUS DP-V1 MCA 101 option module. Communication from a PC

using PROFIBUS DP-V1 can be established using a PROFIBUS PCMCIA card or a card installed in the PC. The PROFIBUS cable from the

drive is connected to the 9-pin sub D socket connector on the card.

Illustration 12: PROFIBS DP-V1 Communication

Consult Siemens www.siemens.com for the latest supported cards for PCs.

N O T I C E

Connectivity via PROFIBUS DP-V1 to a VLT® AutomationDrive FC 302 utilizing the VLT® PROFIBUS Converter MCA 114 with option

firmware version 2.03 is not possible from MCT 10 Set-up Software. Use the fieldbus or USB bus instead.

4.6.1 Configuring PROFIBUS DP-V1

When using a PROFIBUS interface card with the associated driver installed, MCT 10 Set-up Software indicates online drives available

on the specific PROFIBUS after scanning the bus for active drives.

Procedure

AQ283728700891en-000201 / 130R046624 | Danfoss A/S © 2021.09

Page 25

e30bt625.14

VLT® Motion Control Tool MCT 10

Operating Guide

1.

Configure the bus from the Fieldbus Configuration dialog or by right-clicking the appropriate PROFIBUS bus.

Illustration 13: PROFIBUS Fieldbus Configuration

2.

Set the board number.

3.

Set the fieldbus scanning range to the available addresses only to limit the time used for scanning active drives.

4.

Press OK to activate or reset to restore factory default settings.

Set-up of Communication

4.6.2 DP-V1 Connection and PG/PC Interface

The MCT 10 Set-up Software PROFIBUS DP-V1 fieldbus plug-in utilizes the Siemens SoftNet driver available from Step7, or alternatively Simatic NET, to establish connectivity via the supported master class 2 cards such as CP5511 or CP5512.

N O T I C E

STEP7 Lite version does not support the SoftNet driver.

4.6.2.1 Setting Up the PG/PC Interface

This procedure explains how to set up the PG/PC Interface from default configuration to open the PROFIBUS connection from MCT

10.

Cabling and terminations must be in accordance with wiring and cabling requirements for PROFIBUS.

Procedure

AQ283728700891en-000201 / 130R0466 | 25Danfoss A/S © 2021.09

Page 26

e30bt789.10

VLT® Motion Control Tool MCT 10

Operating Guide

1.

Open the PG/PC Interface.

Set-up of Communication

Illustration 14: Set PG/PC Interface

2.

Configure Access Point of the Application to CP_L2_1 pointing to the master class 2 card used.

3.

Set Interface Parameter Assignment Used corresponding to the master class 2 card used.

4.

Select Properties to configure the station- and network parameters.

Station parameters:

-

Set PG/PC is the only master on the bus to Active if no PLC is active on the bus. Use the Diagnostics described later to

select a valid PROFIBUS address.

Network parameters:

-

Set the Transmission rate to the same baud rate as the PLC if it is active.

5.

Use DP as Profile and click OK to close the Properties dialog.

AQ283728700891en-000201 / 130R046626 | Danfoss A/S © 2021.09

Page 27

e30bt790.11

130BT791.10

VLT® Motion Control Tool MCT 10

Operating Guide

6.

Select Diagnostics in the Set PG/PC Interface to verify network- and bus communication.

Set-up of Communication

Illustration 15: Properties Dialog

Illustration 16: Simatic Network Diagnostics Dialog

7.

Select Test to verify the access path and network configuration. If a sharing violation is detected, the test results in an error

message. When the test result is successful, select Read to identify the active PROFIBUS nodes available on the network.

Make sure that the address defined for the PG/PC interface does not conflict with an active node.

AQ283728700891en-000201 / 130R0466 | 27Danfoss A/S © 2021.09

Page 28

VLT® Motion Control Tool MCT 10

Operating Guide

8.

Close the PG/PC interface and start MCT 10.

9.

Right-click a PROFIBUS and select Scan for active drives. MCT 10 Set-up Software identifies the same node IDs, except PLCs.

Set-up of Communication

4.6.3 PROFIBUS Multitelegrams

With the Parameters allowed per telegram drop-down list, it is possible to configure the number of requests to be associated within a

multitelegram. The standard allows up to 40 telegrams to be associated.

The following options are available:

•

Maximum speed (default configuration). Handles the association automatically and adapts the number of telegrams for each

drive according to the series. Can be used in PROFIBUS networks containing both old and new Danfoss drives.

•

Conservative. Always associates 10 telegrams within a multitelegram. This option is useful when communicating only with old

products such as the VLT® Decentral Drives FCD 300, VLT® DriveMotor FCM 300, series derived from VLT® HVAC Drive FC 102,

VLT® AQUA Drive FC 202, and VLT® AutomationDrive FC 302.

•

Single request. Only 1 request per telegram.

4.7 Ethernet-TSC Data Communication

To set up an Ethernet-TSC (transparent socket channel) communication, the VLT® EtherNet/IP MCA 121 option module is required

within the drive. Communication from a PC can be established using a standard Ethernet cable connected to the drive.

4.7.1 Ethernet-TSC Configuration

An Ethernet-TSC bus is scanned using DDP (drive discovery protocol). The protocol does not require an IP port number and IP scan

range. It identifies drives based on the MAC addresses.

N O T I C E

When scanning through different subnets or remotely via a VPN tunnel, it is advised not to utilize the ADDP protocol but to use

an IP range.

Click Refresh to generate a list of all active drives in the Ethernet. The list appears in the Ethernet Fieldbus Settings dialog when the

scan is complete.

AQ283728700891en-000201 / 130R046628 | Danfoss A/S © 2021.09

Page 29

e30bt775.13

VLT® Motion Control Tool MCT 10

Operating Guide

Set-up of Communication

Illustration 17: ADDP Configuration

Drive types without any IP configuration use their Auto IP Class B address, which is 169.254.yy.xx, with yy.xx corresponding to the

last 2 segments in the MAC address. Several uncommissioned drives without any IP configuration can be scanned on the same network.

Select a device from the Discovered Drives list to;

•

Get more information about the device.

•

Assign a static IP address, a subnet mask, or default value to the drive.

•

Set up DHCP (dynamic host configuration protocol) look-up.

AQ283728700891en-000201 / 130R0466 | 29Danfoss A/S © 2021.09

Page 30

e30bt857.11

VLT® Motion Control Tool MCT 10

Operating Guide

Set-up of Communication

Illustration 18: TSC Configure

4.7.1.1 Scanning with IP Range

When scanning using an IP range, the Ethernet telegrams are transmitted as traditional TCP/IP packages routed out in a router,

switch, or manage switch without requiring any changes. The disadvantage is an increased scanning time, and drives without IP

address configured are not identified.

N O T I C E

Identification of drives using the VLT® EtherNet/IP MCA 121 option is possible only from option firmware version 1.03 or newer. If

using options with firmware versions earlier than 1.03, configure parameter 12-89 Transparent Socket Channel Power to 0 to pre-

vent the option from failing to operate.

Procedure

AQ283728700891en-000201 / 130R046630 | Danfoss A/S © 2021.09

Page 31

e30bt852.11

VLT® Motion Control Tool MCT 10

Operating Guide

1.

Configure the IP start address and the transparent socket channel port (parameter 12-89 Transparent Socket Channel Port),

which is factory default 4000 in the drive.

Set-up of Communication

Illustration 19: Scan Range

After the scan, all active drives are identified.

2.

Use a corresponding drive to read or write to a single drive instead of waiting for MCT 10 to scan and identify all drives.

a.

Open the project file and create offline drives manually.

b.

Configure the connection properties.

c.

Right-click the offline drive.

d.

Read and write to the drive without scanning the bus.

4.7.1.2 Filtering

When using multicast, it is possible to filter a range of IP addresses.

Also, use filtering for boosting scan performance.

AQ283728700891en-000201 / 130R0466 | 31Danfoss A/S © 2021.09

Page 32

e30bt851.11

VLT® Motion Control Tool MCT 10

Operating Guide

Set-up of Communication

Illustration 20: Filtering

4.7.2 Wink Drive

During a commissioning process of a system containing several drives, it can be time-consuming physically to locate a drive based

on the MCT 10 project. This is especially the case if the drive is not equipped with an LCP.

Through the Ethernet_TSC fieldbus, it is possible via MCT 10 to use a wink function. This function blinks with the MS, NS1, and NS2

LEDs on all Danfoss Ethernet-based fieldbus options.

On the Ethernet-based fieldbus option, the winking is recognized with all 3 LEDs blinking orange with 1-Hz interval. There is no limit

to the number of drives winking and the duration of winking.

4.7.2.1 Start Winking

N O T I C E

It can take up to 30 s from starting or stopping the winking, until the option responds.

Procedure

1.

Right-click a drive from the Ethernet network.

AQ283728700891en-000201 / 130R046632 | Danfoss A/S © 2021.09

Page 33

e30bt784.11

VLT® Motion Control Tool MCT 10

Operating Guide

2.

Select Start winking or Stop winking.

Set-up of Communication

Illustration 21: Start Winking

4.7.3 Advanced

Use the Advanced tab:

•

To configure Port Number For Range Scan. The default value is 4000.

•

To define the TSC Connection Allocation/Sharing.

The drive has limited simultaneous connections, and with this function it is possible to define if the connections should be released

or not. If selecting Release Idling Connections, the MCT 10 releases unused connections and makes them available to other users in

the network after idle timeout.

AQ283728700891en-000201 / 130R0466 | 33Danfoss A/S © 2021.09

Page 34

e30bt853.11

VLT® Motion Control Tool MCT 10

Operating Guide

Set-up of Communication

Illustration 22: The Advanced Tab

AQ283728700891en-000201 / 130R046634 | Danfoss A/S © 2021.09

Page 35

e30bt638.12

VLT® Motion Control Tool MCT 10

Operating Guide

Parameter Set-up

5 Parameter Set-up

5.1 Introduction

This chapter explains how to control a drive using the MCT 10 Set-up Software. After starting the MCT 10, the main window looks

like the example shown in Illustration 23.

Illustration 23: MCT 10 Set-up Software Main Window

5.2 User Interface

5.2.1 Display

The MCT 10 Set-up Software has 2 views:

•

Left view.

•

Right view.

Left view

The left view shows the network view (real, online) and the project view (simulated, offline) of the drive network.

Use the left view to:

•

Add or delete folders and elements.

•

Store changes into the Project folder.

Store changes made to the real online set-up into the Project folder in the simulated, offline set-up for later use.

For more information on saving data, refer to 6.8.1.1 Saving a Project.

The left view is organized in a tree structure and contents can be expanded or collapsed as required. Click +/- to expand/collapse

the folder.

Right view

The right view shows details of the element highlighted in the left view. In the right view, the elements of the drive network can be

programmed.

AQ283728700891en-000201 / 130R0466 | 35Danfoss A/S © 2021.09

Page 36

e30bt639.12

e30bt712.12

VLT® Motion Control Tool MCT 10

Operating Guide

Parameter Set-up

Illustration 24: Details Shown in the Right View

Toolbar

A toolbar shows icons for the most commonly used functions.

Illustration 25: Toolbar

Activate the toolbar under View in the main menu bar, where the toolbar is tick-marked when it is active. To deactivate the toolbar,

select View⇒Toolbar. Check that the toolbar is no longer tick-marked.

5.2.2 Network and Project Folders

The Network folder gives access to physical devices operating in the field. Use Network to configure the physical drive as with the

LCP. Configuration changes made in the Network folder are therefore saved only in the physical device in the field. The Network

folder contains online data.

The Project folder contains offline data.

N O T I C E

Changes made in the Network folder are not saved automatically to the Project folder.

Network mode - online

The Network folder contains the drives, low harmonic drives, active filters, and/or soft starters online connected to the PC. Monitor

and change the parameter settings exactly as if operating on the control panel.

Data entered online is stored in the drive, low harmonic drive, active filter, or soft starter only, not on the hard disk. For information

on saving data to the hard disk, refer to

Project mode - offline

The Project folder contains the user-defined network of drive, low harmonic drive, active filter, and/or soft starter.

Data entered offline is stored on hard disk.

Use the Project folder to:

6.8.1.1 Saving a Project.

AQ283728700891en-000201 / 130R046636 | Danfoss A/S © 2021.09

Page 37

Name

Purpose

Icon

Folder

Organize drive and/or soft starters that are part of a machine or system.

e30bt713.12

File folder

Organize files belonging to a project. Any file format can be used.

e30bt714.11

Parameter folder

Store parameter settings temporarily or for documentation purposes. The folder can

contain a single parameter, subgroup, parameter group, or the entire parameter database.

e30bt523.12

Scope folder

Analyze the behavior of 1 or several parameters for diagnostic purposes by visualizing

them as a curve.

e30bt715.11

e30bt516.14

VLT® Motion Control Tool MCT 10

Operating Guide

•

Open a project file.

•

Insert folders.

•

Store project-related files in any format, for example Word or PDF.

5.2.3 Other Folders

Four folder types are available for organizing a large system into several smaller systems.

Table 2: Available Folder Types

Parameter Set-up

Insert any folder type in an offline project in 1 of 2 ways:

•

Right-click the project or an existing folder and select New Folder/New File Folder, as shown in Illustration 26.

•

Alternatively, mark the project or an existing folder and select New Folder/New File Folder under Insert in the main menu bar.

Illustration 26: Inserting a Folder Type

AQ283728700891en-000201 / 130R0466 | 37Danfoss A/S © 2021.09

Page 38

e30bt637.12

VLT® Motion Control Tool MCT 10

Operating Guide

Parameter Set-up

5.3 Setting Up Drives and Folders

Sometimes, it is necessary to insert a new folder before setting up new drives. See 5.3.1 Inserting a New Folder for instructions.

The way to set up drives depends on the drive type. The methods are described in 5.3.2 Setting Up Drives, Active Filters, or Soft

Starters and 5.3.3 Setting Up Low Harmonic Drives.

5.3.1 Inserting a New Folder

Procedure

1.

Right-click the Project folder or selectInsert in the main menu bar.

2.

Select New.

3.

Select Folder or File Folder.

5.3.2 Setting Up Drives, Active Filters, or Soft Starters

Insert the drive, the active filter, or the soft starter in a project folder as follows:

Procedure

1.

Right-click in the left view or click Insert in the main menu bar.

2.

Select New.

Select the appropriate device type.

3.

Inserting a drive opens the New Drive window.

Illustration 27: New Drive Window

The New Drive window consists of 4 main sections:

AQ283728700891en-000201 / 130R046638 | Danfoss A/S © 2021.09

Page 39

Name

Enter a unique name for the drive. Any text/number combination is allowed. Also specify with software version

and the voltage in this section.

Select Drive

Type

Information about the drive series and power size. A PUD file (power unit data information) is also available. The

default file is always preselected.

Options

Various information about the installed options.

Connection

The fieldbus used between the PC and the drive associated with the address to communicate. The specific fieldbus type is available from the drop-down menu.

e30bt636.12

VLT® Motion Control Tool MCT 10

Operating Guide

It is mandatory to fill in all fields. The different selections are available from the drop-down menus.

Once the new drive is added to the Project folder, the drive data is stored in the offline Project folder. To view the data, click the

drive icon.

Parameter Set-up

Illustration 28: View the Drive Data

To change the stored drive data, right-click the specific drive icon and select Properties.

5.3.3 Setting Up Low Harmonic Drives

Insert a low harmonic drive in a project folder as follows:

Procedure

1.

Right-click in the left view or select Insert in the main menu bar.

2.

Select New.

3.

Select Drive.

AQ283728700891en-000201 / 130R0466 | 39Danfoss A/S © 2021.09

Page 40

e30bt787.12

e30bt788.11

VLT® Motion Control Tool MCT 10

Operating Guide

4.

Enter all relevant data in the New Drive dialog and click Make LHD.

Parameter Set-up

Illustration 29: Entering Data for a New Low Harmonic Drive

N O T I C E

The Make LHD option is only available when power size and voltage ranges of the drive correspond to the supported low

harmonic drive.

5.

Enter all active filter data in the New filter dialog. Ensure that the fieldbus address used for the active filter is not used for

other components.

The low harmonic drive is visible in the project as a composition of the drive and the active filter.

Illustration 30: Low Harmonic Drive Shown in the Project Folder

5.3.4 All Parameters Folders

A new Drive folder contains an All Parameters folder. This folder comprises a series of subfolders with generic names. There is no

rename function for these folders. The generic folders within most drives consist of the following subfolders:

AQ283728700891en-000201 / 130R046640 | Danfoss A/S © 2021.09

Page 41

e30bt524.13

e30bt525.11

VLT® Motion Control Tool MCT 10

Operating Guide

•

Operation and display.

•

Load and motor.

•

References and limits.

•

Inputs and outputs.

•

Special functions.

•

Serial communication.

•

Technical functions.

The generic folders can vary according to the type of drive selected.

Parameter Set-up

Illustration 31: Subfolders in the All Parameters Folder

The generic folders comprise parameters relevant to the drive type selected.

Illustration 32: Data Example in a Generic Folder

5.3.5 Array Parameters

Parameters containing array data are shown as a matrix in the right view, where the rows of the matrix are defined as ID.1, ID.2, and

so on. For example, array parameters parameter 9-15 PCD Write Configuration and parameter 9-16 PCD Read Configuration are shown

over several entries as 915.1, 915.2, 915.3, and 916.1, 916.2, 916.3 in the right view.

AQ283728700891en-000201 / 130R0466 | 41Danfoss A/S © 2021.09

Page 42

e30bt531.12

e30bt830.11

VLT® Motion Control Tool MCT 10

Operating Guide

Illustration 33: Array Parameters

5.3.6 Sorting

The Danfoss products listed under Network or Project can be sorted according to:

•

Folder name.

•

Series.

•

Software version.

•

Address (communication address).

•

Power size.

•

Voltage.

Click the sorting bar and select the relevant sorting option.

Parameter Set-up

Illustration 34: Sorting Options

5.4 Customized Views

Select View in the main menu bar to see the display options. The following options are available:

Show or hide the toolbar.

•

Show or hide the status bar.

•

Large icons/small icons view.

•

View as list of folders and elements.

•

View with details of network and project elements.

•

AQ283728700891en-000201 / 130R046642 | Danfoss A/S © 2021.09

Page 43

e30bt526.11

e30bt643.12

VLT® Motion Control Tool MCT 10

Operating Guide

Illustration 35: The View Menu

Parameter Set-up

5.4.1 Customize Parameter View Settings

Apply the selected parameter view settings to subfolders, to an entire project, or to the entire application, that is all MCT 10 Set-up

Software folders in network or project mode.

Procedure

1.

Right-click the parameter cell or set-up column.

2.

Select Apply Parameter View Settings.

Illustration 36: Applying Parameter View Settings

3.

Select the relevant option and click OK.

5.4.2 Customize Background Color

To customize the background color of the views, go to Options⇒Online Parameter Grid Settings.

AQ283728700891en-000201 / 130R0466 | 43Danfoss A/S © 2021.09

Page 44

e30bt828.12

e30bt642.12

VLT® Motion Control Tool MCT 10

Operating Guide

Illustration 37: Customizing Background Color

Procedure

1.

Select Restore Default to restore factory default background color for online environment.

2.

Click […] to open a standard true color picker.

3.

Select Add to Custom Colors for customizing colors for later usage.

Parameter Set-up

5.4.3 Customize Parameter View

The parameters shown in the right view are presented in a series of columns, containing ID, parameter name, 4 set-ups, units, and

factory set-up.

Select Parameter view⇒Set-up⇒Remove Menu.

N O T I C E

Changes made to the removed set-up are still stored in the MCT 10 Set-up Software and can be shown by selecting Customize

Columns.

Procedure

1.

Right-click a column.

2.

Select Customize Columns.

3.

In the left view of the Customize Columns dialog, select the field to be added or removed.

Illustration 38: Customize Columns Dialog

4.

Click either Add or Remove.

5.

Change the order of the fields in the right view by clicking Move Up or Move Down.

AQ283728700891en-000201 / 130R046644 | Danfoss A/S © 2021.09

Page 45

e30bt643.12

Setting

Description

Read only

Only read-only parameters are shown.

Read & Write

Only read & write parameters are shown.

Changed parameters

Only parameters that have been changed in the current session are shown.

All

All parameter groups are shown.

Group

One or more parameter groups are shown according to selection.

e30bt489.13

VLT® Motion Control Tool MCT 10

Operating Guide

6.

Right-click a column and select Apply Parameter View Settings.

Illustration 39: Apply Parameter View Settings

7.

Select if the settings should apply to the subfolders, the entire project, or the entire application.

5.4.4 Filtering Parameters

Filter the parameters in the right view according to the following settings:

Table 3: Available Filter Settings

Parameter Set-up

Procedure

1.

Right-click any column in the right view.

2.

Select the appropriate filtering setting or the appropriate filtering group.

Illustration 40: Filtering Columns

5.4.5 Customize Columns

Procedure

1.

Right-click any column.

AQ283728700891en-000201 / 130R0466 | 45Danfoss A/S © 2021.09

Page 46

e30bt529.12

e30bt530.12

VLT® Motion Control Tool MCT 10

Operating Guide

2.

Select Customize Columns.

Illustration 41: Customize Columns Menu

Highlight a field to change the order.

3.

Parameter Set-up

Illustration 42: Change Order of Fields

4.

Select Move Up, Move Down, or Remove.

Removed columns are still stored in the memory and can be retrieved into the right view by highlighting the relevant

field name and selecting Add.

5.5 Parameter Edit

The parameter structures in the MCT 10 and in the drive are the same. Modify the parameter by double-clicking the relevant parameter entry. If an entry cell is shaded, the parameter is read-only and cannot be modified.

AQ283728700891en-000201 / 130R046646 | Danfoss A/S © 2021.09

Page 47

e30bt646.12

Shaded cells indicate read-only parameters

e30bt647.12

VLT® Motion Control Tool MCT 10

Operating Guide

Parameter Set-up

Illustration 43: Editing Parameters

Change parameter set-up by manually entering new values in the cells in the right view. Alternatively, change the parameter set-up

by importing values from an active drive using the Read From Drive function.

If a parameter value is set to an illegal value, an error is shown. Parameters can be edited in 2 different modes:

•

Inline.

•

Dialog-based.

Illustration 44: Edit Parameter View

AQ283728700891en-000201 / 130R0466 | 47Danfoss A/S © 2021.09

Page 48

e30bt532.12

VLT® Motion Control Tool MCT 10

Operating Guide

Inline edit

In inline edit mode, the available setting options are shown without any detailed descriptions of the options. Inline edit is only recommended for experienced users.

Dialog-based edit

To have details of parameters available while editing, use dialog-based edit. The parameter details are:

•

Parameter options.

•

Ranges.

•

Functions.

Enter dialog-based edit by deselecting inline edit.

Parameter Set-up

5.6 Comparison of Parameters

Parameter settings can be compared to the parameter settings in another drive. Comparisons can be made either to another drive

inside the project or to an online drive. The comparison function evaluates whether settings inside the drive have been changed, or

checks if 2 or more drives have the same settings.

Procedure

1.

Activate the function by highlighting the base drive for comparison and select Compare.

Illustration 45: Comparison

2.

Select the drive to compare with.

This drive can be an online drive from the network, or it can be a drive in the offline folder (Project folder).

The result of a comparison can be stored in an ASCII text file for documentation or for subsequent import into a spreadsheet.

It is possible to compare all set-ups, or to compare 1 set-up to another.

AQ283728700891en-000201 / 130R046648 | Danfoss A/S © 2021.09

Page 49

e30bt648.12

e30bu980.10

VLT® Motion Control Tool MCT 10

Operating Guide

Parameter Set-up

Illustration 46: Comparison Result

5.7 Compare Multiple Drives

Comparing multiple drives is done via the menu. The project drive has to have the correct addresses. If necessary, the addresses can

be changed in the project properties by right-clicking the project and selecting Drive's Properties.

Illustration 47: Drive's Properties

Only drives from the same product series can be compared and written. If the series do not match, a status message is shown.

AQ283728700891en-000201 / 130R0466 | 49Danfoss A/S © 2021.09

Page 50

e30bu981.10

e30bu982.10

VLT® Motion Control Tool MCT 10

Operating Guide

Illustration 48: Drive Series Mismatch

To start the comparison, right-click the project drive and select Compare Multiple Drives.

Parameter Set-up

Illustration 49: Selecting Compare Multiple Drives

A window appears showing the relevant drives being read.

AQ283728700891en-000201 / 130R046650 | Danfoss A/S © 2021.09

Page 51

e30bu983.10

e30bu984.10

VLT® Motion Control Tool MCT 10

Operating Guide

Illustration 50: Drives Being Read

Parameter Set-up

When the read is complete, the comparison window appears.

Illustration 51: Comparison Window

The parameters in the red block are those which are set differently in the compared drives.

The parameters in the yellow block have not been compared.

The parameters in the green block have the same settings in the compared drives.

For common setup parameters, only setup 1 is compared. The result is shown as All Setups.

Exceptions

There are some parameters that, for technical reasons, are not written/compared. These parameters include some communication

parameters (8-31, 9-18, and 12-01). Trying to write these parameters would cause loss of communication.

Furthermore, safety parameters are not written.

5.8 View Change Log

When configuring a drive, active filter, or soft starter from the project, it is possible to view the change log containing the changes

made by the user only, or the changes made including the dependent parameters.

User-defined changes can be read out by right-clicking All Parameters and selecting Minimal Changeset.

AQ283728700891en-000201 / 130R0466 | 51Danfoss A/S © 2021.09

Page 52

e30bt805.12

VLT® Motion Control Tool MCT 10

Operating Guide

Parameter Set-up

Illustration 52: Minimal Changeset

Changes made including the dependent parameters can be read out by right-clicking All Parameters and selecting Compare parameters with default values.

AQ283728700891en-000201 / 130R046652 | Danfoss A/S © 2021.09

Page 53

e30bt806.12

VLT® Motion Control Tool MCT 10

Operating Guide

Parameter Set-up

Illustration 53: Compare Parameters with Default Values

5.9 Read Drive Operation Status

The drive can be in 2 different operating conditions:

•

Auto On

•

Off

The operation status can be monitored via the LCP or MCT 10. Use MCT 10 to monitor the actual operation status by clicking a drive

located in the network. Select Refresh Status to update the status information. Parameters can only be written to drives in operation

status Off.

AQ283728700891en-000201 / 130R0466 | 53Danfoss A/S © 2021.09

Page 54

e30bt535.11

VLT® Motion Control Tool MCT 10

Operating Guide

Operation

6 Operation

6.1 Reading and Writing Parameters

Parameter settings can be read from or written to an online connected drive.

Most parameters are read/write and can thus be configured. Other parameters are read-only and cannot be configured. Use the

filter function to view which parameters are read/write or read-only.

Select the values to be read/written and then select the Read From Drive or Write To Drive menu.

The following options are available:

•

A single parameter in the right view.

•

All parameters in the left view.

•

A parameter group in the left view, for example the Load and Motor group.

The read-from-drive and write-to-drive functions apply to the whole section.

Select Options in the menu bar to access a range of functions.

Illustration 54: Select Options

6.1.1 Read From Drive Settings

Select the required options for reading from an active drive.

Setups

Select to read visible set-ups only or to read all set-ups.

Drive differences

If field device software and MCT 10 Set-up Software versions are not identical, specify the acceptable level of compatibility errors.

Select Allow drive differences to ignore all compatibility errors.

Select Allow drive version difference to restrict the acceptable compatibility errors to those occurring in different software versions

but same drive series. Select Do not allow drive differences not to accept differences between online devices and offline devices.

Save as default settings

Activate Read From Drive settings for all reads from the drive.

AQ283728700891en-000201 / 130R046654 | Danfoss A/S © 2021.09

Page 55

e30bt854.11

e30bt855.11

VLT® Motion Control Tool MCT 10

Operating Guide

Operation

Illustration 55: Read from Drive Settings

6.1.2 Write to Drive Settings

Select the required options for writing to an active drive, which then becomes applicable for all writing to drives.

Illustration 56: Write to Drive Settings

Write option

By default, Write All Parameters is selected. This means that all read and write parameters are written to online drives.

If selecting Write Changed Parameters, only the subset of parameters different from default are written. This selection improves performance.

6.1.3 Communication Fault Tolerance

Set an acceptable number of communication faults before disconnecting. The default number of failures is 1000.

AQ283728700891en-000201 / 130R0466 | 55Danfoss A/S © 2021.09

Page 56

e30bt657.12

e30bt536.13

VLT® Motion Control Tool MCT 10

Operating Guide

Illustration 57: Fault Tolerance

Operation

6.2 Connection Properties

To read or write between online and offline drives, configure the connection properties in the offline project. If the fieldbus does

not refer to an available drive in the network tree, MCT 10 Set-up Software is not able to identify the online drive.

Reconfigure the fieldbus by right-clicking the offline project and select Properties⇒Connection.

Configure the fieldbuses added to the network tree in the Fieldbus drop-down list.

6.3 Read from Drive

Values can be read from an active drive by right-clicking a selection and then selecting Read from drive.

Illustration 58: Read from Drive

Once Read from drive is selected, the software accesses the online device and shows the Drives Check window. This window contains

a list of drives with detected compatibility issues.

AQ283728700891en-000201 / 130R046656 | Danfoss A/S © 2021.09

Page 57

e30bt537.13

e30bt856.11

VLT® Motion Control Tool MCT 10

Operating Guide

Operation

Illustration 59: Drives Check Window

Select Details to view details on the different properties between project device (based on database information) and online device

(the connected drive).

Illustration 60: Details

The color codes indicate the level of compatibility between the project drive and the connected drive for each property.

To continue the reading process, define an action in the Drives Check dialog. The default action is Continue. Other available selections are:

AQ283728700891en-000201 / 130R0466 | 57Danfoss A/S © 2021.09

Page 58

130BT658.10

VLT® Motion Control Tool MCT 10

Operating Guide

•

Skip the drive.

•

None.

•

Update project and continue.

The same action can be applied to all devices at a time instead of 1 by 1.

If selecting Skip the drive, MCT 10 Set-up Software does not read that particular device, but continues reading the other devices.

Continue resumes reading. Acknowledge and accept any differences found.

Update project and continue activates the read-from-drive process, and it deletes the data in the project drive and replaces it with

data from the connected drive.

Operation

N O T I C E

The Update from connected selection deletes and replaces all information stored in the project drive. To retain the information

entered into the project drive, select Continue.

Once the read-from-drive process is completed, the display shows details of both the Connected Drive Information and the Database

Information.

Illustration 61: Read-from-drive Process Completed

6.3.1 Changing the PROFINET Host Name

As of MCT 10 version 4.3, the domain name and host name can be changed via the Read-from-drive Process Completed dialog.

Procedure

AQ283728700891en-000201 / 130R046658 | Danfoss A/S © 2021.09

Page 59

e30bu307.10

e30bu308.10

VLT® Motion Control Tool MCT 10

Operating Guide

1.

Click Change domain or host name.

Operation

A dialog for entering the domain name and host name opens.

The values entered in the dialog are written to parameter 12-07 Domain Name and parameter 12-08 Host Name.

6.4 Write to Drive

Procedure

1.

Right-click a parameter column title in the right view or click Communication in the main menu bar.

AQ283728700891en-000201 / 130R0466 | 59Danfoss A/S © 2021.09

Page 60

e30bt538.13

e30bu977.10

VLT® Motion Control Tool MCT 10

Operating Guide

2.

Select Write to drive.

Illustration 62: Write to Drive

Operation

6.5 Write to Multiple Drives

Add addresses in the Address field and in the Secondary Addresses field. Secondary Addresses in the right view is enabled for DP-V1,

Ethernet, Serial, and Dummy.

Illustration 63: New Drive Dialog

Write parameter values to the main address and to secondary addresses. If the drive is not available on the configured address, it

must be skipped.

If a drive is configured with secondary addresses, the Write to Multiple Drives context menu is enabled on the right-view parameters

and on the parameter headers context menu on the left-view group and on the drive menu.

AQ283728700891en-000201 / 130R046660 | Danfoss A/S © 2021.09

Page 61

e30bu979.10

VLT® Motion Control Tool MCT 10

Operating Guide

Illustration 64: Examples, Write to Multiple Drives, Right-View Parameters

Operation

AQ283728700891en-000201 / 130R0466 | 61Danfoss A/S © 2021.09

Page 62

e30bu978.10

VLT® Motion Control Tool MCT 10

Operating Guide

Operation

Illustration 65: Examples, Write to Multiple Drives, Parameter Headers Context Menu, and Drive Menu

6.6 Poll

When in network mode, MCT 10 Set-up Software automatically polls the parameters in the right view to update their status continuously to reflect live operation.

6.6.1 Stop Polling

To stop polling, for example to freeze and analyze a particular moment:

Procedure

1.

Click Communication in the main menu bar.

2.

Select Stop polling.

Alternatively, click the Stop polling icon in the toolbar.

AQ283728700891en-000201 / 130R046662 | Danfoss A/S © 2021.09

Page 63

e30bt660.12

e30bt661.12

e30bt982.11

VLT® Motion Control Tool MCT 10

Operating Guide

Illustration 66: Stop Polling Icon

Operation

6.6.2 Resume Polling

Procedure

1.

Click Communication in the main menu bar.

2.

Click Resume polling.

Alternatively, click the Resume polling icon in the toolbar.

Illustration 67: Resume Polling Icon

6.6.3 Using Smart Polling (Intelligent Scan Frequency)

While the MCT 10 Set-up Software is polling the parameter grid, the LCP becomes slow. To improve LCP usability, configure MCT 10

to enable smart polling. Enabling smart polling slows down the polling when the LCP is connected.

Procedure

1.

Click Options in the main menu bar.

2.

Select Online Parameter Grid Settings.

Illustration 68: Selecting Online Parameter Grid Settings

AQ283728700891en-000201 / 130R0466 | 63Danfoss A/S © 2021.09

Page 64

e30bt983.11

VLT® Motion Control Tool MCT 10

Operating Guide

3.

Tick the checkbox Enable Smart Polling (slow down the polling when the LCP is connected).

Illustration 69: Ticking the Checkbox

Operation

6.7 Changing the Set-up of a Field Device

Procedure

1.

Open the Network folder.

2.

Select the relevant device.

3.

Select Stop on the toolbar to stop polling.

Change the settings in the set-up columns in the right view.

4.

The changes are implemented online in the field device, but are not recorded.

6.8 Save Changes to a Hard Disk

6.8.1 Recoding Online Changes

Procedure

Select the relevant device in the Network folder.

1.

2.

Right-click the device and select Copy.

Select the Project folder.

3.

4.

Right-click and select Paste.

5.

Select File from the main menu bar.

6.

Select Save As.

Save the device file into a directory in the storage location.

7.

6.8.1.1 Saving a Project

Procedure

1.

Click File in the main menu bar.

2.

Select Save.

Alternatively, click the Save icon in the toolbar.

6.8.1.1.1 Including Drive Information

It is not possible to open a project file including a firmware version not supported by MCT 10 Set-up Software. Including the drive

information in the project file makes it possible to open in other installations with MCT 10 without having the firmware installed.

By opening the project file, the drive information is updated similarly to:

AQ283728700891en-000201 / 130R046664 | Danfoss A/S © 2021.09

Page 65

e30bt734.12

VLT® Motion Control Tool MCT 10

Operating Guide

•

Selecting Update Drive Support under Tools in the main menu bar.

•

Downloading the drive information from an online drive.

The drive information is saved in the project file.

6.8.1.1.2 Excluding Drive Information

Procedure

1.

Click Options in the main menu bar.

2.

Select Project properties.

3.

Click Include drive supprt in project.

Operation

Illustration 70: Save Drive Information

6.8.2 Archive/Unarchive

Projects that include links to other documents can store the linked files.

By selecting the Archive function, the MCT 10 Set-up Software generates a file that contains all drives and the linked files into a *.ssa

file. If this file is sent to other computers, the user gets a copy of the linked files on the computer.

6.9 Import of Older Dialog Files